查询L6911C供应商

5 BIT PROGRAMMABLE STEP DOWN CONTROLLER

■

OPERATING SUPPL Y IC VOLTAGE FROM 5V

TO 12V BUSES

■

UP TO 1.3A GATE CURRENT CAPABILITY

■

TTL-COMP A T I BLE 5 BIT P ROGR AMMABLE

OUTPUT CO MPLIANT WITH VRM 8.4 :

1.3V TO 2.05V WITH 0.05V BINARY STEPS

2.1V TO 3.5V WITH 0.1V BINARY STEPS

■

VOLTAGE MODE PWM CONTROL

■

EXCELLENT OUTPUT ACCURACY: ±1%

OVER LINE AND TEMPERATURE

VARIATIONS

■

VERY FAST LOAD TRANSIENT RESPONSE:

FROM 0% TO 100% DUTY CYCLE

■

POWER GOOD OU T PUT VO LTA GE

■

OVERVOLTAGE PROTECTION AND

MONITOR

■

OVERCURRENT PROTECTION REALIZED

USING THE UPPER MOSFET'S R

■

200KHz INTERNAL OSCILLATOR

■

OSCILLATOR EXTERNALLY ADJUST ABLE

FROM 50KHz TO 1MHz

■

SOFT START AND INHIBIT FUNCTIONS

APPLICATIONS

■

POWER SUPPLY FOR ADVANCED

MICROPROCESSOR CORE

■

DISTRIBUTED PO WE R SUPP LY

■

HIGH POWER DC-DC REGULATORS

L6911C

WITH SYNCHRONOUS RECTIFICATION

SO-20

dsON

ORDERING NUMB ERS : L6911C

DESCRIPTION

The device is a power supply controller specifically designed to provide a high performance DC/DC conversion for high current microprocessors. A precise 5-bit

digital to analog converter (DAC) allows adjusting the

output voltage from 1.30V to 2.05V with 50mV binary

steps and from 2.1 0V to 3.50V with 100 mV binary steps.

The high precision internal r eference ass ures the selected output voltage to be within ±1%. The high peak

current gate drive affords to have fast switching to the

external power mos providing low switching losses.

The device assures a fast protection against load

overcurrent and load overvoltage. An ex ternal SCR is

triggered to crowbar the input supply in case of hard

over-voltage. An internal crowbar is also provided

turning on the low side mosfet as long as the overvoltage is detected. In case of ove r-current detection,

the soft start capacitor is discharged and the system

works in HICCUP mode.

L6911CTR

(Tape and Reel)

