L99DZ70XP

Door actuator driver

Features

■ One full bridge for 6 A load (R

■ Two half bridges for 3 A load (R

■ Two half bridges for 0.75 A load

(R

= 1600 mΩ)

on

■ One highside driver for 6 A load (R

■ Two configurable highside drivers for up to

1.5 A load (R

(R

=1800mΩ)

on

■ Two highside drivers for 0.5 A load

(R

= 1600 mΩ)

on

■ Programmable softstart function to drive loads

=500mΩ) or 0.4 A

on

with higher inrush currents as current limitation

value

■ Very low current consumption in standby mode

(I

< 6 µA typ; Tj ≤ 85 °C; ICC < 5 µA typ;

S

T

≤ 85 °C)

j

■ Current monitor output for all highside drivers

■ Device contains temperature warning and

protection

■ Openload detection for all outputs

■ Over-current protection for all otputs

■ Separated half bridges for door lock motor

■ PWM control of all outputs

■ Charge pump output for reverse polarity

protection

■ STM standard serial peripheral interface (ST-

SPI 3.0)

■ Control block for electrochromic element

Table 1. Device summary

= 150 mΩ)

on

= 300 mΩ)

on

on

=90mΩ)

PowerSSO-36

Applications

■ Door actuator driver with 6 bridges for double

door lock control, mirror fold and mirror axis

control, highside driver for mirror defroster,

bulbs and LEDs (replacement for L9950).

Control block with external MOS transistor for

charging / discharging of electrochromic glass.

Description

The L99DZ70XP is a microcontroller driven

multifunctional door actuator driver for automotive

applications. Up to five DC motors and five

grounded resistive loads can be driven with six

half bridges and five highside drivers. An

electrochromic mirror glass can be controlled

using the integrated SPI-driven module in

conjunction with an external MOS transistor. The

integrated SPI controls all operating modes

(forward, reverse, brake and high impedance).

Also all diagnostic information is available via SPI

read.

Package

Order codes

Tube Tape and reel

PowerSSO-36 L99DZ70XP L99DZ70XPTR

November 2010 Doc ID 15162 Rev 3 1/47

www.st.com

1

Contents L99DZ70XP

Contents

1 Block diagram and pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 ESD protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.4.1 Outputs OUT1 - OUT11, ECV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.5 SPI - Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.1 Dual power supply: VS and VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.2 Wake up and active mode / standby mode . . . . . . . . . . . . . . . . . . . . . . . 24

3.3 Charge pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4 Diagnostic functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.5 Overvoltage and undervoltage detection at V

3.6 Overvoltage and undervoltage detection at V

. . . . . . . . . . . . . . . . . . . . 25

S

. . . . . . . . . . . . . . . . . . . 25

CC

3.7 Temperature warning and thermal shutdown . . . . . . . . . . . . . . . . . . . . . . 25

3.8 Inductive loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.9 Open load detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.10 Over-load detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.11 Current monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.12 PWM inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.13 Cross-current protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.14 Programmable soft-start function to drive loads with higher inrush current

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.15 Controller for electrochromic glass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4 Functional description of the SPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2/47 Doc ID 15162 Rev 3

4.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1.1 Chip Select Not (CSN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1.2 Serial Data In (DI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

L99DZ70XP Contents

4.1.3 Serial Clock (CLK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1.4 Serial Data Out (DO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.1.5 SPI communication flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

4.2 Command byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.2.1 Operation code definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4.3 Global status byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.4 Address mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5 SPI - control and status registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.1 Control register 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.2 Control register 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.3 Control register 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.4 Control register 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.5 Status register 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.6 Status register 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.7 Status register 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.8 Configuration register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6 Packages thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7 Package and packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.1 ECOPACK® packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.2 PowerSSO-36 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

7.3 PowerSSO-36 packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Doc ID 15162 Rev 3 3/47

List of tables L99DZ70XP

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

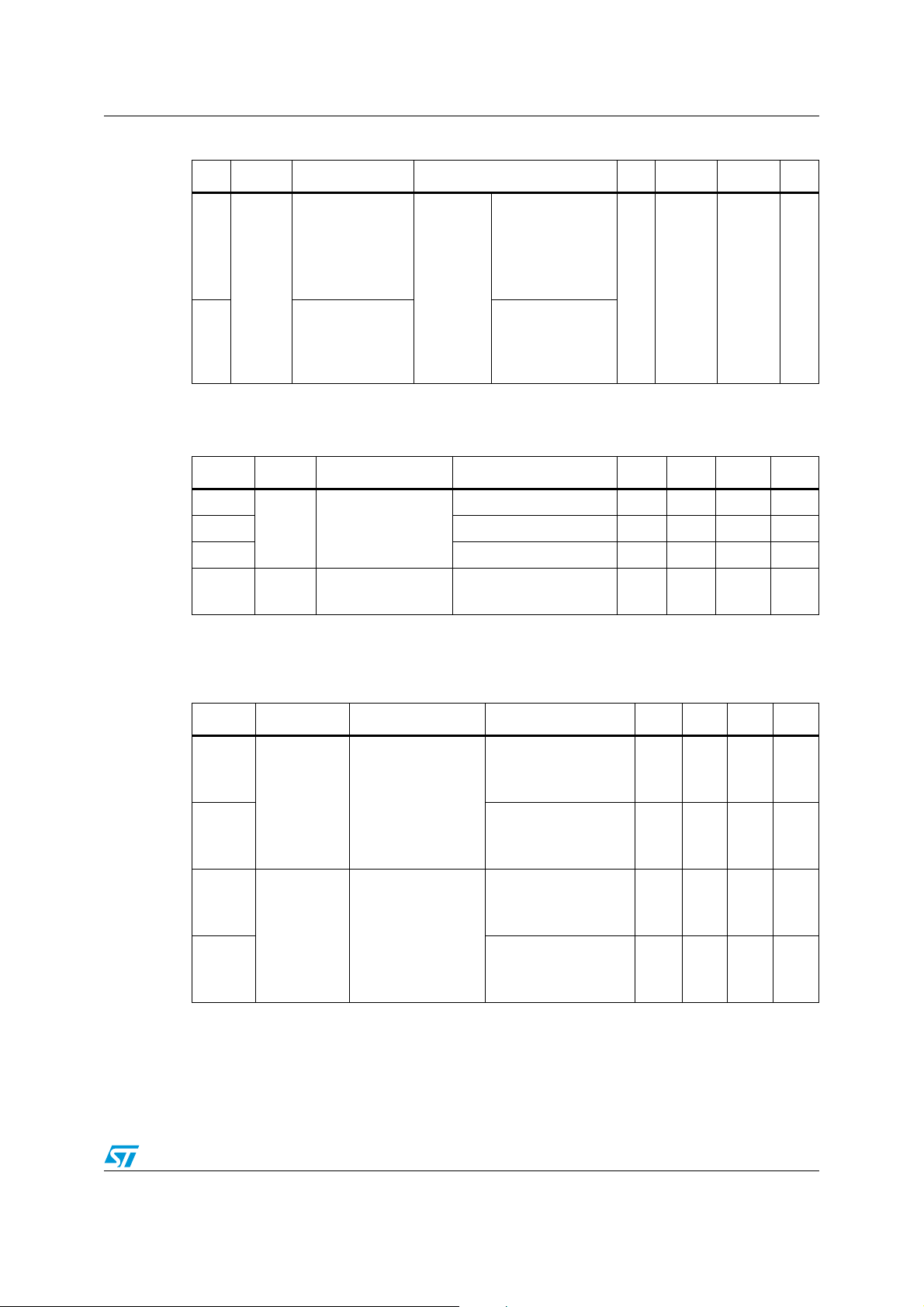

Table 2. Pin definition and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 4. ESD protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 5. Operating junction temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 6. Temperature warning and thermal shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 7. Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 8. Overvoltage and under voltage detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 9. Current monitor output CM / PWM 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 10. Charge pump output CP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 11. On-resistance and switching times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Table 12. Current monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 13. Electrochrome control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 14. Delay time from standby to active mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 15. Inputs: CSN, CLK, PWM1/2 and DI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 16. SDI timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table 17. DO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 18. DO timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 19. CSN timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Table 20. SPI frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 21. Operation code definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 22. Global status byte . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 23. RAM memory map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 24. ROM memory map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 25. Control register 0 (read/write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 26. Control register 1 (read/write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 27. Control register 2 (read/write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 28. Control register 3 (read/write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 29. Status register 0 (read) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 30. Status register 1 (read) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 31. Status register 2 (read) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 32. Configuration register (read/write) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 33. PowerSSO-36 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 34. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4/47 Doc ID 15162 Rev 3

