Page 1

AN5038

Application note

LIS2DW12: always-on 3D accelerometer

Introduction

This document is intended to provide usage information and application hints related to ST’s LIS2DW12 motion sensor.

The LIS2DW12 is a 3D digital accelerometer system-in-package with a digital I²C/SPI serial interface standard output,

performing at 90 µA in high-resolution mode and below 1 µA in low-power mode. Thanks to the ultra-low noise performance

of the accelerometer, the device combines always-on low-power features with superior sensing precision for an optimal motion

experience for the consumer. Furthermore, the accelerometer features smart sleep-to-wakeup (activity) and return-to-sleep

(inactivity) functions that allow advanced power saving.

The device has a dynamic user-selectable full-scale acceleration range of ±2/±4/±8/±16 g and is capable of measuring

accelerations with output data rates from 1.6 Hz to 1600 Hz. The LIS2DW12 can be configured to generate interrupt signals

by using hardware recognition of free-fall events, 6D orientation, tap and double-tap sensing, activity or inactivity, and wake-up

events.

The LIS2DW12 has an integrated 32-level first-in, first-out (FIFO) buffer allowing the user to store data in order to limit

intervention by the host processor.

The LIS2DW12 is available in a small thin plastic land grid array package (LGA) and it is guaranteed to operate over an

extended temperature range from -40 °C to +85 °C.

The ultra-small size and weight of the SMD package make it an ideal choice for handheld portable applications such as

smartphones, IoT connected devices, and wearables or any other application where reduced package size and weight are

required.

AN5038 - Rev 5 - January 2021

For further information contact your local STMicroelectronics sales office.

www.st.com

Page 2

1 Pin description

AN5038

Pin description

Figure 1. Pin connections

Table 1. Internal pin status

Name Function Pin status

Pin #

SCL

1

2 CS

3

4

5 NC Internally not connected. Can be tied to VDD, VDDIO, or GND.

6 GND 0 V supply

7 RES Connect to GND

8 GND 0 V supply

9 VDD Power supply

10 VDD_IO Power supply for I/O pins

11 INT2

12 INT1 Interrupt pin 1 Default: push-pull output forced to ground

1. In order to disable the internal pull-up on the CS pin, write '1' to the CS_PU_DISC bit in CTRL2 (21h).

2. Internal pull-up on SDO/SA0 pin cannot be disabled: do not connect this pin to GND in low-power applications.

I²C serial clock (SCL)

SPC

SPI serial port clock (SPC)

SPI enable

I²C/SPI mode selection

1: SPI idle mode / I²C communication enabled

0: SPI communication mode / I²C disabled

SDO

Serial data output (SDO)

SA0

I²C less significant bit of the device address (SA0)

SDA

I²C serial data (SDA)

SDI

SPI serial data input (SDI)

SDO

3-wire interface serial data output (SDO)

Interrupt pin 2

Clock input when selected in single data conversion on demand.

Default: input without internal pull-up

Default: input with internal pull-up

Default: input with internal pull-up

(1)

(2)

Default: (SDA) input without internal pull-up

Default: push-pull output forced to ground

AN5038 - Rev 5

page 2/51

Page 3

AN5038 - Rev 5

page 3/51

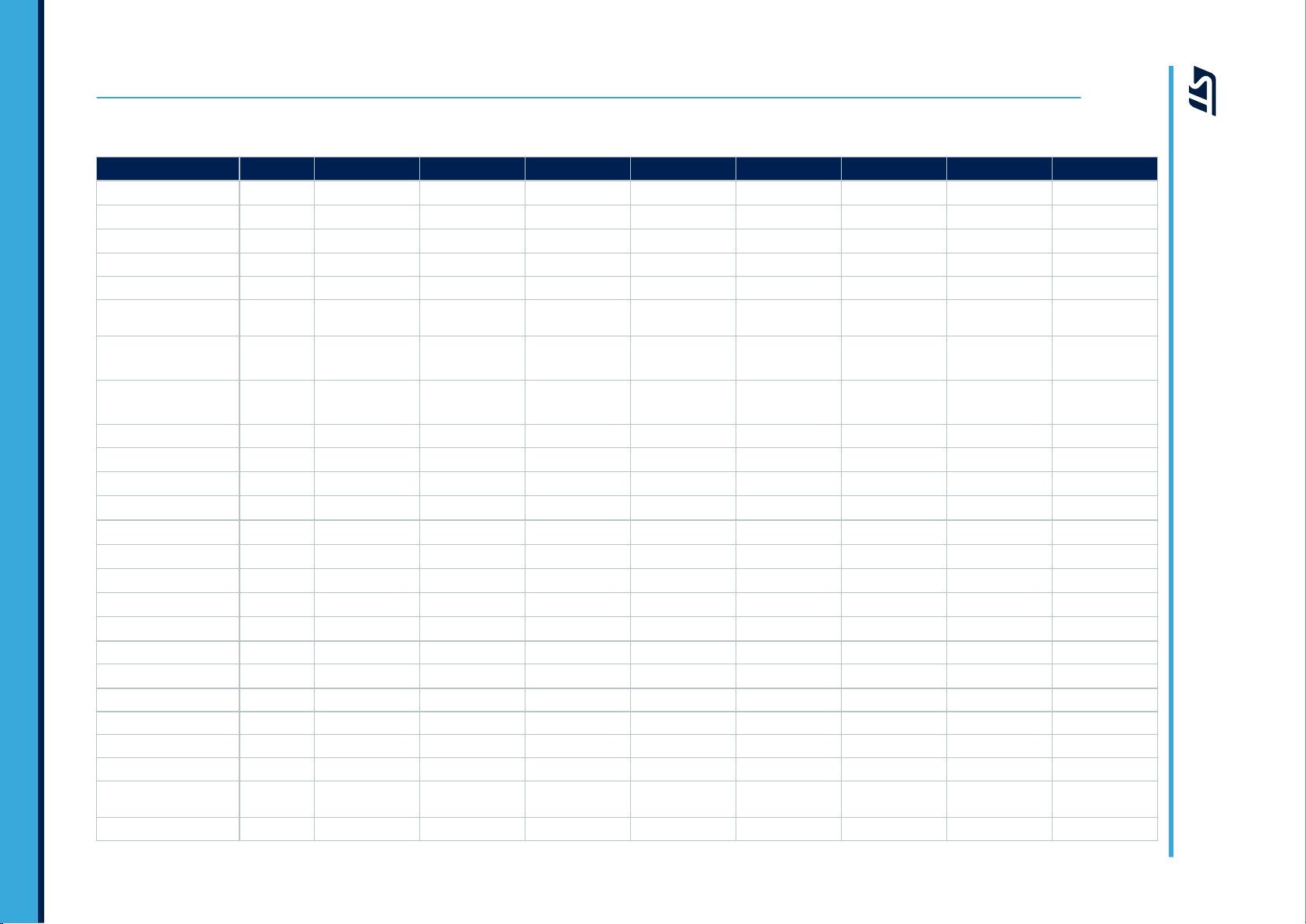

2 Registers

Table 2. Registers

Register name Address Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

OUT_T_L

OUT_T_H

WHO_AM_I

(1)

(1)

(1)

CTRL1 20h ODR3 ODR2 ODR1 ODR0 MODE1 MODE0 LP_MODE1 LP_MODE0

CTRL2 21h BOOT SOFT_RESET 0 CS_PU_DISC BDU IF_ADD_INC I2C_DISABLE SIM

CTRL3 22h ST2 ST1 PP_OD LIR H_LACTIVE 0

CTRL4_INT1_PAD_CTRL 23h INT1_6D

CTRL5_INT2_PAD_CTRL 24h

CTRL6 25h BW_FILT1 BW_FILT0 FS1 FS0 FDS LOW_NOISE 0 0

(1)

OUT_T

(1)

STATUS

OUT_X_L

OUT_X_H

OUT_Y_L

OUT_Y_H

OUT_Z_L

OUT_Z_H

(1)

(1)

(1)

(1)

(1)

(1)

FIFO_CTRL 2Eh FMode2 FMode1 FMode0 FTH4 FTH3 FTH2 FTH1 FTH0

FIFO_SAMPLES

(1)

TAP_THS_X 30h 4D_EN 6D_THS1 6D_THS0 TAP_THSX_4 TAP_THSX_3 TAP_THSX_2 TAP_THSX_1 TAP_THSX_0

TAP_THS_Y 31h TAP_PRIOR_2 TAP_PRIOR_1 TAP_PRIOR_0 TAP_THSY_4 TAP_THSY_3 TAP_THSY_2 TAP_THSY_1 TAP_THSY_0

TAP_THS_Z 32h TAP_X_EN TAP_Y_EN TAP_Z_EN TAP_THSZ_4 TAP_THSZ_3 TAP_THSZ_2 TAP_THSZ_1 TAP_THSZ_0

INT_DUR 33h LATENCY3 LATENCY2 LATENCY1 LATENCY0 QUIET1 QUIET0 SHOCK1 SHOCK0

WAKE_UP_THS 34h

WAKE_UP_DUR 35h FF_DUR5 WAKE_DUR1 WAKE_DUR0 STATIONARY SLEEP_DUR3 SLEEP_DUR2 SLEEP_DUR1 SLEEP_DUR0

0Dh TEMP3 TEMP2 TEMP1 TEMP0 0 0 0 0

0Eh TEMP11 TEMP10 TEMP9 TEMP8 TEMP7 TEMP6 TEMP5 TEMP4

0Fh 0 1 0 0 0 1 0 0

INT2_

SLEEP_ STATE

INT1_

SINGLE_TAP

INT2_

SLEEP_CHG

SLP_MODE

_SEL

INT1_WU INT1_FF INT1_TAP INT1_DIFF5 INT1_FTH INT1_DRDY

INT2_BOOT

INT2_

DRDY_T

INT2_OVR INT2_DIFF5 INT2_FTH INT2_DRDY

SLP_MODE_1

26h TEMP7 TEMP6 TEMP5 TEMP4 TEMP3 TEMP2 TEMP1 TEMP0

27h FIFO_THS WU_IA SLEEP_STATE DOUBLE_TAP SINGLE_TAP 6D_IA FF_IA DRDY

28h X_L7 X_L6 X_L5 X_L4

X_L3

(2)

X_L2

(2)

0 0

29h X_H7 X_H6 X_H5 X_H4 X_H3 X_H2 X_H1 X_H0

2Ah Y_L7 Y_L6 Y_L5 Y_L4

Y_L3

(2)

Y_L2

(2)

0 0

2Bh Y_H7 Y_H6 Y_H5 Y_H4 Y_H3 Y_H2 Y_H1 Y_H0

2Ch Z_L7 Z_L6 Z_L5 Z_L4

Z_L3

(2)

Z_L2

(2)

0 0

2Dh Z_H7 Z_H6 Z_H5 Z_H4 Z_H3 Z_H2 Z_H1 Z_H0

2Fh FIFO_FTH FIFO_OVR Diff5 Diff4 Diff3 Diff2 Diff1 Diff0

SINGLE_

DOUBLE_TAP

SLEEP_ON WK_THS5 WK_THS4 WK_THS3 WK_THS 2 WK_THS 1 WK_THS 0

AN5038

Registers

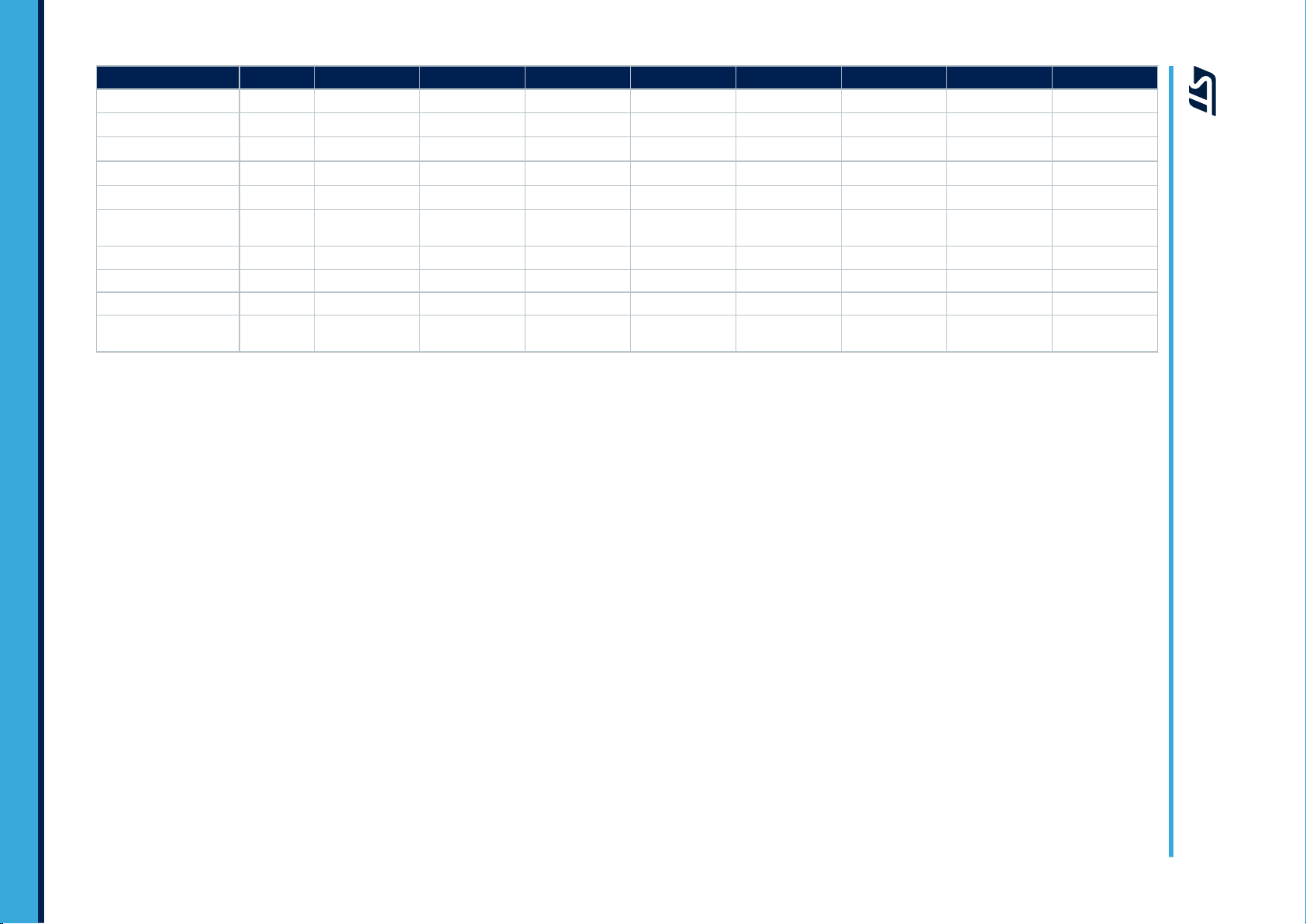

Page 4

AN5038 - Rev 5

Register name Address Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

FREE_FALL 36h FF_DUR4 FF_DUR3 FF_DUR2 FF_DUR1 FF_DUR0 FF_THS2 FF_THS1 FF_THS0

STATUS_DUP

WAKE_UP_SRC

TAP_SRC

SIXD_SRC

(1)

