查询L6917DTR供应商查询L6917DTR供应商

5 BIT PROGRAMMABLE DUAL-PHASE CONTROLLER

■

2 PHASE OPERATION WITH

SYNCRHONOUS RECTIFIER CONTROL

■ ULTRA FAST LOAD TRANSIENT RESPONSE

■

INTEGRATED HIGH CURRENT GATE

DRIVERS: UP TO 2A GATE CURRENT

■

TTL-COMPATIBLE 5 BIT PROGRAMMABLE

OUTPUT COMPLIANT WITH VRM 9.0

■

0.8% INTERNAL REFERENCE ACCURACY

■

10% ACTIVE CURRENT SHARING

ACCURACY

■ DIGITAL 2048 STEP SOFT-START

■

OVERVOLTAGE PROTECTION

■

OVERCURRENT PROTECTION REALIZED

USING THE LOWER MOSFET’S R

SENSE RESISTOR

■

300 kHz INTERNAL OSCILLATOR

■

OSCILLATOR EXTERNALLY ADJUSTABLE

UP TO 1MHz

■ POWER GOOD OUTPUT AND INHIBIT

FUNCTION

■

REMOTE SENSE BUFFER

■ PACKAGE: SO-28

APPLICATIONS

■ POWER SUPPLY FOR SERVER AND

WORKSTATION

■

POWER SUPPLY FOR HIGH CURRENT

MICROPROCESSORS

■

DISTRIBUTED POWER SUPPLY

dsON

ORA

L6917

SO-28

ORDERING NUMBERS: L6917D

L6917DTR (Tape & Reel)

DESCRIPTION

The device is a power supply controller specifically

designed to provide a high performance DC/DC conversion for high current microprocessors.

The device implementsa dual-phase step-down controller with a 180° phase-shift between each phase.

A precise 5-bit digital to analog converter (DAC) allows adjusting the output voltage from 1.100V to

1.850V with 25mV binary steps.

The high precision internal reference assures the se-

lected output voltage to be within ±0.8%. The high

peak current gate drive affords to have fast switching

to the external power mos providing low switching

losses.

The device assures a fast protection against load

over current and load over/under voltage. An internal

crowbar is provided turning on the low side mosfet if

an over-voltage is detected. In case of over-current

or under voltage, the system worksin HICCUP mode.

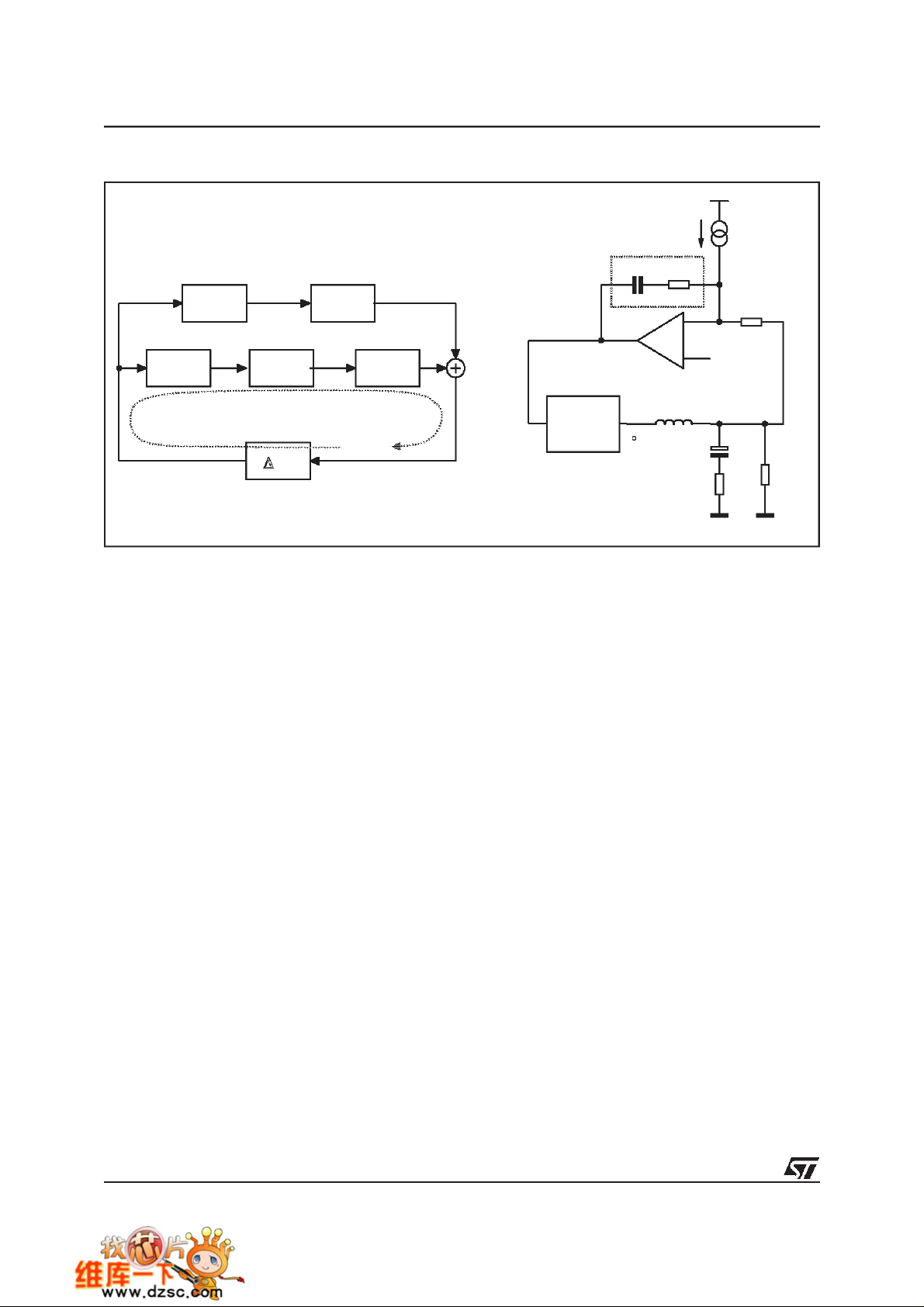

BLOCK DIAGRAM

October 2001

PGOOD

VID4

VID3

VID2

VID1

VID0

FBG

FBR

DIGITAL

SOFT START

DAC

10k

10k

10k

10k

REMOTE

BUFFER

ROSC /INH SGND VCCDR

2 PHASE

OSCILLATOR

LOGIC

AND

PROTECTIONS

CH1OV ER

CURR ENT

IFB

CH2 OVER

CURRENT

VCC

VCCDR

ERROR

AMPLIFIER

PWM1

-

+

CH 1 OVER

CURRENT

CURR ENT

CORRECTION

TOTAL

+

CURRENT

AVG

CURRENT

<>

CH 2 OVER

CURR ENT

CURRENT

CORRECTION

+

-

PWM2

VccCOMPFBVSEN

Vcc

LOGIC PWM

ADAPTIVE ANTI

CROSS-CONDUCTION

CURRENT

READING

CURRENT

READING

LOGIC PWM

ADAPTIVE ANTI

CROSS-CONDUCTION

BOOT1

HS

LS

LS

HS

UGATE1

PHASE1

LGATE1

ISEN1

PGNDS1

PGND

PGNDS2

ISEN2

LGATE2

PHASE2

UGATE2

BOOT2

1/27

Download from www.ICminer.com Electronic-Library Service

L6917

ABSOLUTEMAXIMUM RATINGS

Symbol Parameter Value Unit

Vcc, V

CCDR

V

BOOT-VPHASE

V

UGATE1-VPHASE1

V

UGATE2-VPHASE2

ToPGND 15 V

Boot Voltage 15 V

15 V

LGATE1, PHASE1, LGATE2,PHASE2 to PGND -0.3 to Vcc+0.3 V

All other pins to PGND -0.3 to 7 V

THERMAL DATA

Symbol Parameter Value Unit

R

th j-amb

T

T

storage

P

Thermal Resistance Junction to Ambient 60

Maximum junction temperature 150

max

Storage temperature range -40 to 150

T

Junction Temperature Range -25 to 125 °C

j

Max power dissipation at T

MAX

=25°C2W

amb

°

PIN CONNECTION

C/W

C

°

C

°

LGATE1

VCCDR

PHASE1

UGATE1

BOOT1

VCC

GND

COMP

FB

FBR

FBG

ISEN1

PGNDS1

2

3

4

5

6

7

8

9

10VSEN

11

12

13

14

SO28

28

27

26

25

24

23

22

21

20

19

18

17

16

15

PGND1

LGATE2

PHASE2

UGATE2

BOOT2

PGOOD

VID4

VID3

VID2

VID1

VID0

OSC/INH/FAULT

ISEN2

PGNDS2

2/27

Download from www.ICminer.com Electronic-Library Service

L6917

ELECTRICAL CHARACTERISTICS

(VCC= 12V, T

=25°C unless otherwise specified)

amb

Symbol Parameter Test Condition Min Typ Max Unit

Vcc SUPPLYCURRENT

I

CC

I

CCDR

I

BOOTx

Vcc supply current HGATEx and LGATExopen

V

supply current LGATEx open; V

CCDR

V

CCDR=VBOOT

=12V

=12V 2 3 4 mA

CCDR

Boot supply current HGATExopen; PHASEx to PGND

V

CC=VBOOT

=12V

6810mA

0.5 1 1.5 mA

POWER-ON

Turn-On V

Turn-Off V

Turn-On V

Threshold

Turn-Off V

Threshold

threshold VCCRising; V

CC

threshold VCCFalling; V

CC

CCDR

CCDR

V

CCDR

V

CC

V

CCDR

V

CC

=12V

=12V

Rising

Falling

=5V 7.8 9 10.2 V

CCDR

=5V 6.5 7.5 8.5 V

CCDR

4.2 4.4 4.6 V

4.0 4.2 4.4 V

OSCILLATORAND INHIBIT

f

OSC

Initial Accuracy OSC = OPEN

OSC = OPEN; Tj=0°Cto125°C

278

270

300 322

330

kHz

kHz

f

OSC,Ros

INH Inhibit threshold I

d

MAX

TotalAccuracy RTto GND=74kΩ 450 500 550 kHz

c

=5mA 0.8 0.85 0.9 V

SINK

Maximum duty cycle OSC = OPEN 80 85 %

∆Vosc Ramp Amplitude 1.8 2 2.2 V

REFERENCE AND DAC

I

DAC

Output Voltage

Accuracy

VID pull-up Current VIDx = GND 4 5 6

VID0, VID1, VID2, VID3, VID4

see Table1; Tamb=0°to 70°;

