ST LED7706 User Manual

6-rows 30 mA LEDs driver with boost regulator

Features

■ Boost section

– 4.5 V to 36 V input voltage range

– Internal power MOSFET

– Internal +5 V LDO for device supply

– Up to 36 V output voltage

– Constant frequency peak current-mode

control

– 250 kHz to 1 MHz adjustable switching

frequency

– External synchronization for multi-device

application

– Pulse-skip power saving mode at light load

– Programmable soft-start

– Programmable OVP protection

– Stable with ceramic output capacitors

– Thermal shutdown

■ Backlight driver section

– Six rows with 30 mA maximum current

capability (adjustable)

– Rows disable option

– Less than 500 ns minimum dimming on-

time (1 % minimum dimming duty-cycle at

20 kHz)

– ±2 % current matching between rows

– LED failure (open and short-circuit)

detection

LED7706

for LCD panels backlight

VFQFPN-24 4x4

Description

The LED7706 consists of a high efficiency

monolithic boost converter and six controlled

current generators (rows) specifically designed to

supply LEDs arrays used in the backlighting of

LCD panels. The device can manage an output

voltage up to 36 V (i.e. 10 white LEDs per row).

The generators can be externally programmed to

sink up to 30 mA and can be dimmed via a PWM

signal (1 % dimming duty-cycle at 20 kHz can be

managed). The device allows to detect and

manage the open and shorted LED faults and to

let unused rows floating. Basic protections (output

over-voltage, internal MOSFET over-current and

thermal shutdown) are provided.

Applications

■ LCD monitors and TV panels

■ PDAs panel backlight

■ GPS panel backlight

Table 1. Device summary

Order codes Package Packaging

LED7706

VFQFPN-24 4x4 (exposed pad)

LED7706TR Tape and reel

April 2009 Rev 2 1/46

Tu b e

www.st.com

46

Contents LED7706

Contents

1 Typical application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Operation description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1 Boost section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.1.1 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.1.2 Enable function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1.3 Soft-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.4 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1.5 Switching frequency selection and synchronization . . . . . . . . . . . . . . . 15

5.1.6 Slope compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1.7 Boost current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.8 Thermal protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Backlight driver section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.1 Current generators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.2 PWM dimming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 Fault management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.1 FAULT pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.2 MODE pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.3 Open LED fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3.4 Shorted LED fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2/46

LED7706 Contents

6 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1 System stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.1.1 Loop compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.2 Thermal considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3 Component selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3.1 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3.2 Capacitors selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.3 Flywheel diode selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4 Design example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.4.1 Switching frequency setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.4.2 Row current setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.4.3 Inductor choice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.4.4 Output capacitor choice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4.5 Input capacitor choice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4.6 Over-voltage protection divider setting . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4.7 Compensation network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.8 Boost current limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.9 Power dissipation estimate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.5 Layout consideration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3/46

