查询27C512供应商

512 Kbit (64K x8) UV EPROM and OTP EPROM

FEATURES SUMMARY

■ 5V ± 10% SUPPLY VOLTAGE in READ

OPERATION

■ ACCESS TIME: 45ns

■ LOW POWER “CMOS” CONSUMPTION:

– Active Current 30mA

– Standby Current 100µA

■ PROGRAMMI NG VOLTAGE: 12.75V ± 0.25V

■ PROGRAMMING TIMES of AROUND 6sec.

■ ELECTRONIC SIGNATURE

– Manufacturer Code: 20h

– Device Code: 3Dh

■ PACKAGES

– Lead-Free Versions

M27C512

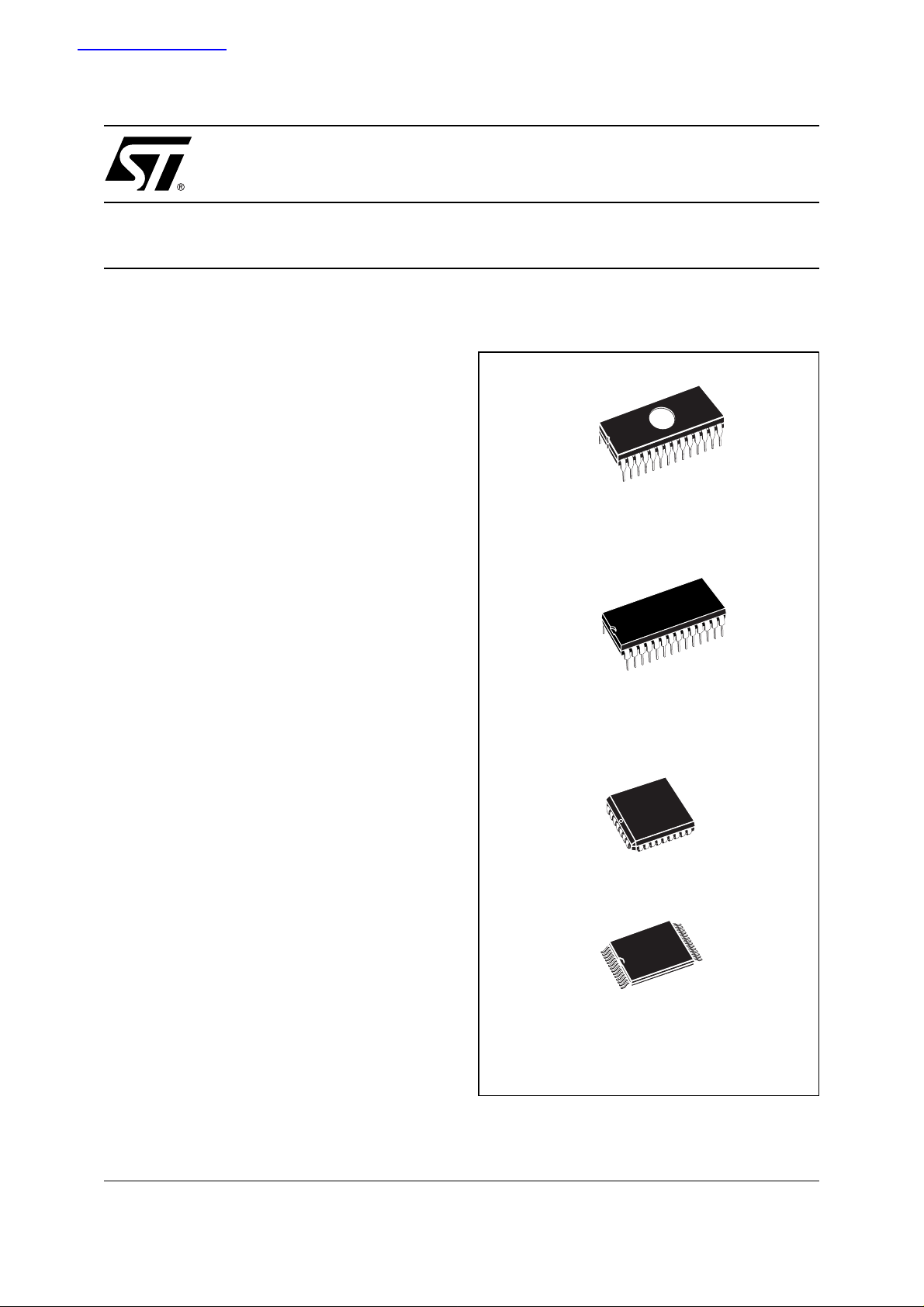

Figure 1. Packages

28

1

FDIP28W (F)

28

PLCC32 (C)

TSOP28 (N)

8 x 13.4 mm

1

PDIP28 (B)

1/22November 2004

M27C512

TABLE OF CONTENTS

FEATURES SUMMARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 1. Packages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SUMMARY DESCRIPTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 2. Logic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 1. Signal Names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3. DIP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 4. LCC Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 5. TSOP Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

DEVICE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Read Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 2. Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3. Electronic Signature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Two Line Output Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

System Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

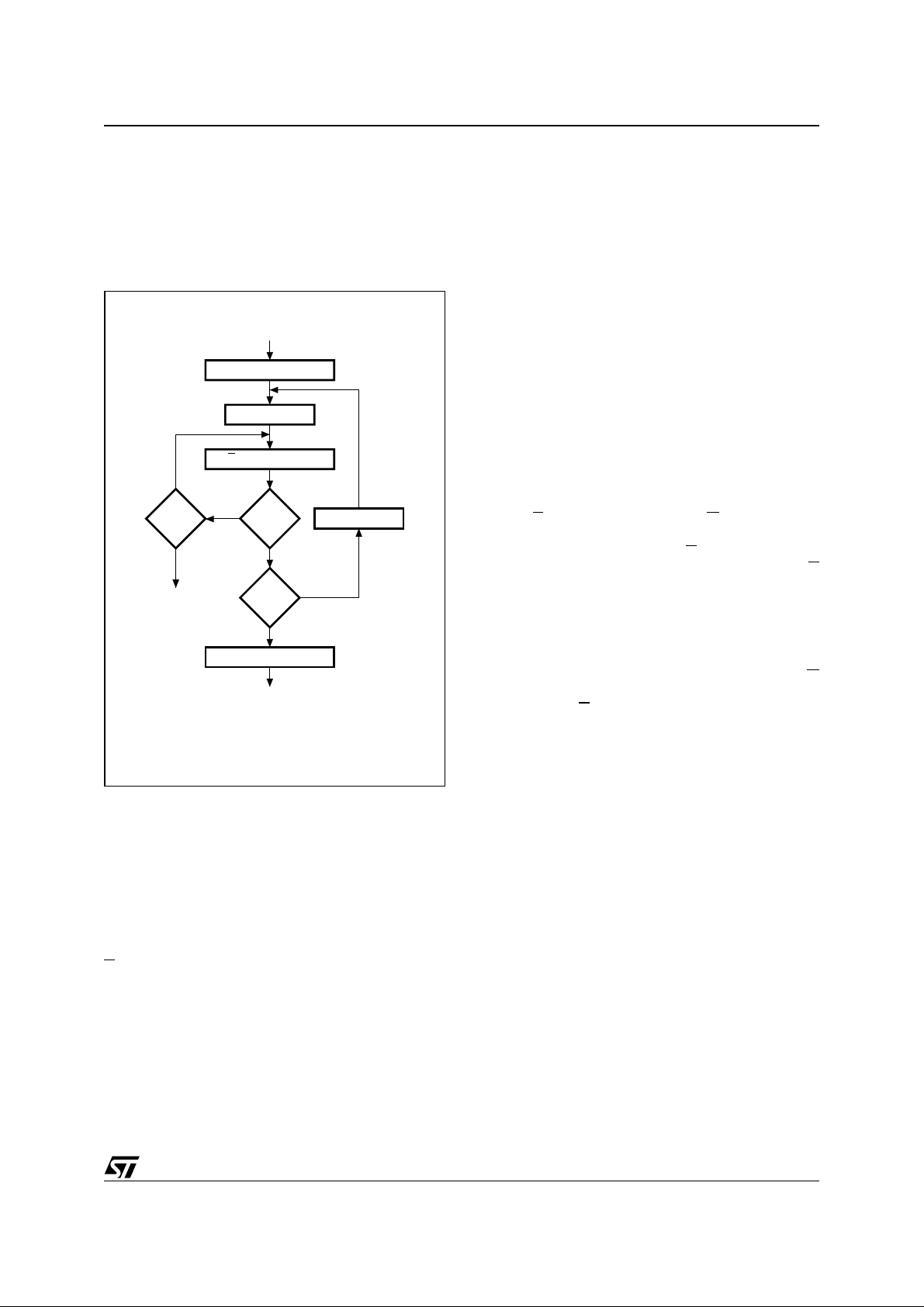

Figure 6. Programming Flowchart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

PRESTO IIB Programming Algorithm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Program Inhibit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Program Verify. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electronic Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ERASURE OPERATION (APPLIES FOR UV EPROM) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

MAXIMUM RATING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 4. Absolute Maximum Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

DC and AC PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 5. AC Measurement Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 7. Testing Input Output Waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 8. AC Testing Load Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 6. Capacitance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 7. Read Mode DC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 8. Read Mode AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 9. Read Mode AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 9. Read Mode AC Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 10. Programming Mode DC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 11. Margin Mode AC Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 10.Margin Mode AC Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 12. Programming Mode AC Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 11.Programming and Verify Modes AC Waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2/22

M27C512

PACKAGE MECHANICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 12.FDIP28W - 28 pin Ceramic Frit-seal DIP, with window, Package Outline. . . . . . . . . . . . 16

Table 13. FDIP28W - 28 pin Ceramic Frit-seal DIP, with window, Package Mechanical Data . . . . 16

Figure 13.PDIP28 - 28 pin Plastic DIP, 600 mils width, Package Outline . . . . . . . . . . . . . . . . . . . . 17

Table 14. PDIP28 - 28 pin Plastic DIP, 600 mils width, Package Mechanical Data . . . . . . . . . . . . 17

Figure 14.PLCC32 - 32 lead Plastic Leaded Chip Carrier, Package Outline . . . . . . . . . . . . . . . . . 18

Table 15. PLCC32 - 32 lead Plastic Leaded Chip Carrier, Package Mechanical Data . . . . . . . . . . 18

Figure 15.TSOP28 - 28 lead Plastic Thin Small Outline, 8 x 13.4 mm, Package Outline . . . . . . . . 19

Table 16. TSOP28 - 28 lead Plastic Thin Small Outline, 8 x 13.4 mm, Package Mechanical Data 19

PART NUMBERING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 17. Ordering Information Scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

REVISION HISTORY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 18. Revision History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3/22

M27C512

SUMMARY DESCRIPTION

The M27C512 is a 512 Kbit EPROM offered in the

two ranges UV (ultra vio let erase) and OTP (o ne

time programmable). It is ideally suited for applications where fast turn-around and pattern experimentation are important requirements and is

organized as 65536 by 8 bits.

The FDIP28W (window ceramic frit-seal package)

has transparent lid which allows the user to expose the chip to ultraviolet light to erase the bit pattern. A new pattern can then be written to the

device by following the programming procedure.

For applications where the content is programmed

only one time and erasure is not required, the

M27C512 is offered in PDIP28, PLCC32 and

TSOP28 (8 x 13.4 mm) packages.

In addition to the standard versions, the packages

are also available in Lead-free versions, in compliance with JEDEC Std J-STD-020 B, the ST ECOPACK 7191395 Specification, and the RoHS

(Restriction of Hazardous Substances) directive.