FBR= V

; FBG = GND

OUT

-0.8 - 0.8 %

VID pull-up Voltage VIDx = OPEN 3.1 - 3.4 V

ERROR AMPLIFIER

DC Gain 80 dB

SR Slew-Rate COMP=10pF 15 V/µs

DIFFERENTIAL AMPLIFIER (REMOTE BUFFER)

DC Gain 1 V/V

CMRR Common Mode Rejection Ratio 40 dB

A

µ

Input Offset FBR=1.100V to1.850V;

FBG=GND

Download from www.ICminer.com Electronic-Library Service

-12 12 mV

3/27

L6917

ELECTRICAL CHARACTERISTICS

(continued)(VCC= 12V, T

=25°C unless otherwise specified)

amb

Symbol Parameter Test Condition Min Typ Max Unit

SR Slew Rate VSEN=10pF 15 V/µs

DIFFERENTIAL CURRENT SENSING

,

I

ISEN1

I

ISEN2

I

PGNDSx

I

ISEN1

I

ISEN2

I

Bias Current Iload=0 45 50 55 µA

Bias Current 45 50 55 µA

,

Bias Current at

Over Current Threshold

Active Droop Current Iload<0%

FB

Positive

80 85

Negative

Iload=100% 47.5

37.5

0

50

90 µA

1

52.5

GATE DRIVERS

t

RISE

HGATE

I

HGATEx

High Side

Rise Time

High Side

V

BOOTx-VPHASEx

C

V

to PHASEx=3.3nF

HGATEx

BOOTx-VPHASEx

=10V;

=10V 2 A

15 30 ns

Source Current

R

HGATEx

High Side

V

BOOTx-VPHASEx

=12V; 1.5 2 2.5 Ω

Sink Resistance

t

RISE

LGATE

Low Side

Rise Time

V

CCDR

C

LGATEx

=10V;

to PGNDx=5.6nF

30 55 ns

µA

µA

µA

I

LGATEx

Low Side

V

=10V 1.8 A

CCDR

Source Current

R

LGATEx

Low Side

V

=12V 0.7 1.1 1.5 Ω

CCDR

Sink Resistance

PROTECTIONS

Rising 109 112 115 %

PGOOD Upper Threshold

/DACOUT)

(V

SEN

PGOOD Lower Threshold

/DACOUT)

(V

SEN

OVP Over Voltage Threshold

)

(V

SEN

UVP Under VoltageTrip

/DACOUT)

(V

SEN

V

PGOOD

PGOOD Voltage Low I

V

SEN

Falling 84 88 92 %

V

SEN

Rising 2.0 2.1 2.2 V

V

SEN

Falling 76 80 84 %

V

SEN

= -4mA 0.3 0.4 0.5 V

PGOOD

FAULT FaultCondition After OVP or 3 HICCUP cycles 4.75 5.0 5.25 V

4/27

Download from www.ICminer.com Electronic-Library Service

Table 1. VID Settings

VID4 VID3 VID2 VID1 VID0 Output Voltage (V)

11111OUTPUT OFF

11110 1.100

11101 1.125

11100 1.150

11011 1.175

11010 1.200

11001 1.225

11000 1.250

10111 1.275

10110 1.300

10101 1.325

10100 1.350

10011 1.375

L6917

10010 1.400

10001 1.425

10000 1.450

01111 1.475

01110 1.500

01101 1.525

01100 1.550

01011 1.575

01010 1.600

01001 1.625

01000 1.650

00111 1.675

00110 1.700

00101 1.725

00100 1.750

00011 1.775

00010 1.800

00001 1.825

00000 1.850

Download from www.ICminer.com Electronic-Library Service

5/27

L6917

PIN FUNCTION

N Name Description

1 LGATE1 Channel 1 low side gate driver output.

2 VCCDR Mosfet driver supply.It can be varied from 5V to 12V Bus.

3 PHASE1 This pin is connected to the source of the upper mosfet and provides the return path for the high

side driver of channel 1.

4 UGATE1 Channel 1 high side gate driver output.

5 BOOT1 Channel 1 bootstrap capacitor pin. Through this pin is supplied the high side driver and the upper

mosfet. Connect through a capacitor to the PHASE1 pin and througha diode to Vcc (cathode vs.

boot).

6 VCC Device supply voltage. The operative supply voltage is 12V.

7 GND All the internal references are referred to this pin. Connect it to the PCB signal ground.

8 COMP This pin is connected to the error amplifier output and is used to compensate the control

feedback loop.

9 FB This pin is connected to theerror amplifier inverting input and is used to compensate the voltage

control feedback loop.

A current proportional to the sum of the current sensed in both channel is sourced from this pin

(50µA at full load, 70µA at the Over Current threshold). Connecting a resistor between this pin

and VSEN pin allows programming the droop effect.

10 VSEN Connected to the output voltage it is able to manage Over & Under-voltage conditions and the

11 FBR Remote sense buffernon-inverting input. It has to be connected to the positive side of the load to

12 FBG Remote sense buffer inverting input. It has to be connected to the negative side of the load to

13 ISEN1 Channel 1 current sense pin. The output current may be sensed across a sense resistor or

PGOOD signal. It is internally connected with the output of the Remote Sense Buffer forRemote

Sense of the regulated voltage.

If no Remote Sense is implemented, connect it directly to the regulated voltage in order to

manage OVP,UVP and PGOOD.

perform a remote sense.

If no remote sense is implemented, connect directly to the output voltage (in this case connect

also the VSEN pin directly to the output regulated voltage).

perform a remote sense.

Pull-down to ground if no remote sense is implemented.

across the low-side mosfet Rds

This pin has to be connected to the low-side mosfet drain or

ON.

to the sense resistor through a resistor Rg in order to program the positive current limit at 140%

as follow:

I

MAX_POS1

35µARg⋅

--------------------------=

R

sense

6/27

14

Where 35µA is the current offset information relative to the Over Current condition (offset at OC

threshold minus offset at zero load).

In the same way the negative current limit threshold results to be set at –50% as follow:

I

MAX_NEG1

12.5– µARg⋅

---------------------------------- -=

R

se ns e

Where –12.5µA is the current offset information relative to the Negative Over Current condition

(offset at Negative OC threshold minus offset at zero load).

The net connecting the pin to the sense point must be routed as close as possible to the

PGNDS1 net in order to couple in common mode any picked-up noise.

PGNDS1 Channel 1 Power Ground sense pin. The net connecting the pin to the sense point (Through a

resistor R

) must be routed as close as possible to the ISEN1 net in order to couple in common

g

mode any picked-up noise.

Download from www.ICminer.com Electronic-Library Service

L6917

PIN FUNCTION

(continued)

N Name Description

15 PGNDS2 Channel 2 Power Ground sense pin. The net connecting the pin to the sense (Through a resistor

R

) point must be routed as close as possible to the ISEN2 net in order to couple in common

g

mode any picked-up noise.

16 ISEN2 Channel 2 current sense pin. The output current may be sensed across a sense resistor or

across the low-side mosfet Rds

This pin has to be connected to the low-side mosfet drain or

ON.

to the sense resistor through a resistor Rg in order to program the positive current limit at 140%

as follow:

I

MAX_POS2

35µARg⋅

--------------------------=

R

sense

Where 35µA is the current offset information relative to the Over Current condition (offset at OC

threshold minus offset at zero load).

In the same way the negative current limit threshold results to be set at –50% as follow

I

MAX_NEG2

12.5µ– ARg⋅

---------------------------------- -=

R

se ns e

Where –12.5µA is the current offset information relative to the Negative Over Current condition

(offset at Negative OC threshold minus offset at zero load).

The net connecting the pin to the sense point must be routed as close as possible to the

PGNDS2 net in order to couple in common mode any picked-up noise.

17

OSC/INH

FAULT

Oscillator switching frequency pin. Connecting an external resistor from this pin to GND,the

external frequency is increased according to the equation:

6

⋅

14.82 10

f

S

300KH z

-----------------------------+=

R

OSC

KΩ()

Connecting a resistor from this pin to Vcc (12V),the switching frequency is reduced according to

the equation:

7

⋅

12.91 10

f

S

300KH z

-----------------------------+=

R

OSC

KΩ()

If the pin is not connected, the switching frequency is 300KHz.

Forcing the pin to a voltage lower than 0.8V, the device stop operation and enter the inhibit state.

The pin is forced high when an over voltage is detected and after three hiccup cycles. This

condition is latched; to recover it is necessary turn off and on VCC.

18-22 VID4-0 Voltage IDentification pins. These input are internally pulled-up and TTL compatible. They are

used to program the output voltage as specified in Table 1 and to set the power good thresholds.

Connect to GND to program a ‘0’ while leave floating to program a ‘1’.

23 PGOOD This pin is an open collector output and is pulled low if theoutput voltage is not within the above

specified thresholds.

If not used may be left floating.

24 BOOT2 Channel 2 bootstrap capacitor pin. Through this pin is supplied thehigh side driver and the upper

mosfet. Connect through a capacitor to the PHASE2 pin and througha diode to Vcc (cathode vs.

boot).

25 UGATE2 Channel 2 high side gate driver output.

26 PHASE2 This pin is connected to the source of the upper mosfet and provides the return path forthe high

side driver of channel 2.

27 LGATE2 Channel 2 low side gate driver output.

28 PGND Power ground pin. This pin is common to both sections and it must be connected through the

closest path to the low side mosfets source pins in order to reduce the noise injection into the

device.