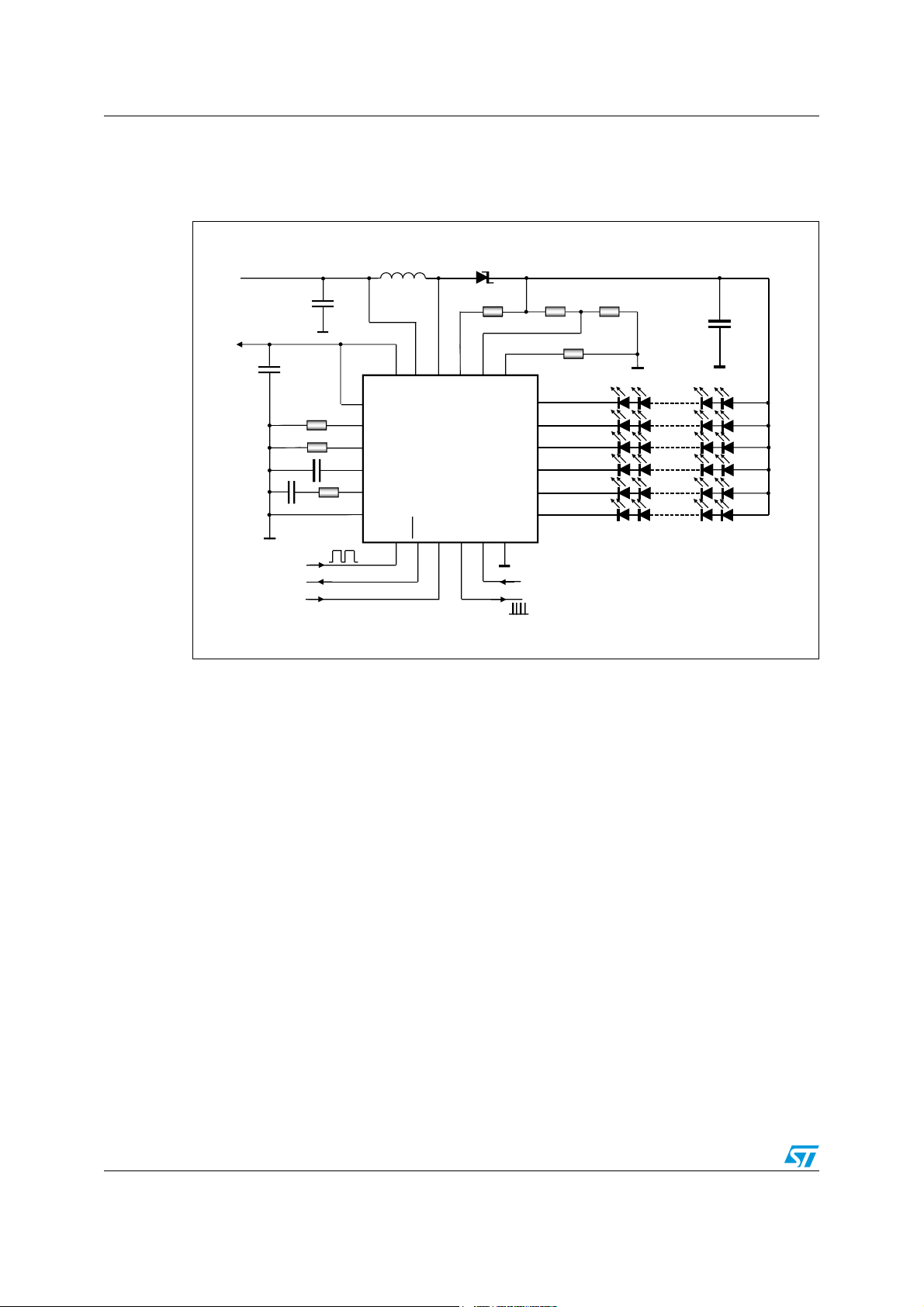

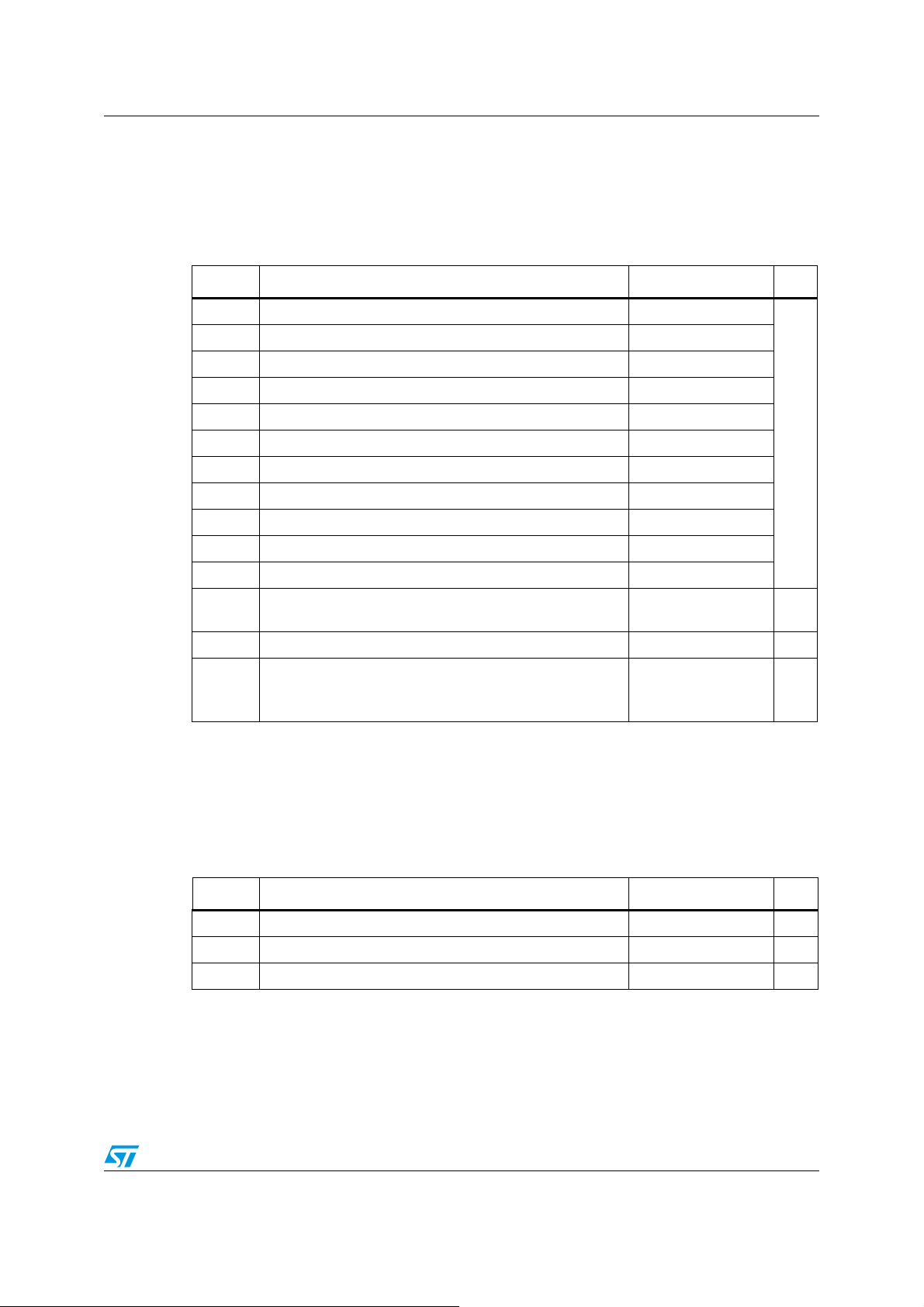

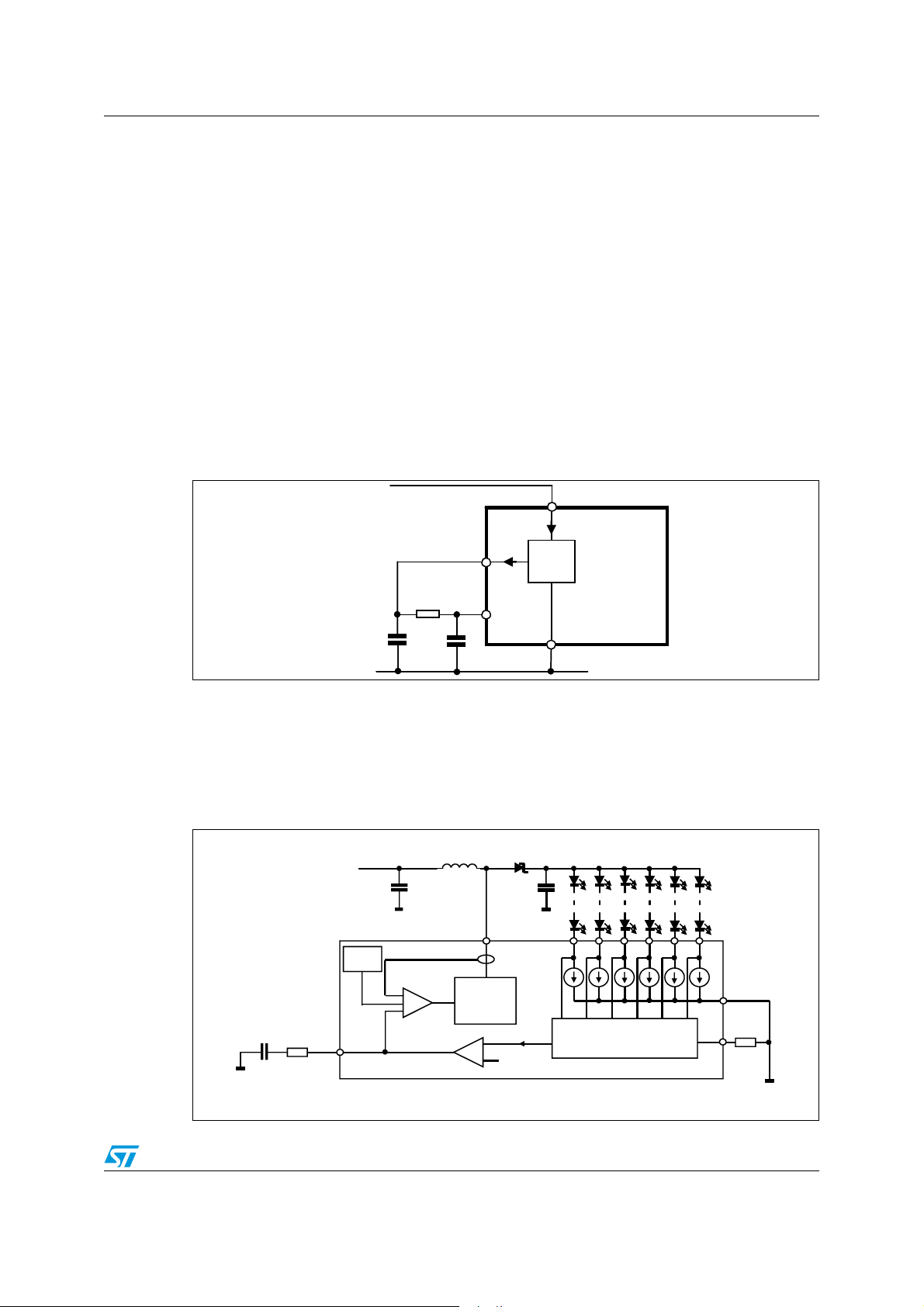

Typical application circuit LED7706

1 Typical application circuit

Figure 1. Application circuit

VIN

+5V

Internal MOS OCP

Rows current selection

Dimming

Fault

Enable

LDO5

BILIM

RILIM

SS

COMP

SGND

L

LX

VIN

AVCC

LED7706

FAULT

DIM

EN

Slope Compensation