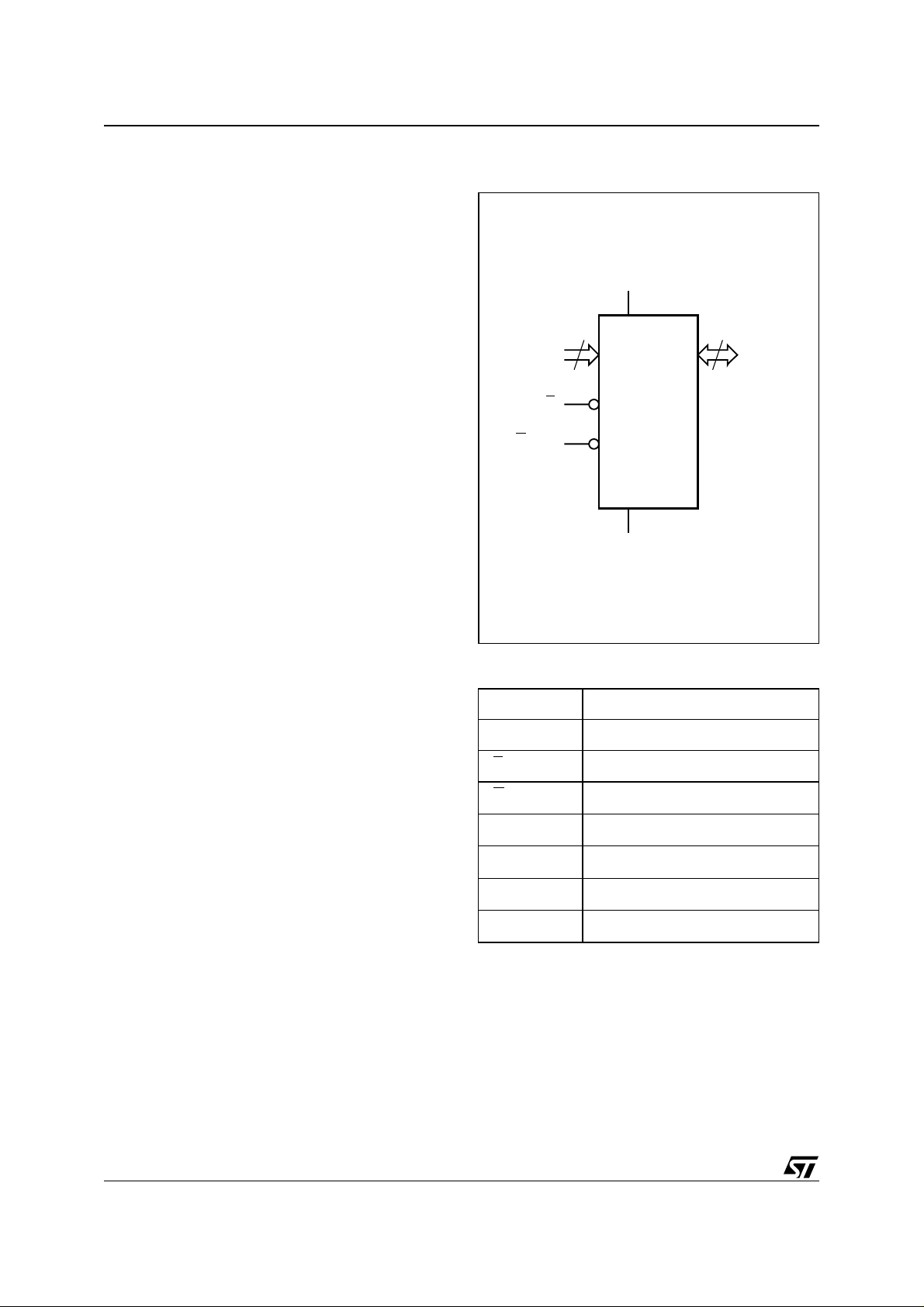

Figure 2. Logic Diagram

V

CC

16

A0-A15

GV

E

PP

M27C512

V

SS

8

Q0-Q7

AI00761B

Table 1. Signal Names

A0-A15 Address Inputs

Q0-Q7 Data Outputs

E

G

V

V

NC

DU

V

CC

SS

PP

Chip Enable

Output Enable / Progra m Sup pl y

Supply Voltage

Ground

Not Connected Internally

Don’t Use

4/22

M27C512

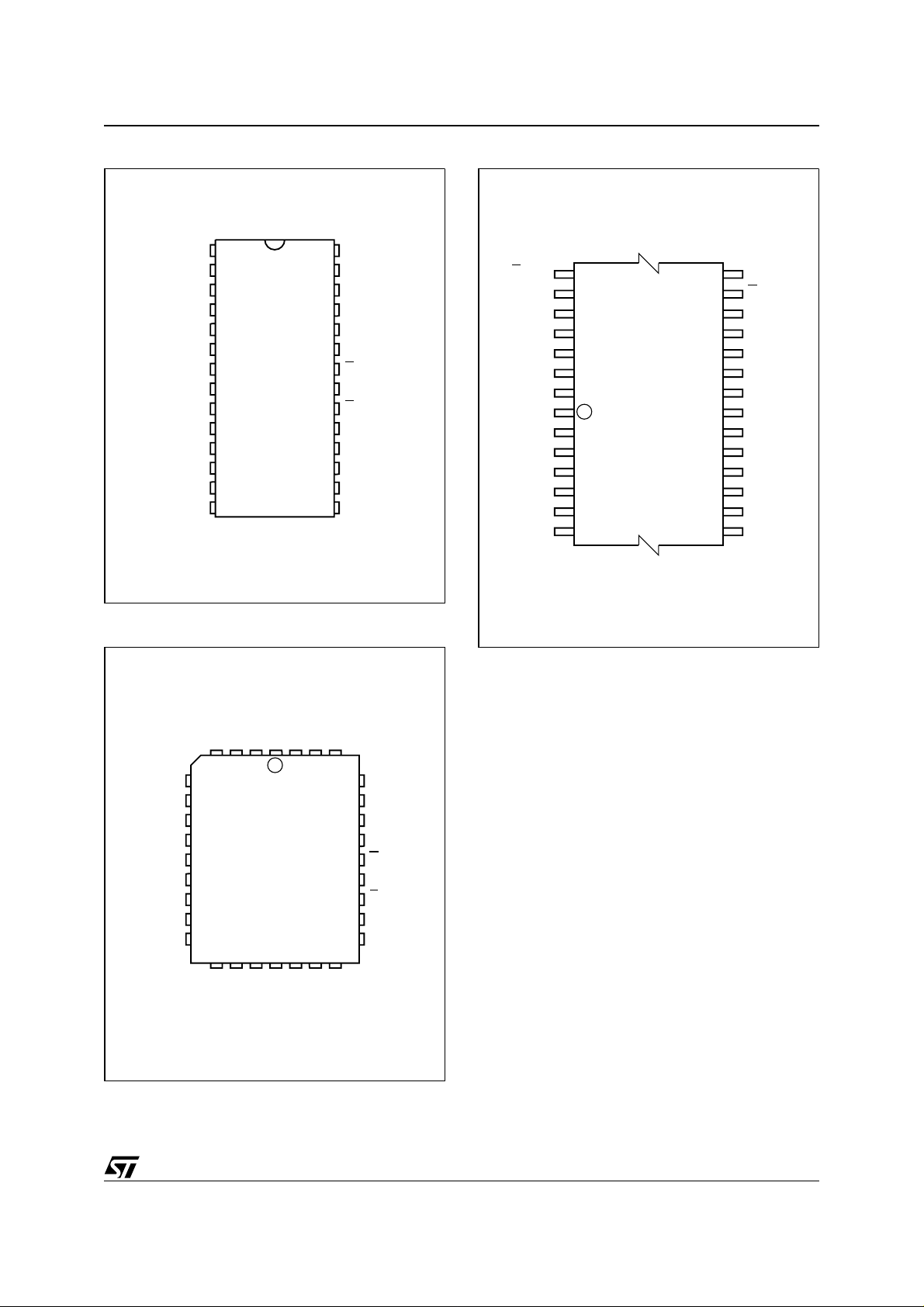

Figure 3. DIP Connections

1

A15 V

2

A12

A7

3

A6

4

A5

5

A4

6

A3

7

M27C512

8

A2

A1

9

A0

10

Q0

11

12

Q2

13

14

SS

28

27

26

25

24

23

22

21

20

19

18

17

16

15

AI00762

CC

A14

A13

A8

A9

A11

GV

A10

E

Q7

Q6

Q5Q1

Q4

Q3V

PP

Figure 5. TSOP Connections

GV

A11

A13

A14

V

A15

A12

PP

A9

A8

CC

A7

A6

A5

A4

A3

22

28

M27C512

1

78

21

15

14

AI00764B

A10

E

Q7

Q6

Q5

Q4

Q3

V

SS

Q2

Q1

Q0

A0

A1

A2

Figure 4. LCC Connections

A15

A6

A5

A4

A3

A2

A1

A0

NC

Q0

A7

9

Q1

DU

A12

1

M27C512

17

Q2

SS

DU

V

32

CC

V

Q3

A14

Q4

A13

25

Q5

A8

A9

A11

NC

GV

A10

E

Q7

Q6

AI00763

PP

5/22

M27C512

DEVICE OPERATION

The modes of operations of the M27C512 are listed in the Operating Modes table. A single power

supply is required in the read mode. All inputs are

TTL levels except for G

Electronic Signature.

Read Mode

The M27C512 has two cont rol functions, both of

which must be logically active in order to obtain

data at the outputs. Chip E nable (E

control and shou ld be used for device selecti on.

Output Enable (G

) is the output control and should

be used to gate data to the output pins, indepen dent of device selection. Assuming that the ad-

Table 2. Operating Modes

Mode E

Read

Output Disable

Program

Program Inhibit

Standby

Electronic Signature

