Page 1

Features

■ Two 5V low-drop voltage regulators (250mA,

100mA continuous mode

■ Low stand-by current: V

45µA, (75µA in cycl. sense)

■ Window watchdog and fail-safe output

■ Interrupt output

■ Wake-up logic with cyclic contact monitoring

■ LIN 2.1 compliant (SAEJ2602 compatible)

transceiver

■ 24 bit SPI interface for mode control and

diagnostic

■ Output drivers

■ 4 High side drivers for e.g. LED or HALL

(R

DSon,typ

= 7 Ω )

■ 1 High side driver Out_HS ( R

■ 2 Relay drivers ( R

DSon,typ

■ Outputs are short circuit protected

■ 2 Op amp's for current sensing in GND return

lines

■ Temperature warning and thermal shutdown

Table 1. Device summary

stby, 7µA; ,V1 stby,

BAT

DSon,typ

= 2 Ω )

= 1 Ω )

L9952GXP

Power management system IC

PowerSSO-36

Applications

■ Automotive ECU’ s such as door zone and

body control modules.

Description

The L9952GXP is a power management system

IC containing two low drop regulators with

advanced contact monitoring and additional

peripheral functions.

The integrated standard serial peripheral interface

(SPI) controls all L9952GXP operation modes

and provides driver diagnostic functions.

Order codes

Package

Tube Tape and reel

PowerSSO-36 L9952GXP L9952GXPTR

July 2009 Doc ID 13518 Rev 5 1/68

www.st.com

1

Page 2

Contents L9952GXP

Contents

1 Pin definitions and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Voltage regulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.1 Voltage regulator: V1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.2 Voltage regulator: V2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Power control in operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.1 Active mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.2 Flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.3 V1 standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2.4 VBAT standby mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3 Wake up events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4 Functional overview (truth table) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.5 Wake up inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6 Hall sensor ports: WU3,4, Dig_Out 3,4 . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.7 Interrupt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.8 Cyclic contact supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.9 Window – watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.10 Fail safe output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.11 Reset – generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.12 V1, V2 fail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.13 Low side driver outputs Rel1, Rel2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.14 PWM inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.15 Operational amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.16 LIN bus interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.17 Error handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.17.1 Dominant TxD time out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.17.2 Short to battery time out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.17.3 Short to ground mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.18 Wake up (from LIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.18.1 Normal wake up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.18.2 Wake up from short to GND condition . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2/68 Doc ID 13518 Rev 5

Page 3

L9952GXP Contents

2.18.3 RxD pin in V1 standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.19 LINPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.20 Serial Peripheral Interface (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.20.1 Chip Select Not (CSN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.20.2 Serial Data In (DI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.20.3 Serial Data Out (DO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.20.4 Serial Clock (CLK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.20.5 Data registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3 Protection and diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 Power supply fail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1.1 Over voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1.2 Under voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.2 Temperature warning and thermal shutdown . . . . . . . . . . . . . . . . . . . . . . 25

3.3 SPI diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4 High side driver outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.5 Low side driver outputs Rel1, Rel2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5 ESD protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.1 Operating junction temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.2 Temperature warning and thermal shutdown . . . . . . . . . . . . . . . . . . . . . . 30

6.3 Package and PCB thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.1 Supply and supply monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.2 Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.3 Power-on reset (Vs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.4 Voltage regulator V1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.5 Voltage regulator V2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

7.6 Reset generator (V1 supervision) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.7 Watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Doc ID 13518 Rev 5 3/68

Page 4

Contents L9952GXP

7.8 High side outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.8.1 Output (Out_HS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.8.2 Outputs (OUT1...4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.9 Relay drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7.10 Wake up inputs ( WU1..WU4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.11 Wake up input (INH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.12 LIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.13 Operational amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7.14 SPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.14.1 Input: CSN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.14.2 Inputs: CLK, DI, PWM 1, PWM 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.14.3 Input PWM 2 Vth for flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.14.4 DI timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.14.5 DO, FSO, Dig_Out3,4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.14.6 DO timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7.14.7 CSN timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

8 SPI control and status registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.1 SPI registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.1.1 Control register 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.1.2 Control register 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.1.3 Control register 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.1.4 Status register 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.1.5 Status register 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9 Package and packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.1 ECOPACK® packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.2 PowerSSO-36 package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.3 PowerSSO-36 packing information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4/68 Doc ID 13518 Rev 5

Page 5

L9952GXP List of tables

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Pins definitions and functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4. Functional overview (truth table). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 5. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Table 6. ESD protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 7. Operating junction temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 8. Temperature warning and thermal shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Table 9. Thermal parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Table 10. Supply and supply monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Table 11. Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 12. Power-on Reset (Vs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 13. Voltage regulator V1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 14. Voltage regulator V2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 15. Reset generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 16. Watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Table 17. High side outputs (Out_HS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Table 18. High side outputs (OUT 1..4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 19. Relay drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 20. Wake up inputs(WU1...WU4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 21. Wake up input (INH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 22. LIN receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 23. LIN DC parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 24. LIN transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 25. LIN timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Table 26. LIN DC values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Table 27. Operational amplifier. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Table 28. SPI (Input CSN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 29. Inputs: CLK, DI, PWM 1, PWM 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 30. Input PWM2 Vth for flash mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 31. DI timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 32. DO, FSO, Digout3,4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 33. DO timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 34. CSN timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Table 35. SPI registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Table 36. Control register 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 37. Configuration bit HSxx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 38. Configuration bit OUT_HSx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 39. Configuration bit RELx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 40. Configuration bit On_V2x . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Table 41. Configuration bit TRIG, GO_VBAT, GO_V1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 42. Control register 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 43. Configuration bit Wx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Table 44. Configuration bit Ux . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 45. Configuration bit Lx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Table 46. Configuration bit Txx. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 47. Configuration bit INT_enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Table 48. Control register 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 49. Configuration bit OLT_HSx, VSLOCK Out, O_HS_REC, LINPU and TXD_TOUT. . . . . . . 59

Doc ID 13518 Rev 5 5/68

Page 6

List of tables L9952GXP

Table 50. Configuration bit LEVx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Table 51. Configuration bit ICxx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 52. Configuration bit LIN slope, LS_ovuv and ICMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Table 53. Status register 0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 54. Configuration bit HSx_OL, HSx_OC and Relx_OC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 55. Configuration bit SHT5V2, WUx, INH, LIN and Cold Start . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 56. Status register 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 57. Configuration bit OV, UV, TW, TSDx and Vx Fail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 58. Configuration bit STx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 59. Configuration bit Rx, WDx, TRIG, SHT_GND, SHT_BAT and DOM_TXD . . . . . . . . . . . . . 63

Table 60. PowerSSO-36 mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Table 61. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6/68 Doc ID 13518 Rev 5

Page 7

L9952GXP List of figures

List of figures

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 2. Pins configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

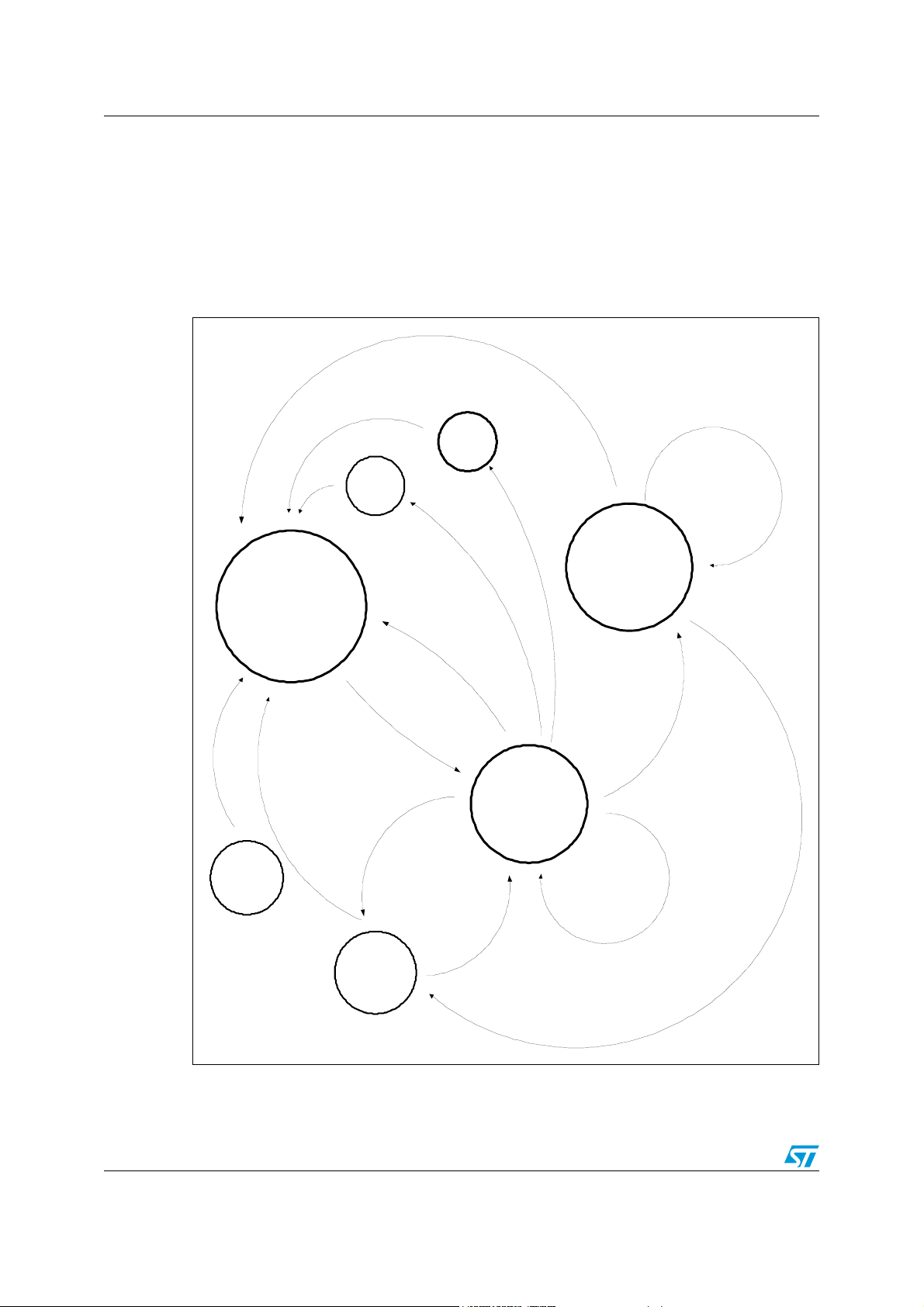

Figure 3. Operating modes, main states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

