Page 1

L6712

Fi

L6712A

TWO-PHASE INTERLEAVED DC/DC CONTROLLER

1 Features

■ 2 PHASE OPERATION WITH

SYNCHRONOUS RECTIFIER CONTROL

■ ULTRA FAST LOAD TRANSIENT RESPONSE

■ INTEGRATED HIGH CURRENT GATE

DRIVERS: UP TO 2A GATE CURRENT

■

3 BIT PROGRAMMABLE OUTPUT FROM

0.900V TO 3.300V OR WITH EXTERNAL REF.

■ ±0.9% OUTPUT VOLTAGE ACCURACY

■ 3mA CAPABLE AVAILABLE REFERENCE

■ INTEGRATED PROGRAMMABLE REMOTE

SENSE AMPLIFIER

■ PROGRAMMABLE DROOP EFFECT

■ 10% ACTIVE CURRENT SHARING

ACCURACY

■ DIGITAL 2048 STEP SOFT-START

■

CROWBAR LATCHED OVERVOLTAGE PROT.

■ NON-LATCHED UNDERVOLTAGE PROT.

■ OVERCURRENT PROTECTION REALIZED

USING THE LOWER MOSFET'S R

dsON

OR A

SENSE RESISTOR

■ OSCILLATOR EXTERNALLY ADJUSTABLE

AND INTERNALLY FIXED AT 150kHZ

■ POWER GOOD OUTPUT AND INHIBIT

FUNCTION

■ PACKAGES: SO-28 & VFQFPN-36

1.1 Applications

■ HIGH CURRENT DC/DC CONVERTERS

■ DISTRIBUTED POWER SUPPLY

2 Description

The device implements a dual-phase step-down controller with a 180 phase-shift between each phase

gure 1. Packages

SO28

VFQFPN-36 (6x6x1.0mm)

Table 1. Order Codes

Package Tube Tape & Reel

SO

VFQFPN

L6712D,

L6712AD

L6712Q,

L6712AQ

L6712DTR,

L6712ADTR

L6712QTR,

L6712AQTR

optimized for high current DC/DC applications.

Output voltage can be programmed through the in-

tegrated DAC from 0.900V to 3.300V; programming the "111" code, an external reference from

0.800V to 3.300V is used for the regulation.

Programmable Remote Sense Amplifier avoids

use of external resistor divider and recovers losses along distribution line.

The device assures a fast protection against load

over current and Over / Under voltage.An internal

crowbar is provided turning on the low side mosfet

if Over-voltage is detected.

Output current is limited working in Constant Current mode: when Under Voltage is detected, the

device resets, restarting operation.