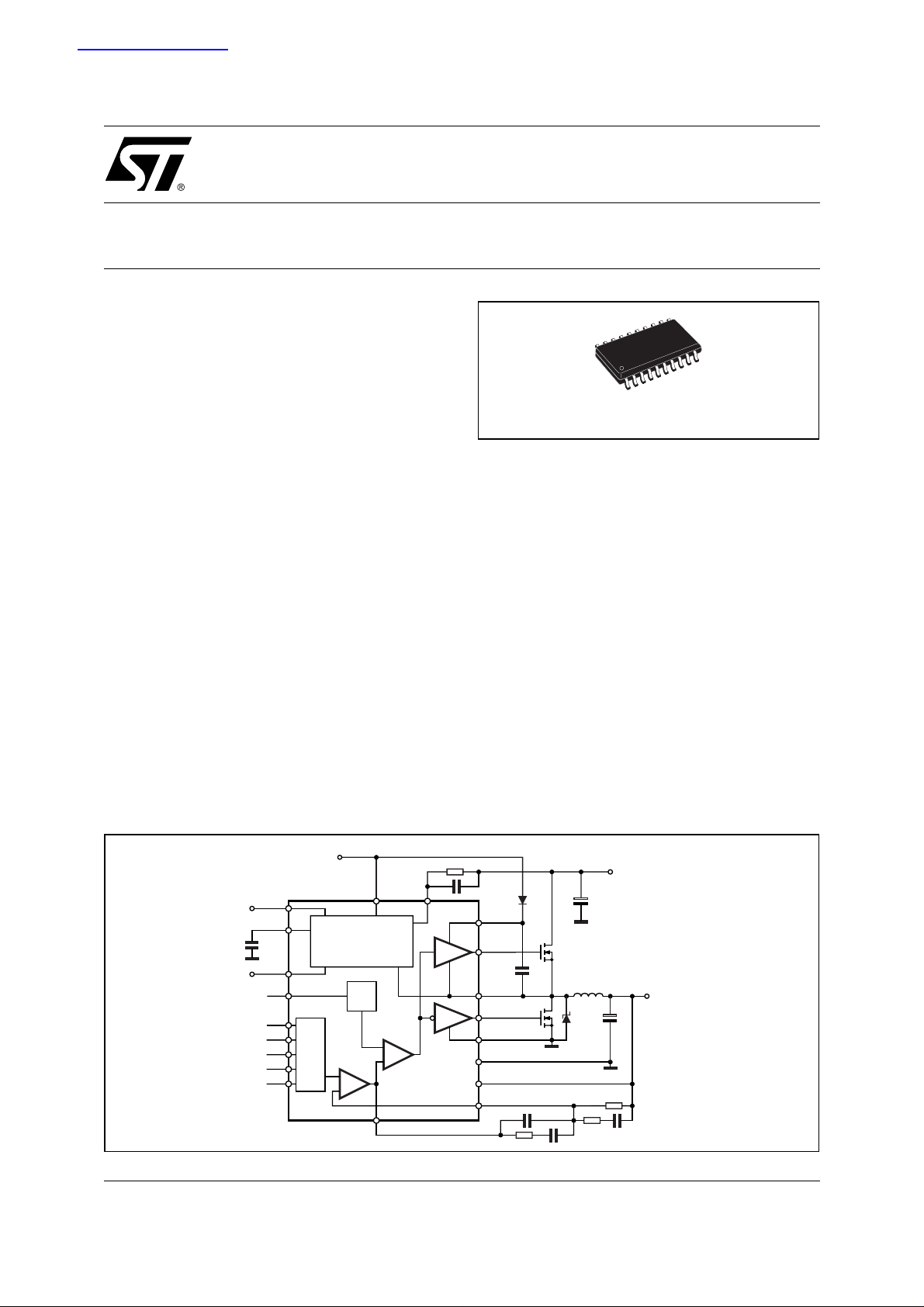

BLOCK DIAGRAM

November 2001

PGOOD

OVP

VD0

VD1

VD2

VD3

VD4

D01IN1260

Vcc 5 to 12V

VCC OCSET

SS

RT

D/A

MONITOR and

PROTECTION

OSC

+

E/A

COMP

+

PWM

BOOT

UGATE

PHASE

LGATE

PGND

GND

VSEN

VFB

Vin 5V to12V

1.300V to 3.500V

Vo

1/20

L6911C

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

CC

V

BOOT-VPHASE

V

HGATE-VPHASE

VCC to GND, PGND 15 V

Boot Voltage 15 V

15 V

OCSET, LGATE, PHASE -0.3 to Vcc+0.3 V

RT, SS, FB, PGOOD, VSEN, VID0-4 7 V

OVP, COMP 6.5 V

THERMAL DATA

Symbol Parameter Value Unit

R

th j-amb

T

PIN CONNECTION

Thermal Resistance Junction to Ambient 110 °

T

Maximum junction temperature 150 °

j

Storage temperature range -40 to 150 °

stg

T

Junction temperature range 0 to 125 °

J

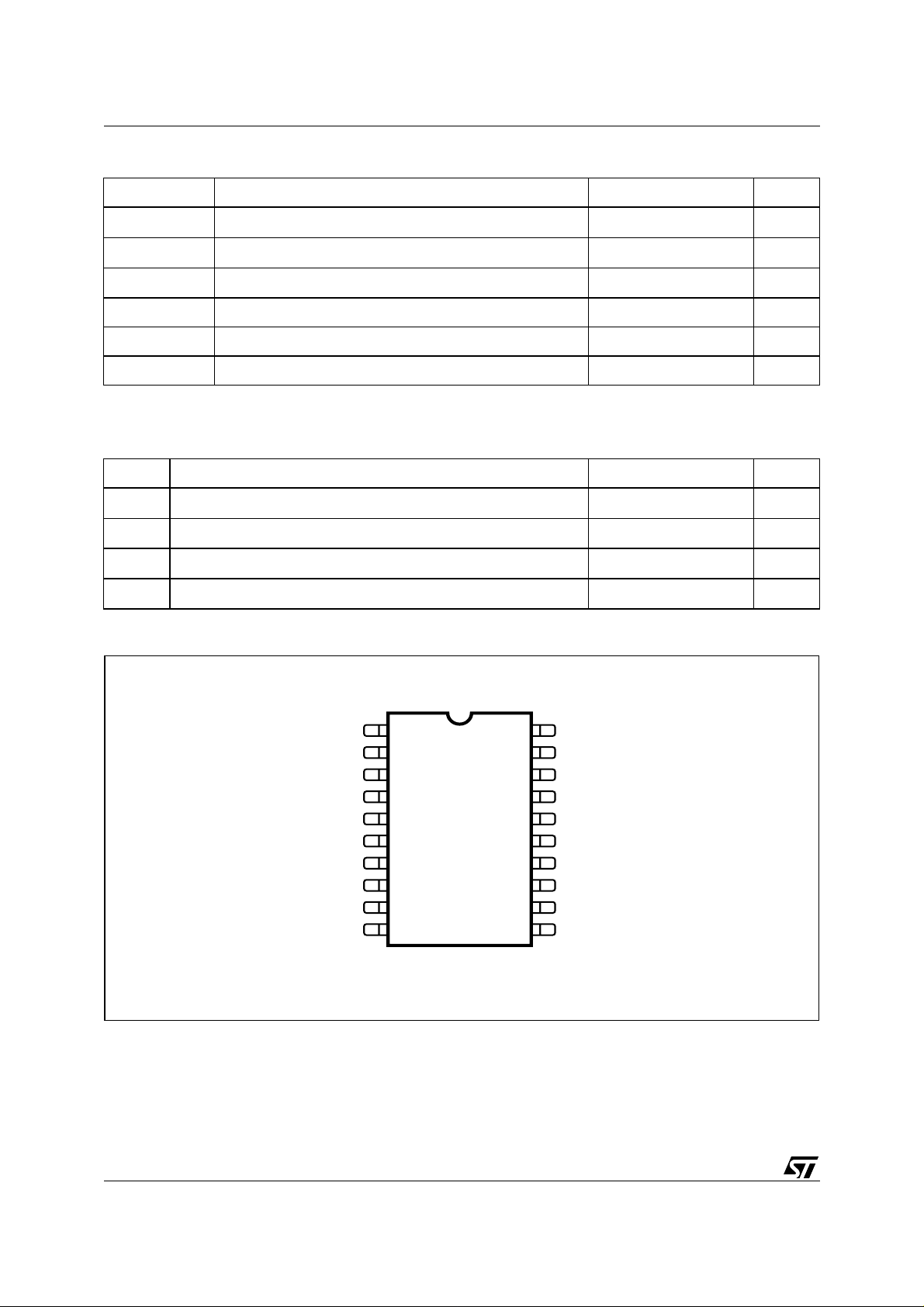

(Top view)

C/W

C

C

C

2/20

VSEN

OCSET

SS/INH

VID0

VID1

VID2

VID3

VID4

COMP PGOOD

FB GND

2

3

4

5

6

7

8

9

10

D98IN958

20

19

18

17

16

15

14

13

12

11

RT1

OVP

VCC

LGATE

PGND

BOOT

UGATE

PHASE

PIN FUNCTION

g

g

g

g

g

g

Pin

Num.

1 VSEN Connected to the output voltage is able to manage over-voltage conditions and the PGOOD

2 OCSET A resistor connected from this pin and the upper Mos Drain sets the current limit protection.

Name Description

signal.

The internal 200µA current

The Over-Current threshold is due to the followin

enerator sinks a current from the drain through the external resistor.

equation:

I

I

--------------------------------------------- -=

P

⋅

OCSETROCSET

R

DSon

L6911C

3 SS/INH

The soft start time is pro

internal current

enerator forces through the capacitor 10µA.

This pin can be used to disable the device forcin

rammed connecting an external capacitor from this pin and GND. The

a voltage lower than 0.4V

4 - 8 VID0 - 4 Voltage Identification Code pins. These input are internally pulled-up and TTL compatible. They

are used to program the output voltage as specified in Table 1 and to set the overvoltage and

power good thresholds.

Connect to GND to program a ‘0’ while leave floating to program a ‘1’.

9 COMP This pin is connected to the error amplifier output and is used to compensate the voltage control

feedback loop.

10 FB This pin is connected to the error amplifier inverting input and is used to compensate the voltage

control feedback loop.

11 GND All the internal references are referred to this pin. Connect it to the PCB signal ground.

12 PGOOD This pin is an open collector output and is pulled low if the output voltage is not within the above

specified thresholds.

If not used may be left floating.

13 PHASE This pin is connected to the source of the upper mosfet and provides the return path for the high

side driver. This pin monitors the drop across the upper mosfet for the current limit

14 UGATE High side gate driver output.

15 BOOT Bootstrap capacitor pin. Through this pin is supplied the high side driver and the upper mosfet.

Connect through a capacitor to the PHASE pin and through a diode to Vcc (cathode vs. boot).

16 PGND Power ground pin. This pin has to be connected closely to the low side mosfet source in order to

reduce the noise injection into the device

17 LGATE This pin is the lower mosfet gate driver output

18 VCC Device supply voltage. The operative nominal supply voltage ranges from 5 to 12V.

DO NOT CONNECT V

TO A VOLTAGE GREATER THAN VCC.

IN

19 OVP Over voltage protection. If the output voltage reaches the 17% above the programmed voltage

this pin is driven high and can be used to drive an external SCR that crowbar the supply voltage.

If not used, it may be left floating.

20 RT Oscillator switching frequency pin. Connecting an external resistor from this pin to GND, the

external frequency is increased according to the equation:

f

S

200kHz

4.94 10

-------------------------+=

R

⋅

kΩ()

T

6

Connecting a resistor from this pin to Vcc (12V), the switching frequency is reduced according to

the equation:

f

S

200kHz

4.306 10

---------------------------- -–=

R

⋅

kΩ()

T

7

If the pin is not connected, the switching frequency is 200KHz.

The volta

e at this pin is fixed at 1.23V (typ). Forcing a 50µA current into this pin, the built in

oscillator stops to switch.

