ST L9954LXP User Manual

L9954LXP

Door actuator driver

Features

■ Three half bridges for 0.75 A loads

(R

■ Two configurable high-side driver for up to 1.5A

load (R

(R

■ One high-side driver for 6 A load

(R

■ Programmable soft start function to drive loads

with higher inrush currents (i.e. current > 6 A,

current > 1.5 A)

■ Very low current consumption in standby mode

(I

■ All outputs short circuit protected

■ Current monitor output for high-side OUT1,

OUT4, OUT5 and OUT6

■ All outputs over temperature protected

■ Open-load diagnostic for all outputs

■ Overload diagnostic for all outputs

■ PWM control of all outputs

■ Charge pump output for reverse polarity

protection

=1600mΩ)

DSon

=500mΩ) or 0.35 A load

DSon

=1800mΩ)

on

=100mΩ)

DSon

< 6 µA typ; Tj ≤ 85 °C)

S

PowerSSO-36

Applications

■ Door actuator driver with bridges for mirror axis

control and high-side driver for mirror defroster

and two 10 W light bulbs and/or LEDs.

Description

The L9954LXP is a microcontroller driven

multifunctional door actuator driver for automotive

applications. Up to two DC motors and three

grounded resistive loads can be driven with three

half bridges and three high-side drivers. The

integrated standard Serial Peripheral Interface

(SPI) controls all operation modes (forward,

reverse, brake and high impedance). All

diagnostic information is available via SPI.

Table 1. Device summary

Package

PowerSSO-36 L9954LXP L9954LXPTR

May 2010 Doc ID 16186 Rev 2 1/35

Order codes

Tube Tape and reel

www.st.com

1

Contents L9954LXP

Contents

1 Block diagram and pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 ESD protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 SPI - electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1 Dual power supply: VS and VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2 Standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3 Inductive loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.4 Diagnostic functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5 Overvoltage and under voltage detection . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.6 Charge pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7 Temperature warning and thermal shutdown . . . . . . . . . . . . . . . . . . . . . . 21

3.8 Open-load detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.9 Overload detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.10 Current monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.11 PWM inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.12 Cross-current protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.13 Programmable soft start function to drive loads with higher inrush current

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Functional description of the SPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.1 Serial Peripheral Interface (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.2 Chip Select Not (CSN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3 Serial Data In (DI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.4 Serial Data Out (DO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.5 Serial Clock (CLK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.6 Input Data Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2/35 Doc ID 16186 Rev 2

L9954LXP Contents

4.7 Status register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.8 SPI - input data and status registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5 Packages thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6 Package and packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.1 ECOPACK® packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 PowerSSO-36 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.3 PowerSSO-36 packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Doc ID 16186 Rev 2 3/35