June 2005

Rev. 3

1/29

Page 2

L6712A L6712

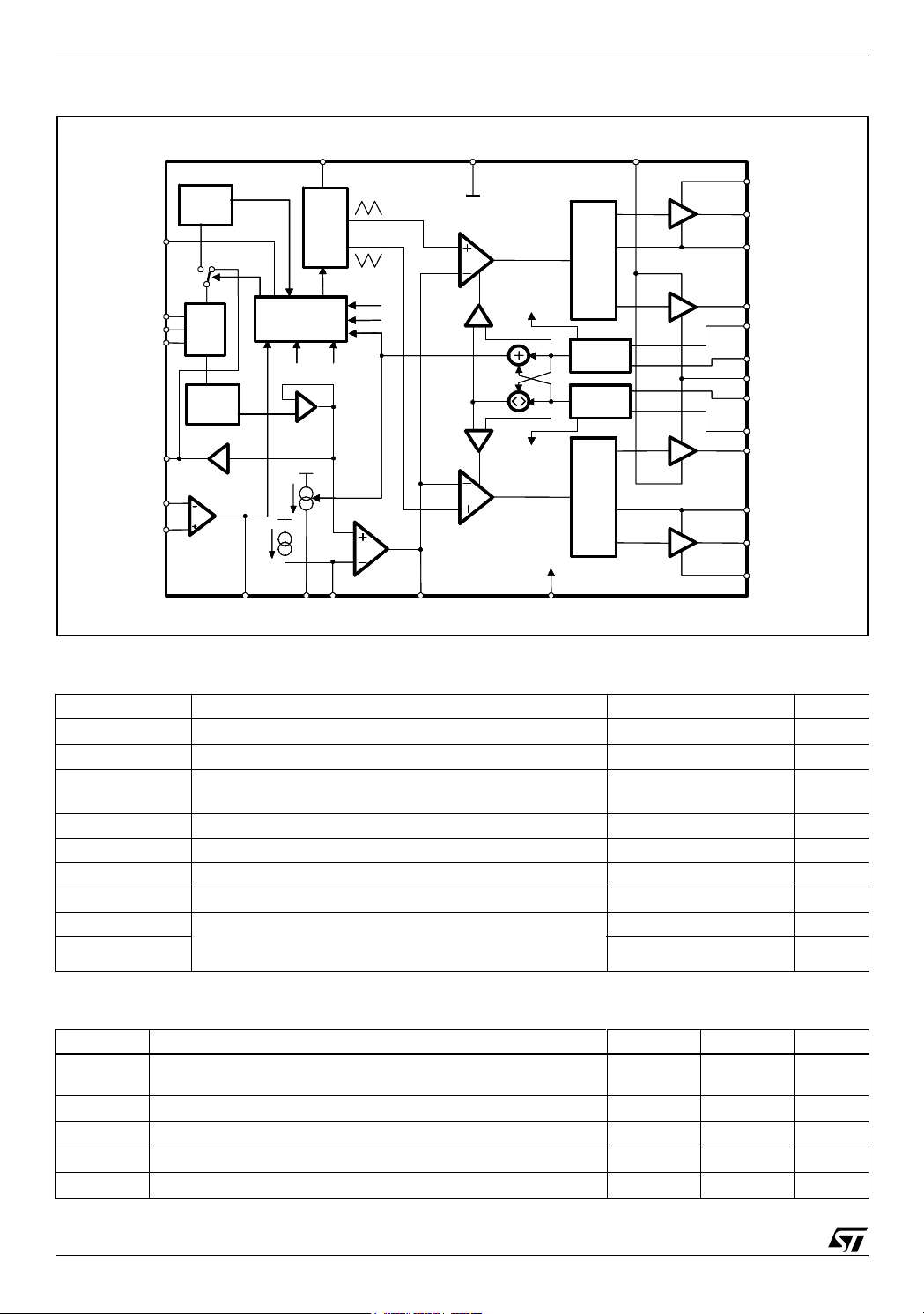

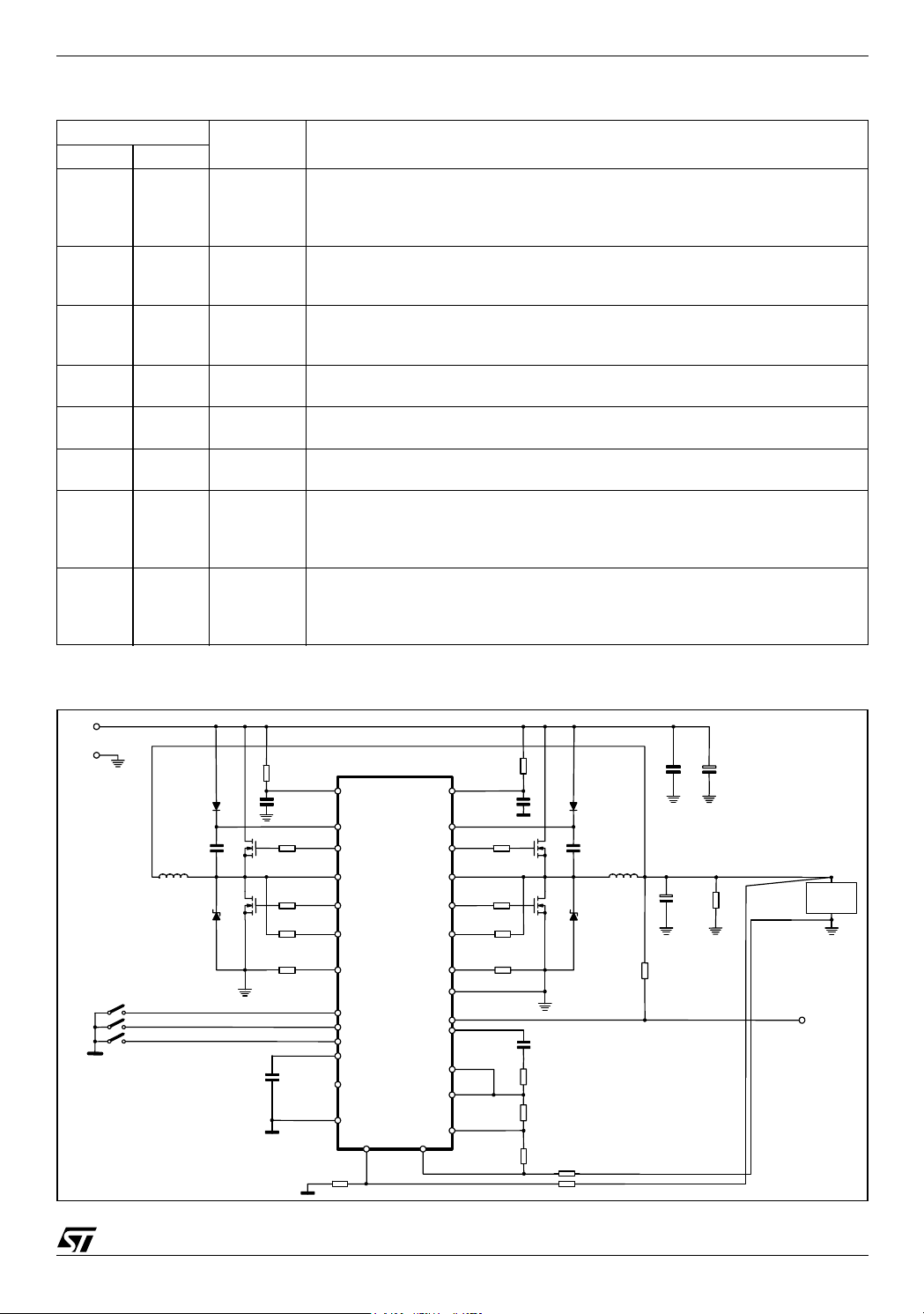

Figure 2. Block Diagram

BAND-GAP

BAND-GAP

REFERENCE

REFERENCE

PGOOD

PGOOD

VID2

VID2

VID1

VID1

VID0

VID0

REF_IN/OUT

REF_IN/OUT

FBG

FBG

FBR

FBR

DAC

DAC

DIGITAL

DIGITAL

SOFT-START

SOFT-START

REMOTE

REMOTE

AMPLIFIER

AMPLIFIER

OSC / INH SGND VCCDR

OSC / INH SGND VCCDR

PWM1

TOTAL

TOTAL

CURRENT

CURRENT

PWM1

CURRENT

CURRENT

PWM2

PWM2

CH1

CH1

OCP

OCP

CURRENT

CURRENT

CORRECTION

CORRECTION

AVG

AVG

CH2

CH2

OCP

OCP

CURRENT

CURRENT

CORRECTION

CORRECTION

Vcc

Vcc

VccCOMPFBVSEN

VccCOMPFBVSEN

LOGIC AND

LOGIC AND

PROTECTIONS

PROTECTIONS

CH1 OCP

CH1 OCP

V

V

PROG

PROG

DROOP

DROOP

I

I

FB_START

FB_START

I

I

DROOP

DROOP

2 PHASE

2 PHASE

OSCILLATOR

OSCILLATOR

CH2 OCP

CH2 OCP

VCC

VCC

VCCDR

VCCDR

ERROR

ERROR

AMPLIFIER

AMPLIFIER

LOGIC PW M

LOGIC PW M

ADAPTIVE ANTI

ADAPTIVE ANTI

CROSS CONDUCTION

CROSS CONDUCTION

CURRENT

CURRENT

READING

READING

CURRENT

CURRENT

READ ING

READ ING

LOGIC PW M

LOGIC PW M

ADAPTIVE ANTI

ADAPTIVE ANTI

CROSS CONDUCTION

CROSS CONDUCTION

HS

HS

LS

LS

HS

HS

BOOT1

BOOT1

UGATE1

UGATE1

PHASE1

PHASE1

LGATE1

LGATE1

ISEN1

ISEN1

PGNDS1

PGNDS1

PGND

PGND

PGNDS2

PGNDS2

ISEN2

ISEN2

LS

LS

LGATE2

LGATE2

PHASE2

PHASE2

UGATE2

UGATE2

BOOT2

BOOT2

Table 2. Absolute Maximum Ratings

Symbol Parameter Value Unit

V

, V

CC

CCDR

V

BOOT-VPHASE

V

UGATE1-VPHASE1

V

UGATE2-VPHASE2

To P G ND 15 V

Boot Voltage 15 V

15 V

LGATE1, PHASE1, LGATE2, PHASE2 to PGND -0.3 to Vcc+0.3 V

VID0 to VID2 -0.3 to 5 V

All other pins to PGND -0.3 to 7 V

V

PHASEx

UGATEX Pins Maximum Withstanding Voltage Range

OTHER PINS ±2000 V

Sustainable Peak Voltage. T<20ns @ 600kHz 26 V

±1500 V

Test Condition: CDF-AEC-Q100-002”Human Body Model”

Acceptance Criteria: “Normal Performance”

Table 3. Thermal Data

Symbol Parameter SO28 VFQFPN36 Unit

R

thj-amb

T

T

P

max

stg

T

MAX

Thermal Resistance Junction to Ambient

60 30 °C/W

4 layer PCB (2s2p)

Maximum junction temperature 150 150 °C

Storage temperature range -40 to 150 -40 to 150 °C

Junction Temperature Range -40 to 125 -40 to 125 °C

j

Max power dissipation at T

= 25°C 23.5W

amb

2/29

Page 3

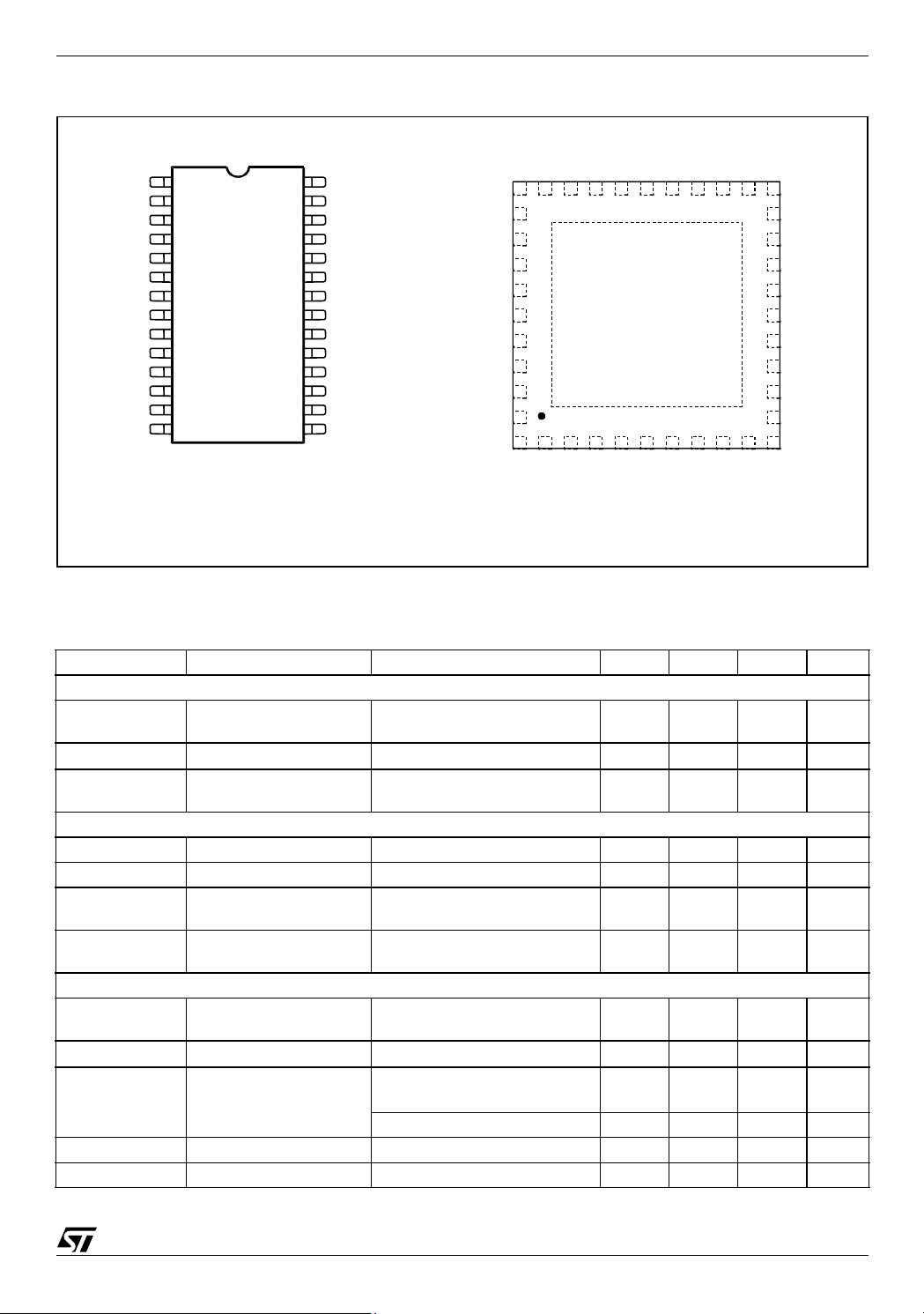

Figure 3. Pin Connection (Top view)

D

LGATE1

VCCDR

PHASE1

UGATE1

BOOT1

VCC

SGND

COMP

FB

DROOP

REF_IN/OUT

VSEN

ISEN1

PGNDS1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SO28

28

27

26

25

24

23

22

21

20

19

18

17

16

15

PGND

LGATE2

PHASE2

UGATE2

BOOT2

PGOOD

VID2

VID1

VID0

FBR

FBG

OSC/INH/FAULT

ISEN2

PGNDS2

L6712A L6712

BOOT2

PGOO

UGATE2

PHASE2

PHASE2

LGATE2

LGATE2

PGND

PGND

PGND

PGND

LGATE1

LGATE1

VCCDR

VCCDR

PHASE1

PHASE1

UGATE1

N.C.

27 26 25 24 23 22 21 20 19

27 26 25 24 23 22 21 20 19

28

28

29

29

30

30

31

31

32

32

33

33

34

34

35

35

36

36

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9

N.C

N.C.

BOOT1

VID0

VID1

VID2

VCC

SGND

SGND

VFQFPN-36

Corner Pin internally connected to the Exposed Pad.

N.C.

FBG

FBR

OSC

OSC

18

18

17

17

N.C.

N.C.

ISEN2

ISEN2

16

16

PGNDS2

PGNDS2

15

15

PGNDS1

PGNDS1

14

14

ISEN1

ISEN1

13

13

VSEN

VSEN

12

12

REF_IN/OUT

REF_IN/OUT

11

11

10

10

N.C.

N.C.

FB

COMP

DROOP

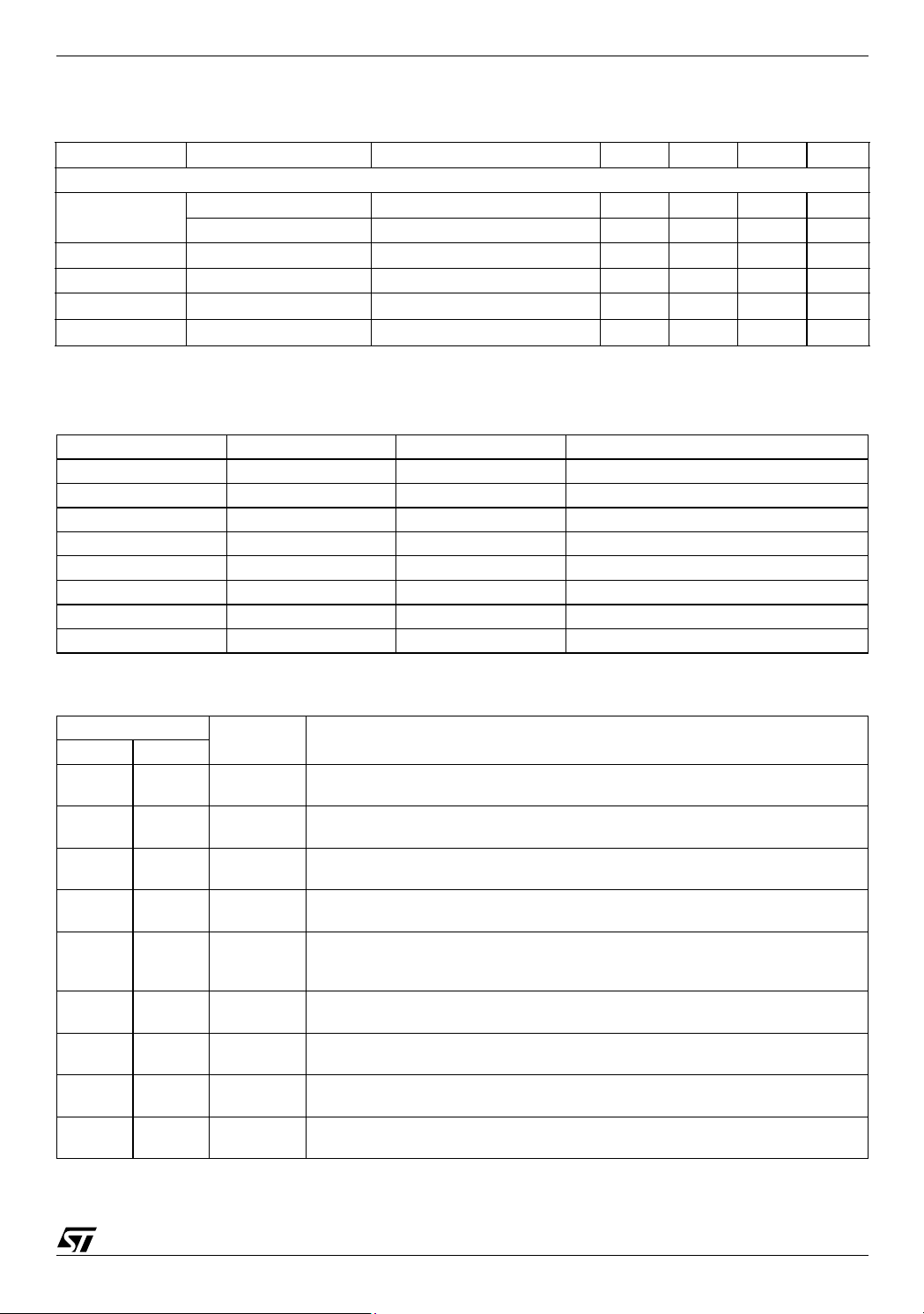

Table 4. Electrical Characteristcs

(V

= 12V±10%, TJ = 0°C to 70°C unless otherwise specified)