(1)

ALL_INT_SRC

(1)

(1)

(1)

37h OVR DRDY_T SLEEP_STATE_IA DOUBLE_TAP SINGLE_TAP 6D_IA FF_IA DRDY

38h 0 0 FF_IA SLEEP_STATE IA WU_IA X_WU Y_WU Z_WU

39h 0 TAP_IA SINGLE_TAP DOUBLE_TAP TAP_SIGN X_TAP Y_TAP Z_TAP

3Ah 0 6D_IA ZH ZL YH YL XH XL

3Bh 0 0

SLEEP_

CHANGE_IA

6D_IA DOUBLE_TAP SINGLE_TAP WU_IA FF_IA

X_OFS_USR 3Ch X_OFS_USR_7 X_OFS_USR_6 X_OFS_USR_5 X_OFS_USR_4 X_OFS_USR_3 X_OFS_USR_2 X_OFS_USR_1 X_OFS_USR_0

Y_OFS_USR 3Dh Y_OFS_USR_7 Y_OFS_USR_6 Y_OFS_USR_5 Y_OFS_USR_4 Y_OFS_USR_3 Y_OFS_USR_2 Y_OFS_USR_1 Y_OFS_USR_0

Z_OFS_USR 3Eh Z_OFS_USR_7 Z_OFS_USR_6 Z_OFS_USR_5 Z_OFS_USR_4 Z_OFS_USR_3 Z_OFS_USR_2 Z_OFS_USR_1 Z_OFS_USR_0

CTRL7 3Fh

DRDY_

PULSED

INT2_ON_INT1

INTERRUPTS

_ENABLE

USR_OFF

_ON_OUT

USR_OFF

_ON_WU

USR_OFF_W HP_REF_MODE LPASS_ON6D

1. Read-only register

2. If Low-Power Mode 1 is enabled, this bit is set to 0.

page 4/51

AN5038

Registers

Page 5

3 Operating modes

3.1 Power mode

Five sets of operating modes have been designed to offer the customer a broad choice of noise/powerconsumption combinations:

• 1 High-Performance Mode: focus on low noise

• 4 Low-Power Modes: trade-off between noise and power consumption

High-Performance Mode Low-Power Mode 4 Low-Power Mode 3 Low-Power Mode 2 Low-Power Mode 1

14-bit 14-bit 14-bit 14-bit 12-bit

These operating modes are selected by writing the MODE[1:0] and LP_MODE[1:0] bits in CTRL1 (20h) shown in

the table below.

AN5038

Operating modes

Table 3. Accelerometer resolution

Table 4. CTRL1 register

b7 b6 b5 b4 b3 b2 b1 b0

ODR3 ODR2 ODR1 ODR0 MODE1 MODE0 LP_MODE1 LP_MODE0

Table 5. Mode selection

MODE[1:0]

00 Low-Power Mode (12/14-bit resolution)

01 High-Performance Mode (14-bit resolution)

10 Single data conversion on-demand mode (12/14-bit resolution)

11 Not allowed

Mode and resolution

Table 6. Low-power mode selection

LP_MODE[1:0]

00 Low-Power Mode 1 (12-bit resolution)

01 Low-Power Mode 2 (14-bit resolution)

10 Low-Power Mode 3 (14-bit resolution)

11 Low-Power Mode 4 (14-bit resolution)

Mode and resolution

AN5038 - Rev 5

From each of these five sets, two configurations have been designed:

• Very low-power(low-noise off)

• Low-noise

Writing the LOW_NOISE bit in CTRL6 (25h) selects the desired configuration. The LOW_NOISE bit in CTRL6

(25h) impacts front-end noise and current consumption. Bandwidths and settling time are not impacted.

page 5/51

Page 6

Table 7 shows the typical values of power consumption for the different operating modes.

Table 7. Power consumption at 1.8 V [μA]

AN5038

Power mode

High

Performance

Output data rate

1.6 Hz

12.5 Hz 90 120 4 5 2.5 3 1.6 2 1 1.1

25 Hz 90 120 8.5 10 4.5 6 3 3.5 1.5 2

50 Hz 90 120 16 20 9 11 5.5 7 3 3.5

100 Hz 90 120 32 39 17.5 21.5 10.5 13 5 6

200 Hz 90 120 63 77 34.5 42 20.5 25 10 12

400/800/1600 Hz 90 120 - - - - - - - -

LOW_NOISE LOW_NOISE LOW_NOISE LOW_NOISE LOW_NOISE

0 1 0 1 0 1 0 1 0 1

- - 0.65 0.7 0.55 0.6 0.45 0.5 0.38 0.4

Low-Power Mode4Low-Power Mode3Low-Power Mode2Low-Power Mode

1

Table 8 and Table 9 show the typical noise values for the different operating modes.

Table 8. High-Performance Mode: noise density [μg/√Hz]

Full scale

±2 g

±4 g 110 100

±8 g 130 120

±16 g 170 160

0 1

110 90

LOW_NOISE

Note: In High-Performance Mode the noise density is the same for all ODRs.

Table 9. Low-Power Mode: RMS noise [mg(RMS)]

Low-Power Mode 4 Low-Power Mode 3 Low-Power Mode 2 Low-Power Mode 1

Full scale

±2 g

±4 g 1.7 1.4 2.3 1.9 3.2 2.7 6.5 5.4

±8 g 1.7 1.5 2.4 2.1 3.3 2.8 6.8 5.8

±16 g 2.0 1.8 2.7 2.4 3.7 3.3 7.7 7.0

0 1 0 1 0 1 0 1

LOW_NOISE LOW_NOISE LOW_NOISE LOW_NOISE

1.6 1.3 2.1 1.8 3.0 2.4 5.5 4.5

Note: In Low-Power Mode the RMS noise is the same for all ODRs.

AN5038 - Rev 5

page 6/51

Page 7

3.2 Continuous conversion

When bits MODE[1:0] in CTRL1 (20h) are set to Low-Power mode (00b) or High-Performance mode (01b), the

device is in continuous conversion and the output data rate can be selected through the ODR[3:0] bits in CTRL1

(20h).

ODR[3:0] Mode and resolution

0000 Power-down

0001 High-Performance 12.5 Hz / Low-Power mode 1.6 Hz

0010 12.5 Hz (independent of power mode)

0011 25 Hz (independent of power mode)

0100 50 Hz (independent of power mode)

0101 100 Hz (independent of power mode)

0110 200 Hz (independent of power mode)

