Page 1

2/3/4 phase controller with embedded drivers for Intel® VR11.1

Features

■ Load transient boost LTB Technology™ to

minimize the number of output capacitors

■ 2 or 3-phase operation with internal driver

■ 4-phase operation with external PWM driver

signal

■ PSI input with programmable strategy

■ Imon output

■ 0.5% output voltage accuracy

■ 8-bit programmable output up to 1.60000 V -

Intel VR11.1 DAC - backward compatible with

VR10/VR11

■ Full differential current sense across inductor

■ Differential remote voltage sensing

■ Adjustable voltage offset

■ LSLess startup to manage pre-biased output

■ Feedback disconnection protection

■ Preliminary overvoltage protection

■ Programmable overcurrent protection

■ Programmable overvoltage protection

■ Adjustable switching frequency

■ SS_END and OUTEN signal

■ VFQFPN-48 7x7 mm package with exposed

pad

Applications

■ High current VRM/VRD for desktop / server /

workstation CPUs

■ High density DC/DC converters

L6716

VFQFPN-48 - 7 x 7 mm

Description

The device implements a two-to-four phases stepdown controller with three integrated high current

drivers in a compact 7x7 mm body package with

exposed pad.

Load transient boost LTB Technology™ reduces

system cost by providing the fastest response to

load transition therefore requiring less bulk and

ceramic output capacitors to satisfy load transient

requirements.

The device embeds VR11.x DACs: the output

voltage ranges up to 1.60000 V managing D-VID

with ±0.5% output voltage accuracy over line and

temperature variations.

The controller assures fast protection against load

overcurrent and under / overvoltage (in this last

case also before UVLO). Feedback disconnection

prevents from damaging the load in case of

disconnections in the system board.

In case of overcurrent, the system works in

constant current mode until UVP.

Table 1. Device summary

January 2010 Doc ID 14521 Rev 3 1/57

Order codes Package Packing

L6716

Tr ay

VFQFPN-48

L6716TR Tape and reel

www.st.com

57

Page 2

Contents L6716

Contents

1 Principle application circuit and block diagram . . . . . . . . . . . . . . . . . . . 4

1.1 Principle application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Pin description and connection diagram . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.1 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5 Voltage identifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7 DAC and Phase number selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8 Power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

9 Current reading and current sharing loop . . . . . . . . . . . . . . . . . . . . . . 23

10 Differential remote voltage sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

11 Voltage positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11.1 Offset (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11.2 Droop function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12 Droop thermal compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

13 Output current monitoring (IMON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

14 Load transient boost technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2/57 Doc ID 14521 Rev 3

Page 3

L6716 Contents

15 Dynamic VID transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

16 Enable and disable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

17 Soft-start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

17.1 Low-side-less startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

18 Output voltage monitor and protections . . . . . . . . . . . . . . . . . . . . . . . . 39

18.1 Undervoltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

18.2 Preliminary overvoltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

18.3 Overvoltage and programmable OVP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

18.4 Overcurrent protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

18.5 Feedback disconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

19 Low power state management and PSI# . . . . . . . . . . . . . . . . . . . . . . . . 44

20 Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

21 Driver section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

22 System control loop compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

23 Tolerance band (TOB) definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

23.1 Controller tolerance (TOBController) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

23.2 External current sense circuit tolerance (TOBCurrSense) . . . . . . . . . . . . 50

23.3 Time constant matching error tolerance (TOBTCMatching) . . . . . . . . . . . 50

23.4 Temperature measurement error (VTC) . . . . . . . . . . . . . . . . . . . . . . . . . . 51

24 Layout guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

24.1 Power components and connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

24.2 Small signal components and connections . . . . . . . . . . . . . . . . . . . . . . . 53

25 Embedding L6716 - based VR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

26 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

27 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Doc ID 14521 Rev 3 3/57

Page 4

Principle application circuit and block diagram L6716

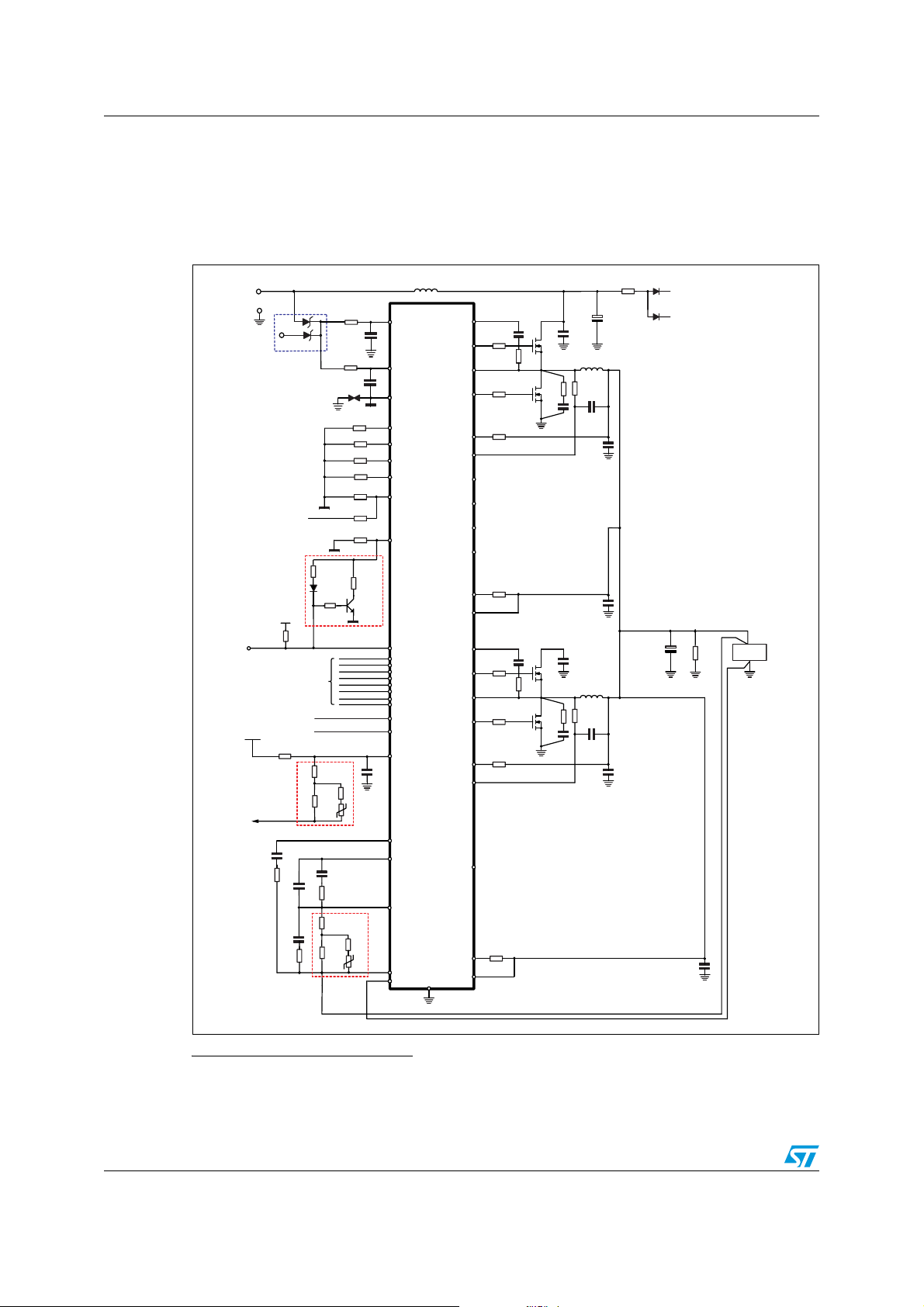

1 Principle application circuit and block diagram

1.1 Principle application circuit

to BOOT1

to BOOT3

220nF

ROUT

(a)

Vcc_core

LOAD

GND_core

Figure 1. Principle application circuit for VR11.1 - 2 phase operation

L

42

VCCDR

3

VCC

2

SGND

12

OVPSEL

13

OCSET/PSI_A

11

OFFSET

10

LTBGAIN

14

OSC/FAULT

15

SSOSC

35

SSEND

33

VID7

32

VID6

31

VID5

30

VID4

29

VID3

28

VID2

27

VID1

26

VID0

34

PSI

16

OUTEN

9

IMON

8

LTB

4

COMP

5

FB

6

VSEN

FBG

7

IN

L6716

PWM4 /

PH_SEL

PGND

49

BOOT1

UGATE1

PHASE1

LGATE1

CS1-

CS1+

BOOT2

UGATE2

PHASE2

LGATE2

CS2-

CS2+

BOOT3

UGATE3

PHASE3

LGATE3

CS3-

CS3+

CS4-

CS4+

47

1

48

45

18

Rg

17

39

40

41

44

20

Rg

19

36

37

38

43

Rg

22

21

25

Rg

24

23

VIN

HS1

LS1

VIN

HS3

LS3

CIN

L1

R

C

220nF

220nF

COUT

L3

R

C

220nF

VIN

GNDIN

5V

SB

Optional:Pre-OVP

Vcc

ROVP

ROCSET

ROFFSET

RLTBGAIN

ROSC_SGND

ROSC_VCC

To Vcc

RSS_FLIM

RSSOSC

Optional:

See DS

VTT

1k

SS_END

+3V3

RIMON_OS

R1

RIMON_TOT

CLTB

RLTB

C

I

R

I

L6716 REF.SCH:

2Phase Operation

R3

CP

To GND CORE

RFLIMT

D

Q

10k

VID bus from CPU

To CPU

To Enable circuitry

R2

NTC

CF

RF

RFB

RFB1

RFB2

RFB3

NTC

CIMON

a. Refer to the application note for the reference schematic.

4/57 Doc ID 14521 Rev 3

Page 5

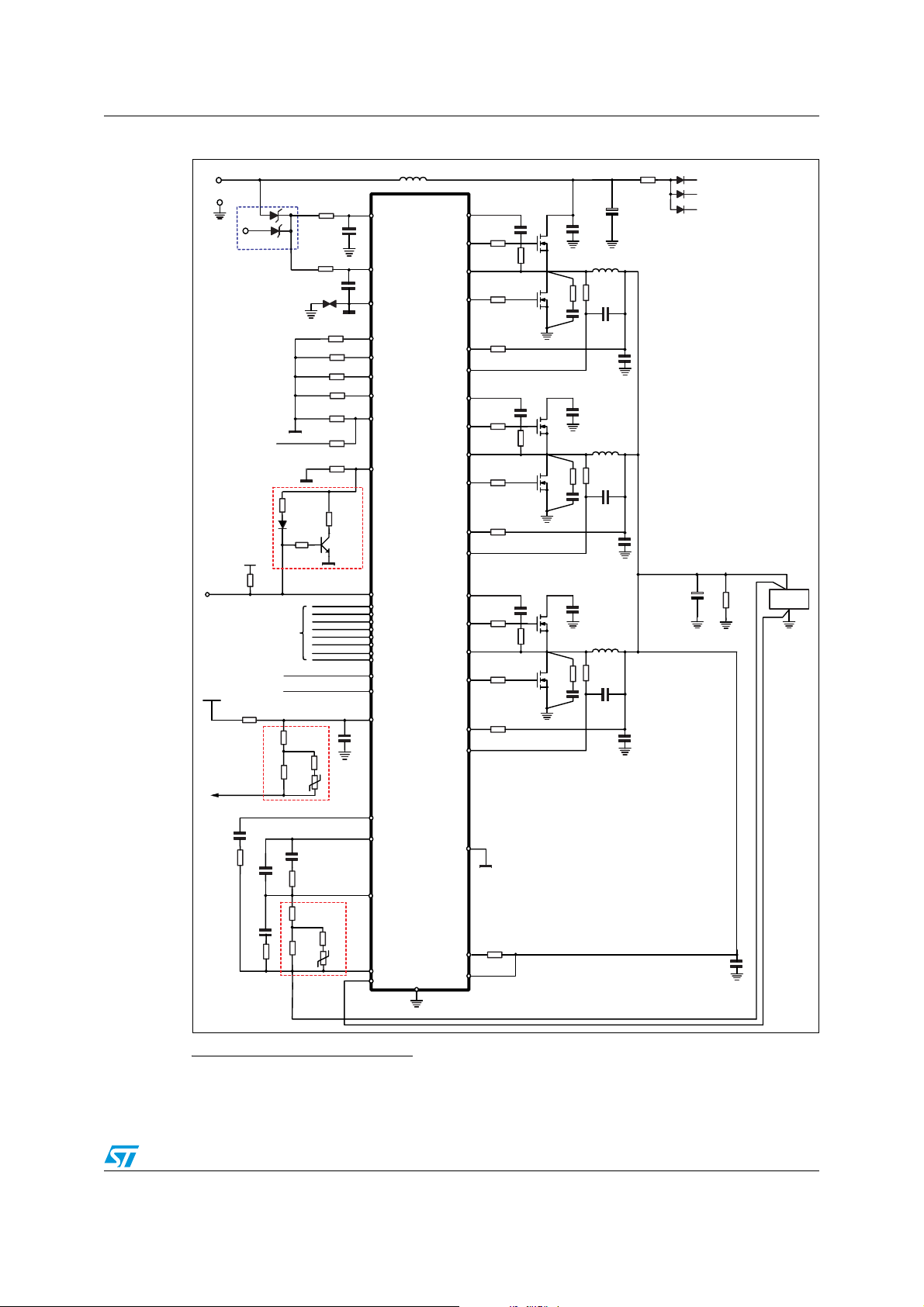

L6716 Principle application circuit and block diagram

Figure 2. Principle application circuit for VR11.1- 3 phase operation

L

V

IN

GND

IN

42

5V

SB

Optional:Pre-OVP

V

cc

3

2

12

R

OVP

R

OCSET

13

R

OFFSET

11

R

LTBGAIN

10

R

OSC_SGND

14

R

Optional:

See DS

To Vcc

R

D

SSOSC

10k

OSC_VCC

R

SS_FLIM

15

R

FLIMT

Q

VTT

R

R

IMON_TOT

1k

IMON_OS

VID bus from CPU

To CPU

To Enable circuitry

R

1

R

2

R

3

NTC

35

33

32

31

30

29

28

27

26

34

16

9

CI

MON

SS_END

+3V3

To GND CORE

8

C

LTB

C

R

LTB

C

I

R

I

F

C

P

R

F

R

FB1

R

FB3

R

R

NTC

4

5

FB

FB2

6

7

L6716 REF.SCH:

3-Phase Operation

IN

VCCDR

VCC

SGND

OVPSEL

OCSET/PSI_A

OFFSET

LTBGAIN

OSC/FAULT

SSOSC

SSEND

VID7

VID6

VID5

VID4

VID3

VID2

VID1

VID0

PSI

OUTEN

IMON

LTB

COMP

FB

VSEN

FBG

PGND

BOOT1

UGATE1

47

PHASE1

LGATE1

CS1-

CS1+

BOOT2

UGATE2

PHASE2

LGATE2

CS2-

CS2+

BOOT3

L6716

UGATE3

38

PHASE3

LGATE3

CS3-

CS3+

PWM4 /

PH_SEL

CS4-

CS4+

49

41

1

48

HS1

V

IN

C

IN

L1

45

LS1

R

C

18

Rg

HS2

220nF

V

IN

17

39

40

L2

44

LS2

R

C

20

Rg

HS3

220nF

V

IN

19

36

37

L3

43

LS3

R

C

Rg

22

21

220nF

25

Rg

24

23

(b)

to BOOT1

to BOOT2

to BOOT3

Vcc_core

C

OUT

LOAD

R

OUT

GND_core

220nF

b. Refer to the application note for the reference schematic.