OVSEL

SLOPE

MODE

SYNC

OVP selection

Switching Frequenc y selection

SWF

ROW1

ROW2

ROW3

ROW4

ROW5

ROW6

PGND

Faults Management Selection

Sync Output

MLCC

Up to 10 WLEDs per row

OUT

V

AM00594v1

4/46

LED7706 Pin settings

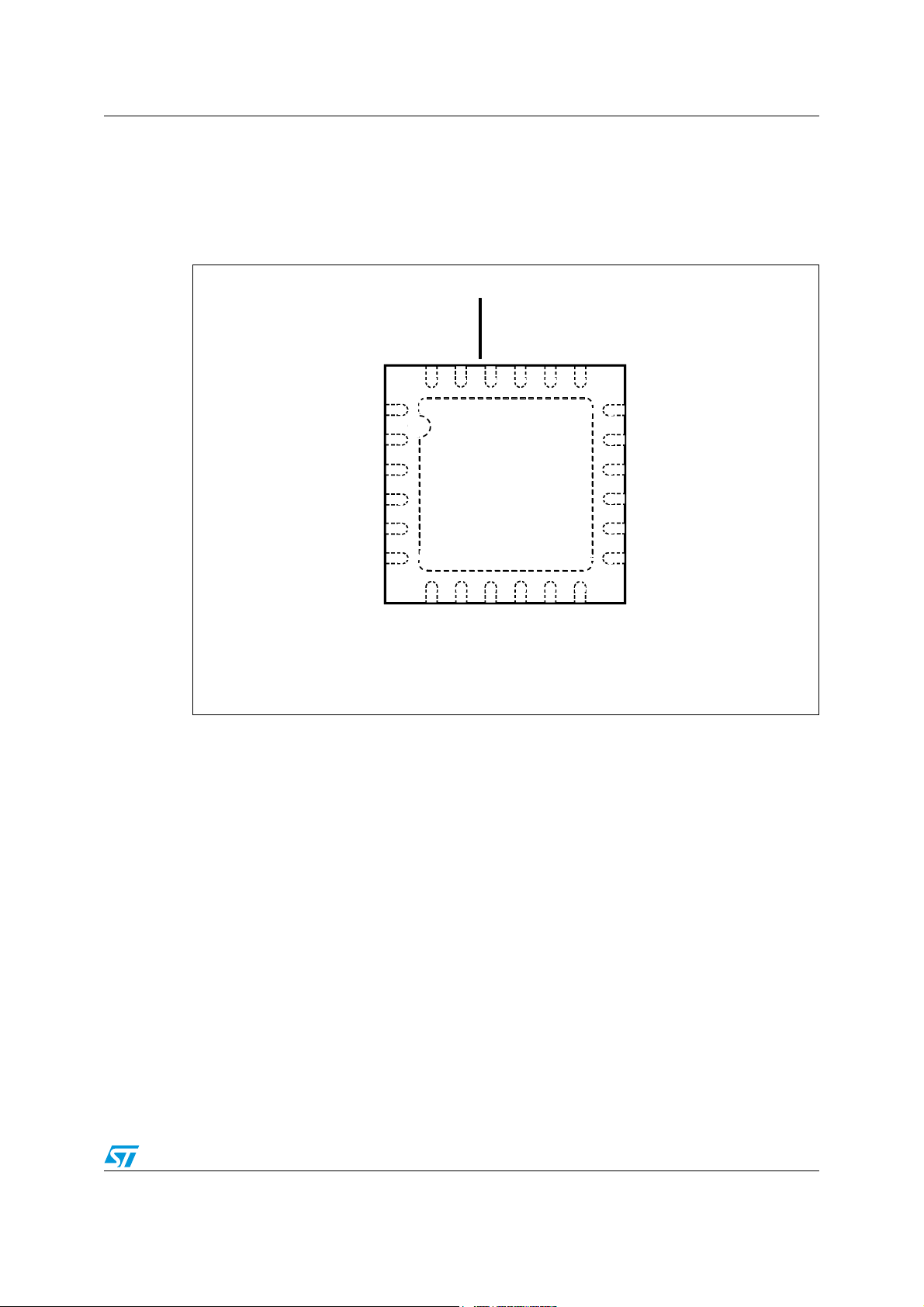

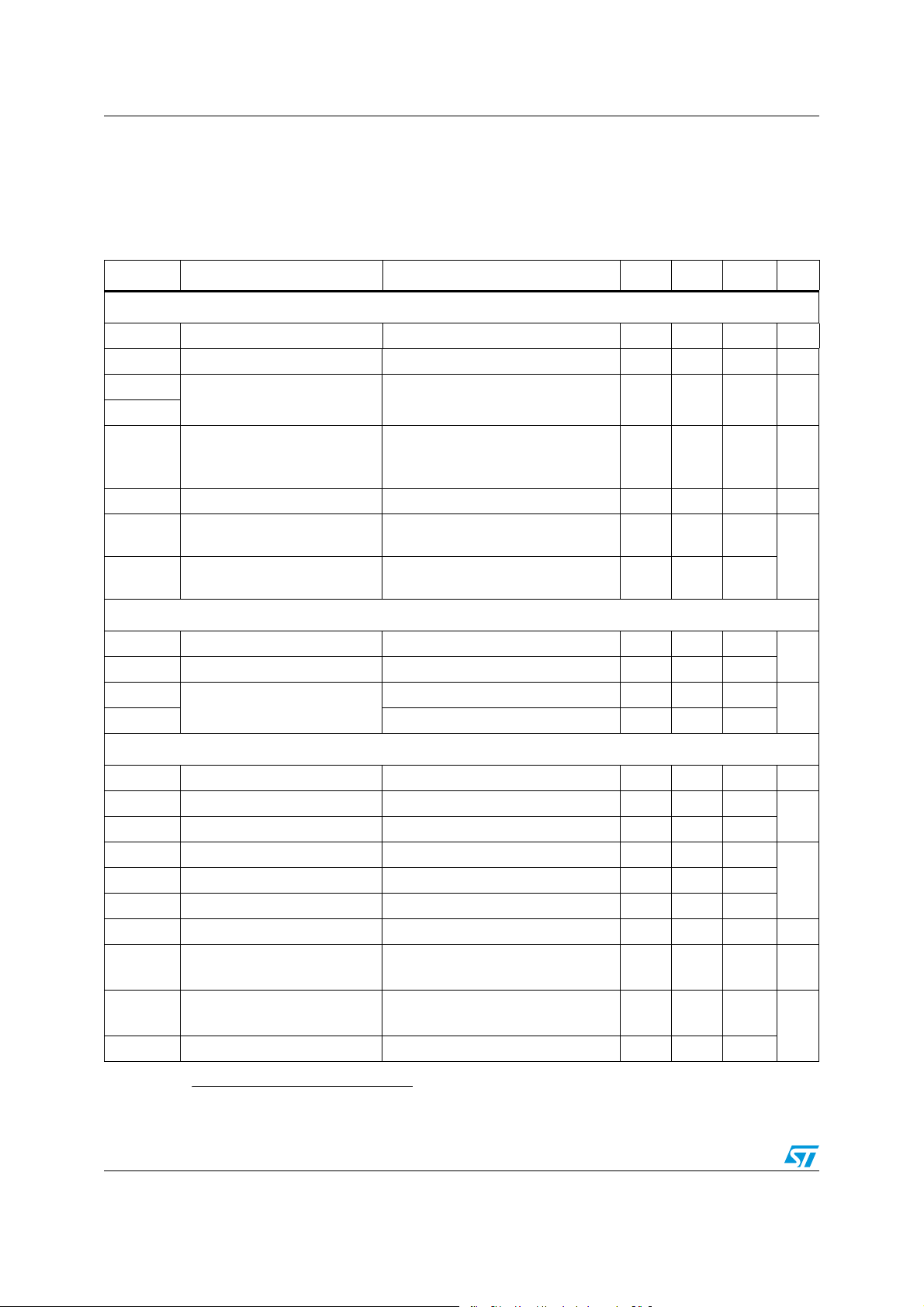

2 Pin settings

2.1 Connections

Figure 2. Pin connection (through top view)

