®

HALF BRIDGE OUTPUTS WITH TYPICAL

R

= 0.7

ON

Ω

OUTPUT CURRENT CAPAB ILITY ±1.2A

OPERATING SUPPLY VOLTAGE RANGE 7V

TO 16.5V

SUPPLY OVERVOLTAGE PROTECTION

FUNCTION FOR V

UP TO 40V

VS

VERY LOW QUIESCENT CURRENT IN

STANDBY MODE < 1µA

CMOS COMPATIBLE INPUTS WITH HYSTERESIS

OUTPUT SHORT-CIRCUIT PROTECTION

THERMAL SHUTDOWN

REAL TIME DIAG NOSTIC: THERMAL OVER-

LOAD, OVERVOLTAGE

L9997ND

DUAL HALF BRIDGE DRIVER

MULTIPOWER BCD TECHNOLOGY

SO20 (12+4+4)

ORDERING NUMBERS:

L9997ND013TR

L9997ND

DESCRIPTION

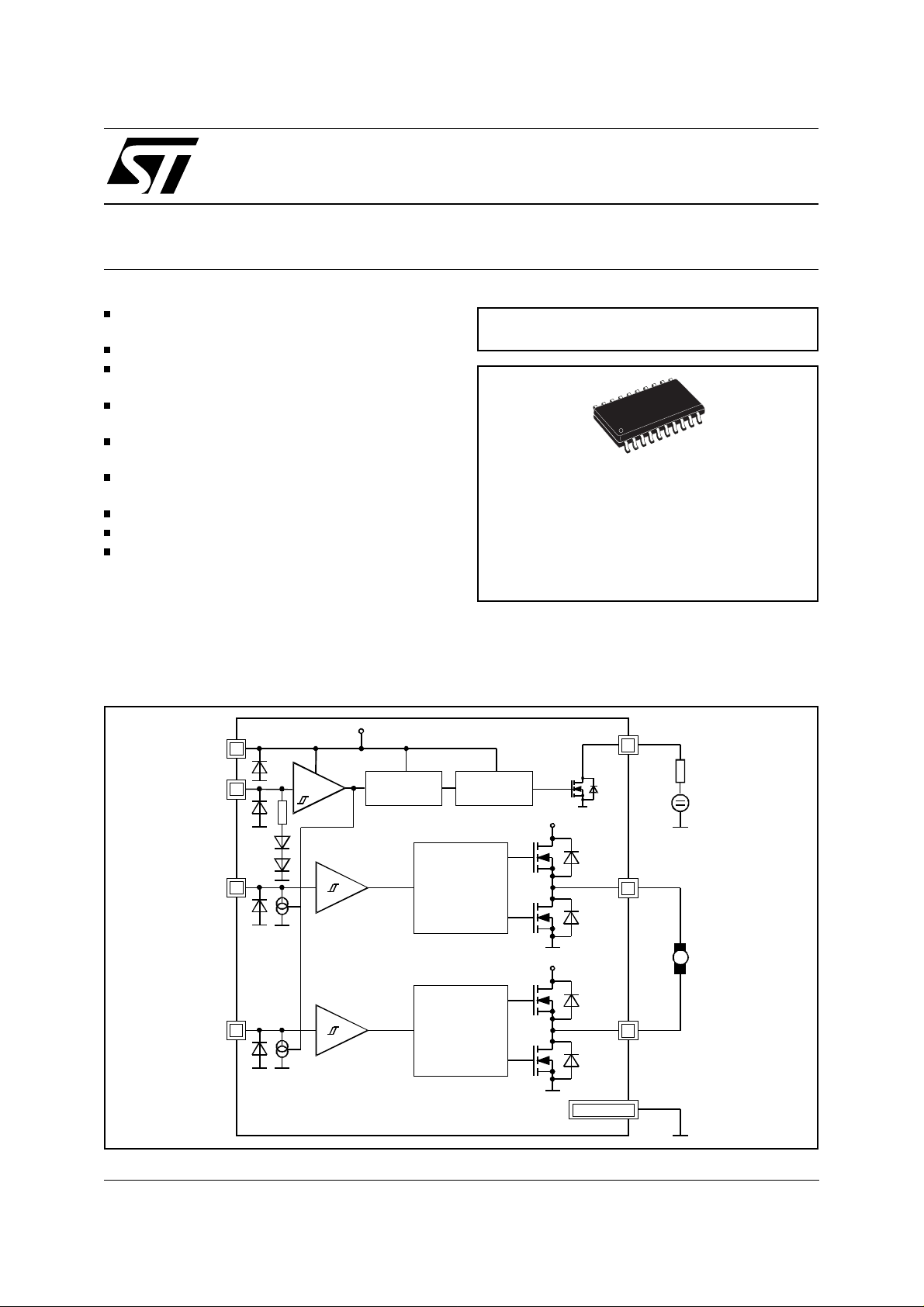

The L9997ND is a monolithic integrated driver, in

BCD technology intended to drive various loads,

BLOCK DIAGRAM

VS VS

1

EN

IN1

IN2

10

12

9

ENABLE

REFERENCE

BIAS

including DC motors. The circuit is optimized for

automotive electronics enviromental conditions.

