Dual intelligent power low side switch

Features

■ Multipower BCD technology

■ Dual power low side driver with 2 x 5 A

■ Low R

■ Internal output clamping diodes V

inductive recirculation

■ Limited output voltage slew rate for low EMI

■ µP compatible enable and input

■ Wide operating supply voltage range 4.5 V to

45 V

■ Real time diagnostic functions:

– Output shorted to GND

– Output shorted to V

– Open load

– Load bypass

– Over temperature

■ Device protection functions:

– Overload disable

– Reverse battery up to -16 V @ V

– Thermal shutdown

Table 1. Device summary

typically 200 mΩ @ TJ = 25 °C

DSON

SS

= 50 V for

FB

S

L9386

SO20

Description

The L9386 is a monolithic integrated dual low side

driver realized in an advanced Multipower BCD

mixed technology.

It is especially intended to drive valves in

automotive environment. Its inputs are µP

compatible for easy driving. Particular care has

been taken to protect the device against failures,

to avoid electro-magnetic interferences and to

offer extensive real time diagnostic.

Part number Order code Package Packing

L9386 L9386MD SO20 (12+4+4) Tube

July 2008 Rev 3 1/14

www.st.com

14

Contents L9386

Contents

1 Block and pins connection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Circuit description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2/14

L9386 Block and pins connection diagrams

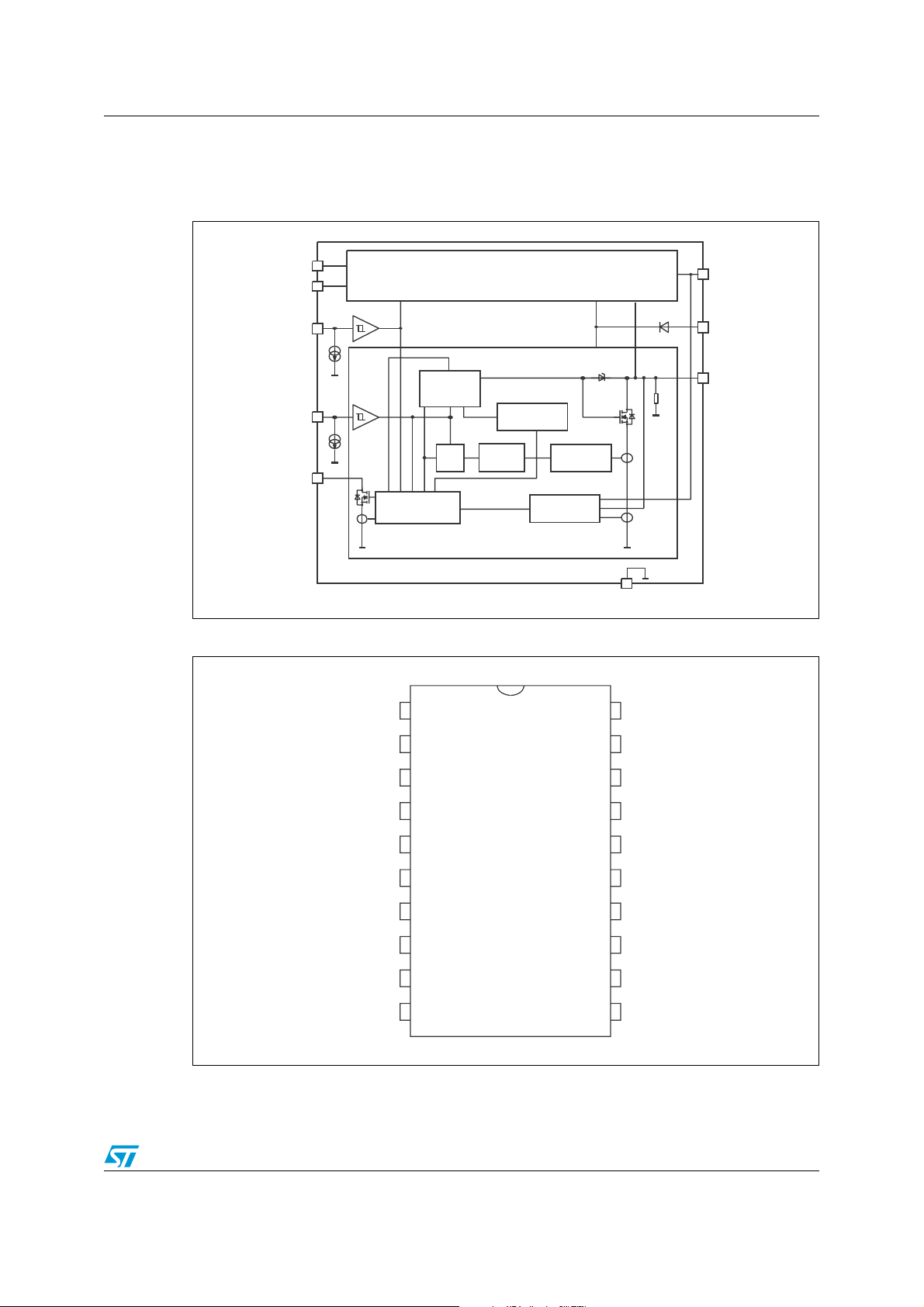

1 Block and pins connection diagrams

Figure 1. Block diagram

IN1

DIAG1

EN

Output

Diagnostic

Control

Control

R

QS

IN2

DIAG2

Channel 2

Figure 2. Pins connection (top view)

Channel 1

Overtemp

Delay

Timer

Overload

Openload

GND

OUT1

VS

OUT2

R

O

IN1

DIAG2

OUT2

GND

GND

GND

GND

N.C.

EN

VS

1

2

3

4

5

6

7

8

9

10

IN2

20

DIAG1

19

OUT1

18

GND

17

GND

16

GND

15

GND

14

13

N.C.

N.C.

12

11

N.C.