Doc ID 14521 Rev 3 5/57

Page 6

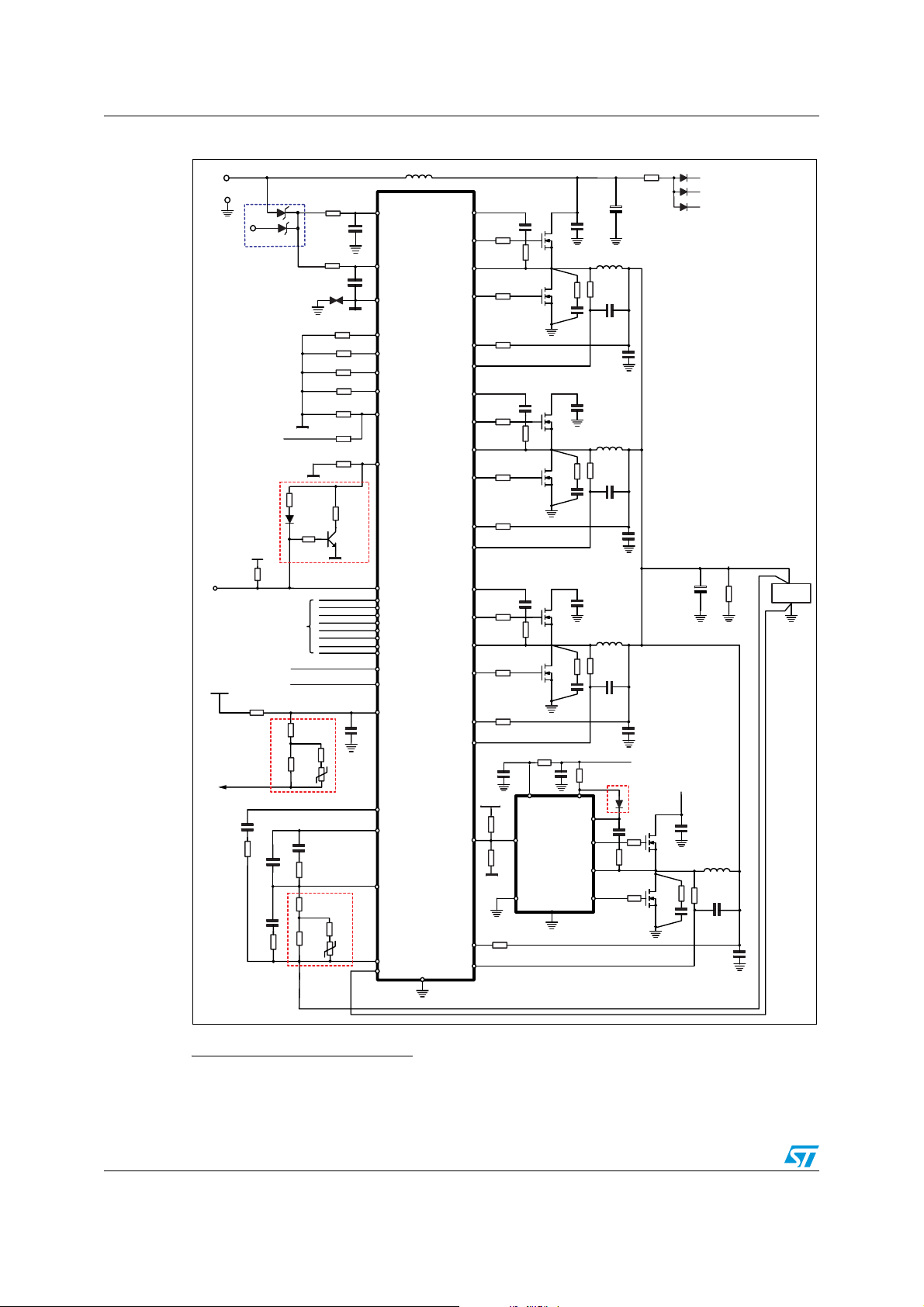

Principle application circuit and block diagram L6716

Figure 3. Principle application circuit for VR11.1- 4 phase operation

L

V

IN

GND

IN

Optional:Pre-OVP

Optional:

See DS

VTT

SS_END

+3V3

R

R

IMON_TOT

To GND CORE

L6716 REF.SCH:

4-Phase Operation

5V

SB

1k

IMON_OS

C

LTB

R

LTB

C

I

R

I

V

To Vcc

R

SSOSC

D

10k

VID bus from CPU

To CPU

To Enable circuitry

R

1

R

2

R

3

NTC

C

F

C

P

R

F

R

FB1

R

FB3

cc

R

OVP

R

OCSET

R

OFFSET

R

LTBGAIN

R

OSC_SGND

R

OSC_VCC

R

SS_FLIM

R

R

NTC

42

3

2

12

13

11

10

14

15

R

FLIMT

Q

35

33

32

31

30

29

28

27

26

34

16

9

CI

MON

8

4

5

FB

FB2

6

7

IN

VCCDR

VCC

SGND

OVPSEL

OCSET/PSI_A

OFFSET

LTBGAIN

OSC/FAULT

SSOSC

SSEND

VID7

VID6

VID5

VID4

VID3

VID2

VID1

VID0

PSI

OUTEN

IMON

LTB

COMP

FB

VSEN

FBG

PGND

BOOT1

48

UGATE1

47

PHASE1

45

LGATE1

18

CS1-

17

CS1+

39

BOOT2

40

UGATE2

41

PHASE2

44

LGATE2

20

CS2-

19

CS2+

36

BOOT3

L6716

37

UGATE3

38

PHASE3

43

LGATE3

CS3-

CS3+

25

PWM4 /

PH_SEL

CS4-

CS4+

49

1

V

IN

C

IN

HS1

L1

LS1

R

C

Rg

220nF

V

IN

HS2

L2

LS2

R

C

Rg

220nF

V

IN

C

OUT

HS3

L3

LS3

R

C

Rg

22

21

220nF

VIN

Optional

VCC

EX_PAD

7

PVCC

BOOT

UGATE

PHASE

L6741

LGATE

V

IN

2

1

5

8

5

HS4

LS4

C

HF

6

3V3

1k

3

PWM

PWM

1k

4

GND

Rg

24

23

(c)

to BOOT1

to BOOT2

to BOOT3

L4

R

220nF

Vcc_core

LOAD

R

OUT

GND_core

C

c. Refer to the application note for the reference schematic.

