Page 1

Features

■ Quad gate driver for external N-channel Power

MOSFETs in high-side configuration:

– Gates driven by PWM output signal

– Adjustable gate charge/discharge currents

– Limited gate-to-source voltages

– Negative clamping for inductive loads

– Advanced run-off control

– Regulation of the power through the glow

plugs

■ Control output for external relay driver

■ Battery-voltage-compatible two-wire interface

■ Supply voltage monitoring with shutdown

■ Battery voltage monitoring with shutdown

■ Junction temperature monitoring with

shutdown

■ Monitoring of currents through the glow plugs

with shutdown at overcurrent (adjustable

threshold)

■ Monitoring of external switches

■ Charge pump voltage monitoring with

shutdown

■ Active clamping during load dump

Table 1. Device summary

L9524C

Glow plug system control IC

SO24

Description

The L9524C is a control IC for up to six glow

plugs of diesel engines. The glow plugs are

switched by up to four external PWM-controlled

N-channel Power MOSFETs or a single relay in

high-side configuration.

Supply voltage, battery voltage, junction

temperature, switches, currents through the glow

plugs, and charge pump voltage are monitored.

A two-wire interface is used to communicate with

the diesel engine management system.

Order code Package Packing

L9524C SO24 Tube

L9524C-TR SO24 Tape and reel

January 2008 Rev 3 1/27

www.st.com

1

Page 2

Contents L9524C

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Pins description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Control input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 Diagnostic output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5 Current monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.6 Switch monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.7 Thermal shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.8 Gate drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.9 Relay output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.10 Gate charge/discharge current variation . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.11 Overcurrent threshold variation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.12 Advanced run-off control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.13 Output timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.14 Power regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5 Application diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2/27

Page 3

L9524C List of tables

List of tables

Table 1. Device summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table 2. Pins description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Table 3. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 4. Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 5. Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 6. Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 7. Go / no-go protocol description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 8. Failure register description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 9. Sense input pin connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Table 10. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3/27

Page 4

List of figures L9524C

List of figures

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Pin connection (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Shunt sense versus transistor sense . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 4. Control input signal in transistor mode (modes 3 to 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 5. Permanent switch on of glow plugs at first falling edge in transistor mode (modes 3 to 6) 14

Figure 6. Control input signal in mode 2 for permanent switch on . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 7. Serial diagnostic interface protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 8. Timing diagram of advanced run-off control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 9. Output timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 10. Mode 1: relay mode, go/no-go diagnostic interface protocol . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 11. Mode 2: relay mode, serial diagnostic interface protocol . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 12. Mode 3: transistor mode, shunt sense, no power regulation . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 13. Mode 4: transistor mode, shunt sense, power regulation . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 14. Mode 5: transistor mode, transistor sense, no power regulation . . . . . . . . . . . . . . . . . . . . 24

Figure 15. Mode 6: transistor mode, transistor sense, power regulation . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 16. SO24 mechanical data and package dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4/27

Page 5

L9524C Block diagram

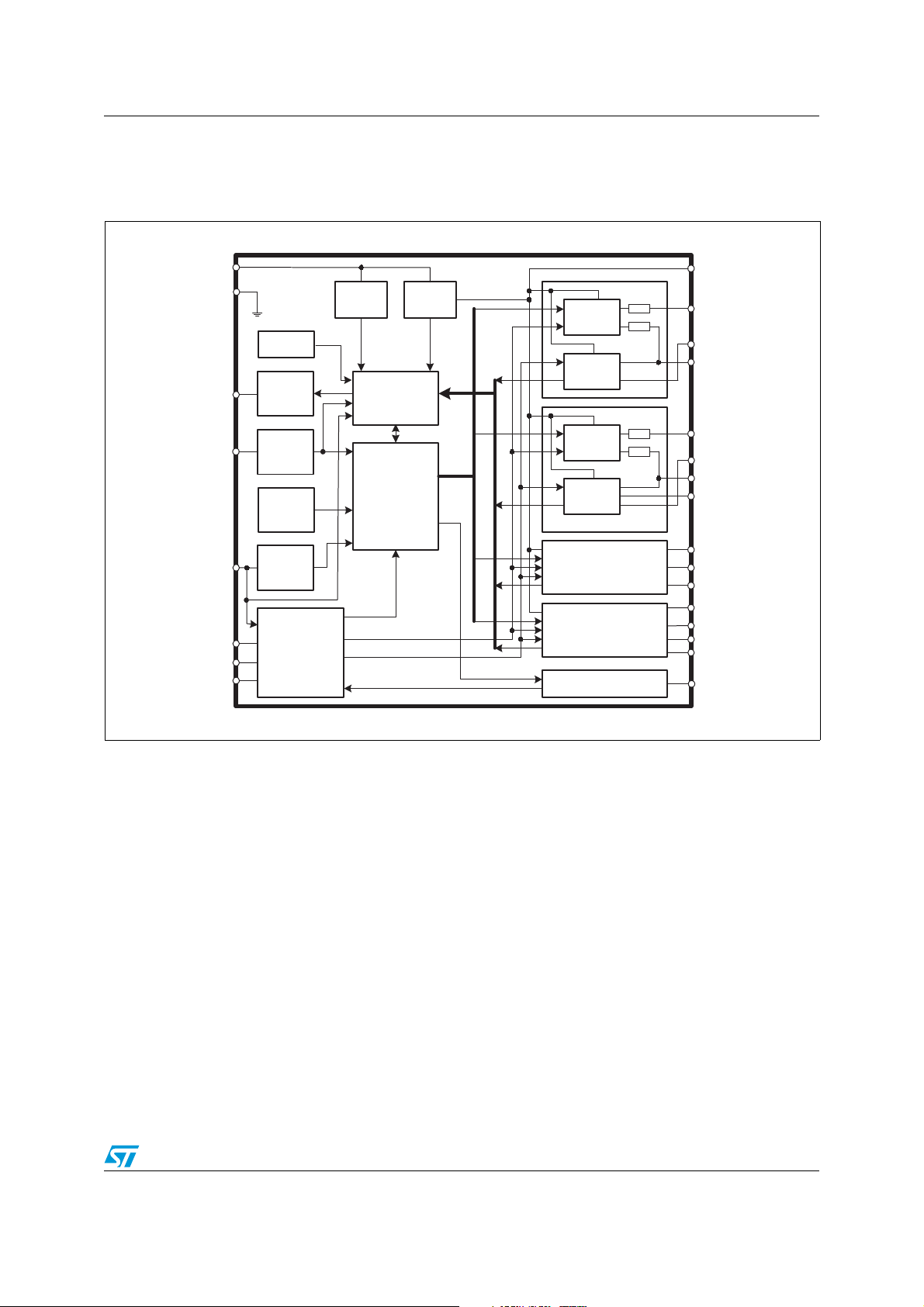

1 Block diagram

Figure 1. Block diagram

VS

GND

DO

BAT

MS

CUR

OCT

CP

Supply

voltage

monitor

Thermal

shutdown

Diagnostic

output

CI

Control

input

Reference

oscillator

Voltage

controlled

oscillator

Program

Charge/discharge current

Charge

Diagnostic

logic

Control

logic

Overcurrent threshold

pump

Gate

driver

Failure

monitor

monitor

(same as channel 1)

(same as channel 2)

