Battery charger system with integrated

Features

■ Fully integrated solution, with a power

MOSFET, reverse blocking diode, sense

resistor, and thermal protection

■ Ideal for coke and graphite anode single-cell L

I

packs

ON

■ Both linear and quasi-pulse operation

■ Closed loop thermal control

■ USB BUS-compatible

■ Programmable charge current up to 1 A

■ Programmable pre-charge current

■ Programmable end-of-charge current

■ Programmable pre-charge voltage threshold

■ Programmable charge timer

■ Programmable output voltage at 4.1 V and 4.2

V, with ± 1 % output voltage accuracy

■ (NTC) or (PTC) thermistor interface for battery

temperature monitoring and protection

■ Flexible charge process termination

■ Status outputs to drive LEDs or to interface

with a host processor

■ Small VFQFPN 16-leads package (3 x 3 mm)

L6924D

power switch for Li-Ion/Li-Polymer

-

I

VFQFPN16

Applications

■ PDAs

■ Handheld devices

■ Cellular phones

■ Digital cameras

■ Standalone chargers

■ USB-powered chargers

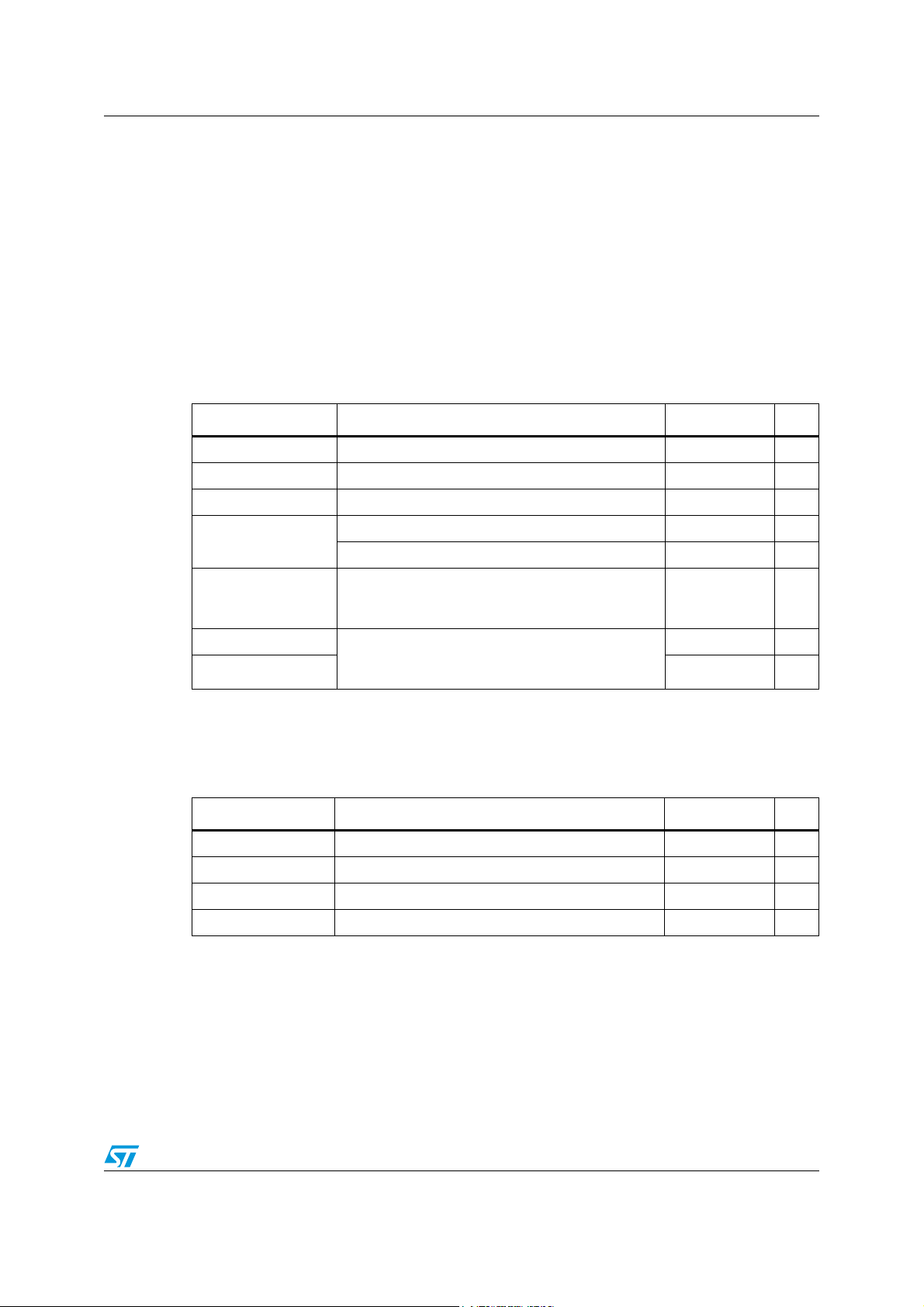

Table 1. Device summary

Order code Package Packaging

L6924D

VFQFPN16

L6924D013TR Tape and reel

September 2010 Doc ID 11908 Rev 9 1/38

Tube

www.st.com

38

Contents L6924D

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pins description and connection diagrams . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Operation description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1 Linear mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2 Quasi-pulse mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7 Applications information: charging process . . . . . . . . . . . . . . . . . . . . 16

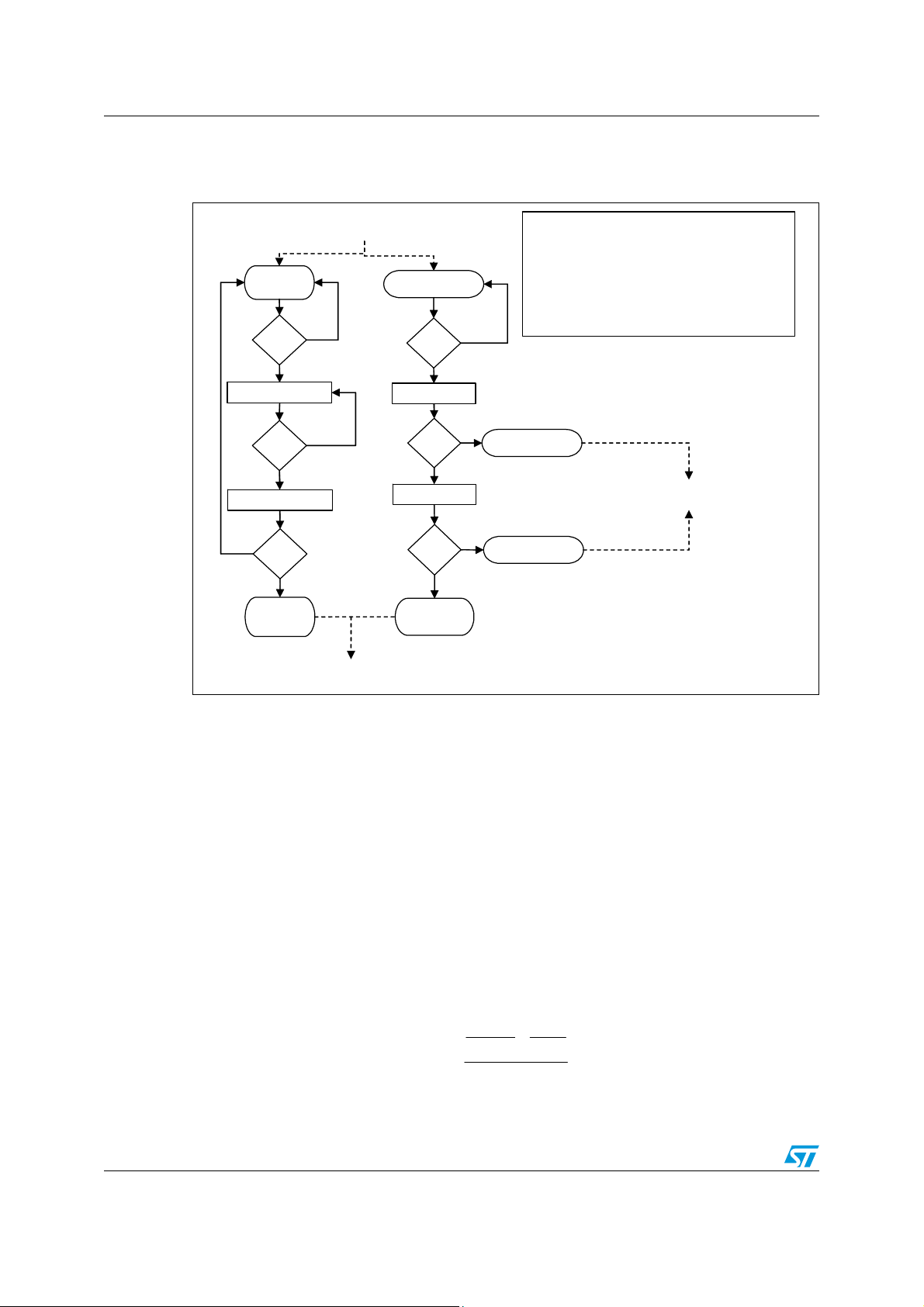

7.1 Charging process flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.2 Pre-charge current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.3 Pre-charge voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.4 Fast charge current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.5 End-of-charge current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

7.6 Recharge flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.7 Recharge threshold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.8 Maximum charging time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.9 Termination modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8 Application information: monitoring and protection . . . . . . . . . . . . . . 23

8.1 NTC thermistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.2 Battery absence detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

8.3 Status pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2/38 Doc ID 11908 Rev 9

L6924D Contents

8.4 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

9 Additional applications information . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.1 Selecting the input capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.2 Selecting the output capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

9.3 Layout guidelines and demonstration board description . . . . . . . . . . . . . 30

10 Application ideas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.1 USB battery charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

11 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

12 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Doc ID 11908 Rev 9 3/38

Description L6924D

1 Description

The L6924D is a fully monolithic battery charger dedicated to single-cell Li-Ion/Polymer

battery packs. It is the ideal solution for space-limited applications, like PDAs, handheld

equipment, cellular phones, and digital cameras. It integrates all of the power elements (the

power MOSFET, reverse blocking diode and the sense resistor) in a small VFQFPN16 (3 x 3

mm) package. When an external voltage regulated wall adapter is used, the L6924D works

in Linear Mode, and charges the battery in a constant current/constant voltage (CC/CV)

profile. Moreover, when a current-limited adapter is used, the device can operate in quasipulse mode, dramatically reducing the power dissipation. Regardless of the charging

approach, a closed loop thermal control avoids device overheating. The device has an

operating input voltage ranging from 2.5 V to 12 V. The L6924D allows the user to program

many parameters, such as pre-charge current, fast-charge current, pre-charge voltage

threshold, end-of-charge current threshold, and charge timer. The L6924D offers two open

collector outputs for diagnostic purposes, which can be used to either drive two external

LEDs or communicate with a host microcontroller. Finally, the L6924D also provides very

flexible control of the charge process termination and Gas Gauge capability, as well as other

functions, such as checking for battery presence, and monitoring and protecting the battery

from unsafe thermal conditions.