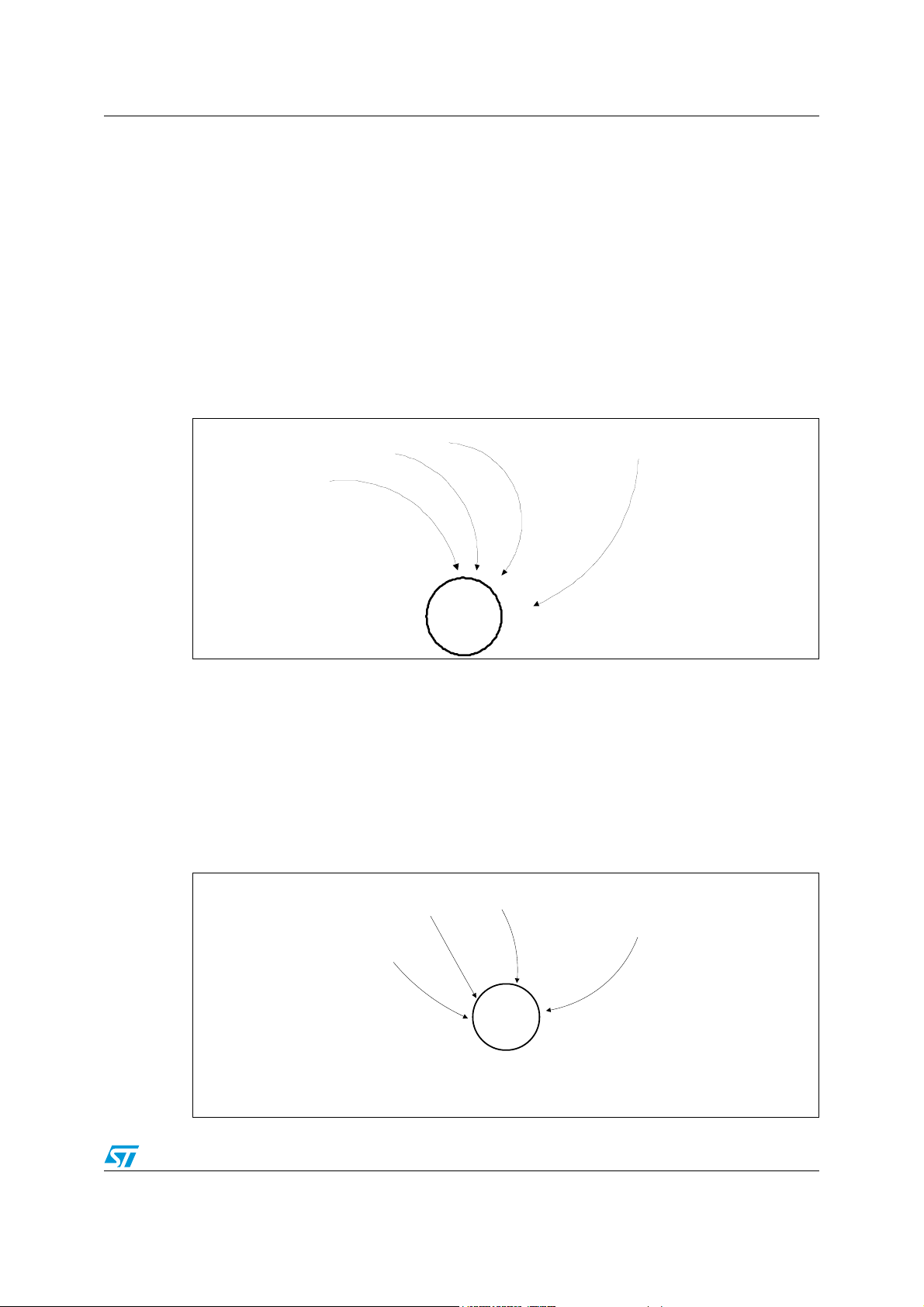

Figure 4. Watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 5. FSO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 6. NReset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

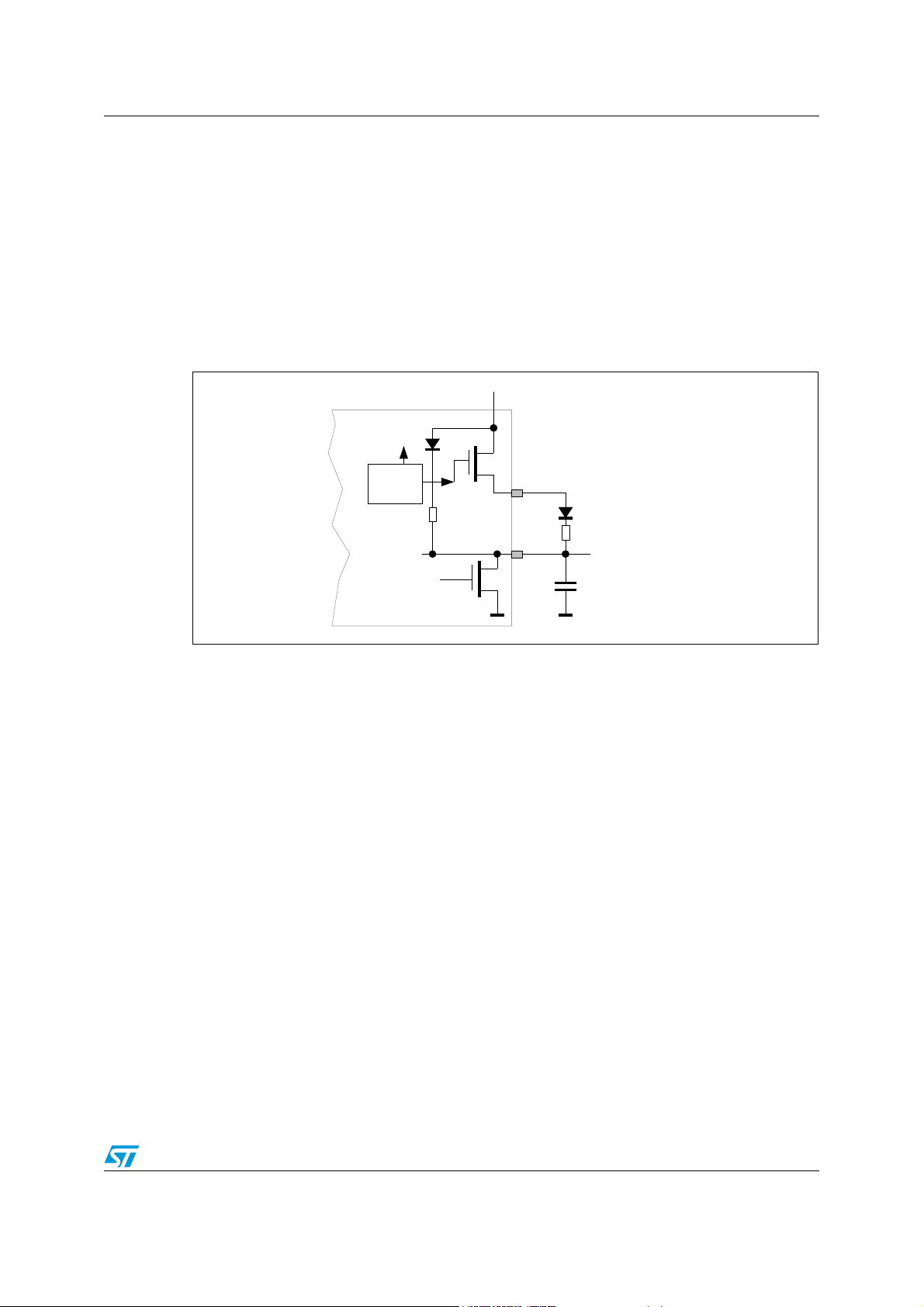

Figure 7. Lin master pull up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 8. Protection and diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 9. PowerSSO-36 PC board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 10. PowerSSO-36 thermal resistance junction ambient Vs. PCB copper area (V1 ON) . . . . . 32

Figure 11. PowerSSO-36 thermal impedance junction ambient single pulse (V1 ON) . . . . . . . . . . . . 32

Figure 12. PowerSSO-36 thermal fitting model (V1 ON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 13. Watchdog timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Figure 14. Watchdog, closed and open window tolerances and save trigger area . . . . . . . . . . . . . . . 39

Figure 15. LIN transmit, receive timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 16. SPI - Input timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 17. SPI - Edges timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 18. SPI - CSN low to high transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 19. SPI - High to low transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 20. PowerSSO-36 package dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 21. PowerSSO-36

Figure 22. PowerSSO-36

tube shipment (no suffix). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

tape and reel shipment (suffix “TR”) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Doc ID 13518 Rev 5 7/68