Mode input / relay output

Gate

driver

Failure

Channel 3

Channel 4

Channel 1

Channel 2

G1

SP1

SN1

G2

SP2

SN2

SN5

G3

SP3

SN3

G4

SP4

SN4

SN6

IO

5/27

Page 6

Pins description L9524C

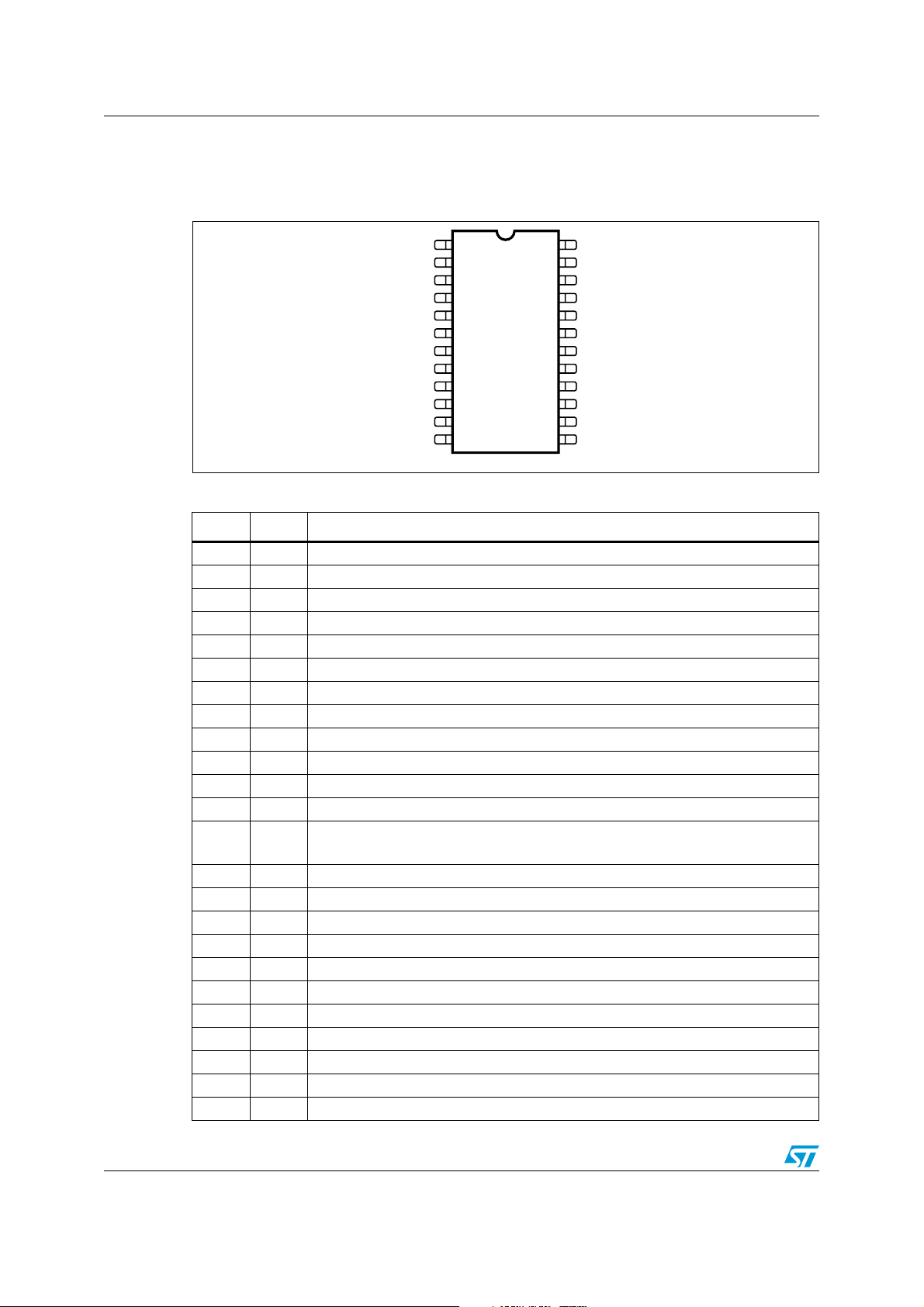

2 Pins description

Figure 2. Pin connection (top view)

Table 2. Pins description

SP1

G1

SN1

SP2

G2

SN5

SN2

BAT

DO GND

VS MS

CP CUR

OCT IO

1

2

3

4

5

6

7

8

9

10

11

SO24

24

SP3

23

G3

22

SN3

21

SP4

20

G4

19

SN6

18

SN4

17

CI

16

15

14

1312

Pins # Name Function

1 SP1 Positive sense input, glow plug 1

2 G1 Driver output for external high-side power MOSFET, transistor 1

3 SN1 Negative sense input, glow plug 1

4 SP2 Positive sense input, glow plugs 2 and 5

5 G2 Driver output for external high-side power MOSFET, transistor 2

6 SN5 Negative sense input, glow plug 5

7 SN2 Negative sense input, glow plug 2

8 BAT Battery voltage input

9 DO Diagnostic output

10 VS Supply voltage input

11 CP Charge pump output

12 OCT Overcurrent threshold setting

13 IO

Transistor mode: input for selection of power regulation feature

Relay mode: output to control external relay driver

14 CUR Power MOSFET gate charge/discharge current setting

15 MS

Mode selection input: transistor modes (transistor sense / shunt sense) / relay mode