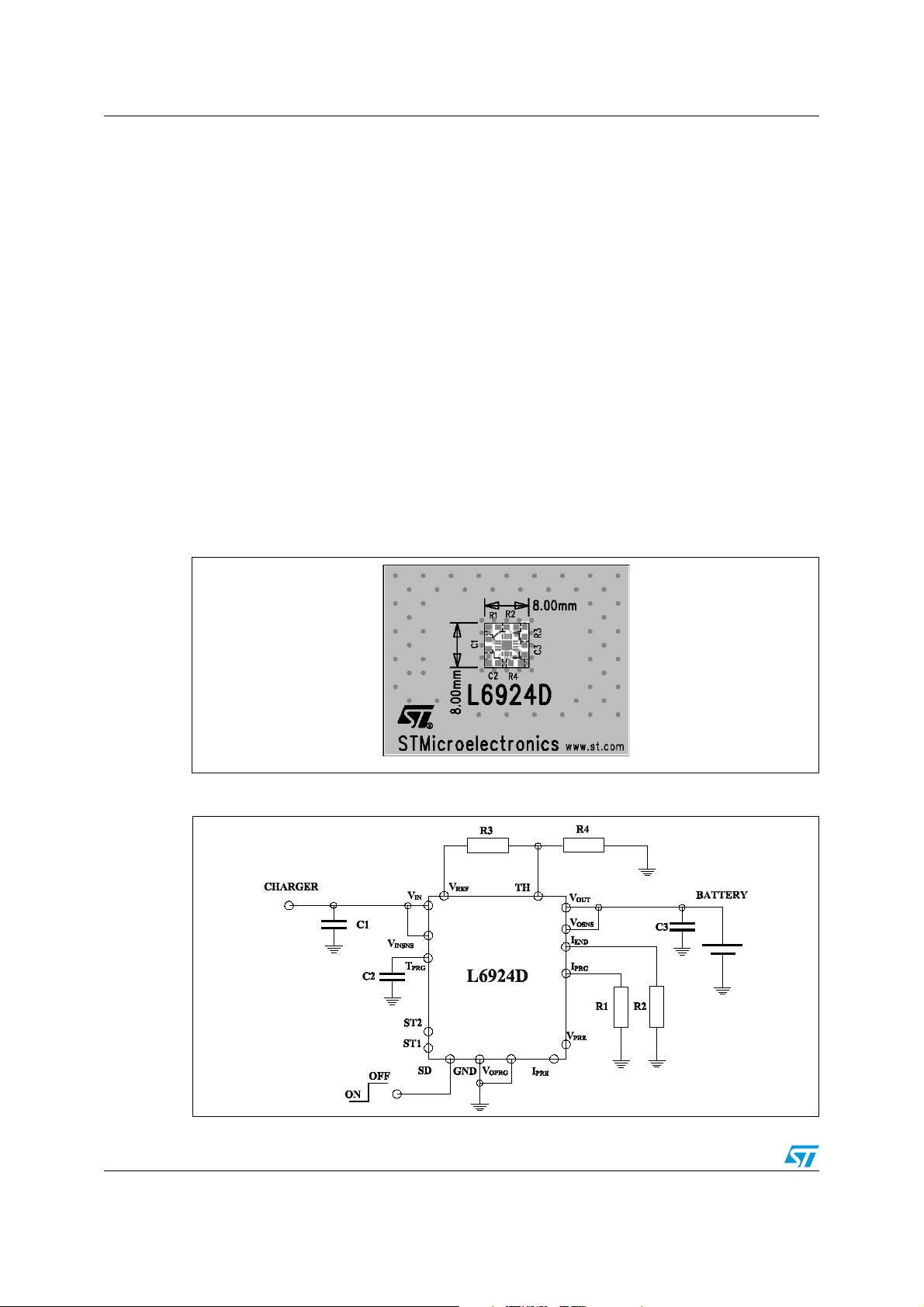

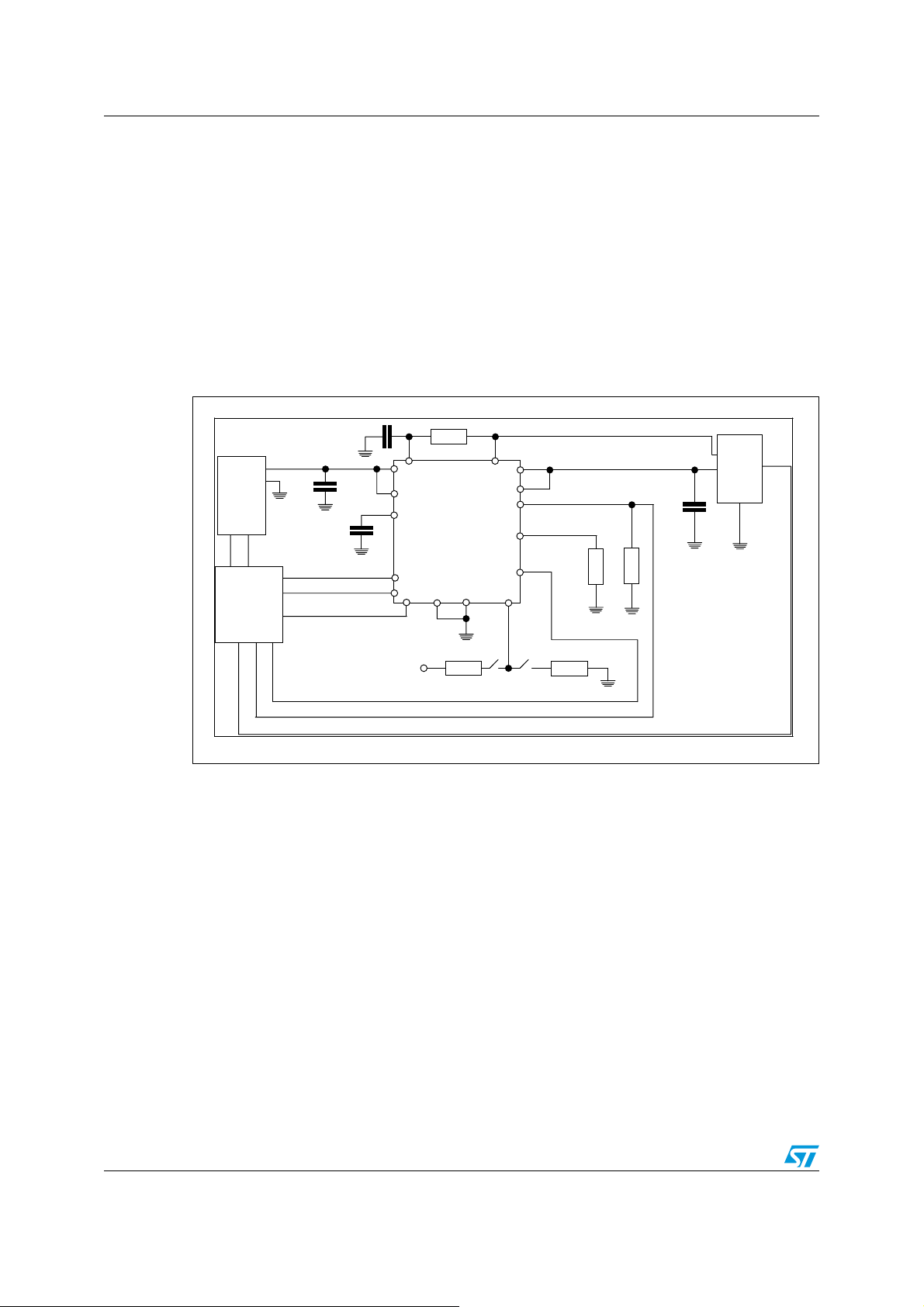

Figure 1. Minimum application size

Figure 2. Basis application schematic

4/38 Doc ID 11908 Rev 9

L6924D Pins description and connection diagrams

2 Pins description and connection diagrams

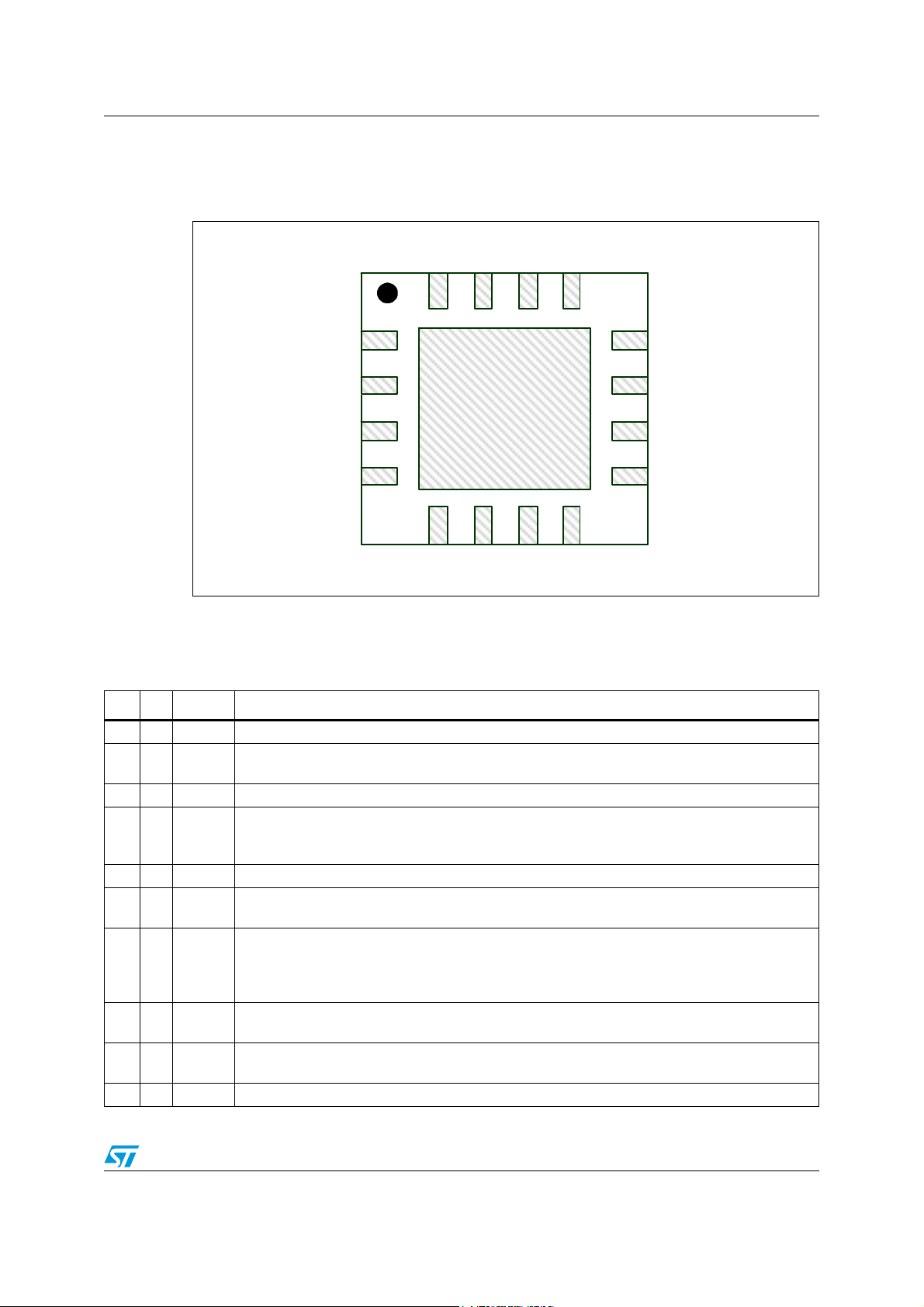

Figure 3. Pins connection (top view)

I

PRG

V

PRE

V

V

INSNS

IN

I

PRE

ST2

ST1

T

PRG

GND SD

2.1 Pin description

Table 2. Pin functions

Pin I/O Name Pin description

1I V

2IV

3-4 O ST

5IT

6 - GND Ground pin.

7I SD

8I TH

9IV

10 I V

11 O V

INSNS

OPRG

OSNS

Input pin of the power stage.

IN

Supply voltage pin of the signal circuitry.

The operating input voltage ranges from 2.5 V to 12 V and the start-up threshold is 4 V.

-ST1Open-collector status pins.

2

Maximum charging time program pin.

It must be connected with a capacitor to GND to fix the maximum charging time, see

PRG

Chapter 7.8: Maximum charging time on page 20

Shutdown pin.

When connected to GND enables the device; when floating disables the device.

Temperature monitor pin.

It must be connected to a resistor divider including an NTC or PTC resistor. The charge

process is disabled if the battery temperature (sensed through the NTC or PTC) is out of the

programmable temperature window see Chapter 8.1: NTC thermistor on page 23.

Output voltage selection pin.

V

= 4.1 V if left floating. V

OUT

Output voltage sense pin.

It senses the battery voltage to control the voltage regulation loop.

Output pin. (connected to the battery)

OUT

= 4.2 V if connected to GND.

OUT

I

I

END

END

TH

V

REF

V

OUT

V

V

OSNS

OSNS

V

OPRG

Doc ID 11908 Rev 9 5/38

Pins description and connection diagrams L6924D

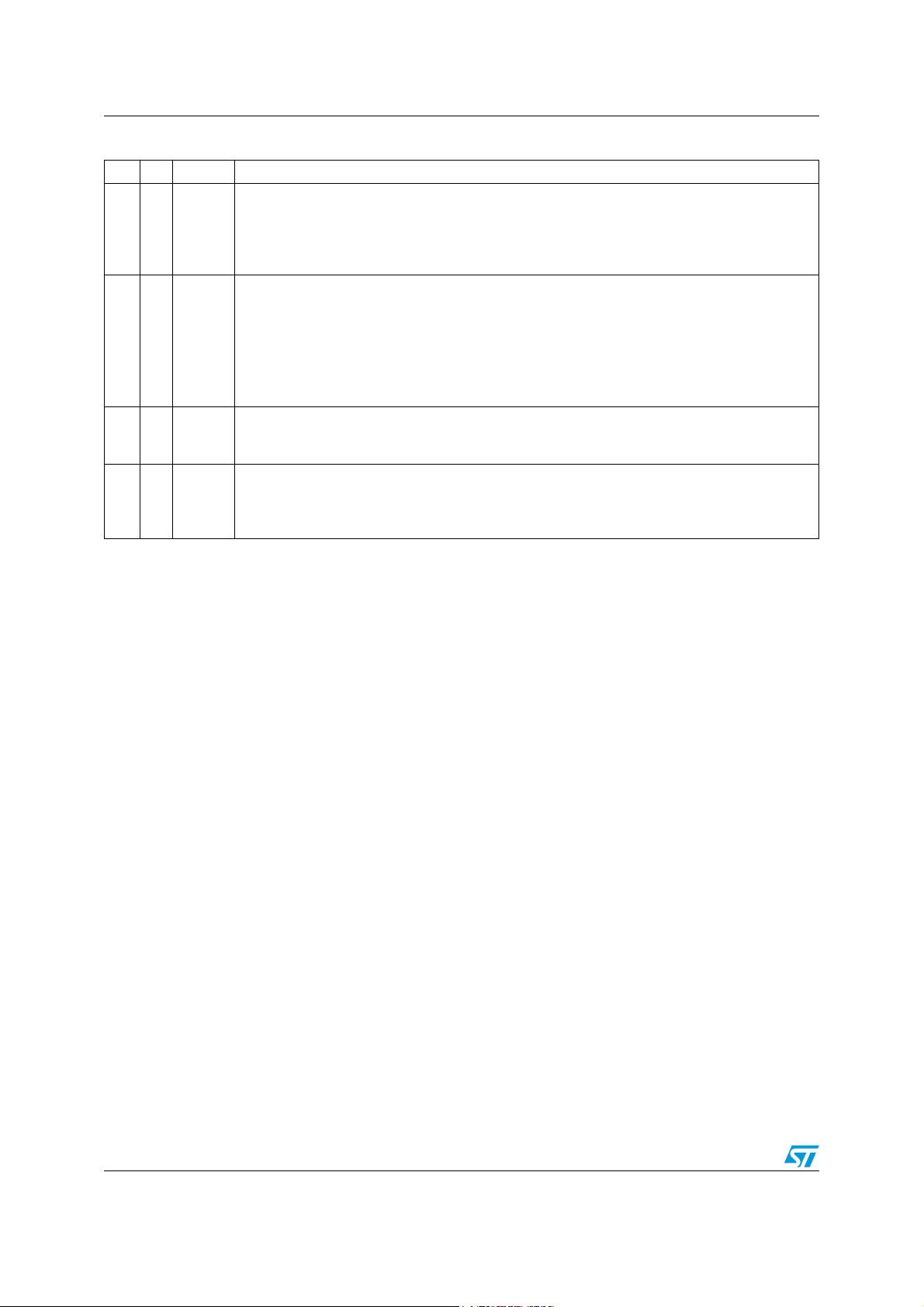

Table 2. Pin functions

12 O V

13 I/O I

14 I V

15 I I

16 I I

External reference voltage pin.(reference voltage is 1.8 V±2%)

REF

Charge termination pin.

A resistor connected from this pin to GND fixes the charge termination current threshold

END

I

ENDTH

: if I < I

, the charger behaves according to the V

ENDTH

status (see Chapter 7.5:

PRE

End-of-charge current on page 19). The voltage across the resistor is proportional to the

current delivered to the battery (Gas Gauge function).

Multifunction pin.

A resistor connected to GND allows the user to adjust the pre-charge voltage threshold

PRETH

.

= 2.8 V. If the voltage on V

PRETH

goes lower than 0.5 V (edge sensitive), the maximum charging time is

PRE

pin is lower than 0.8 V, V

PRE

ENDTH

.

V

If the pin is floating, V

PRE

2.8 V and the charge is not automatically terminated when I < I

If the voltage on V

reset.

Charge current program pin.

A resistor connected from this pin to GND, fixes the fast charge current value (I

PRG

accuracy of 7%.

Pre-charge current program pin.

If the pin is floating I

PRE

different value, the pin has to be connected to GND or V

is equal to 10% of I

PRETH

CHG

. If I

has to be programmed at a

PRETH

,

through a resistor see

REF

Chapter 7.2: Pre-charge current on page 17.

CHG

=

PRETH

), with an

6/38 Doc ID 11908 Rev 9

L6924D Maximum ratings

3 Maximum ratings

Stressing the device above the rating listed in the “absolute maximum ratings” table may

cause permanent damage to the device. These are stress ratings only and operation of the

device at these or any other conditions above those indicated in the operating sections of

this specification is not implied. Exposure to absolute maximum rating conditions for

extended periods may affect device reliability.