0111 High-Performance 400 Hz / Low-Power mode 200 Hz

1000 High-Performance 800 Hz / Low-Power mode 200 Hz

1001 High-Performance 1600 Hz / Low-Power mode 200 Hz

AN5038

Continuous conversion

Table 10. Output data rate selection

AN5038 - Rev 5

page 7/51

Page 8

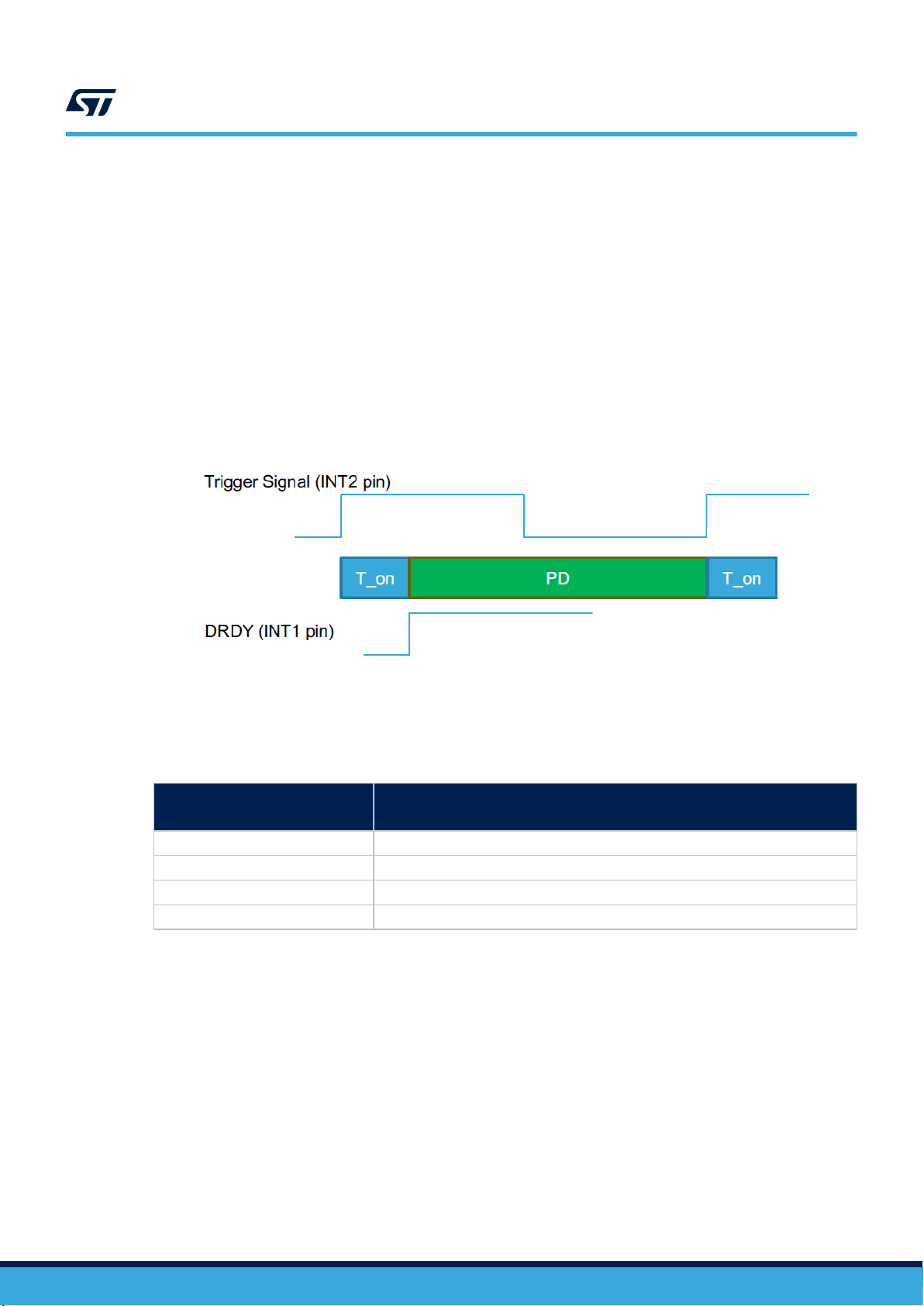

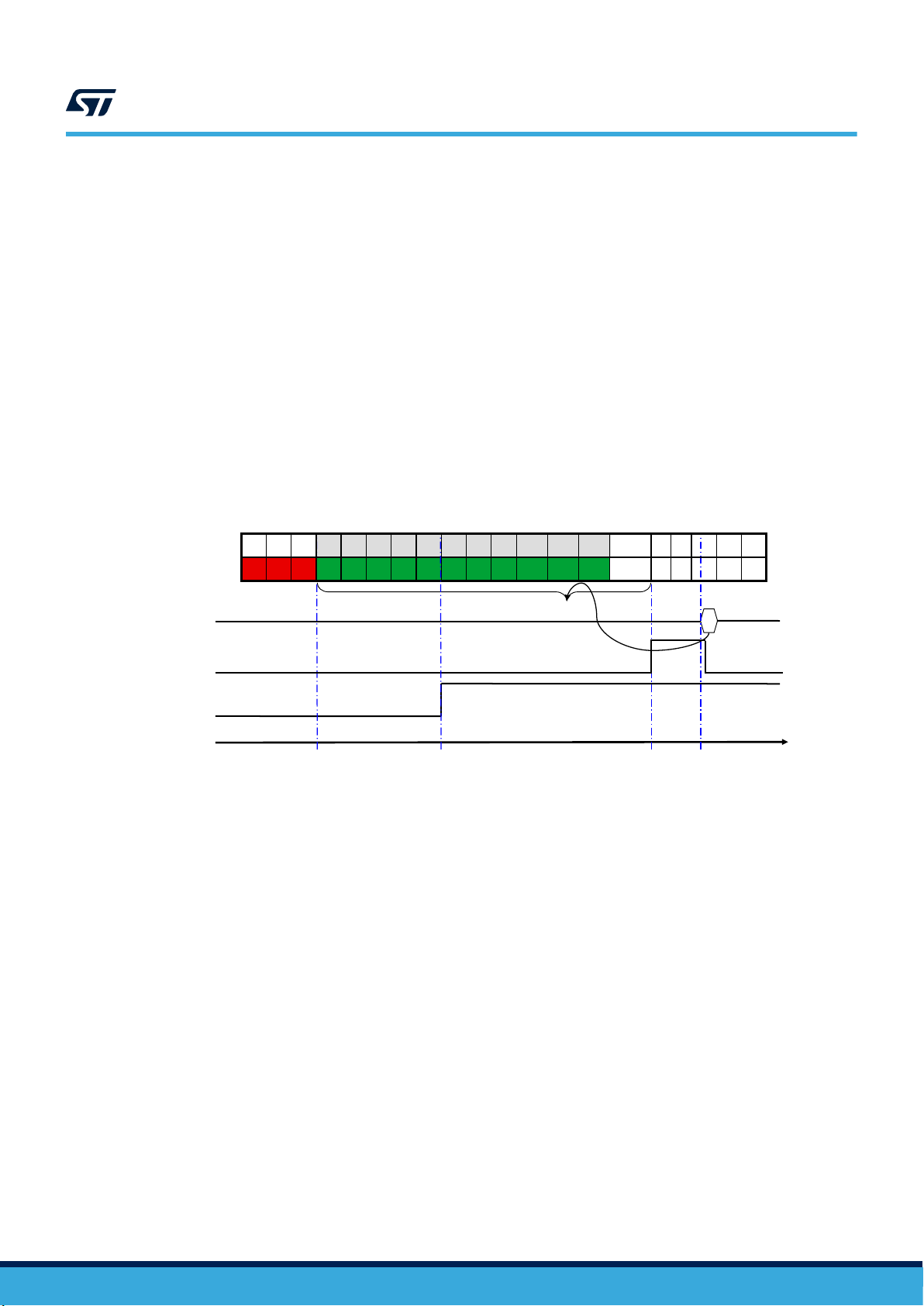

3.3 Single data conversion (on-demand mode)

This mode is available only for low-power modes and it is enabled by writing the MODE[1:0] bits to ‘10' in CTRL1

(20h).

In this configuration the device waits for a trigger signal in order to generate new data according to the selected

power mode LP_MODE[1:0] bits in CTRL1 (20h), after that the device immediately enters power-down.

The trigger can be:

• A rising edge on the INT2 pin (if SLP_MODE_SEL = ‘0' in register CTRL3 (22h)). In this case the

user can detect the end of the conversion using the DRDY bit of the STATUS register (27h) that can also

be routed to the INT1 pin by setting the INT1_DRDY bit to 1 in register CTRL4_INT1_PAD_CTRL (23h).

Minimum duration of trigger signal high level is 20 ns.

• A write of SLP_MODE_1 to ‘1' in register CTRL3 (22h) (if SLP_MODE_SEL ='1' in register CTRL3

(22h)). In this case, the user can detect the end of the conversion using the DRDY bit/signal as in the

previous case, or by checking when the SLP_MODE_1 bit in register CTRL3 (22h) is automatically cleared.

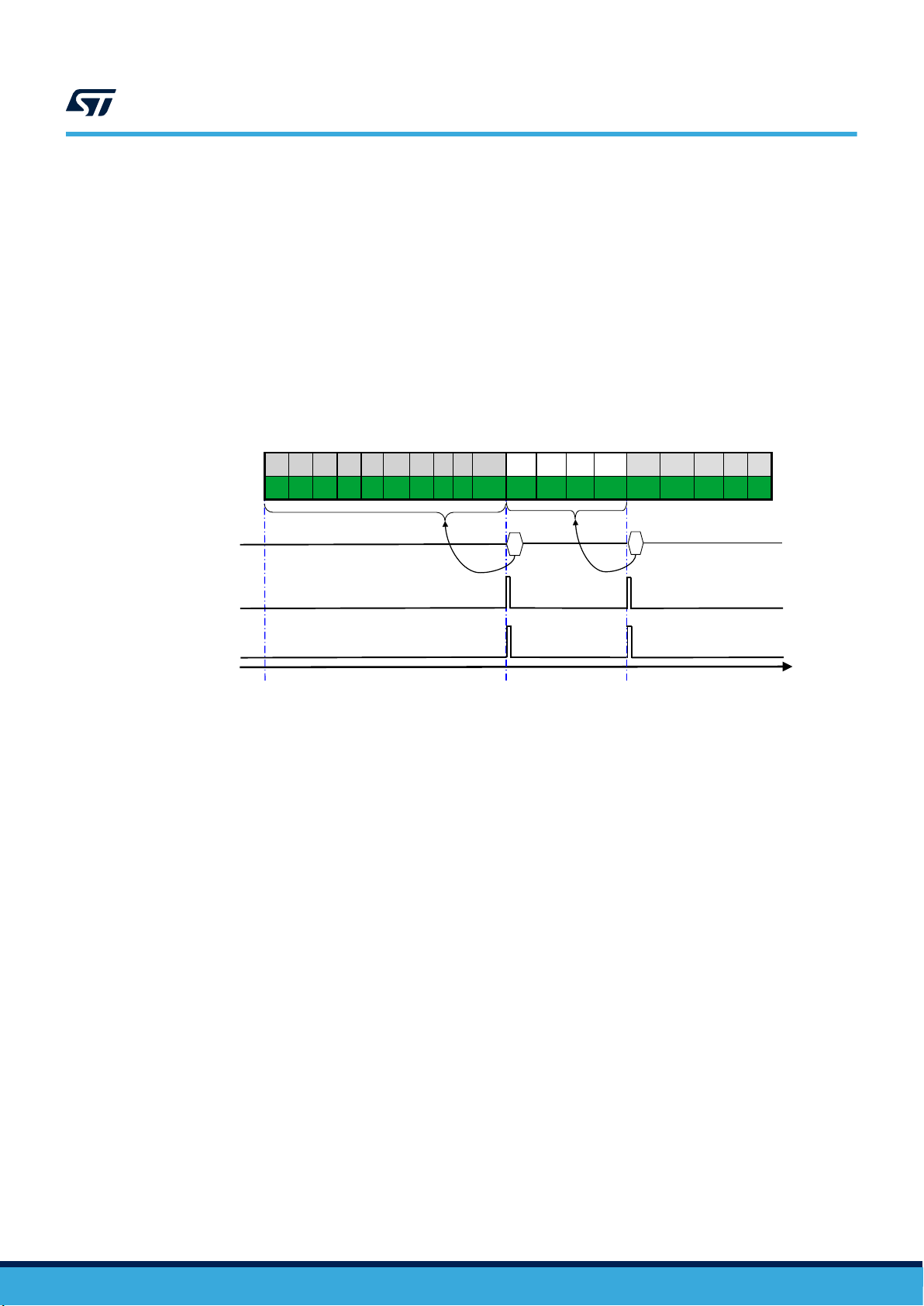

Figure 2. Single data conversion using INT2 as external trigger (SLP_MODE_SEL = 0)

AN5038

Single data conversion (on-demand mode)

The maximum data rate using single data conversion mode is 200 Hz and the time of conversion depends on the

low-power mode selected (refer to the following table).

Table 11. Low-power mode selection

Low-power

Mode 1 1.20 ms

Mode 2 1.70 ms

Mode 3 2.30 ms

Mode 4 3.55 ms

Typical time of conversion

(T_on)

Note: If the ODR[3:0] bits of the CTRL1 register are set to 0000b, the accelerometer is permanently configured in

Power-down mode and no conversion can be triggered. When the single data conversion mode has to be used,

the ODR[3:0] bits of the CTRL1 register must be different than 0000b.

Interrupts, embedded features and FIFO are still supported when using single data conversion mode. Also the

embedded filters LPF1, LPF2 and HP are available in single data conversion (on-demand mode) with the same

bandwidth and settling time of the selected low-power mode (see Section 3.4 Accelerometer bandwidth for

details).

AN5038 - Rev 5

page 8/51

Page 9

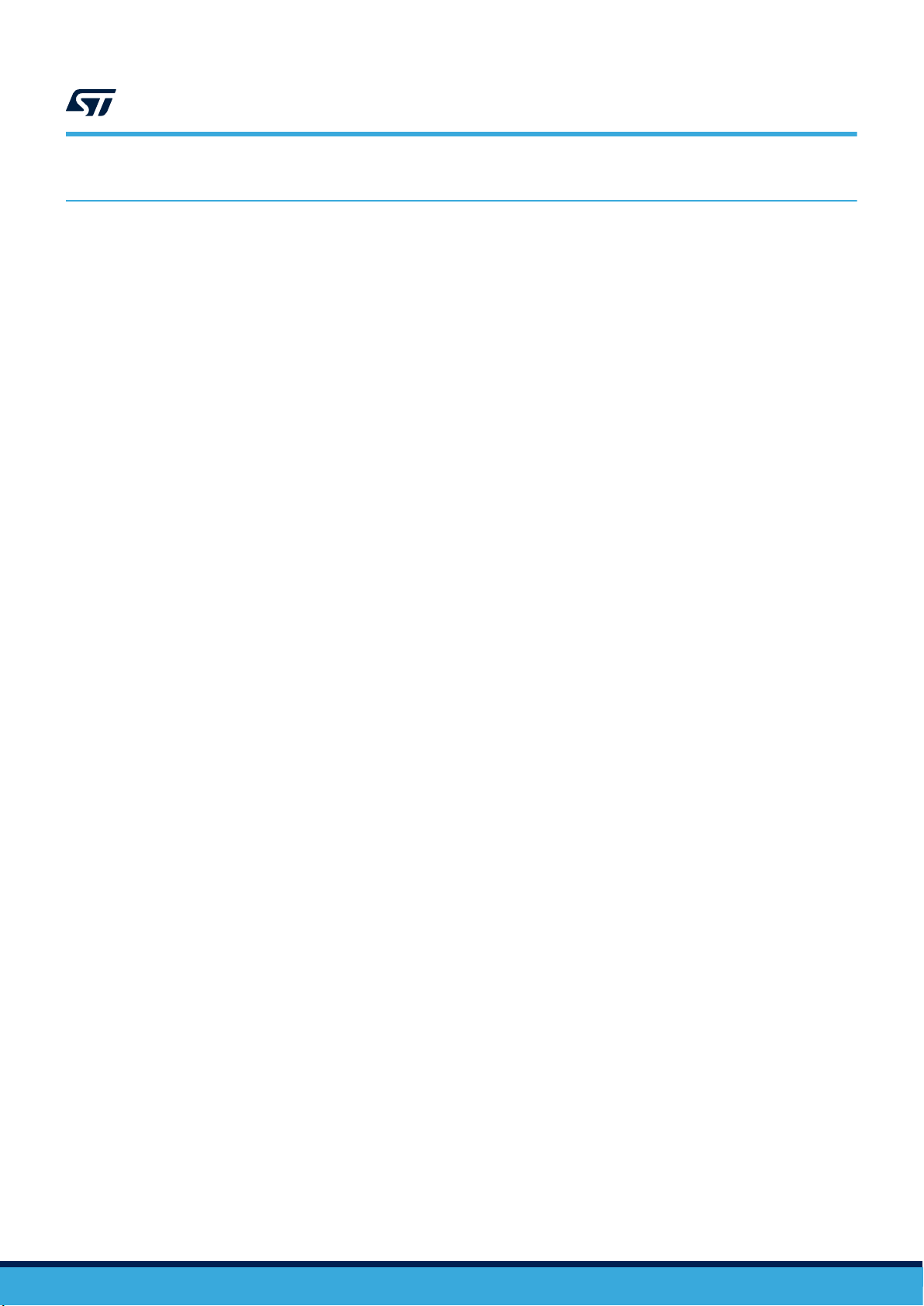

3.4 Accelerometer bandwidth

The accelerometer sampling chain (Figure 3. Accelerometer filtering chain diagram) is represented by a cascade

of a few blocks:

• ADC: Analog-to-digital converter

• Anti-Aliasing Filter: available only in High-Performance Mode (MODE[1:0] = 01) with a cutoff frequency of

400 Hz

• LPF1(2): low-pass filter 1(2)

• HP: high-pass filter

• User offset: configurable values that are subtracted from the sampled data (one for each axis)

Figure 3. Accelerometer filtering chain diagram

AN5038

Accelerometer bandwidth

As shown in the figure above, data can be generated using three different filter paths:

• only LPF1 (green path) : in order to select this path set BW_FILT[1:0] = 00 and FDS = 0. Additional details in

Table 12. Low-pass filter 1 bandwidth.

• LPF1 + LPF2 (purple path) : in order to select this path set BW_FILT[1:0] to a value different from 00 and

FDS = 0. Additional details in Table 13. Bandwidth: low-pass path.

• LPF1 + HP (blue path): these outputs are available by setting FDS = 1. Additional details in

Table 14. Bandwidth: high-pass path.

AN5038 - Rev 5

page 9/51

Page 10

AN5038

Accelerometer bandwidth

Table 12. Low-pass filter 1 bandwidth

BW_FILT[1:0] = 00

Mode ODR selection

Samples to discard

Settling @95%

Low-Power Mode 4 @ each ODR

0 180

Low-Power Mode 3 @ each ODR 0 360

Low-Power Mode 2 @ each ODR 0 720

Low-Power Mode 1 @ each ODR 0 3200

High-Performance @12.5 Hz 0 ODR/2

High-Performance @25 Hz 0 ODR/2

High-Performance @50 Hz 0 ODR/2

High-Performance @100 Hz 1 ODR/2

High-Performance @200 Hz 1 ODR/2

High-Performance @400 Hz 1 ODR/2

High-Performance @800 Hz 1 ODR/2

High-Performance @1600 Hz 2 400

1. The starting condition of ODR[3:0], MODE[1:0], LP_MODE[1:0] and BW_FILT[1:0] do not impact these values. The turn-on

time (first sample available starting from power-down condition) is 1 / ODR.