16 GND Ground pin

17 CI Control input

18 SN4 Negative sense input, glow plug 4

19 SN6 Negative sense input, glow plug 6

20 G4 Driver output for external high-side power MOSFET, transistor 4

21 SP4 Positive sense input, glow plugs 4 and 6

22 SN3 Negative sense input, glow plug 3

23 G3 Driver output for external high-side power MOSFET, transistor 3

24 SP3 Positive sense input, glow plug 3

6/27

Page 7

L9524C Electrical specifications

3 Electrical specifications

3.1 Absolute maximum ratings

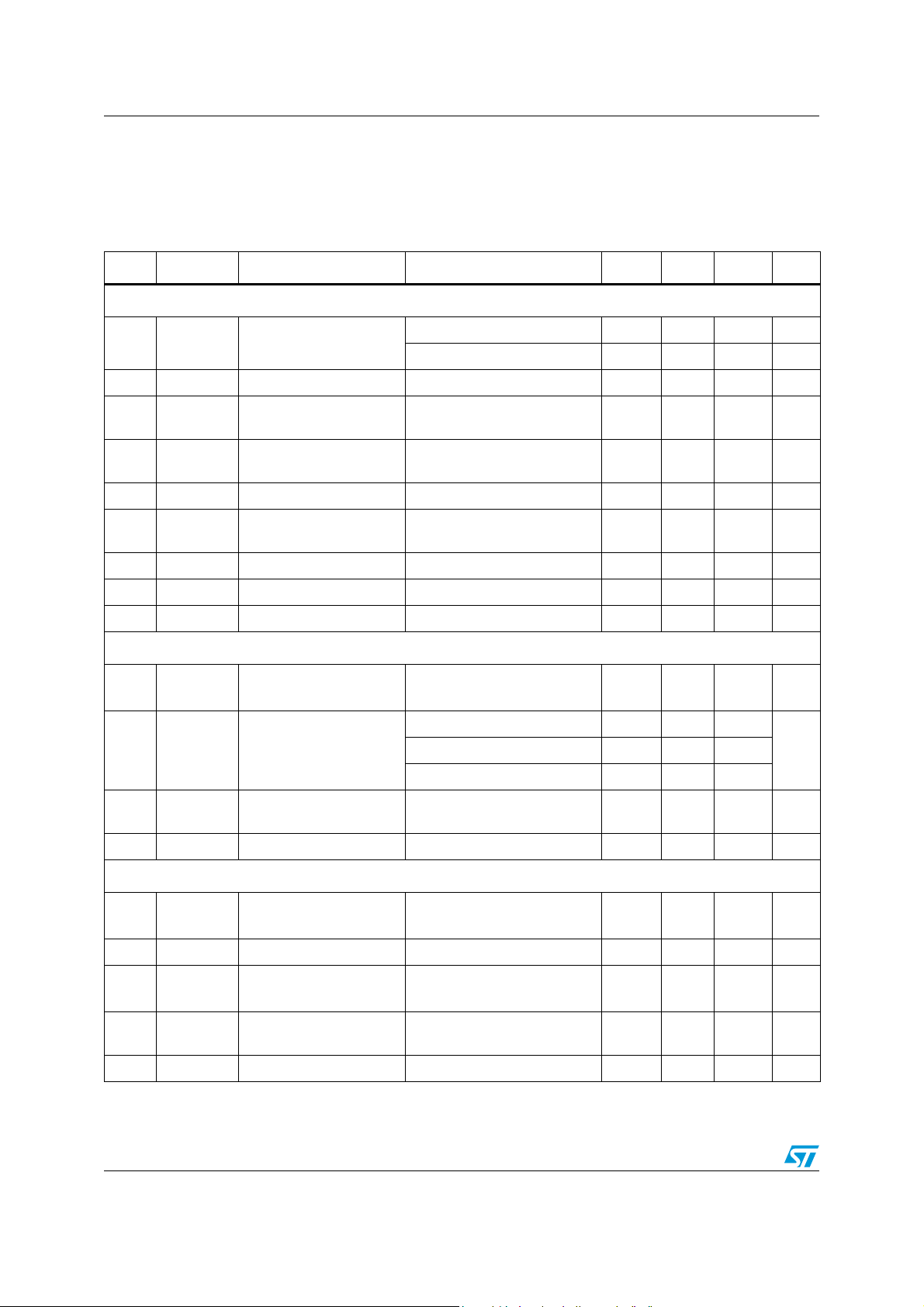

Table 3. Absolute maximum ratings

Symbol Parameter Value Unit

|dV

V

BAT

V

V

V

OCT

VMS, V

V

DO

V

VS

VS

V

CP

, VCI,

SP1-4

SN1-6

, V

, V

Supply voltage range -0.3 to 45 V

/dt| Supply voltage slope 10 V/μs

Charge pump voltage range -0.3 to 45 V

,

Input pin voltage range (BAT, CI, SP1-4, SN1-6) -16 to 45 V

,

CUR

Input pin voltage range (OCT, CUR, MS, IO) -0.3 to 7 V

IO

Output pin voltage range (DO, G1-4) -16 to 45 V

G1-4

Warning: The device may become damaged if using externally applied

All the pin of the IC are protected against ESD. the verification is performed according to:

AEC Q100-002 (HBM) and AEC Q100-011 (CDM).

3.2 Thermal data

Table 4. Thermal data

voltages or currents exceeding these limits!

Symbol Parameter Value Unit

T

T

JSD

Operating junction temperature -40 to 125 °C

J

Junction temperature thermal shutdown threshold 125 to 150 °C

7/27

Page 8

Electrical specifications L9524C

3.3 Electrical characteristics

5V ≤ VVS;V

≤ 18V, -40°C ≤ TJ ≤ 125°C, unless otherwise specified. The voltages are

BAT

referred to GND and currents are assumed positive, when current flows into the pin.

Table 5. Electrical characteristics

Item Symbol Parameter Test condition Min. Typ. Max. Unit

Supply (VS)

1.1 I

1.2 V

1.3 V

1.4 V

1.5 V

1.6 V

1.7 V

1.8 t

1.9 t

Supply (BAT)

VS

VS uv

VS uvh

VS ol

VS ov

VS ovh

VS ld

VS fil

VS ld

Supply current

1520mA

= 12V 1 10 mA

V

S

Undervoltage threshold 4 5 V

Undervoltage threshold

hysteresis

(1)

Open-load detection

threshold

100 400 mV

5.5 7.2 V

Overvoltage threshold 18 22 V

Overvoltage threshold

hysteresis

(1)

0.4 1.6 V

Load dump threshold 28 35 V

Filter time

Load dump delay time

(2)

(1)

12ms

10 μs

2.1 I

2.2 R

2.3 V

2.4 t

BAT leak

BAT

BAT uv

BAT fil

Charge pump (CP)

3.1 V

3.2 I

3.3 V

3.4 f

3.5 t

CP

CP

CP uv

CP

CP fil

V

≤ 3V

Leakage current

VS

0V ≤ V

BAT

≤ 12V

05μA

-40°C 25 43 150

Internal pull-down

resistance

kΩ30°C 25 65 150

125°C 25 106 150

Battery undervoltage

threshold

Filter time

(2)

Charge pump voltage ICP = -100μA

> V

V

MS

(transistor mode) 1 2 V

MS tr

300 760 μs

V

VS

+5V

V

VS

+18V

Charging current VCP = VVS + 5V -1500 -100 μA

Charge pump

undervoltage threshold

Charge pump frequency

(1)

Filter time

(2)