CC

Symbol Parameter Test Condition Min. Typ. Max. Unit

Vcc SUPPLY CURRENT

I

CC

VCC supply current HGATEx and LGATEx open

VCCDR=BOOTx=12V

I

CCDR

I

BOOTx

VCCDR supply current LGATEx open; VCCDR=12V 1.5 3 4 mA

Boot supply current HGATEx open; PHASEx to

PGND; VCC=BOOTx=12V

POWER-ON

Turn-On VCC threshold VCC Rising; VCCDR=5V 8.2 9.2 10.2 V

Turn-Off VCC threshold VCC Falling; VCCDR=5V 6.5 7.5 8.5 V

Turn-On VCCDR

Threshold

Turn-Off VCCDR

Threshold

VCCDR Rising

VCC=12V

VCCDR Falling

VCC=12V

OSCILLATOR AND INHIBIT

f

OSC

Initial Accuracy OSC = OPEN

OSC = OPEN; Tj=0°C to 125°C

INH Inhibit threshold I

d

MAX

Maximum duty cycle

=5mA 0.5 V

SINK

L6712

, OSC = OPEN: I

OSC = OPEN; I

DROOP

DROOP

=70µA

L6712A, OSC = OPEN 85 90 %

∆Vosc Ramp Amplitude 3 V

FAULT Voltage at pin OSC OVP Active 4.75 5.0 5.25 V

7.5 10 12.5 mA

0.5 1 1.5 mA

4.2 4.4 4.6 V

4.0 4.2 4.4 V

135

150 165

127

=0

72

30

80

40

178

kHz

kHz

-

-

%

%

3/29

Page 4

L6712A L6712

Table 4. Electrical Characteristcs (continued)

(V

= 12V±10%, TJ = 0°C to 70°C unless otherwise specified)

CC

Symbol Parameter Test Condition Min. Typ. Max. Unit

REFERENCE AND DAC

(1)

V

OUT

REF_IN/OUT Reference Accuracy VIDx See Table 5, VID ≠ “111” V

V

/ REF_IN/

PROG

OUT

REF_IN/OUT Input impedance 400 kΩ

I

VID

V

VID

VID

IL

VID

IH

ERROR AMPLIFIER

V

OS_EA

SR Slew-Rate COMP=10pF 15 V/µs

I

FB_START

DIFFERENTIAL AMPLIFIER (REMOTE BUFFER)

V

OS_RA

SR Slew Rate VSEN = 10pF 15 V/µs

DIFFERENTIAL CURRENT SENSING

, I

I

ISEN1

ISEN2

I

PGNDSx

I

, I

ISEN1

ISEN2

I

DROOP

GATE DRIVERS

t

RISE HGATE

I

HGATEx

R

HGATEx

t

RISE LGATE

I

LGATEx

R

LGATEx

Output Voltage Accuracy VIDx See Table 5, VID ≠ “11x“ -0.9 - 0.9 %

VID = “110“ -1.0 - 1.0 %

OUT

-5 V

OUTVOUT

+5 mV

Current Capability 3 mA

Load Regulation I

Accuracy with external

reference

= from 0 to 3mA 5.0 mV

REF

VID=“111”;

-2.0 2.0 %

REF_IN/OUT = 0.8V to 3.3V

VID pull-up Current VIDx =SGND 5 µA

VID pull-up Voltage VIDx = OPEN 3 V

VID Input Levels Input Low 0.4 V

Input High 1.0 V

Offset FB = COMP -5 5 mV

DC Gain 80 dB

Start-up Current FB=SGND; During Soft Start… 65 µA

Offset VSEN = FBG -8 8 mV

DC Gain 80 dB

Bias Current I

= 0 455055µA

LOAD

Bias Current 45 50 55 µA

Bias Current at

80 85 90 µA

Over Current Threshold

Droop Current I

High Side

Rise Time

High Side

≤ 001µA

LOAD

I

= 100% 47.5 50 52.5 µA

LOAD

BOOTx-PHASEx=10V;

C

to PHASEx=3.3nF

HGATEx

15 30 ns

BOOTx-PHASEx=10V 2 A

Source Current

High Side

BOOTx-PHASEx=12V; 1.5 2 2.5 Ω

Sink Resistance

Low Side

Rise Time

Low Side

VCCDR=10V;

C

to PGNDx=5.6nF

LGATEx

30 55 ns

VCCDR=10V 1.8 A

Source Current

Low Side

VCCDR=12V 0.7 1.1 1.5 Ω

Sink Resistance

4/29

Page 5

L6712A L6712

Table 4. Electrical Characteristcs (continued)

(V

= 12V±10%, TJ = 0°C to 70°C unless otherwise specified)

CC

Symbol Parameter Test Condition Min. Typ. Max. Unit

PROTECTIONS

PGOOD Upper Threshold VSEN Rising 108 112 115 %

Lower Threshold VSEN Falling 84 88 92 %

OVP Over Voltage Threshold VSEN Rising 115 122 130 %

UVP Under Voltage Trip VSEN Falling 55 60 65 %

V

PGOODL

I

PGOODH

Note: 1. Output voltage is specified including Error Amplifier Offset in the trimming chain. Remote Amplifier is not included.

PGOOD Voltage Low I

PGOOD Leakage V

Table 5. Voltage Identification (VID) Codes.

VID2 VID1 VID0 Output Voltage (V)

111 Ext. Ref.

110 0.900

101 1.250

100 1.500

011 1.715

010 1.800

001 2.500

000 3.300

= -4mA 0.4 V

PGOOD

= 5V 1 µA

PGOOD

Table 6. Pin Function

N. (*)

SO VFQFPN

1 33 LGATE1 Channel 1 LS driver output.

2 34 VCCDR LS drivers supply: it can be varied from 5V to 12V buses.

3 35 PHASE1 Channel 1 HS driver return path. It must be connected to the HS1 mosfet source

4 36 UGATE1 Channel 1 HS driver output.

5 2 BOOT1 Channel 1 HS driver supply. This pin supplies the relative high side driver.

6 4 VCC Device supply voltage. The operative supply voltage is 12V ±10%.

7 5,6 SGND All the internal references are referred to this pin. Connect it to the PCB signal

8 7 COMP This pin is connected to the error amplifier output and is used to compensate the

9 8 FB This pin is connected to the error amplifier inverting input and is used to

Name

Description

A little series resistor helps in reducing device-dissipated power.

Filter locally with at least 1µF ceramic cap vs. PGND.

and provides the return path for the HS driver of channel 1.

A little series resistor helps in reducing device-dissipated power.

Connect through a capacitor (100nF typ.) to the PHASE1 pin and through a diode

to VCC (cathode vs. boot).

Filter with 1µF (Typ.) capacitor vs. GND.

ground.

control feedback loop.

compensate the control feedback loop.

5/29

Page 6

L6712A L6712

Table 6. Pin Function (continued)

N. (*)

SO VFQFPN

10 9 DROOP A current proportional to the sum of the current sensed in both channel is

11 11 REF_IN /

12 12 VSEN Connected to the output voltage it is able to manage Over & Under-voltage

13 13 ISEN1 Channel 1 current sense pin. The output current may be sensed across a sense

14 14 PGNDS1 Channel 1 Power Ground sense pin. The net connecting the pin to the sense

15 15 PGNDS2 Channel 2 Power Ground sense pin. The net connecting the pin to the sense

16 16 ISEN2 Channel 2 current sense pin. The output current may be sensed across a sense

17 18 OSC/INH

18 20 FBG Remote sense amplifier inverting input. It has to be connected to the negative

19 21 FBR Remote sense amplifier non-inverting input. It has to be connected to the positive

Name

OUT

FAULT

Description

sourced from this pin (50µA at full load, 70µA at the Constant Current threshold).

Short to FB to implement the Droop effect: the resistor connected between FB

and VSEN (or the regulated output) allows programming the droop effect.

Otherwise, connect to GND directly or through a resistor (43kΩ max) and filter

with 1nF capacitor. In this last case, current information can be used for other

purposes.

Reference input/output. Filter vs. GND with 1nF ceramic capacitor (a total of

100nF capacitor is allowed).

It reproduces the reference used for the regulation following VID code: when

VID=111, the reference for the regulation must be connected on this pin.

References ranging from 0.800V up to 3.300V can be accepted.

conditions and the PGOOD signal. It is internally connected with the output of the

Remote Sense Amplifier for Remote Sense of the regulated voltage.

Connecting 1nF capacitor max vs. GND can help in reducing noise injection at

this pin.

If no Remote Sense is implemented, connect it directly to the regulated voltage in

order to manage OVP, UVP and PGOOD.

resistor or across the low-side mosfet R

low-side mosfet drain or to the sense resistor through a resistor Rg.

The net connecting the pin to the sense point must be routed as close as

possible to the PGNDS net in order to couple in common mode any picked-up

noise.

point must be routed as close as possible to the ISEN1 net in order to couple in

common mode any picked-up noise.

point must be routed as close as possible to the ISEN2 net in order to couple in

common mode any picked-up noise.

resistor or across the low-side mosfet R

low-side mosfet drain or to the sense resistor through a resistor Rg.

The net connecting the pin to the sense point must be routed as close as

possible to the PGNDS net in order to couple in common mode any picked-up

noise.

Oscillator pin.

It allows programming the switching frequency of each channel: the equivalent

switching frequency at the load side results in being doubled.

Internally fixed at 1.24V, the frequency is varied proportionally to the current sunk

(forced) from (into) the pin with an internal gain of 6kHz/µA (See relevant section

for details). If the pin is not connected, the switching frequency is 150kHz for

each channel (300kHz on the load).

The pin is forced high (5V Typ.) when an Over Voltage is detected; to recover

from this condition, cycle VCC.

Forcing the pin to a voltage lower than 0.6V, the device stops operation and

enters the inhibit state.

side of the load to perform programmable remote sensing through apposite

resistors (see relative section).

side of the load to perform programmable remote sensing through apposite

resistors (see relative section).

This pin has to be connected to the

dsON.

This pin has to be connected to the

dsON.

6/29

Page 7

Table 6. Pin Function (continued)

L6712A L6712

N. (*)

SO VFQFPN

Name

Description

20 to 22 22 to 24 VID0-2 Voltage IDentification pins. These input are internally pulled-up. They are used to

program the output voltage as specified in Table 1 and to set the PGOOD, OVP

and UVP thresholds.

Connect to GND to program a ‘0’ while leave floating to program a ‘1’.

23 25 PGOOD This pin is an open collector output and is pulled low if the output voltage is not

within the above specified thresholds and during soft-start.

It cannot be pulled up above 5V. If not used may be left floating.