3/20

L6911C

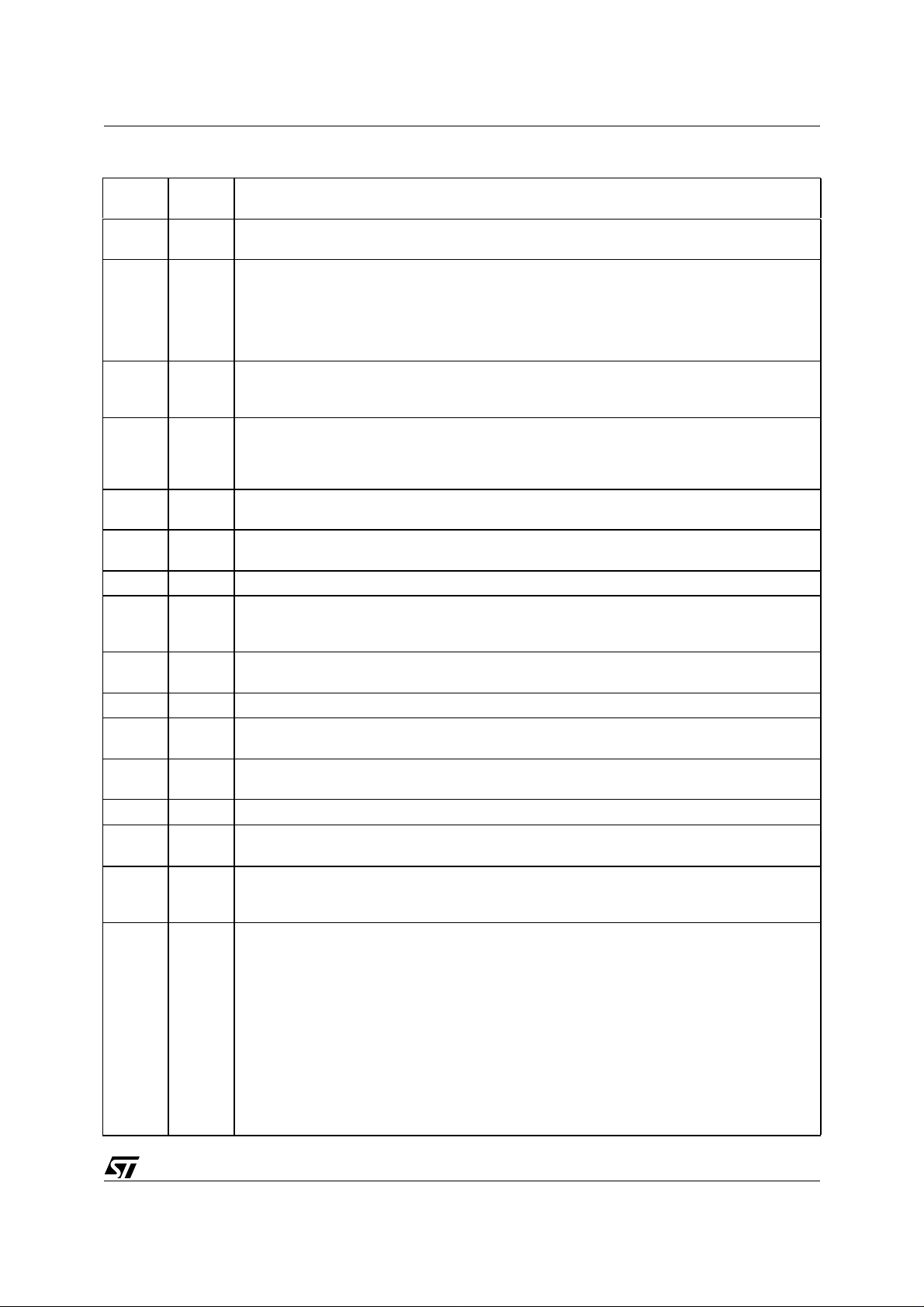

ELECTRICAL CHARACTERISTCS

(VCC = 12V, T

= 25°C unless otherwise specified)

amb

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

SUPPLY CURRENT

CC

Icc Vcc Supply current UGATE and LGATE open 5 mA

POWER-ON

Turn-On Vcc threshold VOCSET=4.5V 4.6 V

Turn-Off Vcc threshold VOCSET=4.5V 3.6 V

Rising V

I

Soft start Current 10 µ

SS

threshold 1.24 V

OCSET

OSCILLATOR

Free running frequency R

Total Variation

∆

Ramp amplitude RT = OPEN 1.9 Vp-p

V

osc

= OPEN 180 200 220 KHz

T

6 KΩ < RT to GND < 200 K

Ω -15 15 %

REFERENCE AND DAC

DACOUT Voltage

Accuracy

VID0, VID1, VID2, VID3, VID4

see Table1; Tamb = 0 to 70°C

-1 1 %

VID Pull-Up voltage 4 V

ERROR AMPLIFIER

DC Gain 88 dB

GBWP Gain-Bandwidth Produ ct 10 MHz

SR Slew-Rate COMP=10pF 10

GATE DRIVERS

I

UGATE

R

UGATE

I

LGATE

High Side Source

Current

High Side Sink

Resistance

Low Side Source

- V

V

BOOT

V

V

I

- V

UGATE

BOOT-VPHASE

= 300mA

UGATE

Vcc=12V, V

PHASE

PHASE

LGATE

=12V,

= 6V

=12V,

= 6V

1 1.3 A

24Ω

0.9 1.1 A

Current

R

LGATE

Low Side Sink

Vcc=12V, I

LGATE

= 300mA

1.5 3 Ω

Resistance

Output Driver Dead Time PHASE connected to GND 120 ns

PROTECTIONS

V

Rising 117 120 %

SEN

= 4.5V 170 200 230 µ

OCSET

> OVP Trip, V

SEN

=0V 60 mA

OVP

I

OCSET

I

OVP

Over Voltage Trip

/DACOUT)

(V

SEN

OCSET Current Source V

OVP Sourcing Current V

POWER GOOD

V

Rising 110 112 114 %

SEN

V

Falling 86 88 90 %

SEN

Upper and Lower threshold 2 %

= -5mA 0.5 V

PGOOD

V

PGOOD

Upper Threshold

/DACOUT)

(V

SEN

Lower Threshold

(V

/DACOUT)

SEN

Hysteresis

(V

/DACOUT)