V

VS

+3.5V

0.6 7 MHz

400 950 μs

V

VS

+5V

8/27

Page 9

L9524C Electrical specifications

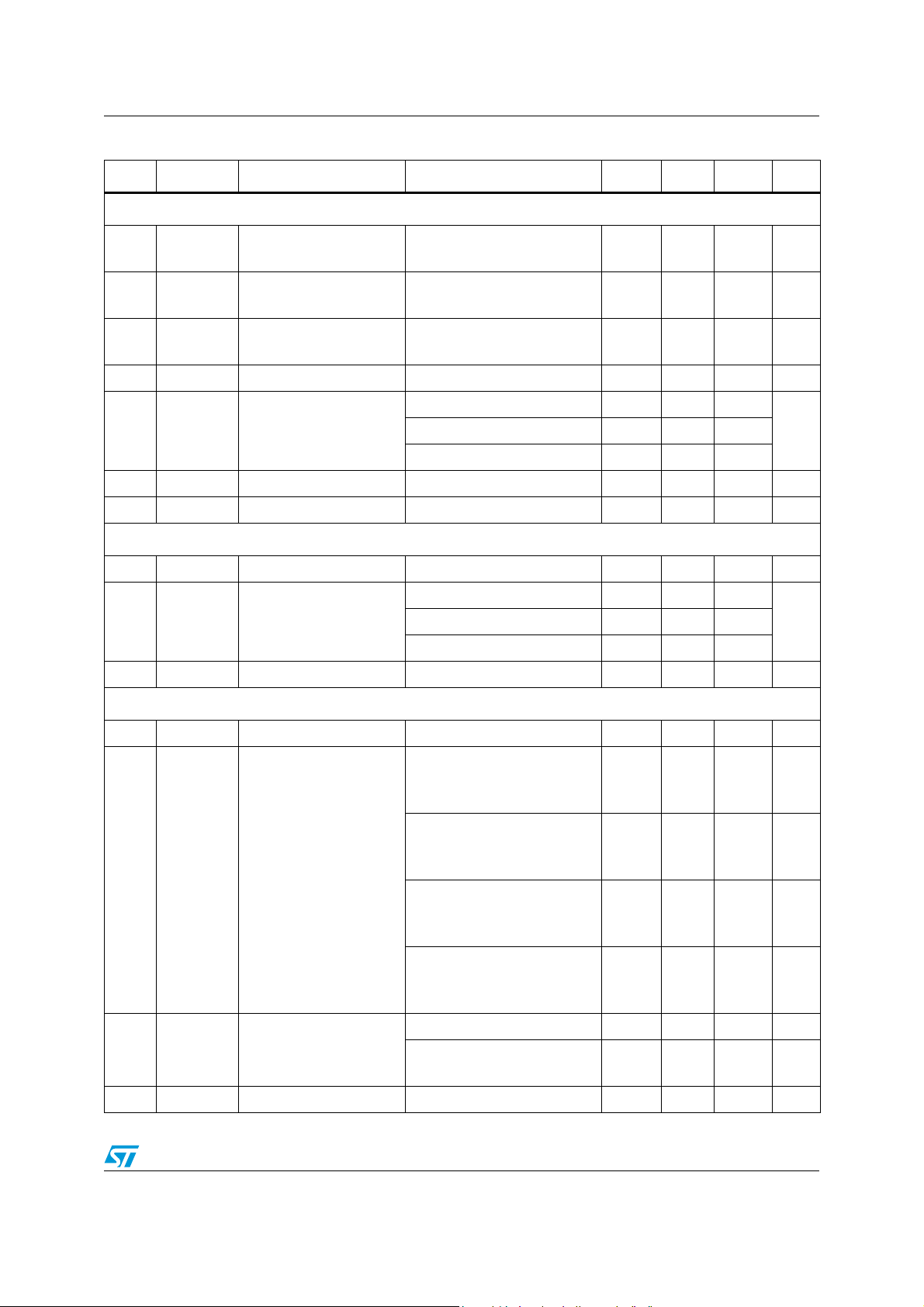

Table 5. Electrical characteristics (continued)

Item Symbol Parameter Test condition Min. Typ. Max. Unit

Control input (CI)

4.1 V

4.2 V

4.3 V

4.4 V

4.5 R

4.6 t

4.7 t

CI off

CI on

CI h

CI to

CI

CI fil

CI to

Input “off” level

Input “on” level

Off-to-on hysteresis

(1)

Input “timeout” threshold 1 1.6 V

≤ VVS; -40°C 20 35 120

V

Internal pull-up

resistance

Filter time

(2)

PWM time-out

(2)

CI

≤ VVS; 30°C 20 53 120

CI

≤ VVS; 125°C 20 87 120

V

CI

0.6 ·

V

VS

0.4 ·

V

VS

0.03 ·

V

VS

0.04 ·

V

VS

0.05 ·

V

VS

0.5 1 ms

50 100 ms

Diagnostic output (DO)

5.1 V

DOL

Output low voltage VVS ≥ 4.5V; IDO ≤ 5mA 0.3 1.5 V

VDO ≤ VVS; -40°C 20 30 120

5.2 R

5.3 I

DO max

DO

Internal pull-up

resistance

≤ VVS; 30°C 20 45 120

DO

V

≤ VVS; 125°C 20 74 120

DO

Current limitation 5 20 mA

Monitoring of currents through glow plugs (SP1-SN1, SP2-SN2, SP3-SN3, SP4-SN4, SP2-SN5, SP4-SN6)

kΩV

kΩV

6.1 ΔV

6.2 ΔV

6.3 TC

6.4 t

OL fil

OL

OC 0

OC

Open-load threshold 6V ≤ V

1.5V ≤ V

VMS < V

OCT pin open

1.5V ≤ V

< V

V

MS

0V ≤ V

Overcurrent threshold

1.5V ≤ V

V

MS>VMS tc

ϑ = -40°C; OCT pin open

1.5V ≤ V

VMS>V

ϑ = -40°C; 0V ≤ V

VMS < V

Overcurrent threshold

temperature coefficient

VMS>V

OCT pin open

Open-load filter time

(2)

VMS > V

SPX;VSNX

SPX;VSNX

MS tc

SPX;VSNX

MS tc

OCT

SPX;VSNX

SPX;VSNX

MS tc

MS tc

MS tc

MS tr

≤ VVS + 3V 6.7 14.7 mV

≤ VVS + 3V

(shunt sense)

≤ VVS + 3V

(shunt sense)

≤ V

CUR

150 185 mV

V

OCT

0.385

·

V

OCT

0.445

·

≤ VVS + 3V

(transistor sense)

≤ VVS + 3V

(transistor sense)

≤ V

OCT

CUR

(shunt sense)

(transistor sense)

150 290 mV

V

·

OCT

0.345

1)

0K

0.008 0.012 K

V

OCT

0.485

·

(transistor mode) 1 2 ms

9/27

-1

-1

Page 10

Electrical specifications L9524C

Table 5. Electrical characteristics (continued)

Item Symbol Parameter Test condition Min. Typ. Max. Unit

6.5 t

OC fil

Overcurrent filter time

Monitoring of external switches (SN1, SN2, SN3, SN4)

7.1 V

SD

Switch defect threshold

(2)

400 950 μs

V

VS

0.4

·

VVS ·

0.6

7.2 t

SD fil

Switch defect filter time

(2)

Gate driver outputs (G1, G2, G3, G4)

8.1 V

8.2 V

8.3 V

8.4 I

8.5 I

G off

G on

G cl

G off

G on

8.6 Slope

8.7 R

8.8 Δt

G on

Gate off voltage IGX ≤ 100μAV

Gate on voltage V

Gate clamping voltage V

Gate discharge current I

Gate charge current I

Gate charge- dischargecurrent I

Output resistance

G

G/ICUR

(1)

Jitter of output on time -300 300 μs

Mode input / relay output (IO)

9.1 V

9.2 R

9.3 I

9.4 I

IO max

9.5 V

9.6 t

IO sup

IO on

IO

IO pr

Output on voltage IIO ≥ -100μA36V

Output resistance IIO ≥ -1mA 100 500 W

IO

Input pull-down current

Current limitation -25 -5 mA

Power regulation

threshold

Pulse suppress time

(2)

Positive sense inputs (SP1, SP2, SP3, SP4)

12ms

V

SNX

V

= V

SNX

SNX

CUR

CUR

-250μA ≤ I

VS

= -20V -18 -16 V

= -125µA 270 540 µA

= -125µA 270 540 µA

≤ -70µA 2.33 4.33

CUR

VS

+5V

SNX

+0.7V

V

VS

+10V

1kΩ

VIO ≥ 1V 25 100 μA

= 0V 50 500 μA

V

VS

12V

2.5 5 ms

10.1 I

10.2 I

SP leak

SP

Leakage current VVS ≤ 3V 0 5 μA

Input pull-down current V

SNX

6V ≤ V

= V

SNX

-40°C

10.3 R

SP1-4

Pull-down resistor

35°C 40 150 270

125°C 40 220 270

Negative sense inputs (SN1, SN2, SN3, SN4, SN5, SN6)

11.1 I

SN

Input pull-down current V

SNX

= V

10/27

≥ 6V 15 780 μA

SPX

= V

SPX

≤ 20V

SPX

40 100 270

≥ 6V 15 780 μA

kΩ

Page 11

L9524C Electrical specifications

Table 5. Electrical characteristics (continued)

Item Symbol Parameter Test condition Min. Typ. Max. Unit

SNX

= V

6V ≤ V

-40°C

11.2 R

SN1-6

Pull down resistor

35°C 40 150 270

125°C 40 220 270

Overcurrent threshold setting (OCT)

