■

ONE FULL BRIDGE FOR 6A LOAD (ron= 150mΩ)

■ THREE HALF BRIDGES FOR 1.6 A LOAD

(r

= 800mΩ)

on

■ ONE HIGHSIDE DRIVER FOR 6A LOAD

(r

= 100mΩ)

on

■ VERY LOW CURRENT CONSUMPTION IN

STANDBY MODE (I

■ SERIAL PERIPHERAL INTERFACE (SPI) TO

< 6µA, typ. Tj ≤ 85°C)

S

MICROCONTROLLER

■

ALL OUTPUTS SHORT CIRCUIT PROTECTED

■ CURRENT MONITOR OUTPUT FOR FULL

BRIDGE AND HIGHSIDE DRIVER

■ ALL OUTPUTS OVER TEMPERATURE

PROTECTED

■

OPEN LOAD DIAGNOSTIC FOR ALL OUTPUTS

■

OVERLOAD DIAGNOSTIC FOR ALL OUTPUTS

L9949

DOOR ACTUATOR DRIVER

MULTIPOWER BCD60III TECHNOLOGY

PowerSO20

ORDERING NUMBER: L9949

FULL BRIDGE FOR DOOR LATCH OR

MIRROR RETRACT, HALF BRIDGES FOR

MIRROR AXIS CONTROL AND HIGH-SIDE

DRIVER FOR MIRROR DEFROSTER

APPLICATIONS

■ FOR AUTOMOTIVE APPLICATI ONS, E.G.

BLOCK DIAGRAM

V

CC

CM

MUX

DI

DO

µC

CLK

CSN

SPI

Driver Interface & Diagnostic

DESCRIPTION

The L9949 is a microprocessor control led power interface for automotive applications. It is realized in

multipower BCD60III technology. Up to three D C mo-

V (battery)

S

OUT1

Full bridge

OUT2

OUT3

Half bridge

OUT4

Half bridge

OUT5

OUT6

Highside driver

M

M

M

e.g. for mirror retract

or door latch

e.g. for mirror

axis control

e.g. for mirror

defroster

September 2002

Ground

1/20

L9949

DESCRIPTION

(continued)

tors and one grounded resistive load can be driven with its three half bridges, one full bridge and one highside

driver power outputs. The integrated standard serial peripheral interface (SPI) controls all operation modes (forward, reverse, brake and high impedance). All diagnostic informations are available via the SPI.

Dual Power Supply: VS and V

CC

The power supply voltage VS supplies the ful l bridge, the half bridges and the highside driver. An internal

charge-pump are used to drive the highside switches. The logic supply voltage V

(stabilized 5V) is used for

CC

the logic part and the SPI of the device. Due to the independent logic supply voltage the control and status information will not be lost, if there are temporary spikes or glitches on the power supply voltage. In case of poweron (V

power-on-reset (POR). If the voltage V

increases from undervoltage t o V

CC

VCC OFF

decreases under the minimum threshold (V

CC

= 4.2V) the ci rcuit i s ini tialized by an internall y generated

VCC ON

= 3.4V), the out-

puts are switched to tristate (high impedance) and the status registers are cleared.

Standby-Mode

The standby mode of the L9949 is activated by setting the bits 12 and 13 of the Input Data Register to zero. All

latched data will be cleared and the inputs and out puts are switc hed to high impedance. In t he st andby mode

the current at V

(VCC) is less than typ. 6µA (40µA) for CSN = high (DO in tristate). By switching the VCC voltage

S

a very low quiescent current can be achieved. If one of the bits 12 and 13 are set to high, the device will be

switched to active mode.

Inductive Loads

Each half bridge is built by internally connected highside and a lowside power DMOS transistor. Due to the builtin reverse diodes of the output transistors inductive loads can be driven at the outputs OUT1 to OUT5 without

external free-wheeling diodes. The highside driver OUT6 is intended to drive resistive loads only hence only a

limited energie (E<1mJ ) can be dissipated by the i nt ernal ESD-diode in f reewheeli ng conditi on. For i nduct ive

loads (L>100

µ

H) an external free-wheeling diode connected to GND and OUT6 is needed.

Diagnostic Functions

All diagnostic functions (over /open load, power supply over-/undervoltage, temperature warning and thermal

shutdown) are internally filtered and the condition has to be valid for at least 10µs (0.5ms, respectively) before

the corresponding status bit in the status registers will be set. The filters are used to improve the noise immunity

of the device. The open load and temperature warning function are intended for informati on purpose and will

not change the state of the output drivers. In contrast, the overload and thermal shutdown condition will disable

the corresponding driver (overload) or all dr ivers ( t hermal shut down), respectiv ely. The micr ocontroller has to

clear the status bits to reactivate the corresponding drivers. This is to avoid an uncontrolled switching behaviour

of the device which may result in a heavy noise on the GND and V

to GND o r V

).

S

lines in case of an fault condition (e.g. short

S

Overvoltage and Undervoltage Detection

If the power supply voltage VS rises above the overvoltage threshold V

SOV OFF

(max. 22V), the outputs OUT1

to OUT6 are switched to high impedance state to protect the load. If the supply voltage recovers to normal operating voltage, the device will return to the programmed state (lockout bit 14 = 0). When the voltage V

below the undervoltage threshold V

SUV OFF

(min. 6V), the output stages are switc hed to high impedance to

drops

S

avoid the operation of the power devices without sufficient gate driving voltage (increased power dissipation). If

the supply voltage V

and the internal charge-pump recovers to normal operating voltage the syste m returns to

S

the programmed state (lockout bit 14 = 0). If the lockout bit 14 is set, the automatic turn-on of the drivers is deactivated. The microcontroller needs to clear the status bits to reactivate the drivers.

2/20

L9949

Temperature Warning and Thermal Shutdown

When the junction temperature rises above T

If the junction temperature increases above the second threshold T

the power DMOS transistors of the out put stages are switched off to protect the devic e. I n order t o reac tivate

the output stages the junction temperature must decrease below T

has to be cleared by the microcontroller.

Open Load Detection

The open load detection monitors the voltage drop of current sense resistors in each highside and lowside driver

of the output stage. The output s i gnal of an open l oad comparator has to be v al id for at l east 0.5 ms (t

set the open load bit (bit 1-11) in the status register 1.

Over Load Detection

In the case of an overcurrent condition an overcurrent fl ag (bit 1-11) is set in the stat us regist er 0 i n the same

way as open load detection. If the overcurrent signal is valid for at least t

and the corresponding driver is switched off to reduce the power dissipation and to protect the integrated circuit.

The microcontroller has to clear the status bits to reactivate the corresponding driver.