6/57 Doc ID 14521 Rev 3

Page 7

L6716 Principle application circuit and block diagram

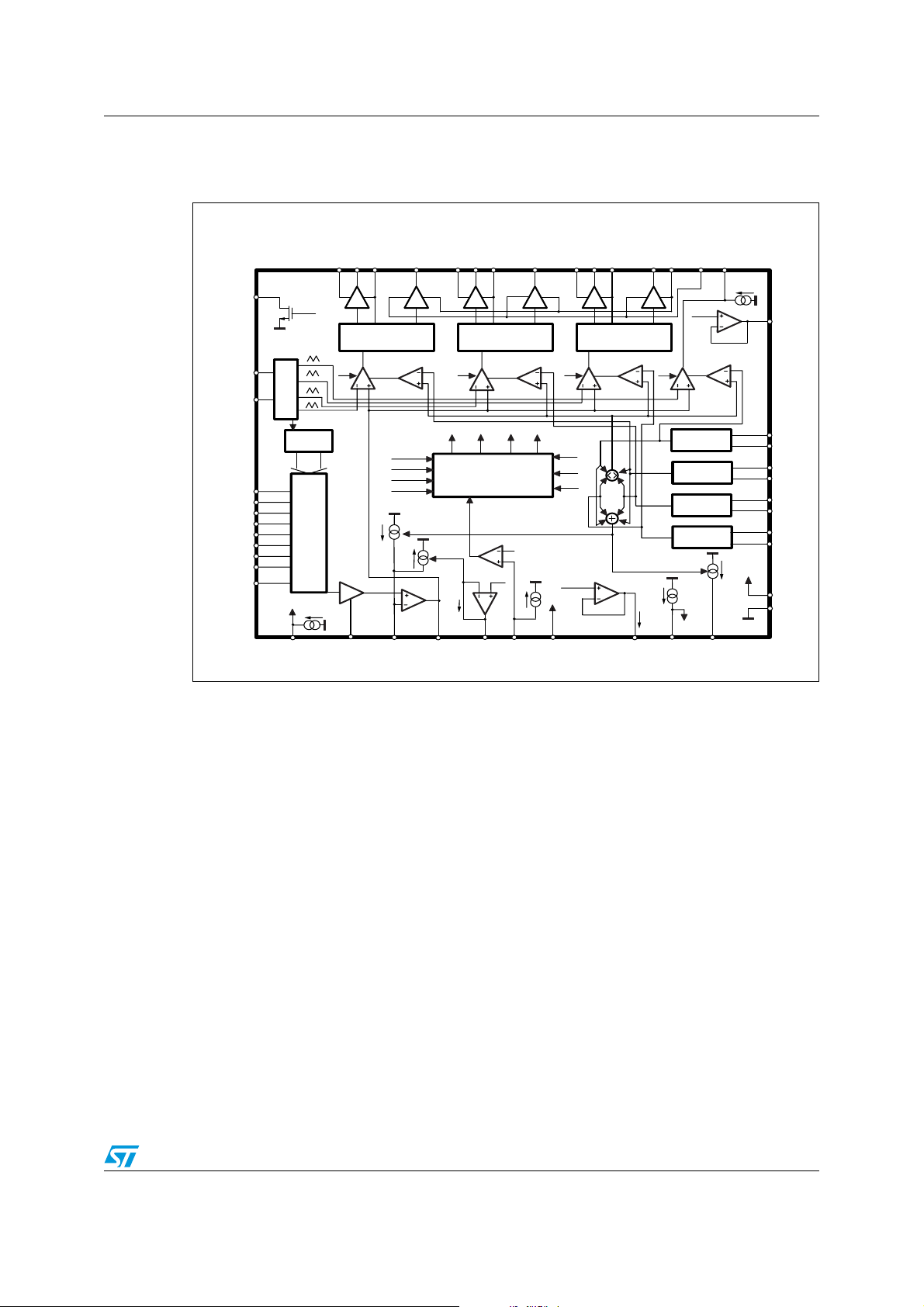

1.2 Block diagram

Figure 4. Block diagram

BOOT1

UGATE1

PHASE1

LGATE1

BOOT2

UGATE2

PHASE2

LGATE2

BOOT3

UGATE3

PHASE3

LGATE3

SS_END

OSC / FAULT

SSOSC

VID0

VID1

VID2

VID3

VID4

VID5

VID6

VID7

PSI

2/4 PHASE

OSCILLATOR

DIGITAL

SOFT START

DAC

OUTEN

OUTEN

HS1 LS1

LTB

VID CONTROL

WITH DYNAMIC

10uA

HS2

LOGIC PWM

ADAPTIVE ANTI

CROSS CONDUCTION

CURRENT SHARING

CORRECTION

PWM1 PWM2 PWM3

VCC

VCCDR

OUTEN

SSOSC

DROOP

I

I

FFSET

O

LTB

PWM1

CONTROL LOGIC

AND PROTECTIONS

VREF

GND DROP

RECOVERY

FBG

ERROR

AMPLIFIER

FB

COMP

OFFSET

I

LS2 HS3

LOGIC PWM

ADAPTIVE ANTI

CROSS CONDUCTION

CURRENT SHARING

CORRECTION

PWM2

PWM3

L6716

TOTAL DELIVERED CURRENT

+175mV / 1.800V / OVP

COMPARATOR

+.1240V

50uA

VSEN

OFFSET

PWM4

OCP

I

PSI

OVP

LTB

LTB

CROSS CONDUCTION

CURRENT SHARING

CORRECTION

LTB

OCSET

+.1240V

LS3

LOGIC PWM

ADAPTIVE ANTI

AVERAGE

CURRENT

OCSET

I

/PSI_A

OCSET

PGND

LTB

CH4 CURRENT

CH1 CURRENT

CH2 CURRENT

CH3 CURRENT

20uA

OVP

OVPSEL

VCCDR

+.1240V

CURRENT SHARING

CORRECTION

PWM4

READING

READING

READING

READING

IMON

PWM4/PH_SEL

10uA

LTBGAIN

CS4-

CS4+

CS1CS1+

CS2CS2+

CS3-

CS3+

VCC

DROOP

I

VCC

SGND

Doc ID 14521 Rev 3 7/57

Page 8

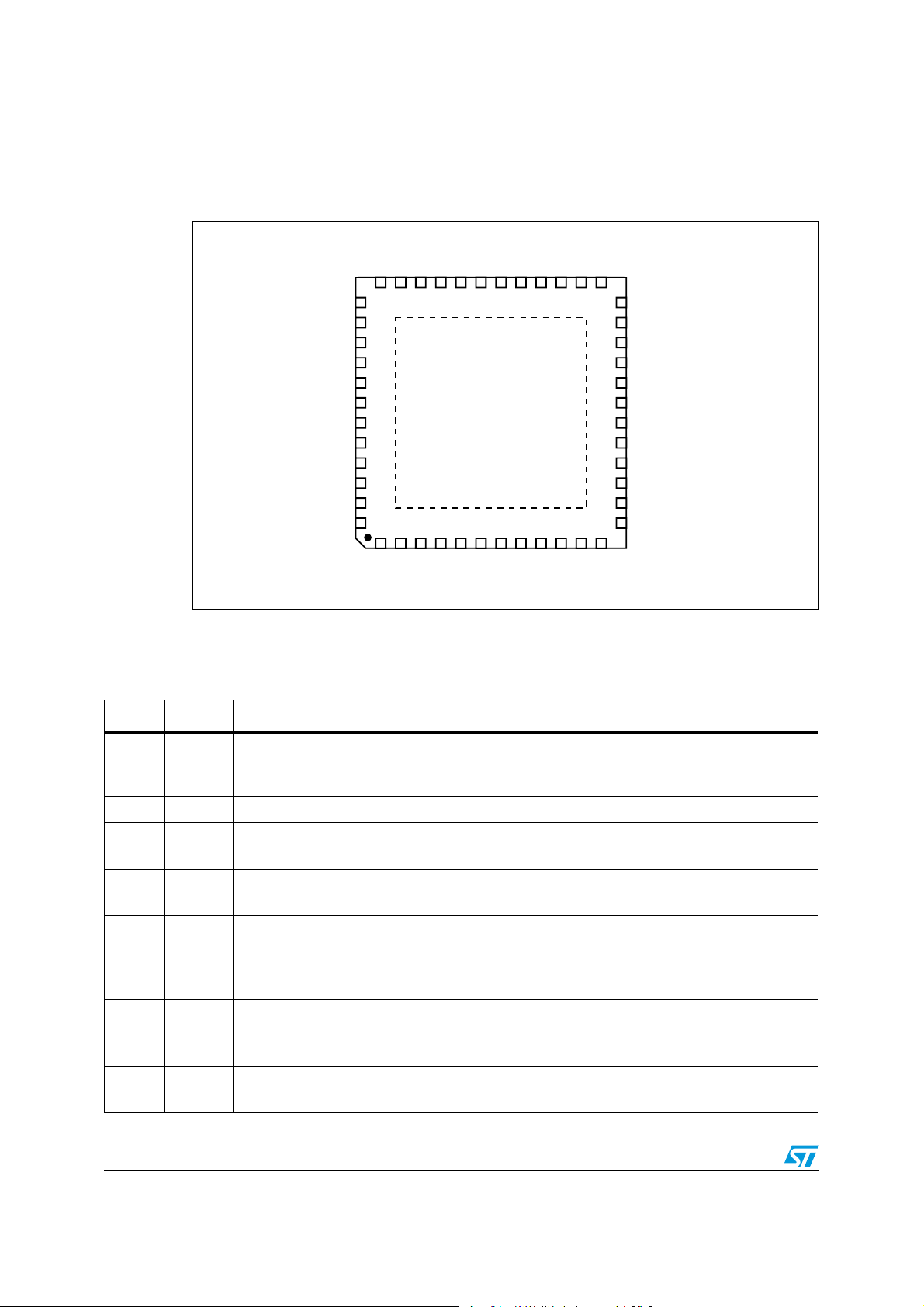

Pin description and connection diagram L6716

2 Pin description and connection diagram

Figure 5. Pin connection (top view)

BOOT3

SSEND

PSI

VID7

VID6

VID5

VID4

VID3

VID2

VID1

VID0

PWM4/

PH_SEL

UGATE3

PHASE3

BOOT2

UGATE2

PHASE2

VCCDR

LGATE3

LGATE2

LGATE1

N.C.

PHASE1

UGATE1

36 35 34 33 32 31 30 29 28 27 26 25

37

38

39

40

41

42

43

44

45

46

47

48

123456789101112

49 PGND

24

23

22

21

20

19

18

17

16

15

14

13

CS4-

CS4+

CS3-

CS3+

CS2-

CS2+

CS1-

CS1+

OUTEN

SSOSC

OSC/FAULT

OCSET/PSI_A

2.1 Pin description

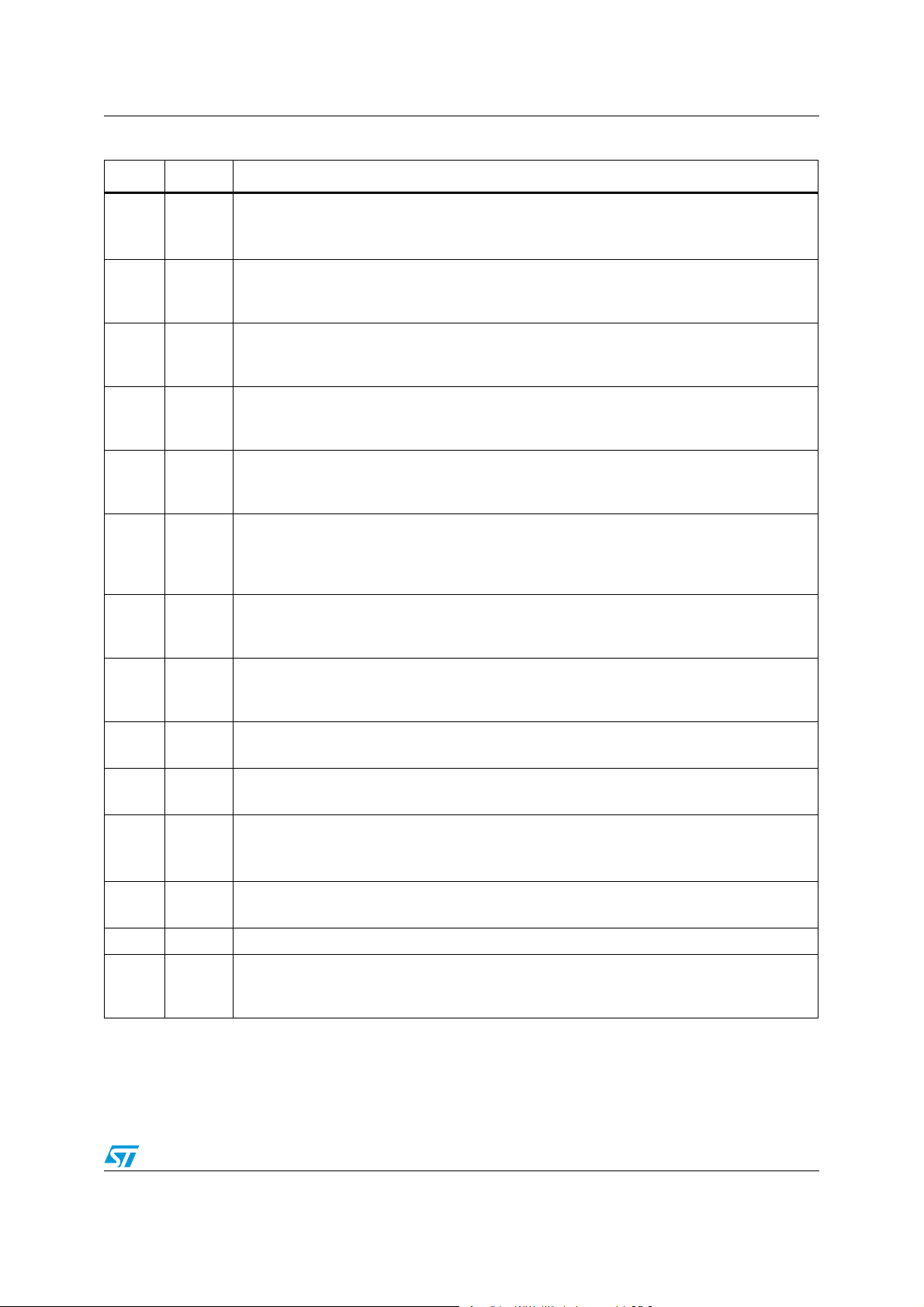

Table 2. Pin description

N° Name Description

Channel 1 HS driver supply.

1BOOT1

2 SGND All the internal references are referred to this pin. Connect it to the PCB signal ground.

3VCC

4COMP

5FB

6VSEN

7FBG

Connect through a capacitor (100 nF typ.) to PHASE1 and provide necessary bootstrap diode.

A small resistor in series to the boot diode helps in reducing boot capacitor overcharge.

Device supply voltage pin.

The operative supply voltage is 12 V ±15%. Filter with at least 1 μF capacitor vs. SGND.

Error amplifier output. Connect with an R

The device cannot be disabled by pulling down this pin.

Error amplifier inverting input pin.

Connect with a resistor R

A current proportional to the load current is sourced from this pin in order to implement the

Droop effect. See “Droop function” Section for details.

Output voltage monitor, manages OVP/UVP protections and FB disconnection.

Connect to the positive side of the load to perform remote sense.

See “Layout guidelines” Section for proper layout of this connection.

Connect to the negative side of the load to perform remote sense.

See “Layout guidelines” Section for proper layout of this connection.

FB

VCC

SGND

BOOT1

FB

COMP

vs. VSEN and with an RF - CF//CP vs. COMP pin.

LT B

FBG

VSEN

IMON

LTBGAIN

- CF//CP vs. FB pin.

F

OFFSET

OVPSEL

8/57 Doc ID 14521 Rev 3

Page 9

L6716 Pin description and connection diagram

Table 2. Pin description (continued)

N° Name Description

Load transient boost pin.

Internally fixed at 2 V, connecting a R

8LTB

boost technology™: as soon as the device detects a transient load it turns on all the PHASEs

at the same time. Short to SGND to disable the function.

See “Load transient boost technology” Section for details.

Current monitor output pin.

9IMON

A current proportional to the load current is sourced from this pin. Connect through a resistor

to FBG to implement a load indicator. Connect the load indicator directly to VR11.1

R

MON

CPUs.The pin voltage is clamped to 1.1 V max to preserve the CPU from excessive voltages.

Load transient boost technology™ gain pin.

10 LTBGAIN

Internally fixed at 1.24 V, connecting a R

the LTB action. See See “Load transient boost technology” Section for details.

Offset programming pin.

Internally fixed at 1.240 V, connecting a R

11 OFFSET

that is mirrored into FB pin in order to program a positive offset according to the selected R

Short to SGND to disable the function.

See “Offset (optional)” Section for details.

Overvoltage programming pin. Internally pulled up by 20 µA (typ) to 3.3 V.

Leave floating to use built-in protection thresholds (OVP

12 OVPSEL

Connect to SGND through a R

threshold to a fixed voltage according to the R

OVP

See “Overvoltage and programmable OVP” Section for details.

Connect to SGND to select VR10/VR11 table. In this case the OVP threshold becomes

1.800 V (typ).

Overcurrent setting, PSI action pin.

13

OCSET/

PSI_A

Connect to SGND through a R

OCSET

It also allows to select the number of phase when PSI mode is selected.

See “Overcurrent protection” Section for details.

Oscillator, FAULT pin.

It allows programming the switching frequency FSW of each channel: the equivalent switching

frequency at the load side results in being multiplied by the phase number N.

14

OSC/

FAULT

Frequency is programmed according to the resistor connected from the pin vs. SGND or VCC

with a gain of 9.1 kHz/µA (see relevant section for details).

Leaving the pin floating programs a switching frequency of 200 kHz per phase.

The pin is forced high (3.3 V typ) to signal an OVP/UVP fault: to recover from this condition,

cycle VCC or the OUTEN pin. See “Oscillator” Section for details.

Soft-start oscillator pin.

By connecting a resistor R

15 SSOSC

Soft-Start time T

implemented to reach V

V

to the programmed VID code. The pin is kept to a fixed 1.240 V.

BOOT

See “Soft-start” Section for details.

will proportionally change with a gain of 25 [µs / kΩ]. The same slope

SS

to GND, it allows programming the soft-start time.

SS

has to be considered also when the reference moves from

BOOT

- C

LT B

LT B

LTBGAIN

OFFSET

vs. V

resistor vs SGND allows setting the gain of

resistor vs. SGND allows setting a current

allows to enable the load transient

OUT

= VID + 175 mV typ).

TH

resistor and filter with 100 pF (max) to set the OVP

resistor.

OVP

resistor to set the OCP threshold for each phase.

FB

.

Doc ID 14521 Rev 3 9/57

Page 10

Pin description and connection diagram L6716

Table 2. Pin description (continued)

N° Name Description

Output enable pin. Internally pulled up by 10 µA (typ) to 3 V.

Forced low, the device stops operations with all MOSFETs OFF: all the protections are

16 OUTEN

17 CS1+

18 CS1-

19 CS2+

20 CS2-

21 CS3+

22 CS3-

disabled except for preliminary overvoltage.

Leave floating, the device starts-up implementing soft-start up to the selected VID code.

Cycle this pin to recover latch from protections; filter with 1 nF (typ) vs. SGND.

Channel 1 current sense positive input.

Connect through an R-C filter to the phase-side of the channel 1 inductor.

See “Layout guidelines” Section for proper layout of this connection.

Channel 1 current sense negative input.

Connect through a Rg resistor to the output-side of the channel 1 inductor.

See “Layout guidelines” Section for proper layout of this connection.

Channel 2 current sense positive input.

Connect through an R-C filter to the phase-side of the channel 2 inductor.

Short to V

when using 2-phase operation.

OUT

See “Layout guidelines” Section for proper layout of this connection.

Channel 2 current sense negative input.

Connect through a Rg resistor to the output-side of the channel 2 inductor.

Still connect to V

through Rg resistor when using 2-phase operation.

OUT

See “Layout guidelines” Section for proper layout of this connection.