7/27

Download from www.ICminer.com Electronic-Library Service

L6917

DeviceDescription

The device is an integrated circuitrealized in BCD technology. It provides complete control logic and protections

for a high performance multiphase step-down DC-DC converter optimized for microprocessor power supply. It

is designed to drive N Channel MOSFETs in a dual-phase synchronous-rectified buck topology. A 180 deg

phase shift is provided between the two phases allowing reduction inthe input capacitor current ripple, reducing

also the size and the losses. The output voltage of the converter can be precisely regulated, programming the

VID pins, from 1.100V to1.850V with 25mV binary steps, with amaximum tolerance of ±0.8% over temperature

and line voltage variations. The device provides an average current-mode control with fast transient response.

It includes a 300kHz free-running oscillator externally adjustable up to 1MHz. The error amplifier features a 15V/µs

slew rate that permits high converter bandwidth for fast transient performances. Current information is read

across the lower mosfets rDSON or across a sense resistor in fully differential mode. The current information

corrects the PWM output in order to equalize the average current carried by each phase. Current sharing between the two phases is then limited at ±10% over static and dynamic conditions. The device protects against

over-current, with an OC threshold for each phase, entering in HICCUP mode. After three hiccup cycles, the

condition is latched and the FAULT pin is driven high. Thedevice performs also an under voltage protection that

causes a hiccupcycle when detected, and anover voltage protectionthat disable immediately the device turning

ON the lower driver and driving high the FAULT pin.

The device is available in SO28 package.

Oscillator

The switching frequency is internally fixed to 300kHz. The internal oscillator generates the triangular waveform

for the PWM charging and discharging with a constant current an internalcapacitor. The current delivered to the

oscillator is typically 25

tween OSC pin and GND or Vcc. Since the OSC pin is maintained at fixed voltage (typ). 1.235V, the frequency

is varied proportionally tothe current sunk (forced) from (into) thepin considering the internal gainof 12KHz/

In particular connecting it to GND the frequency is increased (current is sunk from the pin), while connecting

ROSC to Vcc=12V the frequency is reduced (current is forced into the pin), according to the following relationships:

µA(F

= 300KHz) and maybe varied using an external resistor (R

SW

) connected be-

OSC

µ

A.

R

vs. GND: fS300kHz

OSC

R

OSC

Note that forcing a 25

oscillator.

Figure 1. R

Rosc(KΩ) vs. 12V

vs. Switching Frequency

OSC

7000

6000

5000

4000

3000

2000

1000

0

0 100 200 300

vs. 12V: f

S

300kHz

1.237

----------------------- -------

R

OSC

12 1.237–

------------------------ ------ 12

+

R

OSC

Ω()

K

KΩ()

kHz

-----------⋅+

12

µ

kHz

-----------

⋅

µA

A

300kHz

300kHz

14.82 106⋅

------------------------------+==

R

12.918 107⋅

----------------------- ---------–==

R

OSC

OSC

KΩ()

KΩ()

µA current into this pin, the device stops switching because no current is delivered to the

1000

900

800

700

600

500

400

300

200

Rosc(KΩ) vs. GND

100

0

300 400 500 600 700 800 900 1000

Frequency (KHz)

Frequency(KHz)

8/27

Download from www.ICminer.com Electronic-Library Service

L6917

Digitalto AnalogConverter

The built-in digital to analog converter allows the adjustment of the output voltage from 1.100V to 1.850V with

25mV steps as shown in the previous table 1. The internal reference is trimmed to ensure the precision of 0.8%

and a zero temperature coefficient around 70°C. The internal reference voltage for the regulation is programmed by the voltage identification (VID) pins. These are TTL compatible inputs of an internal DAC that is

realized by means of a series of resistors providing a partition of the internal voltage reference. The VID code

drives a multiplexer that selects a voltage on a precise point of the divider. The DAC output is delivered to an

amplifier obtaining the V

provided (realized with a 5

to leave the pin floating, while to program a logic ”0” it is enough to short the pin to GND.

The voltage identification (VID) pin configuration also sets the power-good thresholds (PGOOD) and the overvoltage protection (OVP) thresholds.

SoftStart and INHIBIT

At start-up a ramp is generated increasing the loop reference from 0V to the final value programmed by VID in

2048 clock periods as shown in figure 2.

Before soft start,the lower power MOS are turned ONafter that V

to discharge the output capacitor and to protect the load from high side mosfet failures. Once soft start begins,

the reference is increased; when it reaches the bottom of the oscillator triangular waveform (1V typ) also the

upper MOS begins to switch and the output voltage starts to increase with closed loop regulation. At the end of

the digital soft start, thePower Good comparator is enabled and the PGOOD signal is then driven high (See fig.

2). The Negative Current Limit comparators and Under Voltage comparator are enabled when the reference

voltage reaches 0.8V.

The Soft-Start will not take place, if both Vcc and VCCDR pins are not above their own turn-on thresholds. During normal operation, if any under-voltage is detected on one of the two supplies the device shuts down.

Forcing the OSC/INH/FAULT pin to a voltage lower than 0.8V the device enter in INHIBIT mode: all the power

mosfets are turned off until this condition is removed. When this pin is freed, the OSC/INH/FAULT pin reaches

the band-gap voltage and the soft start begins.

voltage reference (i.e. the set-point of the error amplifier). Internal pull-ups are

PROG

µA current generator up to 3.3V max); in this way, to program a logic ”1” it is enough

reaches 2V (independently by Vcc value)

CCDR

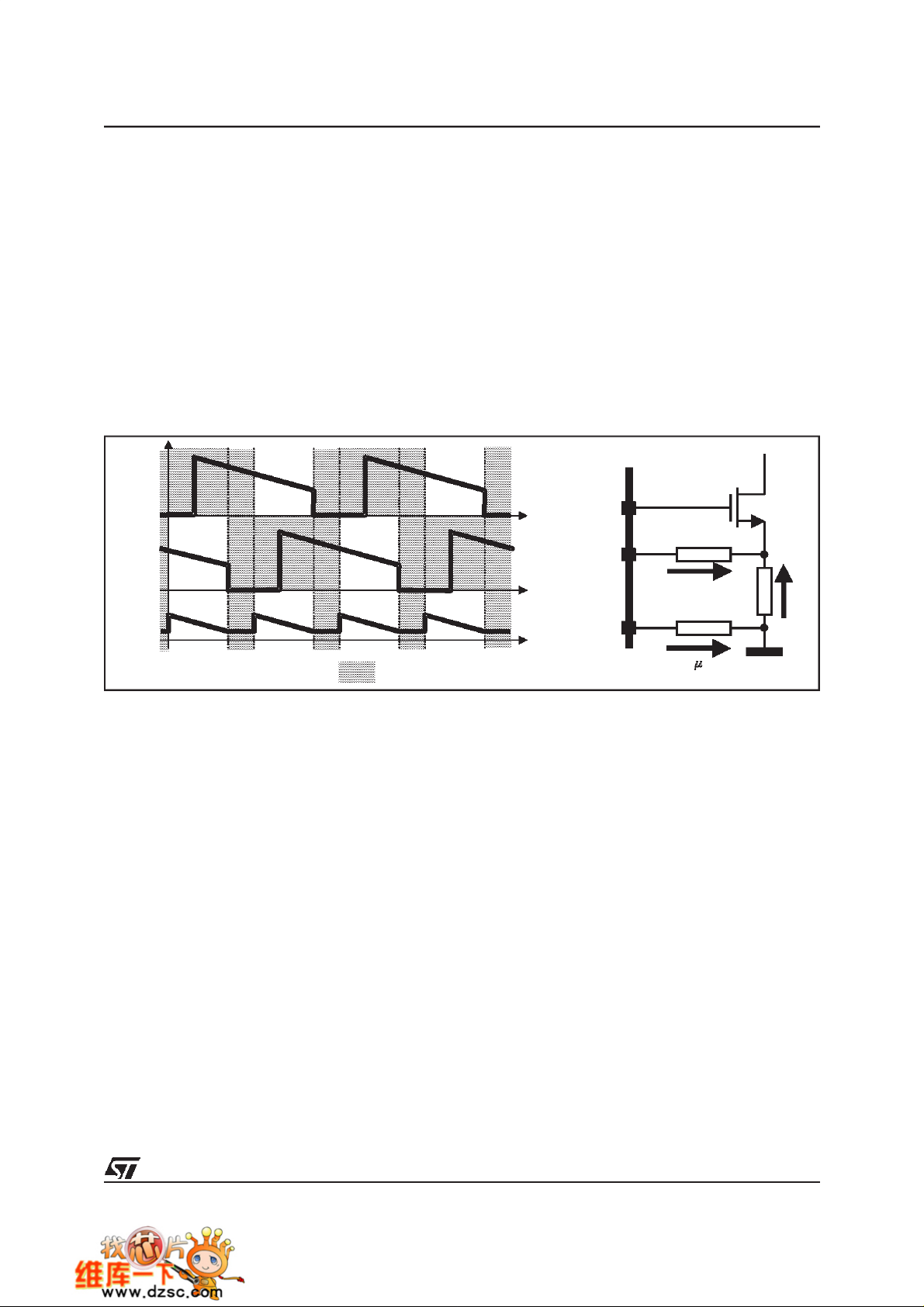

Figure 2. Soft Start

VIN=V

CCDR

V

LGATEx

V

OUT

PGOOD

Turn ON threshold

2V

t

t

t

2048 ClockCycles

Timing Diagram Acquisition:

t

CH1 = PGOOD; CH2 = V

; CH4 = LGATEx

OUT

9/27

Download from www.ICminer.com Electronic-Library Service

L6917

Driver Section

The integrated high-current drivers allow using different types of power MOS (also multiple MOS to reduce the

RDSON), maintaining fast switching transition.

The drivers for the high-side mosfets use BOOTx pins for supply and PHASEx pins for return. The drivers for

the low-side mosfets use VCCDR pin for supply and PGND pin for return. A minimumvoltage of 4.6V at VCCDR

pin is required to start operations of the device.

The controller embodies a sophisticated anti-shoot-through system to minimize low side body diode conduction

time maintaining good efficiency and saving the use of Schottky diodes. The dead time is reduced to few nanoseconds assuring that high-side and low-side mosfets are never switched on simultaneously: when the highside mosfet turns off, the voltage on its source begins to fall; when the voltage reaches 2V, the low-side mosfet

gate drive isapplied with 30ns delay. When the low-side mosfet turnsoff, the voltage at LGATEx pin is sensed.