3.1 Absolute maximum ratings

Table 3. Absolute maximum ratings

Symbol Parameter Value Unit

V

IN

, SD Input voltage –0.3 to V

V

INSNS

V

, V

OUT

OSNS

ST1, ST2

V

REF

V

PRE

, TH, I

, I

T

PRG

PRE

END

, V

, GND

, I

PRG

OPRG

ST1 and TH pins Maximum withstanding voltage range test condition:

Other pins ±2 kV

3.2 Thermal data

Table 4. Thermal data

Symbol Parameter Value Unit

R

thJA

T

STG

T

J

P

TOT

1. Device mounted on demonstration board

Input voltage –0.3 to 16 V

IN

Output voltage –0.3 to 5 V

Output voltage –0.3 to 6 V

Output current 30 mA

,

,

–0.3 to 4 V

±1.5 kV

CDFAEC-Q100-002 (Normal “human body model”

acceptance criteria performance)

Thermal resistance junction to ambient

(1)

75 °C/W

Storage temperature range –55 to 150 °C

Junction temperature range –40 to 125 °C

Power dissipation at T= 70 °C TBD W

V

Doc ID 11908 Rev 9 7/38

Electrical specifications L6924D

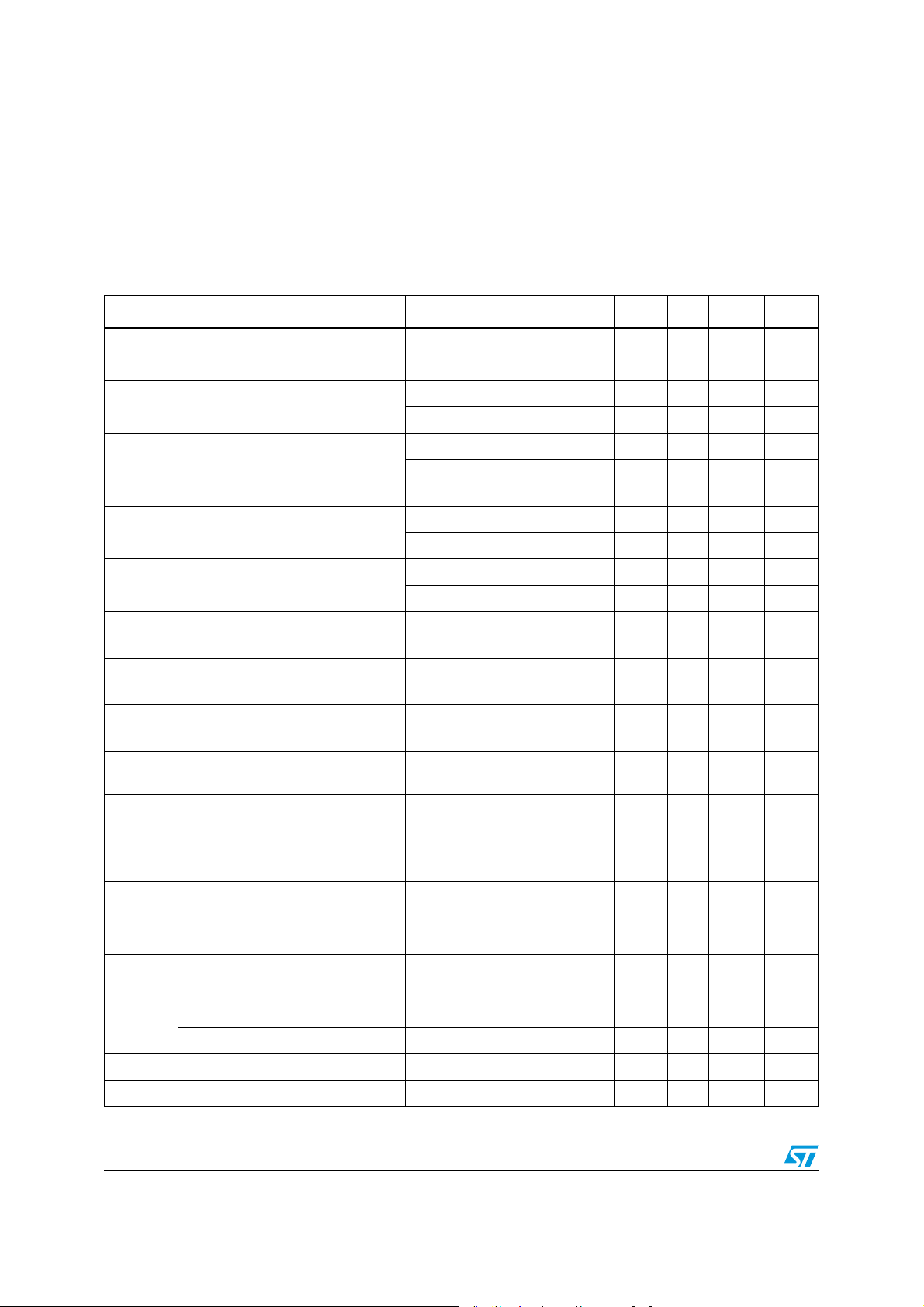

4 Electrical specifications

4.1 Electrical characteristics

TJ = 25 °C, V

Table 5. Electrical characteristics

= 5 V, unless otherwise specified.

IN

Symbol Parameter Test condition Min Typ Max Unit

Operating input voltage 2.5 12 V

(1)

V

IN

I

IN

I

SINK

V

OUT

I

CHG

I

PRECH

I

PRECH

I

PRECH

V

PRETH

V

PRETH

Start up threshold 4.1 V

(1)

Supply current

Current flowing from V

(1)

Battery regulated voltage

OUT

Charge current

Pre-Charge current

[default value = 10% I

CHG

Pre-Charge current

Pre-Charge current

Pre-Charge voltage threshold

[default]

Pre-Charge voltage threshold R

Charging mode (R

Shutdown mode (R

Shutdown mode (R

Stand by mode (R

= 2.5V < V

(V

IN

V

at V

OPRG

V

OPRG

R

PRG

R

PRG

I

PRE

]

R

PRG

R

PRE

R

PRG

R

PRE

R

PRG

V

PRE

VPRE

IN

at GND 4.16 4.2 4.24 V

= 24kΩ 450 490 525 mA

= 12kΩ 905 975 1045 mA

floating

= 24kΩ

= 62kΩ to GND;

= 24kΩ

= 39kΩ to V

= 24kΩ

= V

PRETHDefault

= 13kΩ; R

= 24kΩ)1.82.5mA

PRG

= 24kΩ)6080µA

PRG

= 24kΩ)500nA

PRG

= 24kΩ)

PRG

BATTERY

)

4.06 4.1 4.14 V

41 49 56 mA

57 67 78 mA

;

REF

29.5 35 40.1 mA

= Floating 2.7 2.8 2.9 V

= 12kΩ 2.87 3.03 3.19 V

PRG

500 nA

Pre-Charge voltage threshold

V

PRETH

[default]. Charge termination

2.7 2.8 2.9 V

disabled

I

ENDTH

T

MAXCH

T

MAXCH

(2)

Termination current R

(2)

Maximum charging time

Maximum charging time accuracy

= 3K3 12 16 20 mA

END

C

= 10nF

TPRG

R[I

C

TPRG

R

PRG

PRG

= 24kΩ

] = 24kΩ

= 5.6nF

3 hours

10%

Shutdown threshold high 2 V

SD

TH

Shutdown threshold low 0.4 V

ST1,2 Output status sink current Status on 10 mA

R

DS(on)

Power MOSFET resistance R

DS(on)@ICHG

= 500mA 280 380 mΩ

8/38 Doc ID 11908 Rev 9

L6924D Electrical specifications

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min Typ Max Unit

TH

NTC pin hot threshold voltage 10.625 12.5 14.375 %V

NTC pin cold threshold voltage 45 50 55 %V

1. TJ from –40°C to 125°C.

2. Guaranteed by design.

REF

REF

Doc ID 11908 Rev 9 9/38

Block diagram L6924D

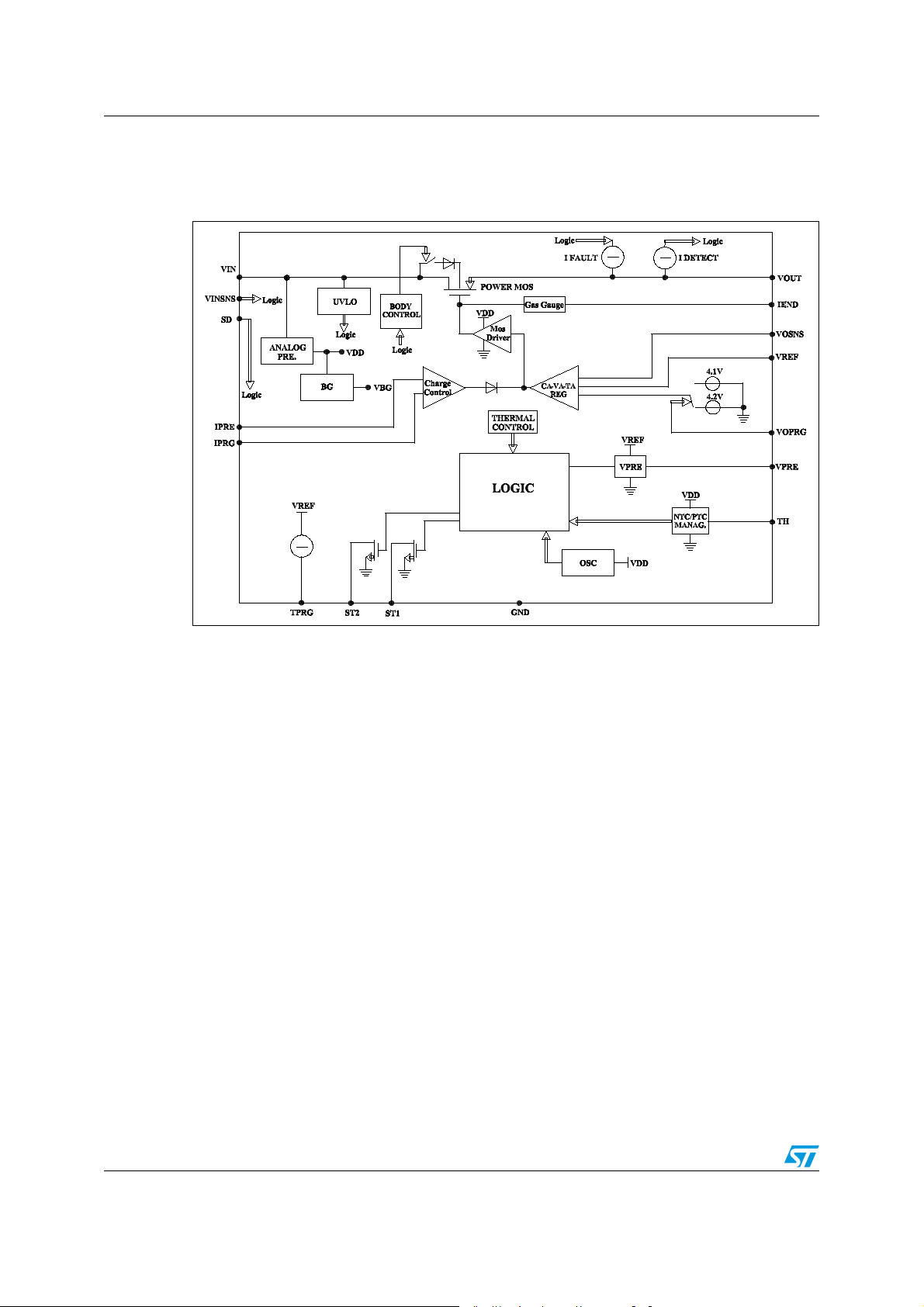

5 Block diagram

Figure 4. Block diagram

10/38 Doc ID 11908 Rev 9

L6924D Operation description

6 Operation description

The L6924D is a fully integrated battery charger that allows a very compact battery

management system for space limited applications. It integrates in a small package, all the

power elements: power MOSFET, reverse blocking diode and the sense resistor.

It normally works as a linear charger when powered from an external voltage regulated

adapter. However, thanks to its very low minimum input voltage (down to 2.5 V) the L6924D

can also work as a Quasi-Pulse charger when powered from a current limited adapter. To

work in this condition, is enough to set the device’s charging current higher than the

adapter’s one (Chapter 7.4 on page 18). The advantage of the linear charging approach is

that the device has a direct control of the charging current and so the designer needn’t to

rely on the upstream adapter. However, the advantage of the Quasi-Pulse approach is that

the power dissipated inside the portable equipment is dramatically reduced.

The L6924D charges the battery in three phases:

● Pre-Charge constant current: in this phase (active when the battery is deeply

discharged) the battery is charged with a low current.

● Fast-Charge constant current: in this phase the device charges the battery with the

maximum current.

● Constant Voltage: when the battery voltage reaches the selected output voltage, the

device starts to reduce the current, until the charge termination is done.

The full flexibility is provided by:

● Programmable pre-charging current and voltage thresholds (I

PRETH

and V

PRETH

)

(Chapter 7.2 on page 17, Chapter 7.3 on page 17).

● Programmable fast-charging current (I

● Programmable end of charge current threshold (I

● Programmable end of charge timer (T

) (Chapter 7.4 on page 18).

CHG

) (Chapter 7.5 on page 19).

ENDTH

) (Chapter 7.8 on page 20).

MAXCH

If the full flexibility is not required and a smaller number of external components is preferred,

default values of I

● If a PTC or NTC resistor is used, the device can monitor the battery temperature in

PRETH

and V

are available leaving the respective pins floating.

PRETH

order to protect the battery from operating in unsafe thermal conditions.

● Beside the good thermal behavior guaranteed by low thermal resistance of the

package, additional safety is provided by the built-in temperature control loop. The IC

monitors continuously its junction temperature. When the temperature reaches

approximately 120°C, the thermal control loop starts working, and reduces the charging

current, in order to keep the IC junction temperature at 120°C.

● Two open collector outputs are available for diagnostic purpose (status pins ST1 and

ST2). They can be also used to drive external LEDs or to interface with a

microcontroller.

The voltage across the resistor connected between I

and GND gives information about

END

the actual charging current (working as a Gas Gauge), and it can be easily fed into a µC

ADC.

Doc ID 11908 Rev 9 11/38

Operation description L6924D

When the V

pin is not used to program the Pre-Charge voltage threshold, it has two

PRE

different functions:

● If the voltage across V

pin is lower than 0.8 V, when I < I

PRE

, the end of charge is

ENDTH

notified by the status pin, but the charging process is not disabled. The charge process

ends when the maximum charging time expires.

● If the voltage at V

pin false under 0.5 V the timer is reset on the falling edge.

PRE

Battery disconnection control is provided thanks to the differentiated sensing and forcing

output pins. A small current is sunk and forced through V

OUT

. If V

doesn’t detect the

OSNS

battery, the IC goes into a standby mode.