3/14

Electrical specifications L9386

2 Electrical specifications

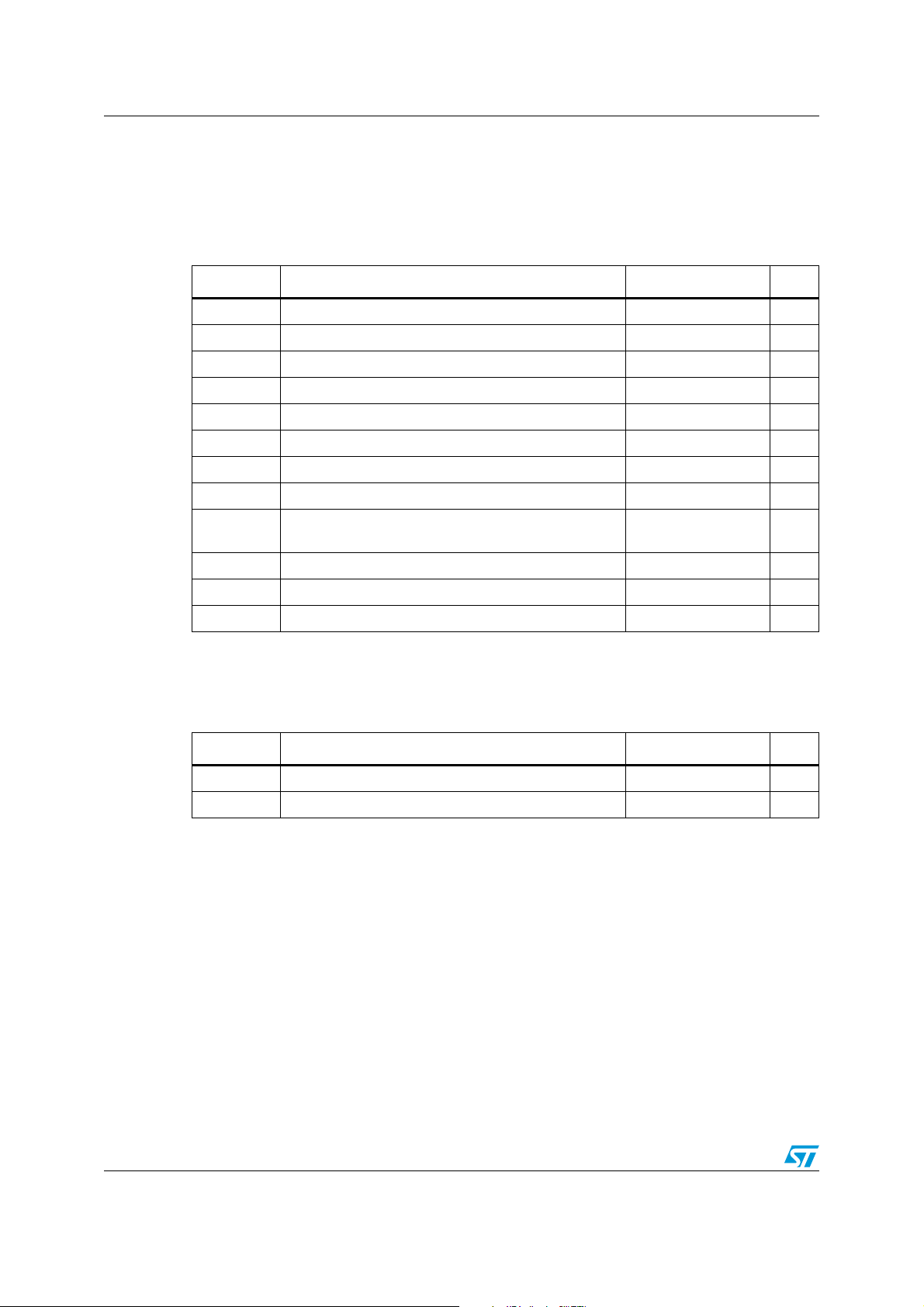

2.1 Absolute maximum ratings

Table 2. Absolute maximum ratings (no damage or latch)

Symbol Parameter Value Unit

V

DC supply voltage -16 to 45 V

SDC

Transient supply voltage (t ≤ 500 ms) 60 V

V

STR

,EN Input voltage (| ≤ | 10 mA |) -1.5 to 6 V

V

IN

V

Diagnostic DC output voltage (| ≤ | 50 mA |) -0.3 to 16 V

DDC

DC output voltage 45 V

V

ODC

Transient output voltage (RL ≥ 4 Ω) 60 V

V

OTR

I

Output load current internal limited

O

Reverse output current limited by load -4 A

I

OR

EO

T

jEO

T

T

stg

Switch-off energy for inductive loads

(t

= 250 µs, T = 5 ms)