Page 8

Pin definitions and functions L9952GXP

1 Pin definitions and functions

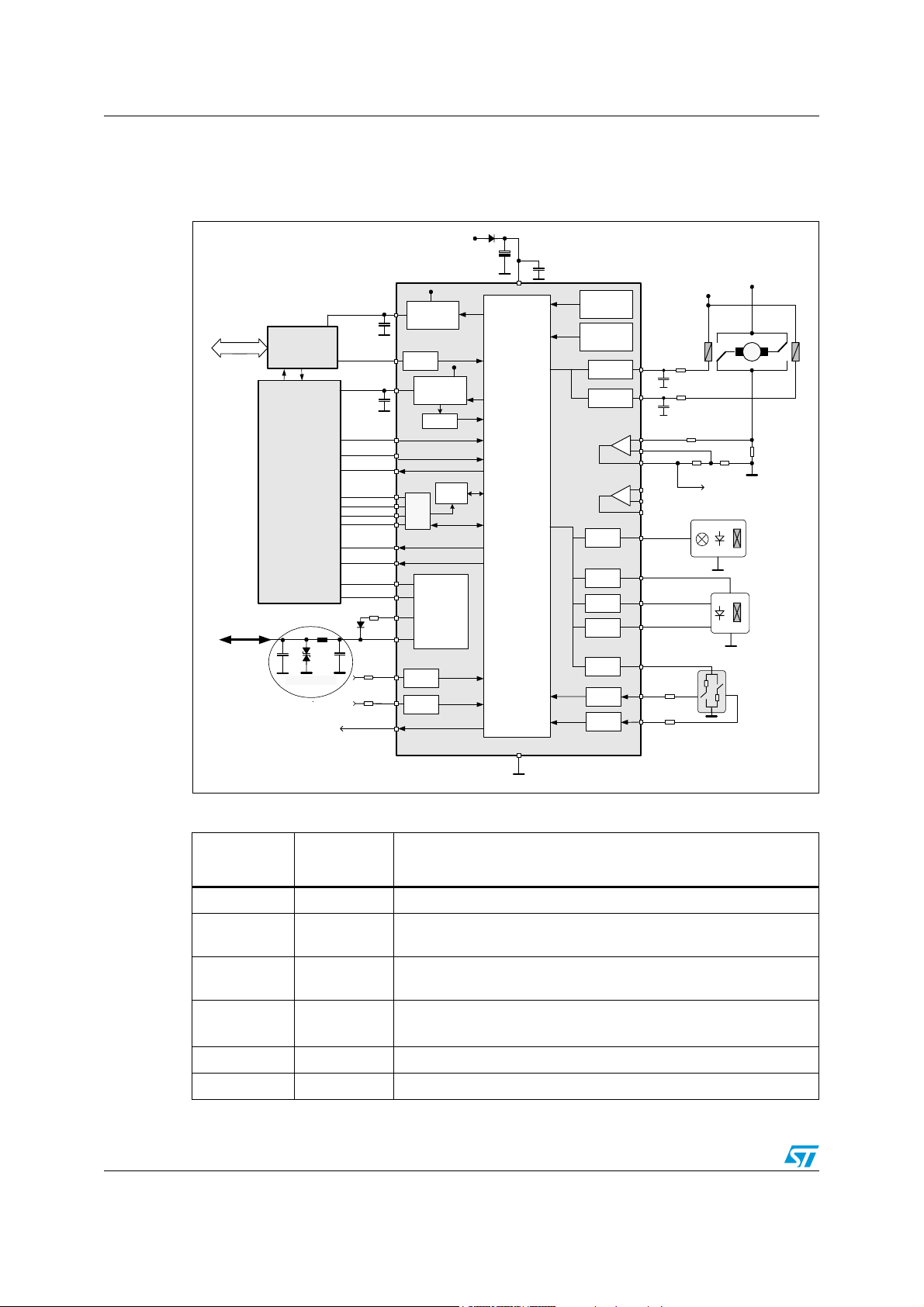

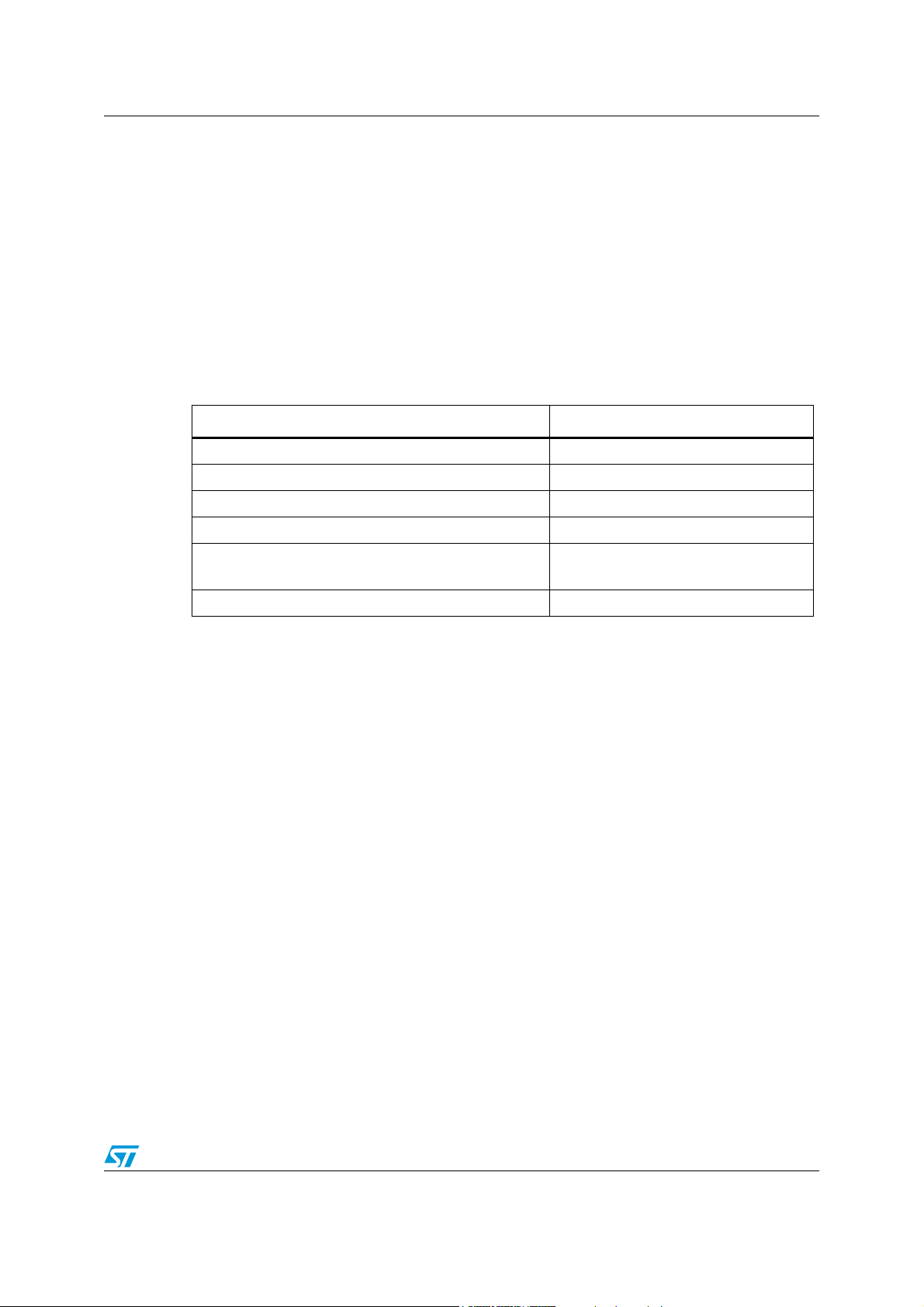

Figure 1. Block diagram

V

V

s

Voltage

Voltage

Regulator 1

Voltage

Monitor

Windo w

Watchd og

LIN 2. 1

SAEJ2602

1)

LIN 2.1 certified

Bat

V

s

Temp Pr ewarnin g

& Shutdown

Under volta ge -

Overvolt age -

Shutdown

R

Output Clamp

Output Clamp

+

-

+

-

Rel1

Rel2

OP1+

OP1OP1o u t

OP2+

OP2OP2o u t

OUT_H S

Out 1

Out 2

Out 3

Out 4

WU1

WU2

C

R

C

V

s

LOGIC

1)

Low S ide

Low S ide

High Side

High Side

High Side

High Side

High Side

Wake Up IN

Wake Up IN

V

S

µC (A DC)

V

Bat

M

e. g . Bu lb,

LED, Hall

Sensor

e. g. LED,

Hall Sensor

Cyclic Contact

Moni tori ng

CAN

LIN

For detailed information

see

EMC tes t report from

IBEE Zwickau

CAN

Microcontroller

ESDLIN1524BJ

Fail-safe Logic

220nF

INH

220nF

PWM1

PWM2

NReset

CSN

CLK

DO

Dig_Out3

Dig_Out 4 /

Inter rupt

TxD

RxD

LINPU

LIN

WU3

WU4

FSO

V2

Regulator 2

Wake Up IN

V1

SPI

DI

Wake Up IN

Wake Up IN

Table 2. Pins definitions and functions

Pin

name

PowerSS0-36 Function

GND 1 Ground

V2 2

V1 3

NReset 4

Voltage regulator 2 output : 5 V supply for external loads e.g. IR

receiver, potentiometer

Voltage regulator 1 output : 5 V supply e.g. micro controller, Can

transceiver

NReset output to micro controller - Internal pull-up of typ. 100KΩ

( reset state = low )

INH 5 Wake-up input e.g. from CAN transceiver

RxD 6 Receiver output of the LIN 2.1 transceiver

8/68 Doc ID 13518 Rev 5

GND

Page 9

L9952GXP Pin definitions and functions

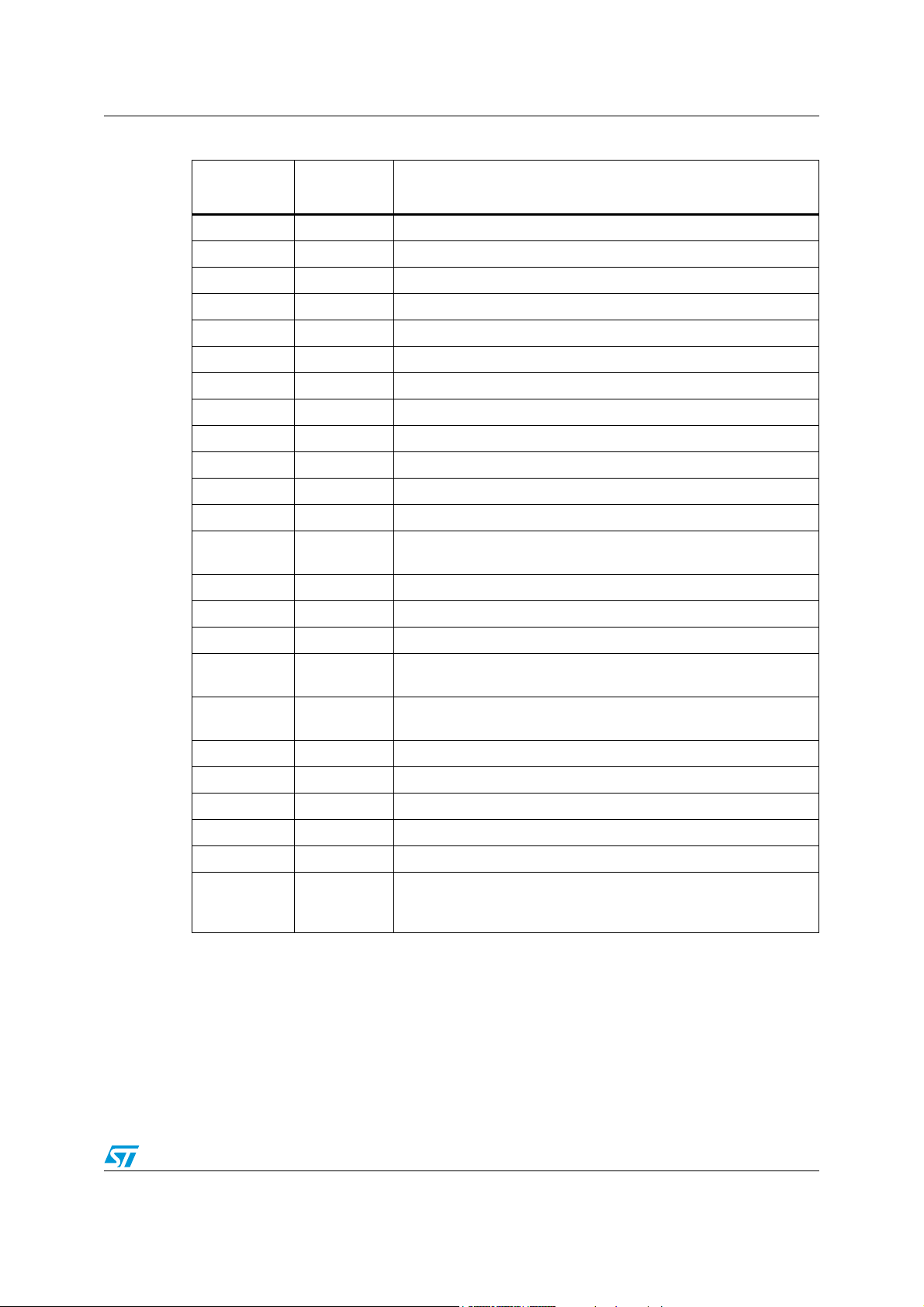

Table 2. Pins definitions and functions (continued)

Pin

name

PowerSS0-36 Function

TxD 7 Transmitter input of the LIN 2.1 transceiver

OP2+ 8 Non inverting input of operational sense amplifier

OP2- 9 Inverting input of operational sense amplifier

OP2

OUT

10 Output of operational sense amplifier

DI 11 SPI : serial data input

DO 12 SPI : serial data output

CLK 13 SPI : serial clock input

CSN 14 SPI : chip select not input

PWM1 15 Pulse width modulation input

PWM2 16 Pulse width modulation input

Dig_Out3 17 Digital output

Dig_Out4/INT 18 Digital output (configurable as Interrupt Output)

Wu

OP1

4..1

OUT

19 to 22

23 Output of operational sense amplifier

Wake-up input: input pins for static or cyclic monitoring of external

contacts

OP1- 24 Inverting input of operational sense amplifier

OP1+ 25 Non inverting input of operational sense amplifier

Out

4..1

26 to 29

Out_HS 30

High side driver (7 Ω,

external contacts

High side drivers (1 Ω,

sensors or external contacts

typ.) - to supply e.g. LED’ s, HALL sensors or

typ.) - to supply e.g. LED’ s, Bulbs, HALL

Vs 31 Power supply voltage

LINPU 32 LIN master pull up

LIN 33 LIN bus line

Rel1 34 Low side driver (2 Ω,

Rel2 35 Low side driver (2 Ω,

typ.) - e.g. relay

typ.) - e.g. relay

Fail safe output - used to supervise or control applications in case of

FSO 36

watchdog and/or V1 under-voltage failure (e.g. to activate

emergency lights)