COMP

RILIM

BILIM

FSW

MODE

AVCC

SYNC

SS

24

1

EN

DIM

FAULT

LX

19

18

OVSEL

PGND

LED7706

ROW6

ROW5

ROW4

ROW3

6

7

13

12

VIN

LDO5

SGND

SLOPE

ROW2

ROW1

AM00595v1

5/46

Pin settings LED7706

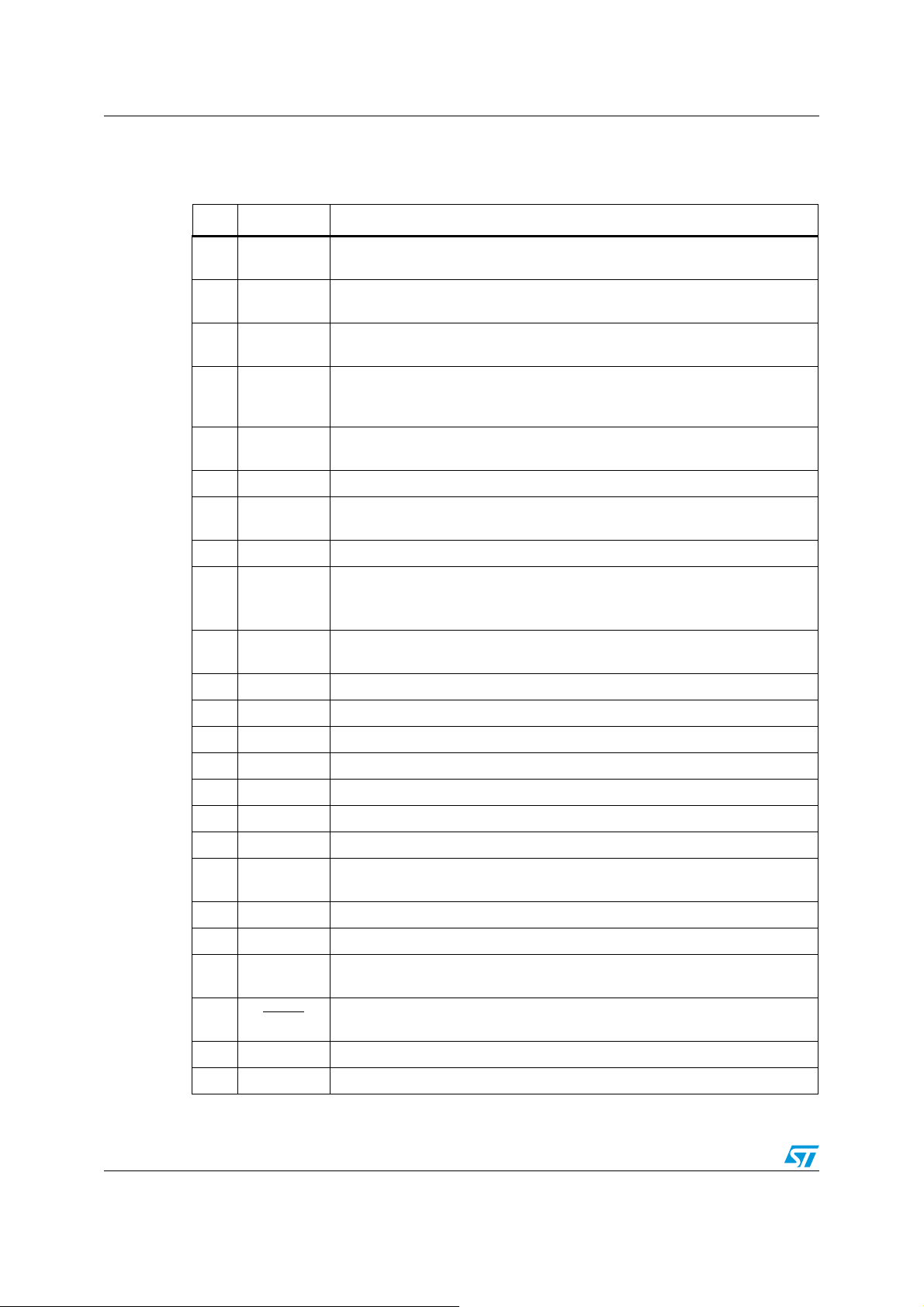

2.2 Pin description

Table 2. Pin functions

N° Pin Function

1COMP

2RILIM

3 BILIM

4FSW

5MODE

6 AVCC + 5 V analog supply. Connect to LDO5 through a simple RC filter.

7LDO5

8 VIN Input voltage. Connect to the main supply rail.

9SLOPE

10 SGND

11 ROW1 Row driver output #1.

Error amplifier output. A simple RC series between this pin and ground is

needed to compensate the loop of the boost regulator.

Output generators current limit setting. The output current of the rows can be

programmed connecting a resistor to SGND.

Boost converter current limit setting. The internal MOSFET current limit can

be programmed connecting a resistor to SGND.

Switching frequency selection and external sync input. A resistor to SGND is

used to set the desired switching frequency. The pin can also be used as

external synchronization input. See

Current generators fault management selector. It allows to detect and manage

LEDs failures. See

+ 5 V LDO output and power section supply. Bypass to SGND with a

1 μF ceramic capacitor.

Slope compensation setting. A resistor between the output of the boost

converter and this pin is needed to avoid sub-harmonic instability.

Refer to

Signal ground. Supply return for the analog circuitry and the current

generators.

Section 6.1 on page 24 for details.

Section 5.3.2 on page 21 for details.

Section 5.1.5 on page 15 for details.

12 ROW2 Row driver output #2.

13 ROW3 Row driver output #3.

14 ROW4 Row driver output #4.

15 ROW5 Row driver output #5.

16 ROW6 Row driver output #6.

17 PGND Power ground. Source of the internal Power MOSFET.

18 OVSEL

19 LX Switching node. Drain of the internal Power MOSFET.

20 DIM Dimming input. Used to externally set the brightness by using a PWM signal.

21 EN

22 FAULT

23 SYNC Synchronization output. Used as external synchronization output.

24 SS Soft-start. Connect a capacitor to SGND to set the desired soft-start duration.

6/46

Over-voltage selection. Used to set the desired OV threshold by an external

divider. See

Enable input. When low, the device is turned off. If tied high or left open, the

device is turned on and a soft-start sequence takes place.

Fault signal output. Open drain output. The pin goes low when a fault condition

is detected (see Section 5.3.1 on page 21 for details).

Section 5.1.4 on page 14 for details.

LED7706 Electrical data

3 Electrical data

3.1 Maximum rating

Table 3. Absolute maximum ratings

(1)

Symbol Parameter Value Unit

V

AVC C

V

LDO5

AVCC to SGND -0.3 to 6

LDO5 to SGND -0.3 to 6

PGND to SGND -0.3 to 0.3

V

V

VIN to PGND -0.3 to 40

IN

LX to SGND -0.3 to 40

LX

LX to PGND -0.3 to 40

RILIM, BILIM, SYNC, OVSEL, SS to SGND -0.3 to V

AVC C

+ 0.3

EN, DIM, SW, MODE, FAULT to SGND -0.3 to 6

ROWx to PGND/ SGND -0.3 to 40

SLOPE to VIN V

- 0.3 to VIN + 6

IN

SLOPE to SGND -0.3 to 40

Internal switch maximum RMS current

(flowing through LX node)

P

Power dissipation @ TA = 25 °C 2.3

TOT

2.0 A

(2)

Maximum withstanding voltage range test condition:

CDF-AEC-Q100-002- “human body model” acceptance

±1000 V

criteria: “normal performance”

1. Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the

device. Exposure to absolute maximum rated conditions for extended periods may affect device reliability.