EO

50 mJ

Junction temperature during switch-off Σt = 30 min 175 °C

Junction temperature -40 to +150 °C

j

Storage temperature -55 to +150 °C

2.2 Thermal data

Table 3. Thermal data

Symbol Parameter Value Unit

T

Thermal disable junction temperature threshold 160 to 190 °C

jDIS

R

Thermal resistance junction to pins 14 °C/W

th j-pins

4/14

L9386 Electrical specifications

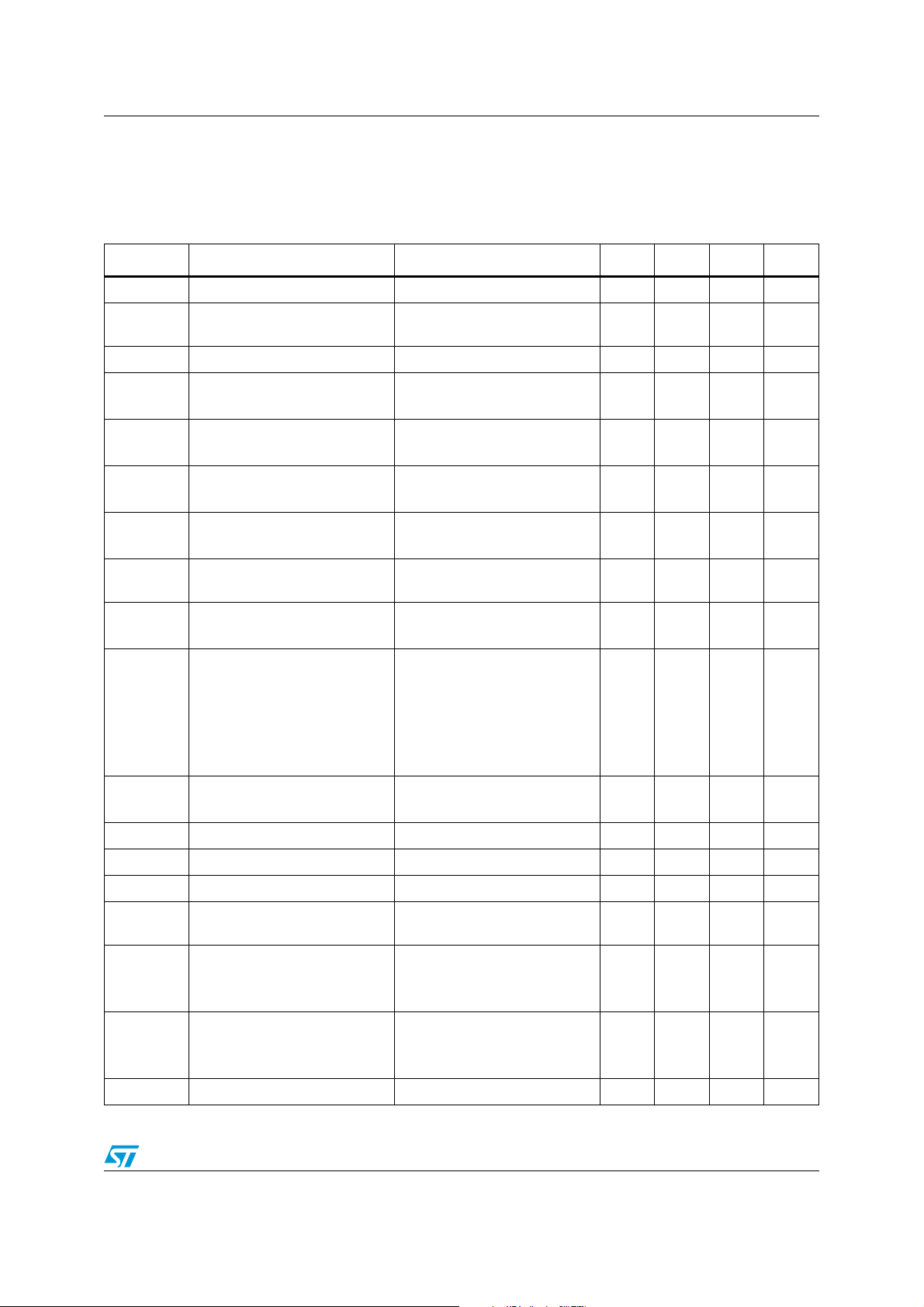

2.3 Electrical characteristics

Table 4. Electrical characteristics

(The electrical characteristics are valid within the below defined operative range, unless

otherwise specified.)

Symbol Parameter Test condition Min. Typ. Max. Unit

V

V

T

IS

SB

IS DC supply current

VD

ID

LE

ID

VO

ΔVO

UV1,2

IO

UC

IO

OC

V

OCL

S

ON,OFF

R

IO

R

DSON

Board supply voltage 4.5 12 32 V

S

Stabilized diagnostic output

D

voltage

Junction temperature -40 150 °C

j

(1)

Static standby supply current

Diagnostic output low voltage

L

Diagnostic output leakage

current

Diagnostic output current

capability

Open load voltage threshold VEN = X, VIN = L

UV

Open load difference voltage

threshold

Open load current threshold

(2)

VEN = L, VO ≤ VOuv

(1)

(2)

VEN = VIN = H

(1)

ID = 2 mA

(2)

ID = 1 mA

= 0 V or VS = open;

V

S

= 5.5 V Tj ≤ 125 °C

V

D

VD ≤ 16 V DIAG = L 2 6 30

(1)

VEN = X, V

≥ VOC ≥ VOUV

V

S

= output voltage of other

VO

C

IN1,2

= L

channel

(2)

(3)

VEN = VIN = H

(2)