Doc ID 13518 Rev 5 9/68

Page 10

Pin definitions and functions L9952GXP

/

_

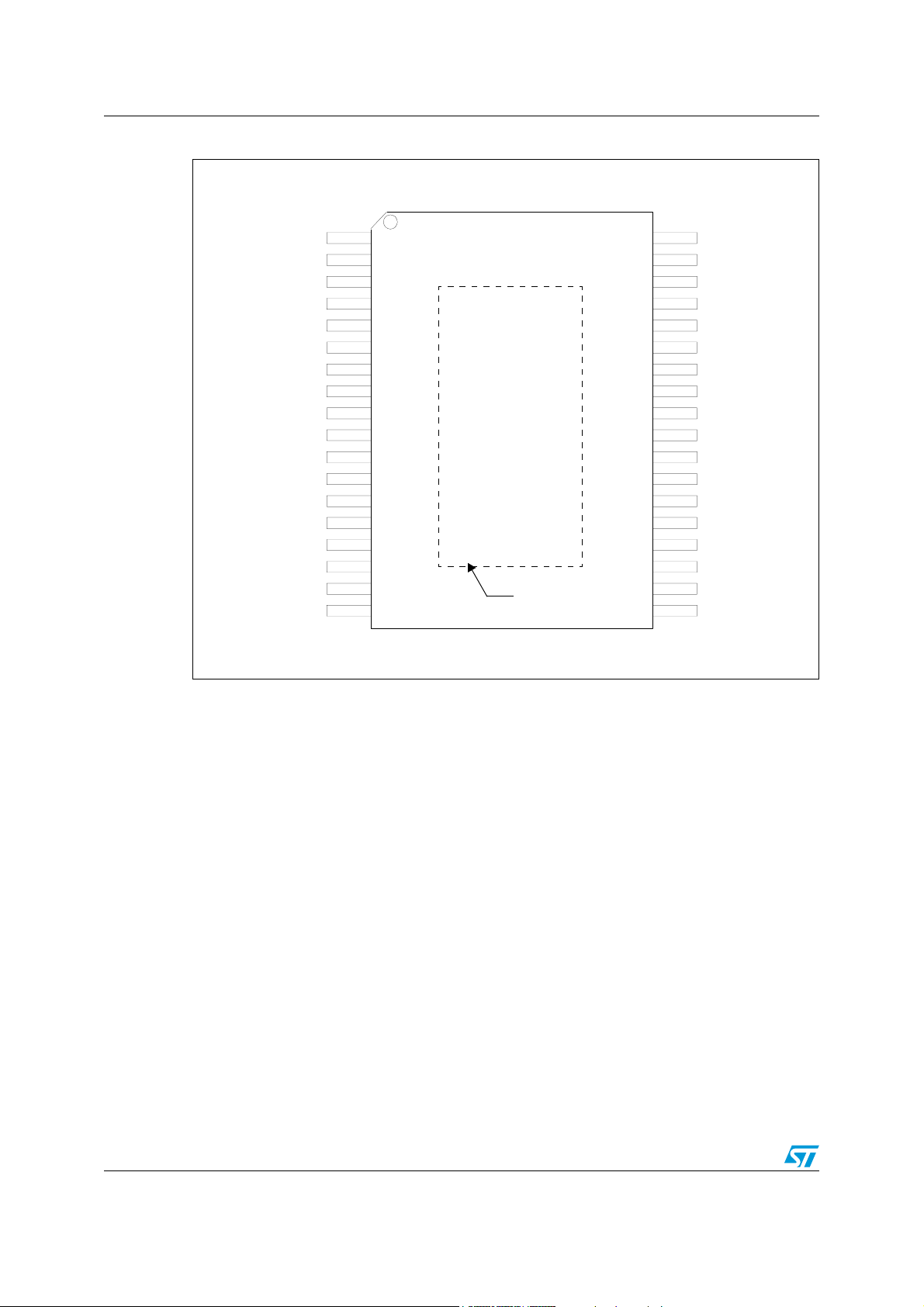

Figure 2. Pins configuration

1

Dig

GND

NRESET

OP

OP2 -

OPOUT

CLK

CSN

PWM

PWM

Dig_Out

4

INT _

Out

V 22

V1 3

INH

RxD

TxD

2+

2

DI

DO

1

2

3

10

11

12

13

14

15

16

17

18

PowerSSO-36

4

5

6

7

8

9

L9952

GXP

TA B = G N D

35

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

FSO 36

REL 2

REL 134

LIN

LINPU

Vs

OUT

HS

OUT 1

OUT 2

OUT 3

OUT 4

OP 1 +

OP 1 -

OPOUT 1

WU 1

WU 2

WU 3

WU 4

10/68 Doc ID 13518 Rev 5

Page 11

L9952GXP Description

2 Description

2.1 Voltage regulator

The L9952GXP contains 2 independent and fully protected low drop voltage regulators,

which are designed for very fast transient response.

The output voltage is stable with loads capacitors >

2.1.1 Voltage regulator: V1

The voltage regulator V1 provides 5V supply voltage and up to 250mA continuous load

current for the external digital logic (micro controller, CAN transceiver ...). In addition the

regulator V1 drives the L9952GXP internal 5V loads. The voltage regulator is protected

against overload and over-temperature. An external reverse current protection has to be

provided by the application circuitry to prevent the output capacitor from being discharged

by negative transients or low input voltage. The output voltage precision is better than +/-2%

(incl. temperature drift and line-/load regulation) for operating mode; respectively +/-3%

during low current mode. Current limitation of the regulator ensures fast charge of external

bypass capacitors. The output voltage is stable for ceramic load capacitors >

If device Temperature exceeds TSD1 threshold, all outputs (Hsx, Lsx, V2, LIN) will be

deactivated except V1. Hence the micro controller has the possibility for interaction or error

logging. In case of exceeding TSD2 threshold (TSD2>TSD1), also V1 will be deactivated

(see state chart Fig. 3.1: “Protection and diagnosis”). A timer is started and the voltage

regulator is deactivated for t

LIN, and WU1...4) are disabled. After 1 sec, the voltage regulator will try to restart

automatically. If TSD2 occurs within one minute and for 8 consecutive times, the L9952GXP

enters the V

In case of short to GND at “V1” after initial turn on (V1 < 2V for at least 4ms) the L9952GXP

enters the V

signals from CAN, LIN, WU1..4, SPI.

- standby mode.

BAT

- standby mode. Reactivation (wake-up) of the device can be achieved with

BAT

220nF.

220nF.

= 1sec. During this time, all other wakeup sources (CAN,

TSD

2.1.2 Voltage regulator: V2

The voltage regulator V2 supplies additional 5V loads (e.g. Logic components, external

sensors, external potentiometers). The continuous load current is 50mA. The regulator

provides accuracy better than +

In case of short to GND at “V2” after initial turn on (V2 < 2V for at least 4ms) the V2

regulator is switched off. Micro processor has to send a clear command to reactivate the V2

regulator.

V2 is protected against:

● Overload

● Over temperature

● Short circuit (short to ground and battery supply voltage)

● Reverse biasing

3% @ 50mA (4% @ 100mA) load current.

Doc ID 13518 Rev 5 11/68

Page 12

Description L9952GXP

2.2 Power control in operating modes

The L9952GXP can be operated in 4 different operating modes:

● Active

● Flash

● V

● V

A cyclic monitoring of wake-up inputs is available in stand-by modes.

2.2.1 Active mode

All functions are available.

2.2.2 Flash mode

To disable the watchdog feature a FLASH program mode is available.

- standby

1

- standby

BAT

The mode can be entered by V

PWM2

≥ 9V

In this case all other functions are the same as in active mode

Watchdog can be disabled as well as soon as L9952GXP enters the V1 standby mode (see

section 2.9 for details)

Note: “High” level for flash mode selection is V

5V logic signals are required. For proper operation PWM

above standard 5V logic.

2.2.3 V1 standby mode

Outputs and internal loads are switched off. To supply the micro controller in a low power

mode, the voltage regulator1 (V1) remains active. The intention of the V1 standby mode is

to preserve the RAM contents. A cyclic contact supply and wake-up input sense feature (for

cyclic monitoring of external contacts) can be activated by SPI.

2.2.4 V

To achieve minimum current consumption during V

functions (except the ones for wake up functionality) are switched off.

In V

(without cyclic sense feature selected).

The transitions from active mode to either V

SPI.

standby mode

BAT

- standby mode the current consumption of the L9952GXP is reduced to 7µA, typical

BAT

≥ 9V. For all other operation modes, standard

PWM2

1 must not be set to a voltage level

standby mode, all L9952GXP

BAT

-standby or V

1

- standby are controlled by

BAT

V

- standby mode is dominant; i.e. if both bits, V1 - standby and V

BAT

“1”, the L9952GXP will enter V

- standby mode.

BAT

12/68 Doc ID 13518 Rev 5

- standby are set to

BAT

Page 13

L9952GXP Description

2.3 Wake up events

A wake-up from standby mode will switch the device to active mode. This can be initiated by

one or more of the following sources:

● Change of the LIN state at LIN bus interfaces

● A current at the INH pin (I ≥200uA) controlled by the CAN-transceiver (the CAN

transceiver is not a part of the IC).

● Positive/negative edge at wake up pins WU1...WU4 -> change of level after going into

stand-by

● Change of open-load state at OUT1 to 4

● SPI access in V1-standby mode (CSN is low and first rising edge on CLK)

Table 3. Wake up events

Wake up source Description

LIN Always active

INH Always active

WU1...4 Can be individually disabled via SPI

Open Load at HS outputs Can be individually disabled via SPI

SPI Access

High level at PWM2 input VPWM2 > 9V

Always active

(except in V

- standby mode)

BAT

(1)

1. Only if internal oscillator is running (e. g. in cyclic sense configuration or after wake-up request).

All wake-up events (except wake-up by LIN, INH or SPI from V1standby mode) generate a

Reset pulse (NReset low for 2ms).

Wake-up events from V1standby by LIN, INH or SPI do not cause a Reset and the Reset

generation is blocked for 2ms, i. e. a watchdog failure during this timeframe will not cause a

reset.