Current monitor

The current monitor output sources a current image at the current monitor output which has a fi xed ratio (1/

10000) of the instantaneous current of the selected highside driver. The bits 12 and 13 of the Input Data register

controls which of the outputs OUT1, OUT2 and OUT6 will be multiplexed to the current monitor output. The current monitor output allows a more precise analyse of the actual s tate of the load rather than the detection of an

open- or overload condition. For example this can be used to detect the motor state (free-running, loaded or

blocked) or the temperature of the heating element.

a temperature warning flag is set and is available via the SPI.

j TW

, the thermal shutdown bit will be set and

j SD

j SD

- T

j SD HYS

ISC

and the thermal shutdown bit

= 10µs, the overcurrent flag is set

dOL

) to

Figure 1. Pin Connection (Top view)

GND GND

OUT3 OUT6

OUT4

OUT5

VS

CLK

DI

VS

OUT1

GND

1

2

3

4

5

6

7

8

9

D99AT455Amod

20

19

18

17

16

15

14

13

12

11

VS

DO

CM

VCC

CSN

VS

OUT2

GND10

3/20

L9949

PIN FUNCTION

N° Pin Description

1, 10,

11, 20

5, 8, 13, 18V

15 V

14 CSN Chip Select Not input:

6CLKSerial clock input:

7 Data In Serial data input:

17 Data Out Serial data output:

16 CM Current monitor output:

GND Ground:

Reference potential

Important:

externally connected !

Power supply voltage (battery):

S

For this input a ceramic capacitor as close as possible to GND is recommended.

Important:

externally connected !

Logic supply voltage:

CC

For this input a ceramic capacitors as close as possible to GND are recommended.

This input is low active and requires CMOS logic levels. The serial data transfer between L9949

and micro controller is enabled by pulling the input CSN to low level. If an input voltage of more

than 9.6V above VCC is applied to CSN pin the L9949 will be switched into a test mode.

This input controls the internal shift register of the SPI and requires CMOS logic levels.

The input requires CMOS logic levels and receives serial data from the microcontroller. The data

is an 16bit control word and the least significant bit (LSB, bit 0) is transferred first.

The diagnosis data is available via the SPI and this tristate-output. The output will remain in

tristate, if the chip is not selected by the input CSN (CSN = high)

Depending on the multiplexer bits 12 and 13 of the Input Data register this output sources an

image of the instant current through the corresponding highside driver with a ratio of 1/10000

For the capability of driving the full current at the outputs all pins of GND must be

For the capability of driving the full current at the outputs all pins of VS must be

9OUT1Halfbridge-output 1:

The output is built by a highside and a lowside switch, which are internally connected. The

output stage of both switches is a power DMOS transistor. Each driver has an internal parasitic

reverse diode (bulk-drain-diode, highside driver from OUT1 to V

OUT1). This output is overcurrent and open load protected.

12 OUT2

2OUT3Halfbridge-output 3:

3OUT4

4OUT5

19 OUT6 Highside-driver-output 6:

Halfbridge-output 2:

The output is built by a highside and a lowside switch, which are internally connected. The

output stage of both switches is a power DMOS transistor. Each driver has an internal parasitic

reverse diode (bulk-drain-diode, highside driver from OUT3 to VS, lowside driver from GND to

OUT3). This output is overcurrent and open load protected.

Halfbridge-output 4:

Halfbridge-output 5:

The output is built by a highside switch and can be used only for a resistive load, because the

internal reverse diode from GND to OUT6 is missing. This highside switch is a power DMOS

transistor with an internal parasitic reverse diode from OUT6 to V

is overcurrent and open load protected.

→ see OUT1 (pin 9)

→ see OUT3 (pin 2)

→ see OUT3 (pin 2)

, lowside driver from GND to

S

(bulk-drain-diode). The output

S

4/20

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

L9949

V

V

CC

VDI VDO

V

CLK

V

CSN

V

CM

I

OUT1,OUT2,

OUT6

I

OUT3,OUT5

Note: All m axim um ra tin gs are a bsol ute r atings . Leav ing the l imi tatio n of any one of thes e val ues m ay c ause an irre vers ibl e dam age of the

integrated circuit!

DC supply voltage -0.3...28 V

S

single pulse t

< 400 ms 40 V

max

stabilized supply voltage, logic supply -0.3 to 6 V

digital input / output voltage -0.3 to VCC + 0.3 V

,

current monitor output -0.3 to VCC + 0.3 V

output current ±10 A

output current ±5 A

ESD PROTECTION

Parameter Value

All pins

output pins: OUT1 – OUT6

(1) HBM according to MIL 883C, Methode 3015.7 or EIA/JESD22-A114-A

(2) HBM with all unzapped pins grounded

±2

±4

(1)

(2)

kV

kV

THERMAL DATA

Symbol Parameter Value Unit

Operating junction temperature:

T

Temperature warning and thermal shutdown:

Symbol Parameter Min. Typ. Max. Unit

T

jTW ON

T

jTW OFF

T

jTW HYS

T

jSD ON

T

jSD OFF

T

jSD HYS

Operating Junction Temperature -40 to 150 °C

j

Temperature Warning Threshold

Tj increasing 150 °C

Junction Temperature

Temperature Warning Threshold

Tj decreasing 120 °C

Junction Temperature

Temperature Warning Hysteresis 10 K

Thermal Shutdown Threshold

Tj increasing 180 °C

Junction Temperature

Thermal Shutdown Threshold

Tj decreasing 150 °C

Junction Temperature

Thermal Shutdown Hysteresis 10 K

5/20

L9949

Figure 2. Thermal Data of Package

Z (˚C/W)

th

PowerSO20 Z

th(j-a)

1x1 sq. mm

2x2 sq. mm

3x3 sq. mm

silicon

diss. area dimensions

10

diss. area

1

die size 6x6 sq. mm

0.1

4x4 sq. mm

5x5 sq. mm

mounted on standard board

T = 20˚C

amb

still air

dissipated power 1 W - single pulse

diss. area located in a corner

0.001 0.01 0.1

1

10 100 1000

Time (s)