(1)

Cutoff [Hz]

Table 13. Bandwidth: low-pass path

BW_FILT[1:0] = 01 BW_FILT[1:0] = 10 BW_FILT[1:0] = 11

Mode

ODR selection

Samples to

discard

(1)

Cutoff [Hz]

Settling @95%

LP

Mode 4

LP

Mode 3

LP

Mode 2

LP

Mode 1

@ each ODR

@ each ODR 1 ODR/4 5 ODR/10 11 ODR/20

@ each ODR 1 ODR/4 5 ODR/10 11 ODR/20

@ each ODR 1 ODR/4 5 ODR/10 11 ODR/20

1 ODR/4 5 ODR/10 11 ODR/20

HP @12.5 Hz 1 ODR/4 5 ODR/10 11 ODR/20

HP @25 Hz 1 ODR/4 5 ODR/10 11 ODR/20

HP @50 Hz 1 ODR/4 5 ODR/10 11 ODR/20

HP @100 Hz 1 ODR/4 5 ODR/10 11 ODR/20

HP @200 Hz 2 ODR/4 5 ODR/10 11 ODR/20

HP @400 Hz 2 ODR/4 5 ODR/10 11 ODR/20

HP @800 Hz 2 ODR/4 5 ODR/10 11 ODR/20

HP @1600 Hz 3 ODR/4 6 ODR/10 12 ODR/20

1. The starting condition of ODR[3:0], MODE[1:0], LP_MODE[1:0] and BW_FILT[1:0] do not impact these values.

Samples to

discard

(1)

Settling @95%

Cutoff

[Hz]

Samples to

discard

(1)

Settling @95%

Cutoff

[Hz]

AN5038 - Rev 5

page 10/51

Page 11

AN5038

Accelerometer bandwidth

Table 14. Bandwidth: high-pass path

BW_FILT[1:0] = 01 / 00 BW_FILT[1:0] = 10 BW_FILT[1:0] = 11

Mode ODR selection

LP

Mode 4

Mode 3

Mode 2

Mode 1

@ each ODR

LP

@ each ODR 1 ODR/4 5 ODR/10 11 ODR/20

LP

@ each ODR 1 ODR/4 5 ODR/10 11 ODR/20

LP

@ each ODR 1 ODR/4 5 ODR/10 11 ODR/20

Samples to

discard

(1)

Settling @95%

Cutoff [Hz]

Samples to discard

Settling @95%

1 ODR/4 5 ODR/10 11 ODR/20

HP @12.5 Hz 1 ODR/4 5 ODR/10 11 ODR/20

HP @25 Hz 1 ODR/4 5 ODR/10 11 ODR/20

HP @50 Hz 1 ODR/4 5 ODR/10 11 ODR/20

HP @100 Hz 1 ODR/4 5 ODR/10 11 ODR/20

HP @200 Hz 2 ODR/4 5 ODR/10 11 ODR/20

HP @400 Hz 2 ODR/4 5 ODR/10 11 ODR/20

HP @800 Hz 2 ODR/4 5 ODR/10 11 ODR/20

HP @1600 Hz 3 ODR/4 6 ODR/10 12 ODR/20

1. The starting condition of ODR[3:0], MODE[1:0], LP_MODE[1:0] and BW_FILT[1:0] do not impact these values.

(1)

Cutoff

Samples to discard

[Hz]

Settling @95%

(1)

Cutoff

[Hz]

Setting USR_OFF_ON_OUT = 1 in CTRL7 does not change the bandwidth of the system. In this configuration,

the values written in registers X_OFS_USR, Y_OFS_USR, Z_OFS_USR are subtracted from the respective axis.

The offset values are signed values (two's complement).

The weight of the bits in registers X_OFS_USR, Y_OFS_USR, Z_OFS_USR is defined through the USR_OFF_W

bit in CTRL7.

AN5038 - Rev 5

page 11/51

Page 12

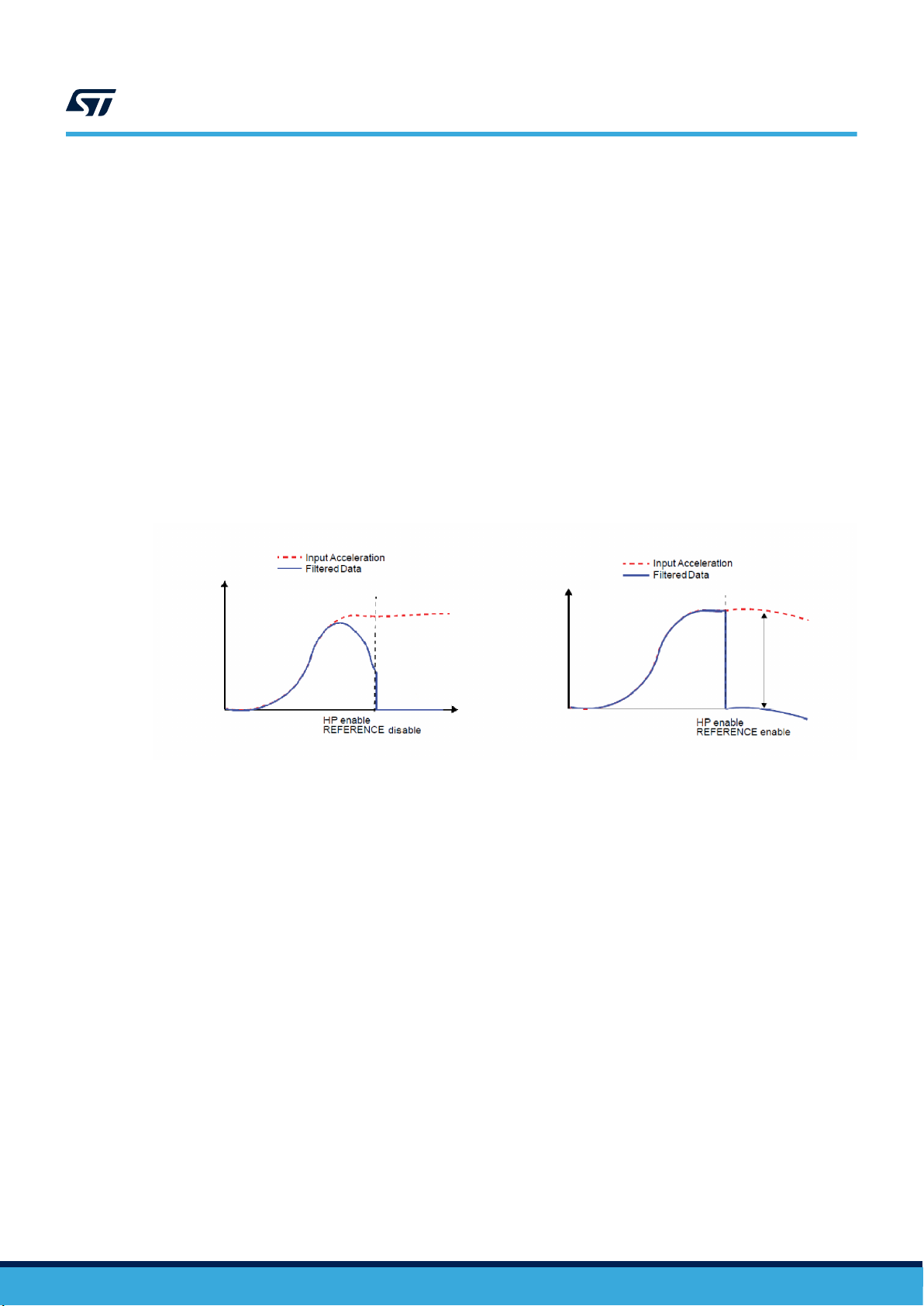

3.5 High-pass filter configuration

The LIS2DW12 provides an embedded high-pass filtering capability to easily delete the DC component of the

measured acceleration. As shown in Figure 3. Accelerometer filtering chain diagram, through the FDS bit in

register CTRL6 the user can route the filter outputs to the output registers.

It is also possible to independently apply the filter to the embedded function data (Figure 6. Embedded functions

in Section 5 Interrupt generation and embedded functions). This means that it is possible to get filtered data

while the interrupt generation works on unfiltered data.

The high-pass filter can be configured in reference mode by setting the HP_REF_MODE bit in the CTRL7 register

to 1. In this configuration the output data is calculated as the difference between the measured acceleration and

the output values captured when reference mode was enabled. In this way only the difference is applied without

any filtering.

As an example, this feature can be combined with the wake-up functionality described in Section 5.4 in order

to detect when the device is displaced with respect to a specific orientation, i.e. the orientation of the device

when the HP_REF_MODE bit was set to 1. When the output acceleration exceeds the wake-up threshold defined

by the WK_THS[5:0] bits in the WAKE_UP_THS register for a duration longer than the one defined by the

WAKE_DUR[1:0] bits in the WAKE_UP_DUR register, an interrupt is generated. If the device is moved back to the

original reference orientation, the interrupt is deactivated.

Figure 4. High-pass filter in normal and reference mode

AN5038

High-pass filter configuration

AN5038 - Rev 5

page 12/51

Page 13

4 Reading output data

4.1 Startup sequence

Once the device is powered up, it automatically downloads the calibration coefficients from the embedded

non-volatile memory to the internal registers. When the boot procedure is completed, i.e. after approximately

20 milliseconds, the accelerometer automatically enters power-down. The default status of the pins with both VDD

and VDDIO "on" is indicated in Table 1. Internal pin status.

Note: VDD cannot be lower than VDDIO. VDD = 0 V and VDDIO "on" is allowed: when this power supply

configuration is applied, an internal pull-up is applied also to the SDA and SCL pins (the other pins maintain the

default status indicated in Table 1).

To turn on the accelerometer and gather acceleration data, it is necessary to select one of the operating modes

through the CTRL1 register.

Refer to Section 3 Operating modes for a detailed description of data generation.

4.2 Using the status register

The device is provided with a STATUS register which can be polled to check when a new set of data is available.

The DRDY bit is set to 1 when a new set of data is available from the accelerometer output.

The read operations should be performed as follows:

1. Read STATUS

2. If DRDY = 0, then go to 1

3. Read OUT_X_L

4. Read OUT_X_H

5. Read OUT_Y_L

6. Read OUT_Y_H

7. Read OUT_Z_L

8. Read OUT_Z_H

9. Data processing

10. Go to 1

AN5038

Reading output data

4.3 Using the data-ready signal

The device can be configured to have one hardware signal to determine when a new set of measurement data is

available to be read.

The data-ready signal is derived from the DRDY bit of the STATUS register. The signal can be driven to the INT1

pin by setting the INT1_DRDY bit of the CTRL4_INT1_PAD_CTRL register to 1 and to the INT2 pin by setting the

INT2_DRDY bit of the CTRL5_INT2_PAD_CTRL register to 1.

The data-ready signal rises to 1 when a new set of data has been measured and is available to be read. In

DRDY latched mode (DRDY_PULSED bit = 0 in CTRL7 register), which is the default condition, the signal gets

reset when the higher part of one of the channels has been read (29h, 2Bh, 2Dh). In DRDY pulsed mode

(DRDY_PULSED = 1) the pulse duration is 75 μs (typical) if the accelerometer is configured in High-Performance

mode, otherwise it can vary between 105 μs and 175 μs. Pulsed mode is not applied to the DRDY bit which is

always latched.

AN5038 - Rev 5

page 13/51

Page 14

Figure 5. Data-ready signal

4.4 Using the block data update (BDU) feature

If reading the accelerometer data is particularly slow and cannot be synchronized (or it is not required) with either

the DRDY event bit in the STATUS register or with the DRDY signal driven to the INT1/INT2 pins, it is strongly

recommended to set the BDU (block data update) bit to 1 in the CTRL2 (21h) register.

This feature avoids reading values (most significant and least significant parts of output data) related to different

samples. In particular, when the BDU is activated, the data registers related to each channel always contain

the most recent output data produced by the device, but, in case the read of a given pair (i.e. OUT_X_H and

OUT_X_L, OUT_Y_H and OUT_Y_L, OUT_Z_H and OUT_Z_L) is initiated, the refresh for that pair is blocked

until both MSB and LSB parts of the data are read.

Note: BDU only guarantees that the LSB part and MSB part of one data channel have been sampled at the same

moment. For example, if the reading speed is too slow, X and Y can be read at T1 and Z sampled at T2.

AN5038

Using the block data update (BDU) feature

4.5 Understanding output data

The measured acceleration data are sent to the OUT_X_H, OUT_X_L, OUT_Y_H, OUT_Y_L, OUT_Z_H, and

OUT_Z_L registers. These registers contain, respectively, the most significant part and the least significant part of

the acceleration signals acting on the X, Y, and Z axes.

The complete output data for the X, Y, Z channels is given by the concatenation OUT_X_H & OUT_X_L,

OUT_Y_H & OUT_Y_L , OUT_Z_H & OUT_Z_L.

Acceleration data is represented as 16-bit numbers, left-aligned and encoded in two’s complement. These values

(LSB) have different resolution according to the selected operating mode.

After calculating the LSB, it must be multiplied by the proper sensitivity parameter to obtain the corresponding

value in mg.

Full Scale

±2 g

±4 g 1.952 0.488

±8 g 3.904 0.976

1. Only Low-Power Mode 1

±16 g 7.808 1.952

Table 15. Sensitivity

Sensitivity [mg/LSB]

12-bit format

0.976 0.244

(1)

14-bit format

AN5038 - Rev 5

page 14/51

Page 15

4.5.1 Example of output data

Below is a simple example of how to use the LSB data and transform it into mg.