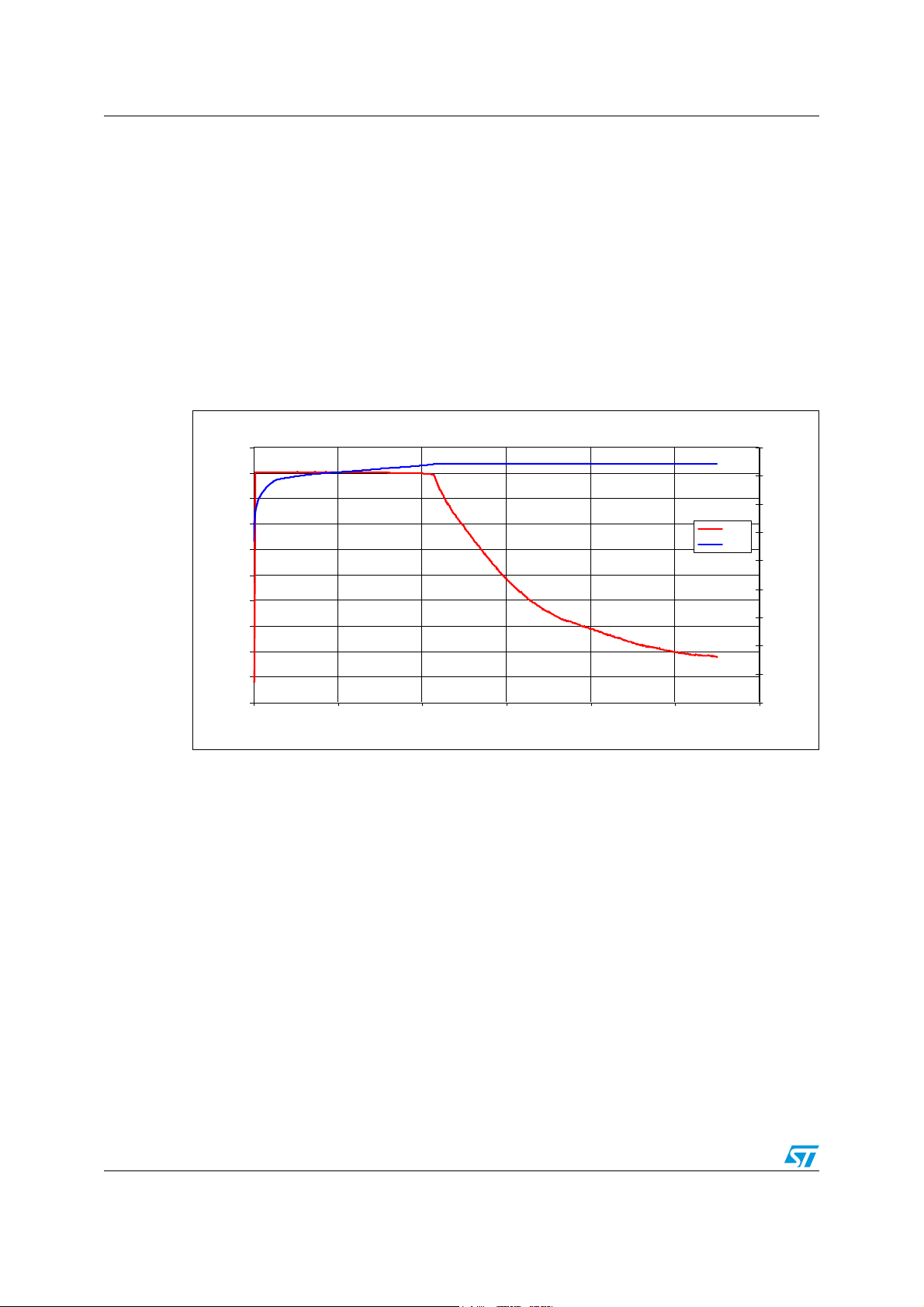

Figure 5 shows the real charging profile of a Li-Ion battery, with a fast charge current of 450

mA (R

PRG

= 26 kΩ),

Figure 5. Li-Ion charging profile

Charging profile

Ich g

Vb a tt

4.500

4.000

3.500

3.000

2.500

2.000

1.500

1.000

0.500

0.000

0.500

0.450

0.400

0.350

0.300

0.250

Ichg (A )

0.200

0.150

0.100

0.050

0.000

0 200 400 600 800 1000 1200

Charging time (sec)

Vbatt (V)

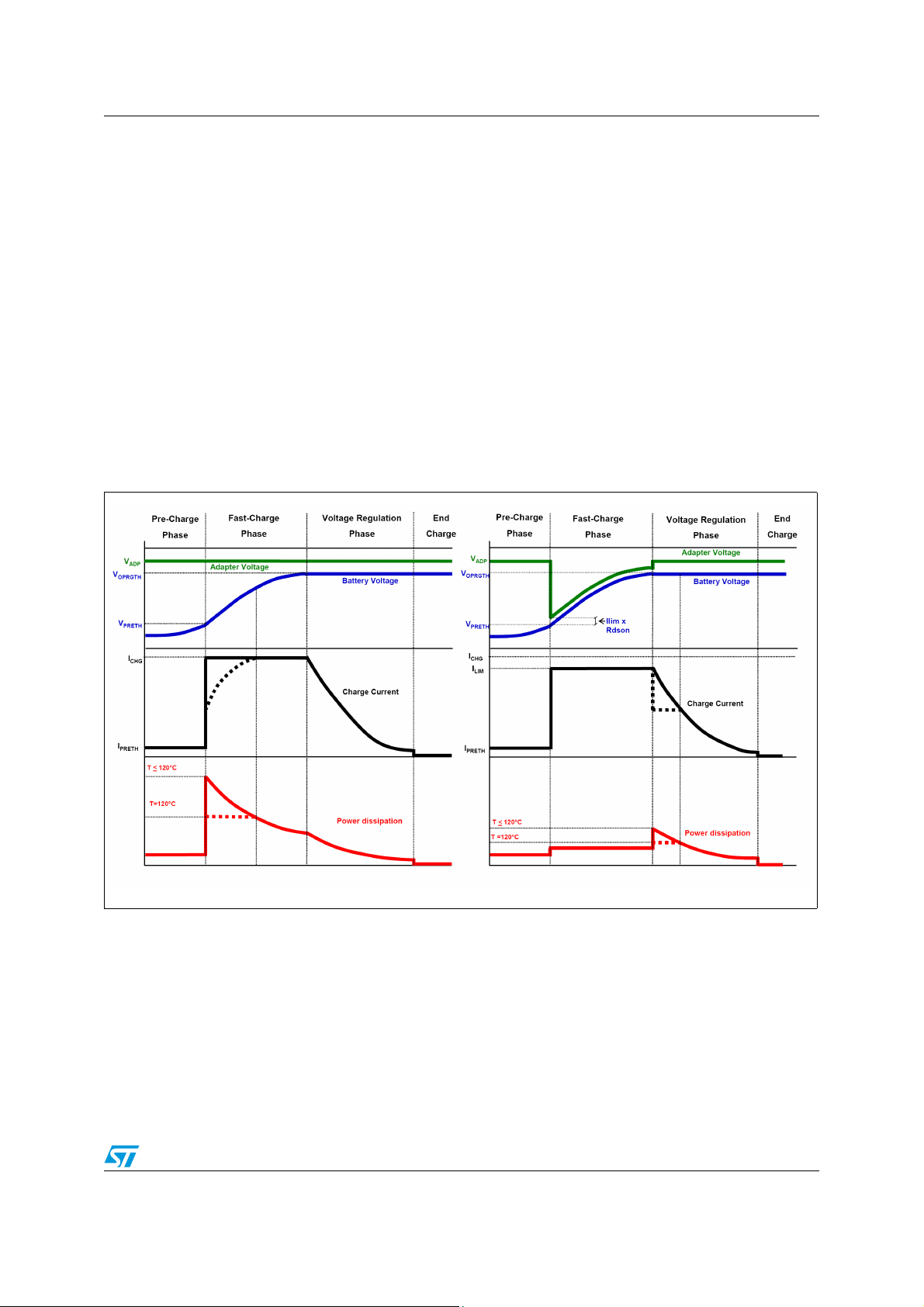

6.1 Linear mode

When operating in linear mode, the device works in a way similar to a linear regulator with a

constant current limit protection.

It charges the battery in three phases:

● Pre-charging current (“Pre-Charge” phase).

● Constant current (“Fast-Charge” phase).

● Constant voltage (“Voltage Regulation” phase).

V

is the output voltage of the upstream AC-DC adapter that is, in turn, the input voltage

ADP

of the L6924D. If the battery voltage is lower than a set pre-charge voltage (V

pre-charge phase takes place. The battery is pre-charged with a low current I

(Chapter 7.2 on page 17).

When the battery voltage goes higher than V

charge current I

, set through an external resistor (Chapter 7.4 on page 18).

CHG

Finally, when the battery voltage is close to the regulated output voltage V

4.2 V), the voltage regulation phase takes place and the charging current is reduced. The

12/38 Doc ID 11908 Rev 9

PRETH

), the

PRETH

PRE

, the battery is charged with the fast

OPRGTH

(4.1 V or

L6924D Operation description

×−=

charging process is usually terminated when the charging current reaches a set value or

when a charging timer expires (Chapter 7.9 on page 22).

Figure 6 shows the different phases.

Figure 6. Typical charge curves in linear mode

V

OPRGTH

V

I

V

ADP

PRETH

I

CHG

PRETH

Pre-Charge

Phase

Fast-Charge

Phase

Adapter Voltage

Voltage-Regulation

Phase

Battery Voltage

Charge Current

Power dissipation

End

Charge

The worst case in power dissipation occurs when the device starts the fast-charge phase. In

fact, the battery voltage is at its minimum value. In this case, this is the maximum difference

between the adapter voltage and battery voltage, and the charge current is at its maximum

value.

The power dissipated is given by the following equation:

Equation 1

IVVP

)(

CHGBATADPDIS

The higher the adapter voltage is, the higher the power dissipated. The maximum power

dissipated depends on the thermal impedance of the device mounted on board.

Doc ID 11908 Rev 9 13/38

Operation description L6924D

Δ+=

=

Δ

6.2 Quasi-pulse mode

The quasi-pulse mode can be used when the system can rely on the current limit of the

upstream adapter to charge the battery. In this case, I

current limit of the adapter. In this mode, the L6924D charges the battery with the same

three phases as in linear mode, but the power dissipation is greatly reduced as shown in

Figure 7.

Figure 7. Typical charge curves in quasi pulse mode

must be set higher than the

CHG

V

OPRGTH

V

I

V

ADP

PRETH

I

CHG

I

LIM

PRETH

Pre-Charge

Phase

Fast-Charge

Phase

Ilim x R dson

Voltage Regulation

Phase

Adapter Voltage

Battery Voltage

Charge Current

End

Charge

The big difference is due to the fact that I

is higher than the current limit of the adapter.

CHG

During the fast-charge phase, the output voltage of the adapter drops and goes down to the

battery voltage plus the voltage drop across the power MOSFET of the charger, as shown in

the following equation:

Equation 2

Where ΔV

is given by:

MOS

Equation 3

V

MOS

14/38 Doc ID 11908 Rev 9

Power dissipation

VVVV

MOSBATADPIN

×=

IR

LIMONDS

)(

L6924D Operation description

×−=

Where,

I

= current limit of the wall adapter, and R

LIM

= resistance of the power MOSFET.

DS(on)

The difference between the set charge current and the adapter limit should be high enough

to minimize the R

value (and the power dissipation). This makes the control loop

DS(on)

completely unbalanced and the power element is fully turned on.

Figure 8 shows the R

values for different output voltage and charging currents for an

DS(on)

adapter current limit of 500 mA.

Figure 8. R

curves vs charging current and output voltage

DS(on)

Neglecting the voltage drop across the charger (ΔV

) when the device operates in this

MOS

condition, its input voltage is equal to the battery one, and so a very low operating input

voltage (down to 2.5 V) is required. The power dissipated by the device during this phase is:

Equation 4

2

IRP ×=

)( LIMonDSCH

When the battery voltage approaches the final value, the charger gets back the control of

the current, reducing it. Due to this, the upstream adapter exits the current limit condition

and its output goes up to the regulated voltage V

. This is the worst case in power

ADP

dissipation:

Equation 5

IVVP

)(

LIMBATADPDIS

In conclusion, the advantage of the linear charging approach is that the designer has the

direct control of the charge current, and consequently the application can be very simple.

The drawback is the high power dissipation.

The advantage of the Quasi-Pulse charging method is that the power dissipated is

dramatically reduced. The drawback is that a dedicated upstream adapter is required.