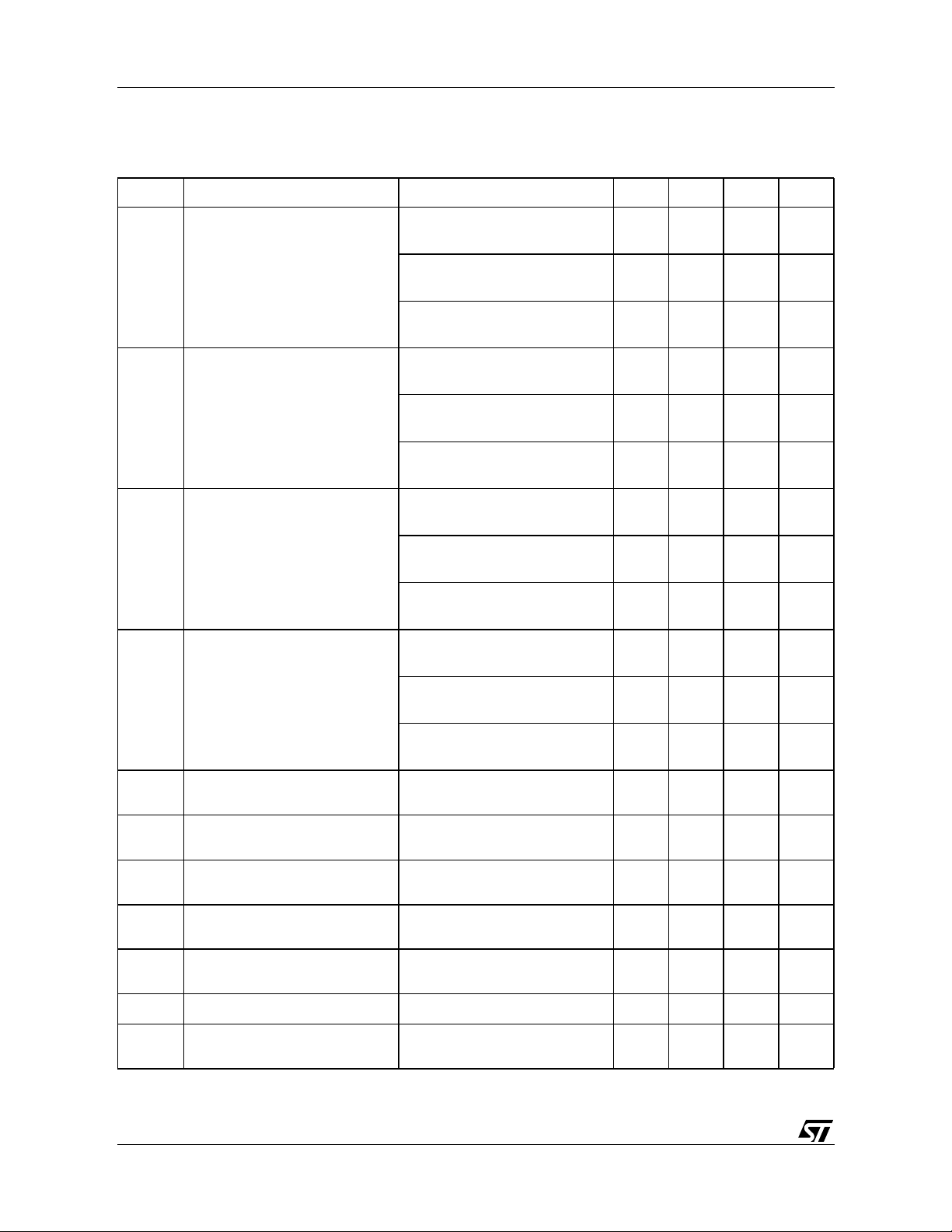

ELECTRICAL CHARACTERISTCS

VS=8to16V, VCC= 4.5 to 5.5 V, Tj= -40 to 150 °C, unless otherwise specified. The voltages are refered to

GND and currents are assumed positive, when the current flows into the pin

Symbol Parameter Test Condition Min. Typ. Max. Unit

.

Supply

V

I

I

S+ICC

Operating Supply Voltage

S

Range

I

DC Supply Current active mode,

S

Quiescent Supply Current standby mode,

DC Supply Current active mode, CSN = VCC,

CC

Quiescent Supply Current

Sum Supply Quiescent Current standby mode, CSN = VCC,

=16V, VCC= 5.3 V,

V

S

OUT1 - OUT6 floating

V

=16V, VCC=0V,

S

T

j

OUT1 - OUT6 floating

V

S

standby mode, CSN = VCC,

VS=16V

T

j

OUT1 - OUT6 floating

VS=16V, VCC= 5.3 V, Tj<85°C

OUT1 - OUT6 floating

(1)

<85°C

=16V; VCC= 5.3 V

, VCC= 5.3V,

(1)

<85°C

728V

720mA

612µA

12mA

40 75 µA

50 90 µA

6/20

L9949

ELECTRICAL CHARACTERISTCS

V

=8to16V, VCC= 4.5 to 5.5 V, Tj= -40 to 150 °C, unless otherwise specified. The voltages are refered to

S

GND and currents are assumed positive, when the current flows into the pin

(continued)

.

Symbol Parameter Test Condition Min. Typ. Max. Unit

(1) Param eter is measured at - 40°C and 25°C. Value fo r 85°C is guaranteed by des i gn

Over- and undervoltage detection

V

SUV ONVS

V

SUV OFFVS

V

SUV hystVS

V

SOV OFFVS

V

SOV ONVS

V

SOV

hyst

V

VCC OFF

V

VCC ON

V

VCC

hyst

UV-Threshold Voltage VS increasing 7.6 V

UV-Threshold Voltage VS decreasing 6 V

UV-hysteresis V

SUV ON

– V

SUV OFF

0.6 V

OV-threshold voltage VS increasing 22 V

OV-threshold voltage VS decreasing 18 V

VS OV-hysteresis V

SOV OFF

– V

SOV ON

1V

Power-on-reset Threshold VCC increasing 4.2 V

Power-on-reset Threshold VCC decreasing 3.4 4 V

Power-on-reset Hysteresis V

VCC OFF

– V

VCC ON

0.3 V

Current Monitor Output

V

I

CM,r

I

CM acc

Functional Voltage Range VCC=5V 0 4 V

CM

Current Monitor Output Ratio:

I

CM/IOUT1,2,6

Current Monitor Accuracy 0V ≤ VCM ≤ 4V,

Outputs: OUT1 - OUT6

R

ON OUT1

R

ON OUT2

On-resistance to Supply or GND VS= 13.5 V, Tj= 25 °C,

On-resistance to Supply or GND VS= 1 3.5 V, Tj= 25 ° C,

0V≤VCM≤ 4V -

=50µA, 600 µA

I

CM

(FS=full scale=600µA)

1

----------------

10000

4%

+

1%FS

8%

+

2%FS

150 mΩ

I

= ±3.0 A

OUT1

VS= 1 3.5 V, Tj= 125 °C,

I

= ± 3.0 A

OUT1

VS= 8.0 V, Tj=25°C,

I

= ± 3.0 A

OUT1

225 mΩ

180 mΩ

150 mΩ

I

= ± 3.0 A

OUT2

= 1 3.5 V, Tj= 125 °C,

V

S

I

= ± 3.0 A

OUT2

VS= 8.0 V, Tj=25°C,

I

= ± 3.0 A

OUT2

225 mΩ

180 mΩ

7/20

L9949

ELECTRICAL CHARACTERISTCS

V

=8to16V, VCC= 4.5 to 5.5 V, Tj= -40 to 150 °C, unless otherwise specified. The voltages are refered to

S

GND and currents are assumed positive, when the current flows into the pin

(continued)

.