24 27 BOOT2 Channel 2 HS driver supply. This pin supplies the relative high side driver.

Connect through a capacitor (100nF typ.) to the PHASE2 pin and through a diode

to VCC (cathode vs. boot).

25 28 UGATE2 Channel 2 HS driver output.

A little series resistor helps in reducing device-dissipated power.

26 29 PHASE2 Channel 2 HS driver return path. It must be connected to the HS2 mosfet source

and provides the return path for the HS driver of channel 2.

27 30 LGATE2 Channel 2 LS driver output.

A little series resistor helps in reducing device-dissipated power.

28 31,

32

PGND LS drivers return path.

This pin is common to both sections and it must be connected through the

closest path to the LS mosfets source pins in order to reduce the noise injection

into the device.

PAD THERMAL

PA D

Thermal pad connects the silicon substrate and makes a good thermal contact

with the PCB to dissipate the power necessary to drive the external

mosfets.Connect to the GND plane with several vias to improve thermal

conductivity.

(*) Pin not reported in QFN column have to be considered as Not Connected, not internally bonded.

Figure 4. Reference Schematic

Vin

GNDin

VCCDR

BOOT1

HS1

L1

LS1

S2

S1

S0

UGATE1

PHASE1

LGATE1

ISEN1

Rg

PGNDS1

Rg

REF_IN/OUT

OSC / INH

L6712A

VID2

VID1

VID0

SGND

FBR FBG

L6712

VCC

BOOT2

UGATE2

PHASE2

LGATE2

ISEN2

PGNDS2

PGND

PGOOD

COMP

DROOP

FB

VSEN

C

IN

HS2

L2

C

LS2

Rg

Rg

C

R

R

OUT

LOAD

PGOOD

7/29

Page 8

L6712A L6712

3 Device Description

The device is an integrated circuit realized in BCD technology. It provides complete control logic and protections for a high performance dual-phase step-down converter optimized for high current DC/DC applications. It is designed to drive N-Channel Mosfets in a two-phase synchronous-rectified buck topology. A

180 deg phase shift is provided between the two phases allowing reduction in the input capacitor current

ripple, reducing also the size and the losses. The output voltage of the converter can be precisely regulated, programming the VID pins, from 0.900 to 3.300V with a maximum tolerance of ±0.9% over temperature and line voltage variations. The programmable Remote Sense Amplifier avoids the use of external

resistor divider allowing recovering drops across distribution lines and also adjusting output voltage to different values from the available reference. The device provides an average current-mode control with fast

transient response. It includes a 150kHz free-running oscillator externally adjustable through a resistor.

The error amplifier features a 15V/µs slew rate that permits high converter bandwidth for fast transient performances. Current information is read across the lower mosfets R

in series to the LS mos in fully differential mode. The current information corrects the PWM outputs in order

to equalize the average current carried by each phase. Current sharing between the two phases is then

limited at ±10% over static and dynamic conditions unless considering the sensing element spread. Droop

effect can be programmed in order to minimize output filter and load transient response: the function can

be disabled and the current information available on the pin can be used for other purposes. The device

protects against Over-Current, with an OC threshold for each phase, entering in constant current mode.

Since the current is read across the low side mosfets, the device keeps constant the bottom of the inductors current triangular waveform. When an Under Voltage is detected the device resets with all mosfets

OFF and suddenly re-starts. The device also performs a crowbar Over-Voltage protection that immediately latches the operations turning ON the lower driver and driving high the FAULT pin.

or across a sense resistor placed

dsON

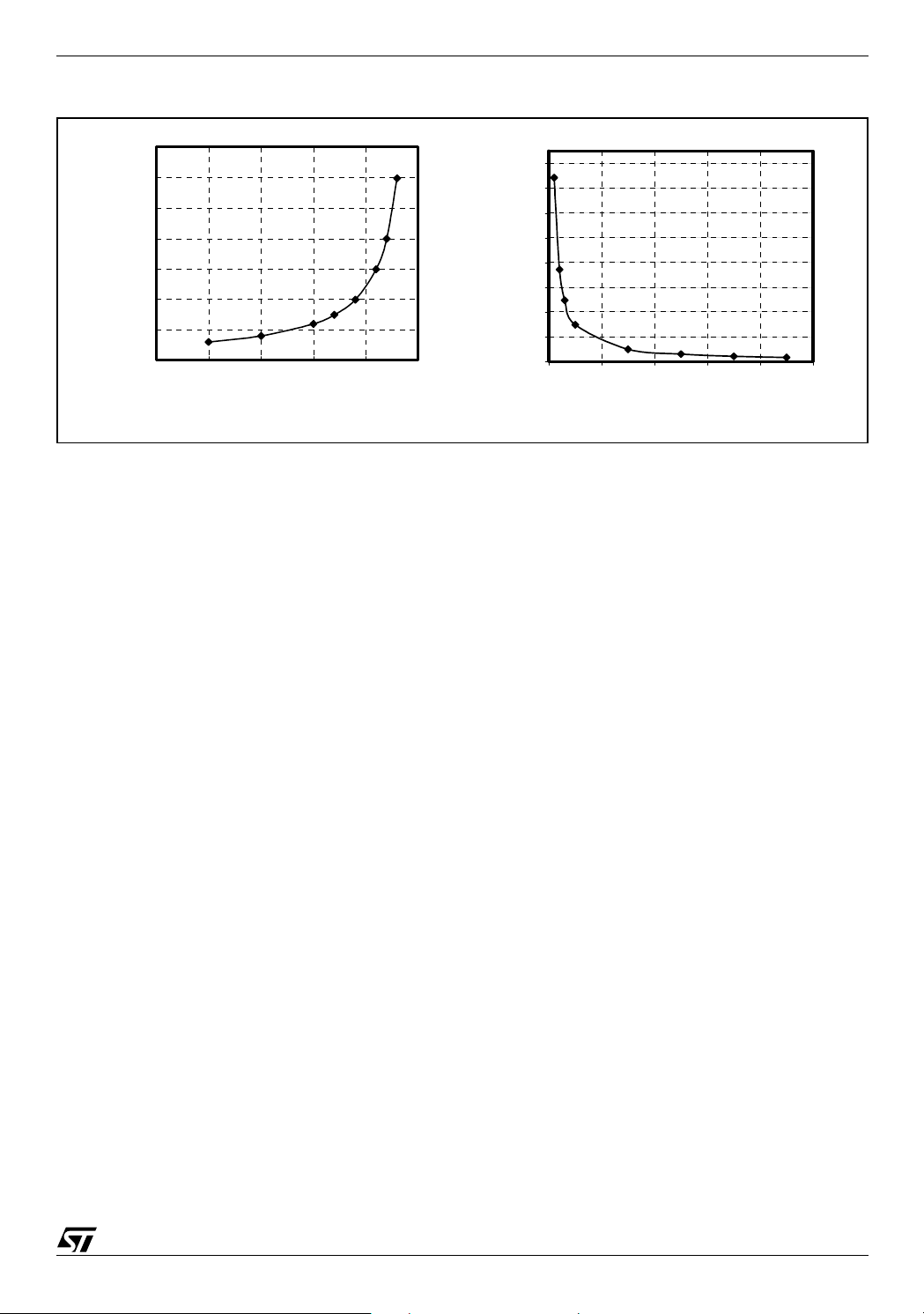

3.1 OSCILLATOR

The switching frequency is internally fixed at 150kHz. Each phase works at the frequency fixed by the oscillator so that the resulting switching frequency at the load side results in being doubled.

The internal oscillator generates the triangular waveform for the PWM charging and discharging with a

constant current an internal capacitor. The current delivered to the oscillator is typically 25µA

(Fsw=150kHz) and may be varied using an external resistor (R

) connected between OSC pin and

OSC

SGND or Vcc. Since the OSC pin is maintained at fixed voltage (Typ. 1.237V), the frequency is varied

proportionally to the current sunk (forced) from (into) the pin considering the internal gain of 6KHz/µA.

In particular connecting it to SGND the frequency is increased (current is sunk from the pin), while connecting R

to Vcc=12V the frequency is reduced (current is forced into the pin), according to the follow-

OSC

ing relationships:

6

⋅

KΩ[]

7

⋅

KΩ[]

kHz[]+=⋅+=

kHz[]–=⋅=

R

R

OSC

OSC

vs. GND:

vs. 12V:

1.237

F

F

SW

150 KH z[]

SW

150 KH z[]

---------------

R

OSC

12 1.237–

------------------------ -– 6

R

OSC

6

kHz

---------- -

µA

kHz

---------- -

µA

7.422 10

150 kHz[]

----------------------------- -

R

150 kH z[]

OSC

6.457 10

----------------------------- -

R

OSC

Forcing 25µA into this pin, the device stops switching because no current is delivered to the oscillator

8/29

Page 9

L6712A L6712

Figure 5. R

14000

12000

10000

8000

) vs. 12V

6000

4000

Rosc(K

2000

vs. Switching Frequency

OSC

0

25 50 75 100 125 150

Frequency (kHz)

800

700

600

500

) vs. GND

400

Ω

300

200

Rosc(K

100

0

150 250 350 450 550 650

Frequency (kHz)

3.2 DIGITAL TO ANALOG CONVERTER AND REFERENCE

The built-in digital to analog converter allows the adjustment of the output voltage from 0.900V to 3.300V

as shown in Figure 6. Different voltages can be reached simply changing the Remote Amplifier Gain that

acts as a resistor divider (See relevant section).

The internal reference is trimmed during production process to have an output voltage accuracy of ±0.9%

and a zero temperature coefficient around 70°C including also error amplifier offset compensation. It is

programmed through the voltage identification (VID) pins. These are inputs of an internal DAC that is realized by means of a series of resistors providing a partition of the internal voltage reference. The VID code

drives a multiplexer that select a voltage on a precise point of the divider (see Figure 6). The DAC output

is delivered to an amplifier obtaining the V

voltage reference (i.e. the set-point of the error amplifier).

PROG

Internal pull-ups are provided (realized with a 5µA current generator up to 3V typ.); in this way, to program

a logic "1" it is enough to leave the pin floating, while to program a logic "0" it is enough to short the pin to

SGND.

The device offers a bi-directional pin REF_IN/OUT: the internal reference used for the regulation is usually

available on this pin with 3mA of maximum current capability except when VID code 111 is programmed;

in this case the device accepts an external reference through the REF_IN/OUT pin and regulates on it.

When external reference is used, it must range from 0.800V up to 3.300V to assure proper functionality of

the device.

Figure 6 shows a block schematic of how the Reference for the regulation is managed when internal or

external reference is used.

The voltage identification (VID) pin configuration or the external reference provided also sets the powergood thresholds (PGOOD) and the Over/Under voltage protection (OVP/UVP) thresholds.