When it drops below 1V, the high-side mosfet gate drive is applied with a delay of 30ns.

If thecurrent flowing in the inductor is negative, the source of high-side mosfet will never drop. To allow the turning on of the low-sidemosfet even in this case, a watchdog controller is enabled: after 240ns, the low side mosfet is switched on so allowing the negative current of the inductor to recirculate. This mechanism allows the

system to regulate even if the current is negative.

The BOOTx andVCCDR pins are separated from IC’s power supply (VCC pin) as well as signal ground (SGND

pin) and power ground (PGND pin) in order to maximize the switching noise immunity. The separated supply

for the different drivers gives highflexibility inmosfet choice, allowing the useof logic-level mosfet. Several combination of supply can be chosen to optimize performance and efficiency of the application. Power conversion

is also flexible, 5V or 12V bus can be chosen freely.

Placement of the power mosfets is critical: long and narrow trace length from UGATEx and LGATEx pins to the

mosfets’ gates may cause high amount of ringing due to the resonance between inductance of the trace and

the gate capacitance of the mosfet. A gate resistance of a few ohms can help in reducing ringing and power

dissipation of the controller without compromising system efficiency.

The peak current is shown for both the upper and the lower driver of the two phases in figure 3. A 10nF capacitive load has been used. For the upper drivers, the source current is 1.9A while the sink current is 1.5A with

V

BOOT-VPHASE

VCCDR = 12V.

= 12V; similarly, for the lower drivers,the source current is 2.4A while the sink current is2A with

Figure 3. Drivers peak current: High Side (left) and Low Side (right)

CH3 = HGATE1; CH4 = HGATE2 CH3 = LGATE1; CH4 = LGATE2

10/27

Download from www.ICminer.com Electronic-Library Service

L6917

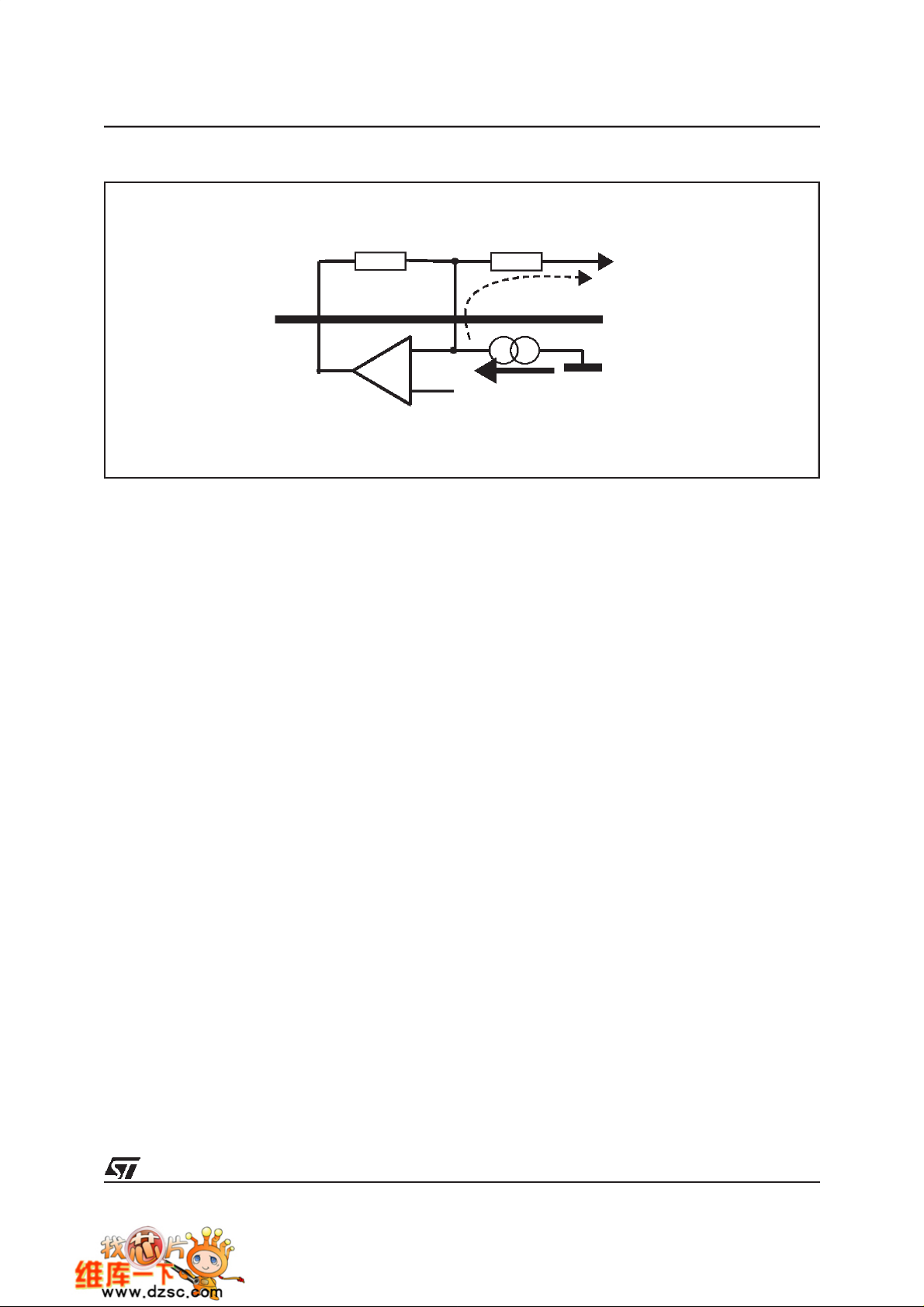

CurrentReadingand Over Current

The current flowing trough each phase is read using the voltage drop across the low side mosfets r

across a sense resistor (R

) and internally converted into a current. The transconductance ratio is issued

SENSE

by the external resistor Rg placed outside the chipbetweenISENx and PGNDSx pins toward the reading points.

The full differential current reading rejects noise and allows to place sensing element in different locations without affecting the measurement’s accuracy. The current reading circuitry reads the current during the time in

which the low-side mosfet is on (OFF Time). During this time, the reaction keeps the pin ISENx and PGNDSx

at the same voltage while during the time inwhich the reading circuitry is off, an internal clamp keeps these two

pins at the same voltage sinking from the ISENx pin the necessary current.

The proprietary current reading circuit allows a very precise and high bandwidth reading for both positive and

negative current. This circuit reproduces the current flowing through the sensing element using a high speed

Track & Hold transconductance amplifier. In particular, it reads the current during the second half of the OFF

time reducing noise injection into the device due to the mosfet turn-on (See fig. 4).

Figure 4.

I

LS1

LGATEX

I

ISENx

Rg

Rg

SENSE

R

I

LS2

Total current

information

ISENX

PGNDSX

DSON

or

PHASE

I

Track & Hold

50µA

This circuit sources a constant 50µA current from the PGNDSx pin and keeps the pins ISENx and PGNDSx at

the same voltage. Referring to figure 4, the current that flows in the ISENx pin is then given by the following

equation:

R

SENSEIPHASE

----------------------- ---------------- -------+

Where R

I

ISENx

is an external sense resistor or the r

SENSE

50µA

tance resistor used between ISENx and PGNDSx pins toward the reading points; I

⋅

+==

R

g

, on of the low side mosfet and Rg is the transconduc-

dson

50µAI

INFOx

is the current carried

PHASE

by each phase and, in particular, the current measured in the middle of the oscillator period

The current information reproduced internally is represented by the second term of the previous equation as

follow:

R

I

INFOx

SENSEIPHASE

------------------------ ---------------- ------=

R

⋅

g

Since the current is read in differential mode, also negative current information is kept; this allow the device to

check for dangerous returning current between the two phases assuring the complete equalization between the

phase’s currents.

From the current information of each phase, information about the total current delivered (I

and the average current for each phase (I

AVG

=(I

INFO1+IINFO2

)/2 ) is taken. I

INFOX

FB=IINFO1+IINFO2

is then compared to I

AVG

to give the correction to the PWM output in order to equalize the current carried by the two phases.

)

11/27

Download from www.ICminer.com Electronic-Library Service

L6917

Figure 5. HICCUP Mode (left) and OCP threshold and Current information (right)

I

FB

2x35µA=70µA

2x25µA=50µA

Hiccup Mode:

CH1 = FAULT;CH2 = V

; CH3 = IL1;CH4=I

OUT

L2

The over current threshold for each phase is set when I

-50%

I

INFOx

=35µA. Since the over current detection gives

INFOx

25µA

-12.5µA

35µA

100%

140%

I

OUT

I

OUT

origin to Hiccup cycles (and the output voltage goes down to zero, with information losses for the microprocessor) the over current threshold must be greater than the nominal current.

Placing the OC threshold at +40% gives a margin to sustain the heavy load transient issued by the processor.

As a consequence, the transconductance resistor Rg has to be designed in order to have current information of

µ

A at 140% of the nominal load, corresponding to 25µA at nominal load. Considering the feedback current

35

(I

), this will be equal to 50µA at nominal load and 70µA at over current threshold as shown in figure 5.

FB

Since the device is able to read negative current, negative current limitis also provided and it is set when I

INFOx

= -12.5µA , corresponding to -50% ofthe full nominal current.No current is sunk from theFB pin in this condition.

According to the above relationship, the positive limiting current (I

LIM_POS

placed at one half of the total delivered maximum current and the limiting negative current (I

I

LIM_POS

35µARg⋅

----------------------- ---- I

R

SENSE

LIM_NEG

12.5– µARg⋅

----------------------- ------------ Rg

R

SENSE

) for each phase, which has to be

LIM_NEG

I

⋅

LIMRSENSE

----------------------- --------------===

35µA

), results:

When over current is detected, all mosfets are turned OFF, the device waits for 2048 clock cycles and another

soft-start is implemented. Over Current is always active, also during soft-start. After three Over Current event,

the condition is latched and the device stops working; Vcc turn OFF and ON is required to restart device operation.

Over current is set anyway when I

venient values for I

. Since the OPC intervention threshold is fixed, to modify the percentage with respect to

FB

reaches 35µA. The full load value isonly aconvention to work with con-

INFOx

the load value, it can be simply considered that, for example, to have on OCP threshold of 170%, this will correspond to I

=35µA(IFB=70µA). The full load current will then correspond to I

INFOx

= 20.5µA(IFB=41µA).