Note: X = VIH or VIL, VID = 12V ± 0.5V.

VPP and 12V on A9 for

) is the power

V

IL

V

IL

VIL Pulse V

V

IH

V

IH

V

IL

dresses are stable, the address access time

(t

) is equal to the delay from E to output

AVQV

). Data i s availa ble at t he output after a delay

(t

ELQV

of t

has been low and the addresses have been sta-

E

ble for at least t

from the falling edge of G , as sumi ng that

GLQV

AVQV-tGLQV

.

Standby Mode

The M27C512 has a standby mode which reduces

the active current from 30mA to 100µA The

M27C512 is placed in the standby mode by applying a CMOS high signal to the E

input. When in the

standby mode, the outputs are in a high impedance state, independent of the G

GV

PP

V

IL

V

IH

PP

V

PP

XXHi-Z

V

IL

A9 Q7-Q0

X Data Out

XHi-Z

XData In

XHi-Z

V

ID

VPP input.

Codes

Table 3. Electronic Signature

Identifier A0 Q7 Q6 Q5 Q4 Q3 Q2 Q1 Q0 Hex Data

Manufacturer’s Code

Device Code

V

IL

V

IH

Two Line Output Control

Because EPROMs are usually used in larger

memory arrays, the product features a 2 line control function which accommodates the use of multiple memory connection. The two line control

function allows:

a. the lowest possible memory power

dissipation,

b. complete assurance that output bus

contention will not occur.

For the most efficient use of these two control

lines, E

should be decoded and used as the primary device selecting function, while G

made a common connect ion to all devices in the

array and connected to the READ

system control bus. This ensures that all deselected memory devices are in their low power standby

mode and that the output pins are only active

00100000 20h

00111101 3Dh

when data is required from a particular memory

device.