9/29

Page 10

L6712A L6712

Figure 6. Reference Management

BAND-GAP

REFERENCE

(1.235V)

CONTROL

LOGIC

VIDx

INTERNAL REFERENCE

EXTERNAL REFERENCE

ERROR

VID3

VID2

VID1

REF_IN/OUT

DAC

AMPLIFIER

DIGITAL

SOFT-START

V

PROG

FB

COMP

The output regulated voltage accuracy can be extracted from the following relationships (worst case condition):

V

OU T _TOT_ACC

%[] V

OUT_ACC

%[]K

OS

V

OS_RA

--------------------

V

OUT

100⋅⋅+ 0.9%±()K

OS

8mV±()

---------------------

V

OUT

100⋅⋅+==

(worst case with internal reference)

V

OU T _TOT_ACC

%[]EXT_REF_Accuracy[%]

V

PROG

-------------------------------------

REF_IN/OUT

[%]

⎝⎠

EXT_REF

100⋅

V

OS_EA

⎛⎞

-------------------------- -

V

OS_RA

--------------------

K

OS

V

100=⋅⋅++ +=

OUT

⎛⎞

EX T _REF _Accuracy [%] 2.0%±()

-------------------------- -

⎝⎠

EXT_REF

5mV±()

100⋅

K

OS

8mV±()

---------------------

V

out

100⋅⋅++ +=

(worst case with external reference)

where V

tively and K

and V

OS_RA

= 1+1/RA_Gain reflects the impact of the Remote Amplifier Gain (RA_Gain) on the regula-

OS

are the offsets related to the Error Amplifier and the Remote Amplifier respec-

OS_EA

tion (see relevant section).

A statistical analysis could consider applying the root-sum-square (RSS) method to calculate the precision

since all the variables are statistically independent as follow:

2

100⋅⋅

V

OU T _TOT_ACC

[%] V

=

OUT_ACC

2

+

[%]()

V

OS

OS_RA

--------------------

V

OUT

⎛⎞

K

⎝⎠

(with internal reference)

V

OU T _TOT_ACC

V

[%] = EXT_REF_Accuracy[%]()

2

PROG

⎛⎞

-------------------------------------

+

⎝⎠

REF_IN/OUT

2

[%]

V

OS_EA

⎛⎞

-------------------------- -

+

⎝⎠

EXT_REF

2

+K

100⋅

V

OS

OS_RA

--------------------

V

OUT

⎛⎞

⎝⎠

2

100⋅⋅

(with external reference)

10/29

Page 11

L6712A L6712

3.3 DRIVER SECTION

The integrated high-current drivers allow using different types of power MOS (also multiple MOS to reduce

the R

The drivers for the high-side mosfets use BOOTx pins for supply and PHASEx pins for return. The drivers

for the low-side mosfets use VCCDR pin for supply and PGND pin for return. A minimum voltage of 4.6V

at VCCDR pin is required to start operations of the device.

The controller embodies a sophisticated anti-shoot-through system to minimize low side body diode conduction time maintaining good efficiency saving the use of Schottky diodes in parallel to the LS mosfets.

The dead time is reduced to few nanoseconds assuring that high-side and low-side mosfets are never

switched on simultaneously: when the high-side mosfet turns off, the voltage on its source begins to fall;

when the voltage reaches 2V, the low-side mosfet gate drive is applied with 30ns delay. When the lowside mosfet turns off, the voltage at LGATEx pin is sensed. When it drops below 1V, the high-side mosfet

gate drive is applied with a delay of 30ns. If the current flowing in the inductor is negative, the source of

high-side mosfet will never drop. To allow the turning on of the low-side mosfet even in this case, a watchdog controller is enabled: if the source of the high-side mosfet don't drop for more than 240ns, the low side

mosfet is switched on so allowing the negative current of the inductor to recirculate. This mechanism allows the system to regulate even if the current is negative.

The BOOTx and VCCDR pins are separated from IC's power supply (VCC pin) as well as signal ground

(SGND pin) and power ground (PGND pin) in order to maximize the switching noise immunity. The separated supply for the different drivers gives high flexibility in mosfet choice, allowing the use of logic-level

mosfet. Several combination of supply can be chosen to optimize performance and efficiency of the application. Power conversion is also flexible; 5V or 12V bus can be chosen freely.

The peak current is shown for both the upper and the lower driver of the two phases in Figure 7. A 10nF

capacitive load has been used. For the upper drivers, the source current is 1.9A while the sink current is

1.5A with V

current is 2A with VCCDR = 12V.

), maintaining fast switching transition.

dsON

BOOT

-V

= 12V; similarly, for the lower drivers, the source current is 2.4A while the sink

PHASE

Figure 7. Drivers peak current: High Side (left) and Low Side (right)

CH3 = HGATE1; CH4 = HGATE2 CH3 = LGATE1; CH4 = LGATE2

3.4 CURRENT READING AND OVER CURRENT

The current flowing trough each phase is read using the voltage drop across the low side mosfets R

or across a sense resistor (R

) in series to the LS mosfet and internally converted into a current. The

SENSE

dsON

transconductance ratio is issued by the external resistor Rg placed outside the chip between ISENx and

PGNDSx pins toward the reading points. The differential current reading rejects noise and allows to place

sensing element in different locations without affecting the measurement's accuracy. The current reading

11/29

Page 12

L6712A L6712

x

E

circuitry reads the current during the time in which the low-side mosfet is on (OFF Time). During this time,

the reaction keeps the pin ISENx and PGNDSx at the same voltage while during the time in which the

reading circuitry is off, an internal clamp keeps these two pins at the same voltage sinking from the ISENx

pin the necessary current (Needed if low-side mosfet R

imum rating overcome on ISENx pin).

The proprietary current reading circuit allows a very precise and high bandwidth reading for both positive

and negative current. This circuit reproduces the current flowing through the sensing element using a high

speed Track & Hold transconductance amplifier. In particular, it reads the current during the second half

of the OFF time reducing noise injection into the device due to the mosfet turn-on (See Figure 8-left). Track

time must be at least 200ns to make proper reading of the delivered current.

This circuit sources a constant 50µA current from the PGNDSx pin: it must be connected through the Rg

resistor to the ground side of the sensing element (See Figure 8-right). The two current reading circuitries

use this pin as a reference keeping the ISENx pin to this voltage.

The current that flows in the ISENx pin is then given by the following equation:

sense is implemented to avoid absolute max-

dsON

R

SENSEIPHASEx

------------------------------------------------- 50µAI

Where R

I

ISENx

is an external sense resistor or the R

SENSE

50µA

ductance resistor used between ISENx and PGNDSx pins toward the reading points; I

⋅

R

g

of the low side mosfet and Rg is the transcon-

dsON

+=+=

INFOx

PHASEx

is the current

carried by the relative phase. The current information reproduced internally is represented by the second

term of the previous equation as follow:

I

INFOx

R

SENSEIPHASEx

-------------------------------------------------=

⋅

R

g

Since the current is read in differential mode, also negative current information is kept; this allow the device to check for dangerous returning current between the two phases assuring the complete equalization

between the phase's currents. From the current information of each phase, information about the total current delivered (I

taken. I

INFOX

FB

= I

INFO1

+I

INFO2

is then compared to I

) and the average current for each phase (I

to give the correction to the PWM output in order to equalize the

AVG

AVG

= (I

INFO1

+I

INFO2

)/2 ) is

current carried by the two phases.

Figure 8. Current reading timing (left) and circuit (right)

I

LS1

LGATEx

I

LS2

IFB

ISENx

PGNDSx

Rg

I

ISEN

Rg

SENSE

R

PHAS

I

Track & Hold

50µA

The transconductance resistor Rg can be designed in order to have current information of 25µA per phase

at full nominal load; the over current intervention threshold is set at 140% of the nominal (I

According to the above relationship, the over current threshold (I

) for each phase, which has to be

OCPx

INFOx

placed at 1/2 of the total delivered maximum current, results:

12/29

= 35µA).

Page 13

L6712A L6712

(

)

T

(

)

⋅

35µARg⋅

I

OCPx

---------------------------

R

SENSE

Rg

Since the device senses the output current across the low-side mosfets (or across a sense resistors in

series with them) the device limits the bottom of the inductor current triangular waveform: an over current

is detected when the current flowing into the sense element is greater than I

■ L6712 - Dynamic Maximum Duty Cycle Limitation

The maximum duty cycle is limited as a function of the measured current and, since the oscillator frequency is fixed once programmed, imply a maximum on-time limitation as follow (where T is the switching period T=1/f

T

ON,MAX

SW

and I

is the output current):

OUT

0.80 IFB– 5.73k⋅()T0.80

R

⎛⎞

⎝⎠

SENSE

--------------------- -

Rg

This linear dependence has a value at zero load of 0.80·T and at maximum current of 0.40·T typical and

results in two different behaviors of the device:

Figure 9. TON Limited Operation

I

OCPxRSENSE

------------------------------------------ -

5.73k⋅⋅–

I

OUT

35µA

⋅=⋅=

T =

==

(I

OCPx

INFOx

⎧

T 0.80 T I

⎪

⎨

T 0.40 T I

⎪

⎩

> 35µA).

FB

FB

0µA=⋅=

70µA=⋅=

V

0.80·V

0.40·V

OUT

IN

IN

TONLimited Output

characteristic

I

=2·I

OCP

OCPx

I

=70µA

DROOP

I

OUT

V

0.80·V

0.40·V

OU

IN

IN

Resulting Output

characteristic

Desired Output

characteristic and

UVP threshold

I

=2·I

OCPx

=70µA

OCP

I

DROOP

I

OUT

a) Maximum output Voltage b) TON Limited Output Voltage

T

Limited Output Voltage.

ON

This happens when the maximum ON time is reached before the current in each phase reaches I

< 35µA).

FOx

Figure 9a shows the maximum output voltage that the device is able to regulate considering the T

itation imposed by the previous relationship. If the desired output characteristic crosses the T

OCPx

limited

ON

ON

(I

IN-

lim-

maximum output voltage, the output resulting voltage will start to drop after crossing. In this case, the device doesn't perform constant current limitation but only limits the maximum duty cycle following the previous relationship. The output voltage follows the resulting characteristic (dotted in Figure 9b) until UVP is

detected or anyway until I

= 70µA.

FB

Constant Current Operation

This happens when ON time limitation is reached after the current in each phase reaches I

OCPx

(I

INFOx

>

35µA).

The device enters in Quasi-Constant-Current operation: the low-side mosfets stays ON until the current

read becomes lower than I

OCPx

(I

< 35µA) skipping clock cycles. The high side mosfets can be turned

INFOx

ON with a TON imposed by the control loop at the next available clock cycle and the device works in the

13/29

Page 14

L6712A L6712

usual way until another OCP event is detected.

This means that the average current delivered can slightly increase also in Over Current condition since

the current ripple increases. In fact, the ON time increases due to the OFF time rise because of the current

has to reach the I

When this happens, the device works in Constant Current and the output voltage decrease as the load

increase. Crossing the UVP threshold causes the device to reset.

Figure 10 shows this working condition.

It can be observed that the peak current (I

I

peakIOCPx

bottom. The worst-case condition is when the ON time reaches its maximum value.

OCPx

peak

VINVout

–

------------------------------------- -

min

L

) is greater than the I

Ton

MAXIOCPx

but it can be determined as follow:

OCPx

VINVout

–

-------------------------------------- -

MIN

L

0.40 T⋅⋅+=⋅+=

Where V

is the minimum output voltage (VID-40% as follow).

outMIN

The device works in Constant-Current, and the output voltage decreases as the load increase, until the

output voltage reaches the under-voltage threshold (Vout

MIN

).