-0.3 5 16 V

0.73 1.5

1.3

0.35 0.5 V

0.1 2 mA

0.51

xVS

VO

0.9V

VO

0.7V

100

-

C

-

C

0.55

xVS

-

VO

C

1.25V

VO

-

C

1.25V

320 480

20

Over load current threshold b) 5 7 A

Output voltage during clamping IOCL ≥ 100mA 45 52 60 V

Output (fall, rise) slew rate

Internal output pull down

resistor

Output on resistance

(3)

see Figure 4 200 1500 3200 V/ms

= L 10 20 40 KΩ

V

EN

V

> 9.5 V IO = 2 A

S

= 25 °C

T

j

200 300

Tj = 150 °C

15

5

15

0.59

xVS

VO

1.6V

VO

1.8V

500

mA

mA

mA

V

-

C

V

-

C

mA

mΩ

V

(EN,IN)L

V

(EN,IN)H

|IEN, IN| ≤ 10 mA

Logic input low voltage

(1)

(2)

-1.5

-1.5

1

0.5

Logic input high voltage 2.2 5.5 V

5/14

V

Electrical specifications L9386

Table 4. Electrical characteristics (continued)

(The electrical characteristics are valid within the below defined operative range, unless

otherwise specified.)

Symbol Parameter Test condition Min. Typ. Max. Unit

V

(EN,IN)hys

I

EN

I

IN

t

DON

t

DOFF

t

DH-L,Diag.

t

DIOu

t

DOL

1. 6.5 V ≤ VS ≤ 16 V (Diagnostic operation range).

2. 4.5 V ≤ V

3. 9 V ≤ V

RL ≤ 6 Ω, IO ≤ IO

Table 5. Diagnostic table (operating range: 4.5 V ≤ VS ≤ 32 V)

Logic input hysteresis 0.2 0.4 1 V

Enable input sink current 1 V ≤ VEN ≤ 5.5 V 10 30 60 µA

Logic input sink current 1 V ≤ VIN ≤ 5.5 V 40 95 180 µA

Output delay ON time

Output delay OFF time

Diag. delay output OFF time

Diagnostic open load delay time

Diagnostic overload delay

switch-off time

< 6.5 V and 16 V < VS ≤ 32 V (Extended operation range).

S

≤ 16 V (Nominal operating range)

S

OC.

(3)

see Figure 4 425µs

(3)

see Figure 4 51530µs

(3)

see Figure 4 53065µs

(3)

see Figure 6 850µs

(3)

see Figure 3 50 160 300 µs

Conditions EN IN Out Diag.

Normal function

GND short VO

Load bypass ΔVO

Open load IO

T

≥ 175 °C overtemperature

j typ

L

H

H

< 0.55 V

typ

≥ 1.25 V

1,2

< 320 mA H H on

typ

(2)

L

H

X

X

X

L

H

X

L

L

H

off

off

(1)

on

off

off

(1)

L

off

off

L

L

H

H

H

H

L

Latched overload IO

Reset overload latch X

1. for 4.5 V ≤ VS < 6.5 V, IO ≤ 2 A diag. table is valid.

2. If one diag. status shows the overtemperature recognition, in parallel this output will be switched OFF internally. The

corresponding channel should be switched OFF additional by its Input or ENABLE signal, otherwise the overload latch will

be set after t

recognition.

is passed. This behavior will be related to the overdrop sensing which will be used as over load

DOL

> 5 A X H off L

min

D.C. D.C.

6/14

L9386 Electrical specifications

Figure 3. Diagnostic overload delay time

UI

5V

t

IO

IO

SC

5A

IO

UC

td

OL

UD

5V

t

Figure 4. Output slope

U

IN

5V

V

(IN)H

V

(IN)L

U

OUT

VO

C

0.85VO

C

VS

VS-VO

CC

0.85VS

VO

UV

0.15VS

V

DIAG

V

D

0.5V

D

t

td

on

S

on

td

off

S

off

t

t

t

D

H-L

Diag

t

7/14

Electrical specifications L9386

Figure 5. Open load voltage detection block diagram

V

Batt.

L1 L2

OUT1 OUT2

IN

1

VS

55%

Enable

R

IO

R

IO

+

-

+

-

IN

2

& &

R

S

Latch

Latch

S

Q

R

Q

& &

8/14

VO

UV1

VO

UV2

L9386 Electrical specifications

Figure 6. Logic diagram

open load

voltage

normal

operation

OFF

ON

latch reset

open load voltage

open load current

off

td

normal

operation

u

on

td

IO

td

latched over.

load diagnostic

OL

td

over load

current

open load

current

normal

operation

u

on

td

IO

td

open load current

normal

operation

OFF ON

EN

V

IN

V

u

VO

o

IO

IO

u

D

V

9/14

Electrical specifications L9386

2.4 Circuit description

The L9386 is a dual low side driver for inductive loads like valves in automotive environment.