List of tables L9954LXP

List of tables

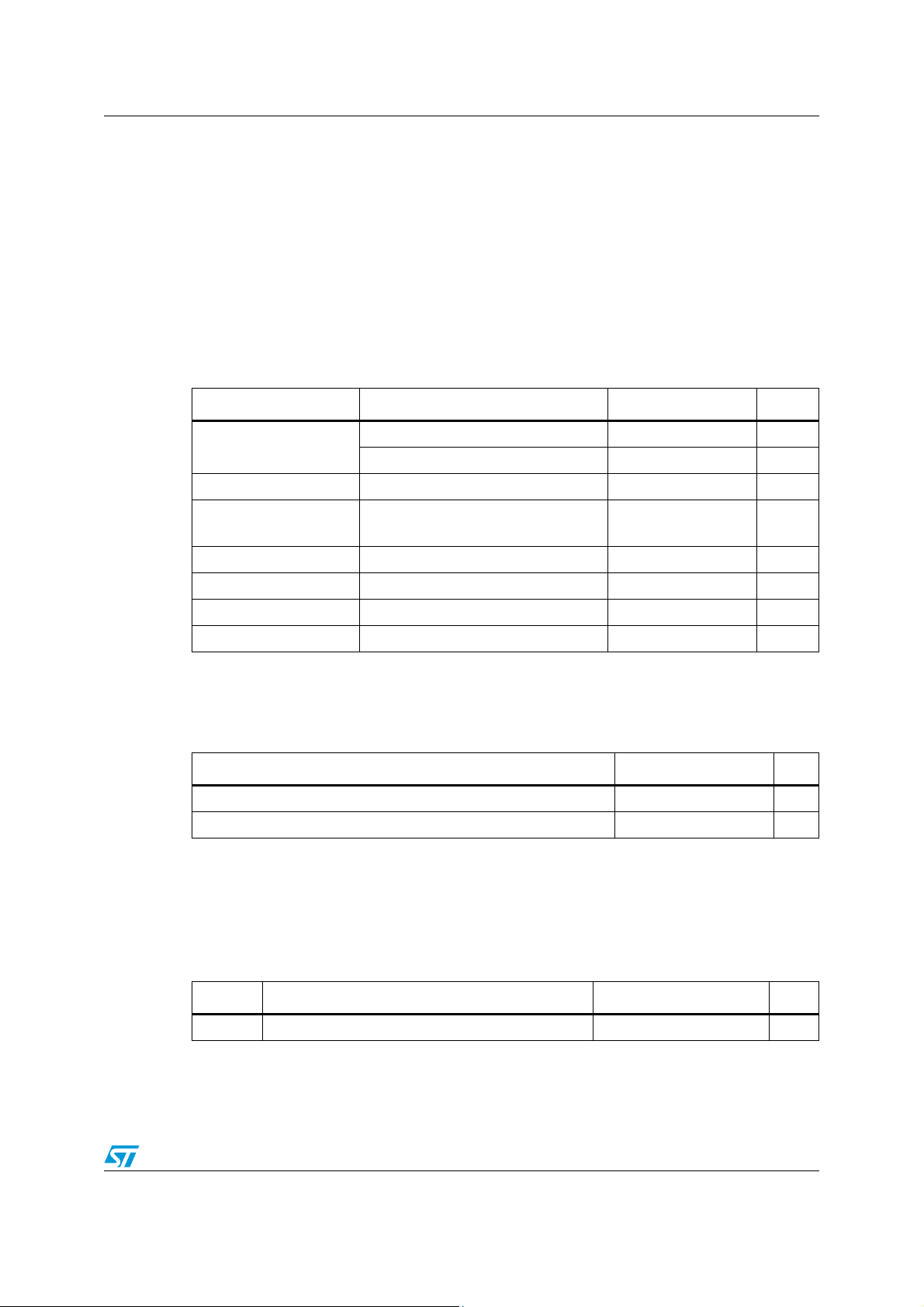

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Pin definitions and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 4. ESD protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 5. Operating junction temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 6. Temperature warning and thermal shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 7. Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 8. Overvoltage and under voltage detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 9. Current monitor output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 10. Charge pump output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 11. OUT1 - OUT6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 12. Delay time from standby to active mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 13. Inputs: CSN, CLK, PWM1/2 and DI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 14. DI timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 15. DO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Table 16. DO timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 17. CSN timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 18. SPI - input data and status registers 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Table 19. SPI - input data and status registers 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 20. PowerSSO-36 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 21. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4/35 Doc ID 16186 Rev 2