Symbol Parameter Test Condition Min. Typ. Max. Unit

R

ON OUT3

R

ON OUT4

R

ON OUT5

On-resistance to Supply or GND VS= 1 3.5 V, Tj= 25 ° C,

I

= ± 0.8 A

OUT3

VS= 1 3.5 V, Tj= 125 °C,

I

= ± 0.8 A

OUT3

VS= 8.0 V, Tj=25°C,

I

= ± 0.8 A

OUT3

On-resistance to Supply or GND VS= 1 3.5 V, Tj= 25 ° C,

I

= ± 0.8 A

OUT4

VS= 1 3.5 V, Tj= 125 °C,

I

= ± 0.8 A

OUT4

VS= 8.0 V, Tj=25°C,

I

= ± 0.8 A

OUT4

On-resistance to Supply or GND VS= 1 3.5 V, Tj= 25 ° C,

I

= ± 0.8 A

OUT5

VS= 1 3.5 V, Tj= 125 °C,

I

= ± 0.8 A

OUT5

800 mΩ

1250 mΩ

980 mΩ

800 mΩ

1250 mΩ

980 mΩ

800 mΩ

1250 mΩ

R

ON OUT6

|I

OUT1

On-resistance to Supply VS= 1 3.5 V, Tj= 25 ° C,

| Output Current Limitation to

VS= 8.0 V, Tj=25°C,

I

= ± 0.8 A

OUT5

I

= - 2.5 A

OUT6

= 1 3.5 V, Tj= 125 °C,

V

S

I

= - 2.5 A

OUT6

= 8.0 V, Tj=25°C,

V

S

I

= - 2.5 A

OUT6

sink and source, current ramp 6 10 A

980 mΩ

100 mΩ

150 mΩ

120 mΩ

Supply or GND

|I

| Output Current Limitation to

OUT2

sink and source, current ramp 6 10 A

Supply or GND

|I

| Output Current Limitation to

OUT3

sink and source, current ramp 1.6 2.5 A

Supply or GND

|I

| Output Current Limitation to

OUT4

sink and source, current ramp 1.6 2.5 A

Supply or GND

|I

| output current limitation to Supply

OUT5

sink and source, current ramp 1.6 2.5 A

or GND

| Output Current Limitation to GND source, current ramp 6.3 11 A

|I

OUT6

|I

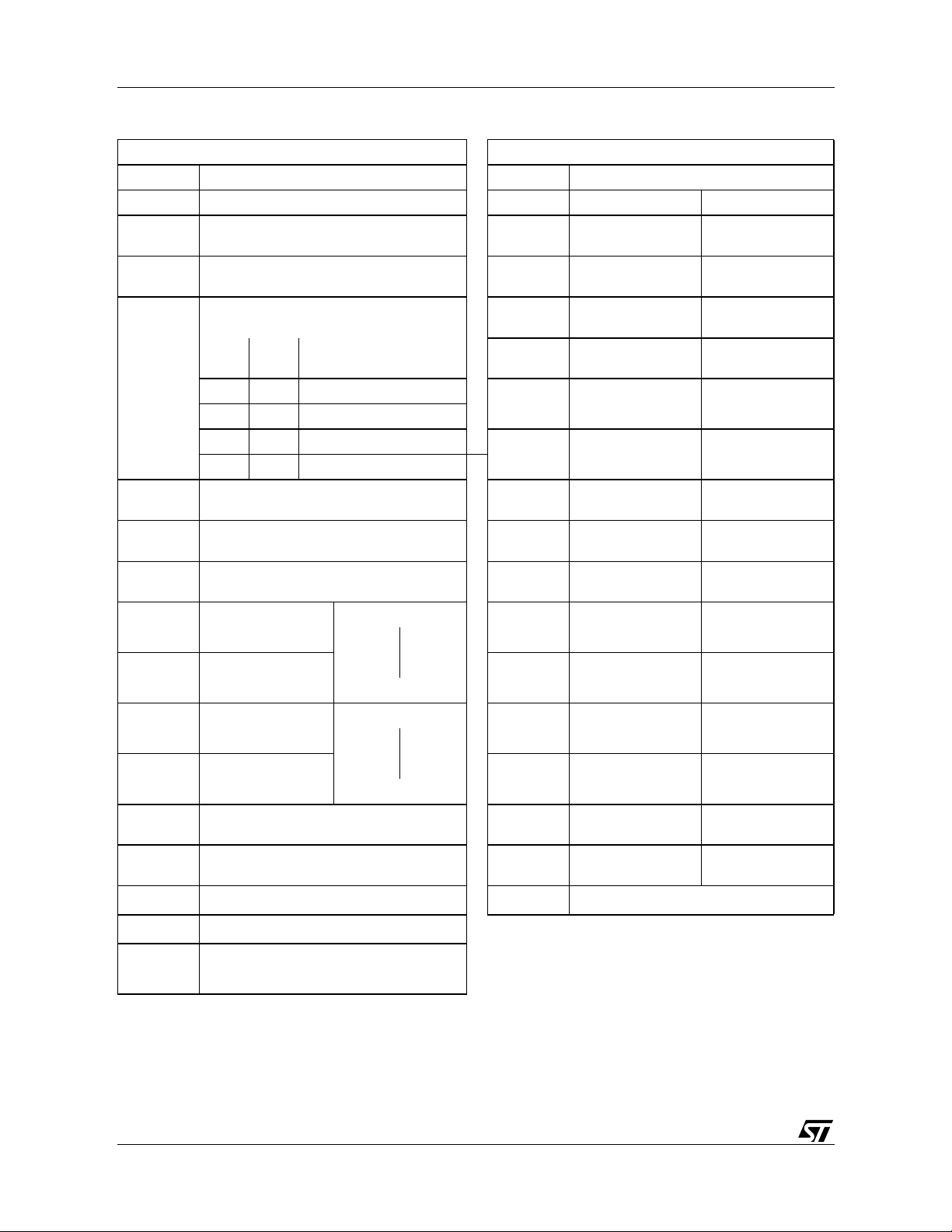

For details of the on-resistance (Ron over temperature) see the figur es „Typical ron characteristics“ for the differential output stages

(FIGURE 3, FIGURE4 , FIGURE 5)

OUT6/res

|

Output Current Limitation to GND

switching into resistive load

source, switching into resistive

load, go-nogo test

5.1 11 A

8/20

Figure 3. TYP ICAL RON CHARACTERISTICS OUT1,2

V

160

140

120

100

L9949

80

60

Ron [mOhm]

40

20

0

-40 -20 0 20 40 60 80 100 120

TEMP [C]

Figure 4. TYP ICAL RON CHARACTERISTICS OUT3,4,5

1100

1000

900

800

700

HS 13.5V

HS 8V

LS 13.5

LS 8V

600

500

400

Ron [mOhm]

300

200

100

0

-40 -20 0 20 40 60 80 100 120

HS 13.5V

HS 8

LS 13.5

LS 8V

TEMP [C]

9/20

L9949

0

Figure 5. TYP ICAL RON CHARACTERISTICS OUT6

110

100

90

80

70

60

50

Ron [m Ohm]

40

30

20

10

0

-40 -20 0 2

40 60 80 100 120

TEMP [C]

HS 13.5V

HS 8V

ELECTRICAL CHARACTERISTCS

VS=8to16V, VCC= 4.5 to 5.5 V, Tj= -40 to 150 °C, unless otherwise specified. The voltages are refered to

GND and currents are assumed positive, when the current flows into the pin

Symbol Parameter Test Condition Min. Typ. Max. Unit

OUTPUTS: OUT1 - OUT6

t

d ON H

Output Delay Time,

Highside Driver On

t

d OFF H

Output Delay Time,

Highside Driver Off

t

d ON L

Output Delay Time,

Lowside Driver On

t

d OFF L

Output Delay Time,

Lowside Driver Off

t

D HL

t

D LH

I

QLH

Dead Time, Source to Sink t

Dead Time, Sink to Source t

Leakage Current Highside

Drivers of OUT1-6

VS= 13,5 V

corresponding low side driver is

not active

VS= 13,5 V 80 150 300 µs

VS= 13,5 V

corresponding highside driver is

not active

VS= 13.5 V 80 150 300 µs

(HS was on) - t

d ON L

d ON H

V

OUT1-6

V

OUT1-6

(LS was on) - t

= 0 V, standby mode 0 2 5 µA

= 0 V, active mode -40 -15 0 µA

d OFF H

d OFF L

.