DIAG

11

PROTECTION

FUNCTIONS

DRIVER 1

DRIVER 2

VS

OUT1

19

VS

OUT2

2

5V

M

April 1999

GND

4...7, 14...17

1/9

L9997ND

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

V

V

V

I

VSDC

VSP

I

OUT

IN1,2

V

EN

DIAG

I

OUT

DIAG

DC Supply Voltage -0.3 to 26 V

Supply Voltage Pulse (T < 400ms) 40 V

DC Output Current

1.8 A

±

DC Input Voltage -0.3 to 7 V

Enable Input Voltage -0.3 to 7 V

DC Output Voltage -0.3 to 7 V

DC Output Short-circuit Current -0.3V < V

< VS + 0.3V internally limited

OUT

DC Sink Current -0.3V < VDG < 7V internally limited

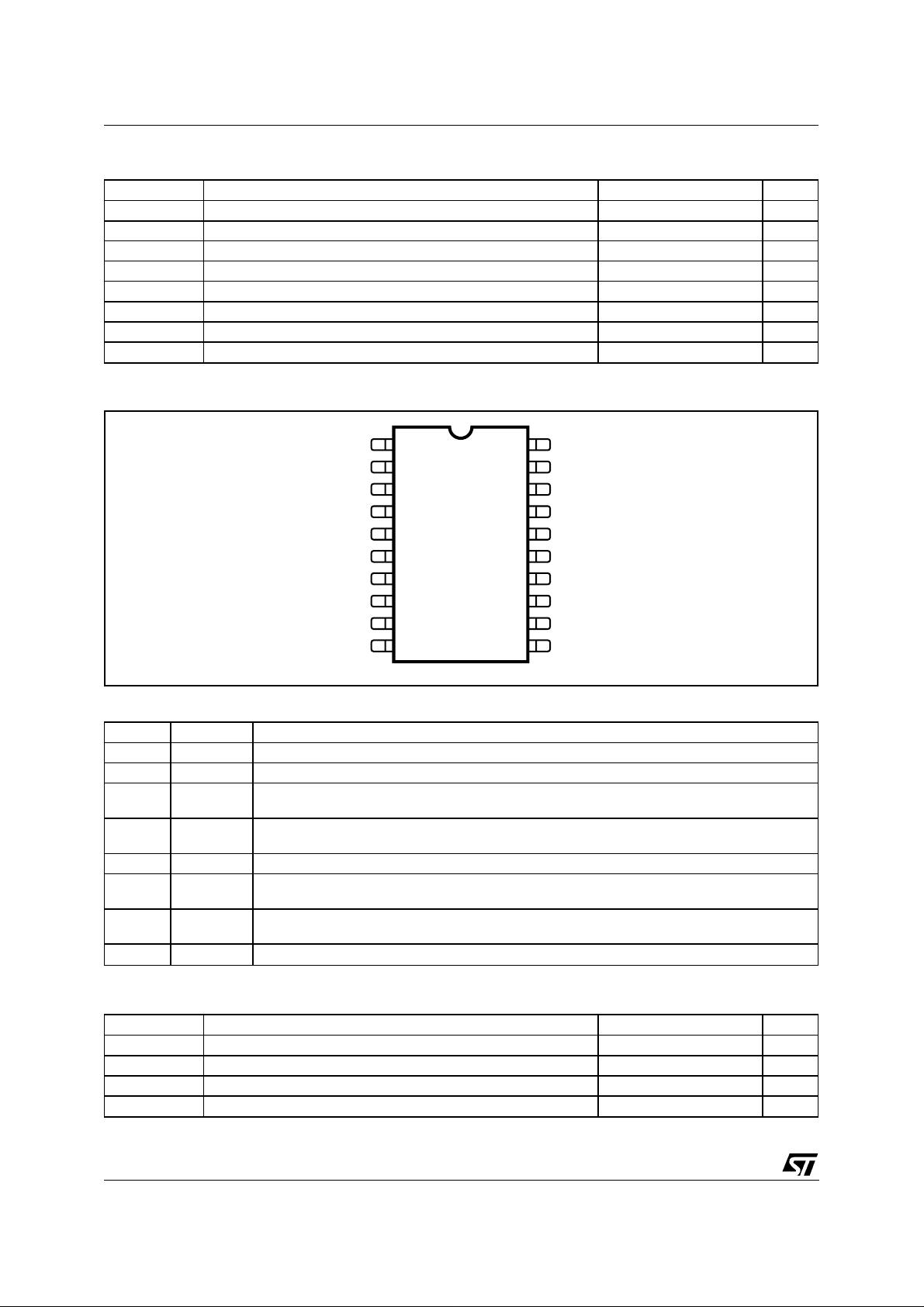

PIN CONNECTION

(Top view)

V

S

OUT2

N.C.

GND

GND

GND

GND

N.C.

IN2 IN1

EN DIAG

2

3

4

5

6

7

8

9

10

D95AT166

20

19

18

17

16

15

14

13

12

11

N.C.1

OUT1

N.C.

GND

GND

GND

GND

N.C.

PIN FUNCTIONS

N. Name Function

1 VS Supply Voltage

2 OUT2 Channel 2: Push-Pull power output with intrinsic body diode

3, 8, 13,

18,20

4 to 7,

14 to 17

9 IN2 Input 2: Schmitt Trigger input with hysteresis (non-inverting signal control)

10 EN Enable: LOW or not connected on this input switches the device into standby mode and the

11 DIAG Diagnostic: Open Drain Output that switches LOW if overvoltage or overtemperature is

12 IN1 Input 1: Schmitt Trigger input with hysteresis (non-inverting signal control)

NC NC: Not Connected

GND Ground: signal - and power - ground, heat sink

outputs into tristate

detected

THERMAL DATA

Symbol Parameter Value Unit

T

jTS

T

jTSH

R

th j-amb

R

th j-pins

(1) With 6cm2 on board heatsink area.

2/9

Thermal Shut-down Junction Temperature 165 °C

Thermal Shut-down Threshold Hysteresis 25 K

Thermal Resistance Junction-Ambient

(1)