L9954LXP List of figures

List of figures

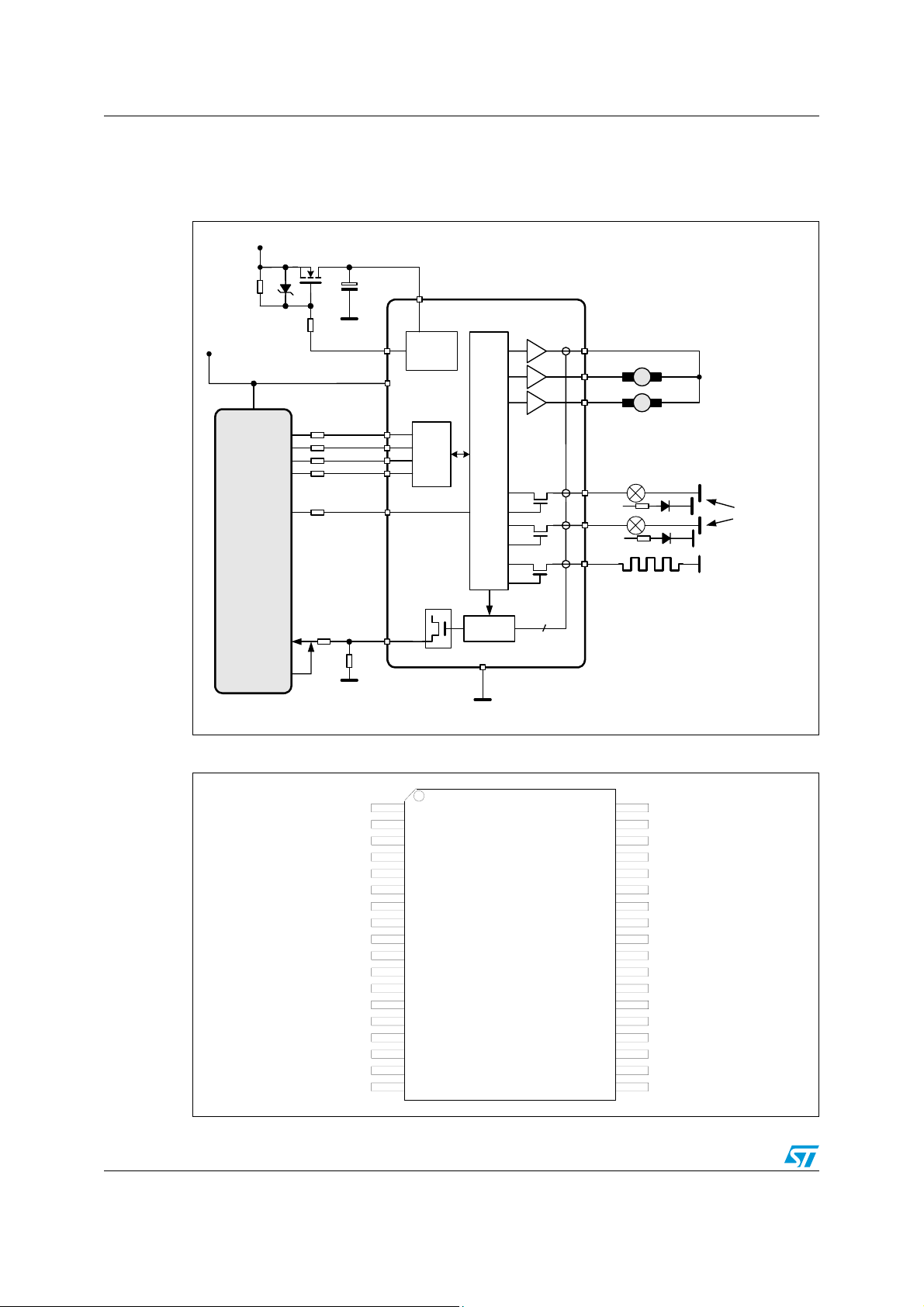

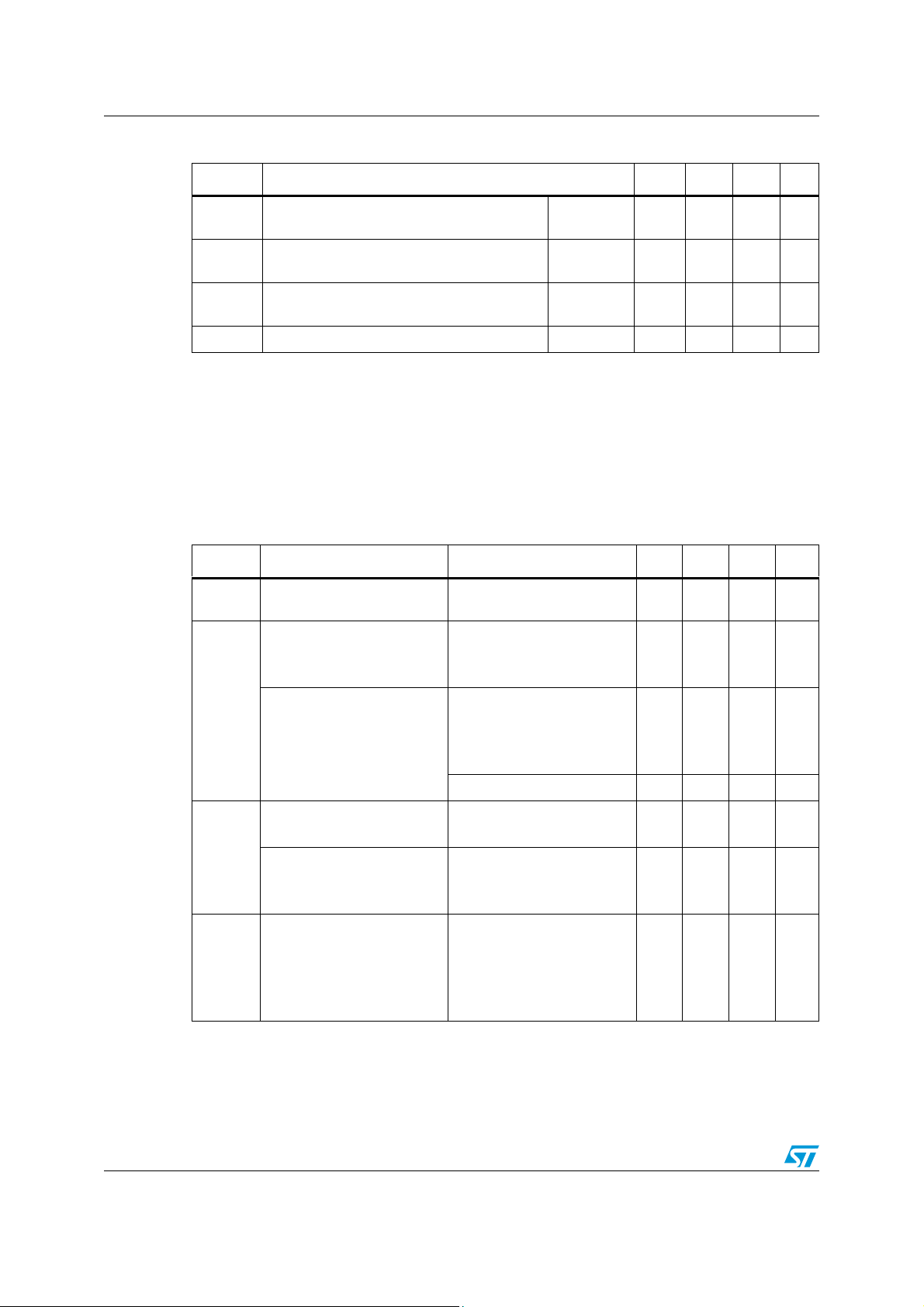

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 2. Configuration diagram (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. SPI - transfer timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 4. SPI - input timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 5. SPI - DO valid data delay time and valid time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 6. SPI - DO enable and disable time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 7. SPI - driver turn-on / off timing, minimum CSN HI time . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 8. SPI - timing of status bit 0 (fault condition) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 9. Programmable soft start function for inductive loads and incandescent bulbs . . . . . . . . . . 23

Figure 10. Packages thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 11. PowerSSO-36 package dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 12. PowerSSO-36

Figure 13. PowerSSO-36

tube shipment (no suffix). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

tape and reel shipment (suffix “TR”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Doc ID 16186 Rev 2 5/35

Block diagram and pin description L9954LXP

1 Block diagram and pin description

Figure 1. Block diagram

V

BAT

Reverse Polarity

Protection

100k

*

100µF

* Note: Value of capacitor has to be choosen carefully to li mit the VS voltage below absolute

maximum ratings in case of an unexpected freewheeling condition ( e.g. TSD, POR)

VS

10k

VCC

Charge

Pump

VCC

**

1k

**

1k

**

1k

**

1k

**

1k

DO

CLK

CSN

PWM1

DI

SPI

Interface

Driver Interface & Diagnostic

µC

PWM2 / CM

**

1k

** Note: Resistors between µC and L9954LXP are recommended to lim it currents

for negative voltage transients at VBAT (e.g. ISO type 1 pulse)

MUX

GND

Figure 2. Configuration diagram (top view)