System Considerations

The power switch ing characteristics of Advanced

CMOS EPROMs require careful decoupling of the

devices. The supply c urrent, I

CC

ments that are of interest to the system desi gner:

the standby current level, th e active cu rrent le vel,

and transient current peak s that are produced b y

the falling and rising edges of E

. The magnitude of

the transient current peaks is dependent on the

capacitive and inducti ve loading of the device at

should be

line from the

the output. The associated transient voltage peaks

can be suppressed by complying with the two line

output control and by properly selected decoupling

capacitors. It is recommended that a 0.1µF ceramic capacitor be used on every device between V

and VSS. This should be a high freq uency capacitor of low inherent inductance and should be

placed as close to the device as possible. In addi-

, has three seg-

CC

6/22

M27C512

tion, a 4.7µF b ulk electroly tic capacitor should be

used between V

and VSS for every eight devic -

CC

es. The bulk ca pac ito r s hou ld be located near the

power supply connection point.The purpose of the

bulk capacitor is to overcome the voltage drop

caused by the inductive effects of PCB traces.

Figure 6. Programming Flowchart

VCC = 6.25V, VPP = 12.75V

SET MARGIN MODE

n = 0

E = 100µs Pulse

NO

NO

VERIFY

YES

Last

NO

Addr

YES

RESET MARGIN MODE

CHECK ALL BYTES

1st: VCC = 6V

2nd: VCC = 4.2V

++ Addr

AI00738B

YES

++n

= 25

FAIL

Programming

When delivered (and after each erasure for UV

EPROM), all bits of the M27C512 are in the '1'

state. Data is introduc ed by selectively programming '0's into the desired bit locations. Although

only '0's will be programmed, both '1's and '0's can

be present in the data word. The only way to

change a '0' to a '1' is by die exposure to ultraviolet

light (UV EPROM). The M27C512 is in the programming mode when V

is pulsed to VIL. The data to be programmed is

E

input is at 12.75V a nd

PP

applied to 8 bits in parallel to the data output pins.

The levels required for the address and data inputs are TTL. V

is specified to be 6.25V ±

CC

0.25V. The M27C512 can use P RESTO IIB Programming Algorithm that drastically reduces the

programming time (typi c ally les s tha n 6 secon d s).

Nevertheless to achieve c ompati bility with all p rogramming equipments, PRESTO Programming

Algorithm can be used as well.

PRESTO IIB Programming Algorithm

PRESTO IIB Programming Algorithm allows the

whole array to be programmed wi th a guarante ed

margin, in a typical time of 6.5 seconds. This can

be achieved with STMicroelectronics M27C512

due to several design innovations described in the

M27C512 datasheet to improve programming efficiency and to provide adequate margin for reliability. Before starting the programming the internal

MARGIN MODE circuit is set in order to guarantee

that each cell is programmed with enough margin.

Then a sequence of 100µs program pulses are applied to each byte until a correct veri fy occurs. No

overprogram pulses are applied since the verify in

MARGIN MODE provides the necessary margin.

Program Inhibit

Programming of multiple M27C512s in parallel

with different data is also easily accomplished. Except for E

, all like inputs including GVPP of the pa rallel M27C512 may be common . A TTL low level

pulse applied to a M27C512's E

input, with VPP at

12.75V, will program that M27C512. A high level E

input inhibits the other M27C512s from being programmed.

Program Verify

A verify (read) should be performed on the programmed bits to determine that they were correctly progra m me d. T he ve r i fy i s ac co mp l is he d w ith G

at VIL. Data should be verified with t

falling edge of E

.

ELQV

after the

Electronic Signature

The Electronic Signature (ES) mode allows the

reading out of a binary code from an EPROM that

will identify its manufacture r and type. This mode

is intended for use by programm ing equip ment to

automatica lly m atc h th e de vice t o be prog ra mmed

with its corresponding programming algorithm.

The ES mode is functional in the 25° C ± 5°C ambient temperature range that is required when programming the M27C512. To activate the ES

mode, the programming equipment must force

11.5V to 12.5V on address line A9 of the

M27C512. Two identifier bytes may then be sequenced from the device ou tputs by toggling address line A0 from V

lines must be he ld at V

ture mode. Byte 0 (A0 = V

ufacturer code and byte 1 (A0 = V

to VIH. All other address

IL

during Electronic Signa-

IL

) represents the man-

IL

) the device

IH

identifier code. For the STMicroelectronics

M27C512, these two identif ier bytes are given in

Table 3. and can be read-out on outputs Q7 to Q0.

7/22

M27C512

ERASURE OPERATION (APPLIES FOR UV EPROM)

The erasure characteristics of the M27C512 is

such that erasure begins when the cells are ex posed to light with wavelengt hs shorter than approximately 4000 Å. It should be noted that

sunlight and some type of fluorescent lamps have

wavelengths in the 3000-4000 Å range.

Research shows that constant ex posure to room

level fluorescent lighting could erase a typical

M27C512 in about 3 years, while it would take approximately 1 week to cause erasure when exposed to direct sunlight. If the M27C5 12 is to be

exposed to these typ es of lighting conditions for

extended periods of time, it is suggested that

opaque labels be put over the M27C512 window to

prevent unintentional e rasu re. The r ecomm ended

erasure procedure for the M27C512 is exposure to

short wave ultraviolet light whi ch has wavelength

2537 Å. The integrated dose ( i.e. UV intensity x

exposure time) for erasur e should be a minimum

of 15 W-sec/cm

age is approximately 15 to 20 minutes using an ultraviolet lamp with 12000 µW/cm

The M27C512 should be placed within 2.5 cm (1

inch) of the lamp tu bes during the erasur e. Some

lamps have a filter on th eir tub es whi ch shoul d be

removed before erasure.

2

. The erasure time with this dos-

2

power rating.