The maximum average current during the Constant-Current behavior results:

I

MA X ,TOT

2I

MAX

⎛⎞

⋅=⋅=

2I

OCPx

⎝⎠

Ipeak I

------------------------------------- -+

–

2

OCPx

In this particular situation, the switching frequency results reduced. The ON time is the maximum allowed

(T

) while the OFF time depends on the application:

onMAX

–

T

OFF

Ipeak I

------------------------------------- -

L

V

OCPx

OUt

f

----------------------------------------- -=⋅=

T

1

ONmaxTOFF

+

Figure 10. Constant Current operation

Ipeak

I

MAX

I

OCPx

Vout

Droop effect

UVP

TonMAX

Over current is set anyway when I

a) Maximum current for each phase b) Output Characteristic

TonMAX

INFOx

to work with convenient values for I

(I

=50µA) 2·I

DROOP

OCPx (IDROOP

reaches 35µA (IFB=70µA). The full load value is only a convention

. Since the OCP intervention threshold is fixed, to modify the per-

FB

MAX,TOT

I

=70µA)

Iout

centage with respect to the load value, it can be simply considered that, for example, to have on OCP

threshold of 200%, this will correspond to I

spond to I

= 17.5µA (IFB = 35µA).

INFOx

= 35µA (IFB = 70µA). The full load current will then corre-

INFOx

Once the UVP threshold has been intercepted, the device resets with all power mosfets turned OFF. Another soft start is then performed allowing the device to recover from OCP once the over load cause has

been removed.

Crossing the UVP threshold causes the device to reset: all mosfets are turned off and a new soft start is

14/29

Page 15

L6712A L6712

then implemented allowing the device to recover if the over load cause has been removed.

■ L6712A - Fixed Maximum Duty Cycle Limitation

The maximum duty cycle is fixed and constant with the delivered current. The device works in constant

current operation once the OCP threshold has overcome. Refer to the above Constant Current section in

which only the different value in the maximum duty has to be considered as follow:

VINVout

I

peakIOCPx

–

------------------------------------- -

min

Ton

L

MAXIOCPx

All the above reported relationships about the deliverable current once in quasi-constant current and constant current are still valid in this case.

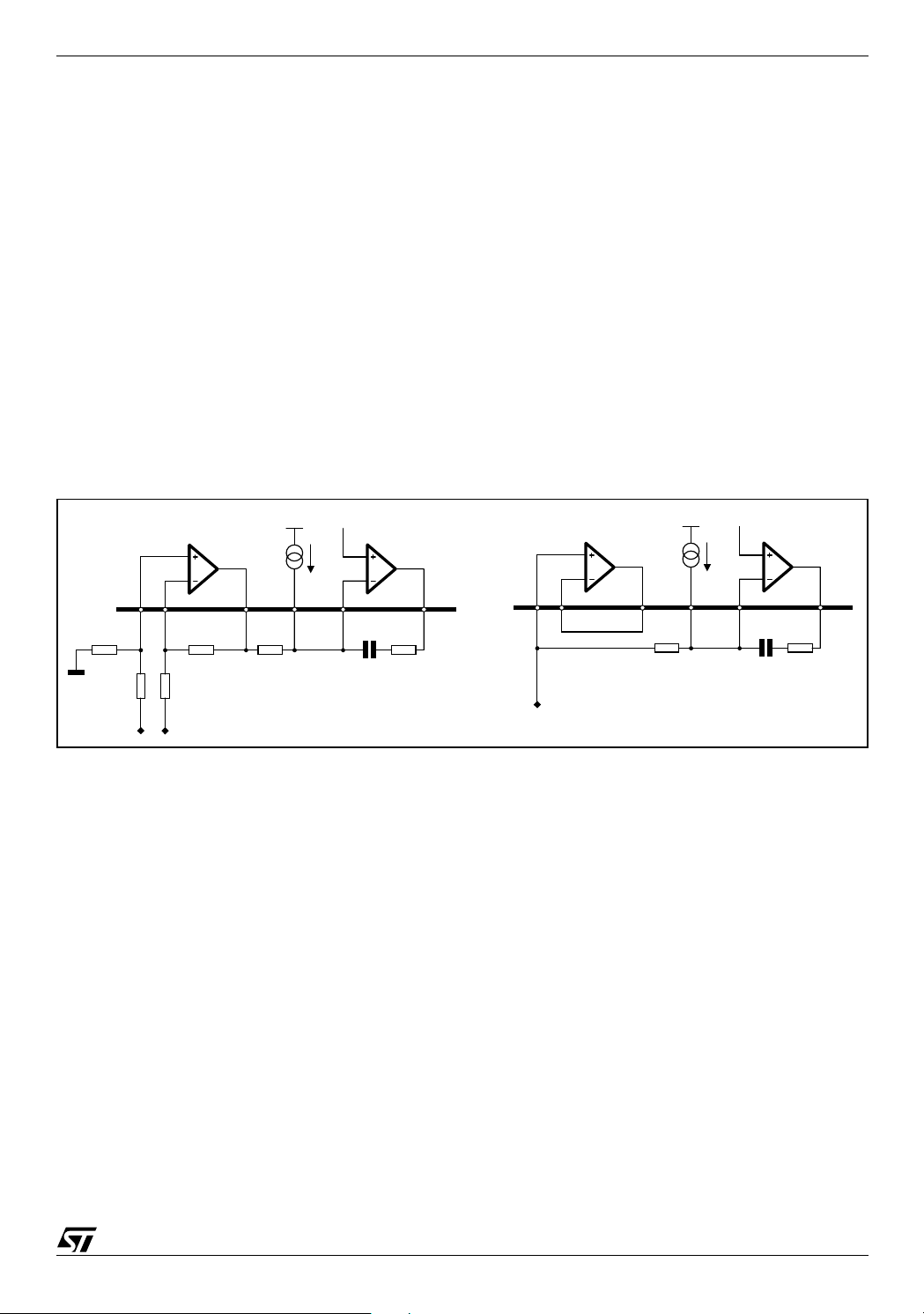

3.5 REMOTE SENSE AMPLIFIER

Remote Sense Amplifier is integrated in order to recover from losses across PCB traces and wiring in high

current DC/DC converter remote sense of the regulated voltage is required to maintain precision in the

regulation. The integrated amplifier is a low-offset error amplifier; external resistors are needed as shown

in Figure 11 to implement a differential remote sense amplifier.

Figure 11. Remote Sense Amplifier Connections

VINVout

–

-------------------------------------- -

MIN

L

0.85 T⋅⋅+=⋅+=

R2

Remote

V

Reference

REMOTE

AMPLIFIER

FBG

FBR

R1

R1

Remote

Ground

OUT

VSEN

R2

RB used RB Not Used

I

DROOP

R

FB

FB

DROOP

ERROR

AMPLIFIER

COMP

R

C

F

F

FBR

V

OUT

FBG

REMOTE

AMPLIFIER

VSEN

R

FB

DROOP

Reference

I

DROOP

FB

ERROR

AMPLIFIER

COMP

R

C

F

F

Equal resistors give to the resulting amplifier a unity gain: the programmed reference will be regulated

across the remote load.

To regulate output voltages different from the available references, the Remote Amplifier gain can be adjusted simply changing the value of the external resistors as follow (see Figure 11):

RA_Gain

----------------------------------------------------------------------------------------=

Remote_V

V

OUT

VSEN

Remote_GND–

R2

------- -=

R1

to regulate a voltage double of the reference, the above reported gain must be equal to ½.

Modifying the Remote Amplifier Gain (in particular with values higher than 1) allows also to regulate voltages lower than the programmed reference.

Since this Amplifier is connected as a differential amplifier, when calculating the offset introduced

in the regulated output voltage, the "native" offset of the amplifier must be multiplied by the term

K

= [1+(1/RA_Gain)] because a voltage generator insisting on the non-inverting input represents

OS

the offset.

If remote sense is not required, it is enough connecting RFB directly to the regulated voltage: VSEN becomes not connected and still senses the output voltage through the remote amplifier. In this case the use

of the external resistors R1 and R2 becomes optional and the Remote Sense Amplifier can simply be connected as a "buffer" to keep VSEN at the regulated voltage (See Figure 11). Avoiding use of Remote Amplifier saves its offset in the accuracy calculation but doesn't allow remote sensing.

15/29

Page 16

L6712A L6712

p

3.6 INTEGRATED DROOP FUNCTION (Optional)

Droop function realizes dependence between the regulated voltage and the delivered current (Load Regulation). In this way, a part of the drop due to the output capacitor ESR in the load transient is recovered.

As shown in Figure 12, the ESR drop is present in any case, but using the droop function the total deviation of the output voltage is minimized.

Connecting DROOP pin and FB pin together, forces a current I

into the feedback resistor R

implementing the load regulation dependence. If RA_Gain is the Remote

FB

Amplifier gain, the Output Characteristic is then given by the following relationship (when droop enabled):

, proportional to the output current,

DROOP

V

OUT

1

------------------------ -

RA_Gain

VID R

⋅–()⋅

FBIDROOP

1

------------------------ -

RA_Gain

⎛⎞

⋅==

VID R

⎝⎠

FB

R

SENSE

--------------------- -

⋅⋅–

Rg

I

OUT

with a remote amplifier gain of 1/2, the regulated output voltage results in being doubled.

The Droop current is equal to 50µA at nominal full load and 70µA at the OC intervention threshold, so the

maximum output voltage deviation is equal to:

1

∆V

FULL POSITIVE– LOAD–

-------------------------

RA_Gain

50µ A ∆V

R⋅

FB

OC INTERVENTION–

Droop function is provided only for positive load; if negative load is applied, and then I

1

-------------------------

RA _Gain

INFOx

70µ A⋅–=⋅–=

R⋅

FB

<0, no current

is sunk from the FB pin. The device regulates at the voltage programmed by the VID.

If this effect is not desired, shorting DROOP pin to SGND, the device regulates as a Voltage Mode Buck

converter.

Figure 12. Load Transient response (Left) and DROOP pin connection (Right).

V

MAX

V

NOM

V

MIN

DROOP PIN = GND

DROOP PIN = FB PIN

ESR DROP

R2

Remote

V

REMOTE

AMPLIFIER

FBG FBR

R1 R1

Remote

Ground

OUT

VSEN

R

FB

Short to GND if DROOP function is not

lemented (Classic Voltage Mode).

im

Reference

I

DROOP

FB COMP

DROOP

R2

C

F

ERROR

AMPLIFIER

R

F

3.7 MONITOR AND PROTECTIONS

The device monitors through pin VSEN the regulated voltage in order to build the PGOOD signal and manage the OVP / UVP conditions.

■ PGOOD. Power good output is forced low if the voltage sensed by VSEN is not within ±12% (Typ.) of

the programmed value (RA_Gain=1). It is an open drain output and it is enabled only after the soft start

is finished (2048 clock cycles after start-up). During Soft-Start this pin is forced low.

■ UVP. If the output voltage monitored by VSEN drops below the 60% of the reference voltage for more

than one clock period, the device turns off all mosfets and resets restarting operations with a new softstart phase (hiccup mode, see Figure 13).

■ OVP. Enabled once VCC crosses the turn-ON threshold: when the voltage monitored by VSEN reaches

115% (min) of the programmed voltage (or the external reference) the controller permanently switches

on both the low-side mosfets and switches off both the high-side mosfets in order to protect the load.

The OSC/ FAULT pin is driven high (5V) and power supply (VCC) turn off and on is required to restart

operations.