1

GND

2

OUT6

3

OUT1

4

OUT2

5

OUT3

6

Vs

7

Vs

8

DI

CM / PWM2

CSN

DO

Vcc

CLK

Vs

NC

NC

NC

GND

9

10

11

12

13

14

15

16

17

18

PowerSSO-36

OUT1

OUT2

OUT3

M

M

Mirror Common

Mirror Vertical

Mirror Horizontal

Lock / Folder

OUT4

Programmable

OUT5

OUT6

4

Bulb (10W) or

LED Mode

Defroster

GND 36

OUT6

35

NC 34

33

OUT5

32

Vs

OUT4

31

NC

30

NC

29

28

Vs

PWM1

27

CP

26

Vs

25

24

NC

NC

23

NC

22

NC

21

20

NC

19

GND

6/35 Doc ID 16186 Rev 2

L9954LXP Block diagram and pin description

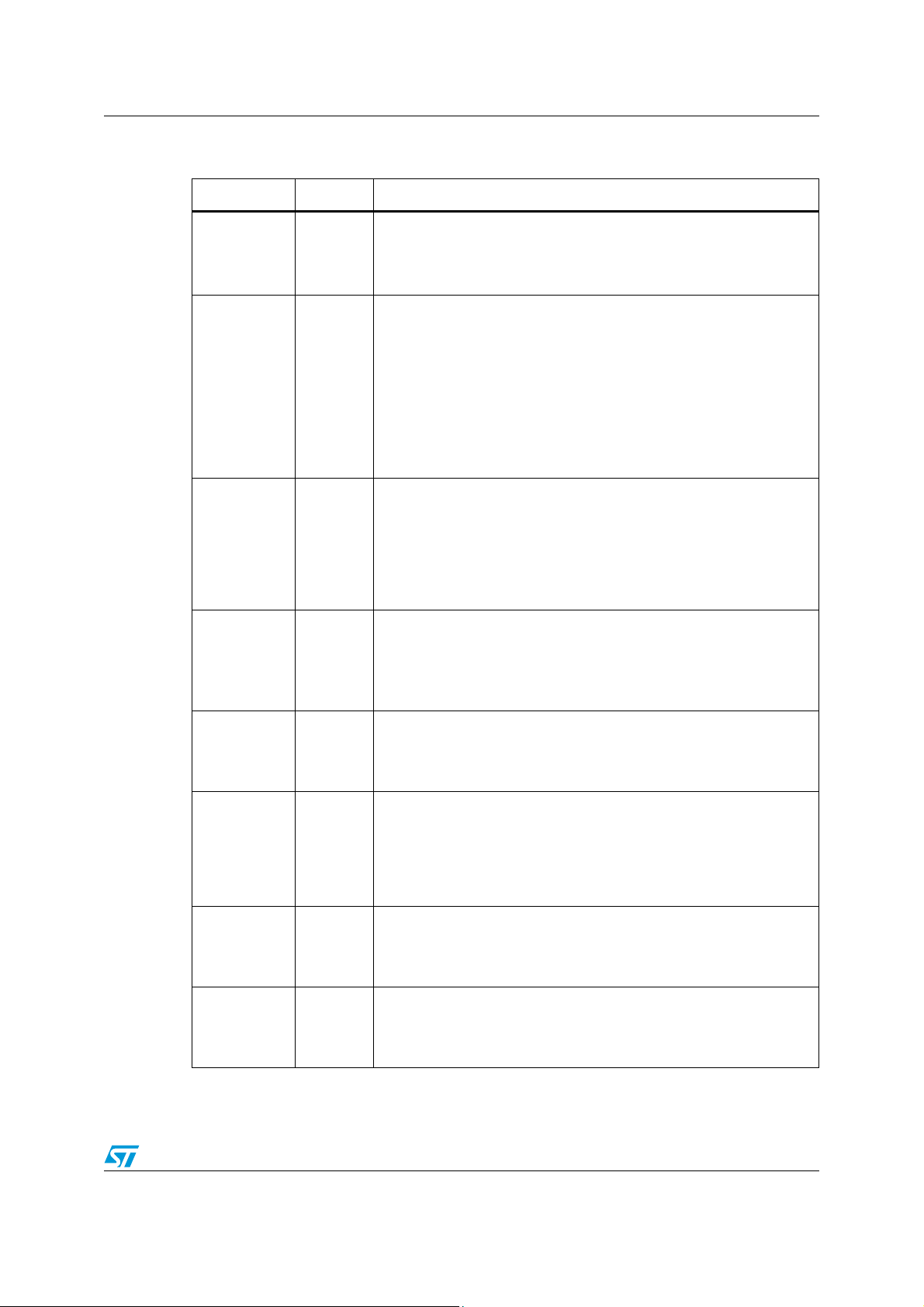

Table 2. Pin definitions and functions

Pin Symbol Function

Ground:

1, 18, 19, 36 GND

2, 35 OUT6

3

4

5

6, 7, 14, 25,

28, 32

OUT1

OUT2

OUT3

V

8DI

9 CM/PWM2

10 CSN

11 DO

reference potential.