Doc ID 13518 Rev 5 13/68

Page 14

Description L9952GXP

2.4 Functional overview (truth table)

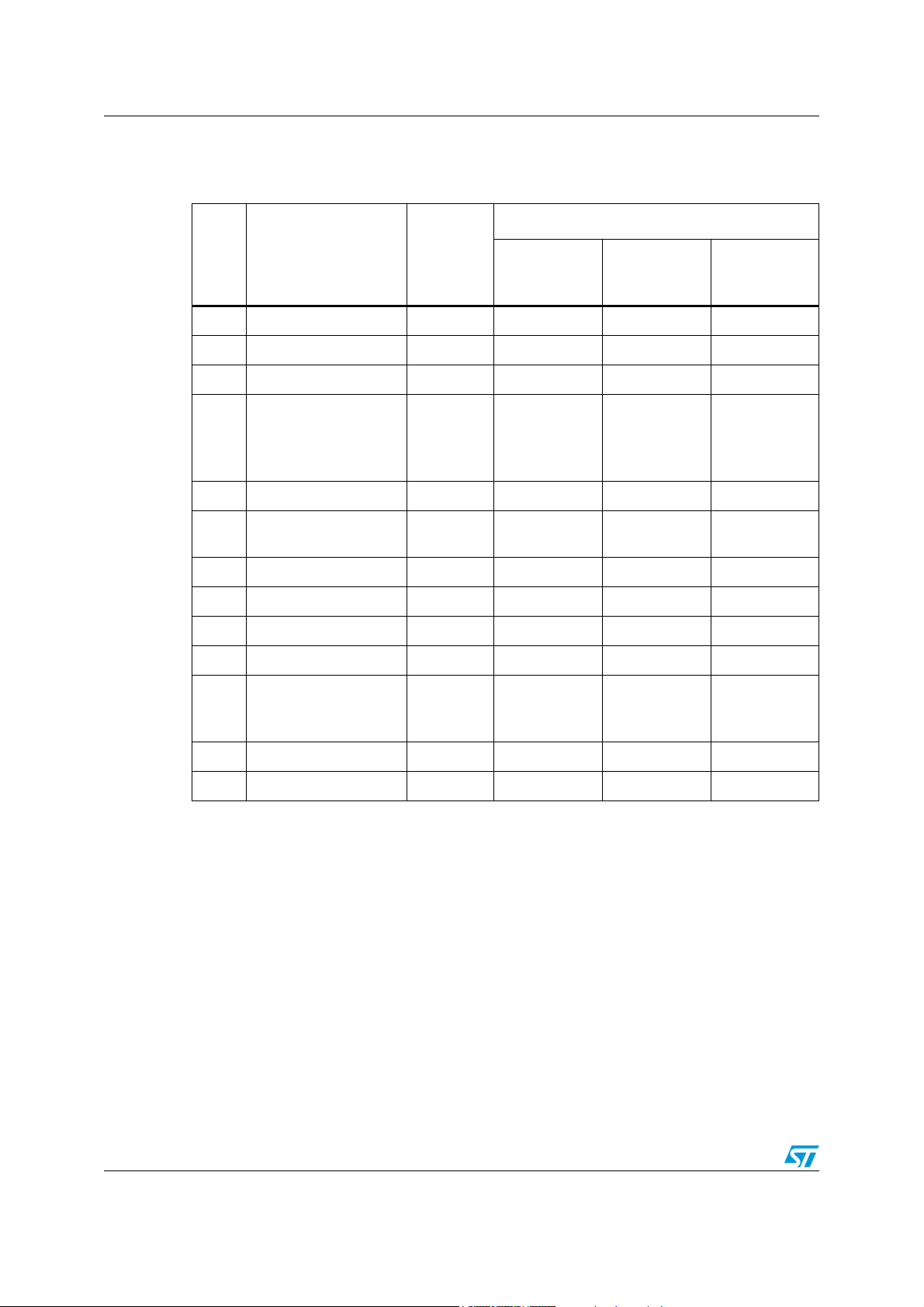

Table 4. Functional overview (truth table)

Operating modes

-standby

Function Comments

Active mode

V

1

static mode

(cyclic sense)

2.3.1 Voltage-regulator, V1 VOUT= 5V On On

2.3.2 Voltage-regulator, V2 VOUT= 5V On / Off

(2)

On

(2)

(1)

/ Off On

V

-standby

BAT

static mode

(cyclic sense)

Off

(2)

2.3.3 Reset-generator On On Off

Off if

2.3.4 Window watchdog V

monitor On

1

2.3.5 Wake up Off

2.3.6 HS-cyclic supply

Oscillator

timebase

On / Off On

(3)

(I_V1 < I

and I

or I

CMP

Active

(2)

CMP

=0)

CMP

= 1

(4)

/ Off On

Off

Active

(2)

2.3.7 Relay driver On Off Off

2.3.8 Operational amplifiers On Off Off

2.3.9 LIN line driver LIN 2.1 On Off Off

2.3.10 LIN line receiver On On On

Hi – no error

Lo – WD or V1

fail

2.3.11 FSO

Fail-safe

output

2.3.12 Oscillator On

2.3.13 Vs-Monitor On

Hi – no error

Lo – WD or V1

fail

(5)

(6)

(7)

Lo -> because

V1= off

(6)

(7)

/ Off

(4)

/ Off

1. Supply the processor in low current mode

2. Only active when selected via SPI

3. Input Status can be read by SPI (Status Register 0); Inputs should be configured for static sense (Control

Register 2)

4. Unless disabled by SPI

5. Watchdog is active in V1 standby mode, until I(V1) is below I

6. Activation = ON if cyclic sense is selected

7. Cyclic activation = pulsed ON during cyclic sense

14/68 Doc ID 13518 Rev 5

current threshold

CMP

Page 15

L9952GXP Description

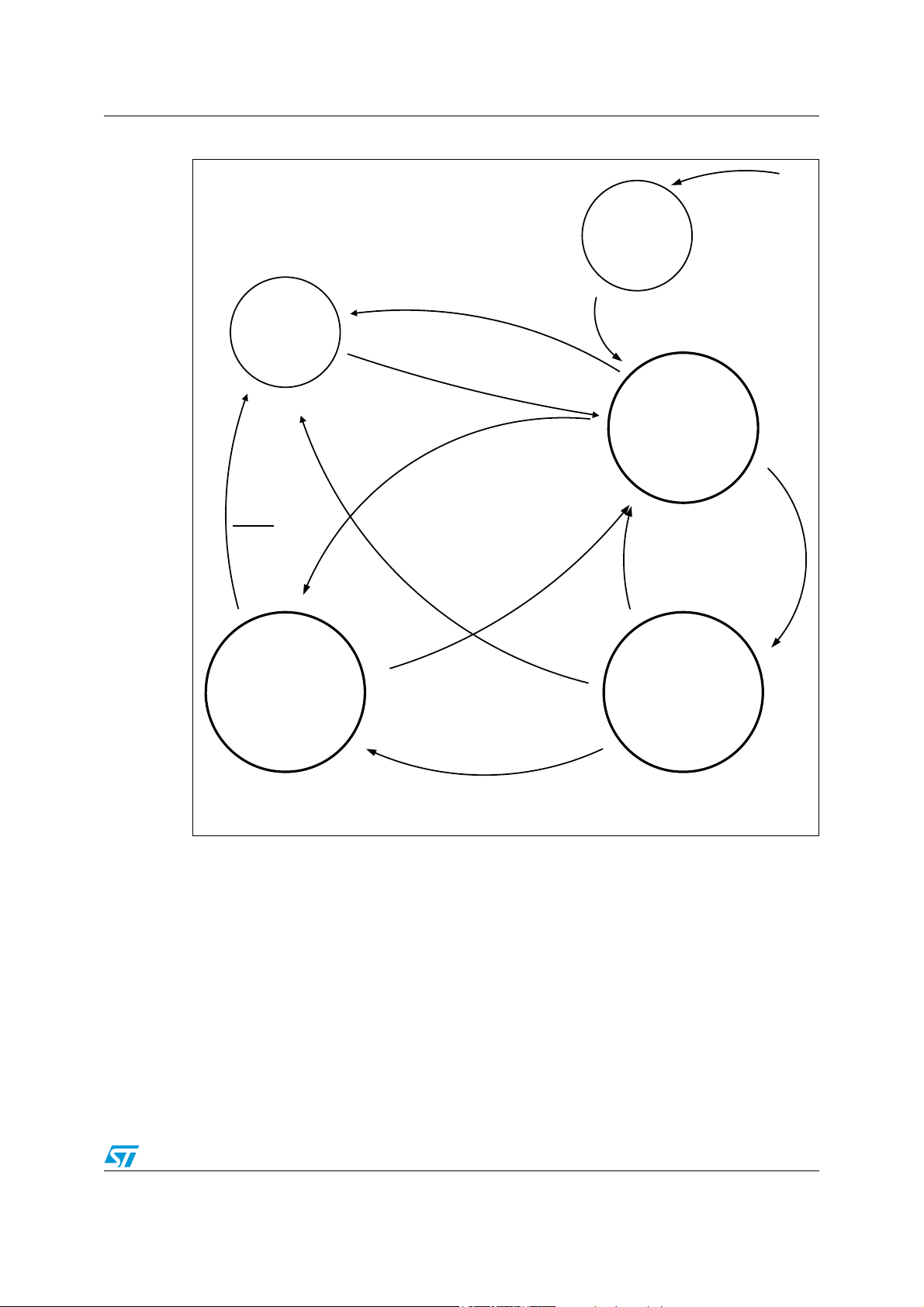

Figure 3. Operating modes, main states

Vs > Vpor

Vbat startup

All registers

clear ed to ‚0',

Cold start bit (D19, SR0)

set to ‚ 1'

Vpwm2>9V

Flash Mode

Watchdog: OFF

Vpwm2<7V

Active

Mode

V1: on

Reset Generator: active

Watchdog: active

Fail Safe Out: active

Vpwm2>9V

Note 1

SPI command: ‚Go Vbat’ ( D20 CR0)

V1 fail (V1 < 2,5V for 4ms after POR)

OR

Thermal Shutdown

OR

=> shor t to GN D

Or

15 x WD Fa ilur e

Vbat Standby

Mode

V1: off

V2: according to SPI settings

Reset Generator: off (Nreset=low)

Watchdog: off

Fail S afe Out : low

HSD, LSD: Off

Not e 1: only if internal oscilla tor is runn ing

Vpwm 2>9V

Note 1

Thermal Shutdown TSD2

OR IV1 > 1mA AND ICMP = 0 AND 15 x WD fail

Wake-up

Event

Wake-up

Event

V1 Stan d b y

Mode

V1: on

Reset Generator: active

Watchdog:

OFF (if Iv 1<I

or ICMP = 1)

cmp

Fail Safe Out: active

SPI command: ‚Go Vcc’

(D21 CR0)

Doc ID 13518 Rev 5 15/68

Page 16

Description L9952GXP

2.5 Wake up inputs

The de-bounced digital inputs WU1...WU4 can be used to wake up the L9952GXP from

standby modes. These inputs are sensitive to any level transition (positive and negative

edge)

For static contact monitoring, a filter time of 64 µs is implemented at WU1-4. The filter is

started when the input voltage passes the specified threshold. At Vin > 1V and Vin < (Vs –

2V), a Wake-up request is processed. During Wake-up request, the internal oscillator and

other circuit blocks are activated in order to allow more accurate monitoring of the inputs.

In addition to the continuous sensing (static contact monitoring) at the wake up inputs, a

cyclic wake up feature is implemented. This feature allows periodical activation of the wakeup inputs to read the status of the external contacts. The periodical activation can be linked

to Timer 1 (0.5sec to 4.0sec in 0.5sec steps) or Timer 2 (50ms). The input signal is filtered

with a filter time of 16us after a programmable delay (80us or 800us). A Wake-up will be

processed if the status has changed versus the previous cycle.

The Outputs OUT_HS and OUT1-4 can be used to supply the external contacts with the

timing according to the cyclic monitoring of the wake-up inputs.

If the wake-up inputs are configured for cyclic sense mode (Icxx in control register 2), the

same input filter timing (Timer1 or Timer2) and the corresponding input filter delay (control

register 2) must be used for the HS Outputs (Hsxx in control register 0) which supply the

external contact switches.

In Standby mode, the inputs WU1-4 are SPI configurable for pull-up or pull-down current

source configuration according to the setup of the external contacts (pull-up for active low

contacts, pull-down for active high contacts). In active mode the inputs have a pull down

resistor of 100 kOhm (typ).

In Active mode, the input status can be read by SPI (Status Register 0). Static sense should

be configured (Control Register 2) before the read operation is started (In cyclic sense

configuration, the input status is updated according to the cyclic sense timing; Therefore,

reading the input status in this mode may not reflect the actual status).

2.6 Hall sensor ports: WU3,4, Dig_Out 3,4

Applications like Hall sensor outputs need high processing speed. The 12V signals

connected to the wakeup inputs WU3 and WU4 can be looped through to the digital outputs

Dig_Out 3 and Dig_Out 4 (5V) in order to avoid read out of the input state by SPI.

The setup is programmable by SPI.

The open load states of the High Side Drivers OUT1 and OUT2 can be looped through the

digital outputs Dig_Out3 and Dig_Out4 without delay. In addition, the status of OUT1 and

OUT2 can be accessed through the SPI interface. This feature is intended for 2-pin HALL

sensors. Open Load information is only valid during ON state.