20 40 80 µs

20 40 80 µs

5200µs

5200µs

I

QLL

Leakage Current Lowside Drivers

V

OUT1-5=VS

, standby mode 0 7 20 µA

of OUT1-5

V

OUT1-5=VS

, active mode -40 -15 0 µA

10/20

L9949

ELECTRICAL CHARACTERISTCS

V

=8to16V, VCC= 4.5 to 5.5 V, Tj= -40 to 150 °C, unless otherwise specified. The voltages are refered to

S

GND and currents are assumed positive, when the current flows into the pin

(continued)

.

Symbol Parameter Test Condition Min. Typ. Max. Unit

OUTPUTS: OUT1 - OUT6

I

OLD12

Open Load Detection Current of

80 160 320 mA

OUT1 and OUT2

I

OLD345

Open load detection current of

20 40 60 mA

OUT3, OUT4 and OUT5

I

OLD6

open load detection current of

60 160 320 mA

OUT6

t

dOL

minimum duration of open load

500 3000 µs

condition to set the status bit

t

minimum duration of overcurrent

ISC

10 100 µs

condition to switch off the driver

dV

/d

t

dV

OUT12

OUT345

slew rate of OUT1 and OUT2 VS=13.5V,

for highside driver: I

for lowside driver: I

/d

t

slew rate of OUT3, OUT4 and

OUT5

VS=13.5V,

for highside driver: I

for lowside driver: I

load

load

load

load

= -3A,

= 3A

= -0.8A,

= 0.8A

0.1 0.2 0.4 V/µs

0.09 0.2 0.4 V/µs

dV

/dt

OUT6

slew rate of OUT6 VS=13.5V, I

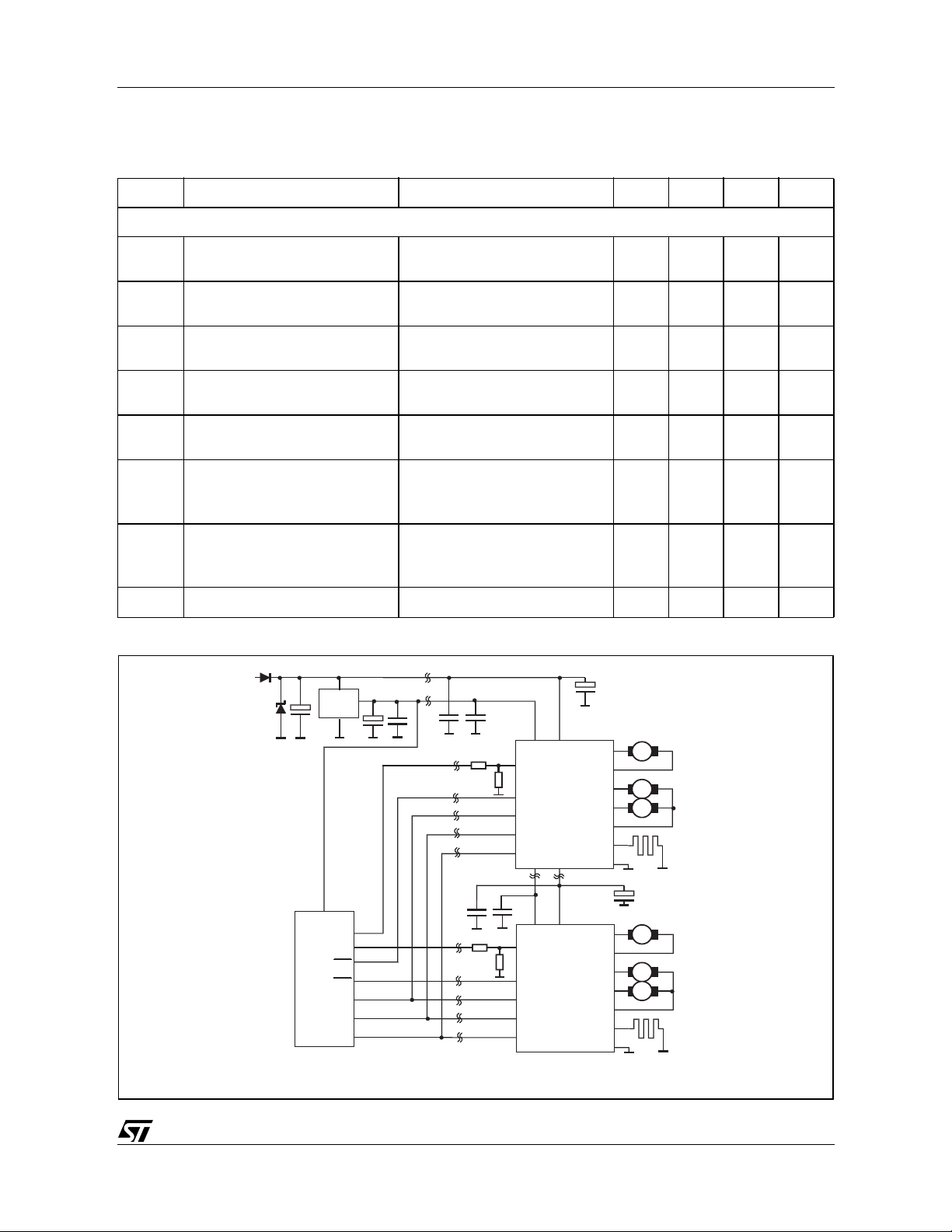

Figure 6. Application Circuit Diagram

VBAT

5V

STXXX

VCC

CM0

CM1

SS0

SS1

µC

SCK

MOSI

MISO

*in case of an unexpected freewheeling condition (e.g. POR, TSD or OV event) capacitor value

must be high enough to limit maximum Vs voltage of L9949 appl_n_wmf below absolute

maximum ratings.