INFOx

Over current is managed as an under voltage: after a combination of three of then, the device latches the condition and the FAULT pin is driven high.

The full differential path helps the designer to place sensing element where wanted. Transconductance Rg resistors must be placed as close as possible to ISENx and PGNDSx pins in order to reject noise from the device.

Keeping the traces parallel and guarded by a power plane results in common mode coupling for any picked-up

noise.

12/27

Download from www.ICminer.com Electronic-Library Service

L6917

CurrentSharing

Active current sharing is implemented using the information from transconductance differential amplifier in an

average current mode control scheme. A current reference equal to the average of the read current (I

internally built;the errorbetween theread current and thisreference is converted to a voltage with a proper gain

and it is used to adjust the duty cycle whose dominant value is set by the error amplifier at COMP pin.

The current sharing control is a high bandwidth control allowing current sharing even during load transients.

The current sharing error is affected by the choose of external components; choose precise Rg resistor (±1%

is necessary) to sense the current. The current sharing error is internally dominated by the voltage offset of

transconductance differential amplifier; considering a voltage offset equal to 2mV across the sense resistor, the

current reading error is given by the following equation:

∆

∆

Where

I

READ

For Rsense=4m

I

READ

--------------------

I

MAX

is the difference between one phase current and the ideal current (I

Ω and Imax=40A the current sharing error is equal to 2.5%, neglecting errors due to Rg and

2mV

---------------------- ------------------=

R

SENSEIMAX

⋅

MAX

/2).

Rsense mismatches.

Figures 6 and 7 show the current sharing error obtained at 0A and 30A using a sense resistor or the low side

mosfet’s R

as sensing element. The static error obtained using the R

dsON

is due to the tolerance of this

dsON

parameter (up to 30%).

AVG

)is

Figure 6. Current Sharing Error using R

CH1 = PHASE1; CH2 = PHASE2; CH3 = IL2; CH4 = I

as sensing element at 0A (left) and 30A (right).

dsON

L1

13/27

Download from www.ICminer.com Electronic-Library Service

L6917

Figure 7. Current Sharing Error using R

CH1 = PHASE1; CH2 = PHASE2; CH3 = IL2;CH4=I

SENSE

as sensing element at 0A (left) and 30A (right)..

L1

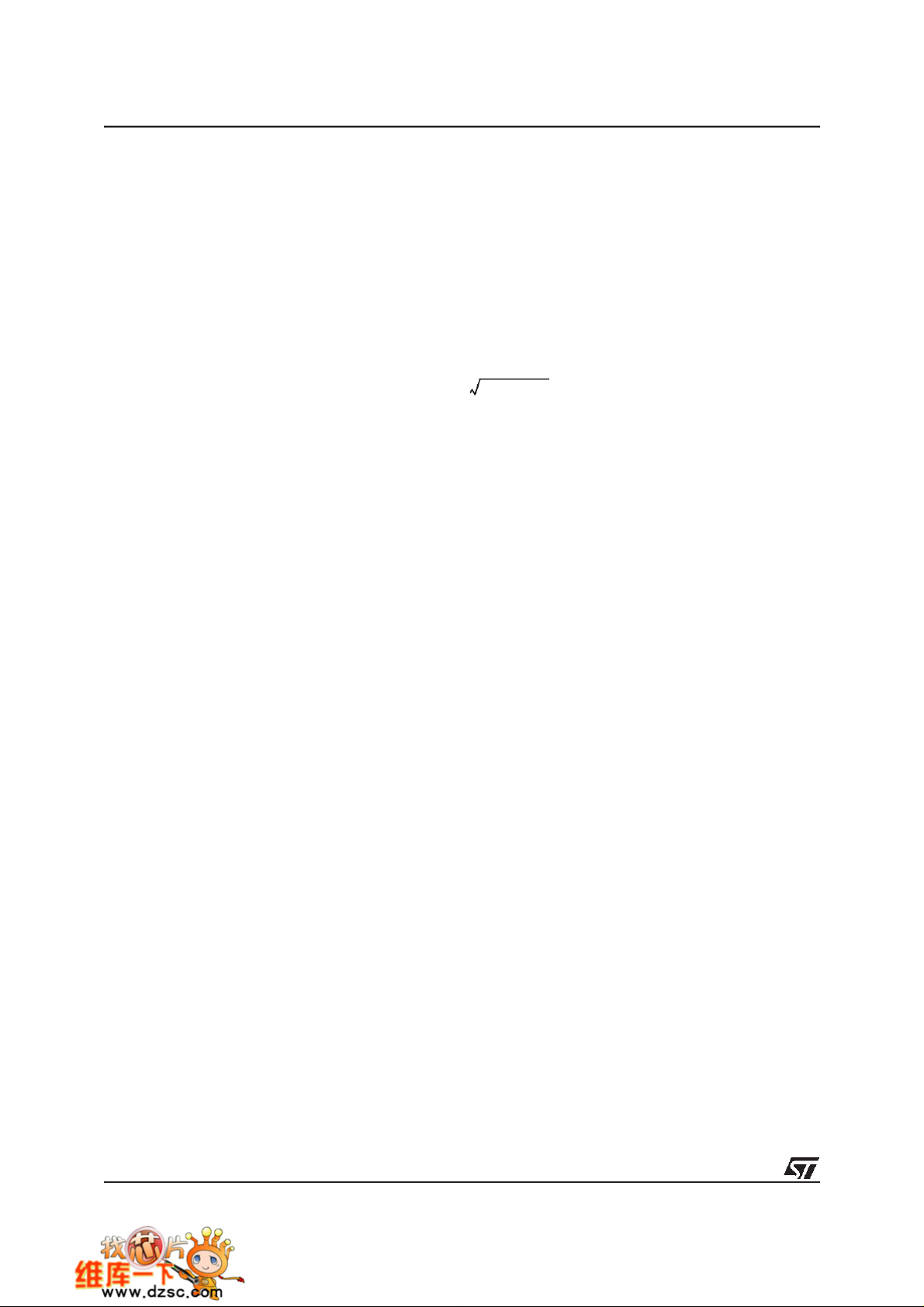

Integrated Droop Function

The device uses a droop function to satisfy the requirements of high performance microprocessors, reducing

the size and the cost of the output capacitor.

This method ”recovers” part of the drop due to the output capacitor ESR in the load transient, introducing a dependence of the output voltage on the load current

As shown in figure 8, the ESR drop is present in any case, but using the droop function the total deviation of the

output voltage is minimized. In practice the droop function introduces a static error (Vdroop in figure 8) proportional to the output current. Since the device has anaverage current mode regulation, the information about the

total current delivered is used to implement the Droop Function. This current (equal to the sum of both I

INFOx

is sourced from the FB pin. Connecting a resistor between this pin and Vout, the total current information flows

only in this resistor because the compensation network between FBand COMP has always a capacitor inseries

(See fig. 9). The voltage regulated is then equal to:

V

OUT=VID-RFB·IFB

Since IFBdepends on the current information about the two phases, the output characteristic vs. load current is

given by:

R

SENSE

V

OUT

VID R

------- ---------- ----- I

⋅⋅–=

FB

Rg

OUT

)

Figure 8. Output transient response without (a) and with (b) the droop function

ESR DROP ESRDROP

VMAX

VNOM

VMIN

(a) (b)

14/27

Download from www.ICminer.com Electronic-Library Service

V

DROOP

Figure 9. Active Droop Function Circuit

L6917

R

COMP

FB

V

PROG

The feedback current is equal to 50µA at nominal full load (IFB=I

FB

I

FB

INFO1+IINFO2

To VOUT

) and 70µA at the OC threshold,

so the maximum output voltage deviation is equal to:

∆V

FULL_POSITIVE_LOAD

Droop function is provided only for positive load; if negative load is applied, and then I

=+RFB·70µA ∆V

POSITIVE_OC_THRESHOLD

=+RFB·70µA

< 0, no current is

INFOx

sunk from the FB pin. The device regulates at the voltage programmed by the VID.

OutputVoltage Protection and Power Good

The output voltage is monitored by pin VSEN. If it is not within +12/-10% (typ.) of the programmed value, the

powergood output is forced low. Power good is an open drain output and it isenabled only after the soft start is

finished (2048 clock cycles after start-up).

The device provides over voltage protection; when the voltage sensed by the V

pin reaches 2.1V (typ.),the

SEN

controller permanently switches on both the low-side mosfets and switches off both the high-side mosfets in order to protect the CPU. The OSC/INH/FAULT pin is driven high (5V) and power supply (Vcc) turn off and on is

required to restart operations. The over Voltage percentage is set by the ratio between the OVP threshold (set

at 2.1V) and the reference programmed by VID.

OVP[%]

---------------------- ----------------- ----------------- ---------------- ---- - 100

Ref er enc e Voltage VID

2.1V

⋅=

()

Under voltage protection is also provided. If the output voltage drops below the 85% of the reference voltage for

more than one clock period the device turns off all mosfets and waits for 2048 clock cycles before another softstart. An Under Voltage event is then managed as an Over Current event; after a combination of three of them,

the device latches the condition and the FAULT is driven high.

Both Over Voltage and Under Voltage are active also during soft start (Under Voltage after than Vout reaches

0.8V). The reference voltage used to determine the UV thresholds is nowthe increasing voltage driven by the

2048 soft start digital counter.

RemoteVoltage Sense

A remote sense buffer is integrated into the device to allowoutput voltage remotesense implementation without

any additional external components. In this way, the output voltage programmed is regulated between the remote buffer inputs compensating motherboard trace losses or connector losses if the device is used for a VRM

module. The low offset amplifier senses the output voltage remotely through the pins FBR and FBG (FBR is for

the regulated voltage sense while FBG is for the ground sense) and reports this voltage internally at VSEN pin

15/27

Download from www.ICminer.com Electronic-Library Service

L6917

with unity gain eliminating the errors. Keeping the FBR and FBG traces parallel and guarded by a power plane

results in common mode coupling for any picked-up noise.

If remote sense is not required, the output voltage is sensed by the VSEN pin connecting it directly to the output

voltage. In this case the FBG and FBR pins must be connected anyway to the regulated voltage.