The Open Load threshold at pins OUT1...4 can be switched from I

I

= 8 mA via SPI .

OLD2

16/68 Doc ID 13518 Rev 5

OLD1

= 2mA to

Page 17

L9952GXP Description

2.7 Interrupt

Dig_Out4 can be configured via SPI as Interrupt output (INT) by setting Bit 20 /

CR1:INT_enable=’1’.

This configuration will enable the following behaviour:

● INT pin is pulled high for 2ms in case of any wake-up from V1 standby mode (WU

inputs, LIN, INH, SPI, open load HS, Iv1 > I

● Wake-up events from V1 standby do not generate a reset (i.e. NRESET is not pulled

CMP

_ris)

low)

● The Dig_Out4 settings in CR1 (Bits 12..14) will be ignored

2.8 Cyclic contact supply

In V1 and V

standby mode, any high side driver output (OUT1..4, OUTHS) can be used

BAT -

to periodically supply external contacts.

The timing is selectable by SPI

Timer 1: period is X sec, the on-time is 10ms resp. 20ms

With X ∈ {0.5, 1.0, 1.5, ... 4 }

Timer 2: period is 50ms, the on- time is 100us resp. 1ms:

Note: Cyclic sense setup: if cyclic sense feature is used for wake-up inputs (Icxx in control register

2), same input filter timing (Timer1 or Timer2) must be used for HS Outputs (Hsxx in control

register 0).

2.9 Window – watchdog

During normal operation the watchdog monitors the micro controller within a nominal trigger

cycle of 10ms.

In V

automatically disabled. However, the watchdog will remain enabled in V1-standby mode

until the current at V1 decreases below I

disabled, if the I

After ‘power-on’, ‘standby mode’ or reset, the window watchdog starts with a long open

window (65ms). The long open window allows the micro controller to run its own setup and

then to trigger the watchdog via the SPI. The trigger is finally accepted when the CSN input

becomes HIGH after the transmission of the SPI word.

-standby , V1-standby and Flash program modes, the watchdog circuit is

BAT

_fall. The V1 current monitoring can be

bit (CR2, D20) is set to '1'.

CMP

CMP

A correct watchdog trigger will start the window watchdog with a closed window (< 6ms)

followed by an open window (< 10ms), see timing diagrams. Subsequently, the micro

controller has to serve the watchdog by alternating the watchdog trigger bit (CR0, D19). The

“negative” or “positive” edge has to meet the open window time. A correct watchdog trigger

signal will immediately start the next closed window.

After 8 watchdog failures in sequence, the V1 regulator is switched off for 200ms. In case of

7 further watchdog failures, the V1 regulator is completely turned off and the device goes

into V

standby mode until a wakeup occurs. (e.g. via LIN, CAN/INH).

BAT -

Doc ID 13518 Rev 5 17/68

Page 18

Description L9952GXP

The watchdog is triggered by toggling the trigger bit (CR0, D19).

Note: The active trigger window will be reset after each correct trigger write operation.

In case of reset (NReset low for 2ms) the trigger bit is set to “0”.

In case of a WD failure, the outputs (Lsx, Hsx, V2) are switched off and NReset is pulled low

for 2ms.

Writing to control register 0 without inverting the WD trigger bit is possible at any time.

Figure 4.

(Nreset =low for 2ms)

LSD: Off (control bits set to ‚0')

HSD: Off (control bits remain

Watchdog

t=200ms

Reset

unchanged)

Wake up event

V1 off

for 200 m s

Watchdog Failure

Vbatstdby

Mode

8x WD Failure

Watchdog Failure (‚long

open window’ passed

without TRIG=1

2ms

8+7

WD Failu res

Toggle WD Trigger Bit

Within nominal window

Watchdog active

With

Normal window

(10ms)

HS D, LSD : accor ding to

CR0

Set WD Tr igger Bit = ‚ 1' or

toggle trigger bit if wake-up

from V1standby

Wake- up eve nt

or exit Flash Mode

Go to st and by mod e or

Power-on

Reset

Flash Mode ( PWM2>9V)

Watchdog

Inactive

(standby modes,

Flash Mode)

INH, LIN, SPI

I(V1)>1mA and ICMP=0

18/68 Doc ID 13518 Rev 5

Watchdog active

with

‚long open wi ndow’

(65ms nom )

HS and LS outputs are

off

or F lash Mode (PWM2>9V )

Set

WD Trigger Bit = ‚0' or write

non-inverting value to tr igger

bit after wake-up from

V1 stand by mod e

Go to standby mode

Page 19

L9952GXP Description

2.10 Fail safe output

After power-on (Vs > V

) or wakeup from V

POR

-standby mode, the output FSO is set to

BAT

“HIGH”, if V1 is above the V1 threshold. FSO is set to “LOW” in case of V1 under voltage or

watchdog failure.

During V1-standby mode, FSO is HIGH unless a V1 under-voltage or watchdog reset

occurs. WD remains enabled in V1 standby mode until I

standby mode, FSO is low. At exit from V

- standby mode, it goes to high as soon as V1

BAT

drops below 150uA. In V

V1

BAT

-

is stable.

At wakeup FSO remains high, provided that the watchdog is triggered successfully. It is set

low if the watchdog is not served during the long open window of if a V1 under-voltage

occurs.

Figure 5. FSO

TSD2

V1 undervoltage

Vbatstdby Mode

FSO = 0

Watchdog Failure

2.11 Reset – generator

IF V1 is turned on and the voltage exceeds the V1 reset threshold, the reset output

“NRESET” is switched to “HIGH” after a 2ms reset delay time. This is necessary for a

defined start of the micro controller when the application is switched on.

As soon as an under voltage condition of the output voltage (V1 < VRT) for more than 8us

appears, the reset output is switched low again.

Figure 6. NReset

Wake-up Event 1)

Vpwm2 < 9V

(Exit Flash Mode)

V1 Undervoltage

Watchdog

Failure

NReset = 0

1) Only if

(INT_en = 0) and (wake-up by WU-input or High Side Open Load)

Doc ID 13518 Rev 5 19/68

Page 20

Description L9952GXP

2.12 V1, V2 fail

The V

In case of a drop below the V

and V2 regulator output voltages are monitored.

1,

– fail thresholds (V

1, V2

bits are latched. The fail bits are cleared by a dedicated SPI command.

If 4ms after turn on of the regulator the V

voltage is below the V

1,2

(independent for V1,2 ), the L9952GXP will identify a short circuit condition at the related

regulator output and the regulator will be switched off.

In case of a V1 failure the device enters V

- standby mode automatically.

BAT

In case of a V2 failure the SHT5V2 bit (SR0 Bit12) is set.

2.13 Low side driver outputs Rel1, Rel2

The outputs Rel1, Rel2 (R

loads.

Typical relays used have the following characteristics:

Relay type 1:

– closed armature: R = 160 Ω +

– open armature: R = 160 Ω +

Relay type 2:

– closed armature: R= 220 Ω +

– open armature: R= 220 Ω +

= 2 Ω typ. @25 °C) are specially designed to drive relay

DSon

10%, L= 300mH

10%, L= 240mH

10%, L= 420mH

10%, L= 330mH

< 2V,typ for t > 2us), the V

1,2

fail thresholds,

1,2

1,2

- fail

The outputs provide an active output zener clamping (40V) feature for the demagnetisation

of the relay coil, even though a load dump condition exists. In case of watchdog failure the

relay drivers will be switched off and the low side driver control bits are cleared.

Note: 1 Due to relays bouncing, high dV/dt and/or dI/dt transients may occur on the low side driver

outputs. In case high currents are switched (for example window lift motor), due to parasitic

capacitive inductive coupling from load side of relays to the relays coils, the Absolute

Maximum Ratings of the Low Side driver outputs may be exceeded. In order to avoid this, it

is recommended to place a 10nF capacitor at the Rel1, Rel2 outputs to GND.

2 If a hard short circuit to V

required with T

> 1µs, R ≥ 1 Ω (see block diagram, the value is given for an output short

RC

is possible at the "Low Side Driver" outputs, an RC network is

BAT

circuit of given di/dt = 5A/µs).

2.14 PWM inputs

The inputs PWM 1,2 can be used to control the output drivers Out1..4 and OUT_HS with a

PWM signal. Each PWM input can be mapped individually to each of the above listed

outputs according to the SPI settings.

20/68 Doc ID 13518 Rev 5

Page 21

L9952GXP Description

2.15 Operational amplifiers

The operational amplifiers are especially designed to be used for sensing and amplifying the

voltage drop across ground connected shunt resistors. Therefore the input common mode

range includes - 0.2 ... 3V.

The operational amplifiers are designed for GND + 3V... GND – 0.2V input voltage swing

and rail-to-rail output voltage range. All Pins (positive, negative and outputs ) are available

to be able to operate in non-inverting and inverting mode. Both operational amplifiers are

on-chip compensated for stability over the whole operating range within the defined load

impedance.

Figure 7. Lin master pull up

Vs

LIN

control

T

SW

control

LIN PU

A dedicated built-in switch “Tsw” enables the LIN to act as a master. (see chapter

2.16 LIN bus interface

General requirements:

● Speed communication up to 20kbit/s

● LIN 2.0 compliant (SAEJ2602 compatible) transceiver

● Function range from +40V to -18V DC at LIN Pin

● GND disconnection fail safe at module level

● Off mode: does not disturb network

● GND shift operation at system level

● Microcontroller Interface with CMOS compatible I/O pins.

● Pull up resistor internal.

● ESD: immunity against automotive transients per ISO7637 specification (see

application note)

● Matched output slopes and propagation delay

In order to further reduce the current consumption in standby mode, the integrated LIN bus

interface offers an ultra low current consumption.

30k

Gnd

LIN

Master node

1k

pull up

2.18)

Doc ID 13518 Rev 5 21/68

Page 22

Description L9952GXP

2.17 Error handling

The L9952GXP provides the following 3 error handling features which are not described in

the LIN Spec. V2.1, but are realized in different stand alone LIN transceivers / micro

controllers to switch the application back to normal operation mode.

2.17.1 Dominant TxD time out

If TXI is in dominant state (low) for more than 12ms (typ) the transmitter will be disabled until

TXI becomes recessive (high). This feature can be disabled via SPI.

2.17.2 Short to battery time out

If TXI changes to dominant (low) state but RXI signal does not follow within 40µs, the

transmitter will be disabled until TXI becomes recessive (high).

2.17.3 Short to ground mode

A wake up caused by a message on the bus will start the voltage regulator and the micro

controller to switch the application back to normal operation mode.

2.18 Wake up (from LIN)

In standby mode the L9952GXP can receive a wake up from LIN bus. For the wake up

feature the L9952GXP logic differentiates two different conditions.

2.18.1 Normal wake up

Normal wake up can occur when the LIN transceiver was set in standby mode while LIN was

in recessive (high) state. A dominant level at LIN for at least 40µs, will switch the L9952GXP

to active mode.

2.18.2 Wake up from short to GND condition

If the LIN transceiver was set in standby mode while LIN was in dominant (low) state,

recessive level at LIN for at least 40us, will switch the L9952GXP to active mode.

2.18.3 RxD pin in V1 standby

In V1 standby condition the RxD is a tristate pin.

22/68 Doc ID 13518 Rev 5

Page 23

L9952GXP Description

2.19 LINPU

The LINPU (LIN pull up) signal is set by L9952GXP logic in order to drive the LIN transceiver

in master mode. The master mode is realized by an internal high side switch and an external

diode in series with an external 1k resistor. In master mode the high side switch is closed

causing an external pull up path in parallel to the internal one (diode & 30k resistor).