L99DZ70XP List of figures

List of figures

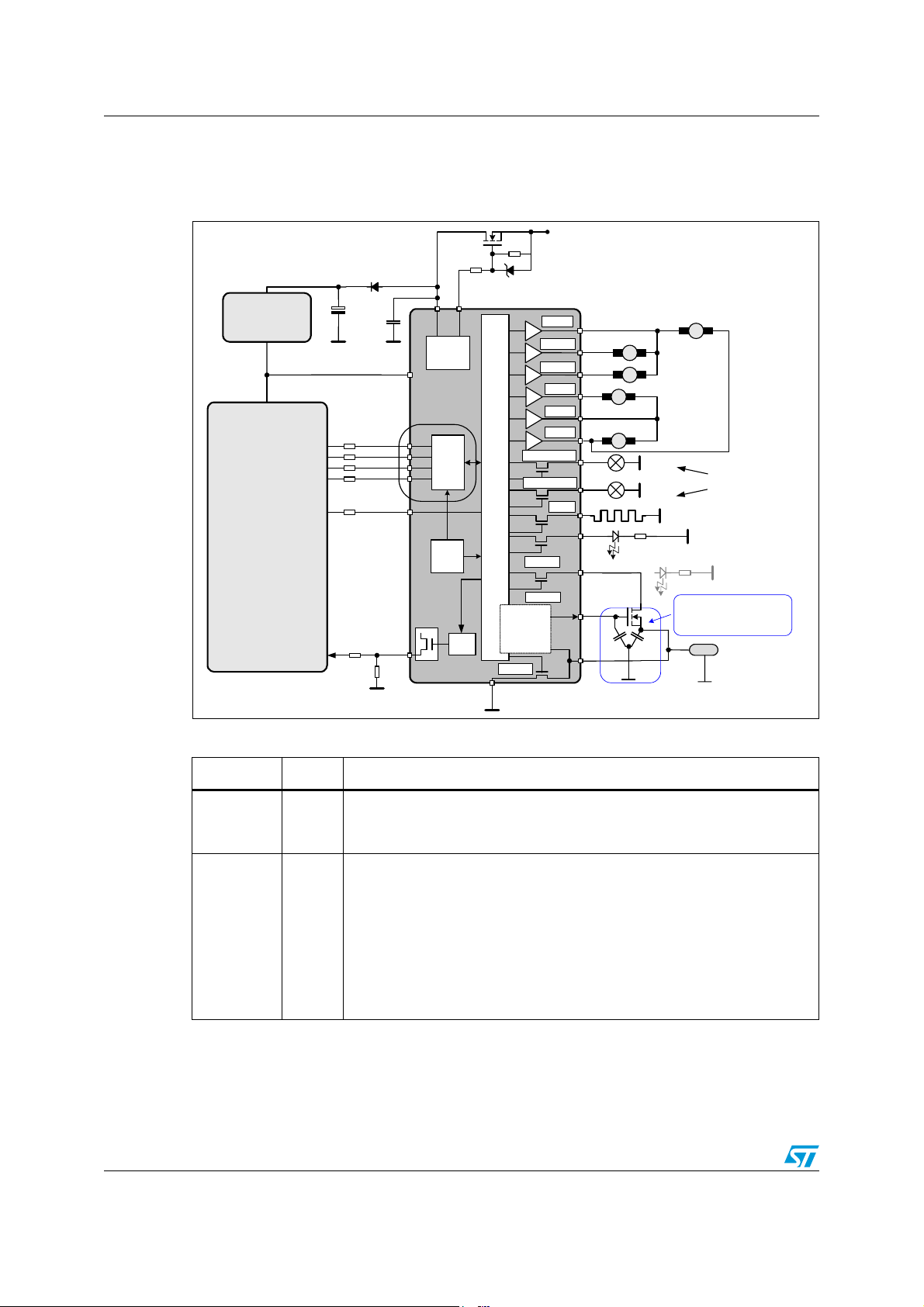

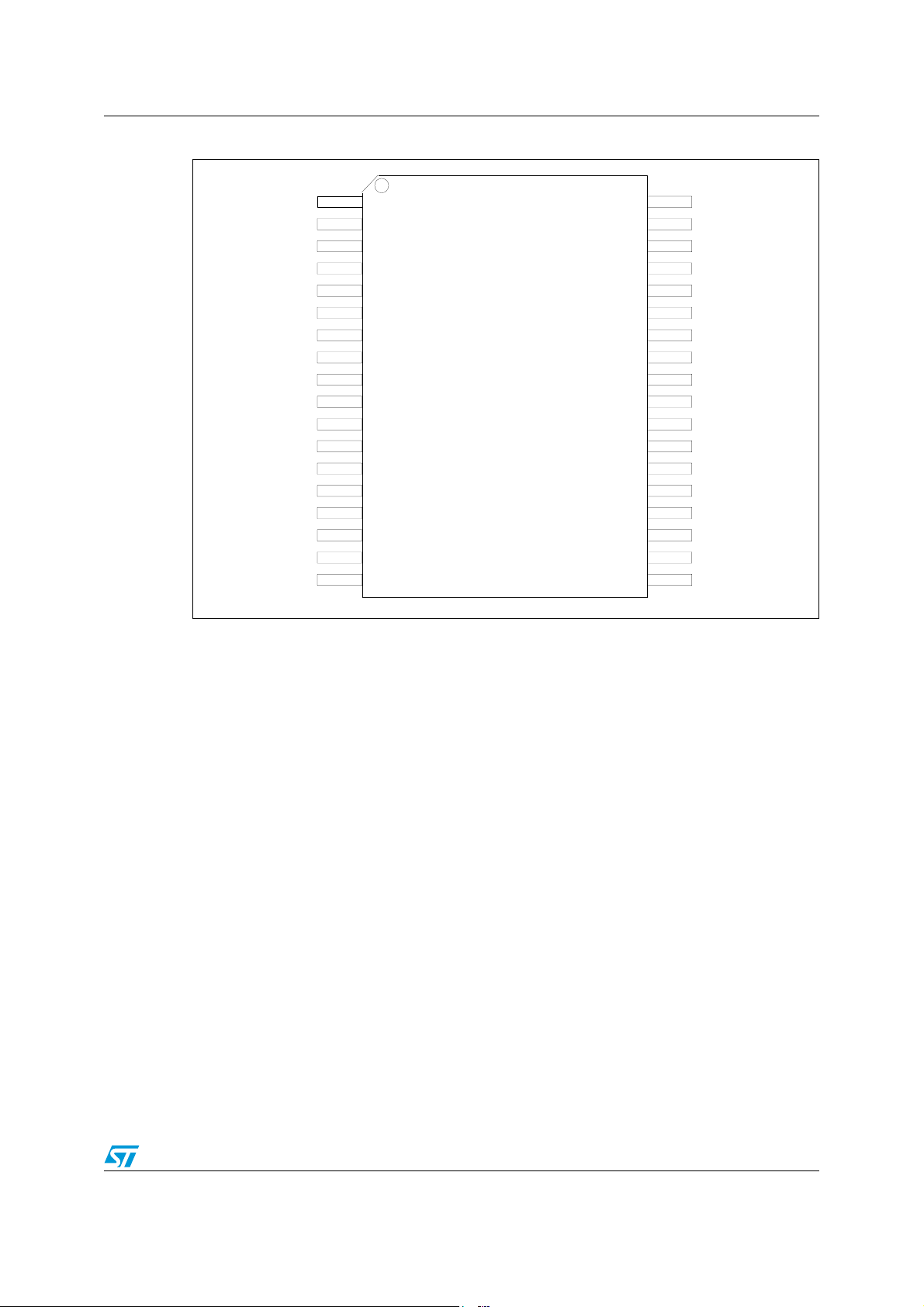

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

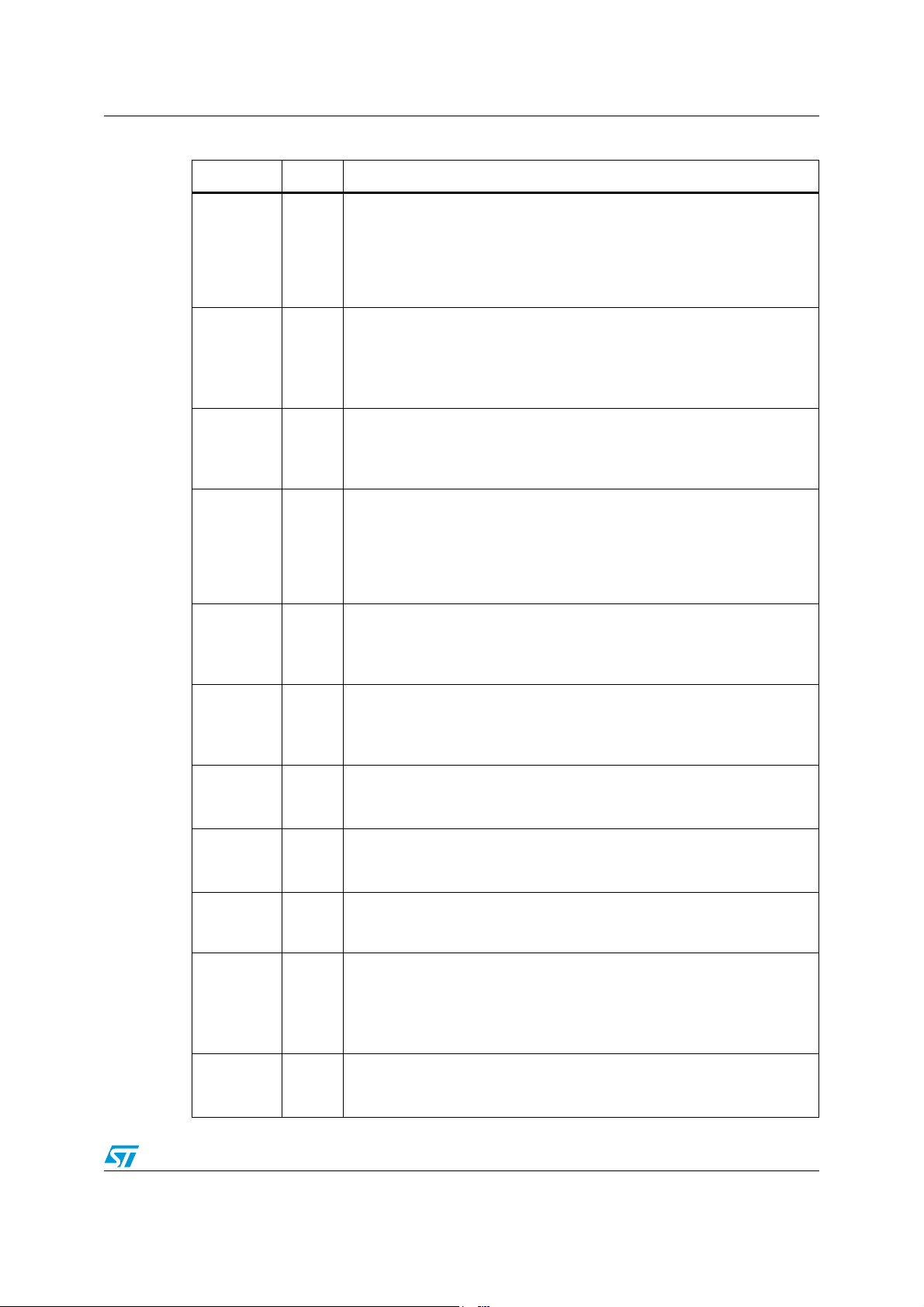

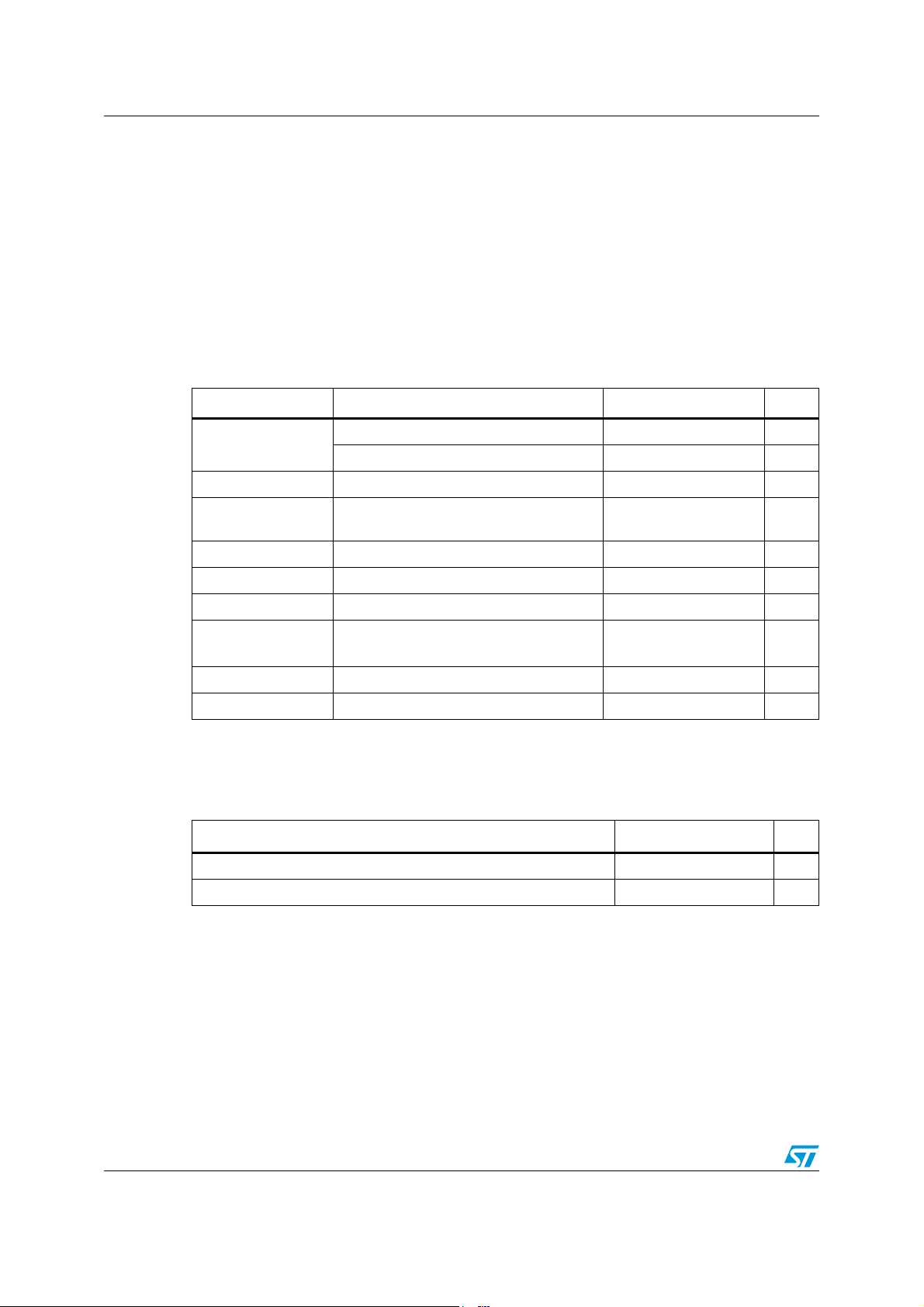

Figure 2. Configuration diagram (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