SEN

PGOOD Voltage Low I

A

V/µS

A

4/20

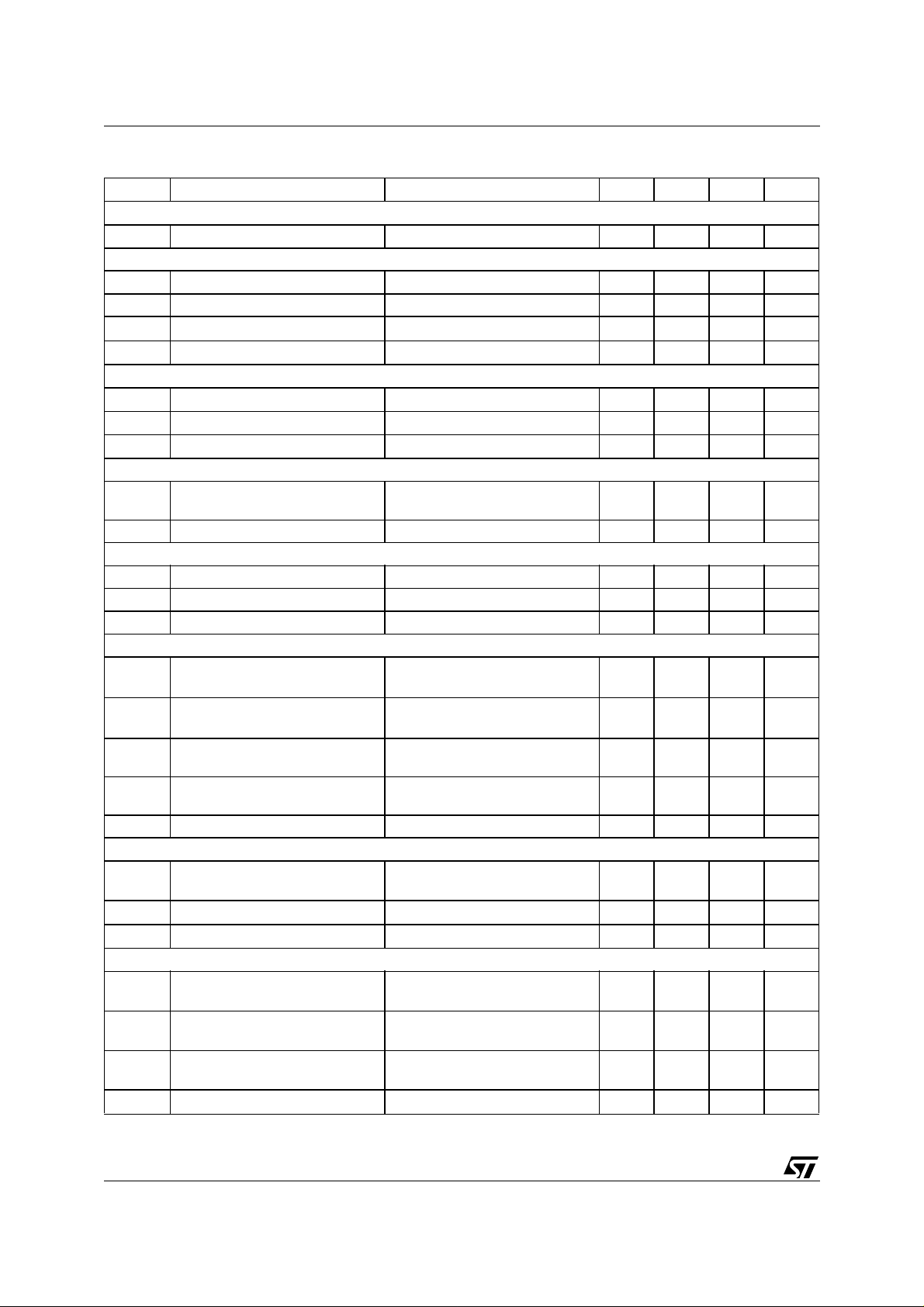

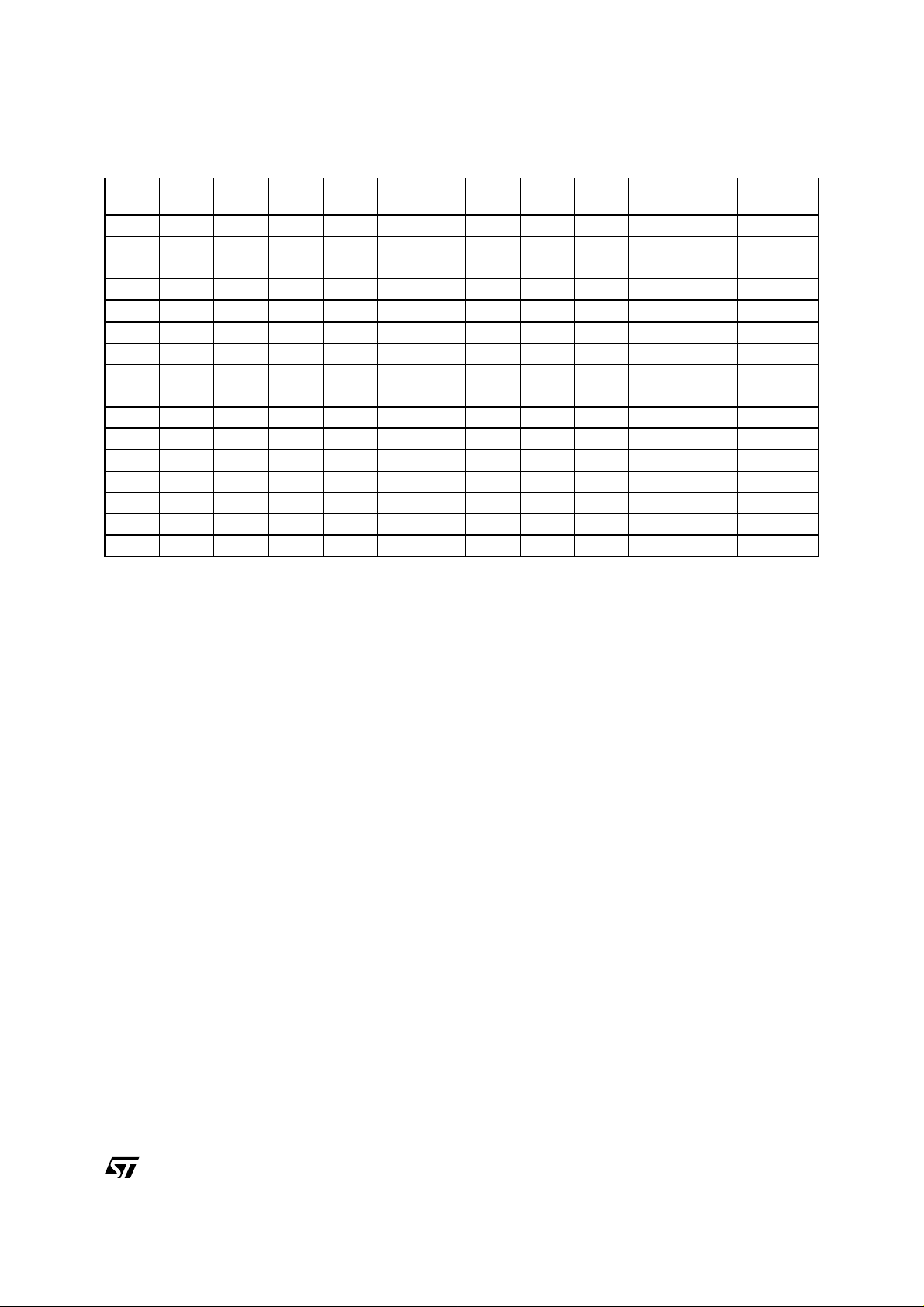

Table 1. VID Settings

VID4 VID3 VID2 VID1 VID0

01111

01110

01101

01100

01011

01010

01001

01000

00111

00110

00101

00100

00011

00010

00001

00000

Output

Voltage (V)

1.30

1.35

1.40

1.45

1.50

1.55

1.60

1.65

1.70

1.75

1.80

1.85

1.90

1.95

2.00

2.05

L6911C

VID4 VID3 VID2 VID1 VID0

11111Output Off

11110 2.1

11101 2.2

11100 2.3

11011 2.4

11010 2.5

11001 2.6

11000 2.7

10111 2.8

10110 2.9

10101 3.0

10100 3.1

10011 3.2

10010 3.3

10001 3.4

10000 3.5

Output

Voltage (V)

Device Description

The device is an i ntegrated circuit r ealized in BCD technol ogy. It provides c omplete control logic and protections

for a high performance step-down DC-DC converter optimized for microprocessor power supply. It is designed

to drive N-Channel Mosfets in a synchronous-rectified buck topology. The device works properly with Vcc ranging from 5V to 12V and regulates the output voltage starting from a 1.26V power stage s upply voltage (Vin). The

output voltage of the converter can be precisely regulated, programming the VID pins, from 1.3V to 2.05V with

50mV binary steps and from 2.1V to 3.5V with 100mV binary steps, with a maximum tol erance of ±1% over temperature and line voltage variations. The device provides voltage-mode control with fast transient response. It

includes a 200kHz free-running oscillator that is adjustable from 50kHz to 1MHz. The error amplifier features a

15MHz gain-bandwidth product and 10V/

µ

sec slew rate which permits high converter bandwidth for fast transient performance. The resulting PWM duty cycle ranges from 0% to 100%. The device protects against overcurrent conditions enter ing i n HICCUP mode. The devi ce moni tors the cur rent by using the r

DS(ON)

of the upper

MOSFET which eliminates the need for a current sensing resistor.

The device is available in SO20 package.

Oscillator

The switching frequency is internally fixed to 200kHz. The internal oscillator generates the triangular waveform

for the PWM charging and discharging with a constant c urrent an internal capacit or. The current deliver ed to the

oscillator is ty pically 50

µ

A (Fsw=200KHz) and may be varied using an external resistor (RT) connected between

RT pin and GND or VCC. Since the RT pin is maintained at fixed voltage (typ. 1.235V), the frequency is varied

proportionally to the current sunk (forced) from (into) the pin.