= -2.5A 0.1 0.2 0.4 V/µs

load

*see comment

below

VCC VS

CM

L9949

CSN

CLK

DI

DO

VCC VS

CM

L9949

CSN

CLK

DI

DO

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

GND

OUT1

OUT2

OUT3

OUT4

OUT5

OUT6

GND

M

M

M

*see comment

below

M

M

M

11/20

L9949

CLK (pi

)CSN (pi

)

Figure 7. Funct i on a l Bl ock D i agram

OUT1

(pin9)

OUT2

(pin12)

VS (pin8)

VS (pin8)

VS (pin13)

VS (pin13)

HS

A-driver

LS

A-driver

HS

B-driver

LS

B-driver

HS

A-driver

LS

A-driver

HS

B-driver

LS

B-driver

Chargepump

Voltage and

Current

Reference

GND

(pins 1,10,1 1,20 )

Driver Interface

Power-On-Reset

Temperature

Protection

Current

Monitor

VCC

(pin 15)

n 6

SPI

Diagnostic

(pin 16)

CM

DI (pin 7)DO (pin 17)

VCC

n 14

VS

(pins 5,8,13,18)

HS

LS

HS

LS

HS

LS

HS

A-driver

HS

B-driver

VS (pin5)

VS (pin5)

VS (pin5)

VS (pin18)

ESD

VS (pin18)

ESD

OUT5

(pin4)

OUT4

(pin3)

OUT3

(pin2)

OUT6

(pin19)

FUNCTIONAL DESCRIPTION OF THE SPI

Serial Peripheral Interface (SPI)

This device uses a standard SPI to communicate with a microcontroller. The SPI can be driven by a microcontroller

with its SPI peripheral running in either of the two following modes: CPOL = CPHA = 0 or CPOL = CPHA = 1.

For these two modes, input data i s sampled by t he l ow to hi gh t ransi t i on of t he c lock CLK, and out put dat a is

changed from the high to low transition of CLK.

The difference of these two modes is the standby polarity of the CLK. For CPOL = 0 the CLK remains low and

for CPOL = 1 the CLK remains high.

This device is not limited to microcontrollers with a build-in SPI. Only three CMOS-compatible output pins and

one input pin will be needed to communicate with the device. A fault condition can be detected by setting CSN

to low. If CSN = 0, the DO-pin will reflect the status bit 0 (fault condition) of the device which is a logical-or of all

bits in the status regi st ers 0 and 1. The microcontroller can pol l t he st atus of t he device wi thout the need of a

full SPI-communication c ycle.

Note:

In contrast to the SPI-standard the least significant bit (LSB) will be tran sfered first ( s ee. FIGURE 8).

Chip Select not (CSN)

The input pin is used to select the serial interface of this device. When CSN is high, the output pin (DO) will be

in high impedance state. A low signal will activate the output driver and a serial communication can be started.

Serial Data In (DI)

The input pin is used to transfer data serial into the device. The data applied to the DI will be sampled at the

12/20

L9949

rising edge of the CLK signal and shifted into an internal 16 bit shift register. At the rising edge of the CSN signal

the c ontents of the shift re gister will be t ra nsfer ed to Da t a I nput R egister (see FIGURE 8).

The SPI uses an internal 16 bit counter which will be reset at the rising edge of the CSN signal. Only the first 16

bits o f t he data input D I will be releva nt. If mo re than 16 bits are transfered the trailing bits will be ignored.

Serial Data Out (DO)

The output driver is activated by a logical low level at the CSN input and will go from high impedance to a low

or high level depending on the status bit 0 (fault condition). The first rising edge of the CLK input after a high to

low transition of the CSN pin will transfer the content of the selected status register into the data out shift register.

Each subsequent falling edge of the CLK will shift the next bit out.

Serial Clock (CLK)

The CLK input is used to synchronize the input and output serial bit streams. The data input (DI) is sampled at

the rising edge of the CLK and the data output (DO) will change with the falling edge of the CLK signal (see

FIGURE 8).

Input Data Register

After the rising edge of CSN the contents of the input shift register will be written to the input data register. Depending on bit 0 the contents of the selected status register will be transfered to DO during the current communication cycle. Bit 1-11 controls the behaviour of the corresponding driver. If bit 12 and bit 13 are zero, the device

will go into the st andby-mode. I f at l east one of bot h bits are one these bits wil l be used t o cont rol t he current

monitor multiplexer. Bit 14 selects the V

the power supply V

will di sab le a ll driv er stages un til the status bit will be cleared by the microcontroller. Bit 15

S

is used to reset all status bits in both status registers. The bits in the status registers will be cleared after the

current communication cycle (rising edge of CSN).

lockout mode. If this bit i s set, an over- or undervoltage condition at

S

Status Register

This devices uses two status registers to store and to monitor the state of the device. Bit 0 is used as a fault bit

and is a logical-NOR combination of all other bits in both status registers. The state of this bit can be polled by

the microcontroller without the need of a full SPI-communication cycle (see FIGU RE 13). If one of the overcurrent bits is set, the corresponding driver will be disabled. The microcontroller has to clear the overcurrent bit to

enable the driver. If the thermal s hutdown bit is set, al l driv ers will go into a hi gh impedance state. Again the

microcontroller has to clear the bit to enable the drivers. The behaviour of the device in case of an over- or undervoltage condition will depend on the V

device will reactivate the drivers if the power supply V

lockout bit (bit 14) in the input data register. If bit 14 is cleared, the

S

returns to normal operating range. In this case no inter-

S

action from the microcontroller is needed.

Test Mode

Due to the current limitations of a single bond wire the out put stages OUT1, 2 and 6 need two bond wires in

parallel. For the full output current driving capability it is necessary to check that both bond wires are connected

correctly to the lead frame. Therefore the drivers and DMOS-transistors of the outputs OUT1, 2 and 6 are splitted into two independet stages, one for each bond wire (see FIGURE 6.4). In normal operating mode the splitted

outputs are connected in parallel. In the test mode bit 5 and 6 of the input data register select the A-driver, bit 7

and 8 the B-driver. If all four bits (5 - 8) are switched to high level, no driver will be activated. For all combinations

beside both high of bi t 5 and 6 or bit 7 and 8 t he output stages OUT3 and OUT4 are cont rol led like i n normal

operating mode. In any case the output stages are protected against shoot through current. Furthermore the

inputs CLK and DI are connected by an OR to the output DO for testing the threshold voltages and the hysteresis. The input CLK can be tested by clamping the input DI to low level and vice versa.

13/20

L9949

SPI Interface – Input Data and Status Register

Input Data Register Status Register

BIT Function BIT Function

Register 0 Register 1

15 High level reset all bits in selected status

register

14 V

13

under- / overvoltage lockout bit 14 VS overvoltage not used

S

Control bits for standby mode and

Current monitor multiplexer

12

bit13 bit12 function 12 Temperature

0 0 standby mode 11 OUT6 – HS driver

01 OUT1

1 0 OUT2 10 OUT5 – HS driver

11 OUT6

11

10

9

OUT6 – HS drive r on/off

OUT5 – HS drive r on/off

OUT5 – LS driver on/off

8 OUT4 – HS driver

(1)

on/off 5

7 OUT4 – LS driver

(1)

on/off 5

6 OUT3 – HS driver

(1)

on/off 5

5 OUT3 – LS driver

(1)

on/off 5

4

3

2

1

OUT2 – HS drive r on/off 5

OUT2 – LS driver on/off

OUT1 – HS drive r on/off

OUT1 – LS driver on/off

(1)

(1)