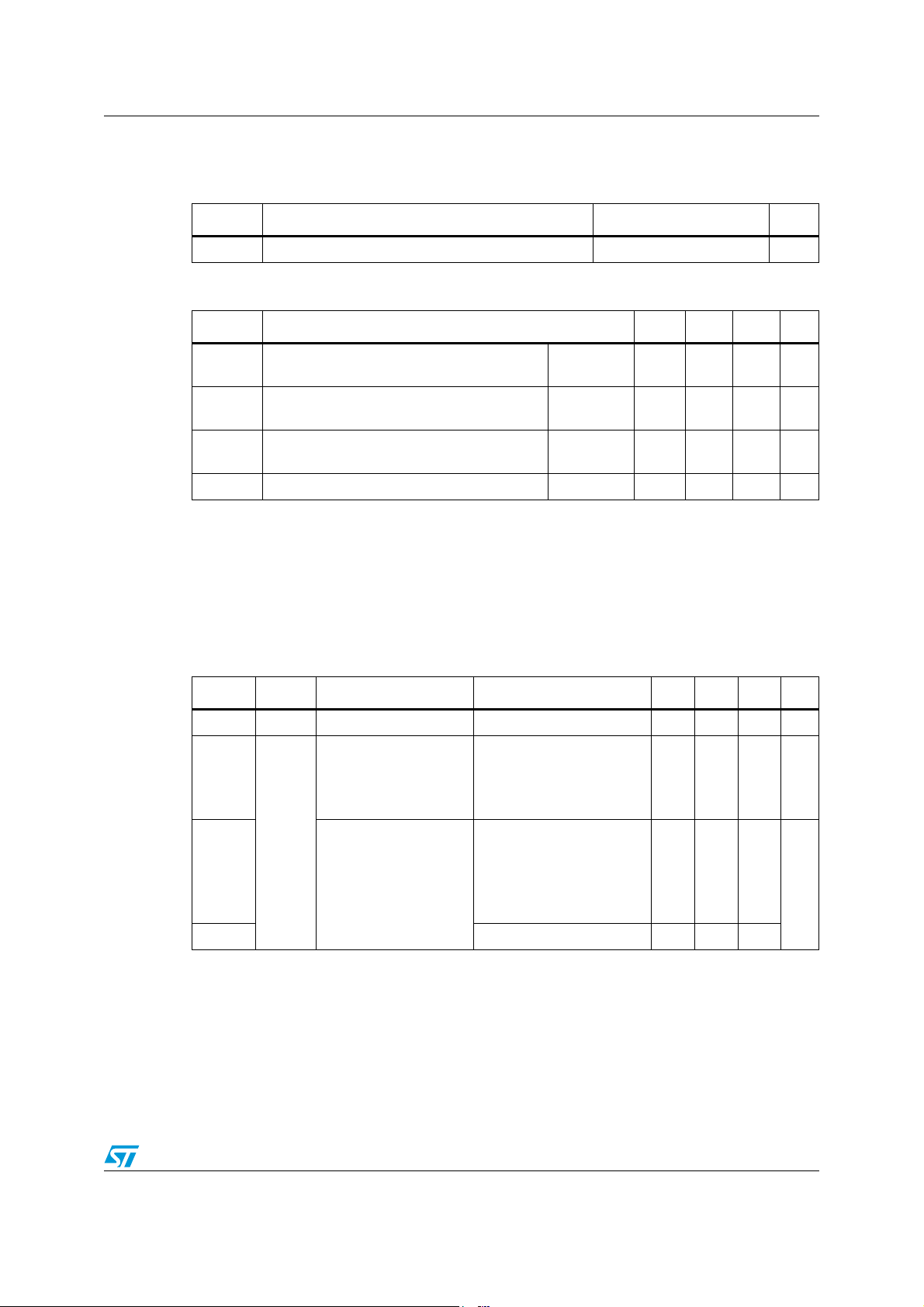

Figure 3. Electrochrome control block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 4. SPI - Transfer timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 5. SPI - Input timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 6. SPI - DO valid data delay time and valid time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 7. SPI - DO enable and disable time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 8. SPI - driver turn on/off timing, minimum CSN HI time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 9. Example of programmable soft-start function for inductive loads . . . . . . . . . . . . . . . . . . . . 27

Figure 10. Write and read SPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 11. Global error flag definition. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 12. Packages thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Figure 13. PowerSSO-36 package dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 14. PowerSSO-36 tube shipment (no suffix) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 15. PowerSSO-36 tape and reel shipment (suffix “TR”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Doc ID 15162 Rev 3 5/47

Block diagram and pin description L99DZ70XP

1 Block diagram and pin description

Figure 1. Block diagram

V

BAT

L99PM62GXP

VCC

SPC560D

100µF

1k

1k

1k

1k

1k

1k

100nF

DI

DO

CLK

CSN

PWM1

CM/PWM2

STD18NF03L

VS

Charge

Pump

VCC

ST SPI

SPI

Standby

Interface

CM

MUX

100k

10k

CP

Ωm300

OUT1

Ωm1600

Ωm1600

Ωm150

Ωm150

Ωm300

Ωm1800/500

Ωm1800/500

Ωm90

Driver Interface & Diagnostic

OUT2

OUT3

OUT4

OUT5

OUT6

OUT7

OUT8

OUT11

OUT9

M

M

M

M

10 Watt

10 Watt

M

progr. Bulb or LED Mode

Ωm1600

OUT10

STD18NF03L

Control Block

6BIT SPI controlled

GND

EC Glass

Ωm1600

Ωm1600

ECDR (VS)

5 nF 100 nF

ECV (VS)

All components to be

placed together as close

as possible

Table 2. Pin definition and functions

Pin

Symbol Function

Ground: reference potential.

1, 18, 19, 36 GND

Important: For the capability of driving the full current at the outputs all pins

of GND must be externally connected!

Highside driver output 11.

The output is built by a highside switch and is intended for resistive loads,

therefore the internal reverse diode from GND to the output is missing. For

ESD reason a diode to GND is present, but the energy which can be

2, 35 OUT11

dissipated is limited. The highside driver is a power DMOS transistor with an

internal parasitic reverse diode from the output to VS (bulk-drain-diode). The

output is over-current protected.

Important: for the capability of driving the full current at the outputs both pins

of OUT11 must be externally connected!

6/47 Doc ID 15162 Rev 3

L99DZ70XP Block diagram and pin description

Table 2. Pin definition and functions (continued)

Pin

3

4

5

Symbol Function

OUT1,

OUT2,

OUT3

6, 7, 14, 15,

23, 24, 28, 29V

8DI

9

CM/

PWM2

10 CSN

11 DO

Halfbridge outputs 1,2,3.

The output is built by a highside and a lowside switch, which are internally

connected. The output stage of both switches is a power DMOS transistor.

Each driver has an internal parasitic reverse diode (bulk-drain-diode:

highside driver from output to VS, lowside driver from GND to output). This

output is over-current protected.

Power supply voltage (external reverse protection required).

For this input a ceramic capacitor as close as possible to GND is

recommended.

S

Important: For the capability of driving the full current at the outputs all pins

of VS must be externally connected!

Serial data input.

The input requires CMOS logic levels and receives serial data from the

microcontroller. The data is a 24 bit control word and the most significant bit

(MSB, bit 23) is transferred first.

Current monitor output/PWM2 input.

Depending on the selected multiplexer bits of the control register this output

sources an image of the instant current through the corresponding highside

driver with a ratio of 1/10.000 or 1/2000. This pin is bidirectional. The

microcontroller can overdrive the current monitor signal to provide a second

PWM input for the outputs OUT5, OUT8 and OUT10.

Chip Select Not input / Testmode.

This input is low active and requires CMOS logic levels. The serial data

transfer between L99DZ70 and the microcontroller is enabled by pulling the

input CSN to low level.

Serial data output.

The diagnosis data is available via the SPI and this tristate-output. The

output will remain in tristate, if the chip is not selected by the input CSN

(CSN = high)

Supply voltage.

12 VCC

For this input a ceramic capacitor as close as possible to GND is

recommended.

Serial clock input.

13 CLK

This input controls the internal shift register of the SPI and requires CMOS

logic levels.

16,17

20,21

22

OUT4,

OUT5,

OUT6

Halfbridge outputs 4,5,6: see OUT1 (pin 3).

Important: For the capability of driving the full current at the outputs both

pins of OUT4 (OUT5, respectively) must be externally connected!

Electrocromic driver output.

If the electrochrome mode is selected this pin is used to control the gate of

25 ECDR

an external MOSFET, otherwise it remains in high-impedance state.

Note: It is possible to connect the pin to VS as in L9950/53/54 applications,

as long as the electrochome mode is not enabled via SPI.

Charge pump output.

26 CP

This output is provided to drive the gate of an external n-channel power

MOS used for reverse polarity protection (see Figure 1.).

Doc ID 15162 Rev 3 7/47

Block diagram and pin description L99DZ70XP

Table 2. Pin definition and functions (continued)

Pin

Symbol Function

27 PWM1

30

31

OUT7,

OUT8,

32 ECV

33 OUT9

34 OUT10

PWM1 input.

This input signal can be used to control the drivers OUT1-4, OUT6-7, OUT9

and OUT11 and ECV by an external PWM signal.

Highside driver outputs 7,8: see OUT9.

By selection of one of the 2 power DMOS at same output is it possible to

supply a bulb with low on-resistance or a LED with higher on-resistance in a

different application.

Electrochrome voltage input and lowside driver output.

This input senses voltage in electrocrome mode for charge monitoring.

The lowside switch provides a fast discharge of electrocromic mirror and can

be used 'stand alone' as lowside switch beside electrocromic mode.

Highside driver output 9.

The output is built by a highside switch and is intended for resistive loads,

hence the internal reverse diode from GND to the output is missing. For

ESD reason a diode to GND is present but the energy which can be

dissipated is limited. The highside driver is a power DMOS transistor with an

internal parasitic reverse diode from the output to VS (bulk-drain-diode). The

output is over-current and open load protected.

Highside driver output 10: see OUT9.

Important: beside the bit10 in control register 1 this output can be switched

on setting bit1 for electrocromic control mode with higher priority.

8/47 Doc ID 15162 Rev 3

L99DZ70XP Block diagram and pin description

Figure 2. Configuration diagram (top view)

GND

1

OUT11

OUT1

OUT2

OUT3

CM / PWM2

OUT4

OUT4

GND

CSN

DO

Vcc

CLK

Vs

Vs

Vs

Vs

DI

10

11

12

13

14

15

16

17

18

2

3

4

5

6

7

8

PowerSSO-36

9

Note: All pins with the same name must be externally connected.

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

GND

OUT11

OUT10

OUT9

ECV

OUT8

OUT7

Vs

Vs

PWM1

CP

ECDR

Vs

Vs

OUT6

OUT5

OUT5

GND

Doc ID 15162 Rev 3 9/47

Electrical specifications L99DZ70XP

2 Electrical specifications

2.1 Absolute maximum ratings

Stressing the device above the rating listed in the “Absolute maximum ratings” table may

cause permanent damage to the device. These are stress ratings only and operation of the

device at these or any other conditions above those indicated in the Operating sections of

this specification is not implied. Exposure to Absolute Maximum Rating conditions for

extended periods may affect device reliability. Refer also to the STMicroelectronics SURE

Program and other relevant quality document.