HS (high side) characteristics:

● HS does not have an over current protection.

● The HS remains active in standby mode.

● Switch off only in case of over temperature (TSD2 = thermal shutdown #2).

● Typical R

DSon

, 10 Ω.

The Linpu is activated by default (LIN master mode) and can be switched off with a SPI

command (see register 2) to reduce current in case of LIN shorted to ground.

2.20 Serial Peripheral Interface (SPI)

A 24 bit SPI command (2 adresses + 22 data bits) is used for bi-directional communication

with the micro controller.

During active mode, the SPI:

1) triggers the watchdog

2) controls the modes and status of all L9952GXP modules (incl. input and output drivers)

3) provides driver output diagnostic

4) provide L9952 diagnostic (incl. over temperature warning, L9952GXP operation status)

Note: During stand-by modes, the SPI is generally deactivated.

The SPI can be driven by a micro controller with its SPI peripheral running in following

mode:

CPOL=0 and CPHA=0.

For this mode input data is sampled by the low to high transition of the clock CLK, and

output data is changed from the high to low transition of CLK.

This device is not limited to micro controller with a build-in SPI. Only three CMOScompatible output pins and one input pin will be needed to communicate with the device. A

fault condition can be detected by setting CSN to low. If CSN = 0, the DO-pin will reflect the

global error flag (fault condition) of the device which is a logical -”OR” of all over current, Vsover / under voltage, temperature warning/shutdown and V1 Fail bits. The micro controller

can poll the status of the device without the need of a full SPI-communication cycle.

2.20.1 Chip Select Not (CSN)

The input pin is used to select the serial interface of this device. When CSN is high, the

output pin (DO) will be in high impedance state. A low signal activates the output driver and

a serial communication can be started. The state during CSN = 0 is called a communication

frame.

Doc ID 13518 Rev 5 23/68

Page 24

Description L9952GXP

2.20.2 Serial Data In (DI)

The input pin is used to transfer data serial into the device. The data applied to the DI will be

sampled at the rising edge of the CLK signal and shifted into an internal 24 bit shift register.

At the rising edge of the CSN signal the contents of the shift register will be transferred to

Data Input Register. The writing to the selected Data Input Register is only enabled if exactly

24 bits are transmitted within one communication frame (i.e. CSN low). If more or less clock

pulses are counted within one frame the complete frame will be ignored. This safety

function is implemented to avoid an activation of the output stages by a wrong

communication frame.

Note: Due to this safety functionality a daisy chaining of SPI is not possible. Instead, a parallel

operation of the SPI bus by controlling the CSN signal of the connected IC's is

recommended.

2.20.3 Serial Data Out (DO)

The data output driver is activated by a logical low level at the CSN input and will go from

high impedance to a low or high level depending on the global error flag (fault condition).

The first rising edge of the CLK input after a high to low transition of the CSN pin will transfer

the content of the selected status register into the data out shift register. Each subsequent

falling edge of the CLK will shift the next bit out.

2.20.4 Serial Clock (CLK)

The CLK input is used to synchronize the input and output serial bit streams. The data input

(DI) is sampled at the rising edge of the CLK and the data output (DO) will change with the

falling edge of the CLK signal. The SPI can be driven with a CLK frequency up to 1MHz.

2.20.5 Data registers

The device has 3 Control registers and 2 Status registers. The first two bits (D22+D23) at

the DI-Input are used to select one of the Control registers. All bits are first shifted into an

input shift register. After the rising edge of CSN the contents of the input shift register will be

written to the selected Control register only if a frame of exact 24 bits is detected. If the

Control register 1 is selected for data transfer, the Status register 1 will be transferred to the

DO during the current communication frame. For the selection of Control register 0 or

Control register 2, the Status register 0 is transferred to DO.

24/68 Doc ID 13518 Rev 5

Page 25

L9952GXP Protection and diagnosis

3 Protection and diagnosis

3.1 Power supply fail

Over and under-voltage detection on Vs.

3.1.1 Over voltage

If the supply voltage Vs reaches the over voltage threshold (V

● The outputs HS1..4, OUT_HS, Rel1,2, and LIN are switched to high impedance state

(load protection)

● The over voltage bit is set and can be cleared with the clear bit (CR1,CLR)

● Automatic recovery after Vs over-voltage; selectable via SPI (CR2, bit4)

3.1.2 Under voltage

If the supply voltage Vs drops below the under voltage threshold voltage(V

● The outputs HS1..4, OUTHS, Rel1,2, and LIN are switched to high impedance state

(load protection)

● The under voltage bit is set

● Automatic recovery after Vs under-voltage; selectable via SPI (CR2, bit4)

3.2 Temperature warning and thermal shutdown

See state chart: “ Protection and diagnosis”.

3.3 SPI diagnosis

Digital diagnosis features are provided by SPI:

● V1 reset threshold programmable

● Over temperature including pre warning

● Open load separately for each output stage

● Overload status

● Vs-supply over/under voltage

● V1 and V2 fail bit

● Status of the WU1...4, LIN and INH pin

● Cold start bit

● Number of unsuccessful V1 restarts after thermal shutdown

● Number of sequential watchdog failures

● Status of watchdog trigger bit TRIG: (SR1, Bit 16)

● LIN status (short to ground, short to V

, dominant TxD)

BAT

See the following state chart: “Protection and diagnosis”.

SOV

)

)

SUV

Doc ID 13518 Rev 5 25/68

Page 26

Protection and diagnosis L9952GXP

Figure 8. Protection and diagnosis

Tj > 155°C

>

T

SPI command: ‚CLR’

(D21 CR1)

Power- on reset

Active

Mode

Standb y Modes

SPI command: ‚CLR’

Autorestart activated

1

e

s

c

OR

SPI command: ‚CLR’

(D21 CR1)

OR

Power-on r eset

(D21 CR1)

OR

(D4 CR2)

TSD1

All outputs except V 1: off

‚TS D 1' -Bit is set (D 3 SR1 )

Tj > 140°C

Temperature

Warning

‚Te mper atu re Wa rnin g' -

Bit set

(D2 S R1)

Tj > 130°C

Vs Undervolt age

8x TSD2

(each TSD2

within 1 min)

Vbatstdby

All outputs incl V2: off

Power- on reset

Vs Overvoltage

TSD2

All outputs: off

V1: off for 1 sec

‚TSD2-bit is set (D4 SR1)

Wake-up event

SPI command: ‚CLR’

(D21 CR1)

Autorestart activated

(D4 CR2)

(during cyclic sense)

OR

Vs Lockout

All outputs : high Impedance

OV Bit set (D0 SR1)

Auto-restart if selected by SPI

8 successive watchdog

26/68 Doc ID 13518 Rev 5

failures

V1 off for

200m s

Vs Lockout

All outputs: off

UV bit set (D1 SR1)

Auto -resta rt if sele cted by SPI

7 additional watchdog failures

in sequence

Vbatstdby

mode

Page 27

L9952GXP Protection and diagnosis

3.4 High side driver outputs

The component provides a total of 4 high side outputs Out1...4, (7 Ω typ. @ 25C) to drive

e.g. LED' s or hall sensors and 1 high side output OUT_HS with 1 Ω typ. @ 25 C).

The high side outputs are protected against

● Over- and under voltage

● Overload (short circuit)

● Over temperature with pre warning

If the output current exceeds the current shutdown threshold the output transistor is turned

off and the corresponding diagnosis bit of the output is set.

The switches are automatically disabled in case of reset condition, Vs-under, Vs-over

voltage or thermal shutdown (TSD1&2).

For OUT_HS an auto recovery feature is available in active mode.

If the OUT_HS output current exceeds the current shutdown threshold, the output transistor

is turned off and the corresponding diagnosis bit of the output is set.

Via SPI command the auto recovery feature can be enabled in order to restart the driver in

case of over current shutdown. This over current recovery feature is intended for loads

which have an initial current higher than the over current limit of the output (e.g. Inrush

current of cold light bulbs).

The device itself can not distinguish between a real overload and a non linear load like a

light bulb. A real overload condition can only be qualified by time. As an example, the micro

controller can switch on light bulbs by setting the over current recovery bit for the first 50ms.

After clearing the recovery bit, the output will be automatically disabled if the overload

condition still exists.

The status of all high side outputs (over-current, open load) can be monitored by SPI

interface.

In case of a watchdog failure, the high side drivers are switched off. The control bits are not

cleared, i.e. the drivers will go to the previous state once the watchdog failure condition

disappears.

ESD structures are configured for nominal currents only. If external loads are connected to

different grounds, the current load must be limited to this nominal current.

Note: Loss of ground or ground shift with externally grounded loads.

3.5 Low side driver outputs Rel1, Rel2

The outputs provide an active output zener clamping feature for the demagnetisation of the

relay coil, even though a load dump condition exists. For safety reasons the relay drivers

are linked with the Watchdog: in case of failure, or missing trigger signal the relay drivers will

switch off.

Doc ID 13518 Rev 5 27/68

Page 28

Absolute maximum ratings L9952GXP

4 Absolute maximum ratings

Table 5. Absolute maximum ratings

Symbol Parameter Value Unit

V

S

V

1

V

2

V

DI VCLK

V

TXD VCSN

V

DO VRXD

V

NRESET VFSO

V

DIGOUT3,4

V

INH

V

PWM1, VPWM2,

V

REL1, VREL2,

V

OUT1..4,, VOUTH

V

WU1...4,

V

OP1+,VOP1-,

V

OP2+, VOP2-,

V

OPOUT1,

V

OPOUT2

V

LIN, VLINPU

I

Input

DC supply voltage / “jump start” -0.3 to +28 V

Single pulse / t

“transient load dump”

Stabilized supply voltage, logic

supply

< 400 ms

max

-0.3 to +40 V

-0.3 to +5.25 V

Stabilized supply voltage -0.3 to +28 V

Logic input / output voltage range -0.3 to V1+0.3 V

Wake up input voltage range

PWM input voltage range

-0.3 to +40 V

Low side output voltage range

High side output voltage range -0.3 to VS + 0.3 V

Wake up input voltage range -0.3 to VS + 0.3 V

Opamp1 input voltage range

Opamp2 input voltage range

-0.3 to V1 + 0.3 V

Analog Output voltage range -0.3 to VS + 0.3 V

LIN bus I/O voltage range -20 to +40 V

Current injection into Vs related

input pins

5mA

Note: All maximum ratings are absolute ratings. Leaving the limitation of any of these values may

cause an irreversible damage of the integrated circuit !