(1)

test mode 6 OUT3 – HS driver

bit 8 bit 7

1 1 5 OUT3 – LS driver

B-driver is active

test mode 4 OUT2 – HS driver

bit 6 bit 5

1 1 3 OUT2 – LS driver

A-driver is active

1

1

1

1

0 Status register select bit

L: status register 0; H: status register 1

15 always H always H

13 V

undervoltage chargepump off

S

shutdown

overcurrent

overcurrent

9 OUT5 – LS driver

overcurrent

8 OUT4 – HS driver

overcurrent

7 OUT4 – LS driver

overcurrent

overcurrent

overcurrent

overcurrent

overcurrent

2 OUT1 – HS driver

overcurrent

1 OUT1 – LS driver

overcurrent

0

no fault condition

H = on; L = off; HS = highside; LS = lowside

– set to L

Temperature

warning

OUT6 – HS driver

open load

OUT5 – HS driver

open load

OUT5 – LS driver

open load

OUT4 – HS driver

open load

OUT4 – LS driver

open load

OUT3 – HS driver

open load

OUT3 – LS driver

open load

OUT2 – HS driver

open load

OUT2 – LS driver

open load

OUT1 – HS driver

open load

OUT1 – LS driver

open load

(2)

(1) If the bits of HS- and LS-driver of the same output stage are high, the internal logic prevents that both drivers of this output stage can

be switched on simult aneously in order to avoid a hi gh internal current from V

(2) A logical NOR- combination of all bits 1 to 14 in both sta tus regist ers. Thi s bit can be polle d by the m i cro-controller wi thout the need

of the full SPI communication (see Figure 13). A broken VCC-connection of the L9949 can be detected by the microcontroller, because

all 15 bits l ow or high is not a valid frame.

to GND.

S

14/20

L9949

SPI INTERFACE ELECTRICAL CHARACTERISTCS

VS=8to16V, VCC= 4.5 to 5.5 V, Tj= -40 to 150 °C, unless otherwise specified. The voltages are refered to

GND and currents are assumed positive, when the current flows into the pin

Symbol Parameter Test Condition Min. Typ. Max. Unit

Delay time from standby to active mode

.

t

set

Delay Time

Inputs: CSN, CLK and DI

V

V

V

INHyst

I

CSNin

I

CLK in

I

DI in

C

DI timing (see Fig. 9 )

t

CLK

t

CLKH

t

CLKL

t

set CSN

Input Low Level VCC=5V 1.5 V

INL

Input High Level VCC=5V 3.5 V

INH

Input Hystersis VCC=5V 0.5 V

Pull Up Current at input CSN V

Pull Down Current at input CLK V

Pull Down Current at input DI VDI=1.5V 10 25 50 µA

(1)

Input Capacitance at input CSN

in

or CL K

(2)

Clock Period VCC= 5 V 1000 ns

Clock High Time VCC= 5 V 400 ns

Clock Low Time VCC= 5 V 400 ns

CSN setup time, CSN low before

rising edge of CLK

Switching from standby to active

200 µs

mode. Time until output drivers are

enabled after CSN going to high.

= 3.5 V -50 -25 -10 µA

CSN

=1.5V 10 25 50 µA

CLK

0V<VCC< 5.5 V 10 15 pF

VCC= 5 V 400 ns

t

set CLK

t

set DI

t

hold DI

t

t

DO

V

V

r-in

f-in

DOL

DOH

CLK setup time, CLK high before

VCC= 5 V 400 ns

rising edge of CSN

DI setup time VCC= 5 V 200 ns

DI hold time VCC= 5 V 200 ns

Rise Time of Input Signal

VCC=5V 100 ns

DI, CLK, CSN

Fall Time of Input Signal

VCC=5V 100 ns

DI, CLK, CSN

Output Low Level VCC=5V, ID=-4mA 0.2 0.4 V

Output High Level VCC=5V, ID=-4mA V

=5V, ID=-200µA; Tj = 25°C V

V

CC

-1.3

CC

CC

V

CC

-1.0

V

V

-0.8

15/20

L9949

010

g

SPI INTERFACE ELECTRICAL CHARACTERISTCS

V

=8to16V, VCC= 4.5 to 5.5 V, Tj= -40 to 150 °C, unless otherwise specified. The voltages are refered to

S

GND and currents are assumed positive, when the current flows into the pin

(continued)

.

Symbol Parameter Test Condition Min. Typ. Max. Unit

I

DOLK

C

Tristate Leakage Current V

Tristate Input Capacitance V

DO

CSN=VCC

CSN=VCC

0V<V

, 0 V < VDO<V

,

<5.5V

CC

CC

-10 10 µA

10 15 pF

DO timing (see Figg. 10 & 11)

t

r DO

t

f DO

t

en DO tri L

t

en DO L tri

t

en DO tri H

t

en DO H tri

DO Rise Time CL=100 pF, I

Data Out Fall Time CL=100 pF, I

DO Enable Time

from tristate to low level

DO Disable Time

from low level totristate

DO Enable Time

from tristate to high level

DO Disable Time

from high level totristate

CL=100 pF, I

pull-up load to V

CL=100 pF, I

pull-up load to V

CL=100 pF, I

pull-down load to GND

CL=100 pF, I

ppull-down load to GND

= -1mA 50 100 ns

load

= 1mA 50 100 ns

load

load

load

load

load

= 1mA

CC

= 4mA

CC

= -1mA

= -4mA

80 250 ns

200 400 ns

80 250 ns

200 400 ns

t

d DO

DO Delay Time VDO< 0.3 VCC, VDO> 0.7 VCC,

C

=100pF

L

(1) Value of inp ut capacity i s not measure d i n production test. Para m et er guarenteed by design.

(2) DI timing parameters tested in production by a passed/fai l ed test:

Tj=-40°C/+25°C: SPI communicat i on @2MHz

Tj=+125°C: SPI communicatio n @1.25MHz

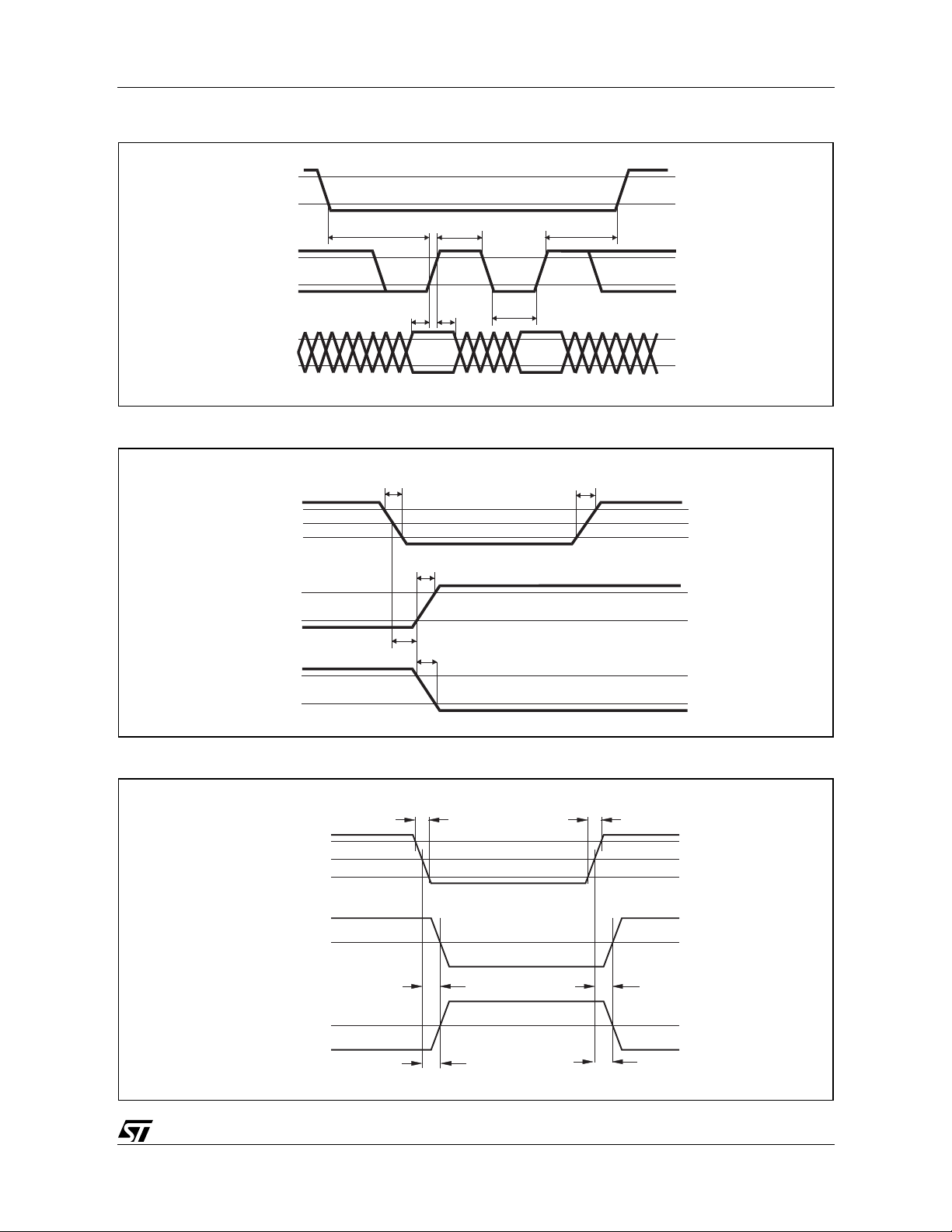

Figure 8. SPI-Interface - Transfer Timing Diagram

CSN high to low: DO enab led

CSN

CLK

DI

DO

e.g.OUT1

123456789101101213141510

DI: data will be accepted on the rising edge of CLK signal

actual data

1234567891011012131415

DO: data will change on the f alling edge of CLK signal

status information

1234567891011012131415

fault bit CSN low to hi

h: actual data is

transfered to output power switches

old data

50 250 ns

time

time

new data

time

1

time

actuall data

time

16/20

Figure 9. SPI-interface - Input Timing

L9949

CSN

t

set CSN

t

CLKH

CLK

t

CLKL

V alid

DI

t

set DI

V alid

t

hold DI

Figure 10. Data Out Valid Data Delay Time and Valid Time

t

f in

CLK

t

r DO

DO

(low to high)

t

d DO

t

f DO

DO

(high to low)

t

set CLK

t

0.8 V

CC

0.2 V

CC

0.8 V

CC

0.2 V

CC

0.8 V

CC

0.2 V

CC

r in

0.8 V

CC

0.5 V

CC

0.2 V

CC

0.7 V

CC

0.3 V

CC

0.7 V

CC

0.3 V

CC

Figure 11. SPI-Interface - Data Out Enable and Disable Time

t

f in r in

CSN

DO

pull-up load to V

CL =100pF

pull-down load to GND

C

=100pF

L

DO

CC

t t

en DO tri L

t

en DO tri H

t

dis DO L tri

t

dis DO H tri

0.8 V

50%

0.2 V

50%

50%

CC

CC

17/20

L9949

t

t

F

e

e

t

Figure 12. SP I-I nte rfa ce - Driver Turn On/O ff Tim i ng

CSN low to high: data fro m shift register

is

ransferred to output pow er sw itc he s

t

r in

CSN

t

dOFF

output current

of a driv

r

output current

of a driv

r

ON sta

eO

OFF

OFF state

t

dON

t

ON

F state

ON state

Figure 13. SP I-Interface - Timin g of Status Bit 0 (Fa ul t Co nd ition)

CSN high to low and CLK stays low: status information of data bit 0 (fault condition) is transfered to Data Out

t

f in

80%

50%

20%

80%

50%

20%

80%

50%

20%

18/20

CSN

CLK

DI

DO

Data In: data is not accepted

0

-

Data Out: status information of data bit 0 (fault condition) will stay as long as CSN is low

time

time

time

time

L9949

DIM.

MIN. TYP. MAX. MIN. TYP . MAX.

mm inch

A 3.6 0.142

a1 0.1 0.3 0.004 0.012

a2 3.3 0.130

a3 0 0.1 0.000 0.004

b 0.4 0.53 0.016 0.021

c 0.23 0.32 0.009 0.013

D (1) 15.8 16 0.622 0.630

D1 9.4 9.8 0.370 0.386

E 13.9 14.5 0.547 0.570

e 1.27 0.050

e3 11.43 0.450

E1 (1) 10.9 11.1 0.429 0.437

E2 2.9 0.114

E3 5.8 6.2 0.228 0.244

G 0 0.1 0.000 0.004

H 15.5 15.9 0.610 0.626

h 1.1 0.043

L 0.8 1.1 0.031 0.043

N 8˚ ( typ.)

S 8˚ (max. )

T 10 0.394

(1) “D and E1” do not include mold flash or protusions.

- Mold flash or protusions shall not exceed 0.15m m (0. 006”)

- Critical dimensions: “E”, “G” and “a3”.

OUTLINE AND

MECHANICAL DA TA

Weight:

1.9gr

JEDEC MO-166

PowerSO20

E2

NN

a2

b

h x 45

DETAIL A

e3

H

D

T

110

e

1120

E1

A

DETAIL B

PSO20MEC

R

lead

a3

Gage Plane

BOTTOM VIEW

E

DETAIL B

0.35

S

D1

L

c

a1

DETAIL A

slug

- C -

SEATING PLANE

GC

(COPLANARITY)

E3

0056635

19/20

L9949

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or patent r i ght s of STMi croelectr oni cs. Spec i fications mentioned i n this publication are s ubj ect

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics product s are not

authorized for use as cri tical comp onents in lif e support devi ces or systems without express written approva l of STMicroel ectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2002 STMic roelectroni cs - All Rig hts Reserved

Austra lia - Brazil - Canada - Chi na - F i nl and - Franc e - Germany - Hong Kong - In di a - Israel - Ita l y - J apan -Malaysia - Malta - Morocco -

Singap ore - Spain - Sw eden - Switze rl and - Unit ed K i ngdom - United States .

STMicroelectronics GROUP OF COMPANIES

http://www.s t. com

20/20

Loading...

Loading...