12.1 I

OCT

Input pull-up current

VVS ≥ 6V

= 3.5V

V

OCT

Power MOSFET gate charge/discharge current setting (CUR)

13.1 V

13.2 I

CUR max

CUR

Output voltage I

Current limitation V

≥ -150μA 2.35 2.5 2.65 V

CUR

≤ 2V -500 -250 μA

CUR

Input pin for mode selection (MS)

14.1 I

14.2 V

14.3 V

MS

MS tr

MS tc

Pull-up current VMS = 3V -60 -15 μA

Transistor mode

threshold

Temperature

compensation threshold

V

≥ 6V 3 4 V

VS

Output timing

15.1 t

15.2 t

15.3 t

del

gap

sup

Delay time

Gap between channels

(2)

Failure suppress time

(2)

(2)

Power regulation

SPX

≤ 20V

40 100 270

kΩ

-40 -10 μA

12V

2.5 5 ms

50 250 μs

400 950 μs

8V ≤ V

30ms ≤ T

16.1 ΔV

RMS

Accuracy

t

CI on/TCI

< 70°C

> 70°C -2 2

1. not tested, guaranteed by design

2. time constants created digitally, verified by scan path test

≤ 16V

BAT

≤ 33ms

CI

≥ 20%

-1.5 1.5%

% ·

V

RMSref

11/27

Page 12

Functional description L9524C

4 Functional description

4.1 Operating modes

The L9524C can operate in a total of 6 modes. The selection is done by short-circuiting the

appropriate pins and voltages as shown in the following table:

Table 6. Mode

Mode Description MS pin BAT pin IO pin CI pin

1 relay mode, go/no-go diagnostic interface protocol ground ground output statical signal

2 relay mode, serial diagnostic interface protocol ground battery output PWM signal

3 transistor mode, shunt sense, no power regulation CUR pin battery

4 transistor mode, shunt sense, power regulation CUR pin battery ground PWM signal

5 transistor mode, transistor sense, no power regulation open battery

6 transistor mode, transistor sense, power regulation open battery ground PWM signal

CUR

pin

CUR

pin

PWM signal

PWM signal

Modes 1 and 2 are for relay usage (referred to as “relay mode”) and modes 3 to 6 for

transistors usage (referred to as “transistor mode”).

In relay mode the protocol of the diagnostic interface (DO pin) can be selected from go/nogo protocol and serial protocol (see section “Diagnostic output” for protocol description).

In transistor mode the protocol of the diagnostic interface is the serial protocol. It can be

distinguished between using shunts for monitoring the current through the glow plugs

(referred to as “shunt sense”) or using the R

of the power MOSFET’s themselves

DS(on)

(referred to as “transistor sense”). In shunt sense mode the resistance of the shunt is

assumed to be constant with respect to the temperature while in transistor sense mode the

R

of the power MOSFET’s is assumed to vary with respect to the temperature and

DS(on)

therefore overcurrent monitoring is adjusted appropriately.

In transistor mode there are two possibilities to control the output timing. In modes 3 and 5

the timing of the PWM control input signal determines the timing of the PWM signals applied

to the external power MOSFET’s (“no power regulation”). In modes 4 and 6 the timing of the

PWM control input signal determines the power through the glow plugs (“power regulation”)

and the timing of the PWM signals applied to the external power MOSFET’s is adjusted

depending on the battery voltage (see section “Power regulation”).

12/27

Page 13

L9524C Functional description

Figure 3. Shunt sense versus transistor sense

shunt sense transistor sense

V

BAT

V

BAT

Gx

SPx

L9524C

SNx

shunt

glow plug

SPx

Gx

L9524C

SNx

glow plug

015

4.2 Supply

The main supply pin of the L9524C is the VS pin. The voltage applied to it (VVS) is

monitored

● to switch off all glow plugs if it is less than V

failure”),

● to switch off all glow plugs if it is greater than V

failure”),

● to switch on all glow plugs if it is greater than V

during load dump”),

● to ignore open-load failures if it is less than V

Note: The glow plugs are switched on again if the corresponding switch-on condition disappears,

except if the glow plugs are switched on because of load dump. Then they remain switched

on until V

is less than V

VS

for at least t

VS ov

VS fil

In modes 2 to 6, the L9524C is additionally supplied by the BAT pin. This auxiliary supply

ensures that the external power MOSFET’s are switched off if no main supply voltage is

available at the VS pin.

VS uv

VS ov

VS ld

VS ol

.

for at least t

for at least t

for at least t

.

(“under voltage

VS fil

(“over voltage

VS fil

(“active clamping

VS ld

The BAT pin is additionally used to sense the battery voltage V

for power regulation in

BAT

modes 4 and 6 (see section “Power regulation”) and for detecting “battery under voltage

failure” (fuse between battery and module is defect) if V

t

in modes 2 to 6.

BAT fil

is less than V

BAT

BAT uv

for at least

An additional supply voltage higher than the main supply voltage is generated by an internal

charge pump which charges an external storage capacitor connected to the CP pin. This

capacitor mainly supplies the gates of the external n-channel power MOSFET’s. The charge

pump voltage V

for at least t

off even if the charge pump voltage becomes greater than V

is monitored and the glow plugs are switched off if it is less than V

CP

(“charge pump under voltage”). Afterwards, the glow plugs remain switched

CP fil

until they are explicitly

CP uv

CP uv

switched on again by the CI (control input) pin.

13/27

Page 14

Functional description L9524C

4.3 Control input

The control input (CI) pin is resistively pulled up RCI to the supply voltage VVS such that

V

CI=VCI off

transitions of V

level changes of V

In transistor mode (modes 3 to 6) the L9524C expects a PWM signal at the CI pin. Each

falling edge starts measuring its on time t

low pulse) and its period T

detected if no falling edge occurs for a time greater than t

switched off. Therefore, it is not possible to switch on the glow plugs permanently with one

exception: if the low voltage level of the first falling edge is greater than V

remain switched on as long as this low pulse lasts.

Figure 4. Control input signal in transistor mode (modes 3 to 6)

and the glow plugs are switched off by default. The L9524C is controlled by

from V

CI

which last shorter than t

CI

to V

CI off

(time until next falling edge). The end of a pulse group is

CI

(falling edge) and vice versa (rising edge). Voltage

CI on

CI on

are ignored.

CI fil

(time until next rising edge, i.e. length of this

and the glow plugs are

CI to

CI to

the glow plugs

V

CI

V

CI off

0.6 . V

0.4 . V

V

CI on

glow plug

1

ON

CI on

T

CI

del

t

CI to

VS

VS

t

t

+t

CI fil

t

CI to

t

CI fil

ignored

(shorter than t

t

CI fil

+t

CI fil

t

t

CI fil

CI to

t

)

del

OFF

t

Figure 5. Permanent switch on of glow plugs at first falling edge in transistor mode

(modes 3 to 6)

V

V

CI off

0.6 . V

0.4 . V

V

CI on

V

CI to

CI

t

CI to

VS

VS

t

CI to

t

glow plug

1

ON

OFF

CI to

14/27

t

CI to

t

t

Page 15

L9524C Functional description

Though in mode 2 (relay mode, serial diagnostic interface protocol) the relay should be

switched permanently the L9524C also expects a PWM signal at the CI pin since the serial

diagnostic interface protocol is synchronized by falling edges of the CI signal (see section

“Diagnostic output”). The relay then is switched on permanently if the off time (time between

rising and falling edge) of the PWM signal is less than t

suppresses pulses shorter than t

(see section “Relay output”). For the same reason the

IO sup

since the relay output

IO sup

relay is switched off permanently if the on time (time between falling and rising edge) of the

PWM signal is less than t

. In all other cases the relay is switched according to the

IO sup

PWM signal at the CI pin.