Doc ID 11908 Rev 9 15/38

Applications information: charging process L6924D

7 Applications information: charging process

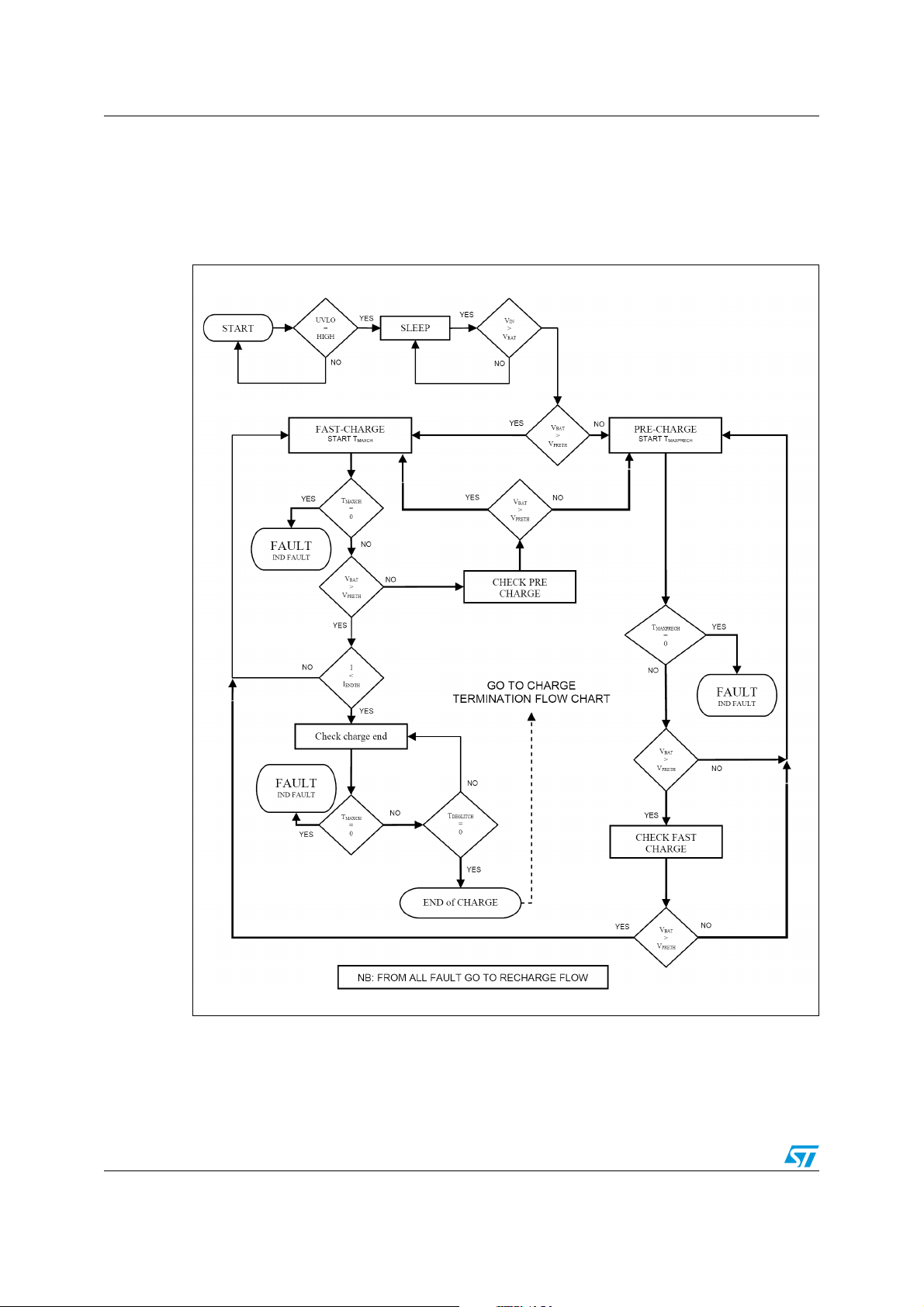

7.1 Charging process flow chart

Figure 9. Charging process flow chart

16/38 Doc ID 11908 Rev 9

L6924D Applications information: charging process

−

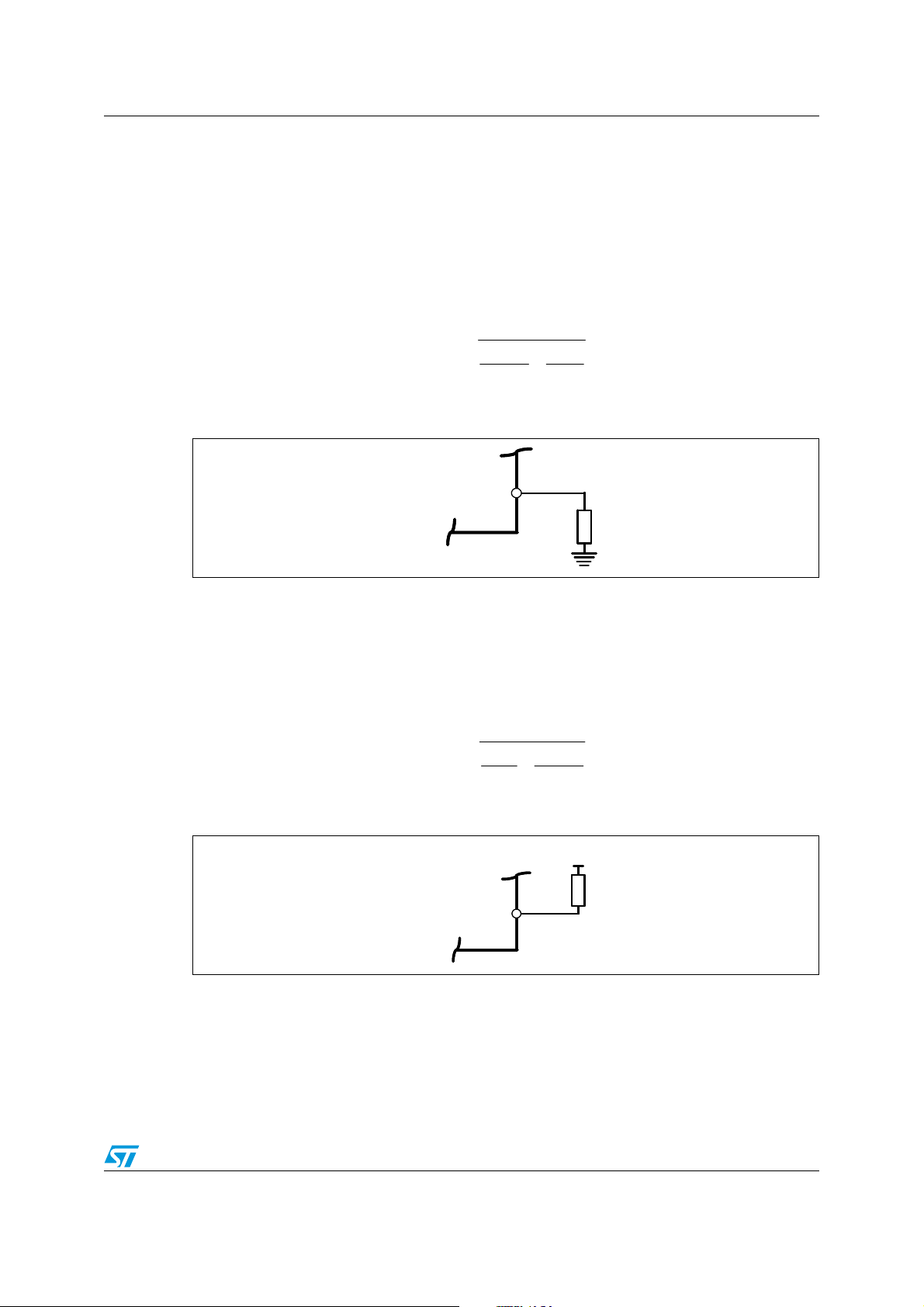

7.2 Pre-charge current

The L6924D allows pre-charging the battery with a low current when the battery voltage is

lower than a specified threshold (V

to 10% of the fast-charge current. However it can be adjusted by connecting a resistor from

the I

pin to GND or V

PRE

(see Figure 10). When the resistor is connected between I

REF

pin and GND, the current is higher than the default value. The R

Equation 6

). The Pre-charge current has a default value equal

PRETH

value is given by:

PRE

V

R−=

PRE

I

PRECH

K

PRE

BG

V

BG

R

PRG

PRE

Figure 10. I

When R

PRE

external reference equal to 1.8 V, V

pin connection

PRE

is connected to V

L6924D

L6924D

, the current is lower than the default value. V

REF

is the internal reference equal to 1.23 V and K

BG

constant equal to 950. See Figure 11.

The relationship is shown in the equation 7:

Equation 7

=

PRE

R

Figure 11. I

pin connection

PRE

I

I

PRE

PRE

is the

REF

BG

VV

REF

I

BG

V

PRG

R

PRECH

−

PRE

K

V

V

REF

REF

PRE

is a

I

I

PRE

PRE

L6924D

L6924D

7.3 Pre-charge voltage

If the V

Otherwise, the device offers the possibility to program this value, with a resistor connected

between the V

equation 8:

pin is floating, a default value of V

PRE

pin and GND (see Figure 12). In this case, the R

PRE

Doc ID 11908 Rev 9 17/38

is set, equal to 2.8 V (V

PRETH

PRETHDefault

is given by the

VPRE

).

Applications information: charging process L6924D

Equation 8

Figure 12. V

Where R

VPRE

pin connection

PRE

is the resistor between V

the charge current (see Section 7.4: Fast charge current), and V

threshold.

A safety timer is also present. If the battery voltage doesn't rise over V

time is expired, a fault is given (see Section 7.8: Maximum charging time). If at the beginning

of the charge process, the battery voltage is higher than the V

is skipped.

7.4 Fast charge current

⎛

RR

L6924D

L6924D

PRE

⎜

×=

PRGVPRE

⎜

V

⎝

V

V

and GND, and R

PRE

PRE

V

R

R

PRETH

PRE

PRE

⎞

⎟

⎟

ltPRETHDefau

⎠

is the resistor used to set

PRG

PRETH

is the selected

PRETH

, before this

PRETH

, the Pre-Charge phase

When the battery voltage reaches the Pre-charge voltage threshold (V

), the L6924D

PRETH

starts the Fast-charge Phase. In this phase, the device charges the battery with a constant

current, I

accuracy of 7% Figure 13. The equation used to select the R

, programmable by an external resistor that sets the charge current with an

CHG

as follows:

PRG

Equation 9

K

I

PRG

CHG

⎞

⎟

⎟

⎠

Figure 13. I

Where K

PRG

pin connection

PRG

is a constant, equal to 9500.

⎛

⎜

BGPRG

VR

×=

⎜

⎝

During this phase, the battery voltage increases until it reaches the programmed output

voltage. A safety timer is also present. If this time expires, a fault is given (Section 7.8:

Maximum charging time).

18/38 Doc ID 11908 Rev 9

L6924D Applications information: charging process

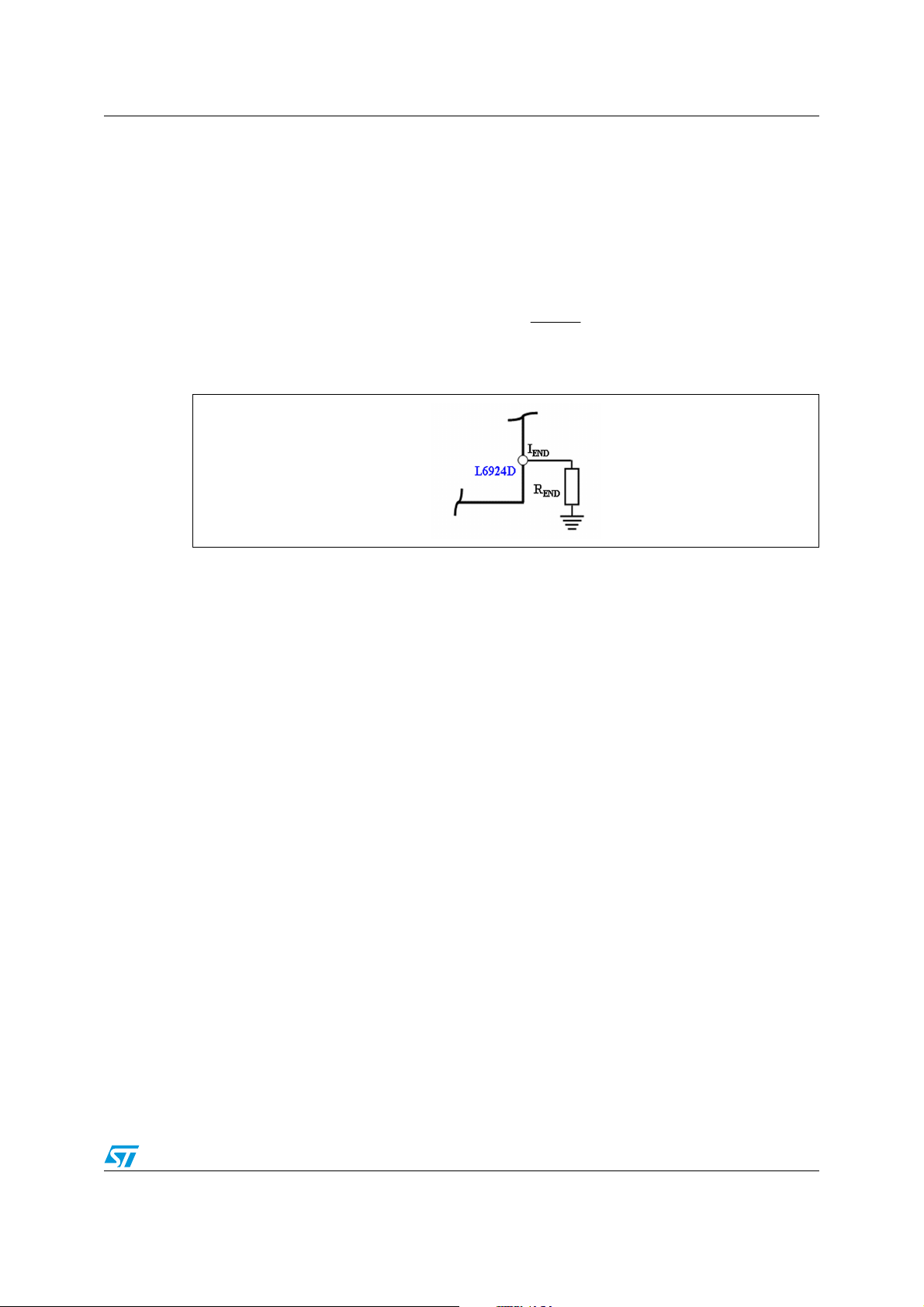

7.5 End-of-charge current

When the charge voltage approaches the selected value (4.1 V or 4.2 V), the voltage

regulation phase takes place. The charge current starts to decrease until it goes lower than

a programmable end value, I

the I

Equation 10

pin and GND (see Figure 14). The equation that describes this relation as follows:

END

, depending on an external resistor connected between

ENDTH

END

K

ENDTH

⎞

⎟

⎟

⎠

is

END

⎛

⎜

MINEND

VR

×=

⎜

I

⎝

Figure 14. I

Where K

Typically, this current level is used to terminate the charge process. However, it is also

possible to disable the charge termination process based on this current level (Chapter 7.9

on page 22).

This pin is also used to monitor the charge current, because the current injected in R

proportional to I

charge status like a gas gauge.

END

pin connection

END

is 1050; and V

. The voltage across R

CHG

is 50 mV.

MIN

can be used by a microcontroller to check the

END

Doc ID 11908 Rev 9 19/38

Applications information: charging process L6924D

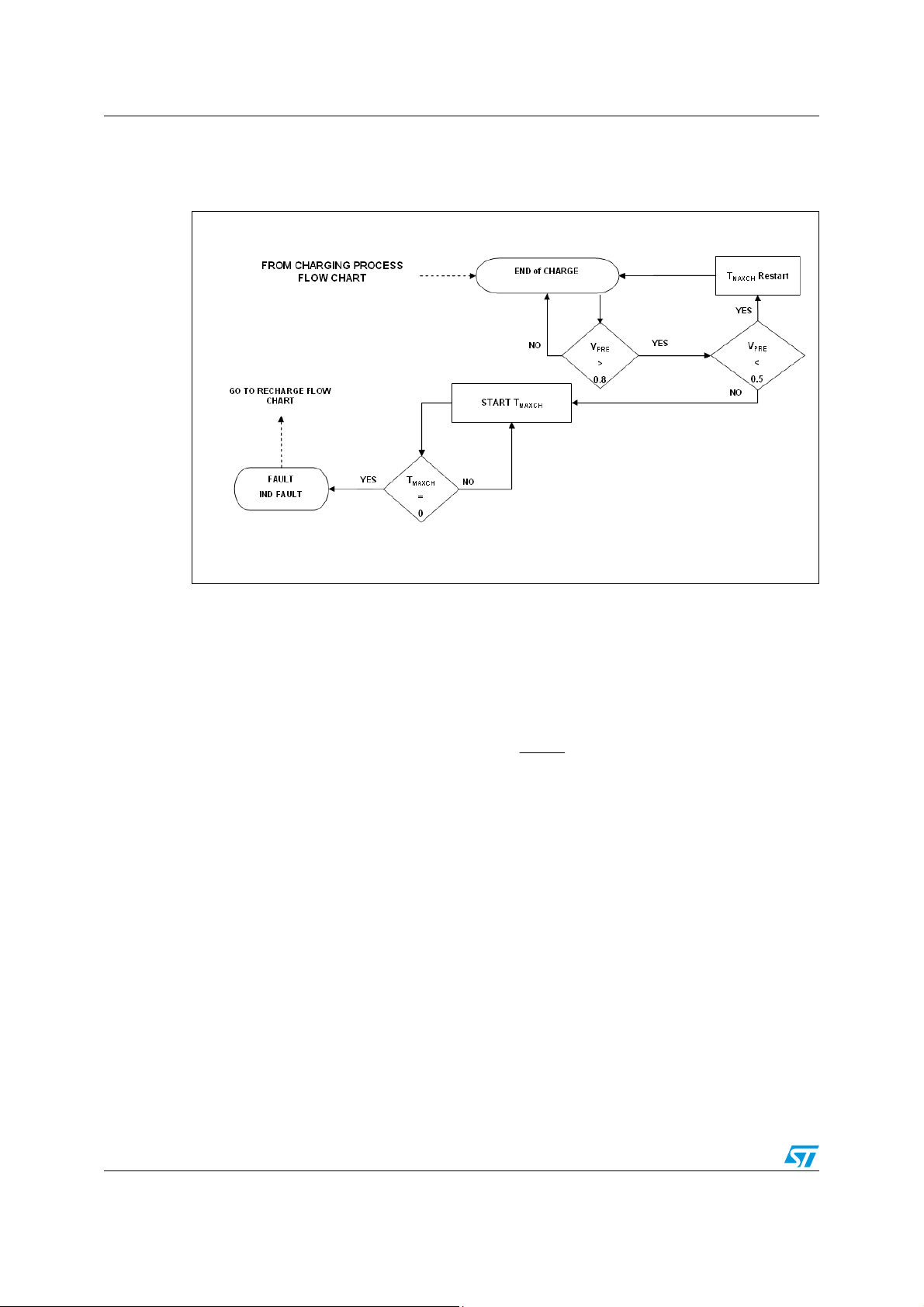

7.6 Recharge flow chart

Figure 15. Recharge flow chart

FROM CHARGING PROCESS FLOW CHART

FAULT

IND FAULT

V

YES

BAT

>

V

RCH

NO

Detect High Fault

V

BAT

YES

<

V

ABS

NO

Detect Low Fault

YES

V

BAT

>

V

PRETH

NO

BATTERY

ABSENT

GO TO BATTERY ABSENT

FLOW CHART

END of CHARGE

V

BAT

>

V

RCH

NO

Detect Low

V

BAT

>

V

PRETH

NO

Detect High

V

BAT

>

V

RCH

NO

BATTERY

ABSENT

YES

YES

YES

DETECT LOW = a I

DETECT HIGH = a I

DETECT LOW FAULT = a I

DETECT HIGH FAULT = a I

V

= V

ABS

OPRG

= V

V

RCH

OPRG

T

= 100ms (Typ.)