2. Power dissipation referred to the device mounted on the demonstration board described in section 5.5

V

W

3.2 Thermal data

Table 4. Thermal data

Symbol Parameter Value Unit

R

T

Thermal resistance junction to ambient 42 °C/W

thJA

Storage temperature range -50 to 150 °C

STG

Junction operating temperature range -40 to 150 °C

T

J

7/46

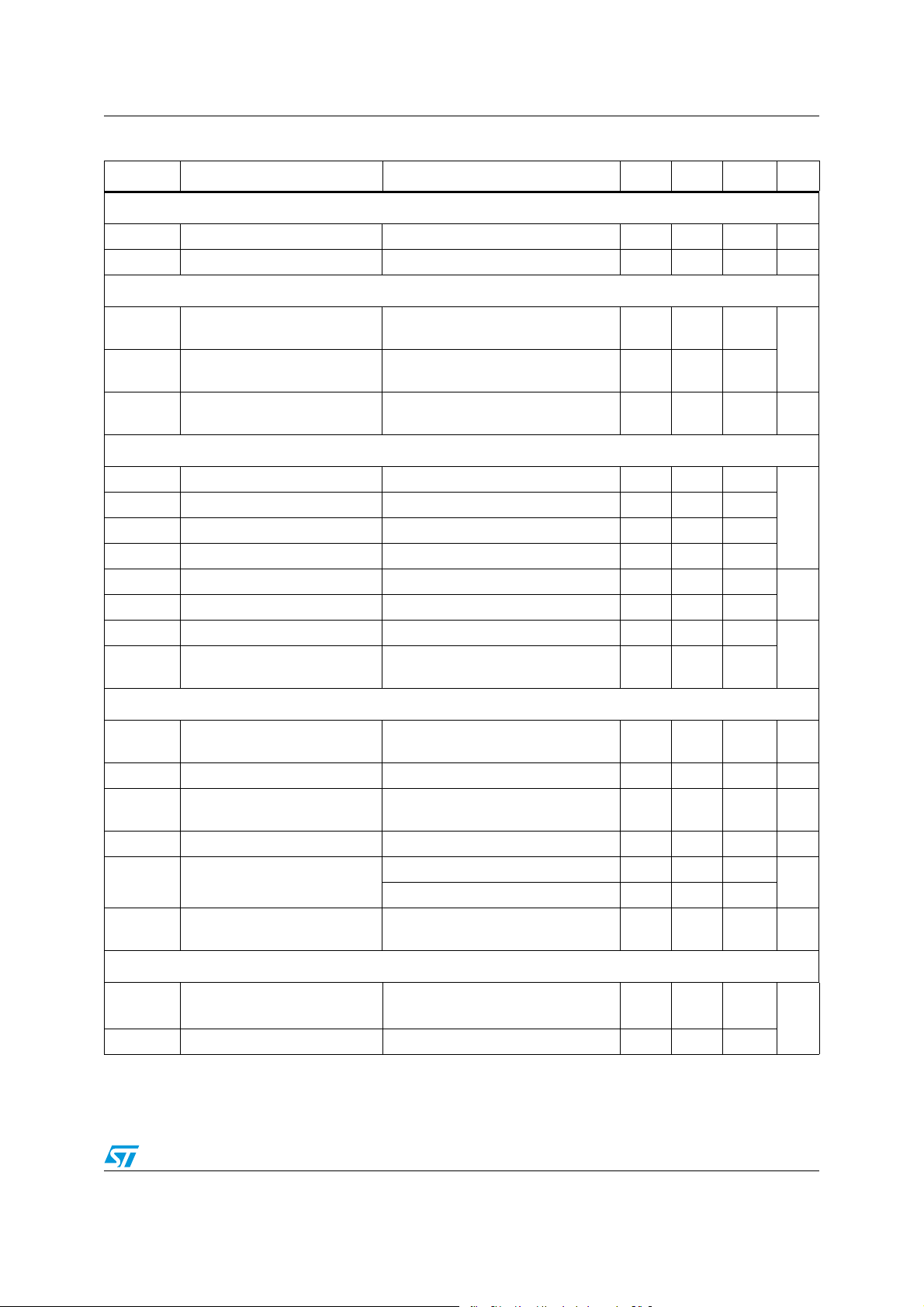

Electrical characteristics LED7706

4 Electrical characteristics

VIN = 12 V; TJ = 25 °C and LDO5 connected to AVCC if not otherwise specified

Table 5. Electrical characteristics

(a)

Symbol Parameter Test condition Min. Typ. Max. Unit

Supply section

V

V

V

I

V

BST

LDO5

AVC C

IN,Q

Input voltage range 4.5 36 V

IN

Boost section output voltage 36

LDO output and IC supply

voltage

Operating quiescent current

EN High

= 0 mA

I

LDO5

= 51 kΩ, R

R

RILIM

R

SLOPE

= 680 kΩ

BILIM

4.4 5 5.5 V

= 220 kΩ,

1mA

DIM tied to SGND.

I

IN,SHDN

V

UVLO,ON

V

UVLO,OFF

Operating current in shutdown EN low 20 30 μA

LDO5 under voltage lock out

upper threshold

LDO5 under voltage lock out

lower threshold

3.3 3.6

3.8 4.0

LDO linear regulator

Line regulation 6 V

LDO dropout voltage V

LDO maximum output current

V

V

IN

LDO5

LDO5

≤ 36 V, I

IN

= 4.3 V, I

> V

UVLO,ON

< V

UVLO,OFF

LDO5

= 30 mA 30

LDO5

= 10 mA 80 120

25 40 60

20 30

≤ V

Boost section

V

mV

mA

t

ON,min

f

SW

Minimum switching on-time 200 ns

Default switching frequency FSW connected to AVCC 570 660 750

Minimum FSW sync frequency 210

FSW sync input threshold 240

FSW sync input hysteresis 20

FSW sync min. ON time 270 ns

SYNC output Duty-Cycle

SYNC output high level I

SYNC output low level I

a. Specification referred to TJ from 0 °C to +85 °C. Specification over the 0 to +85 °C TJ range are assured by

design, characterization and statistical correlation.