8/22

M27C512

MAXIMUM RATING

Stressing the devi ce outside the ratings li sted in

Table 4. may cause permanent damage to the de-

vice. These are stress ratings only, and oper ation

of the device at these, or any other conditions outside those indicated in the Oper ating sections of

Table 4. Absolute Maximum Ratings

Symbol Parameter Value Unit

T

A

T

BIAS

T

STG

T

LEAD

(2)

V

IO

V

CC

(2)

V

A9

V

PP

Note: 1. Compliant with the JEDEC Std J-STD-020B (for small body, Sn-Pb or Pb assermbly), the ST ECOPACK® 7191395 specification,

and the European directive on Restr i ctions on Hazardous Substances (RoHS) 2002/95/EU.

2. Minimum DC voltage on Input or Output is –0.5V with possible undershoot to –2.0V for a period less than 20ns. Maximum DC

voltage on Output is V

3. Depends on range.

Ambient Operatin g Temperature

Temperature Under Bias –50 to 125 °C

Storage Temperature –65 to 150 °C

Lead Temperature during Soldering (note 1) °C

Input or Output Voltage (except A9) –2 to 7 V

Supply Voltage –2 to 7 V

A9 Voltage –2 to 13.5 V

Program Supply Voltage –2 to 14 V

+0.5V with possible overshoot to VCC +2V for a period less than 20ns.

CC

(3)

this specificatio n, is not implied. Exposure to Absolute Maximum Rating conditions for extended

periods may affect de vice rel iability. Refer also to

the STMicroelectroni cs SURE Program and othe r

relevant quality documents.

–40 to 125 °C

9/22

M27C512

DC AND AC PARAMETERS

This section summ arizes the operati ng and measurement conditions , and the D C an d AC charac teristics of the device. The parameters in th e DC

and AC Characteristic tables that follow are derived from tests performed under the Measure-

Table 5. AC Measurement Conditions

Input Rise and Fall Times ≤ 10ns ≤ 20ns

Input Pulse Voltages 0 to 3V 0.4V to 2.4V

Input and Output Timing Ref. Voltages 1.5V 0.8V and 2V

Figure 7. Testing Input Output Waveform Figure 8. AC Testing Load Circuit

High Speed

3V

1.5V

0V

ment Conditions summarized in the relevant

tables. Designers sho uld c heck tha t th e operating

conditions in thei r circui t match the measur ement

conditions when relying on the quoted parameters.

High Speed Standard

1.3V

1N914

Ω

3.3k

Standard

2.4V

0.4V

Table 6. Capacitance

Symbol

C

IN

C

OUT

Note: 1. TA = 25°C, f = 1MHz

2. Sampled only, not 100% tested.

Input Capacitance

Output Capacitance

DEVICE

UNDER

TEST

2.0V

0.8V

AI01822

CL = 30pF for High Speed

CL = 100pF for Standard

CL includes JIG capacitance

Parameter Test Condition

V

= 0V

IN

V

= 0V

OUT

(1,2)

OUT

CL

AI01823B

Min Max Unit

6pF

12 pF

10/22

Table 7. Read Mode DC Characteristics

Symbol

Parameter Test Condition

(1)

M27C512

Min Max Unit

I

I

I

CC

I

CC1

I

CC2

I

V

V

IH

V

V

Note: 1. VCC must be applied simultaneously with or before VPP and removed simultaneously or aft er VPP.

Input Leakage Current

LI

Output Leakage Current

LO

Supply Current

I

OUT

0V ≤ V

0V ≤ V

E

Supply Current (Standby) TTL

Supply Current (Standby) CMOS

Program Current

PP

Input Low Voltage –0.3 0.8 V

IL

(2)

Input High Voltage 2

Output Low Voltage

OL

E

Output High Voltage TTL

OH

Output High Voltage CMOS

2. Maximum DC voltage on Output is V

CC

+0.5V.

≤ V

IN

CC

≤ V

OUT

CC

= VIL, G = VIL,

= 0mA, f = 5MHz

E

= V

IH

> VCC – 0.2V

V

= V

PP

CC

I

= 2.1mA

OL

I

= –1mA

OH

= –100µA VCC – 0.7V

I

OH

3.6 V

Table 8. Read Mode AC Characteristics

M27C512

Symbol Alt Parameter

t

AVQVtACC

t

ELQV

t

GLQVtOE

(2)

t

EHQZ

(2)

t

GHQZ

t

AXQXtOH

Note: 1. VCC must be applied simultaneously with or before VPP and removed simultaneously or aft er VPP.

2. Sampled only, not 100% tested.

3. Speed obtained with High Speed AC measurement conditions .

Address Valid to

Output Valid

Chip Enable Low to

t

CE

Output Valid

Output Enable Low

to Output Valid

Chip Enable High

t

DF

to Output Hi-Z

Output Enable

t

DF

High to Output Hi-Z

Address Transition

to Output Transition

Test Condition

= VIL, G = V

E

= V

G

= V

E

= V

G

= V

E

= VIL, G = V

E

(1)

IL

IL

IL

IL

IL

IL

-45

(3)

-60 -70 -80

MinMaxMinMaxMinMaxMinMax

45 60 70 80 ns

45 60 70 80 ns

25 30 35 40 ns

025025030030ns

025025030030ns

0000ns

±10 µA

±10 µA

30 mA

1mA

100 µA

10 µA

V

CC

+ 1

V

0.4 V

V

Unit

11/22

M27C512

Table 9. Read Mode AC Characteristics

M27C512

Symbol Alt Parameter

Test Condition

(1)

-90

MinMaxMinMaxMinMaxMinMax

t

AVQVtACC

t

ELQV

t

GLQVtOE

(2)

t

EHQZ

(2)

t

GHQZ

t

AXQXtOH

Note: 1. VCC must be applied simultaneously with or before VPP and removed simultaneously or aft er VPP.