DET

I

= I

= 1mA (Typ.)

SINK

INJ

FAST CHARGE

PRE CHARGE

is sunk for a T

SINK

is injected for a T

INJ

– 50mV

– 150mV

RETURN TO CHARGING PROCESS

DET

is sunk for a T

SINK

is injected for a T

INJ

FLOW CHART

from the battery

in the battery

DET

from the battery

DET

in the battery

DET

7.7 Recharge threshold

When, from an end-of-charge condition, the battery voltage goes lower than the recharging

threshold (V

threshold is V

), the device goes back in charging state. The value of the recharge

RCH

OPRG

–150 mV.

7.8 Maximum charging time

To avoid the charging of a dead battery for a long time, the L6924D has the possibility to set

a maximum charging time starting from the beginning of the fast-charge phase. This timer

can be set with a capacitor, connected between the T

external capacitor (in nF) and is given by the following equation:

Equation 11

⎛

T

MAXCH

⎜

K

T

C

Note: The maximum recommended C

20/38 Doc ID 11908 Rev 9

TPRG

⎜

=

TPRG

⎜

V

⎜

⎝

REF

value must be less than 50 nF.

pin and GND. The C

PRG

⎞

V

BG

×

⎟

R

PRG

⎟

9

10×

⎟

⎟

⎠

TPRG

is the

L6924D Applications information: charging process

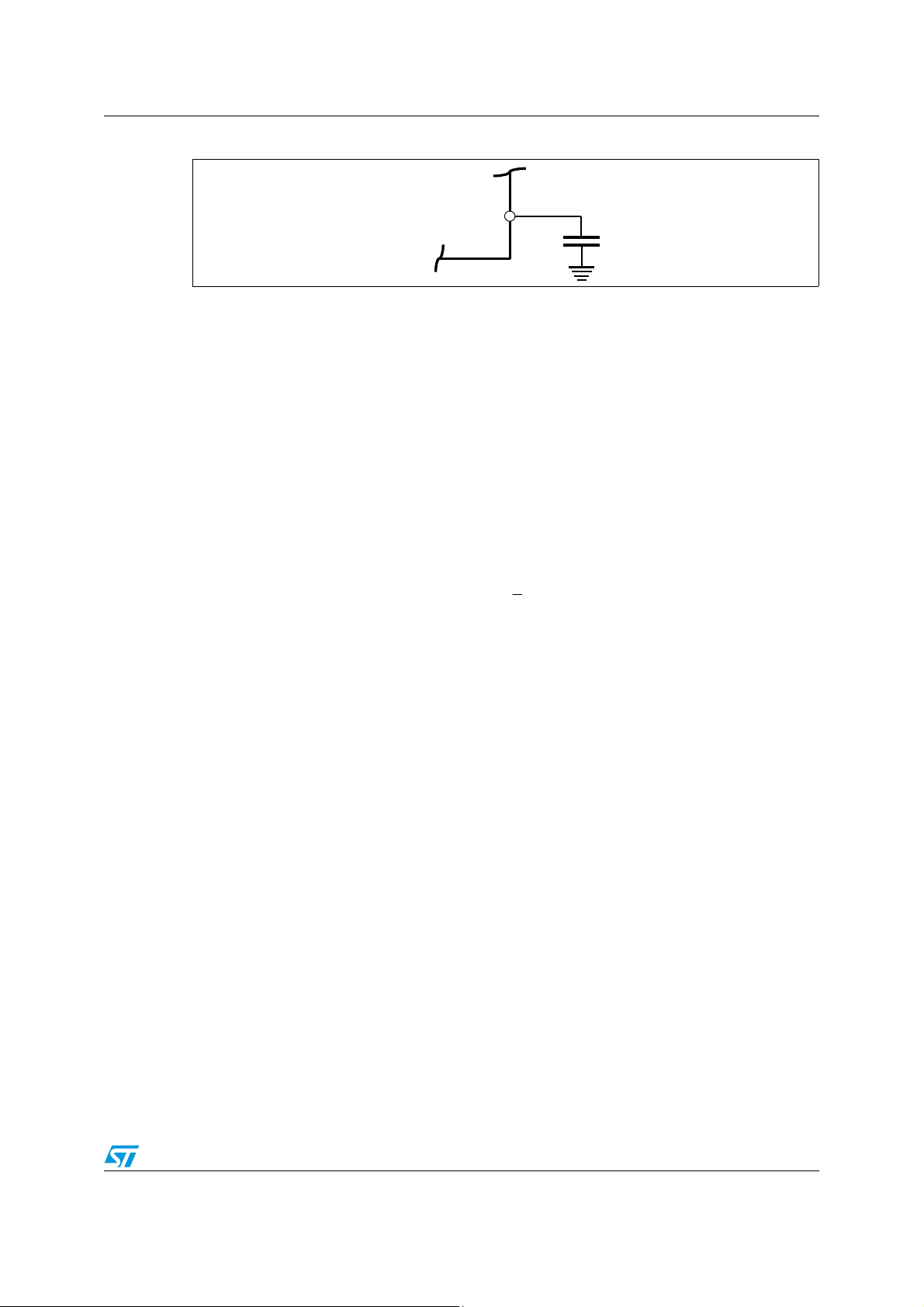

Figure 16. T

pin connection

PRG

L6924D

T

PRG

C

TPRG

Where,

= 1.8V,

V

REF

K

= 279 x 105,

T

V

= 1.23V, and

BG

T

is the charging time given in seconds.

MAXCH

If the battery does not reach the end-of-charge condition before the timer expires, a fault is

issued.

Also during the pre-charge phase there is a safety timer, given by:

Equation 12

1

TT ×=

MAXCHMAXPRECH

8

If this timer expires and the battery voltage is still lower than V

generated, and the charge process is terminated.

, a fault signal is

PRETH

Doc ID 11908 Rev 9 21/38

Applications information: charging process L6924D

7.9 Termination modes

Figure 17. Charge termination flow chart

As shown in Figure 14, it is possible to set an end of charge current I

resistor between the I

pin and GND. When the charge current goes down to this value,

END

ENDTH

connecting a

after a de-glitch time, the status pins notify that the charge process is complete. This deglitch time is expressed as:

Equation 13

T

T =

DEGLITCH

However, the termination of the charger process depends on the status of the V

● If the voltage at the V

pin is higher than 0.8 V, the charge process is actually

PRE

terminated when the charge current reaches I

● If the voltage at V

pin goes lower than 0.8 V, the charge process does not terminate,

PRE

and the charge current can go lower than I

charge as a fault condition, but the device continues the charge. When the T

MAXCH

220

.

ENDTH

. The status pins notify the end-of-

ENDTH

PRE

MAXCH

pin:

elapsed, the charge process ends, and a fault condition is issued.

● If the voltage on V

sets the V

● If the voltage at the V

PRETHDefault

pin is lower than 0.8 V during the Pre-charge Phase, the device

PRE

automatically.

pin goes lower than 0.5 V (edge sensitive), the timer is reset,

PRE

both in pre-charge and in fast-charge phase.

is

22/38 Doc ID 11908 Rev 9

L6924D Application information: monitoring and protection

8 Application information: monitoring and protection

The L6924D uses a VFQFPN 3 mm x 3 mm 16-pin package with an exposed pad that

allows the user to have a compact application and good thermal behavior at the same time.

The L6924D has a low thermal resistance because of the exposed pad (approximately

75°C/W, depending on the board characteristics). Moreover, a built-in thermal protection

feature prevents the L6924D from having thermal issues typically present in a linear charger.

Thermal control is implemented with a thermal loop that reduces the charge current

automatically when the junction temperature reaches approximately 120 °C. This avoids

further temperature rise and keeps the junction temperature constant. This simplifies the

thermal design of the application as well as protects the device against over-temperature

damage.

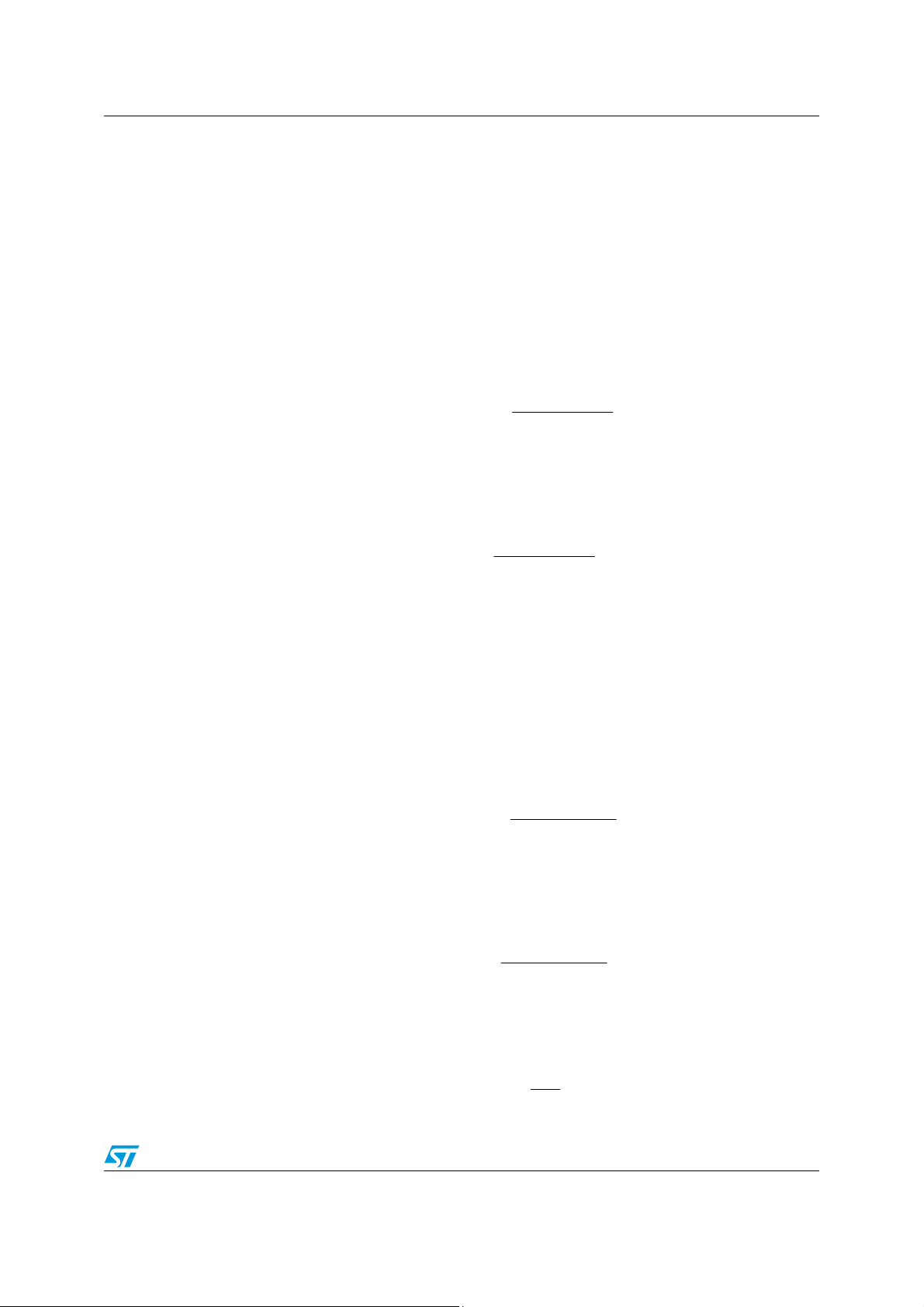

The Figure 18 shows how the thermal loop acts (with the dotted lines), when the junction

temperature reaches 120°C.

Figure 18. Power dissipation both linear and quasi pulse mode with thermal loop

8.1 NTC thermistor

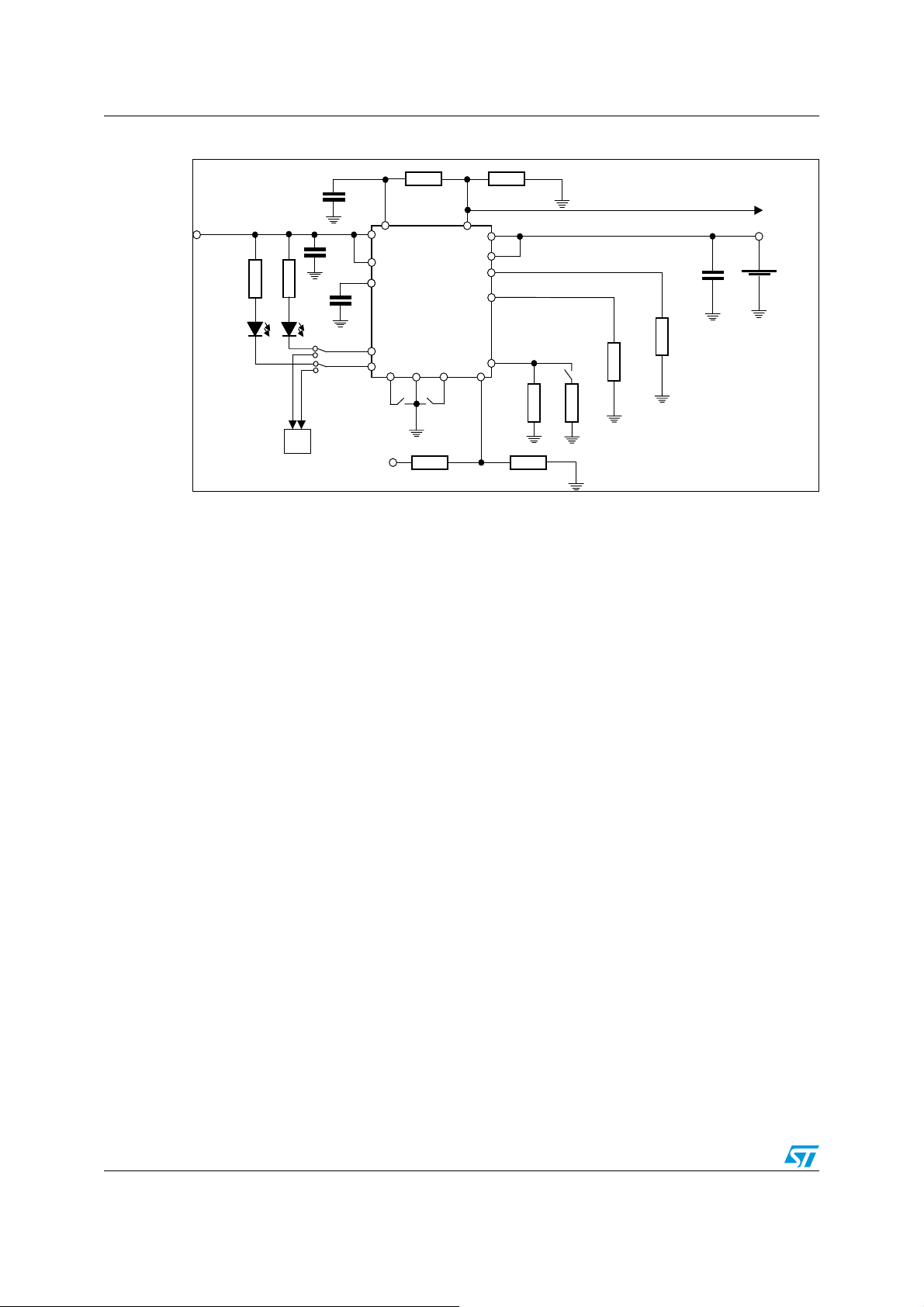

The device allows designers to monitor the battery temperature by measuring the voltage

across an NTC or PTC resistor. Li-Ion batteries have a narrow range of operating

temperature, usually from 0°C to 50 °C. This window is programmable by an external divider

which is comprised of an NTC thermistor connected to GND and a resistor connected to

V

. When the voltage on the TH pin exceeds the minimum or maximum voltage threshold

REF

(internal window comparator), the device stops the charge process, and indicates a fault

condition through the status pin.