Table 3. Absolute maximum ratings

Symbol Parameter Value Unit

Vs

Vcc Stabilized supply voltage, logic supply -0.3 to 5.5 V

VDI, V

DO, VCLK,

V

CSN, VPWM

V

CM

V

CP

V

OUTn, ECDR, ECV

I

OUT,2,3,9,10,

ECV

I

OUT1,6,7,8,

I

OUT4,5,11

DC supply voltage -0.3...28 V

Single pulse t

Digital input / output voltage -0.3 to VCC + 0.3 V

< 400 ms 40 V

max

Current monitor output -0.3 to VCC + 0.3 V

Charge pump output -25 .. VS + 11 V

Static output voltage (n= 1 to 11) -0.3 to VS + 0.3 V

Output current ±1.25 A

Output current ±5 A

Output current ±10 A

2.2 ESD protection

Table 4. ESD protection

Parameter Value Unit

All pins ± 2

Output pins: OUT1 - OUT6, ECV ± 4

1. HBM according to MIL 883C, Method 3015.7 or EIA/JESD22-A114-A.

2. HBM with all unzapped pins grounded.

10/47 Doc ID 15162 Rev 3

(1)

(2)

kV

kV

L99DZ70XP Electrical specifications

2.3 Thermal data

Table 5. Operating junction temperature

Symbol Parameter Value Unit

T

Operating junction temperature -40 to 150 °C

j

Table 6. Temperature warning and thermal shutdown

Symbol Parameter Min. Typ. Max. Unit

T

jTW ON

T

jSD ON

T

jSD OFF

T

jSD HYS

Temperature warning threshold junction

temperature

Thermal shutdown threshold junction

temperature

Thermal shutdown threshold junction

temperature

Thermal shutdown hysteresis 5 °K

2.4 Electrical characteristics

VS = 8 to 16V, VCC= 4.5 to 5.3V, Tj = - 40 to 150°C, unless otherwise specified.

The voltages are referred to GND and currents are assumed positive, when the current

flows into the pin.

Table 7. S u p ply

Item Symbol Parameter Test condition Min. Typ. Max. Unit

7.1 VS Operating voltage range 7 28 V

7.2

7.3

7.4

(1)

VS DC supply current

I

S

quiescent supply

V

S

current

T

130 150 °C

j

Tj

increasing

decreasing

=16V, VCC=5.3V

V

S

Tj

150 °C

active mode

OUT1 - OUT11, ECV,

ECDR floating

=16V, VCC=0V

V

S

standby mode

OUT1 - OUT11, ECV,

ECDR floating

= -40°C, 25°C

T

test

T

= 85°C 6 25

test

170 °C

720mA

412

µA

Doc ID 15162 Rev 3 11/47

Electrical specifications L99DZ70XP

Table 7. Supply (continued)

Item Symbol Parameter Test condition Min. Typ. Max. Unit

VS=16V, VCC=5.3V

7.5

VCC DC supply current

CSN = V

OUT1 - OUT11, ECV,

ECDR floating

V

=16V,

S

V

CC

standby mode

OUT1 - OUT11, ECV,

ECDR floating

T

test

T

test

7.6

7.7

(2)

(1)

I

CC

VCC quiescent supply

current

1. This parameter is guaranteed by design.

2. CM/ PWM 2 = V

Table 8. Overvoltage and under voltage detection

or 0 V.

CC

Item Symbol Parameter Test condition Min. Typ. Max. Unit

, active mode

CC

=5.3V

CSN=VCC

13mA

36

= -40°C, 25°C

= 85°C 5 10

µA

8.1 V

8.2 V

8.3 V

8.4 V

8.5 V

8.6 V

8.7 V

8.8 V

8.9 V

Table 9. Current monitor output CM / PWM 2

SUV onVS

SUV offVS

SUV hystVS

SOV offVS

SOV onVS

SOV hystVS

POR off

POR on

POR hyst

UV-threshold voltage VS increasing 5.6 7.2 V

UV-threshold voltage VS decreasing 5.2 6.1 V

UV-hysteresis V

SUV ON

- V

SUV OFF

0.5 V

OV-threshold voltage VS increasing 18 24.5 V

OV-threshold voltage VS decreasing 17.5 23.5 V

OV-hysteresis V

SOV OFF

- V

SOV ON

1V

Power-on-reset threshold VCC increasing 2.9 V

Power-on-reset threshold VCC decreasing 2.0 V

Power-on-reset hysteresis V

POR OFF

- V

POR ON

0.11 V

Item Symbol Parameter Test condition Min. Typ. Max Unit

9.1 V

Functional voltage

CM

range

0V

-1V V

CC

Current monitor

output ratio:

9.2

I

9.3

CM,r

I

CM/IOUT1,4,5,6,11

and 7,8

(low on-resistance)

I

CM/IOUT2,3,9,10

and 7,8

(high on-resistance)

0V <= VCM <= 4V

=5V

V

CC

1

----------------- -

10.000

1

------------ -

,

2000

12/47 Doc ID 15162 Rev 3

L99DZ70XP Electrical specifications

Table 9. Current monitor output CM / PWM 2 (continued)

Item Symbol Parameter Test condition Min. Typ. Max Unit

Current monitor

accuracy

9.4

I

CM acc

9.5

1. FS (full scale)= I

Table 10. Charge pump output CP

accI

CMOUT1,4,5,6,

11and 7, 8

(low on-res.)

accI

CMOUT2,3,9,10,

and 7, 8

(high on-res.)

OUTmax * ICM,r .

V

CM

3.8V,

V

CC

Item Symbol Parameter Test condition Min. Typ. Max Unit

10.1

10.2 V

V

Charge pump output

CP

voltage

10.3 V

10.4 I

Charge pump output

CP

current

2.4.1 Outputs OUT1 - OUT11, ECV

= 500mA

I

Out,min

I

Out4,5,11max

I

<=

= 5V

Out1,6 max

I

Out7,8 max

I

Out,min

I

Out2,3 max

I

Out9,10max

I

Out8 max

VS = 8V, I

= 10V, I

S

>=12V, ICP = -100µA VS+10 VS+13 V

S

= VS+10V,

V

CP

=13.5V

V

S

= 5.9A

= 2.9A

= 1.3A

4% +

1%FS

(1)

= 100 mA

= 0.6 A

= 0.4 A

= 0.3 A

= -60µA VS+6 VS+13 V

CP

= -80µA VS+8 VS+13 V

CP

95 150 300 µA

8% +

2%FS

(1)

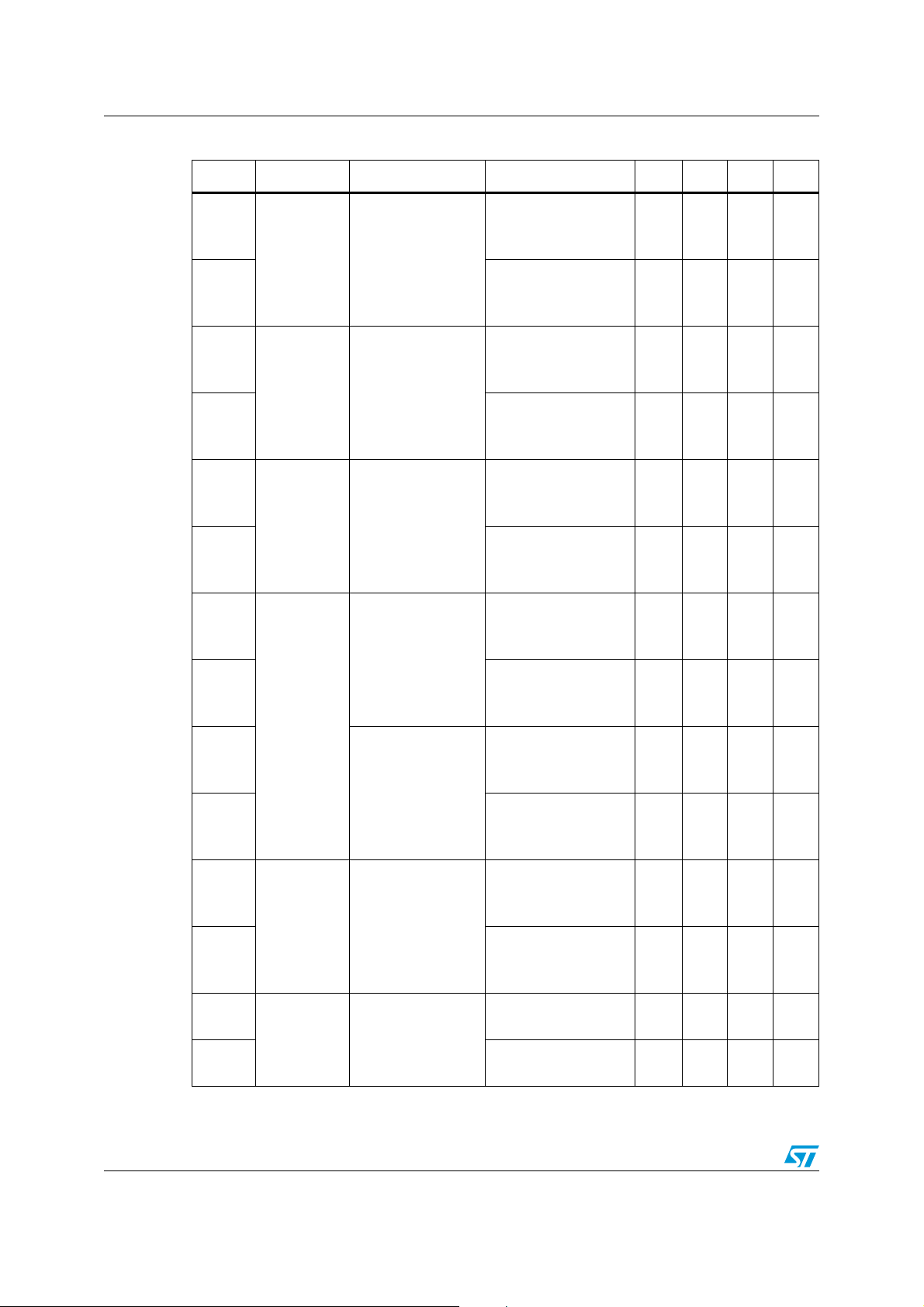

Table 11. On-resistance and switching times

Item Symbol Parameter Test condition Min. Typ. Max. Unit

V

= 13.5 V,

S

11.1

r

ON OUT1,

r

ON OUT6

On-resistance to

supply or GND

11.2

11.3

r

ON OUT2,

r

ON OUT3

On-resistance to

supply or GND

11.4

=25°C,

T

j

=±1.5A

I

OUT1,6

V

= 13.5 V,

S

=125°C,

T

j

I

=±1.5A

OUT1,6

= 13.5 V,

V

S

=25°C,

T

j

I

= ± 0.4A

OUT2,3

V

= 13.5 V,

S

Tj=125°C,

=±0.4A

I

OUT2,3

300 400 mΩ

450 600 mΩ

1600 2200 mΩ

2500 3400 mΩ

Doc ID 15162 Rev 3 13/47

Electrical specifications L99DZ70XP

Table 11. On-resistance and switching times (continued)

Item Symbol Parameter Test condition Min. Typ. Max. Unit

V

= 13.5 V,

S

11.5

r

ON OUT4,

r

ON OUT5

On-resistance to

supply or GND

11.6

11.7

r

ON OUT9,

r

ON OUT10

On-resistance

to supply

11.8

11.9

On-resistance

rON OUT11

to supply

11.10

11.11

On-resistance to

supply in low mode

(control register 1

11.12

11.13

r

ON OUT7

r

ON OUT8

bits 12 to15: 0101)

On-resistance to

supply in high mode

(control register 1

11.14

bits 12 to15: 1010)