FSW connected to AVCC

(Internal oscillator selected)

= 10 μA

SYNC

= -10 μA 20

SYNC

8/46

V

AVC C

-20V

kHz

mVFSW sync low level 350

34 40 %

mV

LED7706 Electrical characteristics

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

Power switch

5

V

R

K

DSon

LX current coefficient R

B

Internal MOSFET on-resistance

OC and OV protections

= 600 kΩ 5·1056·1057·10

BILIM

280 500 mΩ

V

TH,OVP

V

TH,FRD

ΔV

OVP,FRD

Over voltage protection

reference threshold (OVSEL)

Floating channel detection

threshold

Voltage gap between OVP and

FRD thresholds

Soft-start and power management

EN, Turn-on threshold 1.6

EN, Turn-off threshold 0.8

DIM, high level threshold 1.3

DIM, low level threshold 0.8

EN, pull-up current 2.5

SS, charge current 4 5 6

SS, end-of-startup threshold 2.0 2.4 2.8

SS, reduced switching

frequency release threshold

Current generators section

T

DIM-

ON,min

K

ΔK

V

IFB

V

rowx,

FAULT

V

FAU LT,

LOW

Minimum dimming on-time 500 ns

Current generators gain 987 V

R

Current generators gain

(1)

R

accuracy

Feedback regulation voltage 400 mV

Shorted LED fault detection

threshold

FAULT pin low-level voltage I

Thermal shutdown

1.190 1.234 1.280

1.100 1.145 1.190

90 mV

0.8

MODE tied to SGND 3.4

MODE connected to AVCC 6.0

FAULT,SINK

= 4 mA 200 350 mV

V

V

μA

V

±2.0 %

V

1. I

T

SHDN

ROW

Thermal shutdown

turn-off temperature

Thermal shutdown hysteresis 30

= KR / R

, ΔI

RILIM

ROW/IROW ≈ ΔKR/KR

+ ΔR

RILIM/RRILIM

9/46

150

°C

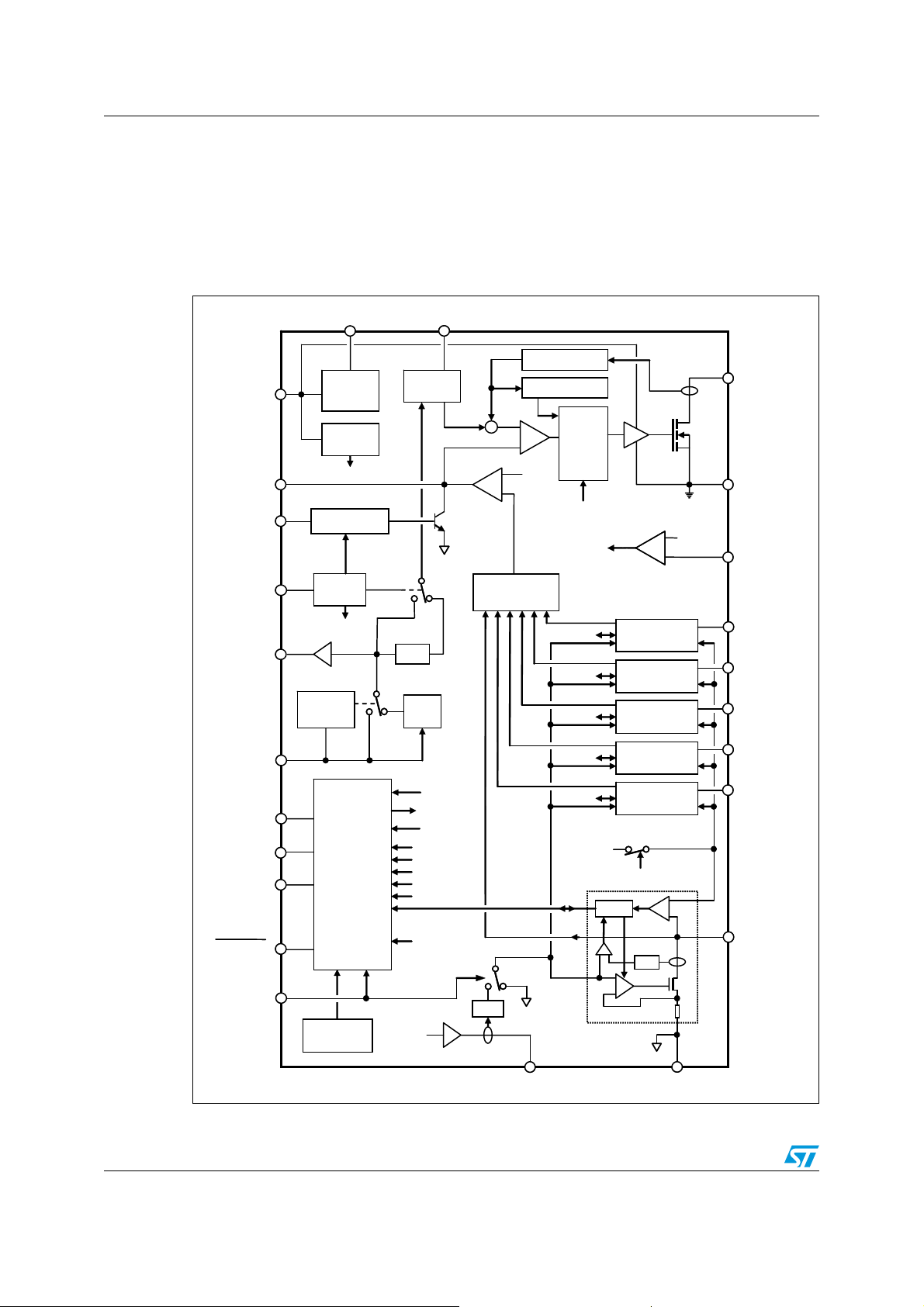

Operation description LED7706

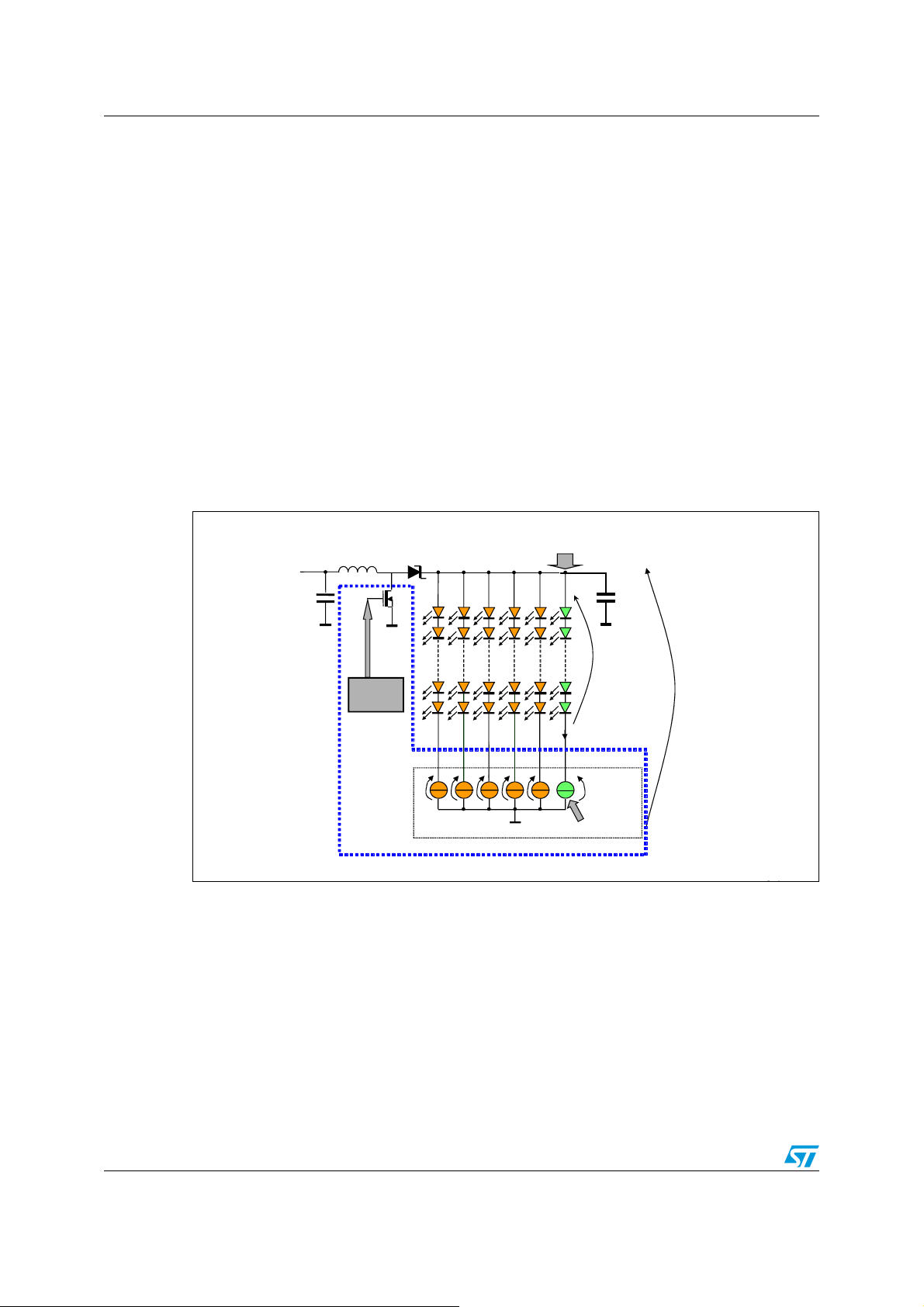

5 Operation description

The device can be divided into two sections: the boost section and the backlight driver

section. These sections are described in the next paragraphs. Figure 3 provides an

overview of the internal blocks of the device.

Figure 3. Simplified block diagram

VIN

LDO5

LDO5

COMP

COMP

BILIM

BILIM

SS

SS

SYNC

SYNC

FSW

FSW

AVCC

AVCC

EN

EN

MODE

MODE

FAULT

FAULT

DIM

DIM

VIN

+5V

+5V

LDO

LDO

UVLO

UVLO

Detector

Detector

UVLO

UVLO

Current Limit

Current Limit

Soft Start

Soft Start

Prot_EN

Prot_EN

Ext Sync

Ext Sync

Detector

Detector

CONTROL

CONTROL

LOGIC

LOGIC

Thermal

Thermal

Shutdown

Shutdown

SLOPE

SLOPE

Ramp

Ramp

Generator

Generator

÷2

÷2

OSC

OSC

Prot_EN

Prot_EN

Boost_EN

Boost_EN

UVLO

UVLO

CTRL6

CTRL6

CTRL5

CTRL5

CTRL4

CTRL4

CTRL3

CTRL3

CTRL2

CTRL2

OVP

OVP

1.2V

1.2V

+

+

+

+

+

+

g

m

g

m

_

_

Min Voltage

Min Voltage

Selector

Selector

CTRL1

CTRL1

ROW1

ROW1

V

V

I to V

I to V

Current Sense

Current Sense

ZCD

ZCD

+

+

Boost

Boost

Control

Control

_

_

Logic

Logic

0.7V

0.7V

Boost_EN

Boost_EN

CTRL6

CTRL6

CTRL5

CTRL5

CTRL4

CTRL4

CTRL3

CTRL3

CTRL2

CTRL2

OVP

OVP

V

ROW6

V

ROW6

V

ROW5

V

ROW5

V

ROW4

V

ROW4

V

ROW3

V

ROW3

V

ROW2

V

ROW2

4V

4V

LOGIC

LOGIC

Current

Current

Generator 1

Generator 1

Current

Current

Generator 6

Generator 6

Current

Current

Generator 5

Generator 5

Current

Current

Generator 4

Generator 4

Current

Current

Generator 3

Generator 3

Current

Current

Generator 2

Generator 2

MODE

MODE

I to V

I to V

+

+

_

_

_

_

+

+_+

V

V

TH,FLT

TH,FLT

1.172V

1.172V

LX

LX

PGND

PGND

OVSEL

OVSEL

ROW6

ROW6

ROW5

ROW5

ROW4

ROW4

ROW3

ROW3

ROW2

ROW2

ROW1

ROW1

10/46

RILIM

RILIM

SGND

SGND

AM00596v1

LED7706 Operation description