Important: for the capability of driving the full current at the outputs all

pins of GND must be externally connected.

High-side driver output 6

The output is built by a high-side switch and is intended for resistive

loads, hence the internal reverse diode from GND to the output is

missing. For ESD reason a diode to GND is present but the energy

which can be dissipated is limited. The high-side driver is a power

DMOS transistor with an internal parasitic reverse diode from the

output to V

(bulk-drain-diode). The output is over-current and open-

S

load protected.

Important: for the capability of driving the full current at the outputs both

pins of OUT6 must be externally connected.

Half-bridge output 1,2,3

The output is built by a high-side and a low-side switch, which are

internally connected. The output stage of both switches is a power

DMOS transistor. Each driver has an internal parasitic reverse diode

(bulk-drain-diode: high-side driver from output to V

, switchs driver

S

from GND to output). This output is over-current and open-load

protected.

Power supply voltage (external reverse protection required)

For this input a ceramic capacitor as close as possible to GND is

recommended.

S

Important: for the capability of driving the full current at the outputs all

pins of V

must be externally connected.

S

Serial data input

The input requires CMOS logic levels and receives serial data from the

microcontroller. The data is an 24bit control word and the least

significant bit (LSB, bit 0) is transferred first.

Current monitor output/PWM2 input

Depending on the selected multiplexer bits of input data register this

output sources an image of the instant current through the

corresponding high-side driver with a ratio of 1/10.000. This pin is

bidirectional. The microcontroller can overdrive the current monitor

signal to provide a second PWM input for the output OUT5.

Chip select not input

This input is low active and requires CMOS logic levels. The serial data

transfer between L9954LXP and micro controller is enabled by pulling

the input CSN to low-level.

Serial data output

The diagnosis data is available via the SPI and this 3-state output. The

output remains in 3-state, if the chip is not selected by the input CSN

(CSN = high)