11.15

r

ON ECV

On-resistance to

GND

11.16

11.17

I

QLH

11.18

Switched-off output

current highside

drivers of OUT1-6,

8-11

=25°C,

T

j

=±3.0A

I

OUT4,5

V

= 13.5 V,

S

=125°C,

T

j

I

=±3.0A

OUT4,5

= 13.5 V,

V

S

Tj=25°C,

V

= 13.5 V,

S

=125°C,

T

j

= 13.5 V,

V

S

=25°C,

T

j

OUT11

V

= 13.5 V,

S

=125°C,

T

j

OUT11

= 13.5 V,

V

S

=-0.4A

=-0.4A

=-3.0A

=-3.0A

I

OUT9,10

I

OUT9,10

I

I

Tj=25°C,

OUT7,8

V

S

=125°C,

T

j

OUT7,8

V

S

=25°C,

T

j

OUT7,8

V

S

=-0.8A

= 13.5 V,

=-0.8A

= 13.5 V,

=-0.2A

= 13.5 V,

I

I

I

Tj=125°C,

OUT7,8

V

S

=25°C,

T

j

V

S

=125°C,

T

j

V

OUT

=-0.2A

= 13.5 V,

=+0.4A

= 13.5 V,

=+0.4A

= 0V,

I

I

OUTECV

I

OUTECV

standby mode

V

= 0V,

OUT

active mode

150 200 mΩ

225 300 mΩ

1600 2200 mΩ

2500 3400 mΩ

90 130 mΩ

130 180 mΩ

500 700 mΩ

700 950 mΩ

1800 2400 mΩ

2500 3400 mΩ

1600 2200 mΩ

2500 3400 mΩ

-5 -2 µA

-10 -7 µA

14/47 Doc ID 15162 Rev 3

L99DZ70XP Electrical specifications

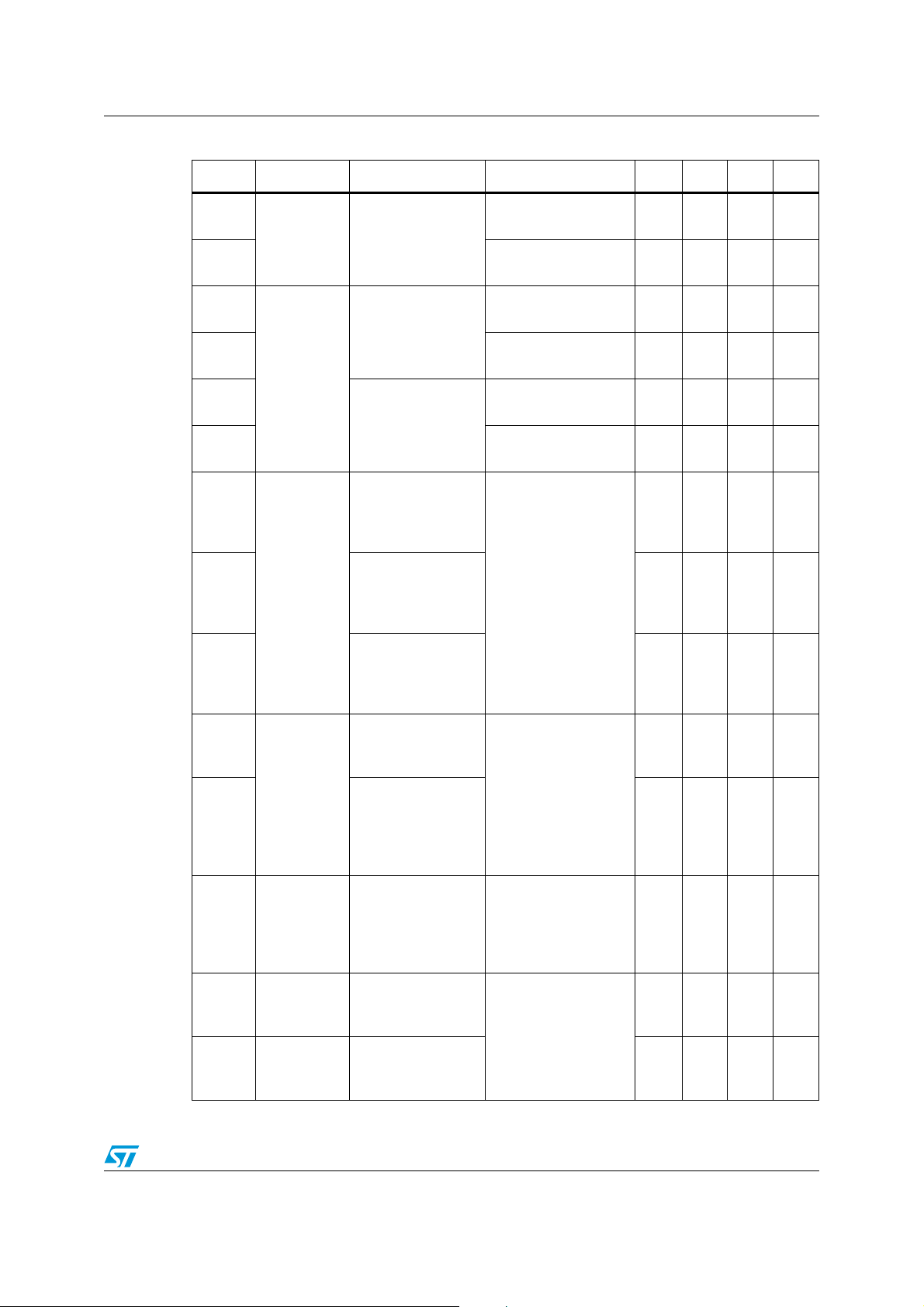

Table 11. On-resistance and switching times (continued)

Item Symbol Parameter Test condition Min. Typ. Max. Unit

= 0V,

V

11.19

11.20

11.21

I

QLH7,8

Switched-off output

current highside

drivers of OUT7-8

Switched-off output

current lowside

11.22

11.23

I

QLL

drivers of OUT1-6

Switched-off output

current lowside

11.24

drivers of ECV

Output delay time,

11.25

highside driver on

except

(OUT

X

OUT

)

7,8

Output delay time,

11.26

t

d ON H

highside driver on

(OUT

R

DSon

in high

7,8

mode)

Output delay time,

11.27

highside driver on

(OUT

R

DSon

in low

7,8

mode)

Output delay time,

11.28

t

d OFF H

highside driver off

(OUT

1, 4, 5, 6, 11

)

Output delay time,

highside driver off

11.29

11.30 t

d ON L

(OUT

R

DSon , 8

R

DSon , 9, 10

Output delay time,

lowside driver On

2,3,7,

high/low

high/low

)

Output delay time,

11.31 t

d OFF L 1-6

lowside driver OUT

1-6 off

Output delay time,

11.32 t

d OFF L ECV

lowside driver ECV

off

OUT

standby mode

V

= 0V,

OUT

active mode

= VS,

V

OUT

standby mode

V

= 0V,

OUT

active mode

= VS,

V

OUT

standby mode

V

= VS,

OUT

active mode

V

= 13.5 V,

S

VCC=5V

(1)(2)(3)

VS= 13.5 V,

(1)(2)(3)

=5V

V

CC

= 13.5 V,

V

S

VCC=5V,

corresponding

highside driver is not

active

V

V

CC

(1)(2)(3)

=13.5V,

S

(1)(2)(3)

=5V

-5 -2 µA

-15 -10 µA

80 120 µA

-10 -7 µA

-15 15 µA

-10 10 µA

20 40 80 µs

15 35 60 µs

10 35 80 µs

60 150 200 µs

40 70 100 µs

15 30 70 µs

40 150 300 µs

15 45 80 µs

Doc ID 15162 Rev 3 15/47

Electrical specifications L99DZ70XP

Table 11. On-resistance and switching times (continued)

Item Symbol Parameter Test condition Min. Typ. Max. Unit

t

11.33 t

D HL

Cross current

protection time

11.34 t

11.35 dV

1. Rload = 16Ω at OUT1, 6 and 7,8 in low on-resistance mode.

2. Rload = 4

3. Rload = 64

is the switch-on delay time if complement in half bridge has to switch-off.

4. t

cc

Table 12. Current monitoring

D LH

OUT

/dt

Slew rate of OUTx

on/off

Ω at OUT4, 5 and 11.

Ω at OUT2, 3, 9, 10, ECV and 7, 8 in high On-resistance mode.

cc ONLS_OFFHS -

t

d OFFH

t

cc ONHS_OFFLS

t

d OFFL

VS= 13.5V,

=5V

V

CC

(4)

(4)

(1)(2)(3))

50 200 400 µs

-

0.1 0.2 0.6 V/µs

Item Symbol Parameter Test condition Min. Typ. Max. Unit

|I

|,

12.1

12.2

12.3

12.4

12.5 |I

12.6

12.7

OC1

|I

|

OC6

|I

|I

|I

|I

|I

|I

OC2

OC3

OC4

OC5

OC9

OC10

OC11

Over-current threshold

|,

|

to supply or GND

|,

|

|,

Over-current threshold

|

to supply

| 6 10 A

Over-current threshold

to supply in low

|I

|I

OC7

OC8

|,

|

on-resistance mode

Over-current threshold

to supply in high

on-resistance mode

V

=13.5V,

S

=5V,

V

CC

sink and source

VS=13.5V,

VCC= 5 V, source

=13.5V, VCC=5V,

V

S

source, control register

1 bits 12 to 15: 0101

=13.5V, VCC=5V,

V

S

source, control register

1 bits 12 to 15: 1010

35A

0.75 1.25 A

610A

0.5 1.0 A

1.5 2.5 A

0.35 0.65 A

12.8 |I

12.9 t

12.10 f

12.11 f

OCECV

FOC

rec0

rec1

|

Output current

limitation to GND

Filter time of

over-current signal

Recovery frequency for OC

recovery duty cycle bit= 0

Recovery frequency for OC

recovery duty cycle bit= 1

16/47 Doc ID 15162 Rev 3

V

=13.5V,

S

VCC= 5 V, source

Duration of over-current

condition to set the

status bit

0.75 1.25 A

10 55 100 µs

1 4 kHz

2 6 kHz

L99DZ70XP Electrical specifications

Table 12. Current monitoring (continued)

Item Symbol Parameter Test condition Min. Typ. Max. Unit

II

I,

12.12

12.13

12.14

12.15

12.16 II

12.17

12.18

12.19

12.20 t

OLD1

II

OLD6

II

OLD2

II

OLD3

II

OLD4

II

OLD5

II

OLD9

II

OLD10

OLD11

II

OLD7

II

OLD8

II

OLDECV

FOL

I

I,

Under-current threshold

I

to supply or GND

I,

I

I,

I

Under-current

=13.5V,

V

S

=5V,

V

CC

sink and source

10 30 80 mA

10 20 30 mA

60 150 300 mA

51015mA

threshold to supply

I30150300mA

Under-current threshold

to supply in low

I,

on-resistance mode

I

Under-current threshold

to supply in high

VS=13.5V,

VCC= 5 V, source

15 40 60 mA

51015mA

on-resistance mode

I

threshold to GND

Under-current

VS=13.5V,

VCC = 5V, sink

10 20 30 mA

Duration of under-

Filter time of under-current

current condition to set

0.5 3 ms

the status bit

Table 13. Electrochrome control

Item Symbol Parameter Test condition Min. Typ. Max. Unit

(3)

-V

(1)

1.4 1.6 V

(1)

1.12 1.28 V

-5%

-1

ECV

LSB

(3)

+5%

+1

LSB

(3)

(2)

mV

13.1

13.2

V

CTRLmax

Maximum EC-control

voltage

bit 0= 1 control reg. 2

bit 0= 0 control reg. 2

13.3 DNL Differential non linearity -1 1 LSB

13.4 IdV

ECV

Voltage deviation

I

between target and

ECV

dV

ECV =Vtarget

II

ECDR

I < 1µA

Toggle

=

ECV

bit 1=1

status

reg. 2

Toggle

bit 0= 1

status

120 mV

-120 mV

is:

Below

it

Above

it

dV

V

target

ECV

- V

13.5 dV

ECVnr

Difference

voltage

between target

and ECV sets

13.6 dV

ECVhi

flag if V

ECV

reg. 3

I

13.7 V

13.8 V

ECDRmin_high

ECDRmax_low

Output voltage range

= -10 µA 4.5 5.5 V

ECDR

I

= 10 µA 0 0.7 V

ECDR

Doc ID 15162 Rev 3 17/47

Electrical specifications L99DZ70XP

Table 13. Electrochrome control (continued)

Item Symbol Parameter Test condition Min. Typ. Max. Unit

13.9

13.10

13.11 R

13.12 I

I

ECDR

ecdrdis

QECDR

Current into ECDR

Pulldown resistance at

ECDR in fast

discharge mode

Quiescent current

V

target >VECV

V

V

target

V

V

V

ECDR

Cntrl Reg 1: bit 8 and bit

1 = 1, all other bits = 0

V

Cntrl. reg 1 bit 1 = 0

ECDR

< V

ECDR

target

V

ECV

ECDR

+ 500mV

= 3.5V

- 500mV,

ECV

= 1.0V;

=1 LSB;

=0.5V

= 0.7V ;

= VS;

,

-100 -10 µA

10 100 µA

5kΩ

1µA

1. Bit 7 to 2 = ‘1’ control register 1: ECV voltage, where II

ECDR

2. 1 LSB (Least Significant Bit)= 23.8 mV.

is set by bit 7 to 2 of control register 1 and bit 0 of control register 2; tested for each individual bit.