In particular connecting it to GND the frequency is increased (current is sunk from the pin), according to the

following relationship:

6

⋅

4.94 10

f

200kHz

S

-------------------------+=

Ω()

R

k

T

Connecting RT to VCC=12V or to VCC=5V the frequency is reduced (current is forced into the pin), according

to the following relationships:

5/20

L6911C

f

S

f

200kHz

S

200kHz

⋅

4.306 10

---------------------------- -+=

R

k

T

⋅

15 10

--------------------+=

R

T

Ω()

Ω()

k

7

V

7

V

CC

CC

= 12V

= 5V

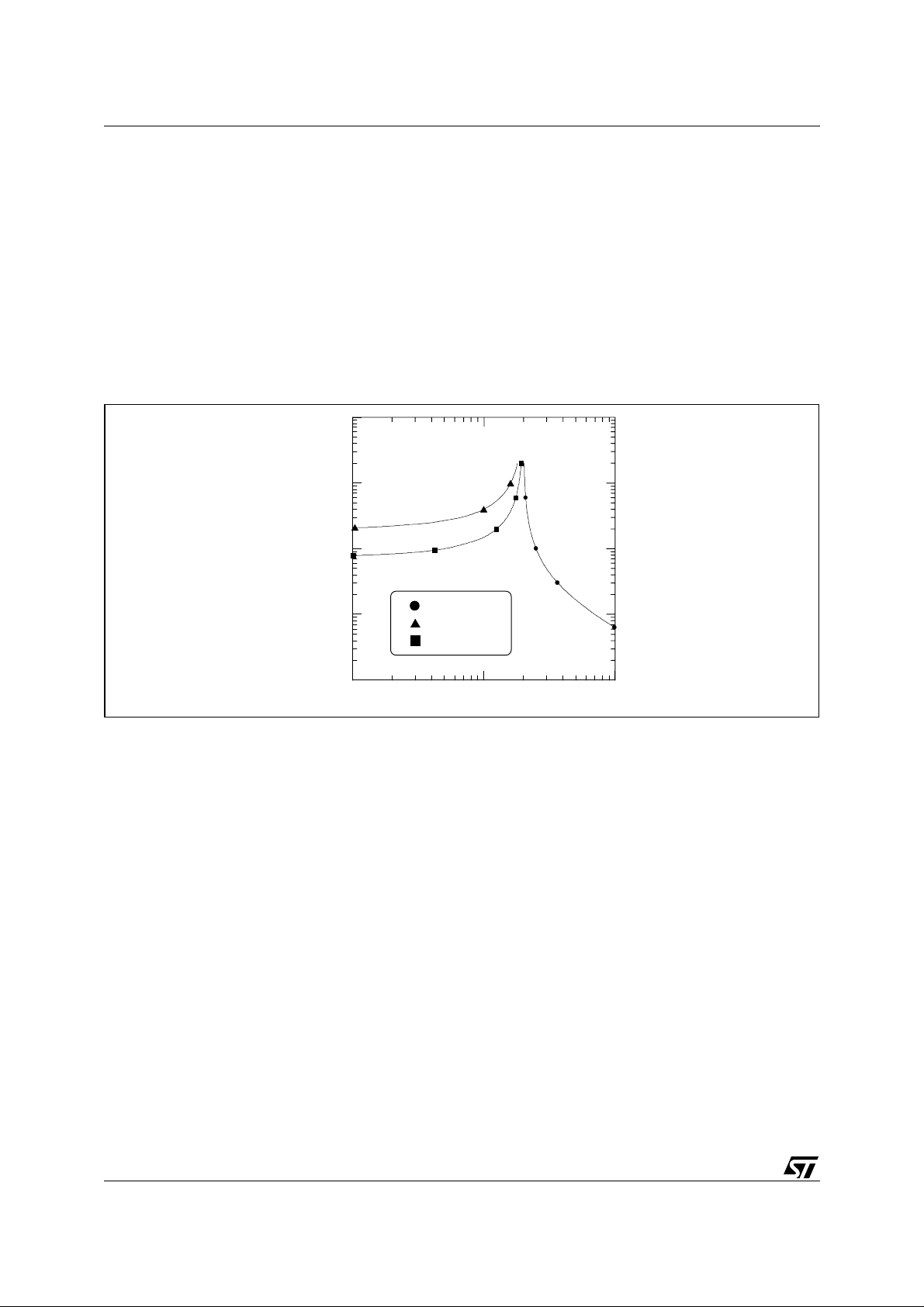

Switching frequency variations vs. R

µ

Note that forcing a 50

A current into this pin, the device stops switching because no current is delivered to the

are reported in Fig.1.

T

oscillator.

Figure 1.

10000

1000

100

Resistance [kOhm]

10

10 100 1000

RT to GN D

RT to VCC =12 V

RT to VCC =5V

Frequency [kHz]

Digital to Analog Converter

The built-in digital to analog converter allows the adjustment of the output voltage from 1.30V to 2.05V with

50mV binary steps and from 2.10V to 3.50V with 100mV binary steps as shown in the previous table 1. The

internal reference is trimmed to ensure the precision of 1%.

The internal reference voltage for the regulation is programmed by the voltage identification (VID) pins. These

are TTL compatible inputs of an internal DAC that is realized by means of a series of resistors providing a partition of the internal voltage reference. The VID code drives a multiplexer that selects a voltage on a precise

point of the divider. The DAC output is delivered to an amplifier obtaining the V

set-point of the error amplifier). Internal pull-ups are provided (realized with a 5

voltage reference (i.e. the

PROG

µ

A current generator); in this

way, to program a logic "1" it is enough to leave the pin floating, while to program a logic "0" it is enough to short

the pin to GND.

The voltage identification (VID) pin configuration also sets the power-good thresholds (PGOOD) and the overvoltage protection (OVP) thresholds.

The VID code "11111" disable the device (as a short on the SS pin) and no output voltage is regulated.

Soft Start and Inhibit

At start-up a ramp is generated charging the external capacitor CSS by means of a 10µA constant current, as

shown in figure 1.

When the voltage across the soft start capacitor (V

6/20

) reaches 0.5V the lower power MOS is turned on to dis-

SS

L6911C

charge the output capacitor. As VSS reaches 1V (i.e. the oscillator triangular wave inferior limit) also the upper

MOS begins to switch and the output voltage starts to increase.

The V

creases, as shown in figure 2. In this phase the system works in open loop. When V

clamp on the output of the error amplifi er is released. In any case another cla mp on the input of the err or amplifier remains active, allowing to V

In this second phase the system works in closed loop with a growing reference. As the output voltage reaches

the desired value V

increases until a maximum value of about 4V.

The Soft-Start will not take place, and the relative pin is internally shorted to GND, if both VCC and OCSET pins

are not above their own turn-on thresholds . During normal operation, if any under -voltage is detected on one of

the two supplies, the SS pin is internally shorted to GND and so the SS capacitor is rapidly discharged.

The device goes in INHIBIT state forcing SS pin below 0.4V. In this conditi on both external MOSFETS are kept

off.

Figure 2. Soft Start

growing voltage initially clamps the output of the error amplifier, and consequently V

SS

to grow with a lower slope (i.e. the slope of the VSS voltage, see figure 2).

OUT

, also the clamp on the error amplifier input is removed, and the soft start finishes. Vss

PROG

is equal to V

SS

linearly in-

OUT

COMP

the

Vcc

Vin

Vss

LGATE

Vout

to GND

Vcc Tu rn-on thresh o l d

Vin Turn-on threshold

1V

0.5V

Timing Diagram

Aquisition: CH1 = PHASE; CH2 = V

CH3 = PGOOD; CH4 = V

SS

OUT

;

Driver Section

The driver capability on the high and low side drivers allows using different types of power MOS (also multiple

MOS to reduce the R

), maintaining fast switching transition.