Input Capacitor

The input capacitor has to sustain the ripple current produced during the on time of the upper MOSFETS. Considering thedual phase topology, the input rms currentis highly reduced because of the peak current is one half

if compared with a single-phase solution.

Input capacitor must have a low ESR to minimize the losses. The rms value of this ripple is:

I

OUT

------------ D1D–

=

I

rms

Where D is the duty cycle. The equation reaches its maximum value width D=0.5. The losses in worst case are:

2

()⋅⋅

PESRI

Input bulk capacitor must be equally divided between high-side drain mosfets and placed as close as possible

to reduce switching noise above all during load transient. A symmetrical power path will help to improve transient response. Input coil may be used taking from this point the supply for the controller VCC and VCCDRV,

designing a ’star connection’.

IC’s power supplies filter capacitor must be placed as close as possible to VCC and VCCDRV pins; for the VCC

pins a typical value is of 1

tering a series resistor of a few tenth ohm is suggested since the device typically works with the same power

supply used for the power conversion (noisy because of the switching mosfet).

Capacitor on VCCDRV pin filter the low-side drivers power supply toward the PGND pin; 1

ommended.

The 12V input power bus can be used to supply the bootstrap capacitor alone or together with a 5.1V zener

diode in series and a 1

side mosfets with a good compromise of efficiency and controller power dissipation. Alternatively a linear regulator can be used to produce the supply for high-side and low-side power mosfet drivers. This can help to optimize the choose of switching frequency, controller power dissipation and overall efficiency.

µF and must be used connected between VCC and SGND pins. For better noise fil-

µF capacitor for filtering. A gate-source voltage of 7V is so ready to switch on the high-

2

⋅=

rms

µF capacitor is rec-

OutputCapacitor

Since the microprocessors require a current variation beyond 50A doing load transients, with a slope in the

range of tenth A/

Dual phase topology reduces the amount of output capacitance needed because of faster load transient response (switching frequency is doubled at the load connections). Current ripple cancellation due to the 180°

phase shiftbetween the twophases also reduces requirements on the output ESR tosustain a specified voltage

ripple.

When a load transient is applied to the converter’s output, for first few microseconds the current to the load is

supplied by the output capacitors. The controller recognizes immediately the load transient and increases the

duty cycle, but the current slope is limited by the inductor value.

The output voltage has a first drop due to the current variation inside the capacitor (neglecting the effect of the

ESL):

µs, the output capacitor is a basic component for the fast response of the power supply.

∆V

A minimum capacitor value is required to sustain the current during the load transient without discharge it. The

16/27

OUT

= ∆I

OUT

· ESR

Download from www.ICminer.com Electronic-Library Service

L6917

voltage drop due to the output capacitor discharge is given by the following equation:

2

Where D

∆

V

OUT

is the maximum duty cycle value. The lower is the ESR, the lower is the output drop during load

MAX

----------------------- ----------------- ----------------- ---------------- ---------------- ---=

2C

OUTVINMINDMAXVOUT

∆

I

OUT

⋅

L

–⋅()⋅⋅

transient and the lower is the output voltage static ripple.

Inductor design

The inductance value is defined by a compromise between the transient response time, the efficiency, the cost

and the size. The inductor has to be calculated to sustain the output and the input voltage variation to maintain

∆

the ripple current

IL between 20% and 30% of the maximumoutput current. The inductance value can be cal-

culated with this relationship:

V

Where f

L

is the switching frequency, VINis the input voltage and V

S

fs IL∆⋅

–

INVOUT

----------------------- -------

=

V

-------------- -

⋅

V

OUT

IN

is the output voltage.

OUT

Increasing the value of the inductance reduces the ripple current but, at the same time, reduces the converter

response time to a load transient. The response time is the time required by the inductor to change its current

from initial to final value. Since the inductor has not finished its charging time, the output current is supplied by

the output capacitors. Minimizing the response time can minimize the output capacitance required.

The response time to a load transient is different for the application or the removal of the load: if during the application ofthe loadthe inductor is charged by a voltage equal tothe difference between the input and the output

voltage, during the removal it is discharged only by the output voltage. The following expressions give approximate response time for DI load transient in case of enough fast compensation network response:

t

application

LI

---------------------- --------=

–

VINV

∆⋅

OUT

t

removal

∆⋅

LI

---------------=

V

OUT

The worst condition depends on the input voltage available and the output voltage selected. Anyway the worst

case is the response time after removal of the load with the minimum output voltage programmed and the maximum input voltage available.

Figure 10. Inductor ripple current vs V

9

out

L=1.5µH, Vin=12V

8

L=2µH,

Vin=12V

L=3µH,

Vin=12V

L=1.5µH,

Vin=5V

L=2µH,

Vin=5V

InductorRipple [A]

7

6

5

4

3

2

1

L=3µH, Vin=5V

0

0.5 1.5 2.5 3.5

OutputVoltage[V]

17/27

Download from www.ICminer.com Electronic-Library Service

L6917

Figure 11. Control Loop Scheme

IFB

RFCF

R

FB

REF

L

IN

Cout

ESR

VOUT

Rout

Av -ZF/RFB

Ac Rs/Rg -ZF

d

VOUT

1/∆V

osc

IFBIOUT

GLOOPI

VCOMP

VCOMP

PWM

Z

F

d•V

AverageCurrent Mode Compensation NetworkDesign

The average current mode control loop is reported in figure 11. The current information IFBsourced by the FB

pin flows into R

implementing the dependence of the output voltage from the read current.

FB

Two different loops are present and precisely a current loop internal to a voltage loop.The current gain (Ac)and

voltage gain (Av) present in the above figure are defined by the following relationships:

()

Av s

Ac s()

V

OUT

-------------- -

d

I

OUT

------------

===

d

{}

....

....{}

V

IN

V

IN

-------------- -

R

OUT

------------------------ ----------------- ----------------- ----------------- --------------- ----------------- ----------------- -⋅===

S2C

OUT

L

---⋅

sESRC

2

1s+ ESR C

----------------------- ----------------- ---------------- ----------------- ---------------- ---------------- ----------------- ---

1s+ESR C

⋅

S2C

⋅

L

---

+

⋅ sESRC

OUT

⋅

2

⋅

⋅⋅

OUT

⋅⋅

OUT

OUT

OUT

L

-----------------------+⋅

2R

⋅

L

-----------------------+

2R

⋅

+⋅+⋅

OUT

1

+

1

OUT

The current loop gain may now be expressed by the following equation:

Rs

--------

Rg

Z

F

----------------- -⋅⋅⋅–==

Vosc

∆

s()

Where

G

LOOPI

Ac s()Rs Z

s

-----------------------------------------------

()

Rg Vosc

∆⋅

s

()⋅⋅

F

-------------- -

R

∆Vosc has a typical value of 2V and Z

V

IN

------------------------------------------------------------------------------------------------------------------------------

2

OUT

C

S

OUT

(s) is the impedance of the series RF-CF. The current loop gain

F

1s+ ESR C

L

---⋅ s ESR C

2

⋅⋅

OUT

OUT

L

---------------------- -+⋅

⋅

2R

1+⋅+⋅

OUT

is designed to obtain a high DC gain to minimize static error and cross the 0dB axes with a constant -20dB/dec

ω

slope with a crossover frequency

poles. Both the poles are fixed once the output filter is designed and alsothe zero (

by the maximum current deliverable by the converter. To obtain the desired shape an R

considered for the Z

(s) implementation. A zero at ωF=1/RFCFis then introduced together with an integrator.

F

. Neglecting the effect of ZF(s), the transfer function has one zero and two

TI

ω

OUT

=1/R

OUTCOUT

series network is

F-CF

) is fixed

This integrator minimizes the static error while placing the zero in correspondence with the L-C resonance a

simple -20dB/dec shape of the gain is assured (See Figure 12).

18/27

Download from www.ICminer.com Electronic-Library Service

Figure 12. Current loop Gain (left) and Voltage loop Gain (right)

L6917

dB

Ac

G

LOOPI

Z

F

ω

TI

ω

OUT

ω

LC

ω

F

ω

dB

⋅

RgRo

⋅

RRs

FB

ω

TV

ω

OUT

ω

ω

ESR

TI

ω

The RFCFnetwork may be designed considering the desired crossover frequencyωTIas follow:

■ Assuming thatω

■

Given the cross-over frequencyωTI, it results:

== =

R

F

■ Since ω

F=ωLC

F=ωLC

Rg

Ro Vosc∆⋅

------- -

--------------------- ----------

⋅⋅

Rs

:

Since the device works in current mode and then the control loop acts to control the current, the highest is

, and that ZF=RFif ω>ωF, it can be observed that:

VINRFR

⋅⋅

--------------------- ----------------- -----

⋅⋅

Ro Vosc∆Rg

LC

⋅⋅

L

---⋅

2

R

F

----------------------- --------------

------------------------ ------------ -

Ro C

Ro Vosc∆⋅

---------------------- ---------

⋅⋅

Vin

C

OUT

----------------------- ----=

F

Vin

G

LOOPI

ωoωTI⋅

------------------- -

2

ω

LC

ω=ω

()

LC

Rg

--------

Rs

C

ω

S

LC

----------

⋅=

ω

O

OUTωTI

2

⋅

OUT

Rg

Vosc∆

------- -

------------------

⋅⋅

Rs

Vin

L

----------------

2 ωTI⋅

ω

TI

the fastest is the device to react after a loadtransient. The placement of this singularity must consider the worst

case for the load and precisely the maximum output current (minimum output resistance R

OUT

).

The voltage loop gain may be expressed by the following relationship:

1

------- ---------- -

Vosc∆

----------------------- --------

⋅⋅

+

1G

LOOPI

R

OUT

---------------------- ------

⋅⋅==

Rs RFB⋅

⋅

Rg

ZFs()

-------------- -

R

FB

1

-------------------

s

---------+

1

ω

TI

Assuming that G

V

OUT

-------------------

G

LOOPV

I>>1 and after substitution and simplification the final expression for GLOOPV is given by:

LOOP

==

s()

V

COMP

V

COMP

-------------------

⋅ Av s()

V

OUT

1 s ESR C

G

LOOPV

s() ...{}

----------------------- ----------------- ------------

1sR

Where the additional pole placed at the current loop

is not always G

>>1. The LC resonance disappears thanks to the average current mode control and the

LOOPI

–

⋅⋅+

⋅⋅+

OUTCOUT

ω

TI

OUT

must be inserted to consider that the current loop gain

system is automatically stable if ESR issmall enough.