Channel 3 current sense positive input.

Connect through an R-C filter to the phase-side of the channel 3 inductor.

See “Layout guidelines” Section for proper layout of this connection.

Channel 3 current sense negative input.

Connect through a Rg resistor to the output-side of the channel 3 inductor.

See “Layout guidelines” Section for proper layout of this connection.

Channel 4 current sense positive input.

23 CS4+

Connect through an R-C filter to the phase-side of the channel 4 inductor.

Short to V

when using 2-phase or 3-phase operation.

OUT

See “Layout guidelines” Section for proper layout of this connection.

Channel 4 current sense negative input.

24 CS4-

Connect through a Rg resistor to the output-side of the channel 4 inductor.

Still connect to V

through Rg resistor when using 2-phase or 3-phase operation.

OUT

See “Layout guidelines” Section for proper layout of this connection.

PWM outputs, phase selection pin.

Internally pulled up by 10 µA to 3.3 V (until the soft-start has not finished), connect to external

driver PWM input when 4-phase operation is used.

The device is able to manage HiZ status by setting the pis floating.

25

PWM4/

PH_SEL

Short to SGND to select 3-phase operation and leave floating to select 2-phase operation.

26 to 33

VID0 to

VID7

Voltage identification pins. (not internally pulled up).

Connect to SGND to program a '0' or connect to the external pull-up resistor to program a '1'.

They allow programming output voltage as specified in Tab l e 7 .

10/57 Doc ID 14521 Rev 3

Page 11

L6716 Pin description and connection diagram

Table 2. Pin description (continued)

N° Name Description

Power saving indicator pin.

34 PSI

35 SSEND

36 BOOT3

37 UGATE3

38 PHASE3

39 BOOT2

40 UGATE2

Connect to the PSI pin of the CPU to manage low-power state.

When asserted (pulled low), the controller will act as programmed on the OCSET/PSI_A.

Soft-start END signal.

Open drain output sets free after ss has finished and pulled low when triggering any

protection. Pull up to a voltage lower than 3.3 V, if not used it can be left floating.

Channel 3 HS driver supply.

Connect through a capacitor (100 nF typ.) to PHASE3 and provide necessary bootstrap

diode.A small resistor in series to the boot diode helps in reducing boot capacitor overcharge.

Channel 3HS driver output.

It must be connected to the HS3 MOSFET gate. A small series resistors helps in reducing

device-dissipated power.

Channel 3 HS driver return path.

It must be connected to the HS3 MOSFET source and provides return path for the HS driver

of channel 3.

Channel 2 HS driver supply.

Connect through a capacitor (100 nF typ.) to PHASE2 and provide necessary bootstrap diode.

A small resistor in series to the boot diode helps in reducing Boot capacitor overcharge. Leave

floating when using 2-Phase operation.

Channel 2HS driver output.

It must be connected to the HS2 MOSFET gate. A small series resistors helps in reducing

device-dissipated power. Leave floating when using 2-Phase operation.

Channel 2 HS driver return path.

41 PHASE2

It must be connected to the HS2 MOSFET source and provides return path for the HS driver

of channel 2. Leave floating when using 2-phase operation.

42 VCCDR

43 LGATE3

LS Driver Supply. VCDDR pin voltage has to be the same of VCC pin.

Filter with 2 x 1 µF MLCC capacitor vs. PGND.

Channel 3LS driver output.

A small series resistor helps in reducing device-dissipated power.

Channel 2LS driver output.

44 LGATE2

A small series resistor helps in reducing device-dissipated power.

Leave floating when using 2-phase operation.

45 LGATE1

Channel 1LS driver output.

A small series resistor helps in reducing device-dissipated power.

46 N.C. Not internally connected.

Channel 1 HS driver return path.

47 PHASE1

It must be connected to the HS1 MOSFET source and provides return path for the HS driver

of channel 1.

Doc ID 14521 Rev 3 11/57

Page 12

Pin description and connection diagram L6716

Table 2. Pin description (continued)

N° Name Description

Channel 1HS driver output.

48 UGATE1

49 PGND

It must be connected to the HS1 MOSFET gate. A small series resistors helps in reducing

device-dissipated power.

Power ground pin (LS drivers return path). Connect to power ground plane.

Exposed pad connects also the silicon substrate. As a consequence it makes a good thermal

contact with the PCB to dissipate the power necessary to drive the external MOSFETs.

Connect it to the power ground plane using 5.2 x 5.2 mm square area on the PCB and with

sixteen vias (uniformly distributed), to improve electrical and thermal conductivity.

12/57 Doc ID 14521 Rev 3

Page 13

L6716 Maximum ratings

3 Maximum ratings

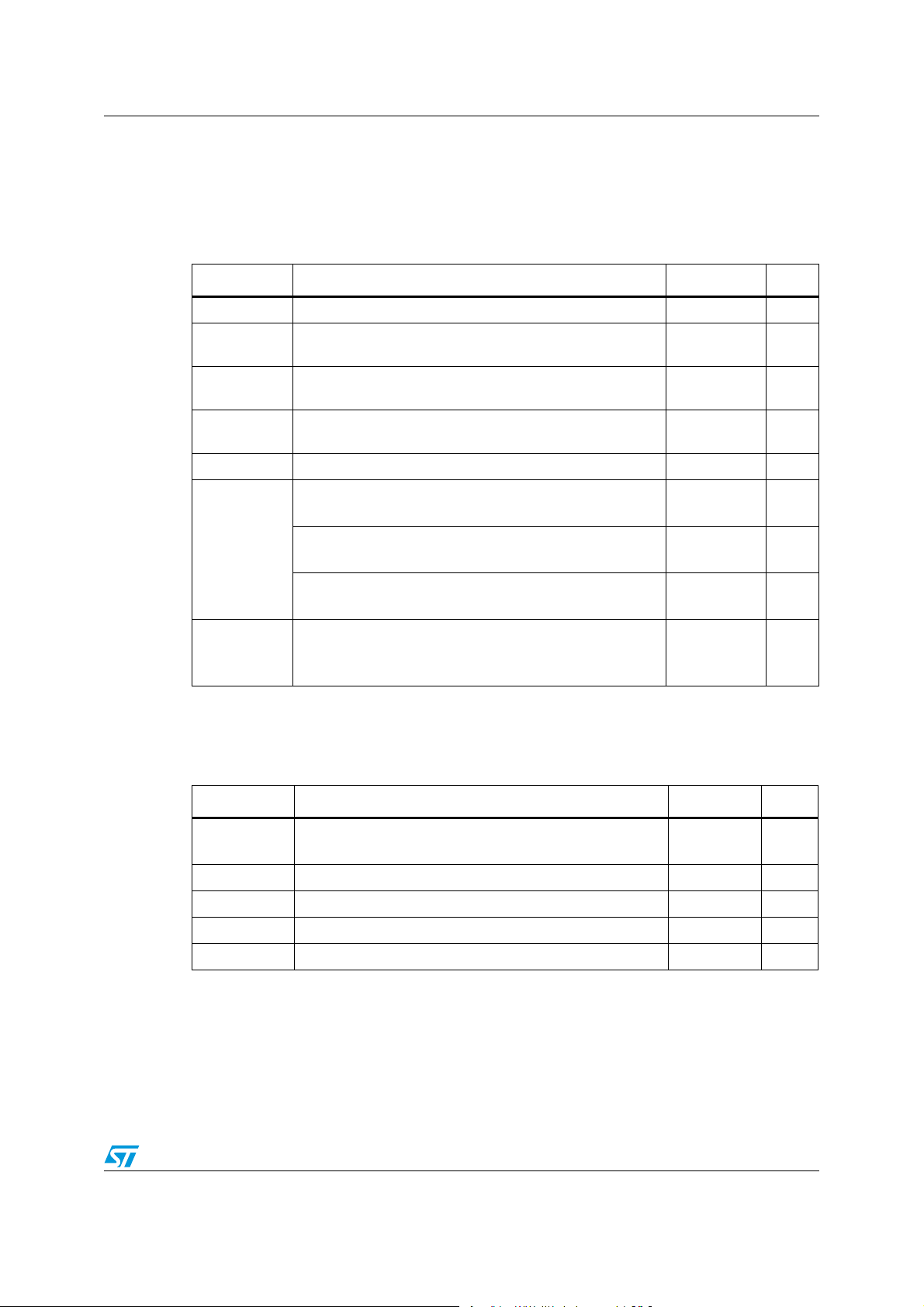

3.1 Absolute maximum ratings

Table 3. Absolute maximum ratings

Symbol Parameter Value Unit

V

CC, VCCDR

V

BOOTx

V

PHASEx

V

UGATEx

V

PHASEx

To P GN D 1 5 V

Boot voltage 15 V

-

LGATEx to PGND

All other pins to PGND -0.3 to 3.6 V

Negative peak voltage to PGND; T < 400 ns

VCC = VCCDR = 12 V

V

PHASE

Positive voltage to PGND

VCC = VCCDR = 12 V

Positive peak voltage to PGND; T < 200 ns

VCC = VCCDR = 12 V

Maximum withstanding voltage range test condition:

CDF-AEC-Q100-002- “human body model”

acceptance criteria: “normal performance”

3.2 Thermal data

15 V

-0.3 to

Vcc+0.3

-8 V

26 V

30 V

+/- 1750 V

V

Table 4. Thermal data

Symbol Parameter Value Unit

R

thJA

T

MAX

T

stg

T

J

P

tot

Thermal resistance junction to ambient

(Device soldered on 2s2p PC board)

40 °C / W

Maximum junction temperature 150 °C

Storage temperature range -40 to 150 °C

Junction temperature range -10 to 125 °C

Max power dissipation at TA = 25 °C 2.5 W

Doc ID 14521 Rev 3 13/57

Page 14

Electrical characteristics L6716

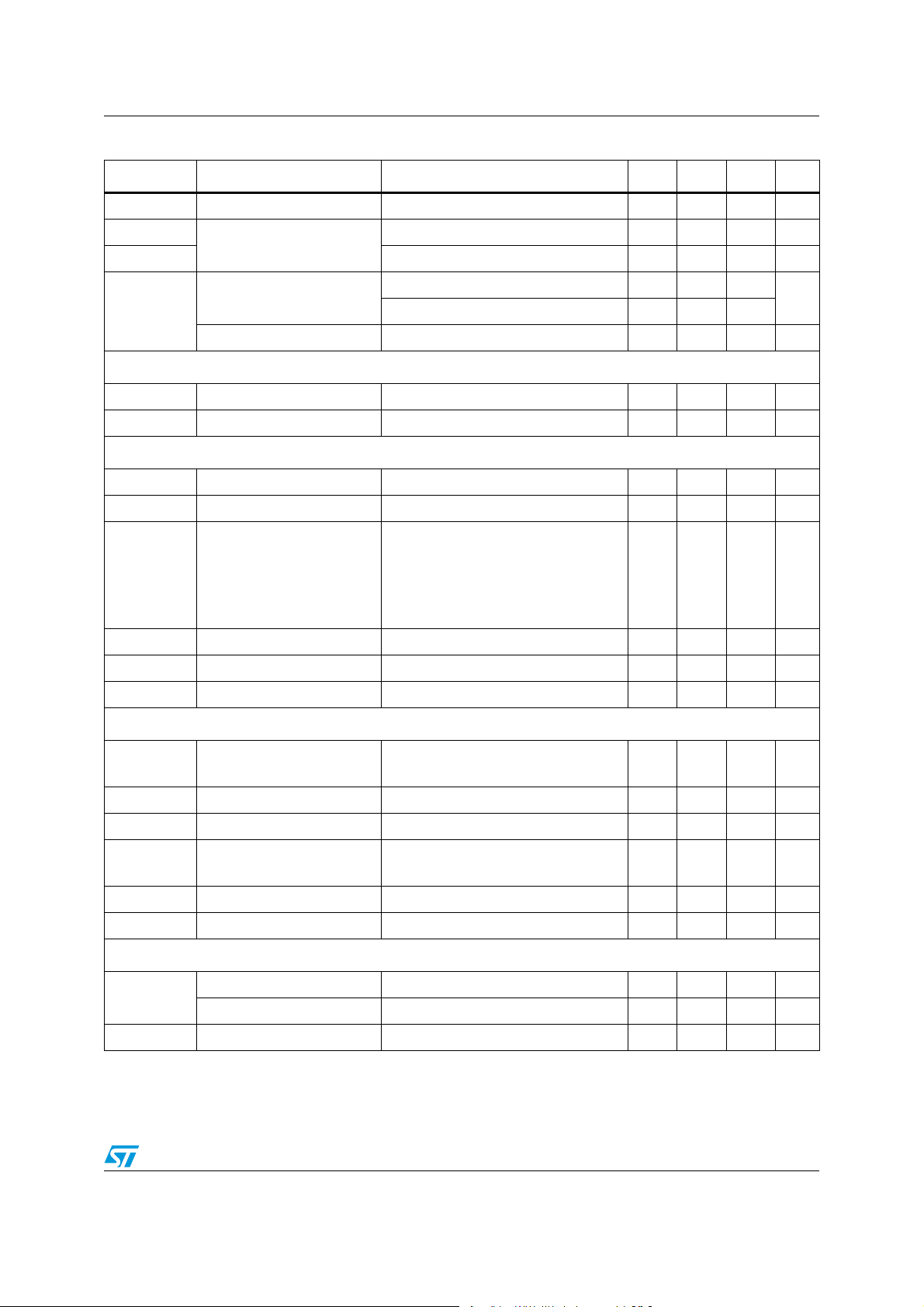

4 Electrical characteristics

4.1 Electrical characteristics

V

= 12 V ± 15%, TJ = 0 °C to 70 °C unless otherwise specified.