Doc ID 11908 Rev 9 23/38

Application information: monitoring and protection L6924D

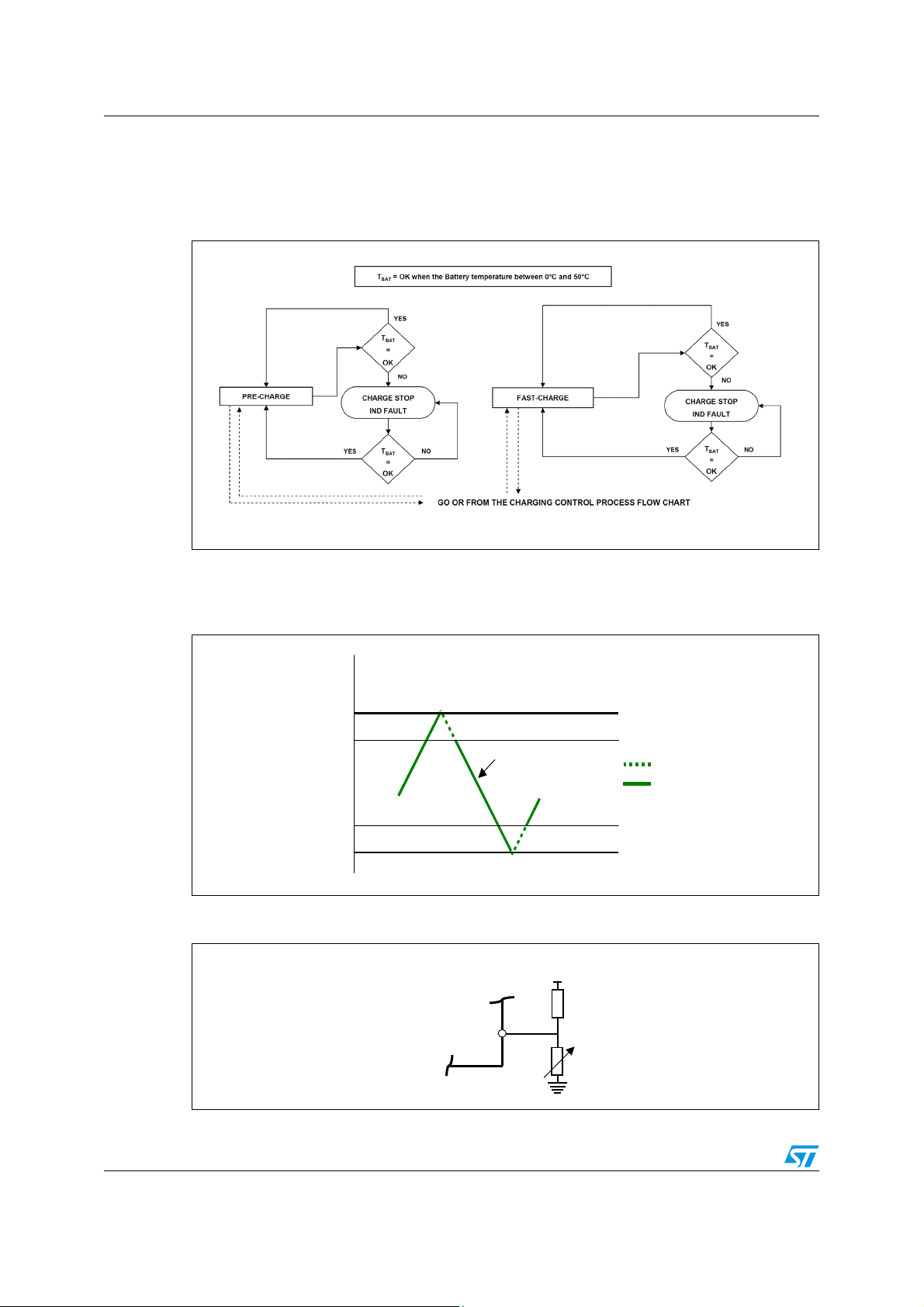

When the voltage (and thus, the temperature), returns to the window range, the device restarts the charging process. Moreover, there is a hysteresis for both the upper and lower

thresholds, as shown in Figure 20.

Figure 19. Battery temperature control flow chart

Note: T

= OK when the battery temperature between 0°C and 50°C

BAT

Figure 20. Voltage window with hysteresis on TH

V

MI N T H

V

MINTH_ HYS

900mV

780mV

Vol t ag e

Vari atio n on TH pi n

V

MAXTH_HYS

V

MAXTH

248mV

225mV

Figure 21. Pin connection

V

TH

L6924D

NTC

Charge disable

Charge enable

REF

24/38 Doc ID 11908 Rev 9

L6924D Application information: monitoring and protection

=

When the TH pin voltage rises and exceeds the V

MINTH

= 50% of V

(900 mV typ), the

REF

L6924D stops the charge, and indicates a fault by the status pins. The device re-starts to

charge the battery, only when the voltage at the TH pin goes under V

MINTH_HYS

= 780 mV

(typ).

For what concerns the high temperature limit, when the TH pin voltage falls under the

V

MAXTH

voltage rises to the V

= 12.5% of V

(225 mV Typ.), the L6924D stops the charge until the TH pin

REF

MAXTH_HYS

= 248 mV (Typ.).

When the battery is at the low temperature limit, the TH pin voltage is 900 mV. The correct

resistance ratio to set the low temperature limit at 0°C can be found with the following

equation:

Equation 14

R

CNTC

°

VV

×=

REFMINTH

Where R

is the pull-up resistor, V

UP

is equal to 1.8 V, and R

REF

NTC at 0°C. Since at the low temperature limit V

+

MINTH

0

RR

CNTCUP

°

0

= 900 mV:

is the value of the

NTC0°C

Equation 15

R

CNTC

°

8.19.0

×=

0

RR

+

CNTCUP

°

0

It follows that:

Equation 16

RR

UPCNTC

°0

Similarly, when the battery is at the high temperature limit, the TH pin voltage is 225 mV. The

correct resistance ratio to set the high temperature limit at 50°C can be found with the

following equation:

Equation 17

Where R

NTC50°C

VV

REFMAXTH

R

×=

is the value of the NTC at 50°C. Considering V

CNTC

°

50

RR

+

CNTCUP

°

50

= 225 mV it follows

MAXTH

that:

Equation 18

8.1225.0

R

×=

CNTC

°

50

RR

+

CNTCUP

°

50

Consequently:

Equation 19

R =

Doc ID 11908 Rev 9 25/38

R

50UPCNTC

°

7

Application information: monitoring and protection L6924D

−

−

−

−

−

Based on Equation 16: and Equation 19: , it derives that:

Equation 20

R

0

CNTC

7

R

=

50

°°CNTC

The temperature hysteresis can be estimated by the equation:

Equation 21

VV

HYSTHTH

=

T

HYS

_

NTCV

×

TTH

Where V

threshold on the falling edge, and NTC

the NTC at temperature (T) expressed in % resistance change per °C. For NTC

is the pin voltage threshold on the rising edge, V

TH

(-%/°C) is the negative temperature coefficient of

T

TH_HYS

is the pin voltage

values, see

T

the characteristics of the NTC manufacturers (e.g. the 2322615 series by VISHAY). At the

low temperature, the hysteresis is approximately:

Equation 22

mVmV

T

=

CHYS

°

0

780900

CNTCmV

°×

0900

Obviously at the high temperature hysteresis is:

Equation 23

mVmV

T

Considering typical values for NTC

CHYS

°

50

and NTC

0°C

=

248225

CNTCmV

°×

50225

, the hysteresis is:

50°C

Equation 24

mVmV

T

=

CHYS

0

°

mV

780900

051.0900

×

o

C

5.2

≅

And:

Equation 25

mVmV

T

=

CHYS

50

°

mV

248225

039.0225

×

o

C

5.2

−≅

If a PTC connected to GND is used, the selection is the same as above, the only difference

is when the battery temperature increases, the voltage on the TH pin increases, and vice

versa. For applications that do not need a monitor of the battery temperature, the NTC can

be replaced with a simple resistor whose value is one half of the pull-up resistor R

UP

.

In this case, the voltage at the TH pin is always inside the voltage window, and the charge is

always enabled.

26/38 Doc ID 11908 Rev 9

L6924D Application information: monitoring and protection

8.2 Battery absence detection

This feature provides a battery absent detection scheme to detect the removal or the

insertion of the battery. If the battery is removed, the charge current falls below the I

At the end of the de-glitch time, a detection current I

output for a time of T

V

, a current equal to I

PRETH

DETECT

. The device checks the voltage at the output. If it is below the

DETECT

is injected in the output capacitor for a T

DETECT

checked to see if the voltage on the output goes higher than V

mV). If the battery voltage changes from V

PRETH

to V

it means that no battery is connected to the charger. The T

, equal to 1 mA, is sunk from the

(the value is V

ABS

and vice versa in a T

ABS

DETECT

is expressed by:

DETECT

Equation 26

T

MAXCH

T

DETECT

=

3

1054 ×

Figure 22. Battery absent detection flow chart

, and it is

OPRGTH

DETECT

ENDTH

-50

time,

.

Detect Low Absent

Detect High Absent

YES

BATTERY

ABSENT

V

BAT

>

V

PRETH

NO

V

BAT

>

V

RCH

YES

NO

DETECT LOW ABSENT = a I

DETECT HIGH ABSENT = a I

= 100ms (Typ.)

T

DET

= I

I

SINK

= 1mA (Typ.)

INJ

FAST CHARGE

PRE CHARGE

is sunk for a T

SINK

is injected for a T

INJ

from the battery

DET

in the battery

DET

8.3 Status pins

To indicate various charger status conditions, there are two open-collector output pins, ST1

and ST2. These status pins can be used either to drive status LEDs, connected to an

external power source, by a resistor, or to communicate to a host processor. These pins

must never be connected to the V

when it exceeds their absolute value (6 V).

IN

Doc ID 11908 Rev 9 27/38

Application information: monitoring and protection L6924D

Figure 23. ST1 and ST2 connection with LEDs or microcontroller

Table 6. Status LEDs indications

Charge condition Description ST1 ST2

Charge in progress When the device is in pre-charge or fast-charge status ON OFF

Charge done When the charging current goes lower than the I

Stand by mode When the input voltage goes under V

Bad battery temperature

Battery absent When the battery pack is removed ON ON

Over time When T

8.4 Shutdown

The L6924D has a shutdown pin (SD) that allows enabling or disabling the device.

If the SD pin voltage is below 0.4 V (e.g. pin connected to GND), the device is enabled,

whereas if the SD pin voltage exceeds 2 V (e.g. the shutdown pin is left floating) the device

is disabled.

When the device enters the shutdown mode, the current consumption is reduced to 60 μA

typ. In this condition, V

The Figure 24 clarifies the SD pin behavior.

ENDTH

-50 mV OFF OFF

BAT

When the voltage on the TH pin is out of the programmable

window, in accordance with the NTC or PTC thermistor

is turned off.

REF

MAXCH

or T

MAXPRECH

is expired ON ON

OFF ON

ON ON

28/38 Doc ID 11908 Rev 9

L6924D Application information: monitoring and protection

Figure 24. Shutdown

SD

SD

pin voltage

pin voltage

device disabled

device disabled

2V

2V

0.4V

0.4V

device enabled

device enabled

SD

SD

SD

SD

TH,high

TH,high

TH,low

TH,low

Doc ID 11908 Rev 9 29/38

Additional applications information L6924D

+×=

9 Additional applications information

9.1 Selecting the input capacitor

In most applications, a 1 µF ceramic capacitor, placed close to the VIN and V

be used to filter the high frequency noise.

INSN

pins can

9.2 Selecting the output capacitor

Typically, 1 µF ceramic capacitor placed close to the V

keep voltage control loop stable. This ensures proper operation of battery absent detection

in removable battery pack applications.

OUT

and V

pin is enough to

OUTSN

9.3 Layout guidelines and demonstration board description

The thermal loop keeps the device at a constant temperature of approximately 120°C which

in turn, reduces I

ensure a good thermal path. Therefore, the exposed pad must be properly soldered to the

board and connected to the other layer through thermal vias. The recommended copper

thickness of the layers is 70 µm or more.

The exposed pad must be electrically connected to GND. Figure 25 shows the thermal

image of the board with the power dissipation of 1 W. In this instance, the temperature of the

case is 89°C, but the junction temperature of the device is given by the following equation:

Equation 27

. However, in order to maximize the current capability, it is important to

CHG

TPRT

−

AMBDISSATHJJ

Where the R

and the ambient temperature is 25 °C.