2. Sampled only, not 100% tested.

Address Valid to

Output Valid

Chip Enable Low to

t

CE

Output Valid

Output Enable Low

to Output Valid

Chip Enable High

t

DF

to Output Hi-Z

Output Enable

t

DF

High to Output Hi-Z

Address Transition

to Output Transition

= VIL, G = V

E

= V

G

= V

E

= V

G

= V

E

= VIL, G = V

E

IL

IL

IL

IL

IL

IL

90 100 120 150 ns

90 100 120 150 ns

40 40 50 60 ns

030030040050ns

030030040050ns

0000ns

Figure 9. Read Mode AC Waveforms

-10 -12 -15/-20/-25

Unit

A0-A15

E

G

Q0-Q7

tAVQV

tELQV

VALID

tGLQV

VALID

tAXQX

tEHQZ

tGHQZ

Hi-Z

AI00735B

12/22

Table 10. Programming Mode DC Characteristics

Symbol

I

LI

I

CC

I

PP

V

IL

V

IH

V

OL

V

OH

V

ID

Note: 1. TA = 25 °C; VCC = 6.25V ± 0.25V; VPP = 12.75V ± 0.25V

2. V

Input Leakage Current

Supply Current 50 mA

Program Current

Input Low Voltage –0.3 0.8 V

Input High Voltage 2

Output Low Voltage

Output High Voltage TTL

A9 Voltage 11.5 12.5 V

must be applied simultaneously with or before VPP and removed simultaneously or aft er VPP.

CC

Parameter Test Condition

V

≤ VIN ≤ V

IL

E

= V

I

= 2.1mA

OL

I

= –1mA

OH

M27C512

(1,2)

IH

IL

Min Max Unit

±10 µA

50 mA

V

CC

+ 0.5

V

0.4 V

3.6 V

13/22

M27C512

Table 11. Margin Mode AC Characteristics

Symbol Alt Parameter

t

A9HVPH

t

VPHEL

t

A10HEH

t

A10LEH

t

EXA10X

t

EXVPX

t

VPXA9X

Note: 1. TA = 25 °C; VCC = 6.25V ± 0.25V; VPP = 12.75V ± 0.25V

2. V

Figure 10. Margin Mode AC Waveforms

t

t

t

AS10VA10

t

AS10VA10

t

AH10

t

t

must be applied simultaneously with or before VPP and removed simultaneously or aft er V

CC

V

CC

A8

VA9 High to VPP High

AS9

VPP High to Chip Enable Low

VPS

High to Chip Enable High (Set)

Low to Chip Enable High (Reset)

Chip Enable Transition to V

Chip Enable Transition to VPP Transition

VPH

VPP Transition to VA9 Transition

AH9

A10

Transition

Test Condition

(1,2)

Min Max Unit

2µs

2µs

1µs

1µs

1µs

2µs

2µs

PP.

A9

GV

PP

E

A10 Set

A10 Reset

Note: A8 High level = 5V; A9 High level = 12V.

tA9HVPH tVPXA9X

tVPHEL

tEXVPX

tA10HEH

tA10LEH

tEXA10X

AI00736B

14/22

Table 12. Programming Mode AC Characteristics

Symbol Alt

t

AVEL

t

QVEL

t

VCHEL

t

VPHEL

t

VPLVPH

t

ELEH

t

EHQX

t

EHVPX

t

VPLEL

t

ELQV

(3)

t

EHQZ

t

EHAX

Note: 1. TA = 25 °C; VCC = 6.25V ± 0.25V; VPP = 12.75V ± 0.25V

2. V

CC

3. Sampled only, not 100% tested.

t

Address Valid to Chip Enable Low 2 µs

AS

t

Input Valid to Chip Enable Low 2 µs

DS

t

t

t

t

t

t

OEH

t

must be applied simultaneously with or before VPP and removed simultaneously or aft er VPP.

VCC High to Chip Enable Low

VCS

VPP High to Chip Enable Low

OES

VPP Rise Time

PRT

Chip Enable Program Pulse Width (Initial) 95 105 µs

PW

Chip Enable High to Input Transition 2 µs

DH

Chip Enable High to VPP Transition

t

VPP Low to Chip Enable Low

VR

t

Chip Enable Low to Output Valid 1 µs

DV

Chip Enable High to Output Hi-Z 0 130 ns

DFP

t

Chip Enable High to Address Transition 0 ns

AH

Parameter Test Condition

(1,2)

M27C512

Min Max Unit

2µs

2µs

50 ns

2µs

2µs

Figure 11. Programming and Verify Modes AC Waveforms

A0-A15

Q0-Q7

V

CC

GV

PP

E

tAVEL

DATA IN

tQVEL

tVCHEL

tVPHEL

tELEH

PROGRAM

VALID

tEHQX

tEHVPX

tVPLEL

tEHAX

DATA OUT

tEHQZ

tELQV

VERIFY

AI00737

15/22

M27C512

PACKAGE MECHANICAL

Figure 12. FDIP28W - 28 pin Ceramic Frit-seal DIP, with window, Package Outline

A2

B1 B

A3

A1AL

e

α

C

eA

D2

eB

D

S

N

∅

1

Note: Drawing is not to scale.

E1 E

FDIPW-a

Table 13. FDIP28W - 28 pin Ceramic Frit-seal DIP, with window, Package Mechanical Data

Symbol

A 5.72 0.225

A1 0.51 1.40 0.020 0.055

A2 3.91 4.57 0.154 0.180

A3 3.89 4.50 0.153 0.177

B 0.41 0.56 0.016 0.022

B1 1.45 – – 0.057 – –

C 0.23 0.30 0.009 0.012

D 36.50 37.34 1.437 1.470

D233.02– –1.300– –

E 15.24 – – 0.600 – –

E1 13.06 13.36 0.514 0.526

e 2.54 – – 0.100 – –

eA 14.99 – – 0.590 – –

eB 16.18 18.03 0.637 0.710

L 3.18 4.10 0.125 0.161

S 1.52 2.49 0.060 0.098

∅ 7.11 – – 0.280 – –

α 4° 11° 4° 11°

N28 28

Typ Min Max Typ Min Max

millimeters inches

16/22

Figure 13. PDIP28 - 28 pin Plastic DIP, 600 mils width, Package Outline

A2

M27C512

A1AL

B1 B e1

D2

α

C

eA

eB

D

S

N

E1 E

1

Note: Drawing is not to scale.