50 K/W

Thermal Resistance Junction-Pins 15 K/W

L9997ND

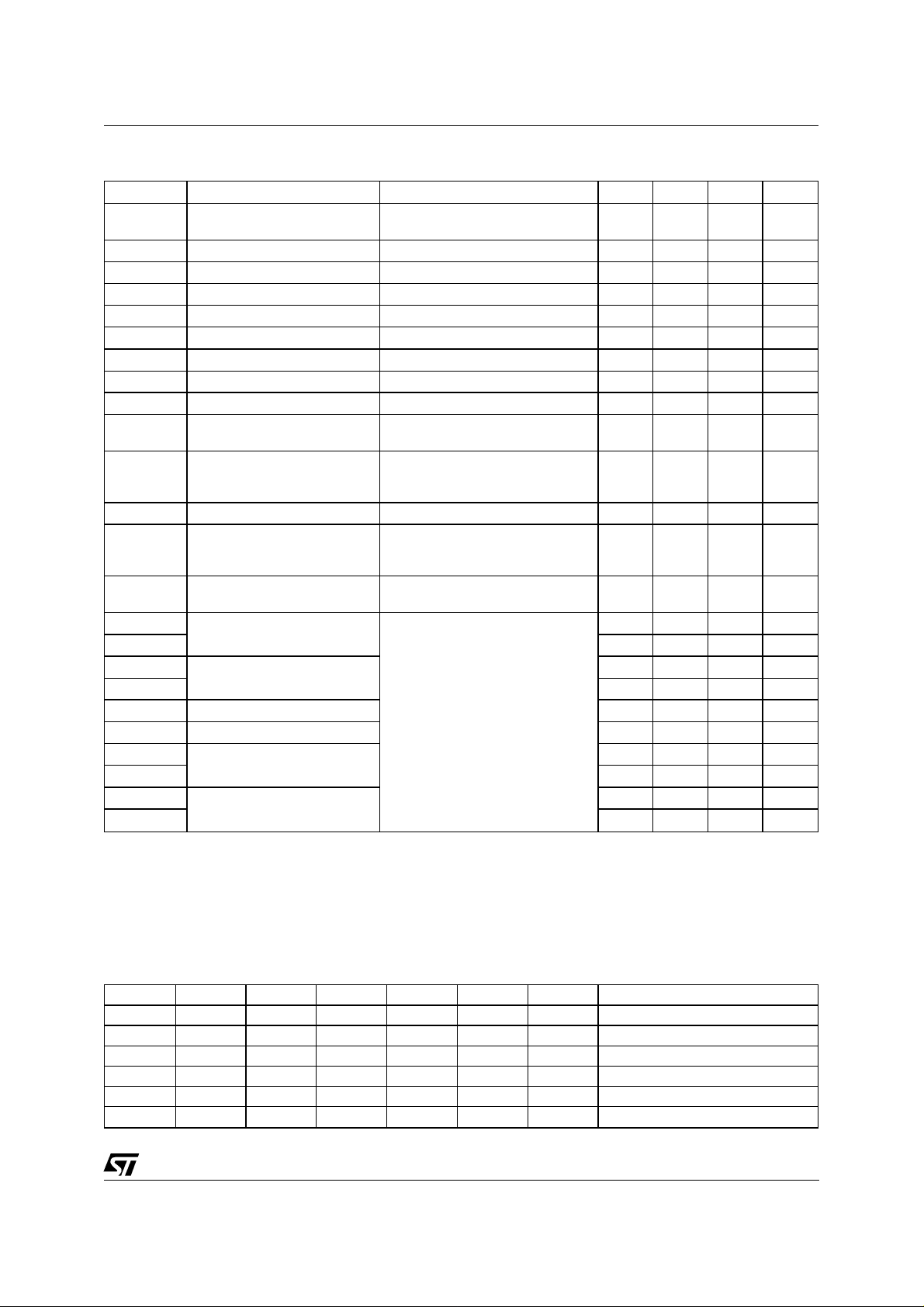

ELECTRICAL CHARACTERISTICS

(7V < V

< 16.5V; -40°C < TJ < 150°C; unless otherwise specified.)