V

3.

target

Figure 3. Electrochrome control block diagram

D

A

C

can change sign.

Ω

Ω

2.5 SPI - Electrical characteristics

VS = 8 to 16V, VCC = 4.5 to 5.5V, Tj = - 40 to 150°C, unless otherwise specified. The

voltages are referred to GND and currents are assumed positive, when the current flows into

18/47 Doc ID 15162 Rev 3

the pin.

L99DZ70XP Electrical specifications

Table 14. Delay time from standby to active mode

Item Symbol Parameter Test condition Min. Typ. Max. Unit

Switching from standby to active

14.1 t

Table 15. Inputs: CSN, CLK, PWM1/2 and DI

set

Delay time

Item Symbol Parameter Test condition Min. Typ. Max. Unit

mode. Time until output drivers are

enabled after CSN going to high and

set bit 0=1 of control register 0.

256 300 µs

15.1 V

15.2 V

15.3 V

15.4 R

15.5 R

15.6 R

15.7 R

PWM1 in

15.8 C

inL

inH

in Hyst

CSN in

CLK in

DI in

(1)

in

Input low level VCC = 5V

Input high level VCC = 5V

0.7*

Vcc

Input hysteresis VCC = 5V 500 mV

V

= 5V

CSN pull up resistor

CLK pull down resistor

DI pull down resistor

PWM1 pull down resistor

Input capacitance at input

CSN, CLK, DI and PWM1/2

0V<V

V

V

CLK

V

V

V

V

PWM1

0 V < V

CC

<0.7V

CSN

= 5V

CC

= 1.5V

= 5V

CC

= 1.5V

DI

= 5V

CC

= 1.5V

< 5.3V 10 pF

CC

30 120 250 kΩ

CC

30 60 150 kΩ

30 60 150 kΩ

30 60 150 kΩ

0.3*

Vcc

1. Value of input capacity is not measured in production test. Parameter guaranteed by design.

Table 16. SDI timing

(1)

Item Symbol Parameter Test condition Min. Typ. Max. Unit

16.1 t

Clock period VCC = 5V 1000 ns

CLK

V

V

16.2 t

16.3 t

16.4 t

16.5 t

16.6 t

16.7 t

CLKH

CLKL

set CSN

set CLK

set DI

hold DI

Clock high time VCC = 5V 115 ns

Clock low time VCC = 5V 115 ns

CSN setup time, CSN low

before rising edge of CLK

CLK setup time, CLK high

before rising edge of CSN

= 5V 400 ns

V

CC

= 5V 400 ns

V

CC

DI setup time VCC = 5V 200 ns

DI hold time VCC = 5V 200 ns

Doc ID 15162 Rev 3 19/47

Electrical specifications L99DZ70XP

Table 16. SDI timing (continued)

(1)

Item Symbol Parameter Test condition Min. Typ. Max. Unit

16.8 t

16.9 t

1. DI timing parameters tested in production by a passed / failed test:

Tj= -40°C / +25°C: SPI communication @ 2MHz.

Tj= +125°C SPI communication @ 1.25 MHz.

Table 17. D O

Rise time of input signal DI,

r in

CLK, CSN

Fall time of input signal DI,

f in

CLK, CSN

= 5V 100 ns

V

CC

V

= 5V 100 ns

CC

Item Symbol Parameter Test condition Min. Typ. Max. Unit

17.1 V

17.2 V

17.3 I

17.4 C

1. Value of input capacity is not measured in production test. Parameter guaranteed by design.

DOLK

DO

Output low level I

DOL

Output high level I

DOH

Tristate leakage

current

Tristate input

(1)

capacitance

= -5 mA 0.2V

DO

= 5 mA 0.8 V

DO

V

CSN

0V < V

V

CSN

0V < V

= VCC,

< V

DO

= VCC,

< 5.3V

CC

CC

CC

-10 10 µA

CC

10 pF

V

V

Table 18. DO timing

Item Symbol Parameter Test condition Min. Typ. Max. Unit

18.1 t

18.2 t

18.3 t

18.4 t

18.5 t

18.6 t

18.7 t

r DO

f DO

en DO tri L

dis DO L tri

en DO tri H

dis DO H tri

d DO

DO rise time C

DO fall time C

DO enable time

from tristate to low

level

DO disable time

from low level to

tristate

DO enable time

from tristate to high

level

DO disable time

from high level to

tristate

DO delay time

= 100 pF 80 140 ns

DO

= 100 pF 50 100 ns

DO

= 100 pF, I

C

DO

pull-up load to V

= 100 pF, I

C

DO

pull-up load to V

=100 pF, I

C

DO

pull-down load to GND

= 100 pF, I

C

DO

pull-down load to GND

V

< 0.3 VCC,

DO

V

> 0.7 VCC,

DO

= 100 pF

C

DO

load

CC

load

CC

load

load

= 1mA

= 4 mA

= -1mA

= -4mA

100 250 ns

380 450 ns

100 250 ns

380 450 ns

50 250 ns

20/47 Doc ID 15162 Rev 3

L99DZ70XP Electrical specifications

Table 19. CSN timing

Item Symbol Parameter Test condition Min. Typ. Max. Unit

Mimimum CSN HI time,

19.1 t

CSN_HI,stb

switching from standby

mode

19.2 t

CSN_HI,min

Minimum CSN HI time,

active mode

Figure 4. SPI - Transfer timing diagram

CSN high to low: DO enabled

CSN high to low: DO enabled

CSN high to low: DO enabled

CSN

CSN

CSN

CLK

CLK

CLK

DI

DI

DI

DO

DO

DO

Input

Input

Input

Data

Data

Data

Register

Register

Register

123456 70

123456 70

123456 70

DI: data will be accepted on the rising edge of CLK signal

DI: data will be accepted on the rising edge of CLK signal

DI: data will be accepted on the rising edge of CLK signal

123 45670

123 45670

123 45670

DO: data will change on the falling edge of CLK signal

DO: data will change on the falling edge of CLK signal

DO: data will change on the falling edge of CLK signal

123 45670

123 45670

123 45670

CSN low to high: actual data is

CSN low to high: actual data is

fault bit

fault bit

fault bit

CSN low to high: actual data is

transfered to output power switches

transfered to output power switches

transfered to output power switches

Transfer of SPI-command

to input register

Transfer of SPI-command

to input register

X

X

X

X

XX

XX

XX

XX

old data new data

old data new data

old data new data

232221201918

232221201918

232221201918

232221201918

232221201918

232221201918

20 50 µs

24µs

01

01

01

time

time

time

01

01

01

time

time

time

0 1

0 1

0 1

time

time

time

time

time

time

time

time

time

Figure 5. SPI - Input timing

CSN

t

set C SN

t

CLKH

t

se t CLK

CLK

set DI

Valid

t

hold DI

t

DI

t

CLKL

Va lid

Doc ID 15162 Rev 3 21/47

0.8 VCC

0.2 VCC

0.8 VCC

0.2 VCC

0.8 VCC

0.2 VCC

Electrical specifications L99DZ70XP

t

f

f

t

t

Figure 6. SPI - DO valid data delay time and valid time

t

in

CLK

t

r DO

DO

(low to high)

t

d DO

t

DO

DO

(high to low)

Figure 7. SPI - DO enable and disable time

f in r in

CSN

r i n

0.8 VCC

0.5 VCC

0.2 VCC

0.8 VCC

0.2 VCC

0.8 VCC

0.2 VCC

0.8 VCC

50%

0.2 VCC

DO

50%

pull-up load to VCC

C = 100 pF

L

DO

t t

en DO tri L

dis DO L tri

50%

pull-down load to GND

C = 100 pF

L

t t

22/47 Doc ID 15162 Rev 3

L99DZ70XP Electrical specifications

C

S

t

r

f

OFF

t

OFF

t

t

FFstat

t

O

p

t

e

r

t

e

r

f

rom shif

t

r

r

r

Figure 8. SPI - driver turn on/off timing, minimum CSN HI time

CSN low to high: data

ansf e

is

ed to output powerswitches

tregister

N

ut curren

out

output voltage

of a driv

of a driver

output curren

output voltage

of a driv

of a driver

t

in

d

eO

ON st a

dON

t

N

OFF state

t

CSN_HI,min

ON sta

e

e

t

in

80%

50%

20%

80%

50%

20%

80%

50%

20%

Doc ID 15162 Rev 3 23/47

Application information L99DZ70XP

3 Application information

3.1 Dual power supply: VS and V

CC

The power supply voltage VS supplies the half bridges and the highside drivers. An internal

charge-pump is used to drive the highside switches. The logic supply voltage V

for the logic part and the SPI of the device.

Due to the independent logic supply voltage the control and status information will not be

lost, if there are temporary spikes or glitches on the power supply voltage.

3.2 Wake up and active mode / standby mode

After power up of VS and Vcc the device operates in standby-mode. Pulling the signal CSN

to low level wakes the device up and the analog part will be activated (active mode).

After at least 10µs, the first SPI communication is valid and bit 0 of the Control Register 0

can be used to set the EN-mode. If bit 0 is not set to 1, the device doesn't remain in the

active mode. After at least 256µs all latched data will be cleared and the inputs and outputs

are switched to high impedance. In standby mode the current at V

(5 µA) for CSN = high (DO in tristate).

3.3 Charge pump

In standby mode the chargepump is turned off. After enabling the device by SPI command

(bit0=1 Control Register 0) the oscillator starts and the voltage begins to increase. The

output drivers are enabled after at least 256 µs after CSN went to high.

is used

CC

(VCC) is less than 6 µA

S

3.4 Diagnostic functions

All diagnostic functions (over/under-current, power supply over-/undervoltage, temperature

warning and thermal shutdown) are internally filtered. The condition has to be valid for at

least 32 µs (open load: 1ms) before the corresponding status bit in the status registers is

set.

The filters are used to improve the noise immunity of the device. The under-current and

temperature warning functions are intended for information purpose and will not change the

state of the output drivers. On contrary, the over-current condition disables the

corresponding driver and thermal shutdown disables all drivers. Without setting the overcurrent recovery bits in the input data register, the microcontroller has to clear the overcurrent status bits to reactivate the corresponding drivers.

24/47 Doc ID 15162 Rev 3

L99DZ70XP Application information

3.5 Overvoltage and undervoltage detection at V

If the power supply voltage VS rises above the overvoltage threshold V

21 V), the outputs OUT1 to OUT11, ECDR and ECV are switched to high impedance state

to protect the load. When the voltage VS drops below the undervoltage threshold V

(UV-switch-OFF voltage), the output stages are switched to high impedance to avoid the

operation of the power devices without sufficient gate driving voltage (increased power

dissipation). If the supply voltage V

recovers (control register 3: bit 4=0) to normal

S

operating voltage then the outputs stages return to the programmed state. If the

undervoltage/overvoltage recovery disable bit is set (control register 3: bit 4=1), the

automatic turn-on of the drivers is deactivated.

The microcontroller needs to clear the status bits to reactivate the drivers. It is

recommended to set bit1 control register 3 to avoid a possible high current oscillation in

case of a shorted output to GND and low battery voltage.