Figure 6. Control input signal in mode 2 for permanent switch on

V

V

CI off

0.6 . V

0.4 . V

V

CI on

relay

CI

VS

VS

ON

OFF

T

CI

In mode 1 (relay mode, go/no-go diagnostic interface protocol) no edges are necessary for

the go/no-go protocol. Therefore the relay is switched on if V

if V

CI

= V

CI off

.

4.4 Diagnostic output

The diagnostic output stage of the L9524C (DO pin) consists of a current-limited low-side

switch and a pull-up resistor R

is given by the drop across the low-side switch and the voltage level of a logical high signal

is equal to V

The L9524C is able to detect the following failures (see sections “Supply”, “Current

monitoring”, and “Switch monitoring”):

● open-load (6 glow plugs),

● overcurrent (6 glow plugs, stored until power-down),

● any switch is defect (4 switches),

● supply voltage (V

● supply voltage (V

● junction temperature (T

● charge pump voltage (V

● battery voltage (V

VS

.

) is too low (“under voltage”),

VS

) is too high (“over voltage”),

VS

BAT

t

IO sup

t

CI fil+tdel

to the VS pin. The voltage level of a logical low signal V

DO

) is too high,

J

) is too low (“charge pump under voltage”), and

CP

CI

= V

t

IO sup

and it is switched off

CI on

) is too low (“battery under voltage”).

t

t

DOL

15/27

Page 16

Functional description L9524C

In order to report the occurrence of any of the above-listed failures to the diesel engine

management system the L9524C provides two protocols: go/no-go protocol for mode 1 and

serial protocol for modes 2 to 6.

The go/no-go protocol is only able to report if any of the above-listed failures occurred. This

is done according to the following table:

Table 7. Go / no-go protocol description

V

V

V

CI

CI off

CI on

VDO at “no failure” VDO at “any failure”

V

DOL

V

VS

Note: overcurrent failures are stored until power-down.

The serial protocol is able to report different kinds of failures and to assign them to the

corresponding glow plugs. Therefore, occurring failures are written into an internal 8-bit

failure register:

Table 8. Failure register description

Bit Meaning of high state

(1)

1 Open-load or overcurrent

2 Open-load or overcurrent

3 Open-load or overcurrent

4 Open-load or overcurrent

5 Open-load or overcurrent

6 Open-load or overcurrent

Overcurrent failure at any glow plug

7

battery voltage (V

BAT

One or more of the following failures (“module failure”):

any switch is defect

supply voltage (V

8

supply voltage (VVS) is too high (“overvoltage”)

) is too low (“undervoltage”)

VS

junction temperature (T

charge pump voltage (V

battery voltage (V

1. overcurrent failures are stored until power-down

2. if battery voltage is too low (“battery under voltage”) bits 7 and 8 are high

BAT

failure at glow plug 1

(1)

failure at glow plug 2

(1)

failure at glow plug 3

(1)

failure at glow plug 4

(1)

failure at glow plug 5

(1)

failure at glow plug 6

(1)

or

) is too low

) is too high

J

CP

) is too low

(2)

(“battery undervoltage”)

) is too low (“charge pump undervoltage”)

(2)

(“battery under voltage”)

V

V

VS

DOL

Bits 1 to 6 are assigned to the glow plugs. Depending on bit 7 they show open-load (bit 7 is

low) or overcurrent failures (bit 7 is high). Bit 8 shows if there is any of the listed failures

(“module failure”). In case of a battery under voltage failure bits 7 and 8 are high and all

other bits are low as long as there is no overcurrent failure stored.

For transmitting the contents of the failure register the PWM signal applied to the CI pin is

used as clock input: at any falling edge of the CI signal (see section “Control input”) the DO

pin shows the value of the next bit of the bit stream after t

16/27

DO del

.

Page 17

L9524C Functional description

Each transmission frame consists of a beginning delimiter (one low bit) followed by the 8 bits

of the failure register beginning with bit 1. After the ending delimiter (one high bit) the

diagnostic output stage is inactive and is resistively pulled up to V

VS

.

The L9524C starts transmitting the first frame at the very first falling edge of the CI signal

after power-on. Since at that time the contents of the failure register are clear the first 9 bits

(beginning delimiter followed by the contents of the 8-bit failure register) which are

transmitted are always low. The L9524C repeats transmission of the frame every 32 falling

edges of the CI signal. Only during the time when the diagnostic output stage is inactive (i.e.

between the transmission of two frames) the contents of the failure register can be written.

Figure 7. Serial diagnostic interface protocol

V

VS

...

V

CI

01234567891011

V

CI off

V

CI on

V

DO

V

VS

low

bit 1

bit 2

bit 3

V

DOL

contents of failure register

(all bits='low' at 1st frame)

delimiter

beginning

bit 4

first frame frame

4.5 Current monitoring

The L9524C is able to monitor the current through 6 glow plugs by measuring the voltage

drop across sense resistors. Therefore, there are 4 positive sense input pins (SP1, SP2,

SP3, SP4) and 6 negative sense input pins (SN1, SN2, SN3, SN4, SN5, SN6). The sense

input pins must be connected to the sense resistors according to the following table:

Table 9. Sense input pin connection

bit 5

bit 6

bit 7

bit 8

ending

high

delimiter

...

diagnostic

output

stage

inactive

31

12345678910

0

low

bit 1

bit 2

bit 3

bit 4

bit 5

contents of failure register

delimiter

beginning

bit 6

bit 7

bit 8

ending

high

delimiter

t

...

t

...

t

Sense resistor of glow plug Positive sense input pin Negative sense input pin

1SP1SN1

2SP2SN2

3SP3SN3

4SP4SN4

5SP2SN5

6SP4SN6

17/27

Page 18

Functional description L9524C

In relay mode (modes 1 and 2) the positive sense input pins are short-circuited since the

relay is the only switch. In transistor mode (modes 3 to 6) glow plug 5 is switched with

transistor 2 and glow plug 6 with transistor 4. Therefore only 4 positive sense input pins are

necessary.

If the voltage drop across the sense resistor is less than ΔV

failure is detected as long as V

for at least t

an overcurrent failure is detected and the corresponding switch is switched

OC fil

off and remains switched off until power-down. The threshold for overcurrent failures ΔV

can be varied by the voltage applied to the OCT pin (see section “Overcurrent threshold

variation”).

In modes 1 to 4 the overcurrent threshold is constant with respect to the temperature

(TC

= 0). But in modes 5 and 6 the overcurrent threshold increases linearly with the

OC

temperature ϑ to compensate the first-order temperature coefficient of the R

external power MOSFET’s which are used as sense resistors in these modes:

Equation 1

4.6 Switch monitoring

The L9524C monitors the voltages across the glow plugs (using the negative sense input

pins SN1, SN2, SN3, and SN4) to detect if the corresponding switches work properly or not.

A switch is detected as defect if it is switched on but the voltage across the corresponding

glow plug(s) is less than V

the glow plug(s) is greater than V

> V

VS

ΔV

= ΔV

OC

for at least t

SD

SD

for at least t

. If it is greater than ΔVOC (see below for definition)

VS ol

(1 + TC

OC 0

SD fil

for at least t

OC

or if it is switched off but the voltage across

SD fil

OL

(ϑ + 40°C)).