S

Symbol Parameter Test Condition Min. Typ. Max. Unit

I

VS_SB

I

VS

V

ENL

V

ENH

V

ENthh

I

EN

V

IN1,2L

V

IN1,2H

V

IN1,2thh

I

IN1,2

R

ON OUT1,2

|I

OUT1,2

V

DIAG

Quiescent Current in Standby

Mode

Supply Current EN = HIGH, I

Low Enable Voltage 1.5 V

High Enable Voltage 3.5 6 V

Enable Threshold Hysteresis 1 V

Enable Input Current VEN = 5V 85 250

Low Input Voltage 1.5 V

High Input Voltage 3.5 V

Input Threshold Hysteresis 1 V

Input Bias Current VIN = 0

ON-Resistance to Supply or

GND

| Output Current Limitation 1.2 1.6 2.2 A

Diagnostic Output Drop I

VEN < 0.3V; VVS <16.5V; Tj < 85°(*)

V

= 0; VVS = 14.5V; T

EN

OUT1,2

V

= 5V, EN = HIGH

IN

I

= ±0.8A; VVS = 7V; Tj = 125°C

OUT

I

= ±0.8A; VVS = 12V; Tj = 125°C

OUT

I

= ±0.8A; VVS = 12V; Tj = 25°C

OUT

= 0.5mA, EN = HIGH

DIAG

= 25°C

j

= 0 2 6 mA

<1

<1

-3

2

0

10

1.2

1.1

90

10

1

50

2.8

2.25

0.7

0.6 V

Overvoltage or Thermal Shutdown

V

VSOVth

Supply Overvoltage

17 19 21 V

Threshold

t

ONLH

t

ONHL

t

OFFHL

t

OFFLH

t

dHL

t

dLH

t

rHS

t

rLS

t

fHS

t

fLS

* Tested at 125°C and guaranteed by correlation

Turn on Delay Time See Fig. 2; VVS = 13.5V

Measured with 93Ω load

50 150

30 150

Turn off Delay Time 10 100

220

Rising Delay Time 115 250

Falling Delay Time 115 250

Rise Time 30 100

60 150

Fall Time 25 100

50 150

A

µ

A

µ

A

µ

A

µ

A

µ

Ω

Ω

Ω

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

FUNCTIONAL DESCRIPTION

The L9997ND is a motor driver two half-bridge

outputs, intended for driving dc motors in automotive systems. The basic function of the device is

shown in the Table 1.

Table 1. Table function.

Status EN IN1 IN2 OUT1 OUT2 DIAG NOTE

1 L X X Tristate Tristate OFF Standby Mode

2 H H H SRC SRC OFF Recommended for braking

3 H H L SRC SNK OFF

4HLHSNKSRCOFF

5 H L L SNK SNK OFF

6 H X X Tristate Tristate ON Overvoltage or Overtemperature

3/9

L9997ND

The device is activated with enable input voltage

HIGH. For enable input floating (not connected)

or LOW the device is in Standby Mode. Very low

quiescent current is defined for V

< 0.3V. When

EN

activating or disactivating the device by the enable input a wake-up time of 50µs is recommended.

For braking of the motor the status 2 is recommended. The reason for this recommendation is

that the device features higher threshold for initialisation of parasitic structures than in state 5.

The inputs IN1, IN2 features internal s ink current

generators of 10µA, disabled in standby mode.

With these input current generators the input level

is forced to LOW for inputs open. In this condition

the outputs are in SNK state.

The circuit features an over voltage disable function referred to the supply voltage V

. This func-

VS

tion assures disabling the power outputs, when

the supply voltage exceeds the over voltage

threshold value of 19V typ. Both outputs are

forced to tristate in this condition and the diagnostic output is ON.

The thermal shut-down disables the outputs (tristate) and activates the diagnostic when the junction temperature increases above the thermal

shut-down threshold temperature of min. 150°C.

For the start of a heavy loaded motor, if t he m otor

current reaches the max. value, it is necessary to

respect the dynamical thermal resistance junction

to ambient. The outputs OUT1 and OUT2 are protected against short circuit to GND or V

, for sup-

S

ply voltages up to the overvoltage disable threshold.