Doc ID 16186 Rev 2 7/35

Block diagram and pin description L9954LXP

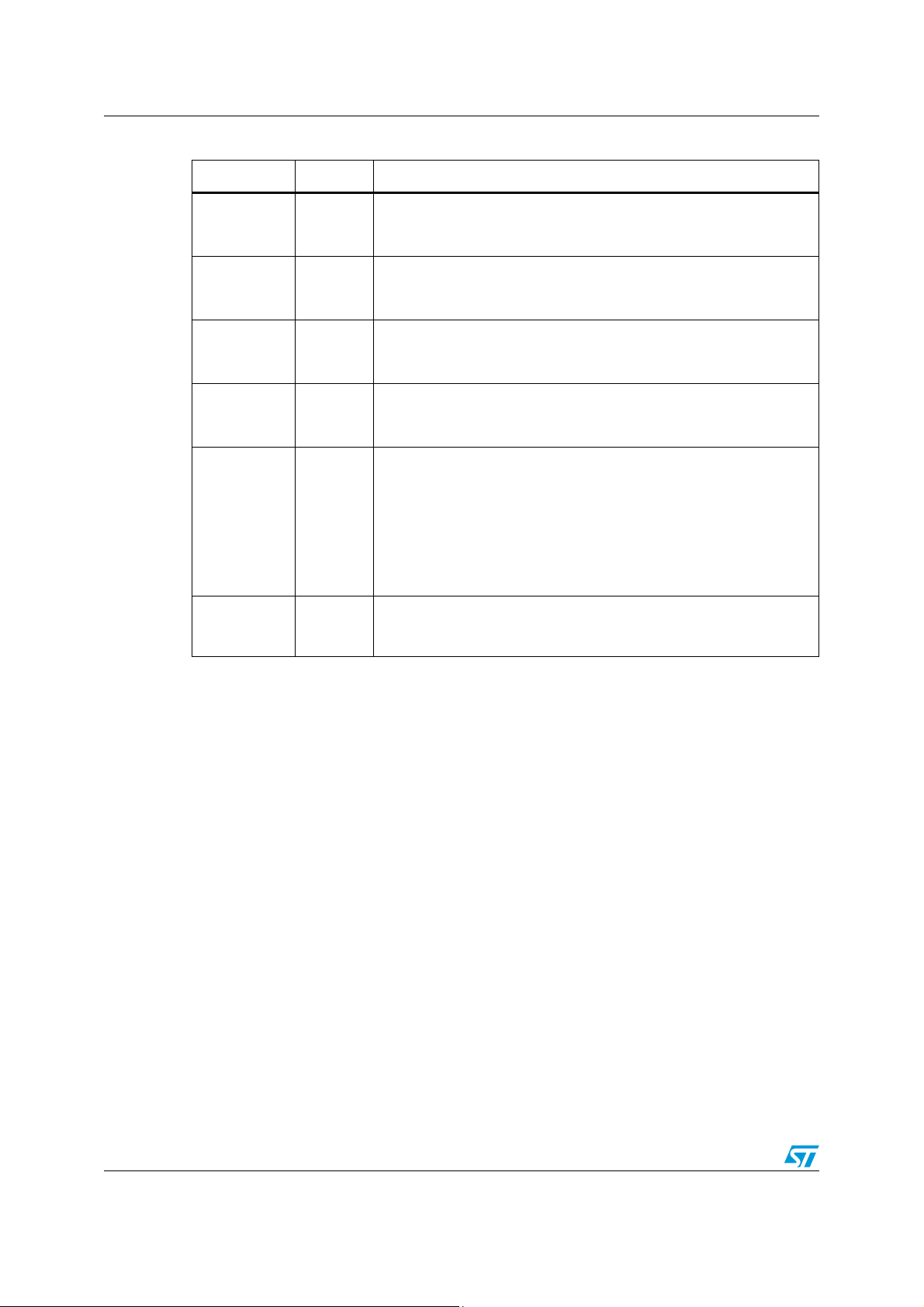

Table 2. Pin definitions and functions (continued)

Pin Symbol Function

Logic supply voltage

12 V

13 CLK

26 CP

27 PWM1

31

33

15, 16, 17, 20,

21, 22, 23, 24,

29, 30, 34

CC

OUT4,

OUT5

NC Not connected pins.

For this input a ceramic capacitor as close as possible to GND is

recommended.

Serial clock input

This input controls the internal shift register of the SPI and requires

CMOS logic levels.

Charge pump output

This output is provided to drive the gate of an external n-channel power

MOS used for reverse polarity protection.

PWM1 input

This input signal can be used to control the drivers OUT1-OUT4 and

OUT6 by an external PWM signal.

High-side driver output 4 and 5

Each output is built by a high-side switch and is intended for resistive

loads, hence the internal reverse diode from GND to the output is

missing. For ESD reason a diode to GND is present but the energy

which can be dissipated is limited. Each high-side driver is a power

DMOS transistor with an internal parasitic reverse diode from each

output to V

(bulk-drain-diode). Each output is over-current and open-

S

load protected.

8/35 Doc ID 16186 Rev 2

L9954LXP Electrical specifications

2 Electrical specifications

2.1 Absolute maximum ratings

Stressing the device above the rating listed in the “Absolute maximum ratings” table may

cause permanent damage to the device. These are stress ratings only and operation of the

device at these or any other conditions above those indicated in the Operating sections of

this specification is not implied. Exposure to Absolute Maximum Rating conditions for

extended periods may affect device reliability. Refer also to the STMicroelectronics SURE