CC

Table 5. Electrical characteristics

Symbol Parameter Test condition Min. Typ. Max. Unit

Supply current and power-on

I

CC

I

CCDR

I

BOOTx

VCC supply current

VCCDR supply current LGATEx = OPEN; VCCDR = 12 V 5 7 mA

BOOTx supply current

UGATEx and LGATEx open;

VCC = VBOOTx = 12 V

UGATEx = OPEN; PHASEx to PGND;

VCC = BOOTx = 12V

22 25 mA

1.8 2.7 mA

Power-on

VCC turn-ON VCC rising; VCCDR = VCC 3.7 4.0 V

UVLO

VCC

VCC turn-OFF VCC falling; VCCDR = VCC 3.3 3.5 V

Pre-OVP turn-ON VCC rising; VCCDR = VCC 3.7 4.0 V

UVLO

Pre-OVP

Pre-OVP turn-OFF VCC falling; VCCDR = VCC 3.3 3.5 V

Oscillator and inhibit

F

OSC

TD

TD

TD

Initial accuracy OSC=OPEN; TJ = 0 to 125 °C 180 200 220 kHz

SS delay time 1 1.5 ms

1

SS TD2 time R

2

SS TD3 time 150 250 μs

3

= 20 kΩ 500 μs

SSOSC

Rising thresholds voltage 0.80 0.85 0.90 V

Output enable

OUTEN

Hysteresis 100 mV

Output pull-up current OUTEN to SGND 10 μA

ΔVosc Ramp amplitude 1.5 V

FAULT Voltage at pin OSC/FAULT OVP and UVP Active 3.3 V

Reference and DAC

VID = 1.000 V to VID = 1.600 V

FB = VOUT; FBG = GNDOUT

K

VID

V

BOOT

Output voltage accuracy

Boot voltage 1.081 V

VID = 0.800 V to VID = 1.000 V

FB = VOUT; FBG = GNDOUT

VID = 0.500 V to VID = 0.800 V

FB = VOUT; FBG = GNDOUT

14/57 Doc ID 14521 Rev 3

-0.5 - 0.5 %

-5 - +5 mV

-8 - +8 mV

Page 15

L6716 Electrical characteristics

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

I

VID

VID

VID

VID pull-up current VIDx to SGND 0 μA

IH

IL

VID thresholds

Input low 0.35 V

Input high 0.8 V

Input low 0.4

PSI thresholds

PSI

Input high 0.8

PSI pull-up current PSI to SGND 0 μA

Error amplifier

A

0

EA DC gain 130 dB

SR EA slew-rate COMP = 10 pF to SGND 25 V/μs

Differential current sensing and offset

I

CSx+

V

OCSET

Bias current 0 μA

OCSET pin voltage 1.105 1.245 1.385 mV

Rg = 1 kΩ;

DROOP

DROOP

DROOP

DROOP

= 25 μA;

= 50 μA;

= 75 μA;

= 100 μA;

-3 - +3 μA

K

IDROOP

K

IOFFSET

I

OFFSET

V

OFFSET

Droop current deviation from

nominal value

1-PHASE, I

2-PHASE, I

3-PHASE, I

4-PHASE, I

Offset current accuracy I

= 50 μA to 250 μA-5-5%

OFFSET

OFFSET current range 0 250 μA

OFFSET pin bias I

= 0 to 250 μA1.240V

OFFSET

Gate drivers

V

t

RISE UGATE

I

UGATEx

R

UGATEx

t

RISE LGATE

I

LGATEx

R

LGATEx

PWM output

PWM4

I

PWM4

High side rise time

BOOTx-PHASEx = 12 V;

C

to PHASEx = 3.3 nF

UGATEx

20 ns

High side source current BOOTx-PHASEx = 12 V 1.5 A

High side sink resistance BOOTx-PHASEx = 12 V 2 Ω

Low side rise time

VCCDR = 12 V;

C

to PGNDx = 5.6 nF

LGATEx

25 ns

Low side source current VCCDR = 12 V 2 A

Low side sink resistance VCCDR = 12 V 1 Ω

Output high I = 1 mA 3 V

Output low I = -1 mA 0.2 V

PWM4 pull-up current Before SSEND = 1; PWM4 to SGND 10 μA

Doc ID 14521 Rev 3 15/57

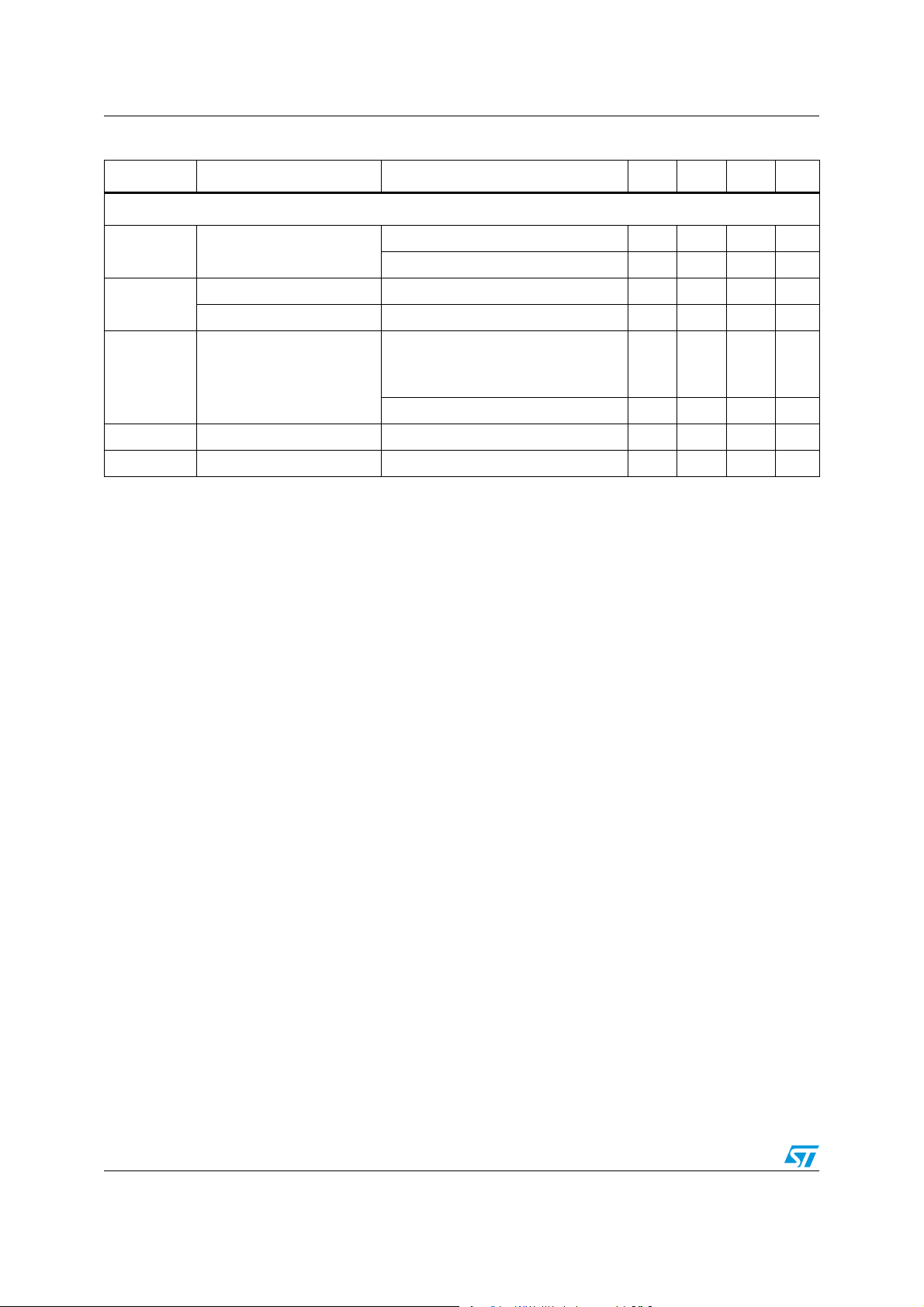

Page 16

Electrical characteristics L6716

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

Protections

OVP

Programmab

le OVP

Pre- OVP

Overvoltage protection

(VSEN rising)

current OVP = SGND 20 22 24 μA

I

OVP

Before V

BOOT

Above VID-19 mV (after TD

) 150 175 200 mV

3

Comparator offset voltage OVP = 1.800 V -20 0 20 mV

< VCC < UVLO

OVP

VCC

VCC

and OUTEN = SGND

1.750 1.800 1.850 V

Preliminary overvoltage

protection

UVLO

VCC> UVLO

VSEN rising

1.24 1.300 V

Hysteresis 350 mV

UVP Under voltage threshold VSEN falling; below VID-19 mV 550 600 650 mV

V

SSEND

SS_END voltage low I = -4 mA 0.4 V

16/57 Doc ID 14521 Rev 3

Page 17

L6716 Voltage identifications

5 Voltage identifications

Table 6. Voltage identification (VID) mapping for intel VR11.1 mode

VID7 VID6 VID5 VID4 VID3 VID2 VID1 VID0

800 mV 400 mV 200 mV 100 mV 50 mV 25 mV 12.5 mV 6.25 mV

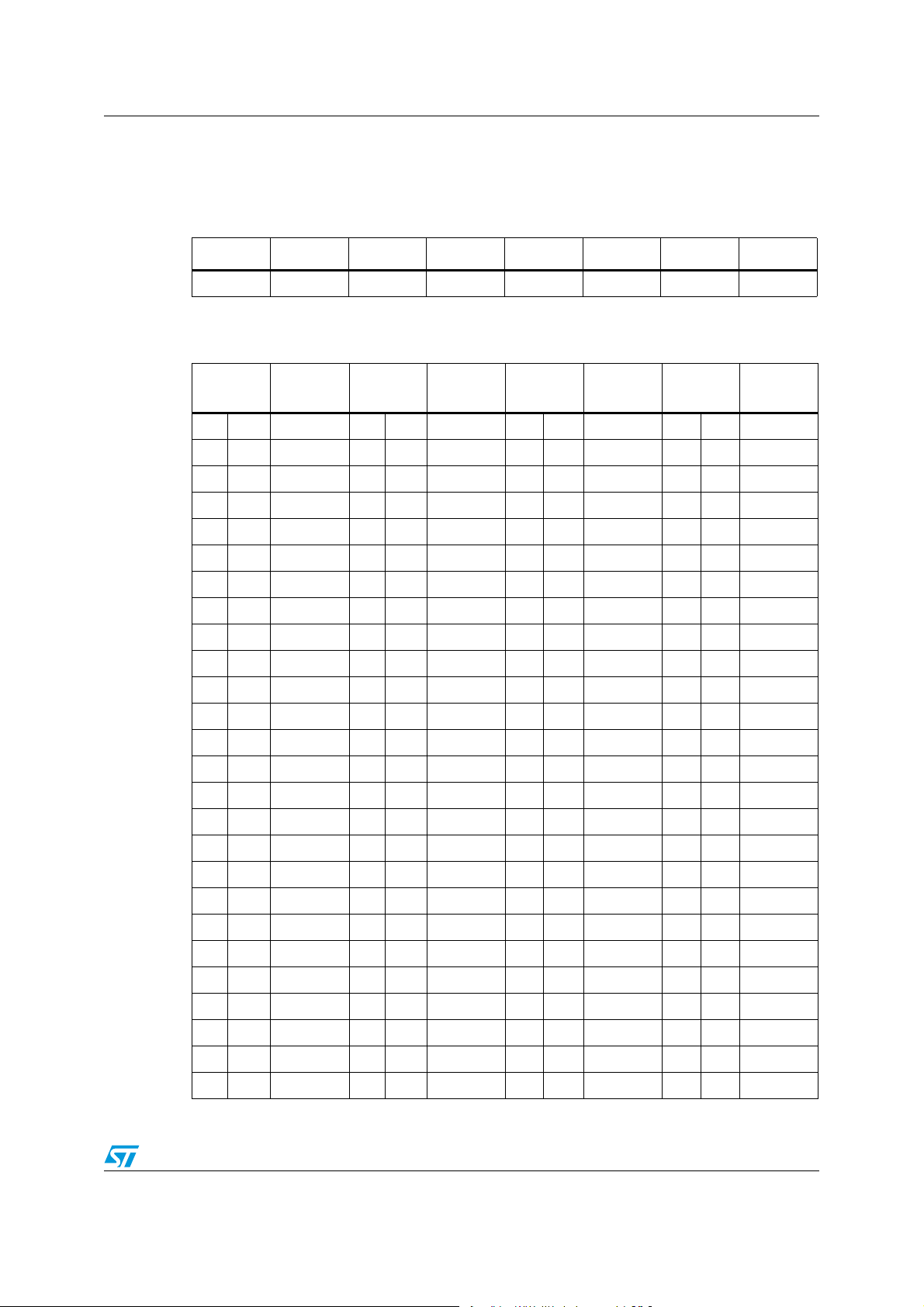

Table 7. Voltage identification (VID) for Intel VR11.1 mode

HEX code

Output

voltage

(1)

HEX code

Output

voltage

HEX code

(1)

Output

voltage

HEX code

(1)

Output

voltage

0 0 OFF 4 0 1.21250 8 0 0.81250 C 0 0.41250

0 1 OFF 4 1 1.20625 8 1 0.80625 C 1 0.40625

0 2 1.60000 4 2 1.20000 8 2 0.80000 C 2 0.40000

0 3 1.59375 4 3 1.19375 8 3 0.79375 C 3 0.39375

0 4 1.58750 4 4 1.18750 8 4 0.78750 C 4 0.38750

0 5 1.58125 4 5 1.18125 8 5 0.78125 C 5 0.38125

0 6 1.57500 4 6 1.17500 8 6 0.77500 C 6 0.37500

0 7 1.56875 4 7 1.16875 8 7 0.76875 C 7 0.36875

0 8 1.56250 4 8 1.16250 8 8 0.76250 C 8 0.36250

0 9 1.55625 4 9 1.15625 8 9 0.75625 C 9 0.35625

0 A 1.55000 4 A 1.15000 8 A 0.75000 C A 0.35000

0 B 1.54375 4 B 1.14375 8 B 0.74375 C B 0.34375

0 C 1.53750 4 C 1.13750 8 C 0.73750 C C 0.33750

0 D 1.53125 4 D 1.13125 8 D 0.73125 C D 0.33125

0 E 1.52500 4 E 1.12500 8 E 0.72500 C E 0.32500

0 F 1.51875 4 F 1.11875 8 F 0.71875 C F 0.31875

(1)