Both Over Voltage and Under Voltage are active also during soft start (Under Voltage after than the

16/29

Page 17

L6712A L6712

x

reference voltage reaches 0.6V). The reference used in this case to determine the UV thresholds is the

increasing voltage driven by the 2048 soft start digital counter while the reference used for the OV

threshold is the final reference programmed by the VID pins or available on the REF_IN/OUT pin.

Figure 13. UVP Protection & Hiccup Mode.

CH1=PGOOD; CH2=Vout; CH3=REF_OUT; CH4=Iout

3.8 SOFT START AND INHIBIT

At start-up a ramp is generated increasing the loop reference from 0V to the final value programmed by

VID in 2048 clock periods as shown in Figure 14.

Once the soft start begins, the reference is increased: upper and lower Mosfets begin to switch and the

output voltage starts to increase with closed loop regulation. At the end of the digital soft start, the Power

Good comparator is enabled and the PGOOD signal is then driven high (See Figure 14).

The Under Voltage comparator is enabled when the increasing reference voltage reaches 0.6V while OVP

comparator is always active with a threshold equal to the +15%_min of the final reference.

The Soft-Start will not take place, if both VCC and VCCDR pins are not above their own turn-on thresholds.

During normal operation, if any under-voltage is detected on one of the two supplies the device shuts

down. Forcing the OSC/INH pin to a voltage lower than 0.5V (Typ.) disables the device: all the power mosfets and protections are turned off until the condition is removed.

Figure 14. Soft Start.

VCC=V

CCDR

V

LGATE

V

PGOOD

OUT

Turn ON threshold

t

t

t

2048 Clock Cy cles

Timing Diagram Acquisition:

t

CH1=PGOOD; CH2=VOUT; CH3=REF_OUT

17/29

Page 18

L6712A L6712

3.9 INPUT CAPACITOR

The input capacitor is designed considering mainly the input RMS current that depends on the duty cycle

as reported in Figure 15. Considering the two-phase topology, the input RMS current is highly reduced

comparing with a single-phase operation.

It can be observed that the input RMS value is one half of the single-phase equivalent input current in the

worst case condition that happens for D=0.25 and D=0.75.

The power dissipated by the input capacitance is then equal to:

P

RMS

ESR I

⋅=

()

2

RMS

Input capacitor is designed in order to sustain the ripple relative to the maximum load duty cycle. To reach

the RMS value needed and also to minimize components cost, the input capacitance is realized by more

than one physical capacitor. The equivalent RMS current is simply the sum of the single capacitor's RMS

current.

Input bulk capacitor must be equally divided between high-side drain mosfets and placed as close as possible to reduce switching noise above all during load transient. Ceramic capacitor can also introduce benefits in high frequency noise de coupling, noise generated by parasitic components along power path.

Figure 15. Input RMS Current vs. Duty Cycle (D) and Driving Relationships.

)

OUT

/I

RMS

0.50

0.25

Rms Current Normalized (I

Duty Cycle (V

Single Phase

Dual Phase

0.50 0.75 0.25

OUT/VIN

)

I

rms

⎧

I

OUT

⎪

------------

⎪

=

⎨

I

⎪

------------

⎪

⎩

2

OUT

2

2D 1 2D–()⋅ if D < 0.5⋅

2D 1–()22D–()⋅ if D > 0.5⋅

Where D = V

OUT/VIN

3.10 OUTPUT CAPACITOR

The output capacitor is a basic component for the fast response of the power supply.

Two-phase topology reduces the amount of output capacitance needed because of faster load transient

response (switching frequency is doubled at the load connections). Current ripple cancellation due to the

180° phase shift between the two phases also reduces requirements on the output ESR to sustain a specified voltage ripple.

Moreover, if DROOP function is enabled, bigger ESR can be used still keeping the same transient tolerances. In fact, when a load transient is applied to the converter's output, for first few microseconds the

current to the load is supplied by the output capacitors. The controller recognizes immediately the load

transient and increases the duty cycle, but the current slope is limited by the inductor value.

The output voltage has a first drop due to the current variation inside the capacitor (neglecting the effect

of the ESL):

∆V

OUT

∆I

OUT

ESR⋅=

A minimum capacitor value is required to sustain the current during the load transient without discharge

18/29

Page 19

L6712A L6712

it. The voltage drop due to the output capacitor discharge is given by the following equation:

2

∆V

OUT

--------------------------------------------------------------------------------=

4C

∆I

OUTVIndmaxVOUT

OUT

L⋅

–⋅()⋅⋅

Where D

is the maximum duty cycle value. The lower is the ESR, the lower is the output drop during

MAX

load transient and the lower is the output voltage static ripple.

3.11 INDUCTOR DESIGN

The inductance value is defined by a compromise between the transient response time, the efficiency, the

cost and the size. The inductor has to be calculated to sustain the output and the input voltage variation

to maintain the ripple current ∆I

between 20% and 30% of the maximum output current. The inductance

L

value can be calculated with this relationship:

V

Where F

L

is the switching frequency, VIN is the input voltage and V

SW

fs ∆I

⋅

–

INVOUT

------------------------------

V

OUT

-------------- -

⋅=

V

L

IN

is the output voltage.

OUT

Increasing the value of the inductance reduces the ripple current but, at the same time, reduces the converter response time to a load transient. The response time is the time required by the inductor to change

its current from initial to final value. Since the inductor has not finished its charging time, the output current

is supplied by the output capacitors. Minimizing the response time can minimize the output capacitance

required.

The response time to a load transient is different for the application or the removal of the load: if during

the application of the load the inductor is charged by a voltage equal to the difference between the input

and the output voltage, during the removal it is discharged only by the output voltage. The following expressions give approximate response time for ∆I load transient in case of enough fast compensation network response:

t

application

L ∆I⋅

------------------------------

V

–

INVOUT

t

removal

L ∆I⋅

-------------- -

V

OUT

==

The worst condition depends on the input voltage available and the output voltage selected. Anyway the

worst case is the response time after removal of the load with the minimum output voltage programmed

and the maximum input voltage available.

3.12 MAIN CONTROL LOOP

The system control loop topology depends on the DROOP pin connection: if connected to FB (droop function active) an Average Current Mode topology must be considered while, if connected to GND (droop

function not active) a Voltage Mode topology must be considered instead.

Anyway, the system control loop encloses the Current Sharing control loop to allow proper sharing to the

inductor' currents. Each loop gives, with a proper gain, the correction to the PWMs in order to minimize

the error in its regulation: the Current Sharing control loop equalize the currents in the inductors while the

output voltage control loop fixes the output voltage equal to the reference programmed by VID (with or

without the droop effect and with or without considering the Remote Amplifier Gain). Figure 16 reports the

block diagram of the main control loop.

19/29

Page 20

L6712A L6712

Figure 16. Main Control Loop Diagram

+

+

PWM1

1/5

1/5

PWM2

ERROR

AMPLIFIER

4/5

CURRENT

SHARING

DUTY CYCLE

CORRECTION

REFERENCE

PROGRAMMED

+

-

BY VID

FBCOMP

I

INFO2

I

INFO1

L

1

L

2

C

O

RA_Gain

R

O

D03IN1518

Z

F(S)

R

FB

3.12.1Current Sharing (CS) Control Loop

Active current sharing is implemented using the information from Trans conductance differential amplifier.

A current reference equal to the average of the read current (I

) is internally built; the error between the

AVG

read current and this reference is converted to a voltage with a proper gain and it is used to adjust the duty

cycle whose dominant value is set by the error amplifier at COMP pin (See Figure 17).

The current sharing control is a high bandwidth control loop allowing current sharing even during load transients.

The current sharing error is affected by the choice of external components; choose precise Rg resistor

(±1% is necessary) to sense the current. The current sharing error is internally dominated by the voltage

offset of Trans conductance differential amplifier; considering a voltage offset equal to 2mV across the

sense resistor, the current reading error is given by the following equation:

∆I

READ

--------------------

I

MAX

2mV

--------------------------------------- -=

R

SENSEIMAX

⋅

Figure 17. Current Sharing Control Loop.

L

+

PWM1

1

20/29

COMP

I

1/5

1/5

+

PWM2

CURRENT

SHARING

DUTY CYCLE

CORRECTION

D02IN1393

INFO2

I

INFO1

L

2

V

OUT

Page 21

L6712A L6712

Where ∆I

For R

SENSE

and R

SENSE

is the difference between one phase current and the ideal current (I

READ

= 4mΩ and I

= 40A the current sharing error is equal to 2.5%, neglecting errors due to Rg

MAX

mismatches.

MAX

/2).

3.12.2Average Current Mode (ACM) Control Loop (DROOP=FB)

The average current mode control loop is reported in Figure 18. The current information I

the DROOP pin flows into R

implementing the dependence of the output voltage from the read current.

FB

DROOP

sourced by

The ACM control loop gain results (obtained opening the loop after the COMP pin):

G

LOOP

s()

PWM Z

----------------------------------------------------------------------------------------------------------------------- -–=

Z

P

s() R

F

DROOP

s() ZLs()+()

Z

F

-------------- - 1

As()

RA_Gain Z⋅Ps()+()⋅⋅

s()

1

⎛⎞

----------- -+

⎝⎠

As()

R

⋅+⋅

FB

Where:

Rsense

■ is the equivalent output resistance determined by the droop function;

R

DROOP

■ Z

(s) is the impedance resulting by the parallel of the output capacitor (and its ESR) and the applied

P

----------------------

Rg

⋅=

R

FB

load Ro;

■ Z

(s) is the compensation network impedance;

F

■ Z

(s) is the parallel of the two inductor impedance;

L

■ A(s) is the error amplifier gain;

V

4

IN

-------------------

■ is the ACM PWM transfer function where ∆V

PWM

-- -

⋅=

∆V

5

OSC

is the oscillator ramp amplitude

OSC

and has a typical value of 3V

■ RA_Gain is the Remote Amplifier Gain.

Removing the dependence from the Error Amplifier gain, so assuming this gain high enough, the control

loop gain results:

G

LOOP

s()

⋅⋅ ⋅–=

5

-------------------

∆V

OSC

------------------------------------

Z

V

4

IN

---

Considering now that in the application of interest it can be assumed that R

R

<<Ro, it results:

DROOP

G

LOOP

s()

4

---

5

V

IN

-------------------

∆V

OSC

s()

Z

F

-------------- -

R

FB

-------------------------------------------------------------------------------------------------------------------------------------------

2

s

Co

L

-- - s

2

s()

Z

F

s() ZLs()+

P

1sCo

--------------- Co ESR Co

2Ro⋅

RA_Gain Z⋅

⎛⎞

Rs

-------------------------------------------- -+

------- -

⎜⎟

Rg

⎝⎠

R

DROOP

⎛⎞

------------------------ - ESR+

⋅⋅+

⎝⎠

RA_Gain

R

L

s()

P

FB

>>RL; ESR<<Ro and

o

L

---------------

⋅+⋅+ 1+⋅+⋅⋅

2Ro⋅

RA_Gain⋅⋅⋅ ⋅–=

21/29

Page 22

L6712A L6712

ω

ωZ

ωLC

Figure 18. ACM Control Loop Gain Block Diagram (left) and Bode Diagram (right).