DSON

The low-side mos driver is supplied directly by Vcc while the high-side driver is supplied by the BOOT pin.

Adaptative dead time control i s implemented to pr event cross-c onduction and allow to use several kinds o f mos-

fets. The upper mos turn-on is avoided if the lower gate is over about 200mV while the lower mos turn-on is

avoided if the PHASE pin is over about 500mV. The upper mos is in any case turned-on after 200nS from the

low side turn-off.

The peak current is shown for both the upper ( fig. 3) and the lower (f ig. 4) driver at 5V and 12V. A 4nF capacitive

load has been used in these measurements.

For the lower driver, the source peak current is 1.1A @ Vcc=12V and 500mA @ Vcc=5V, and the sink peak

current is 1.3A @ Vcc=12V and 500mA @ Vcc=5V.

Similarly, for the upper driver, the source peak current is 1.3A @ Vboot-Vphase=12V and 600mA @ VbootVphase =5V, and the sink peak current is 1.3A @ Vboot-Vphase =12V and 550mA @ Vboot-Vphase = 5V.

7/20

L6911C

Figure 3. High Side driver peak current. Vboot-Vphase=12V (left) Vboot-Vphase=5V (right)

CH1 = High Side Gate CH4 = Gate Current

Figure 4. Low Side driver peak current. Vcc=12V (left) Vcc=5V (right)

CH1 = Low Side Gate CH4 = Gate Current

Monitoring and Protections

The output voltage is monitored by means of pin 1 (VSEN). If it is not w ithin ±12% (typ.) of the programm ed

value, the powergood output is forced low.

The device provi des ov ervoltage pr otection, when the output voltage reache s a value 17% (typ.) gr ater than the

nominal one. If the output voltage exceeds this threshol d, the OVP pin is fo rced high, triggerin g an external SCR

to shuts the supply (VIN) down, and also the lower driver is turned on as long as the over-voltage is detected.

To perform the overcurrent protection the device compares the drop across the high side MOS, due to the

RDSON, with the voltage across the external resistor (ROCS) connected between the OCSET pin and drain of

the upper MOS. Thus the overcurrent threshold (I

Where the typical value of I

R

(also the variation with temperature) and the minimum value of I

DSON

8/20

is 200µA. To calculate the ROCS value it must be considered the maximum

OCS

) can be calculated with the following relationship:

P

⋅

I

OCSROCS

-------------------------------- -=

I

P

R

DSON

. To avoid undesirable trigger of

OCS

L6911C

overcurrent protection this relationship must be satisfied:

∆

l

---- -+≥

=

IPI

OUTMAX

∆

Where

I is the inductance ripple current and I

OUTMAX

is the maximum output current.

In case of output short circuit the soft start capacitor is discharged with constant current (10

the SS pin reaches 0.5V the soft start phase is restarted. During the soft start the over-current protection is always active and if such kind of event occurs, the device turns off both mosfets, and the SS capacitor is discharged again (after reaching the upper threshold of about 4V). The system is now working in HICCUP mode,

as shown in figure 5a. After removing the c ause of the over-current, the device restart w orking normal ly w ithout

power supplies turn off and on.

Figure 5.

I

PEAK

2

µ

A typ.) and when

a: Hiccup Mode

9

8

7

6

5

4

3

2

Inductor Ripple [A]

1

0

0.5 1.5 2.5 3.5

Output Voltage [V ]

b: Indu ctor Ripple Current vs. Vout

L=1.5µH, Vin=12V

L=3µH, Vin=5V

L=2µH,

Vin=12V

L=3µH,

Vin=12V

L=1.5µH,

Vin=5V

L=2µH,

Vin=5V

Inductor design

The inductance value is defined by a compromise between the transient response time, the efficiency, the cost

and the size. The inductor has to be calculated to sustain the output and the input voltage variation to maintain

the ripple current

culated with this relationship:

Where f

SW

the ripple current vs. the output voltage for different values of the inductor, with V

∆

IL between 20% and 30% of the maximum output current. The inductance value can be cal-

–

L

V

INVOUT

------------------------------

∆

⋅

f

S

V

OUT

-------------- -

⋅=

I

V

L

IN

is the switching frequency, VIN is the input voltage and V

is the output voltage. Figure 5b shows

OUT

= 5V and VIN = 12V.

IN

Increasing the value of the inductance reduces the ripple current but, at the same time, reduces the converter

response time to a load transient. If the compensation network is well designed, the device is able to open or

close the duty cycle up to 100% or down to 0%. The response time is now the time required by the inductor to

change its current from initial to final value. Since the ind uctor has not fini shed its char ging tim e, the output current is supplied by the output capacitors. Minimizing the response time can minimize the output capacitance

required.

The response time to a load transient is different for the application or the removal of the load: if during the application of the loa d the inductor is c harged by a voltage equal to the difference between the input and the output

voltage, during the removal it is discharged only by the output voltage. The following expressions give approximate response time for

∆

I load transient in case of enough fast compensation network response:

9/20

L6911C

t

applicatio n

⋅

L∆I

----------------------------- -=

–

V

INVOUT

t

removal

⋅

L∆I

-------------- -=

V

OUT

The worst condition depends on the input voltage available and the output voltage selected. Anyway the worst

case is the response ti me after r emoval o f the load with the minimum output voltage programmed and the maximum input voltage available.

Output Capacitor

Since the microprocessors require a current variation beyond 10A doing load transients, with a slope in the

range of tenth A/

µ

sec, the output capacitor is a basic component for the fast response of the power supply. In

fact for first few microseconds they supply the current to the load. The controller recognizes immediately the

load transient and sets the duty cycle at 100%, but the current slope is limited by the inductor value.

The output voltage has a first drop due to the current variation inside the capacitor (neglecting the effect of the

ESL):

∆

V

OUT

= ∆I

OUT

· ESR

A minimum capacitor value is required to sustain the current during the load transient without discharge it. The

voltage drop due to the output capacitor discharge is given by the following equation:

2

∆

I

L

OUT

–⋅()⋅⋅

Where D

∆

V

OUT

is the maximum duty cycle value that is 100%. The lower is the ESR, the lower is the output drop

MAX

---------------------------------------------------------------------------------------------=

2C

OUTVINMINDMAXVOUT

during load transient and the lower is the output voltage static ripple.

Input Capacitor

The input capacitor has to sustain the ripple current produced during the on time of the upper MOS, so it must

have a low ESR to minimize the losses. The rms value of this ripple is:

I

rmsIOUT

–()⋅=

D1D

Where D is the duty cycle. The equation reaches its maximum value with D=0.5. The losses in worst case are:

2

P ESR I

⋅=

rms

Compensation network design

The control loop is a voltage mode (figure 7) that uses a droop function to satisfy the requirements for a VRM

module, reducing the size and the cost of the output capacitor.

This method "recovers" part of the drop due to the output capacitor ESR in the load transient, introducing a dependence of the output voltage on the load current: at light load the output voltage will be higher than the nominal level, while at high load the output voltage will be lower than the nominal value.