1 0 1.51250 5 0 1.11250 9 0 0.71250 D 0 0.31250

1 1 1.50625 5 1 1.10625 9 1 0.70625 D 1 0.30625

1 2 1.50000 5 2 1.10000 9 2 0.70000 D 2 0.30000

1 3 1.49375 5 3 1.09375 9 3 0.69375 D 3 0.29375

1 4 1.48750 5 4 1.08750 9 4 0.68750 D 4 0.28750

1 5 1.48125 5 5 1.08125 9 5 0.68125 D 5 0.28125

1 6 1.47500 5 6 1.07500 9 6 0.67500 D 6 0.27500

1 7 1.46875 5 7 1.06875 9 7 0.66875 D 7 0.26875

1 8 1.46250 5 8 1.06250 9 8 0.66250 D 8 0.26250

1 9 1.45625 5 9 1.05625 9 9 0.65625 D 9 0.25625

Doc ID 14521 Rev 3 17/57

Page 18

Voltage identifications L6716

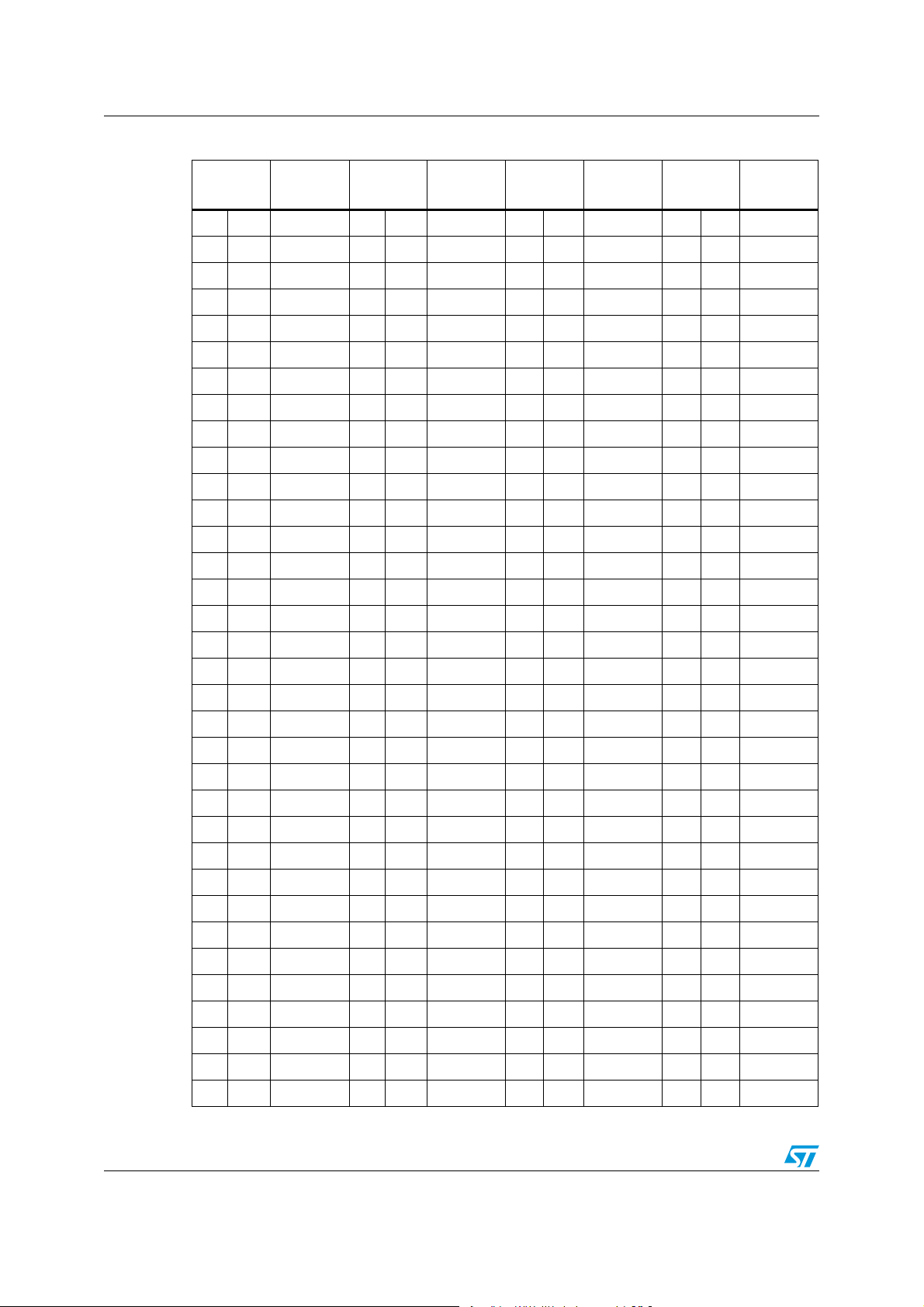

Table 7. Voltage identification (VID) for Intel VR11.1 mode (continued)

HEX code

Output

voltage

(1)

HEX code

Output

voltage

HEX code

(1)

Output

voltage

HEX code

(1)

Output

voltage

1 A 1.45000 5 A 1.05000 9 A 0.65000 D A 0.25000

1 B 1.44375 5 B 1.04375 9 B 0.64375 D B 0.24375

1 C 1.43750 5 C 1.03750 9 C 0.63750 D C 0.23750

1 D 1.43125 5 D 1.03125 9 D 0.63125 D D 0.23125

1 E 1.42500 5 E 1.02500 9 E 0.62500 D E 0.22500

1 F 1.41875 5 F 1.01875 9 F 0.61875 D F 0.21875

2 0 1.41250 6 0 1.01250 A 0 0.61250 E 0 0.21250

2 1 1.40625 6 1 1.00625 A 1 0.60625 E 1 0.20625

2 2 1.40000 6 2 1.00000 A 2 0.60000 E 2 0.20000

2 3 1.39375 6 3 0.99375 A 3 0.59375 E 3 0.19375

2 4 1.38750 6 4 0.98750 A 4 0.58750 E 4 0.18750

2 5 1.38125 6 5 0.98125 A 5 0.58125 E 5 0.18125

2 6 1.37500 6 6 0.97500 A 6 0.57500 E 6 0.17500

2 7 1.36875 6 7 0.96875 A 7 0.56875 E 7 0.16875

2 8 1.36250 6 8 0.96250 A 8 0.56250 E 8 0.16250

2 9 1.35625 6 9 0.95625 A 9 0.55625 E 9 0.15625

2 A 1.35000 6 A 0.95000 A A 0.55000 E A 0.15000

(1)

2 B 1.34375 6 B 0.94375 A B 0.54375 E B 0.14375

2 C 1.33750 6 C 0.93750 A C 0.53750 E C 0.13750

2 D 1.33125 6 D 0.93125 A D 0.53125 E D 0.13125

2 E 1.32500 6 E 0.92500 A E 0.52500 E E 0.12500

2 F 1.31875 6 F 0.91875 A F 0.51875 E F 0.11875

3 0 1.31250 7 0 0.91250 B 0 0.51250 F 0 0.11250

3 1 1.30625 7 1 0.90625 B 1 0.50625 F 1 0.10625

3 2 1.30000 7 2 0.90000 B 2 0.50000 F 2 0.10000

3 3 1.29375 7 3 0.89375 B 3 0.49375 F 3 0.09375

3 4 1.28750 7 4 0.88750 B 4 0.48750 F 4 0.08750

3 5 1.28125 7 5 0.88125 B 5 0.48125 F 5 0.08125

3 6 1.27500 7 6 0.87500 B 6 0.47500 F 6 0.07500

3 7 1.26875 7 7 0.86875 B 7 0.46875 F 7 0.06875

3 8 1.26250 7 8 0.86250 B 8 0.46250 F 8 0.06250

3 9 1.25625 7 9 0.85625 B 9 0.45625 F 9 0.05625

3 A 1.25000 7 A 0.85000 B A 0.45000 F A 0.05000

3 B 1.24375 7 B 0.84375 B B 0.44375 F B 0.04375

18/57 Doc ID 14521 Rev 3

Page 19

L6716 Voltage identifications

Table 7. Voltage identification (VID) for Intel VR11.1 mode (continued)

HEX code

Output

voltage

(1)

HEX code

Output

voltage

HEX code

(1)

Output

voltage

HEX code

(1)

Output

voltage

3 C 1.23750 7 C 0.83750 B C 0.43750 F C 0.03750

3 D 1.23125 7 D 0.83125 B D 0.43125 F D 0.03125

3 E 1.22500 7 E 0.82500 B E 0.42500 F E OFF

3 F 1.21875 7 F 0.81875 B F 0.41875 F F OFF

1. According to INTEL specs, the device automatically regulates output voltage 19 mV lower to avoid any

external offset to modify the built-in 0.5% accuracy improving TOB performances. Output regulated voltage

is than what extracted from the table lowered by 19 mV.

(1)

Doc ID 14521 Rev 3 19/57

Page 20

Device description L6716

6 Device description

L6716 is two-to-four phase PWM controller with three embedded high current drivers

providing complete control logic and protections for a high performance step-down DC-DC

voltage regulator optimized for advanced microprocessor power supply. Multi phase buck is

the simplest and most cost-effective topology employable to satisfy the increasing current

demand of newer microprocessors and modern high current VRM modules. It allows

distributing equally load and power between the phases using smaller, cheaper and most

common external power MOSFETs and inductors. Moreover, thanks to the equal phase shift

between each phase, the input and output capacitor count results in being reduced. Phase

interleaving causes in fact input rms current and output ripple voltage reduction.

L6716 is a dual-edge asynchronous PWM controller featuring load transient boost LTB

Technology™: the device turns on simultaneously all the phases as soon as a load transient

is detected allowing to minimize system cost by providing the fastest response to load

transition. Load transition is detected (through LTB pin) measuring the derivate dV/dt of the

output voltage and the dV/dt can be easily programmed extending the system design

flexibility. Moreover, load transient boost (LTB) Technology™ gain can be easily modified in

order to keep under control the output voltage ring back.

LTB Technology™ can be disabled and in this condition the device works as a dual-edge

asynchronous PWM.

The controller allows to implement a scalable design: a three phase design can be easily

downgraded to two phase and upgraded to four phase (using an external driver).The same

design can be used for more than one project saving development and debug time.

L6716 permits easy system design by allowing current reading across inductor in fully

differential mode. Also a sense resistor in series to the inductor can be considered to

improve reading precision. The current information read corrects the PWM output in order to

equalize the average current carried by each phase limiting the error in the static and

dynamic conditions.

The controller allows compatibility with both Intel VR11.0 and VR11.1 processors

specifications, also performing D-VID transitions accordingly.

The device is VR11.1 compatible implementing IMON signal and managing the PSI# signal

to enhance the system performances at low current in low-power states.

Low-side-less start-up allows soft-start over pre-biased output avoiding dangerous current

return through the main inductors as well as negative spike at the load side.

L6716 provides a programmable overvoltage protection to protect the load from dangerous

over stress, latching immediately by turning ON the lower driver and driving high the

OSC/FAULT pin. Furthermore, preliminary OVP protection also allows the device to protect

load from dangerous OVP when VCC is not above the UVLO threshold or OUTEN is low.

The overcurrent protection is for each phase and externally adjustable through a single

resistor. The device keeps constant the peak of the inductor current ripple working in

constant current mode until the latched UVP.

A compact 7x7 mm body VFQFPN-48 package with exposed thermal pad allows dissipating

the power to drive the external MOSFET through the system board.

20/57 Doc ID 14521 Rev 3

Page 21

L6716 DAC and Phase number selection

7 DAC and Phase number selection

L6716 embeds VRD11.x DAC (see Tab le 7 ) that allows to regulate the output voltage with a

tolerance of ±0.5% recovering from offsets and manufacturing variations.

The device automatically introduces a -19 mV (both VRD11.x and VR10) offset to the

regulated voltage in order to avoid any external offset circuitry to worsen the guaranteed

accuracy and, as a consequence, the calculated system TOB.

Output voltage is programmed through the VID pins: they are inputs of an internal DAC that

is realized by means of a series of resistors providing a partition of the internal voltage

reference. The VID code drives a multiplexer that selects a voltage on a precise point of the

divider. The DAC output is delivered to an amplifier obtaining the voltage reference (i.e. the

set-point of the error amplifier, V

L6716 implements a flexible 2 to 4 interleaved-phase converter. The device allows to select

the phase number operation simply using the PWM4/PHASE_SEL pin, as shown in the

following table.

Table 8. Number of phases setting

PWM4 / PH_SEL pin Number of phases Phases used

REF

).

Floating 2-PHASE Phase1, Phase3

Short to SGND 3-PHASE Phase1, Phase2, Phase3

Connect to PWM driver input 4-PHASE Phase1, Phase2, Phase3, Phase4

Note: PWM4 pin is internally pulled up by 10 µA to 3.3 V, until soft-start is not finished.

For the disabled phase(s), the current reading pins need to be properly connected to avoid

errors in current-sharing and voltage-positioning: CSx+ needs to be connected to the

regulated output voltage while CSX- needs to be connected to V

trough the same RG

OUT

resistor used for the other phases.

Note: To select VR10/VR11 table, short to SGND the OVP pin. In this case the PSI pin becomes

the VIDSEL pin (to select VR10 and VR11 table, in according to the VR11 specification).

Doc ID 14521 Rev 3 21/57

Page 22

Power dissipation L6716

8 Power dissipation

L6716 embeds three high current MOSFET drivers for both high side and low side

MOSFETs: it is then important to consider the power the device is going to dissipate in

driving them in order to avoid overcoming the maximum junction operative temperature.

Exposed pad (PGND pin) needs to be soldered to the PCB power ground plane through

several VIAs in order to facilitate the heat dissipation.

Two main terms contribute in the device power dissipation: bias power and drivers' power.

The first one (P

and it is simply quantifiable as follow (assuming to supply HS and LS drivers with the same

VCC of the device):

) depends on the static consumption of the device through the supply pins

DC

P

DCVCCICCICCDR

N+

I

⋅+()⋅=

BOOTx

D

where N

is the number of internal drivers used.