28/68 Doc ID 13518 Rev 5

Page 29

L9952GXP ESD protection

5 ESD protection

Table 6. ESD protection

Parameter Value Unit

(2)

(1)

+/- 2 kV

+/- 4 kV

+/- 1.5 kV

+/- 8 kV

All pins, except LIN

All output pins

(3)

LIN

(4)

LIN

All pins (charge device model)

Corner pins (charge device model)

(5)

All pins

+/- 500 V

+/- 750 V

+/- 200 V

1. HBM (human body model, 100pF, 1.5 kΩ ) according to MIL 883C, Method 3015.7 or EIA/JESD22A114-A

2. HBM with all none zapped pins grounded

3. Without external components

4. Acc. DIN EN61000-4-2 (330Ω, 150pF), with external components:

- Diode, type ESDLIN1524BJ

- SMD Ferrite bead, type TDKMMZ2012Y202B

- Capacitor C=220pF

For detailed information please see EMC report from IBEE Zwickau (available on request)

5. Acc. Machine Model: C=220pF; L=0.75µH; R=10Ω

Doc ID 13518 Rev 5 29/68

Page 30

Thermal data L9952GXP

6 Thermal data

6.1 Operating junction temperature

Table 7. Operating junction temperature

Item Symbol Parameter Value Unit

6.1.1 Tj Operating junction temperature - 40 to 150 °C

6.1.2 RthjA Thermal resistance junction- ambient See Figure 10. °C/W

6.2 Temperature warning and thermal shutdown

Table 8. Temperature warning and thermal shutdown

Item Symbol Parameter Min. Typ. Max. Unit

6.2.1 T

6.2.2 T

6.2.3 T

6.2.4 T

6.2.5 T

1. Non-overlapping

W ON

SD1 OFF

SD2OFF

SD2 ON

SD12hys

Thermal over temperature

warning threshold

Thermal shutdown

junction temperature 1

Thermal shutdown

junction temperature 2

(1)

T

j

(1)

T

j

(1)

T

j

120 130 140 °C

130 140 150 °C

140 155 170 °C

Hysteresis 5 °C

30/68 Doc ID 13518 Rev 5

Page 31

L9952GXP Thermal data

6.3 Package and PCB thermal data

Figure 9. PowerSSO-36 PC board

Note: Layout condition of Rth and Zth measurements ( board finish thickness 1.6 mm +/- 10%

board double layer, board dimension 129x60, board Material FR4, Cu thickness 0.070mm

(front and back side), thermal vias separation 1.2 mm, thermal via diameter 0.3 mm +/- 0.08

mm, Cu thickness on vias 0.025 mm ).

Doc ID 13518 Rev 5 31/68

Page 32

Thermal data L9952GXP

Figure 10. PowerSSO-36 thermal resistance junction ambient Vs. PCB copper area

(V1 ON)

RTHj _amb(°C/ W)

110

90

70

50

30

0246810

PCB Cu heatsink area (cm^ 2)

Figure 11. PowerSSO-36 thermal impedance junction ambient single pulse (V1 ON)

ZTH (° C/ W)

1000

Footprint

100

2 cm

8 cm

2

2

10

1

0,1

0,01 0,1 1 10 100 1000

Time ( s)

32/68 Doc ID 13518 Rev 5

Page 33

L9952GXP Thermal data

Equation 1: pulse calculation formula

Z

THδ

where δ = t

R

P

TH

/T

δ Z

THtp

1 δ–()+⋅=

Figure 12. PowerSSO-36 thermal fitting model (V1 ON)

Table 9. Thermal parameters

Area/island (cm2)Footprint28

R1 (°C/W) 5

R2 (°C/W) 18 10 10

R3 (°C/W) 29 22 7,8

R4 (°C/W) 51 29 21

C1 (W.s/°C) 0,0003

C2 (W.s/°C) 0,35 1 1

C3 (W.s/°C) 1,5 1,3 1,3

C4 (W.s/°C) 5 15 15

Doc ID 13518 Rev 5 33/68

Page 34

Electrical characteristics L9952GXP

7 Electrical characteristics

7.1 Supply and supply monitoring

The voltages are referred to ground and currents are assumed positive, when the current

flows into the pin. 6V <

unless otherwise specified.

Table 10. Supply and supply monitoring

Item Symbol Parameter Test condition Min. Typ. Max. Unit

V

< 18V; 4.8V < V1 < 5.2V; all outputs open; Tj = -40°C...130°C,

S

7.1.1 V

7.1.2 V

7.1.3 V

7.1.4 V

7.1.5 V

7.1.6 I

7.1.7 I

7.1.8 I

V(BAT)CS

7.1.9 I

7.1.10 I

7.1.11 I

V(BATWU)

V(V1WU)

S

SUV

hyst_UV

SOV

hyst_OV

V(act)

V(BAT)

V(V1)

Supply voltage range 6 13.5 18 V

V

increasing /

VS UV-threshold voltage

S

decreasing

5.11 5.81 V

Undervoltage hysteresis 0.04 0.1 0.15 V

VS OV-threshold voltage

S

decreasing

18 22 V

increasing /

V

Overvoltage hysteresis Hysteresis 0.5 1 1.5 V

Vs=12V, TxD LIN

Current concumption in

active mode

high, V2 on,

Outputs off

2.7 20 mA

Iv1=Iv2=0A

VS=12V, both

Current consumption in

V

- standby mode

BAT

voltage regulators

deactivated, no

1 7 10 µA

wake-up request

V

=12V, both

Current consumption in

- standby mode

V

BAT

S

voltage regulators

deactivated, (cyclic

40 75 100 µA

sense)

V1=5V, VS=12V,

Current consumption in

-standby mode

V

1

Voltage regulator

V1 active, without

cyclic sense, no

10 45 70 µA

wake-up request

Current consumption in

-standby mode with a

V

BAT

1.5V<VWU<(Vs-3V) 220 320 µA

pending wake up request

Current consumption in

V1- standby mode with a

1.5V<VWU<(Vs-3V) 300 410 µA

pending wake up request

34/68 Doc ID 13518 Rev 5

Page 35

L9952GXP Electrical characteristics

7.2 Oscillator

6V < V

Table 11. Oscillator

< 18V; all outputs open; Tj = -40°C...130°C, unless otherwise specified.

S

Item Symbol Parameter Test condition Min. Typ. Max. Unit

7.2.1 F

CLK

Oscillation frequency Vs = 6V...18V

7.3 Power-on reset (Vs)

All outputs open; Tj = - 40°C...130 °C, unless otherwise specified.

Table 12. Power-on Reset (Vs)

Item Symbol Parameter Test condition Min. Typ. Max. Unit

7.3.1 V

7.3.2 V

THUP_POR

Hys_POR

V

POR

7.4 Voltage regulator V1

The voltages are referred to ground and currents are assumed positive, when the current

flows into the pin. 5.25V <

Table 13. Voltage regulator V1

V

S

0.808

1.01 1.35 MHz

threshold 2.8 3.45 4.1 V

Hysteresis 200 mV

< 27V; Tj = -40°C...130°C, unless otherwise specified.

Item Symbol Parameter Test condition Min. Typ. Max. Unit

7.4.1 V1 Output voltage 5.0 V

I

= 1mA...

7.4.2 V1

7.4.3 Vhc1

7.4.4 VSTB1

7.4.5 VDP1

7.4.6 ICC1

Output voltage tolerance

Active mode

Output voltage tolerance

Active mode, high current

Output voltage tolerance

in low current mode

Drop-out voltage in

undervoltage conditions

Output current in active

mode

LOAD

100mA,

VS = 13.5V

I

= 100mA ...

LOAD

250mA,

VS = 13.5V

I

= 250mA

LOAD

VS = 13.5V,

>80°C

T

j

0mA< I

LOAD<ICMP

VS = 13.5V

I

= 50mA,

LOAD

VS = 4.5V

= 100mA,

I

LOAD

=4.5V

V

S

Max. continuous

load current

+/- 2 %

+/- 3 %

+/- 4 %

0.2

0.3

+/- 4 %

0.4

0.5V V

250 mA

Doc ID 13518 Rev 5 35/68

Page 36

Electrical characteristics L9952GXP

Table 13. Voltage regulator V1 (continued)

Item Symbol Parameter Test condition Min. Typ. Max. Unit

7.4.7 ICCmax1

Short circuit output

current

7.4.8 Cload1 Load capacitor1 Ceramic

7.4.9 tTSD

7.4.10 I

7.4.11 I

7.4.12 I

CMP_ris

CMP_fal

CMP

_hys Current comp. hysteresis 0.5 mA

V1 deactivation time after

thermal shutdown

Current comp. rising

threshold

Current comp. falling

threshold

7.4.13 V1fail V1 fail threshold V1 forced 2 V

1. Placement close to the PAD

7.5 Voltage regulator V2

The voltages are referred to ground and currents are assumed positive, when the current

flows into the pin. 5.25V <

Table 14. Voltage regulator V2

Item Symbol Parameter Test condition Min. Typ. Max. Unit

V

S

Current limitation 400 600 950 mA

(1)

0.22 µF

1 s

Rising current 0.9 2.5 4 mA

Falling current

Tj= -40°C...130°C

Tj= 25°C...130°C

0.75

0.85

1.95

1.95

< 27V; Tj = -40°C...130°C, unless otherwise specified.

mA

7.5.1 V

7.5.2 V

7.5.3 V

7.5.4 V

7.5.5 V

7.5.6 I

7.5.7 I

7.5.8 C

7.5.9 V2

1. Placement close to the PAD

2

2

hc1

STB2

DP2

CC2

CCmax2

load

fail

Output voltage 5.0 V

Output voltage tolerance

Active mode

Output voltage tolerance

Active mode, high current

Output voltage tolerance in

low current mode

Drop-out voltage

Output current in Active

mode

I

= 1mA ...

LOAD

50mA, V

I

LOAD

= 13.5V

S

= 50mA ...

100mA, VS = 13,5V

I

= 0uA ...1mA

LOAD

V

= 13,5V

S

I

= 25mA,

LOAD

= 5 V

V

S

= 50mA,

I

LOAD

= 5 V

V

S

Max. continuous

load current

0,3

0.4

+/- 3 %

+/- 4 %

+/- 5 %

0,4

0.7 VV

100 mA

Short circuit output current Current limitation 200 300 500 mA

Load capacitor Ceramic

(1)

0.22 µF

V2 fail threshold V2 forced 2 V

36/68 Doc ID 13518 Rev 5

Page 37

L9952GXP Electrical characteristics

7.6 Reset generator (V1 supervision)

The voltages are referred to GND and currents are assumed positive, when the current

flows into the pin. 5.25V < V

Table 15. Reset generator

Item Symbol Parameter Test condition Min. Typ. Max. Unit

= 18V; Tj = -40 to 130 °C, unless otherwise specified.

S

7.6.1 V

7.6.2 V

7.6.3 V

7.6.4 R

7.6.5 t

RT1

RT2

RESET

RESET

RR

7.6.6 V1 under-voltage filter time 16 µs

7.7 Watchdog

6V < VS < 18V; 4.8V < V1 < 5.2V; Tj = -40 to 130 °C, unless otherwise specified

Table 16. Watchdog

Item Symbol Parameter Test condition Min. Typ. Max. Unit

7.7.1 t

7.7.2 t

7.7.3 t

7.7.4 t

1. See Figure 13.

LW

CW

OW

WDR

Reset threshold voltage1

Reset threshold voltage2

Reset pin low output

voltage

V

V

I

inc. /

S, VV1

decreasing

inc. /

S, VV1

decreasing

V1 > 1V,

= 1mA

RESET

4.5 4.63 4.75 V

4.25 4.37 4.5 V

0,2 0,4 V

Reset pull up int. resistor 60 110 204 kΩ

Reset reaction time @Iload = 1mA 6 40 µs

(1)

Long open window 48,75 65 81,25 ms

Closed window 4.5 6 7.5 ms

Open window 7.5 10 12.5 ms

Watchdog reset pulse time 1.5 2 2. 5 ms

Doc ID 13518 Rev 5 37/68

Page 38

Electrical characteristics L9952GXP

Figure 13. Watchdog timing

Normal startup operation and timeout failures

WDtrigger

NRESOut

0

Missing uC trigger signal

= correct trigger timing

= early trig ger timin g

= missin g trigg er

TCW+ T

OW

T

LW

normal operation m issing

TCW+ T

OW

trigger

TLW= long window < 65ms

T

= closed window < 6ms

CW

T

= open window < 10ms

OW

T

= watchdog reset = 2ms

WDR

T

CW

trigger signal

time / ms

time / ms

WDR

early

write

T

LW

T

LW

T

WDR

T

WDtrigger

T

LW

T

LW

T

LW

time / ms

NRESOut

0