The device is enabled by a common CMOS compatible ENABLE high signal. The internal

pull down current sources at the ENABLE and INPUT pins protect the device in open input

conditions against malfunctions. An output slope limitation for du/dt is implemented to

reduce the EMI. An integrated active flyback voltage limitation clamps the output voltage

during the flyback phase to 50V.

Each driver is protected against short circuit and thermal overload. In short circuit condition

the output will be disabled after a short delay time t

latched until a negative slope occur at the correspondent input pin. The thermal disable for

T

> 175 °C of the output will be resetted if the junction temperature decreases about 20 °C

J

below the disable threshold temperature.

For the real time error diagnosis the voltage and the current of the outputs are compared

with internal fixed values V

(R

≥ 20 kΩ, RL > 38Ω) in ON and OFF conditions. The diagnostic operates also in the

L

extended supply voltage range of 4.5 V ≤ V

Also the output voltages VO

fixed offset of ΔVO

UV 1,2

for OFF and I

OUV

are compared against each other in OFF condition with a

1,2

OUC

≤ 32 V.

S

to recognize GND bypasses. To suppress mail ΔVO diagnoses

during the flyback phases of the compared output, the ΔVO diagnostic

to suppress spikes. This disable is

DOL

for ON conditions to recognize open load

includes a latch function. Reaching the flyback clamping voltage VO

the diagnostic signal

C

is resetted by a latch. To activate again this kind of diagnostic a low signal at the

correspondent INPUT or the ENABLE pin must occur (see also Figure 5).

The diagnostic output level in connection with different ENABLE and INPUT conditions

allows to recognize different fail states, like overtemperature, short to VSS, short to GND,

bypass to GND and disconnected load (see also Table 5 on page 6).

The diagnostic output is also protected against short to UD

current threshold IO

overload delay switch-off time t

, the output current will be limited internally during the diagnostic

o

DOL

.

. Oversteping the over load

max

10/14

L9386 Electrical specifications

Figure 7. Open load voltage detection block diagram

+5V

µ P

Controller

IN1

DIAG1

EN

IN2

DIAG2

Diagnostic

Control

Output

Control

R

QS

Channel 1

Overtemp

Delay

Timer

Channel 2

Overload

Openload

GND

Z

VALVE

OUT1

VS

OUT2

R

O

Z

VALVE

V

Batt

11/14

Package information L9386

3 Package information

In order to meet environmental requirements, ST (also) offers these devices in ECOPACK®

packages. ECOPACK

®

packages are lead-free. The category of second Level Interconnect

is marked on the package and on the inner box label, in compliance with JEDEC Standard

JESD97. The maximum ratings related to soldering conditions are also marked on the inner

box label.

ECOPACK is an ST trademark. ECOPACK specifications are available at: www.st.com.

Figure 8. SO20 mechanical data and package dimensions

DIM.

A 2.35 2.65 0.093 0.104

A1 0.10 0.30 0.004 0.012

B 0.33 0.51 0.013 0.200

C 0.23 0.32 0.009 0.013

(1)

D

E 7.40 7.60 0.291 0.299

e 1.27 0.050

H 10.0 10.65 0.394 0.419

h 0 .25 0.75 0.010 0.0 30

L 0 .40 1.27 0.016 0.0 50

k 0˚ (min.), 8˚ (max.)

ddd 0.10 0.004

(1) “D” dimensio n does not include mold flash, prot usions or gate

burrs. Mol d flash, protus ions or gat e burrs shall no t exceed

0.15mm per sid e.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

12.60 13.00 0.496 0.512

OUTLINE AND

MECHANICAL DATA

SO20

12/14

0016022 D

L9386 Revision history

4 Revision history

Table 6. Document revision history

Date Revision Changes

16-Jan-2002 1 Initial release.

20-Sep-2003 2 Changed company name and logo.

16-Jul-2008 3

Document reformatted.

Added Table 1: Device summary on page 1.

13/14

L9386

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

14/14

Loading...

Loading...