10/20

L6911C

Figure 6. Output transient response without (a) and with (b) the droop function

ESR DROP ESR DROP

V

MAX

V

V

NOM

V

MIN

(a) (b)

As shown in figure 6, the ESR drop is pr esent in any c ase, but using the droop func tion the total deviation of the

output voltage is minimized. In practice the droop function introduces a static error (Vdroop in figure 6) proportional to the output current. Since a sense resistor is not present, the output DC current is measured by using

the intrinsic resistance of the inductance (a few m

Ω

). So the low-pass filtered inductor voltage (that is the inductor current) is added to the feedback signal, implementing the droop function in a simple way. Referring to the

schematic in figure 7, the static characteristic of the closed loop system is:

⋅

R 8 // R9

V

OUT

V

PROGVPROG

+

R3 R8 // R9

-------------------------------------

R2

R

L

---------------------------------- -

R8

⋅–⋅+=

I

OUT

DROOP

Where V

resistance. The second term of the equation allows a positive offset at zero load (

the droop effect (

is the output voltage of the di gital to ana log conv erter (i .e. the set po int) and RL is the inductance

PROG

∆

V

). Note that the droop effect is equal the ESR drop if:

DROOP

⋅

R8 // R9

R

L

---------------------------------- -

R8

=

ESR

∆

V+); the third term introduces

Figure 7. Compensatio n ne tw o rk

V

IN

V

COMP

C18

R9

C25

R

L

V

PWM

Z

F

C20 R4

R3

PROG

V

R2

PHASE

Z

I

L2

R8

V

OUT

ESR

C6-15

Considering the previous relationships R2, R3, R8 and R9 may be determined in order to obtain the desired

droop effect as follow:

■

Choose a value for R2 in the range of hundreds of KΩ to obtain realistic values for the other

components.

11/20

L6911C

■

From the above equations, it results:

R8

=

R9 R8

+

∆

⋅

V

R2

-----------------------

V

PROG

∆

V

DROOP

-------------------------- -

⋅⋅

⋅

R

LIMAX

⋅

R

LIMAX

-------------------------- -

⋅=

∆

V

DROOP

1

------------------------------------ -

∆

V

DROOP

-------------------------- -+

1

⋅

R

LIMAX

;

;

Where I

■

The component R3 must be chosen in order to obtain R3<<R8//R9 to permit these and successive

is the maximum output current.

MAX

simplifications.

Therefore, with the droop function the output voltage decreases as the load current increases, so the DC output

impedance is equal to a resistance R

. It is easy to verify that the output voltage deviation under load tran-

OUT

sient is minimum when the output impedance is constant with frequency.

To choose the other components of the compensation network, the transfer function of the voltage loop is con-

sidered. To simplify the analysis is supposed that R3 << Rd, where Rd = (R8//R9).

Figure 8. Compensatio n ne tw o rk def i ni t io n

|Av |

2

|R|

R

|Gloop |

G

f

LC

0

D

f

0

2

f

f

CE

1

f

f

ECfCC

3

f

f

f

fc

f

⋅⋅=

π

CRfingularityonNetworkSCompensati

2/1

⋅=

π

fingularityConverterS

LC

f

CE

f

EC

f

CC

⋅⋅=

π

CESR

2/1

π

2/1

π

2/1

OUT

⋅⋅=

⋅⋅=

doublepoleLC

ESRzero

1

byIntroducedCceramicESR

acitorCeramicCapCceramicRceramic

2

3

f

d

2042/1

π

π

π

⋅+⋅=

CRRf

20)43(2/1

⋅⋅=

CRf

2532/1

⋅⋅=

CRd

252/1

The transfer function may be evaluated neglecting the connection of R8 to PHASE because, as will see later,

this connection is important only at low frequencies. So R4 is considered connected to VOUT. Under this assumption, the voltage loop has the following transfer function:

12/20

Gloop s()Av s()Rs

()⋅

()

Av s

()

Zf s

------------- -

⋅==

()

Zi s

Where

()

Av s

Vin

--------------- -

∆

V

osc

()

s

Z

C

------------------------------------ -

⋅=

s()ZLs

Z

C

L6911C

()+

Where Z

The expression of Z

Where:

(s) and ZL(s) are the output capacitor and inductor impedance respectively.

C

(s) may be simplified as follow:

I

==

()

s

Z

I

τ

= R4×C20,

1

1

-- -

⋅⋅

Rd

--------------------------------- -

Rd

C25

s

1

-- -+

⋅

C25

s

τ

= (R4+R3)×C20 and

2

1

-- -

R4

----------------------------------------------------- -+

R4

⋅+

s

1

-- -

⋅+

s

=

Rd

⋅

C20

C20

-------------------------------------------------------------------- -

R3

+

R3

------- - τ

1s

R

1s

τ

= Rd×C25.

d

R3

⋅+

d

⋅+()

τ

2

Rd 1 s

-------------------------------------------------------------------------------------------------- -

⋅+()⋅

1s

d

τ

⋅+()⋅

1s

τ

1τd

1s

τ

1

d

+()

⋅+()

τ

2

2

R3

------- -

⋅⋅⋅+⋅+

s

1s

τ

1τd

R

d

τd⋅+()⋅

=

The regulator transfer function became now:

()

Rs

------------------------------------------------------------------------------------------------------- -

≈

sC18R

1s

2

R3

------- -

1s

d

R

⋅+()

τ

Figure 8 shows a method to select the regul ator components (pleas e note that the fr equencies f

1s

⋅+

τ

d

d

⋅+()⋅

τ

d

⋅+()⋅⋅⋅ ⋅

1s

τ

1

and fCC cor-

EC

responds to the singularities introduced by additional ceramic capacitors in parallel to the output main electrolytic capacitor).

■

To obtain a flat frequency response of the output impedance, the droop time constant

τ

has to be equal

d

to the inductor time constant (see the note at the end of the section):

L

τ

d

■

To obtain a constant -20dB/dec Gloop(s) shape the singularity f1 and f2 are placed in proximity of fCE

and f

respectively. This implies that:

LC

⋅

RdC25

f

2

----

f

1

f1 f

■

To obtain a Gloop bandwidth of fC, results:

G0f

⋅ 1f

LC

=== ==

⇒⋅ A

C

G

⋅

0

0R0

------ - τ

R

L

f

LC

-------- -

R4⇒R3

f

CE

C20

CE

C20 // C25

VIN

⋅

----------------- -

Vosc∆

-----------------------------

L

C18

⇒

C25

f

LC

-------- -1–

⋅==

f

CE

1

-- - π

R4 f

2

f

C

C18⇒

------- -

f

LC

L

-----------------------=== =

⋅()

R

LRd

⋅⋅⋅=⇒=

CE

----------------- -

Vosc∆

-----------------------------

C20 C25

+

C20 C25⋅

VIN

⋅⋅

f

------- -

f

LC

C

Note.

To understand the reason of the previous assumption, the scheme in figure 9 must be considered.

In this scheme, the inducto r current has been subs tituted by the l oad current, becaus e in the fr equenci es range

of interest for the Droop function these current are substantially the same and it was supposed that the droop

network don't represent a charge for the inductor.

13/20

L6911C

E

Figure 9. Voltage regulation with droop function block scheme

LOOP

VoutVcomp

1

R

⋅

OUT

1

R

OUT

s

τ

⋅+

L

s

τ

⋅+

d

⋅== =

+

τ

1s

-----------------+

τ

1s

Iout

L

d

It results:

Z

OUT

V

o

--------------- -

I

LOAD

Av(s)

R(s)

+

τ

1s

L

------------------

⋅⋅

R

d

+

τ

1s

d

G

LOOP

---------------------------- +

1G

Because in the interested range |Gloop|>>1.

To obtain a flat shape, the relationship considered will naturally follow.

Demo Board Description

The L6911C demo board shows the operation of the device in a standard VRM 8.4 application. This evaluation

board allows voltage adjustability (1.3V - 3.5V) through the switches S1-S5 and high output current capability

(up to 14A). The device is supplied by the 12V input rail while the power conversion starts from the 5V input rail.

The device is also able to operate with a 5V supply voltage; in this case 12V input can be directly connected to

the 5V power source. The four layers demo board's c opper thickness is of 70

µ

m in order to minimi ze conduction

losses considering the high current that the circuit is able to deliver. Figure 10 shows the demo board's schematic circuit.