Since all the above modeling are valid at frequencies much lower than the switching frequency, the highest is

this, the highest may be the converter’s loop bandwidth (both current and voltage). In this way the converter is

able to fast react after a load transient following, with the current delivered by the inductors, the currentrequired

by the load minimizing the number of the output capacitor required.

The average current mode compensation network is then designed as follow:

,

19/27

Download from www.ICminer.com Electronic-Library Service

L6917

■

Given the voltage loop bandwidth

Rs RFB⋅

== =

ω

TI

■ Once the current loop bandwidth is defined, the R

-----------------------

ω

⋅⋅ω

TV

Ro Rg⋅

ω

, the current loop bandwidth wTI is extracted from the following:

TV

ω

ESR

-------------- -

ω

O

Rs RFB⋅

-----------------------

⋅⋅ ω

TV

Ro R g⋅

FCF

Ro C

⋅

⋅

OUT

OUT

TV

---------------------- ---------- -

ESR C

network may be designed as shown previously.

Rs RFB⋅

----------------------- --

⋅

ESR R g⋅

DemoBoard Description

The L6917 demo board shows the operation of the device in a dual phase application. This evaluation board

allows voltage adjustability (1.100V - 1.850V) through the switches S0-S4 and high output current capability.

The 12V input rail supplies both the device and the high-side drain for the power conversion.

2

The board has been layed out with the possibility to use up to two D

PACK mosfets for the low side switch in

order to give maximum flexibility in the mosfet’s choice.

The four layers demo board’s copper thickness is of 70

µm in order to minimize conduction losses considering

the high current that the circuit is able to deliver.

Figure 13 shows the demo board’s schematic circuit.

Figure 13. Demo Board Schematic

Vin

GNDin

DZ1

JP1

L1

D1

Q1a Q3a

S4

S3

S2

S1

S0

JP2

R16

D4C6

Q2C4

Q1

R2

VCCDR

BOOT1

UGATE1

PHASE1

LGATE1

ISEN1

PGNDS1

OSC / INH

SGND

VID4

VID3

VID2

VID0VID1

2

5

4

3

1

13

U1

14

L6917

22

21

20

19

18

17

7

11 12

FBR FBG

C8

R15

R18

R13

R6

R5

6

24

25

26

27

16

15

28

23

10

9

8

VCC

BOOT2

UGATE2

PHASE2

LGATE2

ISEN2

PGNDS2

PGND

PGOOD

VSEN

FB

COMP

R14

R17

R12

R10

C7

D3

Q4 C3

Q3

R3

R4

R7

R8

C2

C5

L2

D2

R1

JP3

C1

R9

C9,C10

C14,

C24

C11..C13

R19

R20

VoutCORE

GNDCORE

PGOOD

JP5JP4

FBG

FBR

20/27

Download from www.ICminer.com Electronic-Library Service

L6917

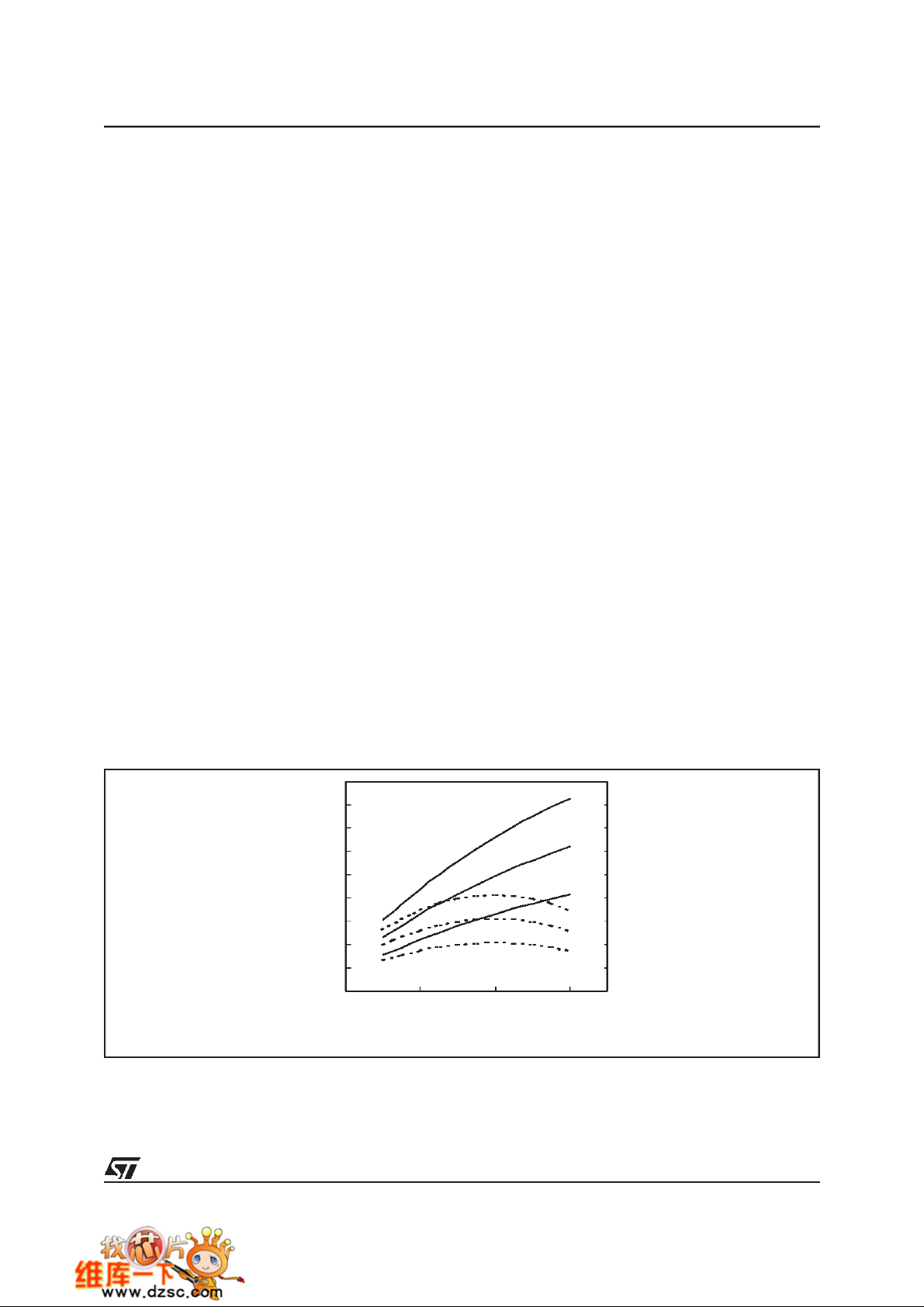

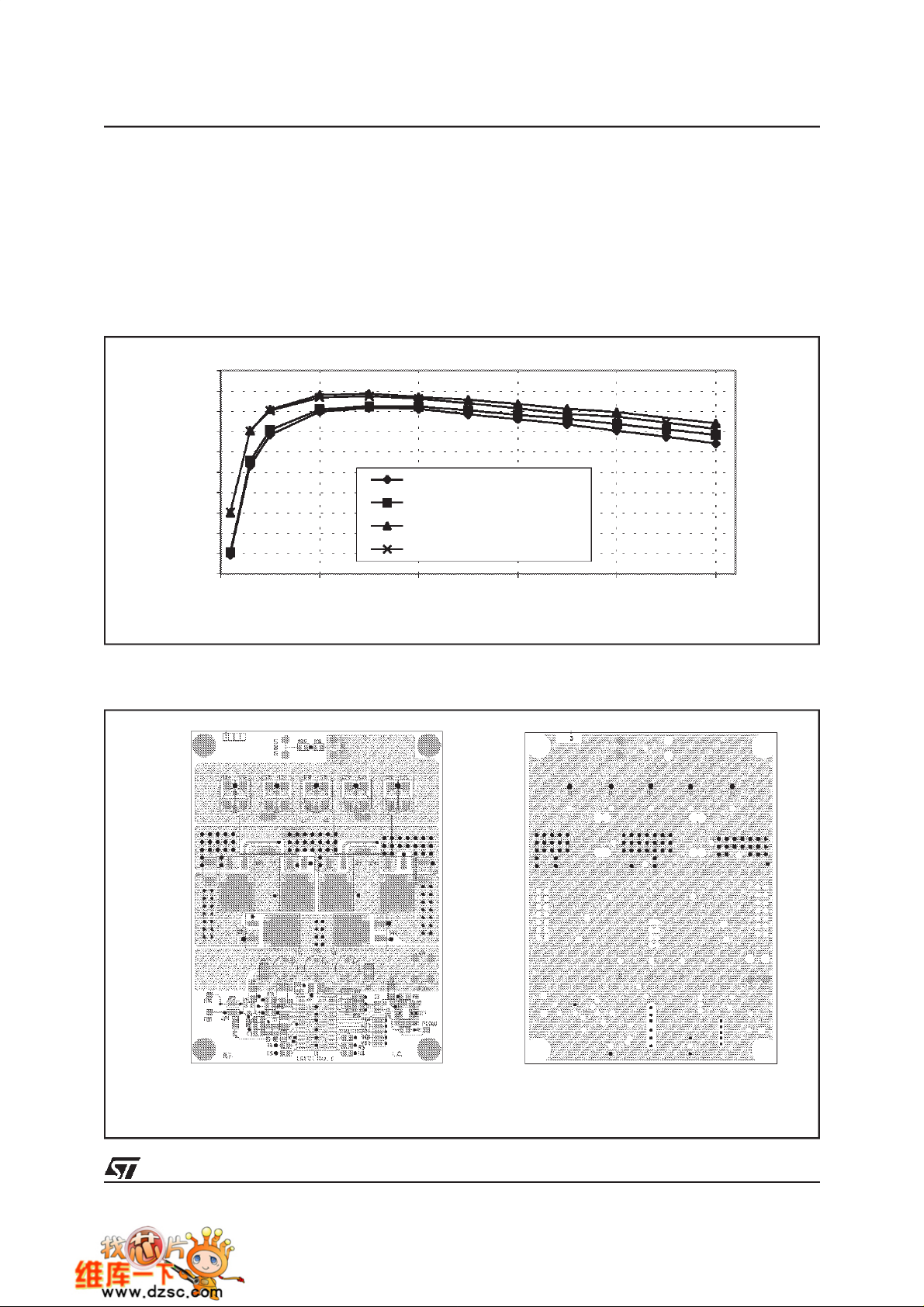

Efficiency

Figure 14 shows the demo board measured efficiency versus load current for different values of input voltage

and mosfet configurations.