The values are given under the hypothesis of ideal device calibration (i.e., no offset, no gain error, etc.).

Get raw data from the sensor (High-Performance mode, ±2 g):

OUT_X_L: 60h

OUT_X_H: FDh

OUT_Y_L: 78h

OUT_Y_H: 00h

OUT_Z_L: FCh

OUT_Z_H: 42h

Do register concatenation:

AN5038

Understanding output data

OUT_X_H & OUT_X_L: FD60h

OUT_Y_H & OUT_Y_L: 0078h

OUT_Z_H & OUT_Z_L: 42FCh

Apply sensitivity (e.g., 14-bit resolution, 0.244 at full scale ±2 g):

X: -672 / 4 * 0.244 = -41 mg

Y: +120 / 4 * 0.244 = +7 mg

Z: +17148 / 4 * 0.244 = +1046 mg

AN5038 - Rev 5

page 15/51

Page 16

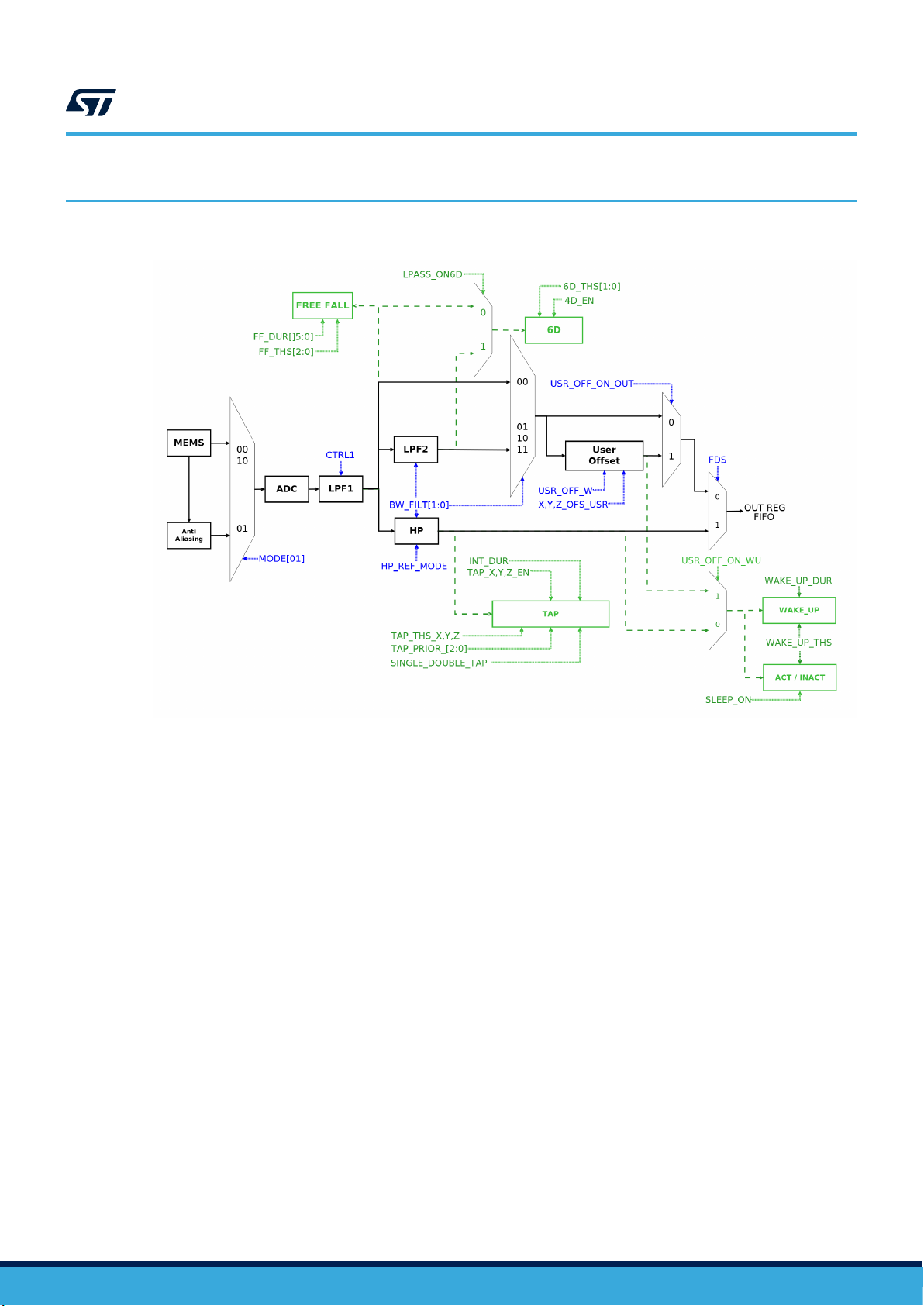

Interrupt generation and embedded functions

5 Interrupt generation and embedded functions

Figure 6. Embedded functions

AN5038

In order to generate an interrupt, the LIS2DW12 device has to be set in an active operating mode (not in

power-down) because generation of the interrupt is based on accelerometer data.

The interrupt generator can be configured to detect:

• Free-fall;

• Wake-up;

• 6D/4D orientation detection;

• Single-tap and double-tap sensing;

• Activity/Inactivity detection.

All these interrupt signals, together with the FIFO interrupt signals and sensor data-ready, can be driven to the

INT1 and/or INT2 interrupt pins or checked by reading the dedicated source register bits.

The H_LACTIVE bit of the CTRL3 register must be used to select the polarity of the interrupt pins. If this bit

is set to 0 (default value), the interrupt pins are active high and they change from low to high level when the

related interrupt condition is verified. Otherwise, if the H_LACTIVE bit is set to 1 (active low), the interrupt pins are

normally at high level and they change from high to low when the interrupt condition is reached.

The PP_OD bit of CTRL3 allows changing the behavior of the interrupt pins also when the DRDY signal is routed

to them from push-pull to open drain. If the PP_OD bit is set to 0, the interrupt pins are in push-pull configuration

(low-impedance output for both high and low level). When the PP_OD bit is set to 1, only the interrupt active state

is a low-impedance output.

The LIR bit of CTRL3 allows applying the latched mode to the interrupt signals (not affecting the DRDY signal).

When the LIR bit is set to 1, once the interrupt pin is asserted, it must be reset by reading the related interrupt

source register. If the LIR bit is set to 0, the interrupt signal is automatically reset when the interrupt condition is

no longer verified or after a certain amount of time in function of the type of interrupt.

Note: If latched mode is enabled (LIR = 1), it is not recommended to continuously poll ALL_INT_SRC or the

dedicated source registers because by reading them the embedded functions are internally reset; a synchronous

(with interrupt event) read of the source registers is recommended in this case.

AN5038 - Rev 5

page 16/51

Page 17

5.1 Interrupt pin configuration

The device is provided with two pins that can be activated to generate:

• device status signals (such as data-ready and boot);

• embedded function interrupt signals;

• notification FIFO signals.

All the embedded function interrupt signals are subordinate to the INTERRUPTS_ENABLE bit in register CTRL7.

If this bit is set, the embedded functions are enabled and the interrupts signals can be routed to the INT1 and/or

INT2 pins; otherwise, if this bit is not set, the embedded functions are disabled. The INT2 pin can also become an

input pin when it is used as an external trigger in single data conversion (on-demand) mode. In order to configure

the device in this mode the user must set bits MODE[1:0] = 10 in register CTRL1 and bit SLP_MODE_SEL = 0 in

register CTRL3. It is possible to route all the INT2 pin signals on the INT1 pin by setting bit INT2_ON_INT1 = 1 in

register CTRL7.

AN5038

Interrupt pin configuration

Figure 7. Interrupt pin configuration

AN5038 - Rev 5

The description of the interrupt control registers appears below; the default value of their bits is equal to 0, which

corresponds to "disable". In order to enable the routing of a specific interrupt signal on the pin, the corresponding

bit has to be set to 1.

Table 16. CTRL4_INT1_PAD_CTRL

b7

INT1_6D

b6 b5 b4 b3 b2 b1 b0

INT1_

SINGLE_TAP

INT1_WU INT1_FF INT1_TAP INT1_DIFF5 INT1_FTH INT1_DRDY

• INT1_6D: 6D recognition is routed to the INT1 pin.

• INT1_SINGLE_TAP: Single-tap event recognition is routed to the INT1 pin.

• INT1_WU: Wakeup event recognition is routed to the INT1 pin.

• INT1_FF: Free-fall event recognition is routed to the INT1 pin.

• INT1_TAP: Double-tap event recognition is routed to the INT1 pin.

page 17/51

Page 18

• INT1_DIFF5: FIFO full recognition is routed to the INT1 pin.

• INT1_FTH: FIFO threshold event is routed to the INT1 pin.

• INT1_DRDY: Accelerometer data-ready is routed to the INT1 pin.

Table 17. CTRL5_INT2_PAD_CTRL

b7 b6 b5 b4 b3 b2 b1 b0

INT2_

SLEEP_STATE

INT2_

SLEEP_CHG

INT2_BOOT INT2_DRDY_T INT2_ OVR INT2_DIFF5 INT2_FTH INT2_DRDY

• INT2_SLEEP_STATE: Enable routing of SLEEP_STATE to the INT2 pin.

• INT2_SLEEP_CHG: Sleep change status routed to the INT2 pin.

• INT2 _BOOT: Boot state routed to the INT2 pin.

• INT2_DRDY_T: Temperature data-ready is routed to the INT2 pin.

• INT2 _OVR: FIFO overrun interrupt is routed to the INT2 pin.

• INT2_DIFF5: FIFO full recognition is routed to the INT2 pin.

• INT2_FTH: FIFO threshold event is routed to the INT2 pin.

• INT2_DRDY: Accelerometer data-ready to the INT2 pin.

AN5038

Event status

5.2 Event status

If multiple interrupt signals are routed on the same pin (INTx), the logic level of this pin is the “OR” combination of

the selected interrupt signals. In order to know which event has generated the interrupt condition, the application

should read the proper status register, which also will clear the event.

As indicated below, the STATUS register is partially duplicated at address 37h in order to allow a multiple read of

consecutive registers.

• STATUS (27h) or STATUS_DUP (37h);

• WAKE_UP_SRC (38h);

• TAP_SRC (39h);

• SIXD_SRC (3Ah);

• ALL_INT_SRC (3Bh).

AN5038 - Rev 5

page 18/51

Page 19

5.3 Free-fall interrupt

Free-fall detection refers to a specific register configuration that allows recognizing when the device is in free-fall:

the acceleration measured along all the axes goes to zero. In a real case a “free-fall zone” is defined around the

zero-g level where all the accelerations are small enough to generate the interrupt. Configurable threshold and

duration parameters are associated to free-fall event detection: the threshold parameter defines the free-fall zone

amplitude; the duration parameter defines the minimum duration of the free-fall interrupt event to be recognized

(Figure 8. Free-fall interrupt).

AN5038

Free-fall interrupt

Figure 8. Free-fall interrupt

The free-fall event signal can be routed to the INT1 pin by setting the INT1_FF bit of the

CTRL4_INT1_PAD_CTRL register to 1; it can also be checked by reading the FF_IA bit of the STATUS register.

If latch mode is disabled (LIR bit of CTRL3 is set to 0), the interrupt signal is automatically reset when the

free-fall condition is no longer verified. If latch mode is enabled and the free-fall interrupt signal is driven to the

interrupt pins, once a free-fall event has occurred and the interrupt pin is asserted, it must be reset by reading

the WAKE_UP_SRC or ALL_INT_SRC register. If the latch mode is enabled, but the interrupt signal is not driven

to the interrupt pins, the latch feature does not take effect (the FF_IA bit in STATUS is reset when the free-fall

condition is no longer verified).

The free-fall detection parameters can be modified by configuring the FREE_FALL (contains bits FF_THS[2:0]

and FF_DUR[4:0]) and WAKE_UP_DUR (contains MSB of duration parameter - FF_DUR5) registers. The

threshold value can be set through the FF_THS[2:0] bits and is described in Table 18. Free-fall threshold value.

The values given in this table are valid for any accelerometer full-scale configuration.

Table 18. Free-fall threshold value

FREE_FALL - FF_THS[2:0]

000 ~156 mg

001 ~219 mg

010 ~250 mg

011 ~312 mg

100 ~344 mg

101 ~406 mg

110 ~469 mg

111 ~500 mg

Threshold value

AN5038 - Rev 5

Duration time is measured in N/ODR, where N is the content of the FF_DUR[5:0] field of the FREE_FALL /

WAKE_UP_DUR registers and ODR is the accelerometer data rate.

page 19/51

Page 20

AN5038

Free-fall interrupt

A basic SW routine for free-fall event recognition is given below.

1. Write 64h in CTRL1 // Turn on the accelerometer

// ODR = 200 Hz, High-Performance

2. Write 04h in CTRL6 // FS ±2 g, LOW_NOISE enabled

3. Write 00h in WAKE_UP_DUR // Set event duration (FF_DUR5 = 0)

4. Write 33h in FREE_FALL // Set FF threshold (FF_THS[2:0] = 011b)

// Set six sample event duration (FF_DUR[5:0] = 000110b)

5. Write 10h in CTRL4_INT1_PAD_CTRL // FF interrupt driven to INT1 pin

6. Write 10h in CTRL3 // Latch interrupt

7. Write 20h in CTRL7 // Enable interrupts

The sample code exploits a threshold set to ~312 mg for free-fall recognition and the event is notified by hardware

through the INT1 pin. The FF_DUR[5:0] field of the FREE_FALL / WAKE_UP_DUR registers is configured to

ignore events that are shorter than 6/ODR = 6/200 Hz = 30 ms in order to avoid false detections.