In this case the junction temperature is:

Equation 28

30/38 Doc ID 11908 Rev 9

of the device mounted on board is 75 °C/W, the power dissipated is 1 W,

TH J-A

J

o

CT

10025175 =+×=

L6924D Additional applications information

Figure 25. Thermal image of the demonstration board

The V

pin can be used as a remote sense; it should be therefore connected as closely

OSNS

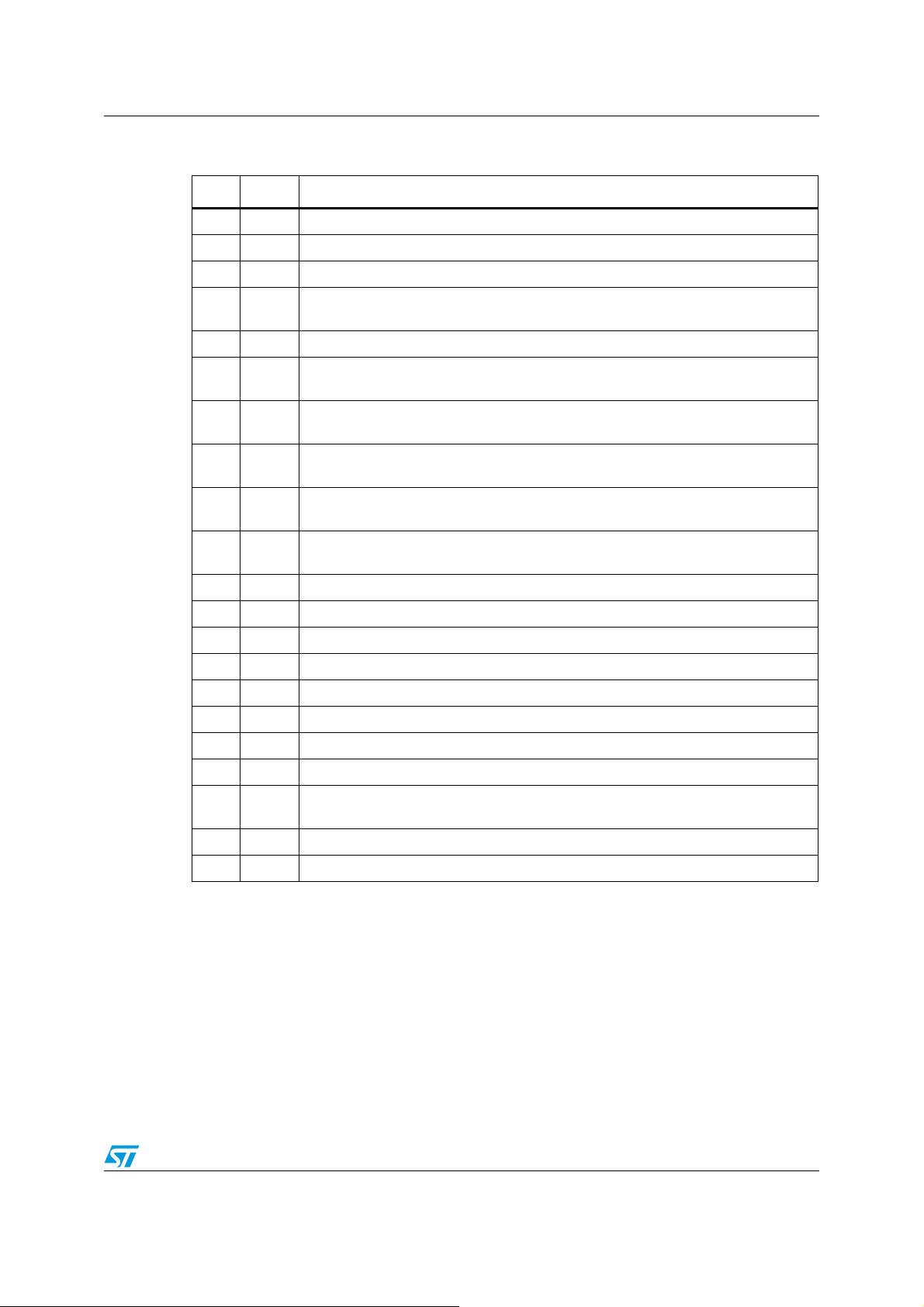

as possible to the battery. The demonstration board layout and schematic are shown in

Figure 26, Figure 27 and Figure 28.

Figure 26. Demonstration board layout, top side

Figure 27. Demonstration board layout, bottom side

Doc ID 11908 Rev 9 31/38

Additional applications information L6924D

Figure 28. Demonstration board schematic

R9

V

OUT

V

OSNS

I

END

I

PRG

V

PRE

I

PRE

CHARGER

R1 R2

LD1 LD2

μC

R3

C4

V

REF

V

IN

TH

C1

V

INSNS

T

PRG

C2

J2

ST2

L6924D

ST1

J1

SHDN

GND

J3

V

OPRG

J4

Vref

R7

NTC

BATTERY

C3

R4

R5

J5

R6

R10

R8

32/38 Doc ID 11908 Rev 9

L6924D Additional applications information

Table 7. Demonstration board components description

Name Value Description

R1 1k Pull up resistor. To be used when the ST1 is connected to a LED.

R2 1k Pull up resistor. To be used when the ST1 is connected to a LED.

R3 1k Pull up resistor. Connected between V

R4 3k3

End of charge current resistor. Used to set the termination current and, as a “Gas

Gauge” when measuring the voltage across on it.

and TH pin.

REF

R5 24k Fast-charge current resistor. Used to set the charging current.

R6 N.M.

R7 N.M.

R8 68k

R9 470R

R10 N.M.

V

mounted, the V

I

the default one. If not mounted, the I

I

the default one. If not mounted, the I

If a NTC is not used, a half value of R3 must be mounted to keep the TH voltage in

the correct window.

It has the same function of R6. Moreover, if it is replaced with a short-circuit, when

J5 is closed, the timer is reset (falling edge).

resistor. Used to set programmable pre-charge voltage threshold. If not

PRETH

PRETHDefault

resistor. Used to set the programmable pre-charge current threshold below

PRETH

resistor. Used to set the programmable pre-charge current threshold above

PRETH

, equal to 2.8V, is set.

PRETHDefault

PRETHDefault

is set.

is set.

C1 1µF Input capacitor.

C2 10nF T

capacitor. Used to set the maximum charging time.

MAX

C3 4.7µF Output capacitor.

C4 1nF V

filter capacitor.

REF

LD1 GREEN ST1 LED.

LD2 RED ST2 LED.

J1 ST1 jumper. Using to select the LED or the external µC.

J2 ST2 jumper. Using to select the LED or the external µC.

J3

J4 V

J5 V

SD jumper. If open, the device is in shutdown mode; when closed, the device starts

to work.

jumper. If closed, the 4.2V output voltage is set; if open, the 4.1V is set.

OPRG

jumper. If closed with R10 in short-circuit with GND, resets the timer.

PRE

Doc ID 11908 Rev 9 33/38

Application ideas L6924D

10 Application ideas

10.1 USB battery charger

With a voltage range between 4.75 V and 5.25 V, and a maximum current up to 500 mA, the

USB power bus is an ideal source for charging a single-cell Li-Ion battery. Since it is not

possible to rely on the USB current limit to charge the battery, a linear approach must be

adopted. Therefore, it is only necessary to set the I

500 mA, and the device will charge the battery in Linear mode.

Figure 29 shows an example of USB charger application schematic.

Figure 29. USB charger application

with a maximum value lower than

CHG

V

BUS

GND

D- D+

SYSTEM

AND

USB

CONTROLLER

V

V

T

ST1

ST2

IN

INSNS

PRG

R1

V

REF

L6924D

GND

SD

TH

V

OUT

V

OSNS

I

END

I

PRG

V

PRE

I

V

PRE

OPRG

R4

R2 R3

R5

C3

BATTERY

PACK

C4

C1

C2

34/38 Doc ID 11908 Rev 9

L6924D Package mechanical data

11 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

Doc ID 11908 Rev 9 35/38

Package mechanical data L6924D

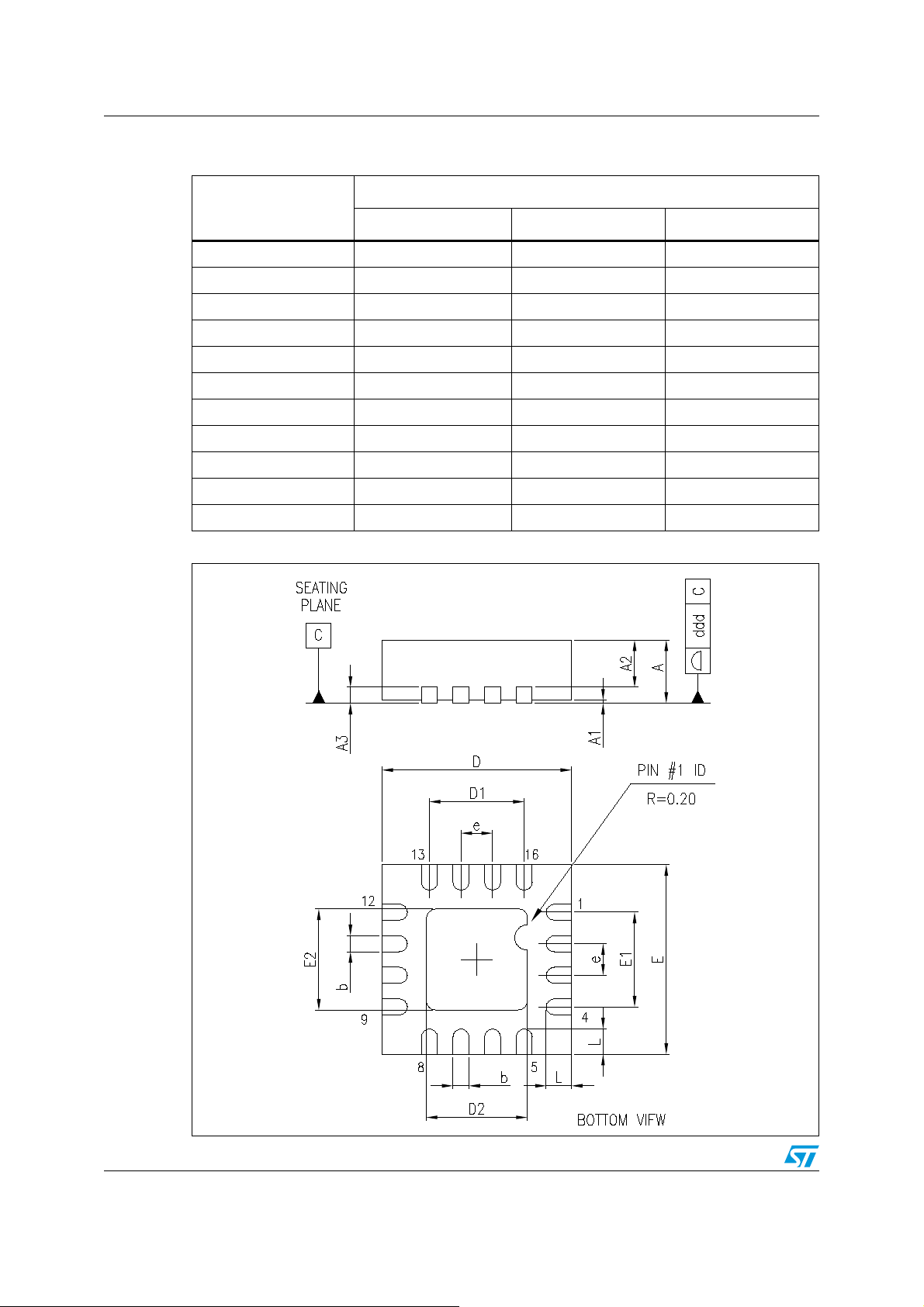

Table 8. VFQFPN16 (3 x 3 mm.) mechanical data

mm.

Dim.

Min. Typ. Max.

A 0.80 0.90 1.00

A1 0.02 0.05

A2 0.65 1.00

A3 0.20

b 0.18 0.25 0.30

D 2.85 3.00 3.15

D2 1.45 1.60 1.75

E 2.85 3.00 3.15

E2 1.45 1.60 1.75

e 0.45 0.50 0.55

L 0.30 0.40 0.50

Figure 30. Package dimensions

36/38 Doc ID 11908 Rev 9

7185330_G

L6924D Revision history

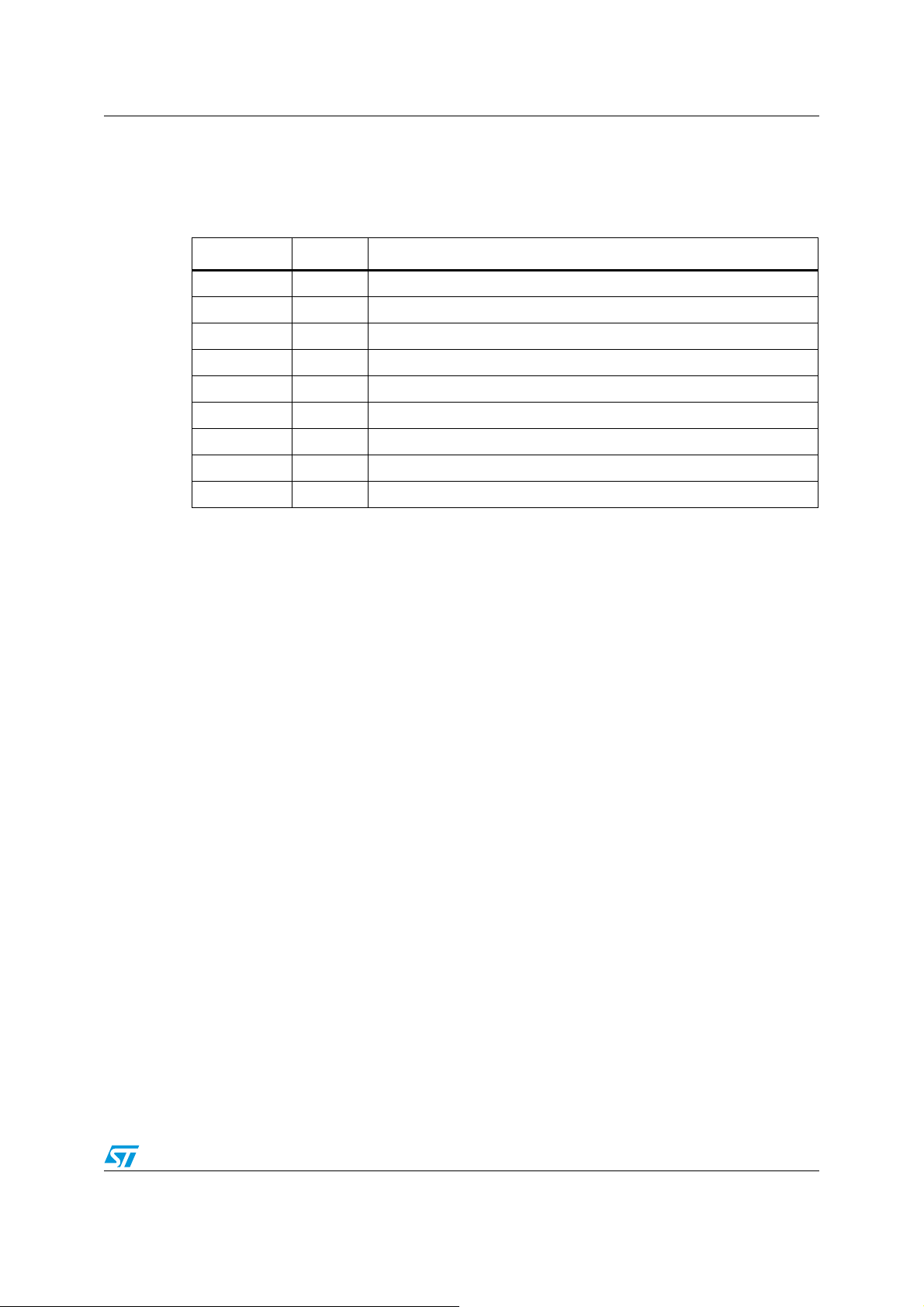

12 Revision history

Table 9. Document revision history

Date Revision Changes

16-Dec-2005 1 First draft

20-Dec-2005 2 Package dimensions updated

10-Jan-2006 3 Few updates

14-Feb-2006 4 Part number updated

03-Jul-2006 5 Updates to equation in page 22, updated block diagram Figure 4.

07-Sep-2006 6 Added Note: on page 20, updated value C

29-Jun-2007 7 Updated capacitor values C2, C3 in Table 7 on page 33

05-Jul-2010 8 Updated Table 5 on page 8 and Section 8.4 on page 28

22-Sep-2010 9 Updated Ta b le 8 and Figure 30 on page 36. Minor changes.

TPRG

page 8

Doc ID 11908 Rev 9 37/38

L6924D

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

38/38 Doc ID 11908 Rev 9

Loading...

Loading...