5.1 Boost section

5.1.1 Functional description

The LED7706 is a monolithic LEDs driver for the backlight of LCD panels and it consists of a

boost converter and six PWM-dimmable current generators.

The boost section is based on a constant switching frequency, peak current-mode

architecture. The boost output voltage is controlled such that the lowest row's voltage,

referred to SGND, is equal to an internal reference voltage (400 mV typ. see Figure 5). The

input voltage range is from 4.5 V up to 36 V. In addition, the LED7706 has an internal LDO

that supplies the internal circuitry of the device and is capable to deliver up to 40 mA. The

input of the LDO is the VIN pin.

The LDO5 pin is the LDO output and the supply for the power MOSFET driver at the same

time. The AVCC pin is the supply for the analog circuitry and should be connected to the

LDO output through a simple RC filter in order to improve the noise rejection.

Figure 4. AVCC filtering

VIN

VIN

LDO5

CLDO5

CLDO5

1uF

1uF

Rfilt

Rfilt

4R7

4R7

C

C

AVCC

AVCC

100nF

100nF

LDO5

AVCC

AVCC

LDO

LDO

SGND

SGND

LED7706

LED7706

AM00597v1

Two loops are involved in regulating the current sunk by the generators.

The main loop is related to the boost regulator and uses a constant frequency peak currentmode architecture to regulate the power rail that supplies the LEDs (Figure 5), while an

internal current loop regulates the same current (flowing through the LEDs) at each row

according to the set value (RILIM pin).

Figure 5. Main loop and current loop diagram

V

IN

LX

Slope

PWM

ROWx

SGND

COMP

RILIM

E/A

Error amplifier

Minimum voltage drop

selector

0.4V

11/46

AM00598v1

Operation description LED7706

A dedicated circuit automatically selects the lowest voltage drop among all the rows and

provides this voltage to the main loop that, in turn, regulates the output voltage. In fact, once

the reference generator has been detected, the error amplifier compares its voltage drop to

the internal reference voltage and varies the COMP output. The voltage at the COMP pin

determines the inductor peak current at each switching cycle. The output voltage of the

boost regulator is thus determined by the total forward voltage of the LEDs strings (see

Figure 6):

Equation 1

m

N

OUT

ROWS

=

1i

LEDS

Σ

=

mV400)V(maxV

+=

j,F

1j

where the first term represents the highest total forward voltage drop over N active rows and

the second is the voltage drop across the leading generator (400 mV typ.).

The device continues to monitor the voltage drop across all the rows and automatically

switches to the current generator having the lowest voltage drop.

Figure 6. Calculation of the output voltage of the boost regulator

Row with the highest voltage

V

IN

drop across LEDs

5.1.2 Enable function

The LED7706 is enabled by the EN pin. This pin is active high and, when forced to SGND,

the device is turned off. This pin is connected to a permanently active 2.5 μA current source;

when sudden device turn-on at power-up is required, this pin must be left floating or

connected to a delay capacitor. When turned off, the LED7706 quickly discharges the

soft-start capacitor and turns off the power MOSFET, the current generators and the LDO.

The power consumption is thus reduced to 20 μA only.

In applications where the dimming signal is used to turn on and off the device, the EN pin

can be connected to the DIM pin as shown in Figure 7.