D

Drivers' power is the power needed by the driver to continuously switch on and off the

external MOSFETs; it is a function of the switching frequency and total gate charge of the

selected MOSFETs. It can be quantified considering that the total power P

dissipated to

SW

switch the MOSFETs (easy calculable) is dissipated by three main factors: external gate

resistance (when present), intrinsic MOSFET resistance and intrinsic driver resistance. This

last term is the important one to be determined to calculate the device power dissipation.

The total power dissipated to switch the MOSFETs results:

SW

NDF

SWQGHSVBOOT

P

⋅ Q

⋅+()⋅⋅=

GLSVCCDR

External gate resistors helps the device to dissipate the switching power since the same

power P

will be shared between the internal driver impedance and the external resistor

SW

resulting in a general cooling of the device. When driving multiple MOSFETs in parallel, it is

suggested to use one gate resistor for each MOSFET.

Figure 6. L6716 dissipated power (quiescent + switching)

22/57 Doc ID 14521 Rev 3

Page 23

L6716 Current reading and current sharing loop

9 Current reading and current sharing loop

L6716 embeds a flexible, fully-differential current sense circuitry that is able to read across

inductor parasitic resistance or across a sense resistor placed in series to the inductor

element. The fully-differential current reading rejects noise and allows placing sensing

element in different locations without affecting the measurement's accuracy.

Reading current across the inductor DCR, the current flowing trough each phase is read

using the voltage drop across the output inductor or across a sense resistor in its series and

internally converted into a current. The trans-conductance ratio is issued by the external

resistor Rg placed outside the chip between CSx- pin toward the reading points.

The current sense circuit always tracks the current information, no bias current is sourced

from the CSx+ pin: this pin is used as a reference keeping the CSx- pin to this voltage. To

correctly reproduce the inductor current an R-C filtering network must be introduced in

parallel to the sensing element.

The current that flows from the CSx- pin is then given by the following equation (see

Figure 7):

DCR

1 s L DCR()⁄⋅+

-------------

I

CSx-

------------------------------------------ -

⋅=

Rg

1sRC⋅⋅+

I⋅

PHASEx

Where I

is the current carried by the relative phase.

PHASEx

Figure 7. Current reading connections

I

PHASEx

Lx

DCR

PHASEx

R

CSx+

x

C

NO Bias

I

CSx-=IINFOx

CSx-

Rg

Inductor DCR Current Sense

Considering now to match the time constant between the inductor and the R-C filter applied

(Time constant mismatches cause the introduction of poles into the current reading network

causing instability. In addition, it is also important for the load transient response and to let

the system show resistive equivalent output impedance), it results:

Where I

L

------------- RC I

DCR

is the current information reproduced internally.

INFOx

CSx-

DCR

-------------

⋅=⇒⋅ I

Rg

I

PHASEx

INFOx

I

INFOX

DCR

-------------

Rg

⋅=⇒==

I

PHASEx

The Rg trans-conductance resistor has to be selected using the following formula, in order

to guarantee the correct functionality of internal current reading circuitry:

MAX

I

DCR

------------------------

Rg

Where I

OUT

MAX

is the maximum output current, DCR

20μA

MAX

OUT

--------------------------

⋅=

N

MAX

the maximum inductor DCR and N

number of phases.

Doc ID 14521 Rev 3 23/57

Page 24

Current reading and current sharing loop L6716

For the disabled phase(s), the current reading pins need to be properly connected to avoid

errors in current-sharing and voltage-positioning: CSx+ needs to be connected to the

regulated output voltage while CSX- needs to be connected to V

trough the same RG

OUT

resistor used for the other phases, as shown in figure Figure 9.

Figure 8. Current reading connections for the disabled phase

Current Sense connection

Disabled Phase

CSx+

VOUT

CSx-

Current sharing control loop reported in Figure 9: it considers a current I

the current delivered by each phase and the average current . The error

between the read current I

and the reference I

INFOx

Rg

proportional to

INFOx

ΣI

is then converted into a voltage that

AVG

AVG

INFOx

N⁄=

with a proper gain is used to adjust the duty cycle whose dominant value is set by the

voltage error amplifier in order to equalize the current carried by each phase. Details about

connections are shown in Figure 9.

Figure 9. Current sharing loop

I

AVG

INFO1

I

AVG

I

INFO2

From EA

I

INFO3

PWM1 Out

PWM2 Out

PWM3 Out

I

INFO4

(PHASE4 Only when using 4-PHASE Operation - PHASE2 when using 3 or 4 PHASE Operation)

24/57 Doc ID 14521 Rev 3

PWM4 Out

Page 25

L6716 Differential remote voltage sensing

10 Differential remote voltage sensing

The output voltage is sensed in fully-differential mode between the FB and FBG pin.

The FB pin has to be connected through a resistor to the regulation point while the FBG pin

has to be connected directly to the remote sense ground point.

In this way, the output voltage programmed is regulated between the remote sense point

compensating motherboard or connector losses.

Keeping the FB and FBG traces parallel and guarded by a power plane results in common

mode coupling for any picked-up noise.

Figure 10. Differential remote voltage sensing connections

V

PROG

GND DROP

RECOVERY

I

OFFSET

I

DROOP

V

REF

ERROR AMPLIFIER

FBG

FBG

To GND_core

(Remote Sense)

To VCC_core

(Remote Sense)

VSEN

FB

R

FB

R

COMP

F

C

F

C

P

Doc ID 14521 Rev 3 25/57

Page 26

Voltage positioning L6716

11 Voltage positioning

Output voltage positioning is performed by selecting the internal reference value through

VID pins and by programming the droop function and offset to the reference (see Figure 11).

The currents sourced/sunk from FB pin cause the output voltage to vary according to the

external R

The output voltage is then driven by the following relationship:

where:

FB

.

V

()V

OUTIOUT

PROGRFBIDROOPIOUT

V

PROG

I

DROOPIOUT

I

OFFSET

VID 19mV–=

()

------------------------=

R

DCR

-------------

Rg

1.240V

OFFSET

()I

I

⋅=

OUT

–[]⋅–=

OFFSET

OFFSET function can be disabled shorting to SGND the OFFSET pin.

Figure 11. Voltage positioning (left) and droop function (right)

V

PROG

GND DROP

RECOVERY

FBG

FBG

To GND_core

(Remote Sense)

11.1 Offset (optional)

The OFFSET pin allows programming a positive offset (VOS) for the output voltage by

connecting a resistor R

considered in addition to the one already introduced during the production stage

(V

OFFSET function can be disabled shorting to SGND the OFFSET pin.

The OFFSET pin is internally fixed at 1.240 V (See Tab l e 5) a current is programmed by

connecting the resistor R

then properly sunk from the FB pin as shown in Figure 12. Output voltage is then

programmed as follow:

=VID-19 mV).

PROG

To VCC_core

(Remote Sense)

V

I

OFFSET

VSEN

OFFSET

OFFSET

()V

OUTIOUT

ERROR AMPLIFIER

V

REF

V

I

DROOP

FB

R

R

FB

COMP

F

C

F

C

P

MAX

V

NOM

V

MIN

RESPONSE WITHOUT DROOP

ESR Drop

RESPONSE WITH DROOP

vs. SGND as shown in Figure 12; this offset has to be

between the pin and SGND: this current is mirrored and

PROGRFBIDROOPIOUT

()

1.240V

------------------------–⋅–=

R

OFFSET

26/57 Doc ID 14521 Rev 3

Page 27

L6716 Voltage positioning

where:

1.240V

V

OSRFB

------------------------

⋅=

R

OFFSET

Offset resistor can be designed by considering the following relationship (RFB is fixed by the

Droop effect):

1.240V

R

OFFSETRFB

------------------ -

⋅=

V

OS

Offset automatically given by the DAC selection differs from the offset implemented through

the OFFSET pin: the built-in feature is trimmed in production and assures ±0.5% error over

load and line variations.

Figure 12. Voltage positioning with positive offset

ERROR AMPLIFIER

V

REF

I

DROOP

1.240V

OFFSET

I

V

PROG

GND DROP

RECOVERY

I

OFFSET

OFFSET

11.2 Droop function

This method “recovers” part of the drop due to the output capacitor ESR in the load

transient, introducing a dependence of the output voltage on the load current: a static error

proportional to the output current causes the output voltage to vary according to the sensed

current.

As shown in Figure 11, the ESR drop is present in any case, but using the droop function

the total deviation of the output voltage is minimized. Moreover, more and more highperformance CPUs require precise load-line regulation to perform in the proper way.

DROOP function is not then required only to optimize the output filter, but also becomes a

requirement of the load.

The device forces a current I

resistor implementing the load regulation dependence. Since I

current information about the N phases, the output characteristic vs. load current is then

given by (neglecting the OFFSET voltage term):

V

OUTVPROGRFBIDROOP

ROFFSET

To GND_core

(Remote Sense)

DROOP

⋅– V

FBG

FBG

To VCC_core

(Remote Sense)

VSEN

FB

R

R

FB

COMP

C

F

F

C

P

, proportional to the read current, into the feedback RFB

depends on the

DROOP

DCR

-------------

REFRFB

⋅⋅– V

Rg

I

OUT

PROGRDROOPIOUT

⋅–== =

Where DCR is the inductor parasitic resistance (or sense resistor when used) and I

OUT

is

the output current of the system. The whole power supply can be then represented by a

“real” voltage generator with an equivalent output resistance R

V

. RFB resistor can be also designed according to the R

PROG

R

FB

R

DROOP

Doc ID 14521 Rev 3 27/57

-------------

⋅=

DCR

Rg

DROOP

DROOP

and a voltage value of

specifications as follow:

Page 28

Droop thermal compensation L6716

12 Droop thermal compensation

Current sense element (DCR inductor) has a non-negligible temperature variation. As a

consequence, the sensed current is subjected to a measurement error that causes the

regulated output voltage to vary accordingly (when droop function is implemented).

To recover from this temperature related error, NTC resistor can be added into feedback

compensation network, as shown in Figure 13.

The output voltage is then driven by the following relationship (neglecting the OFFSET

voltage term):

V

OUT

V

PROGRFBIDROOP

⋅()–=

where R

is the equivalent feedback resistor and it depends on the temperature through

FB

NTC resistor.

Considering the relationships between I

V

(, )[]V

OUTTIOUT

and the I

DROOP

⎛⎞

–=

PROGRFB

⎝⎠

, the output voltage results:

OUT

DCR T[]

----------------------

T[]

⋅⋅

Rg

I

OUT

where T is the temperature.

If the inductor temperature increases the DCR inductor increases and NTC resistor

decreases. As a consequence the equivalent R

resistor decreases keeping constant the

FB

output voltage respect to temperature variation.

NTC resistor must be placed as close as possible to the sense elements (phase inductor).

Figure 13. NTC connections for DC load line thermal compensation

V

PROG

GND DROP

RECOVERY

To GND_core

(Remote Sense)

FBG

FBG

To VCC_core

(Remote Sense)

I

OS

R

FB

R

FB3

NTC

R

FB2

I

DROOP

R

V

REF

ERROR AMPLIFIER

FB

R

FB1

COMP

C

F

F

C

P

28/57 Doc ID 14521 Rev 3

Page 29

L6716 Output current monitoring (IMON)

DCR

13 Output current monitoring (IMON)

The device sources from IMON pin a current proportional to the load current (the sourced

current is a copy of Droop current).

Connect IMON pin through a R

resistor to remote ground (GND core) to implement a

IMON

load indicator, as shown in Figure 14.

As Intel VR11.1 specification required, on the IMON voltage as to be added a small positive

offset to avoid under-estimation of the output load (due to elements accuracy).

The voltage across IMON pin is given by the following formula:

V

MONITORING

⋅

IMONROS

-----------------------------------

R

+

IMONROS

⋅ V

I

DROOP

REF

R

IMON

-----------------------------------

⋅+=

R

+

IMONROS

R

where:

-------------

I

I

DROOP

Rg

⋅=

OUT

The IMON pin voltage is clamped to 1.100 V max to preserve the CPU from excessive

voltages as Intel VR11.1 specification required.

Figure 14. Output monitoring connection (left) and thermal compensation (right)

VREF = +3V3

IMON_OS

R

To CPU

To GND_core

(Remote Sense)

I

DROOP

IMON

R

IMON

VREF = +3V3

C

IMON

IMON_OS

R

To CPU

To GND_core

(Remote Sense)

NTC

I

DROOP

IMON

C

IMON

R3

R2

R

IMON

R1

Current sense element (DCR inductor) has a non-negligible temperature variation. As a

consequence, the sensed current is subjected to a measurement error that causes the

monitoring voltage to vary accordingly.

To recover from this temperature related error, NTC resistor can be added into monitoring

network, as shown in Figure 14.

The monitoring voltage is then driven by the following relationship (neglecting the offset term

for simplicity):

V

MONITORING

where now the R

R

⋅

IMONROS

-----------------------------------

R

+

IMONROS

is the equivalent monitoring resistor and it depends on the

IMON

I

⋅

DROOP

R

⋅

IMONROS

-----------------------------------

R

+

IMONROS

DCR

-------------

⋅⋅==

Rg

I

OUT

temperature through NTC resistor.

Considering the relationships between I

V

MONITORINGTIOUT

(, )[]

and the I

DROOP

R

--------------------------------------------- -

R

IMON

IMON

TR

TR

, the voltage results:

OUT

⋅

+

OS

OS

DCR T[]

----------------------

⋅⋅=

Rg

I

OUT

where T is the temperature.

Doc ID 14521 Rev 3 29/57

Page 30

Output current monitoring (IMON) L6716

If the inductor temperature increases the DCR inductor increases and NTC resistor

decreases. As a consequence the equivalent R

resistor decreases keeping constant

IMON

the monitoring voltage respect to temperature variation. NTC resistor must be placed as

close as possible to the sense elements (phase inductor).

30/57 Doc ID 14521 Rev 3

Page 31

L6716 Load transient boost technology

14 Load transient boost technology

LTB Technology™ further enhances the performances of dual-edge asynchronous systems

by reducing the system latencies and immediately turning ON all the phases to provide the

correct amount of energy to the load.