.

an open-load

OL fil

DS(on)

of the

OC

4.7 Thermal shutdown

If the junction temperature becomes greater than T

are switched on again if the junction temperature falls below T

4.8 Gate drivers

The L9524C contains four gate drivers (Gx pins) for external n-channel power MOSFET’s in

high-side configuration. Each gate driver provides a slope control by charging and

discharging the gates of the external power MOSFET’s with constant currents (I

). To adjust the slopes these currents can be varied using the CUR pin (see section “Gate

off

charge/discharge current variation”). The charging current source is supplied by an external

capacitor connected to the charge pump output (CP) pin. The gate-to-source voltages are

limited internally and without supply voltage (V

power MOSFET’s are short-circuited.

During free-wheeling of inductive loads the gates of the external power MOSFET’s are

clamped to V

the inductive loads is recirculated through the power MOSFET’s.

. As a result, the power MOSFET’s become conducting and the energy in

G cl

all glow plugs are switched off. They

JSD

) the gates and the sources of the external

VS

JSD

.

or I

G on

G

18/27

Page 19

L9524C Functional description

4.9 Relay output

In relay mode (modes 1 and 2) the IO pin is used as output pin to control an external relay

driver (e.g. a low-side switch which drives the relay). If the output stage of the IO pin is

switched on it behaves like a voltage source (V

off a pull-down current source is activated (I

than t

such that the relay can be permanently switched by applying appropriate PWM

IO sup

) with output resistance RIO. If it is switched

IO

). The relay output suppresses pulses shorter

IO

signals to the CI pin (see section “Control input”).

In transistor mode (modes 3 to 6) the IO pin is used as input pin. Left open it is pulled down

to ground and the power regulation feature (see section “Power regulation”) is activated

(V

IO<VIO pr

the CUR pin (V

). To deactivate the power regulation feature the IO pin must be connected to

IO

= V

CUR

> V

IO pr

).

4.10 Gate charge/discharge current variation

The CUR pin provides a constant current-limited output voltage V

discharge) current is a multiple of the current flowing out of the CUR pin and can therefore

be varied by applying a resistor to the CUR pin.

In order to select the mode of operation the IO pin and/or the MS pin may be connected to

the CUR pin (see section “Modes”). The IO pin contains a pull-down current source and the

MS pin contains a pull-up current source. These currents are compensated if the

corresponding pin is connected to the CUR pin in order not to affect the gate

charge/discharge current.

4.11 Overcurrent threshold variation

The overcurrent threshold ΔVOC can be varied by connecting the OCT pin to an external

resistive voltage divider between CUR pin and ground. If the OCT pin is left open it is pulled

up to an internal supply voltage by a current source and a default value is used for the

overcurrent threshold. This default value corresponds to the condition: V

order not to de tune the voltage divider the pull-up current I

any glow plug is switched on.

. The gate charge (or

CUR

= V

source is deactivated when

OCT

OCT

CUR

/6. In

19/27

Page 20

Functional description L9524C

4.12 Advanced run-off control

In transistor mode (modes 3 to 6) the glow plugs are switched by an advanced run-off

control. The target is to minimize changes in the load current. Therefore, the PWM signals

applied to the glow plugs are phase-shifted to each other. There is a 5-step start-up

procedure at the beginning of a switching sequence. In step 1 the phase shift between the

glow plugs is set to a fixed value t

first period of the PWM control input signal (CI) and are heated up quite simultaneously.

During the start-up procedure the phase shift becomes a value equal to the on time of one

glow plug. As a result, after the start-up procedure the glow plugs are switched on one after

the other to get minimal changes in the load current.

Figure 8. Timing diagram of advanced run-off control

. Therefore, all glow plugs are switched on once in the

del

4.13 Output timing

In transistor mode (modes 3 to 6) there is a delay t

and switching on the next one to avoid overlaps. Additionally, failures occurring during the

slope (i.e. in the time period t

Figure 9. Output timing

20/27

after switching) are suppressed in all modes.

sup

between switching off one glow plug

gap

Page 21

L9524C Functional description

4.14 Power regulation

The power through each glow plug (here expressed by V

voltage across one glow plug) depends on the battery voltage V

/TG of the PWM signal applied to the external power MOSFET’s:

on

which is the root-mean-square

RMS

and the duty cycle t

BAT

Equation 2

t

V

RMS

V

BAT

G on

------------⋅=

T

G

In order to regulate the power through the glow plugs the L9524C measures V

adjusts t

G on/TG

of the gate drivers (G1...4) such that V

RMS

= V

RMS ref

, where V

represents the desired power through each glow plug.

The desired power V

is given by the input duty cycle t

RMS ref

CI on/TCI

which represents the

desired output duty cycle at a nominal battery voltage of 12V:

Equation 3

t

V

RMS ref

12V

CI on

------------- -⋅=

t

CI

As a result, the actual output duty cycle of the gate drivers is given by:

Equation 4

t

t

G on

------------

T

G

⎛⎞

⎝⎠

12V

--------------

V

BAT

2

CI on

------------- -

⋅=

T

CI

and

BAT

RMS ref

G

Note: The L9524C varies both the on time t

vary the duty cycle t

G on/TG

.

The accuracy of the power regulation is given by

The output jitter (electrical characteristics Item 8.8) is not taken in considuration while the

average is zero over some periodes.

and the period TG of the PWM output signal to

G on

Δ

V

RMS

= V

RMS

- V

RMS ref

.