AN5038 - Rev 5

page 20/51

Page 21

5.4 Wake-up interrupt

+ WK Threshold

- WK Threshold

WK Interrupt

WK Duration

HIGH-PASS FILTER OUTPUTS

In the LIS2DW12 device the wake-up feature can use the high-pass filter or the offset outputs, this choice can be

done through the USR_OFF_ON_WU bit in CTRL7 as illustrated in Figure 6. Embedded functions.

If “offset output” is selected, every axis can have offset with a different value, writing registers X_OFS_USR,

Y_OFS_USR, Z_OFS_USR. Bit weight is defined through the USR_OFF_W bit in register CTRL7.

The wake-up interrupt signal is generated if a certain number of consecutive data exceed the configured threshold

(Figure 9. Wake-up event recognition (using the HP filter)).

The unsigned threshold value is defined using the WK_THS [5:0] bits of the WAKE_UP_THS register; the value of

1 LSB of these 6 bits depends on the selected accelerometer full scale: 1 LSB = FS/64. The threshold is applied

to both positive and negative data: for a wake-up interrupt generation at least one of the three axes must be

bigger than the threshold.

The duration parameter defines the minimum duration of the wake-up event to be recognized; its value is set

using the WAKE_DUR [1:0] bits of the WAKE_UP_DUR register: 1 LSB corresponds to 1*ODR time, where ODR

is the accelerometer output data rate. It is important to appropriately define the duration parameter to avoid

unwanted wake-up interrupts due to spurious spikes of the input signal.

This interrupt signal can be driven to the INT1 interrupt pin by setting the INT1_WU bit of the

CTRL4_INT1_PAD_CTRL register to 1; it can also be checked by reading the WU_IA bit of the STATUS register.

The X_WU, Y_WU, Z_WU bits of the WAKE_UP_SRC register indicate which axis has triggered the wake-up

event.

If latch mode is disabled (LIR bit of CTRL3 is set to 0), the interrupt signal is automatically reset when the filtered

data falls below the threshold. If latch mode is enabled and the wake-up interrupt signal is driven to the interrupt

pins, once a wake-up event has occurred and the interrupt pin is asserted, it must be reset by reading the

WAKE_UP_SRC or ALL_INT_SRC register. The X_WU, Y_WU, Z_WU bits are maintained at the state in which

the interrupt was generated until the read is performed, and released at the next ODR cycle. In case the WU_X,

WU_Y, WU_Z bits have to be evaluated (in addition to the WU_IA bit), it is recommended to directly read the

WAKE_UP_SRC register (do not use ALL_INT_SRC register for this specific case). If latch mode is enabled but

the interrupt signal is not driven to the interrupt pins, the latch feature does not take effect (the WU_IA bit in the

WAKE_UP_SRC or ALL_INT_SRC register is reset when the wake-up condition is no longer verified).

AN5038

Wake-up interrupt

Figure 9. Wake-up event recognition (using the HP filter)

AN5038 - Rev 5

page 21/51

Page 22

AN5038

Wake-up interrupt

The example code which implements the SW routine for wake-up event recognition using the HP filter is given

below.

1. Write 64h in CTRL1 // Turn on the accelerometer

// ODR = 200 Hz, High-Performance

2. Write 04 in CTRL6 // FS ±2 g, LOW_NOISE enabled

3. Write 20h in CTRL7 // Use HP filter, enable interrupts

4. Write 00h in WAKE_UP_DUR // No duration

5. Write 02h in WAKE_UP_THS // Set wake-up threshold

6. Write 20h in CTRL4_INT1_PAD_CTRL // Wake-up interrupt driven to INT1 pin

Since the duration time is set to zero, the wake-up interrupt signal is generated for each X,Y,Z data from HP

filter exceeding the configured threshold. The WU_THS field of the WAKE_UP_THS register is set to 000010b,

therefore the wake-up threshold is 62.5 mg (= 2 * FS / 64).

The example code which implements the SW routine for the wake-up event using USER OFFSET recognition is

given below.

1. Write 04h in CTRL6 // FS ±2 g LOW_NOISE enabled

2. Write 34h in CTRL7 // Use X/Y/Z_OFS_USR registers

// X/Y/Z_OFS_USR weight 15.6 mg/LSb

// Enable interrupts

3. Write 00h in X_OFS_USR // Set X offset as 0

4. Write 00h in Y_OFS_USR // Set Y offset as 0

5. Write 40h in Z_OFS_USR // Set Z offset as 1 g

6. Write 00h in WAKE_UP_DUR // No duration

7. Write 02h in WAKE_UP_THS // Set wake-up threshold

8. Write 20h in CTRL4_INT1_PAD_CTRL // Wake-up interrupt driven to INT1 pin

9. Write 64h in CTRL1 // Turn on the accelerometer

// ODR = 200 Hz, High-Performance

Since the duration time is set to zero, the wake-up interrupt signal is generated for each X,Y,Z data from the

difference between the data measured and the X_OFS_USR, Y_OFS_USR, Z_OFS_USR registers exceeding

the configured threshold. The WU_THS field of the WAKE_UP_THS register is set to 000010b, therefore the

wake-up threshold is 62.5 mg (= 2 * FS / 64).

AN5038 - Rev 5

page 22/51

Page 23

5.5 6D/4D orientation detection

The LIS2DW12 device provides the capability to detect the orientation of the device in space, enabling easy

implementation of energy-saving procedures and automatic image rotation for mobile devices.

5.5.1 6D orientation detection

Six orientations of the device in space can be detected; the interrupt signal is asserted when the device switches

from one orientation to another. The interrupt is not re-asserted as long as the position is maintained.

6D interrupt is generated when only one axis exceeds a selected threshold and the acceleration values measured

from the other two axes are lower than the threshold: the ZH, ZL, YH, YL, XH, XL bits of the SIXD_SRC register

indicate which axis has triggered the 6D event.

In more detail:

b7 b6 b5 b4 b3 b2 b1 b0

0 6D_IA ZH ZL YH YL XH XL

• 6D_IA is set high when the device switches from one orientation to another.

• ZH (YH, XH) is set high when the face perpendicular to the Z (Y,X) axis is almost flat and the acceleration

measured on the Z (Y,X) axis is positive and in the absolute value bigger than the threshold.

• ZL (YL, XL) is set high when the face perpendicular to the Z (Y,X) axis is almost flat and the acceleration

measured on the Z (Y,X) axis is negative and in the absolute value bigger than the threshold.

The 6D_THS[1:0] bits of the TAP_THS_X register are used to select the threshold value used to detect the

change in device orientation. The threshold values given in Table 20. Threshold for 4D/6D function are valid for

each accelerometer full-scale value.

AN5038

6D/4D orientation detection

Table 19. SIXD_SRC register

Table 20. Threshold for 4D/6D function

6D_THS[1:0]

00 80

01 70

10 60

11 50

Threshold value [degrees]

This interrupt signal can be driven to the INT1 interrupt pin by setting the INT1_6D bit of the

CTRL4_INT1_PAD_CTRL register to 1; it can also be checked by reading the 6D_IA bit of the SIXD_SRC

register.

If latch mode is disabled (LIR bit of CTRL3 is set to 0), the interrupt signal is active only for 1/ODR[s] then it

is automatically deasserted (ODR is the accelerometer output data rate). If latch mode is enabled and the 6D

interrupt signal is driven to the interrupt pins, once an orientation change has occurred and the interrupt pin

is asserted, a read of the SIXD_SRC or ALL_INT_SRC register clears the request and the device is ready to

recognize a different orientation. The XL, XH, YL, YH, ZL, ZH bits are not affected by the LIR configuration: they

correspond to the current state of the device when the D6D_SRC register is read. If latched mode is enabled but

the interrupt signal is not driven to the interrupt pins, the latch feature does not take effect.

Referring to the six possible cases illustrated in Figure 10. 6D recognized orientations, the content of the

SIXD_SRC register for each position is shown in Table 21. SIXD_SRC register for 6D positions.

AN5038 - Rev 5

page 23/51

Page 24

Figure 10. 6D recognized orientations

AN5038

6D/4D orientation detection

Table 21. SIXD_SRC register for 6D positions

Case

(a) 1 0 0 0 0 0 1

(b) 1 0 0 0 1 0 0

(c) 1 0 0 1 0 0 0

(d) 1 0 0 0 0 1 0

(e) 1 1 0 0 0 0 0

(f) 1 0 1 0 0 0 0

6D_IA ZH ZL YH YL XH XL

The following example implements a SW routine for 6D orientation detection:

1.

Write 64h in CTRL1 // Turn on the accelerometer

// ODR = 200 Hz, High-Performance

2. Write 04h in CTRL6 // FS ±2 g, LOW_NOISE enabled

3. Write 20h in CTRL7 // Do not use low-pass filter for 6D, enable interrupts

4. Write 40h in TAP_THS_X // Set 6D threshold (6D_THS[1:0] = 10b = 60 degrees)

5. Write 80h in CTRL4_INT1_PAD_CTRL // 6D interrupt driven to INT1 pin

AN5038 - Rev 5

page 24/51

Page 25

5.5.2 4D orientation detection

The 4D direction function is a subset of the 6D function especially defined to be implemented in mobile devices

for portrait and landscape computation. It can be enabled by setting the 4D_EN bit of the TAP_THS_X register to

1. In this configuration, Z-axis position detection is disabled, therefore reducing position recognition to cases (a),

(b), (c), and (d) of Table 21. SIXD_SRC register for 6D positions.

5.6 Single-tap and double-tap recognition

The single-tap and double-tap recognition functions featured in the LIS2DW12 help to create a man-machine

interface with little software loading. The device can be configured to output an interrupt signal on a dedicated pin

when tapped in any direction.

If the sensor is exposed to a single input stimulus, it generates an interrupt request on the interrupt pin INT1.

A more advanced feature allows the generation of an interrupt request when a double input stimulus with

programmable time between the two events is recognized, enabling a mouse button-like function.

In the LIS2DW12 device the single-tap and double-tap recognition functions use the high-pass filter to detect tap

events.

This function can be fully programmed by the user in terms of expected amplitude and timing of the high-pass

filtered data by means of a dedicated set of registers.

The recommended accelerometer ODR for single and double-tap recognition is 400 Hz or higher.

AN5038

Single-tap and double-tap recognition

AN5038 - Rev 5

page 25/51

Page 26

5.6.1 Single-tap

If the device is configured for single-tap event detection, an interrupt is generated when the high-pass filtered data

exceeds the programmed threshold and returns below it within the shock time window.

In the single-tap case, if the LIR bit of the CTRL3 register is set to 0, the interrupt is kept high for the duration of

the quiet window.

In order to enable the latch feature on the single-tap interrupt signal, the LIR bit of CTRL3 has to be set to 1: the

interrupt is kept high until the TAP_SRC or ALL_INT_SRC register is read.

The SINGLE_DOUBLE_TAP bit of WAKE_UP_THS has to be set to 0 in order to enable single-tap recognition

only.

In case (a) of Figure 11. Single-tap event recognition the single-tap event has been recognized, while in case (b)

the tap has not been recognized because the signal falls below the threshold after the shock time window has

expired.

AN5038

Single-tap and double-tap recognition

Figure 11. Single-tap event recognition

AN5038 - Rev 5

page 26/51

Page 27

5.6.2 Double tap

If the device is configured for double-tap event detection, an interrupt is generated when, after a first tap, a

second tap is recognized. The recognition of the second tap occurs only if the event satisfies the rules defined by

the shock, the latency and the quiet time windows.

In particular, after the first tap has been recognized, the second tap detection procedure is delayed for an

interval defined by the quiet time. This means that after the first tap has been recognized, the second tap

detection procedure starts only if the high-pass filtered data exceeds the threshold after the quiet window but

before the latency window has expired. In case (a) of Figure 12. Double-tap event recognition (LIR bit = 0), a

double-tap event has been correctly recognized, while in case (b) the interrupt has not been generated because

the high-pass filtered data exceeds the threshold after the latency window interval has expired.

Once the second tap detection procedure is initiated, the second tap is recognized with the same rule as the first:

the high-pass filtered data must return below the threshold before the shock window has expired.

It is important to appropriately define the quiet window to avoid unwanted taps due to spurious bouncing of the

input signal.

In the double-tap case, if the LIR bit of the CTRL3 register is set to 0, the interrupt is kept high for the duration of

the quiet window. If the LIR bit is set to 1, the interrupt is kept high until the TAP_SRC or ALL_INT_SRC register is

read.

AN5038

Single-tap and double-tap recognition

Figure 12. Double-tap event recognition (LIR bit = 0)

AN5038 - Rev 5

page 27/51

Page 28

5.6.3 Single-tap and double-tap recognition configuration

The LIS2DW12 device can be configured to output an interrupt signal when tapped (once or twice) in any

direction: the TAP_X_EN, TAP_Y_EN and TAP_Z_EN bits of the TAP_THS_Z register must be set to 1 to enable

the tap recognition on X, Y, Z directions, respectively.

The TAP_THSX[4:0], TAP_THSY[4:0], TAP_THSZ[4:0] bits of the TAP_THS_X, TAP_THS_Y, TAP_THS_Z

registers are used to select the unsigned threshold value used to detect the tap event. The value of 1 LSB

of these 5 bits depends on the selected accelerometer full scale: 1 LSB = FS/32. The unsigned threshold is

applied to both positive and negative high-pass filtered data.

The user can also define the “priority report” of the single / double-tap interrupt event through TAP_PRIOR_[2:0]

in register TAP_THS_Y. This feature is useful in case of a contemporary tap event on more than one axis because

only the tap event related to the axis having higher priority is given in the source register.