PDIP

Table 14. PDIP28 - 28 pin Plastic DIP, 600 mils width, Package Mechanical Data

Symbol

Typ Min Max Typ Min Max

A 4.445 0.1750

A1 0.630 0.0248

A2 3.810 3.050 4.570 0.1500 0.1201 0.1799

B 0.450 0.0177

B1 1.270 0.0500

C 0.230 0.310 0.0091 0.0122

D 36.830 36.580 37.080 1.4500 1.4402 1.4598

D2 33.020 – – 1.3000 – –

E 15.240 0.6000

E1 13.720 12.700 14.480 0.5402 0.5000 0.5701

e1 2.540 – – 0.1000 – –

eA 15.000 14.800 15.200 0.5906 0.5827 0.5984

eB 15.200 16.680 0.5984 0.6567

L 3.300 0.1299

S 1.78 2.08 0.070 0.082

α 0° 10° 0° 10°

N28 28

millimeters inches

17/22

M27C512

Figure 14. PLCC32 - 32 lead Plastic Leaded Chip Carrier, Package Outline

D

D1

1 N

A1

A2

B1

E2

E3

E1 E

F

0.51 (.020)

B

E2

e

1.14 (.045)

D3

R

A

CP

D2 D2

PLCC-A

Note: Drawing is not to scale.

Table 15. PLCC32 - 32 lead Plastic Leaded Chip Carrier, Package Mechanical Data

Symbol

A 3.18 3.56 0.125 0.140

A1 1.53 2.41 0.060 0.095

A2 0.38 – 0.015 –

B 0.33 0.53 0.013 0.021

B1 0.66 0.81 0.026 0.032

CP 0.10 0.004

D 12.32 12.57 0.485 0.495

D1 11.35 11.51 0.447 0.453

D2 4.78 5.66 0.188 0.223

D3 7.62 – – 0.300 – –

E 14.86 15.11 0.585 0.595

E1 13.89 14.05 0.547 0.553

E2 6.05 6.93 0.238 0.273

E310.16– –0.400– –

e 1.27 – – 0.050 – –

F 0.00 0.13 0.000 0.005

R 0.89 – – 0.035 – –

N32 32

Typ Min Max Typ Min Max

millimeters inches

18/22

Figure 15. TSOP28 - 28 lead Plastic Thin Small Outline, 8 x 13.4 mm, Package Outline

A2

M27C512

1

N

e

E

B

N/2

D1

D

DIE

A

CP

C

TSOP-a

Note: Drawing is not to scale

LA1 α

Table 16. TSOP28 - 28 lead Plastic Thin Small Outline, 8 x 13.4 mm, Package Mechanical Data

millimeters inches

Symbol Typ Min Max Typ Min Max

A 1.250 0.0492

A1 0.200 0.0079

A2 0.950 1.150 0.0374 0.0453

B 0.170 0.270 0.0067 0.0106

C 0.100 0.210 0.0039 0.0083

CP 0.100 0.0039

D 13.200 13.600 0.5197 0.5354

D1 11.700 11.900 0.4606 0.4685

e 0.550 – – 0.0217 – –

E 7.900 8.100 0.3110 0.3189

L 0.500 0.700 0.0197 0.0276

α 0° 5° 0° 5°

N28 28

19/22

M27C512

PART NUMBERING

Table 17. Ordering Information Scheme

Example: M27C512 -70 X C 1 TR

Device Type

M27

Supply Voltage

C = 5V

Device Function

512 = 512 Kbit (64Kb x8)

Speed

(1)

= 45 ns

-45

-60 = 60 ns

-70 = 70 ns

-80 = 80 ns

-90 = 90 ns

-10 = 100 ns

-12 = 120 ns

-15 = 150 ns

-20 = 200 ns

-25 = 250 ns

VCC Tolerance

blank = ± 10%

X = ± 5%

Package

F = FDIP28W

B = PDIP28

C = PLCC32

N = TSOP28: 8 x 13.4 mm

Temperature Range

1 = 0 to 70 °C

3 = –40 to 125 °C

6 = –40 to 85 °C

Options

Blank = Standard Packing

TR = Tape and Reel Packing

E = Lead-free and RoHS Package, Standard Packing

F = Lead-free and RoHS Package, T ape and Reel Packing

Note: 1. High Speed, see AC Characteristics section for further information.

For a list of available options (speed, package,

etc.) or for further information on any aspect of this

device, please conta ct yo ur nearest ST Sal es Office.

20/22

REVISION HISTORY

Table 18. Revision History

Date Version Revision Details

November 1998 1.0 First Issue

25-Sep-2000 1.1 AN620 Reference removed

02-Apr-2001 1.2 FDIP28W mechanical dimensions changed (Table 13.)

29-Aug-2002 1.3

08-Nov-2004 2.0

Package mechanical data clarified for PDIP28 (Table 14.),

PLCC32 (Table 15., Figure 14.) and TSOP28 (Table 16., Figure 15.)

Details of ECOPACK lead-free package options added.

Additional Burn-in option removed

M27C512

21/22

M27C512

Information furnished is be lieved to be a ccur ate and reli able. Howe ver, STMicroele ctronic s assu mes no r esponsib ilit y for th e consequences

of use of such information nor for any infrin gement of patent s or other rights of third parties which ma y result from it s use. No license is granted

by implication or otherwi se under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without not ice. This pub licat ion su persed es and repl aces all in format ion previou sly su pplie d. STMicroele c tronic s prod ucts ar e no t

authorized for use as critical compone nts in life support devices or systems witho ut express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2004 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

STMicroelectronics group of companies

www.st.com

22/22

Loading...

Loading...