By properly designing the LTB network, as well as the LTB gain, the undershoot and the

ring-back can be minimized also optimizing the output capacitors count.

LTB Technology™ monitors the output voltage through a dedicated pin (see Figure 16)

detecting load-transients with selected dV/dt, it cancels the interleaved phase-shift, turningon simultaneously all phases.

It then implements a parallel independent loop that (bypassing error amplifier (E/A)

latencies) reacts to load-transients in very short time (<< 200 ns).

LTB Technology™ control loop is reported in Figure 15.

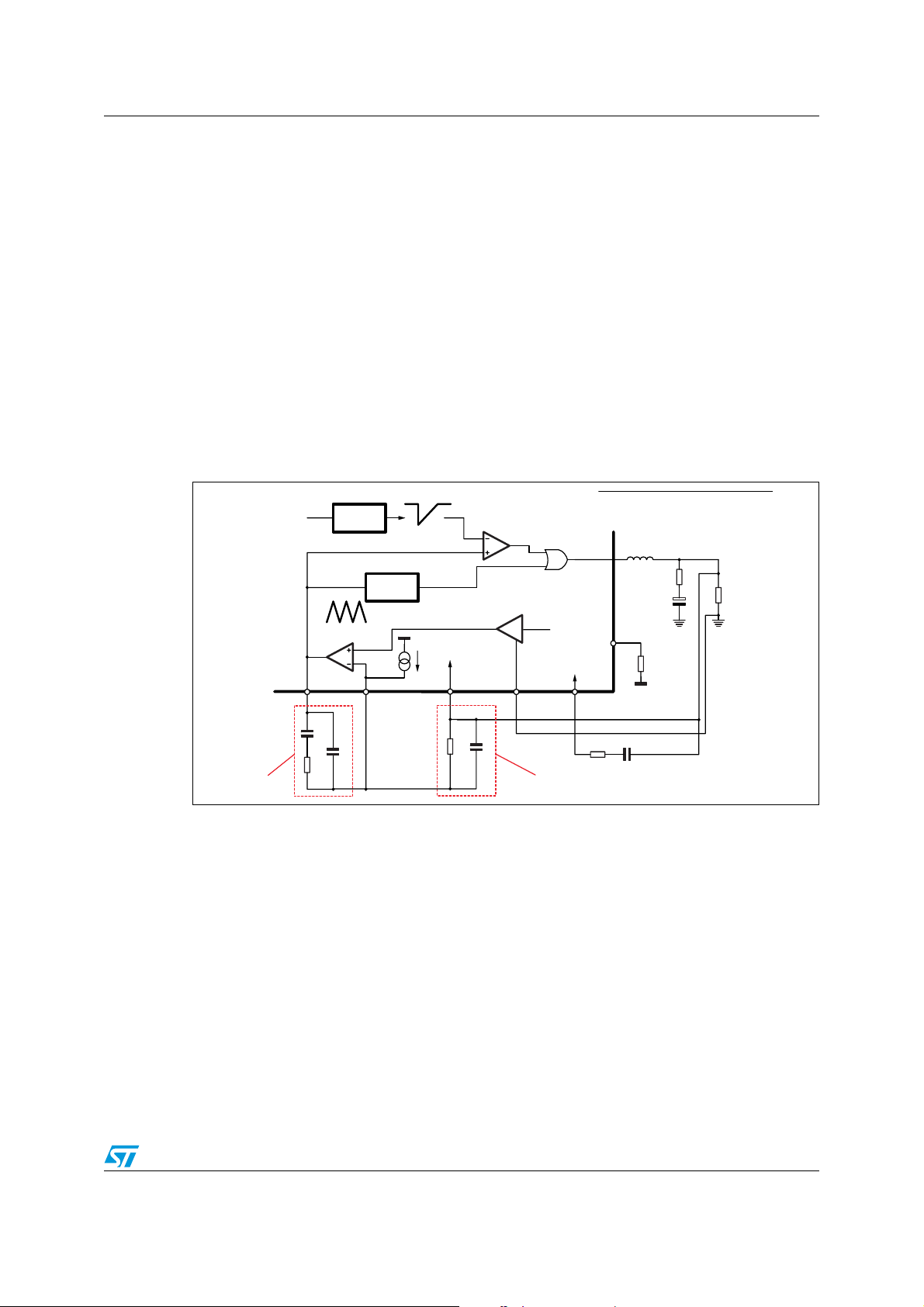

Figure 15. LTB Technology™ control loop

LTB Ramp

LTB

LT Detect

PWM_BOOST

d V

PWM

COMP

V

F

C

F

ZF(s) Z

R

Ref

FBCOMP

P

C

COMP

V

GND DROP

DROOP

I

Monitor

VSEN

FB

R

RECOVERY

FBG

FB

C

PROG

FB

LT Detect

LTB

(s)

LTBGAIN

R

LTBCLTB

L/N

ESR

C

O

R

LTBGAIN

V

OUT

R

O

The LTB detector is able to detect output load transients by coupling the output voltage

through an R

LT B

- C

network. After detecting a load transient, the LTB ramp is reset and

LT B

then compared with the COMP pin level. The resulting duty-cycle programmed is then ORed with the PWMx signal of each phase by-passing the main control loop. All the phases will

then be turned-on together and the EA latencies results bypassed as well.

Short LTB pin to SGND to disable the LTB Technology™: in this condition the device works

as a dual-edge asynchronous PWM controller.

Sensitivity of the load transient detector and the gain of the LTB ramp can be programmed in

order to control precisely both the undershoot and the ring-back.

● Detector design. R

which is desired the controller to be sensitive as follow:

LT B

R

- C

LTB

is design according to the output voltage deviation dV

LT B

dV

OUT

------------------= C

25μA

LTB

------------------------------------------------- -=

2π R

1

LTB

NF

SW

⋅⋅⋅

Doc ID 14521 Rev 3 31/57

OUT

Page 32

Load transient boost technology L6716

e

● Gain design. Through the LTBGAIN pin it is possible to modify the slope of the LTB

Ramp in order to modulate the entity of the LTB response once the LT has been

detected. In fact, the response depends on the board design and its parasites requiring

different actions from the controller.

Connect R

LTBGAIN

to SGND using the following relationship in order to select the

default value (slope of the LTB ramp equal to 1/2 of the OSC ramp slope).

3

10

Where F

2 1240 10

R

LTBGAIN

is the selected switching frequency (in kHz).

SW

kΩ[]

------------------------------------------------------------------- -=

⋅⋅

Fsw kHz[]200–

⎛⎞

------------------------------------------- -

20

+

⎝⎠

LTB Technology™ design tips.

● Decreases R

smaller dV

● Increase C

to increase the system sensitivity making the system sensitive to

LT B

.

OUT

to increase the system sensitivity making the system sensitive to higher

LT B

dV/dt.

● Decrease R

LTBGAIN

to decrease the width of the LTB pulse reducing the system ring-

back or vice versa.

Figure 16. LTB connections (left) and waveform (right)

LT B

V

OUT

To VCC_Cor

R

LTB

C

LTB

PH

1

PH

2

PH

3

32/57 Doc ID 14521 Rev 3

Page 33

L6716 Dynamic VID transitions

15 Dynamic VID transitions

The device is able to manage dynamic VID code changes that allow output voltage

modification during normal device operation.

OVP and UVP signals are masked during every VID transition and they are re-activated

after the transition finishes with a

transition.

When changing dynamically the regulated voltage (D-VID), the system needs to charge or

discharge the output capacitor accordingly. This means that an extra-current I

be delivered, especially when increasing the output regulated voltage and it must be

considered when setting the overcurrent threshold.

This current can be estimated using the following relationships:

15 µs (typ) delay to prevent from false triggering due to the

needs to

D-VID

dV

OUT

I

DVID–

C

OUT

------------------

⋅=

dT

VID

where d

is the selected DAC LSB (6.25 mV for VR11.1) and T

VOUT

is the time interval

VID

between each LSB transition (externally driven).

Overcoming the OC threshold during the dynamic VID causes the device to enter the

constant current limitation slowing down the output voltage dV/dt also causing the failure in

the D-VID test.

In order to avoid this situation the device automatically increases the OCP threshold to

150% of the selected OCP threshold during every VID transition (adding an extra

15 µs of

delay).

If the DVID (dynamic VID change) happens during low power state (PSI low), the device

turns on all the N phases in order to follow the DVID change reducing the over/under shoot

of the output voltage.

L6716 checks for VID code modifications (See Figure 17) on the rising edge of an internal

additional DVID-clock and waits for a confirmation on the following falling edge. Once the

new code is stable, on the next rising edge, the reference starts stepping up or down in LSB

increments every VID-clock cycle until the new VID code is reached. During the transition,

VID code changes are ignored; the device re-starts monitoring VID after the transition has

finished on the next rising edge available. VID-clock frequency (F

) is in the range of 1.8

DVI D

MHz to assure compatibility with the specifications.

Note: If the new VID code is more than 1 LSB different from the previous, the device will execute

the transition stepping the reference with the DVID-clock frequency F

until the new code

DVI D

has reached: for this reason it is recommended to carefully control the VID change rate in

order to carefully control the slope of the output voltage.

Doc ID 14521 Rev 3 33/57

Page 34

Dynamic VID transitions L6716

Figure 17. Dynamics VID transitions

VID Sampled

VID Clock

VID Sampled

VID Stable

VID Sampled

Ref Moved (1)

Ref Moved (2)

Ref Moved (3)

VID Sampled

Ref Moved (4)

VID Sampled

VID Sampled

VID Sampled

Ref Moved (1)

VID Sampled

VID Sampled

VID Stable

Ref Moved (1)

VID Sampled

VID Sampled

VID Stable

Ref Moved (1)

VID Sampled

VID Stable

VID Sampled

Ref Moved (1)

VID Sampled

VID Stable

VID Sampled

VID Sampled

VID Sampled

VID [0,7]

Int. Reference

V

T

DVID

T

out

sw

x 4 Step VID Transition

Vout Slope Controlled by internal

DVID-Clock Oscillator

T

VID

4 x 1 Step VID Transition

Vout Slope Controlled by external

driving circuit (T

t

t

t

t

)

VID

34/57 Doc ID 14521 Rev 3

Page 35

L6716 Enable and disable

16 Enable and disable

L6716 has three different supplies: VCC pin to supply the internal control logic, VCCDR to

supply the low side drivers and BOOTx to supply the high side drivers.

If the voltage at pin VCC is not above the turn on threshold specified in the Section 4:

Electrical characteristics on page 14, the device is shut down: all drivers keep the

MOSFETs off to show high impedance to the load.

Once the device is correctly supplied, proper operation is assured and the device can be

driven by the OUTEN pin to control the power sequencing. Setting the pin free, the device

implements a soft-start up to the programmed voltage. Shorting the pin to SGND, it resets

the device (SS_END is shorted to SGND in this condition) from any latched condition and

also disables the device keeping all the MOSFET turned off to show high impedance to the

load.

Doc ID 14521 Rev 3 35/57

Page 36

Soft-start L6716

17 Soft-start

L6716 implements a soft-start to smoothly charge the output filter avoiding high in-rush

currents to be required to the input power supply. The device increases the reference from

zero up to the programmed value and the output voltage increases accordingly with closed

loop regulation.

The device implements soft-start only when all the power supplies are above their own turnon thresholds and the OUTEN pin is set free.

At the end of the digital soft-start, SS_END signal is set free.

Protections are active during soft-start: under voltage is enabled when the reference voltage

reaches 0.6 V while overvoltage is always enabled.

Note: If the PSI is already low during the start-up, the device implements the soft-start using the N

phases selected trough PWM4 pin. When the soft-start is finished the device turns OFF

some phases in according to the PSI strategy.

Figure 18. Soft-start

OUTEN

V

OUT

SS_END

OVP

TD1TD2TD3T

T

SS

T

D4

D5

t

t

t

Once L6716 receives all the correct supplies and enables, it initiates the Soft-Start phase

with a T

V - 19 mV) in T

=1.5 ms (typ) delay. After that, the reference ramps up to V

D1

according to the SSOSC settings and waits for T

D2

= 1.081 V (1.100

BOOT

= 200 μsec (typ) during

D3

which the device reads the VID lines. Output voltage will then ramps up to the programmed

value in T

with the same slope as before (see Figure 18).

D4

SSOSC defines the frequency of an internal additional soft-start-oscillator used to step the

reference from zero up to the programmed value; this oscillator is independent from the

main oscillator whose frequency is programmed through the OSC pin.

The current flowing from SSOSC pin before the end of soft-start is used to program the

desiderated soft-start time (T

SS

).

After that the soft-start is finished the current flowing from SSOSC pin is used to program

the maximum LTB switching frequency (F

In the Figure 19 is shown the SSOSC connection in order to select both parameter (T

F

) in independent way.

LIMIT

In particular, it allows to precisely programming the start-up time up to V

LIMIT

).

and

SS

(TD2) since it

BOOT

is a fixed voltage independent by the programmed VID. Total soft-start time dependence on

the programmed VID results (see Figure 20).

36/57 Doc ID 14521 Rev 3

Page 37

L6716 Soft-start

Note: If during TD3 the programmed VID selects an output voltage lower than V

voltage will ramp to the programmed voltage starting from V

BOOT

.

Figure 19. SSOSC connection

SSOSCSS_END

R

SSOSC

V

Pull-Up

(1.2V)

to SSEND Logic

R

SSOSC

TSSμs[] 200 μs[]

+=

R

Pull-Up

(1k)

kΩ[]TD2μs[]40 10

⎧

R

SSOSC

---------------------------------- -

⎪

⎪

40 10

⎨

⎪

⎪

⎩

⋅

R

SSOSC

---------------------------------- -

40 10

⋅

D

R

FLIMIT

Rb(10k)

Soft Start time and FLIMIT

selected in indipendent way.

⋅⋅ ⋅=

kΩ[]

---------------------------------------------- -

⋅⋅if V

3–

1.24 V

kΩ[]

---------------------------------------------- -

3–

1.24 V

3–

1.24

DIODE

1.24