Program and other relevant quality document

Table 3. Absolute maximum ratings

Symbol Parameter Value Unit

V

S

V

CC

V

, V

DI

DO, VCLK

V

CSN, Vpwm1

V

CM

V

CP

I

OUT1,2,3,4,5

I

OUT6

,

2.2 ESD protection

Table 4. ESD protection

All pins ± 2

Output pins: OUT1 - OUT6 ± 8

1. HBM according to MIL 883C, Method 3015.7 or EIA/JESD22-A114-A.

2. HBM with all unzapped pins grounded.

DC supply voltage -0.3 to 28 V

Single pulse t

< 400 ms 40 V

max

Stabilized supply voltage, logic supply -0.3 to 5.5 V

Digital input / output voltage -0.3 to V

+ 0.3 V

CC

Current monitor output -0.3 to VCC + 0.3 V

Charge pump output -25 to VS + 11 V

Output current ±5 A

Output current ±10 A

Parameter Value Unit

(1)

(2)

kV

kV

2.3 Thermal data

Table 5. Operating junction temperature

Symbol Parameter Value Unit

T

Operating junction temperature -40 to 150 °C

j

Doc ID 16186 Rev 2 9/35

Electrical specifications L9954LXP

Table 6. Temperature warning and thermal shutdown

Symbol Parameter Min. Typ. Max. Unit

T

T

T

T

jTW On

jSD On

jSD Off

jSD HYS

Temperature warning threshold junction

temperature

Thermal shutdown threshold junction

temperature

Thermal shutdown threshold junction

temperature

Thermal shutdown hysteresis 5 °K

2.4 Electrical characteristics

Values specified in this section are for VS = 8 to 16 V, VCC = 4.5 to 5.3 V, Tj = - 40 to 150 °C,

unless otherwise specified. The voltages are referred to GND and currents are assumed

positive, when the current flows into the pin.

Table 7. Su p ply

Symbol Parameter Test condition Min. Typ. Max. Unit

V

I

Operating supply voltage

S

range

VS DC supply current

I

S

quiescent supply current

V

S

VCC DC supply current

CC

V

quiescent supply

CC

current

increasing

decreasing

VS = 16 V, VCC = 5.3 V

active mode

OUT1 - OUT6 floating

= 16 V, VCC = 0 V

V

S

standby mode

OUT1 - OUT6 floating

= -40 °C, 25 °C

T

test

T

= 85 °C

test

V

= 16 V, VCC = 5.3 V

S

CSN = V

= 16 V, VCC = 5.3 V

V

S

CSN = V

(1)

active mode

CC ,

standby mode

CC

OUT1 - OUT6 floating

130 150 °C

T

j

Tj

Tj

150 °C

170 °C

728V

720mA

412µA

625µA

13mA

25 50 µA

= 16 V, VCC = 5.3 V

V

S

IS + I

1. Guaranteed by design.

Sum quiescent supply

CC

current

CSN = V

standby mode

OUT1 - OUT6 floating

T

= 130 °C

test

CC

10/35 Doc ID 16186 Rev 2

50 200 µA

L9954LXP Electrical specifications

Table 8. Overvoltage and under voltage detection

Symbol Parameter Test condition Min. Typ. Max. Unit

V

SUV OnVS

V

SUV OffVS

V

SUV hystVS

V

SOV OffVS

V

SOV OnVS

V

SOV hystVS

V

POR Off

V

POR On

V

POR hyst

Table 9. Current monitor output

UV-threshold voltage VS increasing 5.7 7.2 V

UV-threshold voltage VS decreasing 5.5 6.9 V

UV-hysteresis V

SUV On

- V

SUV Off

0.5 V

OV-threshold voltage VS increasing 18 24.5 V

OV-threshold voltage VS decreasing 17.5 23.5 V

OV-hysteresis V

SOV Off

- V

SOV On

1V

Power-on reset threshold VCC increasing 4.4 V

Power-on reset threshold VCC decreasing 3.1 V

Power-on reset hysteresis V

POR Off

- V

POR On

0.3 V

Symbol Parameter Test condition Min. Typ. Max. Unit

V

I

CM,r

Functional voltage range VCC = 5 V 0 4 V

CM

Current monitor output ratio:

I

CM/IOUT6

Current monitor output ratio:

ICM/I

OUT1

Current monitor output ratio:

I

CM/IOUT4,5

low R

DSon

mode

Current monitor output ratio:

I

CM/IOUT4,5

high R

DSon

mode

0V ≤ V

=5V

V

CC

CM

≤ 4V,

1

----------------

10000

1

------------ -

3800

1

----------------

10200

1

------------ -

2400

-

Doc ID 16186 Rev 2 11/35

Loading...

Loading...