The shock time window defines the maximum duration of the overthreshold event: the acceleration must

return below the threshold before the shock window has expired, otherwise the tap event is not detected. The

SHOCK[1:0] bits of the INT_DUR register are used to set the shock time window value: the default value of these

bits is 00b and corresponds to 4/ODR time, where ODR is the accelerometer output data rate. If the SHOCK[1:0]

bits are set to a different value, 1 LSB corresponds to 8/ODR time.

In the double-tap case, the quiet time window defines the time after the first tap recognition in which there must

not be any overthreshold. When latch mode is disabled (LIR bit of CTRL3 is set to 0), the quiet time also defines

the length of the interrupt pulse (for both single and double-tap). The QUIET[1:0] bits of the INT_DUR register

are used to set the quiet time window value: the default value of these bits is 00b and corresponds to 2/ODR

time, where ODR is the accelerometer output data rate. If the QUIET[1:0] bits are set to a different value, 1 LSB

corresponds to 4/ODR time.

In the double-tap case, the latency time window defines the maximum time between two consecutive detected

taps. The latency time period starts just after the completion of the quiet time of the first tap. The LATENCY[3:0]

bits of the INT_DUR register are used to set the latency time window value: the default value of these bits is

0000b and corresponds to 16/ODR time, where ODR is the accelerometer output data rate. If the LATENCY[3:0]

bits are set to a different value, 1 LSB corresponds to 32/ODR time.

Figure 13. Single and double-tap recognition (LIR bit = 0) illustrates a single-tap event (a) and a double-tap

event (b). These interrupt signals can be driven to the INT1 interrupt pin by setting the INT1_SINGLE_TAP

bit of the CTRL4_INT1_PAD_CTRL register to 1 for the single-tap case, and setting the INT1_TAP bit of the

CTRL4_INT1_PAD_CTRL register to 1 for the double-tap case.

Configurable parameters for tap recognition functionality are the tap threshold and the shock, quiet and latency

time windows. Valid ODRs are 400 Hz, 800 Hz and 1600 Hz.

No single/double-tap interrupt is generated if the accelerometer is in inactivity status (see Section 5.7 Activity/

Inactivity recognition for more details).

AN5038

Single-tap and double-tap recognition

AN5038 - Rev 5

page 28/51

Page 29

Single-tap and double-tap recognition

Figure 13. Single and double-tap recognition (LIR bit = 0)

AN5038

The tap interrupt signals can also be checked by reading the TAP_SRC register, described in Table 22. TAP_SRC

register.

Table 22. TAP_SRC register

b7

0 TAP_IA

b6 b5 b4 b3 b2 b1 b0

SINGLE

_TAP

DOUBLE

_TAP

TAP

_SIGN

X_TAP Y_TAP Z_TAP

• TAP_IA is set high when a single-tap or double-tap event has been detected.

• SINGLE_TAP is set high when a single tap has been detected.

• DOUBLE_TAP is set high when a double tap has been detected.

• TAP_SIGN indicates the acceleration sign when the tap event is detected. It is set low in case of positive

sign and it is set high in case of negative sign.

• X_TAP (Y_TAP, Z_TAP) is set high when the tap event has been detected on the X (Y, Z) axis

Single and double-tap recognition works independently. Setting the SINGLE_DOUBLE_TAP bit of

WAKE_UP_THS to 0, only single-tap recognition is enabled: double-tap recognition is disabled and cannot be

detected. When the SINGLE_DOUBLE_TAP bit is set to 1, both single and double-tap recognition are enabled,

and the single-tap event is always recognized first, followed by the double-tap event.

If latch mode is enabled and the interrupt signal is driven to the interrupt pins, the value assigned to

SINGLE_DOUBLE_TAP also affects the behavior of the interrupt signal: when it is set to 0, latch mode is applied

to the single-tap interrupt signal; when it is set to 1, latch mode is applied to the double-tap interrupt signal only.

The latched interrupt signal is kept high until the TAP_SRC or ALL_INT_SRC register is read. The TAP_SIGN,

X_TAP, Y_TAP, Z_TAP bits are maintained at the state in which the interrupt was generated until the read is

performed, and released at the next ODR cycle. In case the TAP_SIGN, X_TAP, Y_TAP, Z_TAP bits have to be

evaluated (in addition to the TAP_IA bit), it is recommended to directly read the TAP_SRC register (do not use

ALL_INT_SRC register for this specific case). If latched mode is enabled but the interrupt signal is not driven to

the interrupt pins, the latch feature does not take effect.

AN5038 - Rev 5

page 29/51

Page 30

5.6.4 Single-tap example

The following example code implements a SW routine for single-tap detection.

1. Write 74h in CTRL1 // Turn on the accelerometer

2. Write 04h in CTRL6 // FS ±2 g, LOW_NOISE enabled

3. Write 09h in TAP_THS_X // Set tap threshold for X-axis

4. Write E9h in TAP_THS_Y // Set tap threshold for Y-axis

5. Write E9h in TAP_THS_Z // Enable tap detection on X, Y, Z-axis

6. Write 06h in INT_DUR // Set quiet and shock time windows

7. Write 00h in WAKE_UP_THS // Only single-tap enabled (SINGLE_DOUBLE_TAP = 0)

8. Write 40h in CTRL4_INT1_PAD_CTRL // Single-tap interrupt driven to INT1 pin

9. Write 20h in CTRL7 // Enable interrupts

AN5038

Single-tap and double-tap recognition

// ODR = 400 Hz, High-Performance

// Set TAP priority Z-Y-X

// Set tap threshold for Z-axis

In this example the threshold for each axis is set to 01001b, therefore the tap threshold is 562.5 mg

(= 9 * FS / 32).

The SHOCK field of the INT_DUR register is set to 10b: an interrupt is generated when the high-pass filtered data

exceeds the programmed threshold and returns below it within 40 ms (= 2 * 8 / ODR) corresponding to the shock

time window.

The QUIET field of the INT_DUR register is set to 01b: since the latch mode is disabled, the interrupt is kept high

for the duration of the quiet window, therefore 10 ms (= 1 * 4 / ODR).

AN5038 - Rev 5

page 30/51

Page 31

5.6.5 Double-tap example

The example code which implements the SW routine for single-tap detection is given below.

1. Write 74h in CTRL1 // Turn on the accelerometer

2. Write 04h in CTRL6 // FS ±2 g, LOW_NOISE enabled

Write 0Ch in TAP_THS_X // Set tap threshold for X-axis

Write ECh in TAP_THS_Y // Set tap threshold for Y-axis

3. Write ECh in TAP_THS_Z // Enable tap detection on X, Y, Z-axis

4. Write 7Fh in INT_DUR // Set duration, quiet and shock time windows

5. Write 80h in WAKE_UP_THS // Single and double-tap enabled

6. Write 08h in CTRL4_INT1_PAD_CTRL // Single-tap interrupt driven to INT1 pin

7. Write 20h in CTRL7 // Enable interrupts

AN5038

Activity/Inactivity recognition

// ODR = 400 Hz, High-Performance

// Set TAP priority Z-Y-X

// Set tap threshold for Z axis

// (SINGLE_DOUBLE_TAP = 1)

5.7

In this example the threshold for each axis is set to 01100b, therefore the tap threshold is 750 mg (= 12 * FS / 32).

For interrupt generation, during the first and the second tap the high-pass filtered data must return below the

threshold before the shock window has expired. The SHOCK field of the INT_DUR register is set to 11b, therefore

the shock time is 60 ms (= 3 * 8 / ODR).

For interrupt generation, after the first tap recognition there must not be any high-pass filtered data overthreshold

during the quiet time window. Furthermore, since latch mode is disabled, the interrupt is kept high for the duration

of the quiet window. The QUIET field of the INT_DUR register is set to 11b, therefore the quiet time is 30 ms

(= 3 * 4 / ODR).

For the maximum time between two consecutive detected taps, the LAT field of the INT_DUR register is set to

0111b, therefore the duration time is 560 ms (= 7 * 32 / ODR).

Activity/Inactivity recognition

The activity/inactivity recognition function allows reducing system power consumption and developing new smart

applications.

The activity/inactivity function is enabled by setting the SLEEP_ON bit of WAKE_UP_THS (34h) register to 1. If

the sleep state condition is detected, the LIS2DW12 automatically goes to 12.5 Hz ODR in the low-power mode

previously selected by the LP_MODE[1:0] bits in CTRL1 (20h). The LIS2DW12 wakes up from the sleep state

as soon as a wake-up event has been detected, switching to the operating mode and ODR configured in CTRL1

(20h) register.

With this feature the system may be efficiently switched from low-power consumption to full performance and

vice-versa depending on user-selectable acceleration events, thus ensuring power saving and flexibility.

The activity/inactivity recognition function can use the high-pass filter or the offset outputs, this choice can be

done through the USR_OFF_ON_WU bit in CTRL7 as illustrated in Figure 6. Embedded functions.

In case of “offset output” are selected, every axis can be offset with a different value, writing registers

X_OFS_USR, Y_OFS_USR, Z_OFS_USR. Bit weight is defined through the USR_OFF_W bit in register CTRL7.

This function can be fully programmed by the user in terms of expected amplitude and timing of the high-pass

filtered data by means of a dedicated set of registers (Figure 14. Activity/Inactivity recognition (using the HP

filter)).

The unsigned threshold value is defined using the WK_THS[5:0] bits in the WAKE_UP_THS register; the value of

1 LSB of these 6 bits depends on the selected accelerometer full scale: 1 LSB = 1 / 64 of FS. The threshold is

applied to both positive and negative high-pass filtered data.

AN5038 - Rev 5

page 31/51

Page 32

AN5038

Activity/Inactivity recognition

When a certain number of consecutive X,Y,Z high-pass filtered data is smaller than the configured threshold, the

ODR [3:0] bits of the CTRL1 register are bypassed (inactivity) and the accelerometer is internally set to 12.5 Hz

although the content of CTRL1 is left untouched. The duration of the inactivity status to be recognized is defined

by the SLEEP_DUR[3:0] bits of the WAKE_UP_DUR register: 1 LSB corresponds to 512/ODR time, where ODR

is the accelerometer output data rate.

During the inactivity status of the device, the SLEEP_STATE bit in STATUS is set high. This bit can be

routed to the INT2 pin setting to 1 both the INT2_SLEEP_STATE and INT2_SLEEP_STATE_CHG bits in

CTRL5_INT2_PAD_CTRL. Please note that this signal is not compatible with "latched notification mode", the

LIR bit of CTRL3 should be set to 0.

Every time the device status changes from activity to inactivity or vice-versa, the SLEEP_CHANGE_IA bit in

ALL_INT_SRC is set for about 1.2 ms. This bit can be routed on the INT2 pin using the INT2_SLEEP_CHG bit in

CTRL5_INT2_PAD_CTRL. The typical duration of the sleep change event pulse on the interrupt pin depends on

the selected power mode and Activity / Inactivity transition (when using High-Performance mode).

Table 23. Pulse duration on interrupt pin

Power mode Activity to Inactivity pulse duration Inactivity to Activity pulse duration

Low-Power Mode 1 1.20 ms 1.20 ms

Low-Power Mode 2 1.70 ms 1.70 ms

Low-Power Mode 3 2.30 ms 2.30 ms

Low-Power Mode 4 3.55 ms 3.55 ms

High-Performance mode

0.71 ms + pulse duration of the selected

Low-Power Mode

1 / ODR

When a single sample of high-pass filtered data on one axis becomes bigger than the threshold, the CTRL1

register settings are immediately restored (activity). The wake-up interrupt event can be delayed in function of the

value of the WU_DUR[1:0] bits of the WAKE_UP_DUR register: 1 LSB corresponds to 1/ODR time, where ODR

is the accelerometer output data rate. In order to generate the interrupt at the same time as the inactivity/activity

event, WU_DUR[1:0] have to be set to 0.

When the wake-up event is detected, the interrupt is set high for 1/ODR period, then it is automatically deasserted

(the WU_IA event on the pin must be routed by setting the INT1_WU bit of CTRL4_INT1_PAD_CTRL register

to 1).

AN5038 - Rev 5

page 32/51

Page 33

Activity/Inactivity recognition

Figure 14. Activity/Inactivity recognition (using the HP filter)

AN5038

The code provided below is a basic routine for activity/inactivity detection implementation.

1.

Write 50h in CTRL1 // Turn on the accelerometer

// ODR = 200 Hz, FS = ±2 g

2. Write 42h in WAKE_UP_DUR // Set duration for inactivity detection

// Set duration for wake-up detection

3. Write 42h in WAKE_UP_THS // Set activity/inactivity threshold

// Enable activity/inactivity detection

4. Write 20h in CTRL4_INT1_PAD_CTRL // Activity (wakeup) interrupt driven to INT1 pin

5. Write 20h in CTRL7 // Enable interrupts

In this example the WU_THS field of the WAKE_UP_THS register is set to 000010b, therefore the activity/

inactivity threshold is 62.5 mg (= 2 * FS / 64).

Before inactivity detection, the X,Y,Z high-pass filtered data must be smaller than the configured threshold for

a period of time defined by the SLEEP_DUR field of the WAKE_UP_DUR register: this field is set to 0010b,

corresponding to 5.12 s (= 2 * 512 / ODR). After this period of time has elapsed, the accelerometer ODR is

internally set to 12.5 Hz.

The activity status is detected and the CTRL1 register settings immediately restored if the high-pass filtered

data of (at least) one axis is bigger than the threshold and the wake-up interrupt was notified after an interval

defined by the WU_DUR field of the WAKE_UP_DUR register: this field is set to 10b, corresponding to 10 ms

(= 2 * 1 / ODR).

AN5038 - Rev 5

page 33/51

Page 34

The following routine describes how to route the sleep change event on the INT2 pin.