VCOMP

PWM

ZF

COMP

d•VIN

IDROOP

RF CF

L/2

Cout

ESR

FB

DROOP

RFB

RA_Gain

VID

VOUT

Rout

K

dB

G

LOOP

(s)

Z

F

ωT

⎡

V

4

K

IN

⎢

∆V

5

⎣

⎤

1

⋅⋅=

⎥

R

FBOSC

⎦

dB

The ACM control loop gain is designed to obtain a high DC gain to minimize static error and cross the 0dB

axes with a constant -20dB/dec slope with the desired crossover frequency ω

. Neglecting the effect of

T

ZF(s), the transfer function has one zero and two poles. Both the poles are fixed once the output filter is

designed and the zero is fixed by ESR and the Droop resistance.

To obtain the desired shape an R

at ω

=1/RFCF is then introduced together with an integrator. This integrator minimizes the static error

F

series network is considered for the ZF(s) implementation. A zero

F-CF

while placing the zero in correspondence with the L-C resonance a simple -20dB/dec shape of the gain is

assured (See Figure 18). In fact, considering the usual value for the output filter, the LC resonance results

to be at frequency lower than the above reported zero.Compensation network can be simply designed

placing ω

= ωLC and imposing the cross-over frequency ωT as desired obtaining:

Z

L

-- -

Co

⋅

2

------------------- -=⋅⋅ ⋅=

R

F

R

F

RFB∆V

⋅

---------------------------------- -

OSC

V

IN

5

-- -

4

----------------------------------------------------------

ω

T

⎛⎞

2

⋅

⎝⎠

L

R

DROOP

------------------------ - ESR+

RA_Gain

C

F

3.12.3Voltage Mode (VM) Control Loop (DROOP = SGND)

Disconnecting the DROOP pin from the Control Loop, the system topology becomes a Voltage Mode. The

simplest way to compensate this loop still keeping the same compensation network consists in placing the

RF-CF zero in correspondence with the L-C filter resonance.

The loop gain becomes now:

G

LOOP

s()

V

IN

------------------ -

V

∆

OSC

s()

Z

F

-------------- -

R

FB

s()

Z

P

------------------------------------

Z

s() ZLs()+

P

RA_Gain⋅⋅ ⋅–=

3.13 LAYOUT GUIDELINES

Since the device manages control functions and high-current drivers, layout is one of the most important

things to consider when designing such high current applications.

A good layout solution can generate a benefit in lowering power dissipation on the power paths, reducing

radiation and a proper connection between signal and power ground can optimize the performance of the

control loops.

22/29

Page 23

L6712A L6712

Integrated power drivers reduce components count and interconnections between control functions and

drivers, reducing the board space.

Here below are listed the main points to focus on when starting a new layout and rules are suggested for

a correct implementation.

■ Power Connections.

These are the connections where switching and continuous current flows from the input supply towards

the load. The first priority when placing components has to be reserved to this power section, minimizing

the length of each connection as much as possible.

To minimize noise and voltage spikes (EMI and losses) these interconnections must be a part of a power

plane and anyway realized by wide and thick copper traces.

Figure 19. Power connections and related connections layout guidelines (same for both phases).

HGATEx

PHASEx

LGATEx

PGNDx

HS

VIN

R

gate

L

C

LS

R

gate

D

C

IN

OUT

LOAD

PHASEx

SGND

BOOTx

VCC

C

BOOTx

+VCC

HS

VIN

L

C

LS

D

C

IN

C

VCC

OUT

LOAD

a. PCB power and ground planes areas b. PCB small signal components placement

The critical components, i.e. the power transistors, must be located as close as possible, together and to

the controller. Considering that the "electrical" components reported in figure are composed by more than

one "physical" component, a ground plane or "star" grounding connection is suggested to minimize effects

due to multiple connections.

Figure 19a shows the details of the power connections involved and the current loops. The input capacitance (C

), or at least a portion of the total capacitance needed, has to be placed close to the power sec-

IN

tion in order to eliminate the stray inductance generated by the copper traces. Low ESR and ESL

capacitors are required.

■ Power Connections Related.

Figure 19b shows some small signal components placement, and how and where to mix signal and power

ground planes. The distance from drivers and mosfet gates should be reduced as much as possible. Propagation delay times as well as for the voltage spikes generated by the distributed inductance along the

copper traces are so minimized.

In fact, the further the mosfet is from the device, the longer is the interconnecting gate trace and as a consequence, the higher are the voltage spikes corresponding to the gate PWM rising and falling signals.

Even if these spikes are clamped by inherent internal diodes, propagation delays, noise and potential

causes of instabilities are introduced jeopardizing good system behavior. One important consequence is

that the switching losses for the high side mosfet are significantly increased.

For this reason, it is suggested to have the device oriented with the driver side towards the mosfets and

the GATEx and PHASEx traces walking together toward the high side mosfet in order to minimize distance

(see Figure 20). In addition, since the PHASEx pin is the return path for the high side driver, this pin must

be connected directly to the High Side mosfet Source pin to have a proper driving for this mosfet. For the

LS mosfets, the return path is the PGND pin: it can be connected directly to the power ground plane (if

23/29

Page 24

L6712A L6712

(

(

implemented) or in the same way to the LS mosfets Source pin. GATEx and PHASEx connections (and

also PGND when no power ground plane is implemented) must also be designed to handle current peaks

in excess of 2A (30 mils wide is suggested).

Gate resistors of few ohms help in reducing the power dissipated by the IC without compromising the system efficiency.

The placement of other components is also important:

– The bootstrap capacitor must be placed as close as possible to the BOOTx and PHASEx pins to min-

imize the loop that is created.

– Decoupling capacitor from VCC and SGND placed as close as possible to the involved pins.

– Decoupling capacitor from VCCDR and PGND placed as close as possible to those pins. This capac-

itor sustains the peak currents requested by the low-side mosfet drivers.

– Refer to SGND all the sensible components such as frequency set-up resistor (when present) and

Remote Amplifier Divider.

– Connect SGND to PGND plane on a single point to improve noise immunity. Connect at the load side

(output capacitor) if Remote Sense is not implemented to avoid undesirable load regulation effect.

– An additional 100nF ceramic capacitor is suggested to place near HS mosfet drain. This helps in re-

ducing noise.

– PHASE pin spikes. Since the HS mosfet switches in hard mode, heavy voltage spikes can be ob-

served on the PHASE pins. If these voltage spikes overcome the max breakdown voltage of the pin,

the device can absorb energy and it can cause damages. The voltage spikes must be limited by prop-

er layout, the use of gate resistors, Schottky diodes in parallel to the low side mosfets and/or snubber

network on the low side mosfets, to a value lower than 26V, for 20ns, at F

– Boot Capacitor Extra Charge. Systems that do not use Schottky diodes in parallel to the LS mosfet

might show big negative spikes on the phase pin. This spike can be limited as well as the positive

spike but has an additional consequence: it causes the bootstrap capacitor to be over-charged. This

extra-charge can cause, in the worst case condition of maximum input voltage and during particular

transients, that boot-to-phase voltage overcomes the abs. max. ratings also causing device failures.

It is then suggested in this cases to limit this extra-charge by:

– adding a small resistor in series to the boot diode (one resistor can be enough for all the diodes if

placed upstream the diode anode)

– using low capacitance diodes.

of 600kHz max.

SW

Figure 20. Device orientation (left) and sense nets routing (right).

To LS mosfet

or sense resistor)

To LS mosfet

or sense resistor)

To regula ted out put

ST L6917

■ Sense Connections.

Towards HS mosfet

(30 mils wide)

Towards LS mosfet

(30 mils wide)

Towards HS mosfet

(30 mils wide)

Remote Amplifier: Place the external resistors near the device to minimize noise injection and refer to

SGND. The connections for these resistors (from the remote load) must be routed as parallel nets in order

to compensate losses along the output power traces and also to avoid the pick-up of any noise. Connecting these pins in points far from the load will cause a non-optimum load regulation, increasing output tol-

24/29

Page 25

L6712A L6712

erance.

Current Reading: The Rg resistor has to be placed as close as possible to the ISENx and PGNDSx pins

in order to limit the noise injection into the device. The PCB traces connecting these resistors to the reading point must be routed as parallel traces in order to avoid the pick-up of any noise. It's also important to

avoid any offset in the measurement and to get a better precision, to connect the traces as close as possible to the sensing elements, dedicated current sense resistor or low side mosfet R

Moreover, when using the low side mosfet R

as current sense element, the ISENx pin is practically

dsON

connected to the PHASEx pin. DO NOT CONNECT THE PINS TOGETHER AND THEN TO THE HS

SOURCE! The device won't work properly because of the noise generated by the return of the high side

driver. In this case route two separate nets: connect the PHASEx pin to the HS Source (route together

with HGATEx) with a wide net (30 mils) and the ISENx pin to the LS Drain (route together with PGNDSx).

Moreover, the PGNDSx pin is always connected, through the Rg resistor, to the PGND: DO NOT CONNECT DIRECTLY TO THE PGND! In this case the device won't work properly. Route anyway to the LS

mosfet source (together with ISENx net).

Right and wrong connections are reported in Figure 21.

Symmetrical layout is also suggested to avoid any unbalance between the two phases of the converter.

Figure 21. PCB layout connections for sense nets.

NOT CORRECT CORRECT

VIA to GND plane

To PHASE

connection

.

dsON

To LS Drain

and Source

To HS Gate

and Source

Wrong (left) and correct (right) connections for the current reading sensing nets.

25/29

Page 26

L6712A L6712

4 Package informations

Figure 22. SO-28 Mechanical Data & Package Dimensions

DIM.

A 2.65 0.104

a1 0.1 0.3 0.004 0.012

b 0.35 0.49 0.014 0.019

b1 0.23 0.32 0.009 0.013

C 0.5 0.020

c1 45° (typ.)

D 17.7 18.1 0.697 0.713

E 10 10.65 0.394 0.419

e 1.27 0.050

e3 16.51 0.65

F 7.4 7.6 0.291 0.299

L 0.4 1.27 0.016 0.050

S8

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

(max.)

°

OUTLINE AND

MECHANICAL DATA

SO-28

26/29

Page 27

Figure 23. VFQFPN-36 Mechanical Data & Package Dimensions

L6712A L6712

mm inch

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 0.800 0.900 1.000 0.031 0.035 0.039

A1 0.020 0.050 0.0008 0.0019

A2 0.650 1.000 0.025 0.039

A3 0.250 0.01

b 0.180 0.230 0.300 0.007 0.009 0.012

D 5.875 6.000 6.125 0.231 0.236 0.241

D2 1.750 3.700 4.250 0.069 0.146 0.167

E 5.875 6.000 6.125 0.231 0.236 0.241

E2 1.750 3.700 4.250 0.069 0.146 0.167

e 0.450 0.500 0.550 0.018 0.020 0.022

L 0.350 0.550 0.750 0.014 0.022 0.029

ddd 0.080 0.003

OUTLINE AND

MECHANICAL DATA

VFQFPN-36 (6x6x1.0mm)

Very Fine Quad Flat Package No lead

7185332 F

27/29

Page 28

L6712A L6712

5 Revision History

Table 7. Revision History

Date Revision Description of Changes

March 2004 2 First Issue in EDOCS.

June 2005 3 Changed look and feel.

Inserted “Boot Capacitor Extra Charge” paragraph to page 27.

28/29

Page 29

L6712A L6712

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2005 STMicroelectronics - All rights reserved