Boost

controller

Current

generators

section

I

LED

400 mV

generator

max

Σ

Leading

V

F

V

BOOST

AM00599v1

12/46

LED7706 Operation description

Figure 7. Enable pin driven by dimming signal

DIM

DIM

BAS69

BAS69

EN

220kΩ

220kΩ

100nF

100nF

EN

LED7706

LED7706

SGND

SGND

AM00600v1

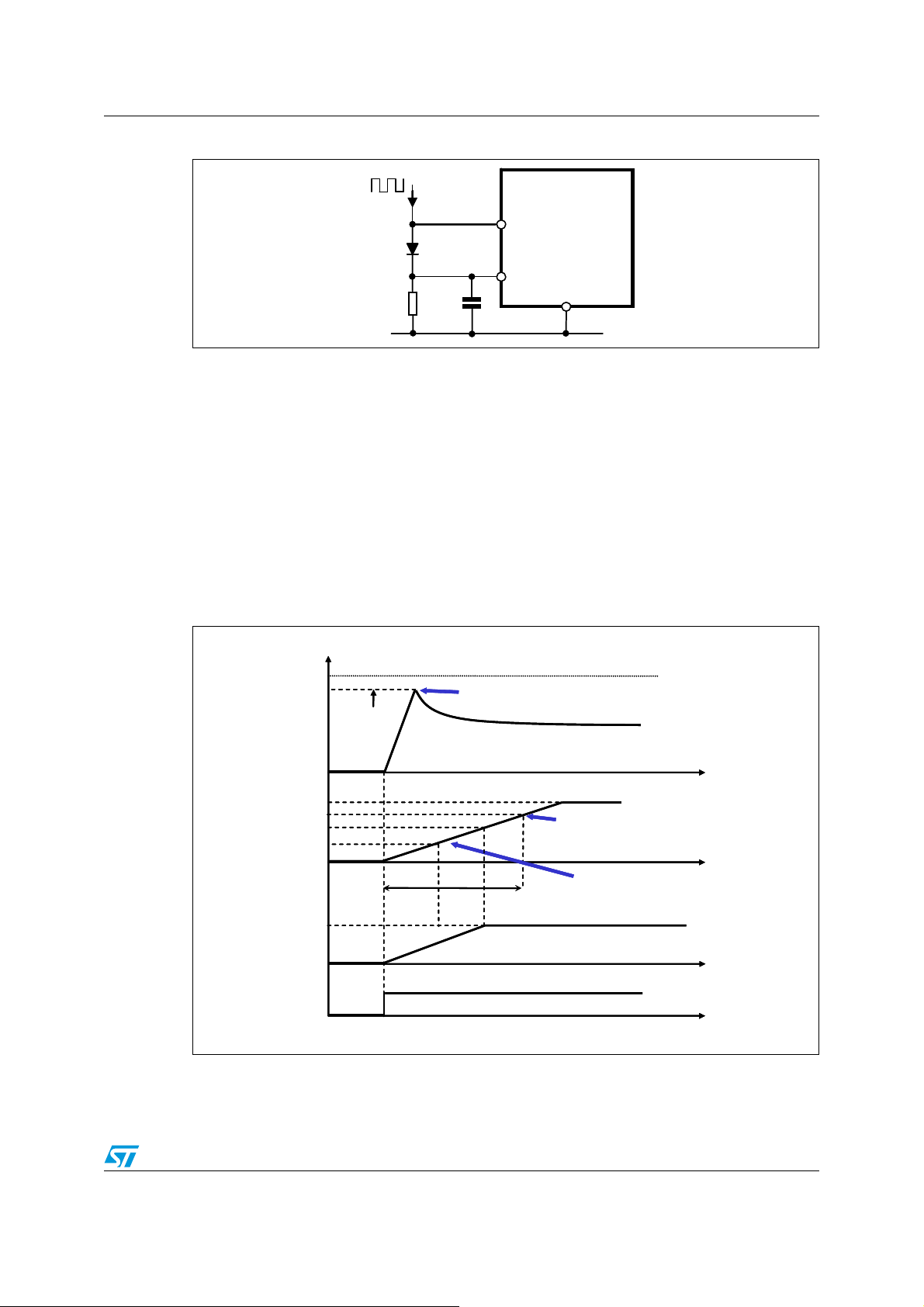

5.1.3 Soft-start

The soft-start function is required to perform a correct start-up of the system, controlling the

inrush current required to charge the output capacitor and to avoid output voltage overshoot.

The soft-start duration is set connecting an external capacitor between the SS pin and

ground. This capacitor is charged with a 5 μA (typ.) constant current, forcing the voltage on

the SS pin to ramp up. When this voltage increases from zero to nearly 1.2 V, the current

limit of the power MOSFET is proportionally released from zero to its final value. However,

because of the limited minimum on-time of the switching section, the inductor might saturate

due to current runaway. To solve this problem the switching frequency is reduced to one half

of the nominal value at the beginning of the soft-start phase. The nominal switching

frequency is restored after the SS pin voltage has crossed 0.8 V.

Figure 8. Soft-start sequence waveforms in case of floating rows

OVP

OVP

Floating ROWs detection

Floating ROWs detection

95% of

95% of

OVP

AVCC

AVCC

2.4V

2.4V

1.2V

1.2V

0.8V

0.8V

100%

100%

OVP

t

ss

t

ss

Current limit

Current limit

Output voltage

Output voltage

SS pin voltage

SS pin voltage

Protections turn active

Protections turn active

Nominal switching

Nominal switching

frequency release

frequency release

EN pin voltage

EN pin voltage

t

t

AM00601v1

During the soft-start phase the floating rows detection is also performed. In presence of one

or more floating rows, the voltage across the involved current generator drops to zero. This

voltage becomes the inverting input of the error amplifier through the minimum voltage drop

13/46

Operation description LED7706

selector (see Figure 5). As a consequence the error amplifier is unbalanced and the loop

reacts by increasing the output voltage. When it reaches the floating row detection (FRD)

threshold (95% of the OVP threshold), the floating rows are managed according to

Section 5.3 on page 21). After the SS voltage reaches a 2.4 V threshold, the start-up

(see

finishes and all the protections turn active. The soft-start capacitor C

can be calculated

SS

Ta bl e 6

according to equation 2.

Equation 2

⋅

tI

≅

C

SS

SSSS

4.2

Where I

= 5 µA and tSS is the desired soft-start duration.

SS

5.1.4 Overvoltage protection

An adjustable over-voltage protection is available. It can be set feeding the OVSEL pin with a

partition of the output voltage. The voltage of the central tap of the divider is thus compared

to a fixed 1.234 V threshold. When the voltage on the OVSEL pin exceeds the OV threshold,

the FAULT pin is tied low and the device is turned off; this condition is latched and the

LED7706 is restarted

occurs when the LDO output falls below the lower UVLO threshold and subsequently

crosses the upper UVLO threshold during the rising phase of the input voltage). Normally,

the value of the high-side resistors of the divider must be chosen as high as possible (but

lower than 1 M

(during the off phase of the dimming cycle). The R2/R1 ratio is calculated to trigger the OVP

circuitry as soon as the output voltage is 2 V higher than the maximum value for a given LED

string (see equation 3). Two additional filtering capacitors, C

improve noise rejection at the OVSEL pin, as shown in

in the 100 pF-330 pF range, while the C

Equation 3

by toggling the EN pin or by performing a Power-On Reset (the POR

Ω) to reduce the output capacitor discharge when the boost converter is off

Figure 9. The typical value for C10 is

13 value is given by equation 4.

RR

⋅=

12

OVP,OUT

V234.1

−+

10 and C13, may be required to

)V234.1V2V(

Equation 4

14/46

R

2

C2C ⋅=

1013

R

1

Loading...

Loading...