Measures were done at Vin=5V and Vin=12V with low side mosfet composed by a single STB90NF03L (30V,

Ω

5.6m

When 5V input is considered, the 12V bus supplies the IC and the mosfet’ drivers.

Figure 14. Efficiency

typ @ Vgs=10V) or a couple of STB70NF03L (30V, 8mΩtyp @ Vgs=10V) to reduce equivalent R

95

90

85

80

75

70

65

Efficiency [%]

60

55

50

45

0 1020304050

Vin = 12V; LS=STB90NF03L

Vin = 12V; LS=2xSTB70NF03L

Vin = 5V; LS=2xSTB70NF03L

Vin = 5V; LS=STB90NF03L

OutputCurrent [A]

dsON

.

PCB and Components Layouts

Figure 15. PCB and Components Layouts

Component Side Internal PGND Plane

21/27

Download from www.ICminer.com Electronic-Library Service

L6917

Figure 16. PCB and Components Layouts

Internal SGND Plane Solder Side

DesignExample.

■

Output Voltage (nominal) 1.700V

■

Output Current (nominal) 45A

■

Static tolerance +100mV; -50mV

Considering the high slope for the load transient, a high switching frequency has to be used. In addition to fast

reaction, this helps in reducing output and input capacitor. Inductance value is also reduced.

A switching frequency of 300kHz for each phase is then considered allowing large bandwidth for the compensation network.

■ Current Reading Network and Over Current:

Since the maximum output current is 45A, the over current threshold has to be set at 140% of the

maximum nominal current, the over-current threshold has thento be setat 31.5A. Considering tosense

the output current across the low-side mosfet RdsON, STB90NF03L has 6.5mΩ max at25°that

becomes 9.1mΩ considering the temperature variation (+40%); the resulting transconductance resistor

Rg has to be:

I

■

Droop function Design:

Rg

RdsON⋅

MAX

----------------------- --------------- -

35

µ

⋅

31.5 9.1m

----------------------- -------

µ

35

8.2k

Ω===

(R3 to R6)

Considering a voltage drop of 100mV at full load, the feedback resistor RFB has to be

==

R

FB

voltage drop at OCP threshold results in 140mV.

22/27

100mV

-------------------

50µA

(R7)

2kΩ

Download from www.ICminer.com Electronic-Library Service

■

Inductor design:

Each phase has to deliver up to 22.5A; considering a current ripple of 5A (<25%), the resulting

inductance value is:

L6917

■

Output Capacitor:

L

Vin Vout–

----------------------- ------

I∆

d

-----------⋅

Fsw

12 1.7–

---------------------

5

1.7

--------

12

1

--------------------⋅⋅ 1µH== =

300000

(L1, L2)

Six PANASONIC SP-CAP EEFUE0D27 (270µF, 15mΩmax) has been used implementing a resulting

ESR of 2.5mΩresulting in a voltage drop of 45A*2.5mΩ=112.5mV after a load transient.

■ Compensation Network:

A voltage loop bandwidth of 40kHz is considered to let the device fast react after load transient.

⋅

The R

FCF

■

VID settings:

fTV= 20kHz=>

network results:

Rg

------- -

R

F

Rs

Rs R

f

TIfTV

∆

Vosc

------------------

⋅⋅⋅

Vin

C

----------------------- ----

F

---------------------- ---

⋅ 20k

ESR Rg⋅

L

-- -

ω

2

-----------------------

2C

⋅

R

-------------

TI

7.8m

L

OUT

F

FB

8.2k

--- -- -

⋅⋅⋅⋅

12

------------------------

2 1.62m⋅

------------------------ ----- 3.4nF== =

8.2k

⋅ 15.2kHz== =

µ

2

1

------ - 2

2

1 µ

⋅

7.8m 2k

----------------------- -------

2.5m 8.2k⋅

π

15.2k

(C2)

Ω== =

8.2k

(R8)

Considering the 100mV voltage drop programmed by thefeedback resistor and the static tolerance, the

VID are set for 1.775V (00011 code) in order to have a ±25mV of margin in the regulation.

Part List

R1 10k SMD 0805

R2, R9, R20 Not Mounted SMD 0805

R3, R4, R5, R6 8.2k 1% SMD 0805

R7 2k 1% SMD 0805

R8 10k SMD 0805

R10 82Ω SMD 0805

R12 to R15 0

C2 4.7n SMD 0805

C3, C4 100n SMD 0805

C5, C6, C7 1µ Ceramic SMD 1206

C8, C9, C10 10

C11, C12, C13 100µ / 20V OSCON 20SA100M Radial 10x10.5

C19 to C24 270µ/ 2V PANASONIC SP-CAP SMD 7343

L1, L2 1µ 77121 Core – 7 Turns or

U1 L6917 STMicroelectronics SO28

Q1, Q3 STB90NF03L STMicroelectronics

Q2, Q4 STB70NF03L STMicroelectronics

D1, D2 STPS340U STMicroelectronics SMB

D3, D4 1N4148 STMicroelectronics SOT23

Ω

µ

Ceramic SMD 1206

TO50-52B Core – 6 Turns

SMD 0805

2

D

PACK

2

D

PACK

23/27

Download from www.ICminer.com Electronic-Library Service

L6917

Application Idea: 12V input 3.3V / 5V 40A output

Figure 17 shows the device in a high current server power supply application.

Adding an external resistor divider after the remote sense buffer gives the possibility to increase the regulated

voltage. Considering for example a divider by two (two equal resistors)the DAC range is doubled from 2.200V

to 3.700V with 50mV binary steps. It is then possible to regulate the 3.3V and 2.5V rails from the 12V available

from the AC/DC converter. The 5V railcan be obtained modifying the external divider. The regulator assures all

the advantages of the dual phase conversion (especially in the 5V conversion where the duty cycle is near the

50% and practically no ripple is present in the input capacitors) and a 300kHz free-running frequency that reduces components size. Output current ranges from 35A up to 50A.

Figure 17. Server power supply schematic

Vin

GNDin

R16

D4C6

Q2C4

L1

Q1

D1

S4

S3

S2

S1

S0

R2

VCCD R

D5

BOOT 1

UGATE1

P HASE1

LGATE1

ISEN1

PGND S1

OSC / INH

VID4

VID2VID3

VID1

VID0

2

5

4

3

1

13

U1

14

L6917

22

21

20

19

18

17

7

11 12

FB R FBG

C8

R15

R18

R13

R6

R5

6

24

25

26

27

16

15

28

23

10

9

8

VCC

BOOT 2

UGA TE2

P HASE2

LGATE2

ISEN 2

P GNDS2

P GND

P GOOD

VSEN

FB

COMPSG ND

R10

C7

D3

Q4 C3

R14

R17

Q3

R12

D6

R3

R4

R7

R8

C2

C5

L2

D2

C1

R9

C9,C10

C11..C13

R19

C14,

C24

R20

R1

VoutCORE

GNDCORE

PGOOD

FBG

FBR

Part List

R1 10k SMD 0805

R3, R4, R5, R6 8.2k 1% SMD 0805

R7 820 1% SMD 0805

R8 10k SMD 0805

R10

R12 to R16 0Ω SMD 0805

R17, R18 0

R19, R20 330Ω SMD 0805

C2 4.7n SMD 0805

C3, C4 100n SMD 0805

C5, C6, C7 1µ Ceramic SMD 1206

C8 10µ Ceramic SMD 1206

C9 to C13

24/27

82

Ω

47µ

Ω

SMD 0805

SMD 0805

Ceramic SMD 1026

Download from www.ICminer.com Electronic-Library Service

Part List

C14, C15 1500µ / 6.3V Radial

L1, L2 4

µ

77121 Core – 10T (30A Out) or

77848 Core – 11T (45A Out)

U1 L6917 STMicroelectronics SO28

Q1, Q3 STB90NF03L STMicroelectronics

Q2, Q4 STB70NF03L STMicroelectronics

D

D

2

PACK

2

PACK

D1, D2 STPS340U STMicroelectronics SMB

D3, D4 1N4148 STMicroelectronics SOT23

Figure 18.

vout

1.700

1.698

1.696

1.694

1.692

1.690

OutputVoltage[V]

1.688

1.686

1.684

-40 -20 0 20 40 60 80 100 120 140

Temperature [C]

L6917

Output Voltage vs. Temperature

49

48

47

46

45

44

IPGNDS [A]

43

42

41

-40 -20 0 20 40 60 80 100 120 140

Temperature [C]

PGNDS Bias Current vs. Temperature

25/27

Download from www.ICminer.com Electronic-Library Service

L6917

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 2.65 0.104

a1 0.1 0.3 0.004 0.012

b 0.35 0.49 0.014 0.019

b1 0.23 0.32 0.009 0.013

C 0.5 0.020

c1 45° (typ.)

D 17.7 18.1 0.697 0.713

E 10 10.65 0.394 0.419

e 1.27 0.050

e3 16.51 0.65

F 7.4 7.6 0.291 0.299

L 0.4 1.27 0.016 0.050

S8°(max.)

mm inch

OUTLINE AND

MECHANICALDATA

SO28

26/27

Download from www.ICminer.com Electronic-Library Service

L6917

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of useof such information nor forany infringementof patents orotherrights ofthird partieswhichmayresult from its use.No license isgranted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2001 STMicroelectronics - All Rights Reserved

Australia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - United States.

STMicroelectronics GROUP OF COMPANIES

http://www.st.com

27/27

Download from www.ICminer.com Electronic-Library Service

Loading...

Loading...