3.6 Overvoltage and undervoltage detection at V

In case of power-on (VCC increases from undervoltage to V

initialized by an internally generated power-on-reset (POR). If the voltage VCC decreases

below the minimum threshold (V

POR ON

= 2.0 V), the outputs are switched to tristate (high

impedance) and the status registers are cleared.

POR OFF

S

SOV OFF

(typical

SUV OFF

CC

= 2.9 V) the circuit is

3.7 Temperature warning and thermal shutdown

If the junction temperature rises above T

32 µs and it can be read via the SPI. If the junction temperature increases above the second

threshold T

, the thermal shutdown bit is set and the power DMOS transistors of all output

jSD

stages are switched off to protect the device after at least 32 µs.

The temperature warning and thermal shutdown flags are latched and the bits must be

cleared by the microcontroller. This is possible only if the temperature has decreased below

trigger temperature. If the thermal shutdown bit has been cleared the output stages are

reactivated.

, a temperature warning flag is set after at least

j TW

3.8 Inductive loads

Each half bridge is built by internally connected highside and lowside power DMOS

transistors. Due to the built-in reverse diodes of the output transistors, inductive loads can

be driven at the outputs OUT1 to OUT6 without external free-wheeling diodes. The highside

drivers OUT7 to OUT11 are intended to drive resistive loads. Therefore only a limited energy

(E<1mJ) can be dissipated by the internal ESD-diodes in freewheeling condition. For

inductive loads (L>100µH) an external free-wheeling diode connected between GND and

the corresponding output is required.

The low side driver at ECV does not have a freewheel diode built into the device.

Doc ID 15162 Rev 3 25/47

Application information L99DZ70XP

3.9 Open load detection

The open load detection monitors the load current in each activated output stage. If the load

current is below the open load detection threshold for at least 1 ms (t

) the corresponding

dOL

open load bit is set in the status register. Due to mechanical/electrical inertia of typical loads

a short activation of the outputs (e.g. 3 ms) can be used to test the open load status without

changing the mechanical/electrical state of the loads.

3.10 Over-load detection

In case of an over-current condition a flag is set in the status register in the same way as

during open load detection. If the over-current signal is valid for at least t

(typ) = 55 µs, the

ISC

over-current flag is set and the corresponding driver is switched off to reduce the power

dissipation and to protect the integrated circuit. If the over-current recovery bit of the output

is zero, the microcontroller has to clear the status bits to reactivate the corresponding driver.

3.11 Current monitor

The current monitor output sources a current image at the current monitor output which has

two fixed ratios of the instantaneous current of the selected highside driver. Outputs with a

resistance of 500 mΩ and higher have a ratio of 1/2000 and those with a lower resistance of

1/10000. The signal at output CM is blanked after switching on the driver until correct

settlement of the circuitry (at least for 64 µs). The bits 0 to 3 of the control register 3 define

which of the outputs are multiplexed to the current monitor output CM/PWM2. The current

monitor output allows a more precise analysis of the actual state of the load rather than the

detection of an open- or overload condition. For example it can be used to detect the motor

state (starting, free-running, stalled). Moreover, it is possible to control the power of the

defroster more precisely by measuring the load current. The current monitor output is

bidirectional (PWM inputs).

3.12 PWM inputs

Each driver has a corresponding PWM enable bit, which can be programmed by the SPI

interface. If the PWM enable bit is set in control registers 2 or 3, the output is controlled by

the logically AND-combination of the PWM signal and the output control bit in Control

Registers 0 and 1. The outputs OUT1-4, 6, 7, 9, OUT11 are controlled by the PWM1 input

and the outputs OUT5, 8 and OUT10 are controlled by the bidirectional input CM/PMW2.

For example, the two PWM inputs can be used to dim two lamps independently by external

PWM signals. In case of switching off a high/low side switch in PWM mode a minimum off

time of appr. (256 µs – td

the high/low side again during the negative slope. For a PWM frequency of 100Hz this

means the maximum duty cycle is about 98%. Larger duty cycles can be realized by

applying pulse skipping.

26/47 Doc ID 15162 Rev 3

on

+ td

) is predefined by the state machine, to avoid switching on

off

L99DZ70XP Application information

3.13 Cross-current protection

The six half-brides of the device are cross-current protected by an internal delay time. If one

driver (LS or HS) is turned off, the activation of the other driver of the same half bridge will

be automatically delayed by the cross-current protection time. After the cross-current

protection time is expired the slew-rate limited switch-off phase of the driver is changed to a

fast turn-off phase and the opposite driver is turned-on with slew-rate limitation. Due to this

behaviour it is always guaranteed that the previously activated driver is completely turned off

before the opposite driver starts to conduct.

3.14 Programmable soft-start function to drive loads with higher inrush current

Loads with start-up currents higher than the over-current limits (e.g. inrush current of lamps,

start current of motors and cold resistance of heaters) can be driven by using the

programmable softstart function (i.e. overcurrent recovery mode). Each driver has a

corresponding over-current recovery bit. If this bit is set, the device automatically switches

the outputs on again after a programmable recovery time. The duty cycle in over-current

condition can be programmed by the SPI interface to about 12% or 25%. The PWM

modulated current will provide sufficient average current to power up the load (e.g. heat up

the bulb) until the load reaches operating condition. The PWM frequency settles at 1.7kHz

and 3kHz. The device itself cannot distinguish between a real overload and a non linear load

like a light bulb. A real overload condition can only be qualified by time. For over-load

detection the microcontroller can switch on the light bulbs by setting the over-current

recovery bit for the first e.g. 50ms. After clearing the recovery bit the output will be

automatically switched off, if the overload condition remains. This over-load detection

procedure has to be followed in order make it possible to switch on the low-side driver of a

bridge output, if the associated high-side driver has been used in recovery mode before.

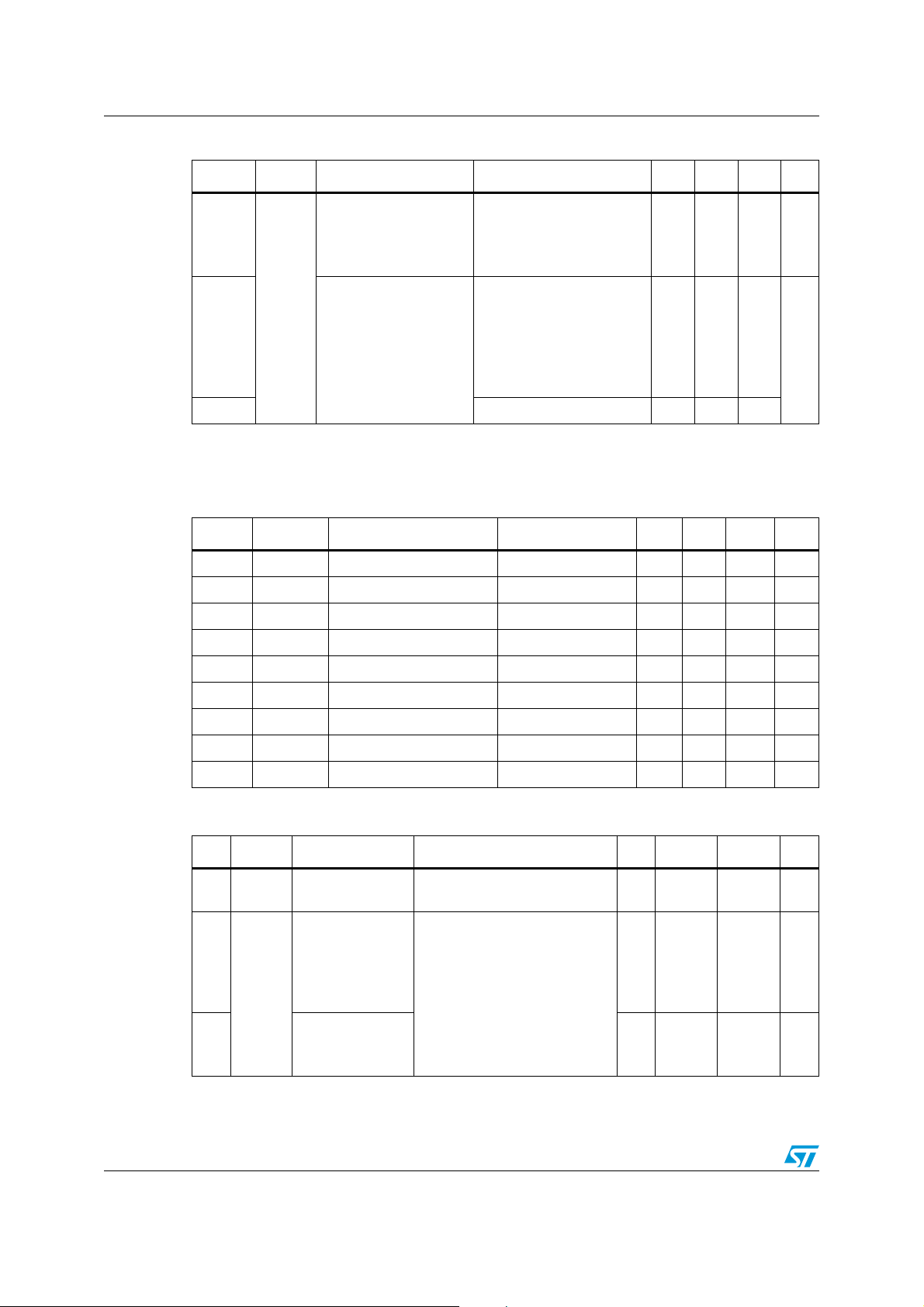

Figure 9. Example of programmable soft-start function for inductive loads

Doc ID 15162 Rev 3 27/47

Application information L99DZ70XP

3.15 Controller for electrochromic glass

The voltage of an electrochromic element connected at pin ECV can be controlled to a

target value, which is set by the bits 7 down to 2 of control register 1. Setting bit 1 of control

register 1 enables this function. An on-chip differential amplifier and an external MOS

source follower, with its gate connected to pin ECDR and which drives the electrochrome

mirror voltage at pin ECV, form the control loop. The drain of the external MOS transistor is

supplied by OUT10. A diode from pin ECV (anode) to pin ECDR (cathode) has been placed

on the chip to protect the external MOS source follower. A capacitor of at least 5 nF has to

be added to pin ECDR for loop-stability.

The target voltage is binary coded with a full scale range of 1.5V. If Bit 0 of control register 2

is set to '1', the maximum controller output voltage is clamped to 1.2V without changing the

resolution of bits 7-2 of control register 1. When setting the target voltage to 0V and

programming the ECVLS driver to on-state, the voltage at pin ECV is pulled to ground by a

1.6 Ohm low-side switch (fast discharge).

The status of the voltage control loop is reported via SPI. Bit 0 in the status register 2 is set,

if the voltage at pin ECV is higher, whereas Bit 1 in the same status register is set, if the

voltage at pin ECV is lower than the target value. Both status bits are valid, if they are stable

for at least 150 µs.

Since OUT10 is the output of a high-side driver, it contains the same diagnose functions as

the other high-side drivers (e.g. During an over current detection, the control loop is

switched off). In electrochrome mode OUT10 cannot be controlled by PWM mode. For EMS

reasons the loop capacitor at pin ECDR as well as the capacitor between ECV and GND

have to be placed to the respective pins as close as possible.

28/47 Doc ID 15162 Rev 3

L99DZ70XP Functional description of the SPI

4 Functional description of the SPI

4.1 General description

Standard ST-SPI Interface Version 3.0.

The SPI communication is based on a Serial Peripheral Interface interface structure using

CSN (Chip Select Not), DI (Serial Data In), DO (Serial Data Out/Error) and CLK (Serial

Clock) signal lines.

4.1.1 Chip Select Not (CSN)

The input pin is used to select the serial interface of this device. When CSN is high, the

output pin (DO) is in high impedance state. A low signal wakes up the device and a serial

communication can be started. The state when CSN is going low until the rising edge of

CSN will be called a communication frame.