1. Write 50h in CTRL1 // Turn on the accelerometer

2. Write 02h in WAKE_UP_DUR // Set duration for inactivity detection

3. Write 42h in WAKE_UP_THS // Set activity/inactivity threshold

4. Write 40h in CTRL5_INT2_PAD_CTRL // Sleep change interrupt driven to INT2 pin

5. Write 20h in CTRL7 // Enable interrupts

This example is similar to the previous one but the event routed is "Sleep change" on the INT2 pin.

5.8 Stationary/Motion detection

Stationary / Motion detection is a particular case of the Activity / Inactivity functionality in which no ODR /

power mode changes occur when a sleep condition (equivalent to Stationary condition) is detected. Stationary /

Motion detection is activated by setting the STATIONARY bit to 1 in the WAKE_UP_DUR register. If both the

STATIONARY bit and SLEEP_ON bit in the WAKE_UP_THS register are set to 1, Stationary / Motion detection is

selected.

AN5038

Stationary/Motion detection

// ODR = 200 Hz, FS = ±2 g

// Enable activity/inactivity detection

5.9 Boot status

After the device is powered up, the LIS2DW12 performs a 20 ms boot procedure to load the trimming parameters

(register addresses: 02h; from 07h to 0Bh; from 10h to 1Fh). After the boot is completed, the accelerometer is

automatically configured in power-down mode.

During the boot time the registers are not accessible.

After power-up, the trimming parameters can be reloaded by setting the BOOT bit of the CTRL2 register to 1.

No toggle of the device power lines is required and the content of the device control registers is not modified,

so the device operating mode doesn’t change after boot. If a reset to the default value of the control registers is

required (registers addresses: from 20h to 25h; 2Eh; from 30h to 36h; from 3Ch to 3Fh), it can be performed by

setting the SOFT_RESET bit of the CTRL2 register to 1. The software reset procedure can take 5 μs.

The boot status signal can be driven to the INT2 interrupt pin by setting the INT2_BOOT bit of the

CTRL5_INT2_PAD_CTRL register to 1: the signal goes to ‘1’ while a boot is taking place, and returns to ‘0’

when it is done.

The flow must be performed serially (from ANY operating mode) as shown in the example below:

1. Set SOFT_RESET bit to '1'

2. Wait 5 μs (or wait until the SOFT_RESET bit of the CTRL2 register returns to 0)

3. Set BOOT bit to '1'

4. Wait 20 ms

In order to avoid conflicts, the reboot and the software reset must not be executed at the same time (do not set to

1 at the same time both the BOOT bit and SOFT_RESET bit of the CTRL2 register).

AN5038 - Rev 5

page 34/51

Page 35

6 First-in first-out (FIFO) buffer

In order to limit intervention by the host processor and facilitate post-processing data for recognition of events, the

LIS2DW12 embeds a first-in, first-out buffer (FIFO) for each of the three output channels, X, Y, and Z.

FIFO use allows consistent power saving for the system, it can wake up only when needed and burst the

significant data out from the FIFO.

The FIFO buffer can work according to five different modes that guarantee a high level of flexibility during

application development: Bypass mode, FIFO mode, Continuous mode, Bypass-to-Continuous and Continuousto-FIFO mode.

A programmable watermark level and the FIFO full event can be enabled to generate dedicated interrupts on the

INT1 or INT2 pins.

6.1 FIFO description

The FIFO buffer is able to store up to 32 acceleration samples stored with the resolution according to bits

MODE[1:0] and LP_MODE[1:0] in register CTRL1.

The data sample set consists of 6 bytes (Xl, Xh, Yl, Yh, Zl, and Zh) and they are released to the FIFO at the

selected output data rate defined in ODR[3:0] register CTRL1.

The new sample set is placed in the first empty FIFO slot until the buffer is full, therefore, the oldest value is

overwritten.

AN5038

First-in first-out (FIFO) buffer

Table 24. FIFO buffer full representation (32nd sample set stored)

Output registers

FIFO index

FIFO(0) Xl(0) Xh(0) Yl(0) Yh(0) Zl(0) Zh(0)

FIFO(1) Xl(1) Xh(1) Yl(1) Yh(1) Zl(1) Zh(1)

FIFO(2) Xl(2) Xh(2) Yl(2) Yh(2) Zl(2) Zh(2)

FIFO(3) Xl(3) Xh(3) Yl(3) Yh(3) Zl(3) Zh(3)

... ... ... ... ... ... ...

FIFO(30) Xl(30) Xh(30) Yl(30) Yh(30) Zl(30) Zh(30)

FIFO(31) Xl(31) Xh(31) Yl(31) Yh(31) Zl(31) Zh(31)

28h 29h 2Ah 2Bh 2Ch 2Dh

Xl Xh Yl Yh Zl Zh

FIFO sample set

Table 25. FIFO buffer full representation (33rd sample set stored and 1st sample discarded)

Output registers

FIFO index

FIFO(0) Xl(1) Xh(1) Yl(1) Yh(1) Zl(1) Zh(1)

FIFO(1) Xl(2) Xh(2) Yl(2) Yh(2) Zl(2) Zh(2)

FIFO(2) Xl(3) Xh(3) Yl(3) Yh(3) Zl(3) Zh(3)

FIFO(3) Xl(4) Xh(4) Yl(4) Yh(4) Zl(4) Zh(4)

... ... ... ... ... ... ...

FIFO(31) Xl(32) Xh(32) Yl(32) Yh(32) Zl(32) Zh(32)

28h 29h 2Ah 2Bh 2Ch 2Dh

Xl Xh Yl Yh Zl Zh

Sample set

AN5038 - Rev 5

page 35/51

Page 36

AN5038

FIFO registers

Table 24. FIFO buffer full representation (32nd sample set stored) represents the FIFO full status when 32

samples are stored in the buffer while Table 25. FIFO buffer full representation (33rd sample set stored and 1

sample discarded) represents the next step when the 33rd sample is inserted into FIFO and the 1st sample is

overwritten. The new oldest sample set is made available in the output registers.

When FIFO is enabled and the mode is different from Bypass, the LIS2DW12 output registers (28h to 2Dh)

always contain the oldest FIFO sample set.

6.2 FIFO registers

The FIFO buffer is managed by two different registers, one allows enabling and configuring the FIFO behavior, the

other one provides information about the buffer status.

A few other registers are used to route FIFO events on the INT1 and INT2 pins to interrupt the application

processor. These are discussed in Section 6.3 FIFO interrupts.

6.2.1 FIFO_CTRL (2Eh)

The FIFO_CTRL register contains the mode in which the FIFO is set. At reset, by default, the FIFO mode is

Bypass which means that the FIFO is off; the FIFO is enabled and starts storing the samples as soon as the

mode is set to a mode other than Bypass.

b7 b6 b5 b4 b3 b2 b1 b0

FMode2 FMode1 FMode0 FTH4 FTH3 FTH2 FTH1 FTH0

st

Table 26. FIFO_CTRL register

The FMode[2:0] bits select the FIFO buffer behavior:

1. FMode[2:0] = 000b: Bypass mode (FIFO turned off)

2. FMode[2:0] = 001b: FIFO mode

3. FMode[2:0] = 011b: Continuous-to-FIFO mode

4. FMode[2:0] = 100b: Bypass-to-Continuous mode

5. FMode[2:0] = 110b: Continuous mode

FTH[4:0] bits are discussed in Section 6.3.1 FIFO threshold.

6.2.2 FIFO_SAMPLES (2Fh)

This register is updated at every ODR and provides information about the FIFO buffer status.

b7 b6 b5 b4 b3 b2 b1 b0

FIFO_FTH FIFO_OVR Diff5 Diff4 Diff3 Diff2 Diff1 Diff0

• FIFO_FTH bit is set high when FIFO content is greater than or equal to the watermark level. This flag can be

routed to the INT1 or INT2 pin (see Section 6.3 FIFO interrupts).

• FIFO_OVR bit is set high when the first sample is overwritten after the FIFO buffer is full. This means that

the FIFO buffer contains 32 unread samples. The FIFO_OVR bit is reset when the first sample set has been

read.

• Diff5 bit is used together with bits Diff[4:0] to provide information of how many FIFO entries are used

(000000b means FIFO empty, 100000b means FIFO full). This flag can be routed to the INT1 or INT2 pin

(see Section 6.3 FIFO interrupts).

The register content is updated synchronous to the FIFO write and read operation.

Table 27. FIFO_SAMPLES register

AN5038 - Rev 5

page 36/51

Page 37

Table 28. FIFO_SAMPLES behavior assuming FTH[4:0] = 15

AN5038

FIFO interrupts

FIFO_FTH

0 0 0 00000 0 t0

0 0 0 00001 1 t0 + 1/ODR

0 0 0 00010 2 t0 + 2/ODR

... ... ... ... ... ...

0 0 0 01110 14 t0 + 14/ODR

1 0 0 01111 15 t0 + 15/ODR

... ... ... ... ... ...

1 0 0 11111 31 t0 + 31/ODR

1 1 0 00000 32 t0 + 32/ODR

1 1 1 00000 32 t0 + 33/ODR

(FIFO_FULL)

6.3 FIFO interrupts

There are three specific FIFO events that can be routed to the pins in order to interrupt the main processor: FIFO

threshold, FIFO full, and FIFO overrun.

All FIFO events can be routed to the INT1 and INT2 pins.

6.3.1 FIFO threshold

The FIFO threshold is a configurable feature that can be used to generate a specific interrupt in order to know

when the FIFO buffer contains at least the number of samples defined as the threshold level. The user can select

the desired level in a range from 0 to 31 using the FTH[4:0] field in the FIFO_CTRL register.

If the number of entries in FIFO (Diff[5:0]) is greater than or equal to the value programmed in FTH[4:0], the

FIFO_FTH bit is set high in the FIFO_SAMPLES register.

Diff[5:0] increases by one step at the ODR frequency and decreases by one step every time that a sample set

reading is performed by the user.

The threshold flag (FIFO_FTH) can be routed to the INT1 and INT2 pins to provide a dedicated interrupt for the

application processor that can, as a consequence, consume less power between interrupts. The INT1_FTH bit of

CTRL4_INT1_PAD_CTRL register and the INT2_FTH bit of CTRL5_INT2_PAD_CTRL register are dedicated to

this task.

Diff5

FIFO_OVR Diff[4:0] Unread FIFO samples Timing

6.3.2 FIFO full

It is possible to configure the device to generate an interrupt whenever the FIFO becomes full. To do so,

just set the INT1_DIFF5 bit of the CTRL4_INT1_PAD_CTRL register to ‘1’ (or the INT2_DIFF5 bit of the

CTRL5_INT2_PAD_CTRL register to ‘1’). To avoid losing samples, the FIFO reading operation must start and

complete inside 1 ODR window.

6.3.3 FIFO overrun

It is possible to configure the device to generate an interrupt if the overrun event occurs in FIFO. To do so just set

the INT2_OVR bit of the CTRL5_INT2_PAD_CTRL register to ‘1’.

6.4 FIFO modes

The LIS2DW12 FIFO buffer can be configured to operate in five different modes selectable by the FMODE[2:0]

field in the FIFO_CTRL register. Available configurations ensure a high-level of flexibility and extend the number

of usable functions in application development.

Bypass, FIFO, Continuous, Bypass-to-Continuous and Continuous-to-FIFO modes are described in the following

paragraphs.

AN5038 - Rev 5

page 37/51

Page 38

6.4.1 Bypass mode

t

FIFO mode

enabled

FIFO

stops

FIFO_OVR

FIFO Mode

enabled

FIFO Reading

FIFO

Bypass

…

3332

…

31

……

543210

…

F1F0

…

F31

……

F5F4F3F2F1F0

FIFO_FULL interrupt

When Bypass mode is enabled, the FIFO is not operational: buffer content is cleared, output registers (0x28 to

0x2D) are frozen at the last value loaded, and the FIFO buffer remains empty until another mode is selected.

Bypass mode is activated by setting the FMODE[2:0] field to 000b in the FIFO_CTRL register.

Bypass mode must be used in order to stop and reset the FIFO buffer when a different mode is operating. Note

that placing the FIFO buffer into Bypass mode clears the whole buffer content.

6.4.2 FIFO mode

In FIFO mode, the buffer continues filling until full (32 sample sets stored). As soon as the FIFO_OVR flag goes to

‘1’, the FIFO stops collecting data and its content remains unchanged until a different mode is selected.

FIFO mode is activated by setting the FMODE[2:0] field to 001b in the FIFO_CTRL register.

By selecting this mode, FIFO starts data collection and Diff[5:0] changes according to the number of samples

stored. At the end of the procedure, the FIFO_OVR flag rises to 1, and data can then be retrieved, performing a

32 sample set reading from the output registers. Communication speed is not so important in FIFO mode because

data collection is stopped and there is no risk of overwriting acquired data. Before restarting FIFO mode, at the

end of the reading procedure it is necessary to exit Bypass mode.

In order to serve the FIFO full (Diff5 bit) event as soon as possible, it is recommended to route it to the pin in order

to generate an interrupt, which will then be managed by a specific handler:

1. Set INT1_DIFF5 to ‘1’: Enables FIFO_FULL interrupt

2. Set FMode[2:0] = 001b: Enables FIFO mode

When the FIFO FULL interrupt is generated or the FIFO_OVR bit is high (polling mode):

1. Read data from the accelerometer output registers

AN5038

FIFO modes

As indicated in Figure 15. FIFO mode behavior, when FIFO mode is enabled, the buffer starts to collect data and

fills all 32 slots (from F0 to F31) at the selected output data rate. When the buffer is full, as the next sample comes

in and overrides the buffer, the FIFO_OVR bit goes high and data collection is permanently stopped; the user can

decide to read FIFO content at any time because it is maintained unchanged until Bypass mode is selected. The

reading procedure may be performed inside an interrupt handler triggered by a FIFO FULL condition (Diff5) and

it is composed of a 32 sample set of 6 bytes for a total of 192 bytes and retrieves data starting from the oldest