Figure 10. Demo Board Schematic

L1

F1

+5 VIN

14/20

GNDIN

+12Vcc

GND12

Q8

D1

BOOT

15

C17

S1

S2

S3

S4

S5

C16

VCC

18

GND

11

VID0

4

VID1

5

VID2

VID3

VID4

OSC

R1

6

L6911C

7

8

SS

3

20

9

COMP

U1

C18

C19

R5

G1

C24

OVP

19

OCSET

2

UGATE

14

PHASE

13

LGATE

17

PGND

16

PGOOD

12

VSEN

1

10

VFB

R3

C20

R2

C23

R7

R13

Q1-2

R14

Q4-5

R4

C21-22

D2

C1-5

L2

C6-15

R8

R9

C25

VOUTCOR

R12

GNDCORE

PWRGD

L6911-L6912 EVALUATION KIT REV.

L6911C

Efficiency

Figure 11 shows the m easured effi ciency versu s load current for different values of ou tput vol tage. The measure

was done at Vin=5V for different values of the output voltage (2.05V and 2.75V). Two different measurements

were done using IC supply voltage of 5V and 12V.

In the application two mosfets STS12NF30L (30V, 10m

both the low and the high side.

The board has been layed out with the possibility to use up to three SO8 mosfets for both high and low side

switch. Two D

2

PACK mosfets (one for each high and low side) may also be used in order to allow the maximum

flexibility in meeting different requirements.

Figure 11. Efficiency vs. load

95

90

85

80

75

70

Efficiency [%]

65

60

55

0 2 4 6 8 10 12 14 16

Vout = 1.7V

Vout = 2.0V

Vout = 2.5V

Output Current [A]

Ω

typ @ Vgs=4.5V) connected in parallel are used for

95

90

85

80

75

70

Efficiency [%]

65

60

55

0 2 4 6 8 10 12 14 16

Vou t = 1.7V

Vou t = 2.0V

Vou t = 2.5V

Output Current [A]

Vcc = 12V; Vin = 5V Vcc = Vin = 5V

Load Transient Response

Figure 12 shows the demo board response to a load

transient application. The load transient applied

changes from 0A to 14A on the output current (Channel 4). It may be observed that output vol t age (Channel 1) remains within the 100mV toler ance across the

regulated voltage. Figure 13 shows details about the

the circuit response during current rising and falling

edge; it is possible to observe that the duty cycle of

the Phase signal (Channel 2) goes up to 100% or

down to 0% if necessary.

Figure 12. Load Transient Response

Figure 13. Load Transient Response Details

15/20

L6911C

Inductor selection

Since the maximum output current is equal to 14A, to have a 30% ripple (4A) in worst case a 3µH inductor has

been chosen. So the ripple is 4.1A @ 3.5V with V

In worst case the peak is equal to 18.1A.

Output Capacitor

In the demo ten Sanyo capacitors, model 6MV1000GX are used, with a maximum ESR equal to 69mΩ. Therefore, the resultant ESR is 69m

Ω

/10 = 1.9mΩ. For a load transient of 14A in worst case the drop results:

∆

Vout = 14 * 0.00069 = 96.6mV

The voltage drop due to the c apacitor di scharge duri ng load transient, consi deri ng that the maxi mum duty cyc le

is equal to 100% results in 13mV with 2.5V of programmed output.

Input Capacitor

For I

= 14A and D = 0.5 (worst case for input ripple current), Irms is equal to 7A. Five Sanyo electrolytic

OUT

capacitors 25MV330GX, with a maximum ESR equal to 69m

resultant ESR is equal to 69m

Ω

/5 = 13.8mΩ. So the losses in worst case are:

==

P ESR I

Over-Current Protection

Substituting the demo board parameters in the relationship reported in the relative section, (I

I

= 19A; R

P

DSONMAX

= 9mΩ) it results that R

=12V and 1.7A @ 3.5V with VIN = 5V.

IN

Ω

, are chosen to sustain the ripple. Therefore, the

2

OCS

⋅

rms

= 1kΩ.

670mW

OCSMIN

= 170µA;

Part List

R2 499k 1% SMD 0805

R3, R7 1k 1% SMD 0805

R4 20 SMD 0805

R5, R8 20k SMD 0805

R9 15k SMD 0805

R12 1K SMD 0805

R13, R14 0 SMD 0805

C1, C2…C5

C6, C7…C15 1000µ SANYO – 6MV1000GX Radial 8x20mm

C16, C17, C24, C25 100n Ceramic SMD 0805

C18 2.2n Ceramic SMD 0805

C19 8.2n Ceramic SMD 0805

C20 82n Ceramic SMD 0805

C21, C22 1µ Ceramic SMD 1206

C23 1n Ceramic SMD 0805

L1

L2 3µ T50-52B Core, 10T-16AWG

U1 L6911C STMicroelectronics SO20

Q1, Q2…Q6 STS12NF30L STMicroelectronics SO8

D1 1N4148 STMicroelectronics SOT23

D2 STPS3L25U STMicroelectronics SMB

F1 251015A-15° Littlefuse AXIAL

µ SANYO – 25MV330GX Radial 8x20mm

330

µ T44-52 Core, 7T-18AWG

1.5

16/20

PCB AND COMPONENTS LAYOUTS

Figure 14. PCB and Components Layouts

Component Side Internal Ground Plane

Figure 15. PCB and Components Layouts

L6911C

Internal Layer Solder Side

17/20

L6911C

Application Circuit Examples

Figure 16 reports the schematic circuit for a motherboard chipset power supply. This application works from a

single 5V power supply and is able to deliver up to 10A with a 300KHz switching frequency.

Figure 16. Motherboard chipset power supply; 2.5Vout, 10A

+5 VIN

GNDIN

CoilCraft DO3316P

10A fuse

1uH

100nF

100n

3x220uF

43k

1N4148

VCC

GND

VID0

VID1

VID2

VID3

VID4

SS

OSC

15

18

11

4

5

6

L6911C

7

8

3

20

9

COMP

BOOT

680pF

U1

220pF

100k

750k

100n

OVP

19

OCSET

2

UGATE

14

PHASE

13

LGATE

17

PGND

16

PGOOD

12

VSEN

1

10

VFB

10k

5.6n

220

STS12NF 30L

STS12NF 30L

1n

1k

2x1uF

ceramic

CoilCraft DO5022P

1.5uH

STPS3L25U

Sanyo

5x470uF

10k

Sanyo TP B

VOUTCORE

GNDCORE

PWRGD

18/20

L6911C

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 2.35 2.65 0.093 0.104

A1 0.1 0.3 0.004 0.012

B 0.33 0.51 0.013 0.020

C 0.23 0.32 0.009 0.013

D 12.6 13 0.496 0.512

E 7.4 7.6 0.291 0.299

e 1.27 0.050

H 10 10.65 0.394 0.419

h 0.25 0 .75 0.010 0.030

L 0.4 1.27 0.016 0.050

K 0˚ (min.)8˚ (max.)

mm inch

OUTLINE AND

MECHANICAL DATA

SO20

B

e

D

1120

110

L

h x 45˚

A

K

A1

C

H

E

SO20MEC

19/20

L6911C

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or p at ent rights of STMicroelectronics. Spec i fications mentioned i n this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri t i cal compone nts in life support device s or systems without express written approval of STMicroel ectronics.

The ST logo is a registered trademark of STMicroelectronics

2001 STMi croelectronics - All Ri ghts Rese rved

Australi a - Brazil - Chin a - Finland - Franc e - Germany - Hong Kong - India - Ita l y - Japan - Malaysi a - Malta - Morocco - Singapore - Spain

STMicroelectronics GROUP OF COMPANIES

- Sweden - Sw itzerlan d - United Kin gdom - U.S.A.

http://www.s t. com

20/20

Loading...

Loading...