21/27

Page 22

Application diagrams L9524C

KL87

KL31

KL31

Vbatt

KL30

Vs

GND

G1

G2

G3

G4

BAT

SP1

SN1

SP2

SN2

SP3

SN3

SP4

SN4

SN5

SN6

MS

CUR

OCT

IO

CP

Glow plug

470P

220N

220N

V

OCT

L9524

Rs

Rs

Rs

Rs

Rs

Rs

47R

47R

47R

47R

47R

I

CUR

DO

CI

10K

100R

Diagnosis

Control

470P

220R

5 Application diagrams

Figure 10. Mode 1: relay mode, go/no-go diagnostic interface protocol

L9524

KL87

KL31

Control

Diagnosis

V

220N

10K

100R

OCT

I

CUR

Vs

GND

CI

DO

IO

MS

CUR

OCT

BAT

SP1

SN1

SP2

SN2

SP3

SN3

SP4

SN4

SN5

SN6

CP

G1

G2

G3

G4

220N

470P

47R

47R

47R

47R

47R

Rs

Rs

Rs

Rs

Vbatt

KL30

Rs

Rs

Glow plug

Figure 11. Mode 2: relay mode, serial diagnostic interface protocol

22/27

KL31

Page 23

L9524C Application diagrams

Figure 12. Mode 3: transistor mode, shunt sense, no power regulation

KL87

KL31

Control

Diagnosis

220N

100R

100R

V

OCT

10K

I

CUR

Vs

GND

CI

DO

IO

MS

CUR

OCT

L9524

BAT

CP

G1

G2

G3

G4

SP1

SN1

SP2

SN2

SP3

SN3

SP4

SN4

SN5

SN6

220N

470P

470P

220R

100R

47R

47R

47R

47R

47R

Glow plug

STB100NF04 STB100NF04

STP85NF55STP85NF55

Rs

Rs

Rs

KL31

100N

Rs

Vbatt

KL30

Rs

Rs

Figure 13. Mode 4: transistor mode, shunt sense, power regulation

KL87

KL31

Control

Diagnosis

220N

100R

100R

V

OCT

10K

I

CUR

Vs

GND

CI

DO

IO

MS

CUR

OCT

L9524

BAT

CP

G1

G2

G3

G4

SP1

SN1

SP2

SN2

SP3

SN3

SP4

SN4

SN5

SN6

220N

470P

470P

220R

100R

47R

47R

47R

47R

47R

Glow plug

STB100NF04 STB100NF04

STP85NF55

Rs

STP85NF55

Rs

Rs

KL31

100N

Rs

Vbatt

KL30

Rs

Rs

23/27

Page 24

Application diagrams L9524C

Figure 14. Mode 5: transistor mode, transistor sense, no power regulation

L9524

KL87

220N

470P

Vs

BAT

220R

STP85NF55

100N

Vbatt

KL30

KL31

Control

Diagnosis

100R

100R

V

OCT

10K

I

CUR

GND

CI

DO

IO

MS

CUR

OCT

CP

G1

G2

G3

G4

SP1

SN1

SP2

SN2

SP3

SN3

SP4

SN4

SN5

SN6

220N

100R

470P

47R

47R

47R

47R

47R

Glow plug

Figure 15. Mode 6: transistor mode, transistor sense, power regulation

L9524

KL87

220N

470P

Vs

BAT

220R

STP85NF55

KL31

100N

Vbatt

KL30

KL31

Control

Diagnosis

100R

100R

V

OCT

10K

I

CUR

GND

CI

DO

IO

MS

CUR

OCT

CP

G1

G2

G3

G4

SP1

SN1

SP2

SN2

SP3

SN3

SP4

SN4

SN5

SN6

220N

470P

100R

47R

47R

47R

47R

47R

Glow plug

Glow plug

24/27

KL31

Page 25

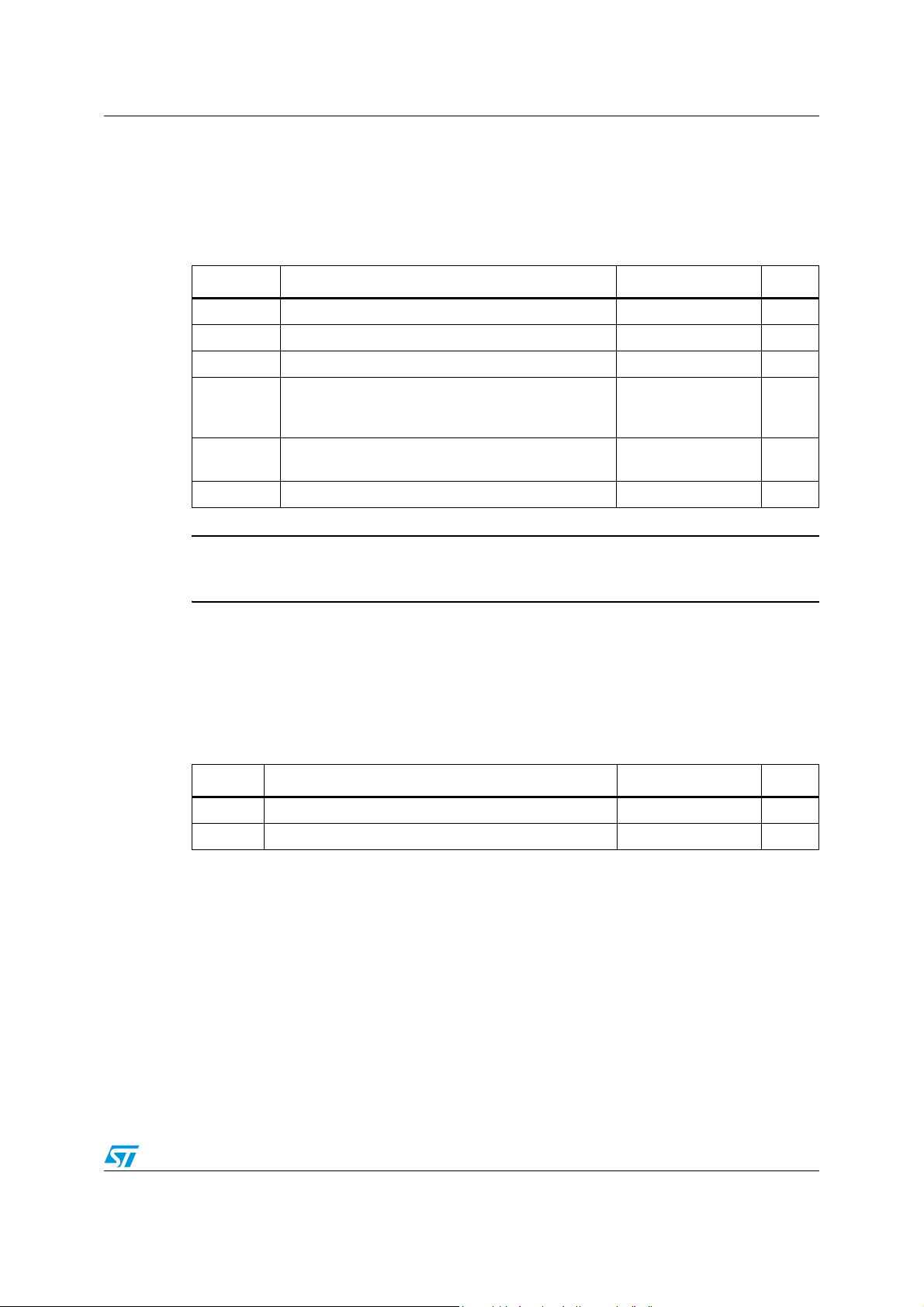

L9524C Package information

6 Package information

In order to meet environmental requirements, ST (also) offers these devices in ECOPACK®

packages. ECOPACK

®

packages are lead-free. The category of second Level Interconnect

is marked on the package and on the inner box label, in compliance with JEDEC Standard

JESD97. The maximum ratings related to soldering conditions are also marked on the inner

box label.

ECOPACK is an ST trademark. ECOPACK specifications are available at: www.st.com.

Figure 16. SO24 mechanical data and package dimensions

DIM.

A 2.35 2.65 0.093 0.104

A1 0.10 0.30 0.004 0.0 12

B 0.33 0.51 0.013 0.200

C 0.23 0.32 0.009 0.013

(1)

D

E 7.40 7.60 0.291 0.299

e 1.27 0 .050

H 10.0 10.65 0.394 0.4 19

h 0.25 0.75 0.010 0.0 30

L 0.40 1.27 0.016 0.0 50

k 0˚ (min.), 8˚ (max.)

ddd 0.10 0.004

(1) “D” dimension does not include mold flash, protusions or gate

burrs. Mold f lash, protus ions or gate b urrs shall no t exceed

0.15mm per side.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

15.20 15.60 0.598 0.6 14

OUTLINE AND

MECHANICAL DATA

Weight: 0.60gr

SO24

0070769 C

25/27

Page 26

Revision history L9524C

7 Revision history

Table 10. Document revision history

Date Revision Description of changes

22-Sep-2006 1 Initial release

29-Sep-2007 2 Updated the Section 3.3: Electrical characteristics.

Modified the Figure 5 and Figure 7.

Added the sub-title Section 4.3: Control input.

9-Jan-2008 3

Modified the values of the items 1.8, 6.4 and 7.2, and the

parameter definition of the item 8.6 in the Section 3.3:

Electrical characteristics.

26/27

Page 27

L9524C

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

27/27

Loading...

Loading...