The output power DMOS transistors works in linear mode for an output current less than 1.2A. Increasing the output load current ( > 1.2A) the out-

put transistor changes in the current regulation

mode, see Fig.6, with the typical output current

value below 2A. The SRC output power DMOS

transistors requires a voltage drop ~3V to activate

the current regulation. Below this voltage drop is

the device also protected. The output current heat

up the power DMOS transistor, the R

DSON

increases with the junction temperature and decreases the output current. The power dissipation

in this condition can activate the thermal shutdown . In the case of output disable due to thermal overload the output remains disabled untill

the junction temperature decreases under the

thermal enable threshold.

Permanent short circuit condition with power dissipation leading to chip overheating and activation

of the thermal shut- down leads to t he thermal oscillation. The junction temperature difference between the switch ON and OFF points is the thermal hysteresis of the thermal protection. This

hysteresis together with the thermal impedance

and ambient temperature determines the frequency of this thermal oscillation, its typical values are in the range of 10kHz.

The open drain diagnostic output needs an external pull-up resistor to a 5V supply. In systems

with several L9997ND the diagnostic outputs can

be connected together with a common pull-up resistor. The DIAG output current is internally limited.

Fig. 1 shows a typical application diagram for the

DC motor driving. To assure the safety of the circuit in the reverse battery condition a reverse protection diode D

is necessary. The transient pro-

1

tection diode D2 must assure that the maximal

supply voltage V

line will be limited to a value lower than the

V

BAT

during the transients at the

VS

absolute maximum rating for VVS.

Figure 1:

5V

4/9

Application Circuit Diagram.

CONTROL

LOGIC

Ω

47K

IDIAG1

IIN1

IIN2

IEN

DIAG1

IN1

IN2

EN

S

V

L9997ND

GND

I

s

S

C

OUT1

IOUT1

OUT2

IOUT2

1

D

V

BAT

2

D

IM

VM

M

GND

Figure 2. Timing Diagram.

L9997ND

Standby Mode Operating Mode Overtemperature

EN

IN1

IN2

DIAG

OUT1

OUT2

Tristate

Tristate

t

10%

dLH

90%

t

r

t

dHL

t

t

ONHL

t

ONLH

90%

50%

10%

t

rf

t

dHL

t

f

t

dLH

or Overvoltage

t

dLH

Tristate

t

dHL

Tristate

t

t

dHL

dLH

Standby Mode

t

OFFLH

Tristate

t

OFFHL

Tristate

Figure 3. Typical RON - Characteristics of Source and Sink Stage

5/9

L9997ND

Figure 4. Quiescent current in standby mode versus supply voltage.

Figure 5. ON-Resistance versus supply voltage.

6/9

L9997ND

Figure 6. I

versus V

OUT

(pulsed measurement with TON = 500µs, T

OUT

= 500ms).

OFF

Figure 7. Test circuit.

12V

V

EN

V

IN1

100µF

V

IN2

200nF

EN

IN1

IN2

VS

L9997ND

GND

DIAG

OUT1

OUT2

10k

15

15

Ω

Ω

Ω

5V

7/9

L9997ND

8/9

L9997ND

Information furnishe d is beli eved to be accu rate and reliable. However, STMicroelec tronics assumes no res ponsibility for the consequences

of use of such i nformation nor for any i nfringement of patents or ot her rights of third par ties which may result from its use. No license i s

granted by impli cation or otherwis e under any patent or patent righ ts of STMicroelect ronics. Specifica tion mentioned in this publication are

subject to change without notic e. This public ation supers edes and replaces all information prev iously supplied. STMic roelec tronic s products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelect roni cs

© 1999 STMicroelectronics – Printed in Italy – All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - France - Germany - Italy - Japan - Korea - Malaysia - Malta - Mexico - Morocco - The Netherlands -

Singapore - Spain - Sweden - Switzerland - Taiwan - Thailand - United Kingdom - U.S.A.

http://www.st.com

9/9

Loading...

Loading...