4.1.2 Serial Data In (DI)

The input pin is used to transfer data serially into the device. The data applied to the DI will

be sampled at the rising edge of the CLK signal.

4.1.3 Serial Clock (CLK)

This input signal provides the timing of the serial interface. The Data Input (DI) is latched at

the rising edge of Serial Clock CLK . The SPI can be driven by a micro controller with its SPI

peripheral running in following mode: CPOL = 0 and CPHA = 0. Data on Serial Data Out

(DO) is shifted out at the falling edge of the serial clock (CLK). The serial clock CLK must be

active only during a frame (CSN low). Any other switching of CLK close to any CSN edge

could generate set up/hold violations in the SPI logic of the device.

The clock monitor counts the number of clock pulses during a communication frame (while

CSN is low). If the number of CLK pulses does not correspond to the frame width indicated

in the <SPI-frame-ID> (ROM address 03H) the frame is ignored and the <frame error> bit in

the <Global Status Byte> is set.

Note: Due to this safety functionality, daisy chaining the SPI is not possible. Instead, a parallel

operation of the SPI bus by controlling the CSN signal of the connected ICs is

recommended.

4.1.4 Serial Data Out (DO)

The data output driver is activated by a logical low level at the CSN input and will go from

high impedance to a low or high level depending on the global status bit 7 (Global Error

Flag). The first rising edge of the CLK input after a high to low transition of the CSN pin will

transfer the content of the selected status register into the data out shift register. Each

subsequent falling edge of the CLK will shift the next bit out.

Doc ID 15162 Rev 3 29/47

Functional description of the SPI L99DZ70XP

4.1.5 SPI communication flow

At the beginning of each communication the master can read the contents of the <SPIframe-ID> register (ROM address 03H) of the slave device. This 8-bit register indicates the

SPI frame length (24 bit) and the availability of additional features.

Each communication frame consists of a command byte which is followed by 2 data bytes.

The data returned on DO within the same frame always starts with the <Global Status>

Byte. It provides general status information about the device. It is followed by 2 data bytes (i.

e. ‘In-frame-response’).

For Write cycles the <Global Status> Byte is followed by the previous content of the

addressed register.

Figure 10. Write and read SPI

30/47 Doc ID 15162 Rev 3

L99DZ70XP Functional description of the SPI

Table 20. SPI frame

Bit 23 22 212919181716 151413121110 9 8

Name OC1 OC0 A5 A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0

Command Byte Data Byte Data Byte

76543210

Ocx: Operation code

Ax: Address

Dx: Data Bit

4.2 Command byte

Each communication frame starts with a command byte. It consists of an operating code

which specifies the type of operation (<Read>, <Write>, <Read and Clear>, <Read Device

Information>) and a 6 bit address. If less than 6 address bits are required, the remaining bits

are unused but are reserved.

4.2.1 Operation code definition

Table 21. Operation code definition

OC1 OC0 Meaning

0 0 <Write Mode>

0 1 <Read Mode>

1 0 <Read and Clear Mode>

1 1 <Read Device Information>

The <Write Mode> and <Read Mode> operations allow access to the RAM of the device.

A <Read and Clear Mode> operation is used to read a status register and subsequently

clear its content.

The <Read Device Information> allows access to the ROM area which contains device

related information such as <ID-Header>, <Product Code>, <Silicon Version and Category>

and <SPI-frame-ID>.

Doc ID 15162 Rev 3 31/47

Functional description of the SPI L99DZ70XP

4.3 Global status byte

Table 22. Global status byte

Bit 7 6 5 4 3 2 1 0

Name GL_ER CO_ER C_RESET TSD TW UOV_OC OL NR

Reset 0 0 1 0 0 0 0 0

Description:

● GL_ER : Global Error Flag. Failures of Bits 0-6 are always linked to the Global Error

Flag. This flag is generated by an OR combination of all failure events of the device. It

is reflected via the DO pin while CSN is held low and no clock signal is available. The

flag will remain as long as CSN is low. This operation does not cause the

Communication Error bit in the <Global Status> to be set. The signal TW bit3 and OL

bit1can be masked.

● CO_ER : Communication Error. If the number of clock pulses within the previous frame

is not 24 the frame is ignored and this bit is set.

● C_RESET : Chip RESET. If a stuck at ‘1’ on input DI during any SPI frame occurs, or if

a Power On Reset (VCC monitor) occurs. C_RESET will be reset (‘1’) with any SPI

command. When STK_RESET_Q is active (‘0’), the Gate drivers are switched off

(resistive path to source).

After a startup of the circuit the STK_RESET_Q is active because of the POR pulse

and the Gate drivers are switched off. The Gate drivers can only be activated after the

STK_RESET_Q has been reset with a SPI command.

● TSD : Thermal shutdown due to an internal sensor. All the gate drivers and the charge

pump must be switched off (resistive path to source). The TSD bit has to be cleared

through a software reset to reactivate the gate drivers and the charge pump.

● TW : Thermal Warning. This bit is maskable by configuration register.

● UOV_OC : Logical OR among the filtered under-/over-voltage signals and over-current

signals.

● OL : Open Load. Logical OR among the filtered under-current signals. This bit is

maskable by configuration register.

● NR : Not Ready. After switching the device from standby mode to active mode an

internal timer is started to allow chargepump to settle before the outputs can be

activated. This bit is cleared automatically after start up time has finished.

32/47 Doc ID 15162 Rev 3

L99DZ70XP Functional description of the SPI

Figure 11. Global error flag definition

4.4 Address mapping

Table 23. RAM memory map

Address Name Access Content

00h Control register 0 Read/write Enable of device and bridge control

01h Control register 1 Read/write

02h Control register 2 Read/write

03h Control register 3 Read/write

High/low-side control and Electrocrome block set

up

Bridge recovery mode and PWM set up and

Electrocrome block set up

Highside recovery mode and PWM set up and

current monitor selection

10h Status register 0 Read only Bridge over-current diagnosis

11h Status register 1 Read only Bridge open load (under-current) diagnosis

12h Status register 2 Read only

3Fh

Table 24. ROM memory map

Configuration

register

Read/write

Open load (under-current) diagnosis, VS and

electrocrome diagnosis

Mask of bits in global status register and for global

error bit

Address Name Access Content

00h ID header Read only 4300h (ASSP ST_SPI)

01h Version Read only 0300h

02h Product code 1 Read only 4300h (67 ST_SPI)

03h Product code 2 Read only 4800h (H ST_SPI)

3Eh SPI-frame ID Read only 0200h SPI-Frame-ID register (ST_SPI)

Doc ID 15162 Rev 3 33/47

SPI - control and status registers L99DZ70XP

5 SPI - control and status registers

5.1 Control register 0

Table 25. Control register 0 (read/write)

Bit Name Comment

9

8

7

6

5

4

OUT1 – HS

on/off

OUT1 – LS

on/off

OUT2 – HS

on/off

OUT2 – LS

on/off

OUT3 – HS

on/off

OUT3 – LS

on/off

OUT4 – HS

on/off

OUT4 – LS

on/off

OUT5 – HS

on/off

OUT5 – LS

on/off

OUT6 – HS

on/off

OUT6 – LS

on/off

15

14

13

12

11

10

30

If a bit is set the selected output driver is switched on. If the corresponding

PWM enable bit is set the driver is only activated if PWM1 (PWM2) input

signal is high. The outputs of OUT1-OUT6 are half bridges. If the bits of

HS- and LS-driver of the same half bridge are set, the internal logic

prevents that both drivers of this output stage can be switched on

simultaneously in order to avoid a high internal current from Vs to GND.

Reserved (has to be set to '0')20

10

0 Enable bit

If enable bit is set the device will be switched in active mode. If enable bit is

cleared, the device enters standby mode and all bits are cleared.

34/47 Doc ID 15162 Rev 3

L99DZ70XP SPI - control and status registers

5.2 Control register 1

Table 26. Control register 1 (read/write)

Bit Name Comment

OUT7 – HS1

15

14

13

12

11

10

9

on/off

OUT7 – HS2

on/off

OUT8 – HS1

on/off

OUT8 – HS2

on/off

OUT9 – HS

on/off

OUT10 – HS

on/off

OUT11 – HS

on/off

8 ECV – LS on/off

7EC bit 5

6EC bit 4

5EC bit 3

4EC bit 2

3EC bit 1

2EC bit 0

OUT

7/8

HS1 HS2 Mode

11 Off

1 0 Low on-resistance

0 1 High on-resistance

00 Off

If a bit is set, the selected output driver is switched on. If the corresponding

PWM enable bit is set the driver is only activated if PWM1 (PWM2) input

signal is high. The outputs of OUT1-OUT6 are half bridges. If the bits of HSand LS-driver of the same half bridge are set, the internal logic prevents that

both drivers of this output stage can be switched on simultaneously in order to

avoid a high internal current from VS to GND.

Reference value for difference voltage amplifier at pin ECV is binary coded.

Full scale value is set in control register 2. If all EC bits are set to zero the

reference value is 0V. For fast discharge a lowside switch can be activated at

pin ECV, if the ECV – LS on/off bit is set to '1'..

In case this bit is set to 1, the electrochrome control is active and enables the

driver at pin ECDR for the external MOS transistor. The bit switches the

1 EC switch

highside OUT10 directly on, ignoring bit 10 in control register 1. If the drain of

the external MOS transistor is connected to OUT10, the current from supply

VS to the load at ECV can be monitored.

0 0 Reserved (has to be set to '0')

Doc ID 15162 Rev 3 35/47

SPI - control and status registers L99DZ70XP

5.3 Control register 2

Table 27. Control register 2 (read/write)

Bit Name Comment

15

14

13

12

11

10

9

OUT1 – OCR

enable

OUT2 – OCR

enable

OUT3 – OCR

enable

OUT4 – OCR

enable

OUT5 – OCR

enable

OUT6 – OCR

enable

ECV – OCR

enable

In case of an over-current event the over-current status bit (Status

Register 0) is set and the output is switched off. If the Over-current

Recovery Enable bit (OCR) is set, the output will be automatically

reactivated after a delay time resulting in a PWM modulated current with

a programmable duty cycle (bit 5 of control register 3).

Depending on occurrence of over-current event and internal clock phase

it is possible that one recovery cycle is executed even if this bit is set to

zero. The ECV-OCR enable bit is disabled in electrochrome mode

(bit1=1 control register 1).

8 0 Reserved (has to be set to '0')

7

6

5

4

3

2

OUT1 PWM1

enable

OUT2 PWM1

enable

OUT3 PWM1

enable

OUT4 PWM1

enable

OUT5 PWM2

enable

OUT6 PWM1

enable

If the PWM1/2 Enable bit is set and the output is enabled (control

register 0 or 1) the output is switched on if PWM1/2 input is high and

switched off if PWM1/2 input is low. OUT5, 8 and OUT10 are controlled

by PWM2 input, all other outputs are controlled by PWM1 input.

1

ECV PWM1

enable

The maximum ECV voltage in electrochrome mode is 1.5V. It

corresponds to the full scale range of the digital to analog converter DAC

0ECV-low voltage

set by the bits 7 to 2 of control register 1. If the ECV_low voltage bit is

set to '0', the maximum voltage is limited to 1.2V without changing the

resolution of the DAC. This is the default mode.

36/47 Doc ID 15162 Rev 3

L99DZ70XP SPI - control and status registers

5.4 Control register 3

Table 28. Control register 3 (read/write)

Bit Name Comment

15 OUT7-OCR enable In case of an over-current event the over-current status bit (Status

14 OUT8-OCR enable

13 OUT9-OCR enable

12 OUT10-OCR enable

11 OUT11-OCR enable

10 OUT7 PWM1 enable

9 OUT8 PWM2 enable

8 OUT9 PWM1 enable

7 OUT10 PWM2 enable

6 OUT11 PWM1 enable

register 1) is set and the output is switched off. If the Over-current