Enhanced high voltage resonant controller

3/.

Features

■ Symmetrical duty cycle, variable frequency

control of resonant half bridge

■ Self-adjusting adaptive deadtime

■ High-accuracy oscillator

■ 2-level OCP: frequency-shift and immediate

shutdown

■ Interface with PFC controller

■ Anti-capacitive-mode protection

■ Burst-mode operation at light load

■ Input for brownout protection or power-on/off

sequencing

■ “Safe-start” procedure prevents hard switching

at startup

■ 600 V rail compatible high-side gate driver with

integrated bootstrap diode and high dv/dt

immunity

■ -300/800 mA high-side and low-side gate

drivers with UVLO pull-down

■ SO16N package

L6699

Datasheet − production data

Applications

■ SMPS for LCD TVs, desktop and AIO PCs,

servers, Telecom power

■ AC-DC adapter, open frame SMPS

Table 1. Device summary

Order codes Package Packing

L6699D

SO16N

L6699DTR Tape and reel

Tube

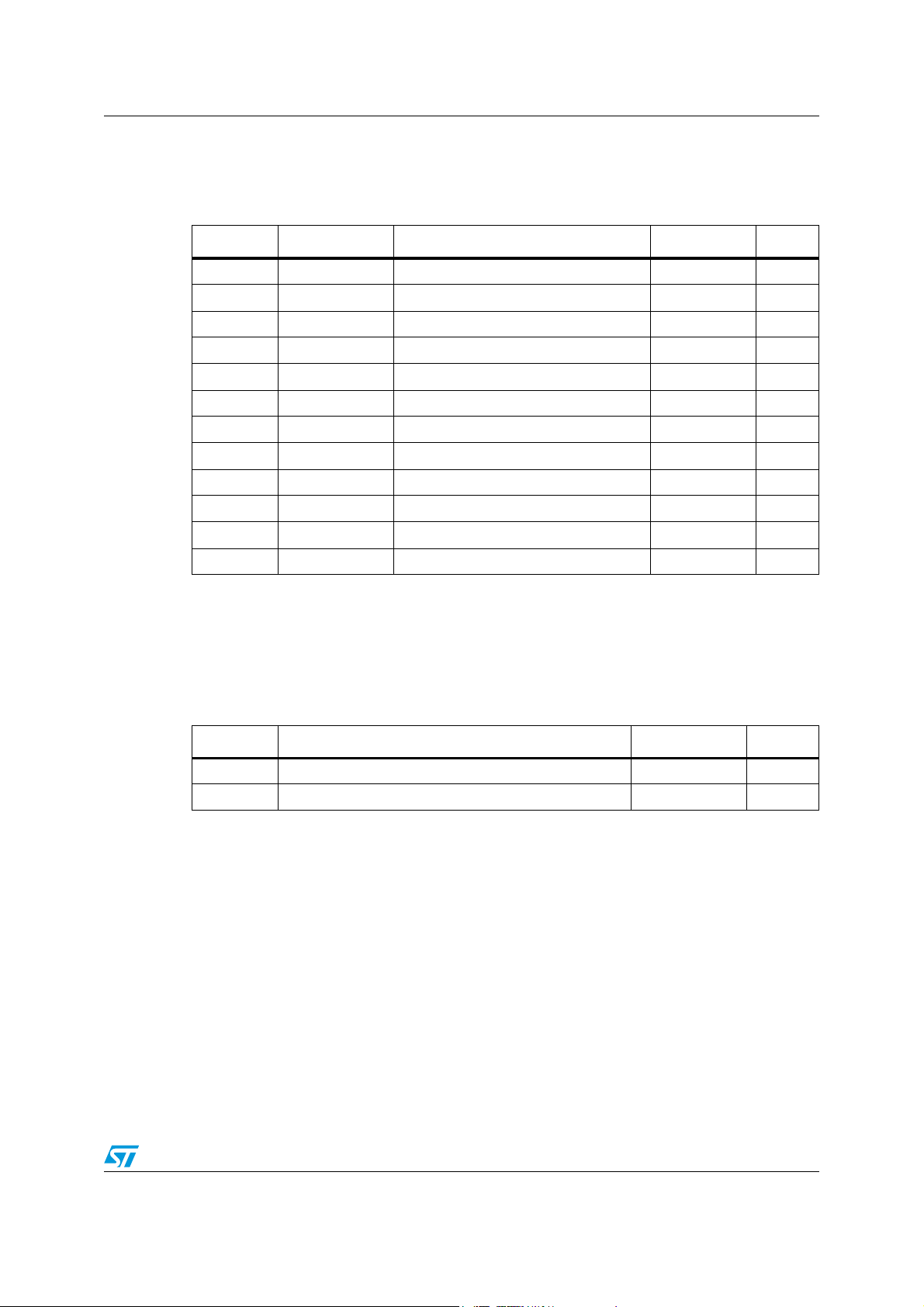

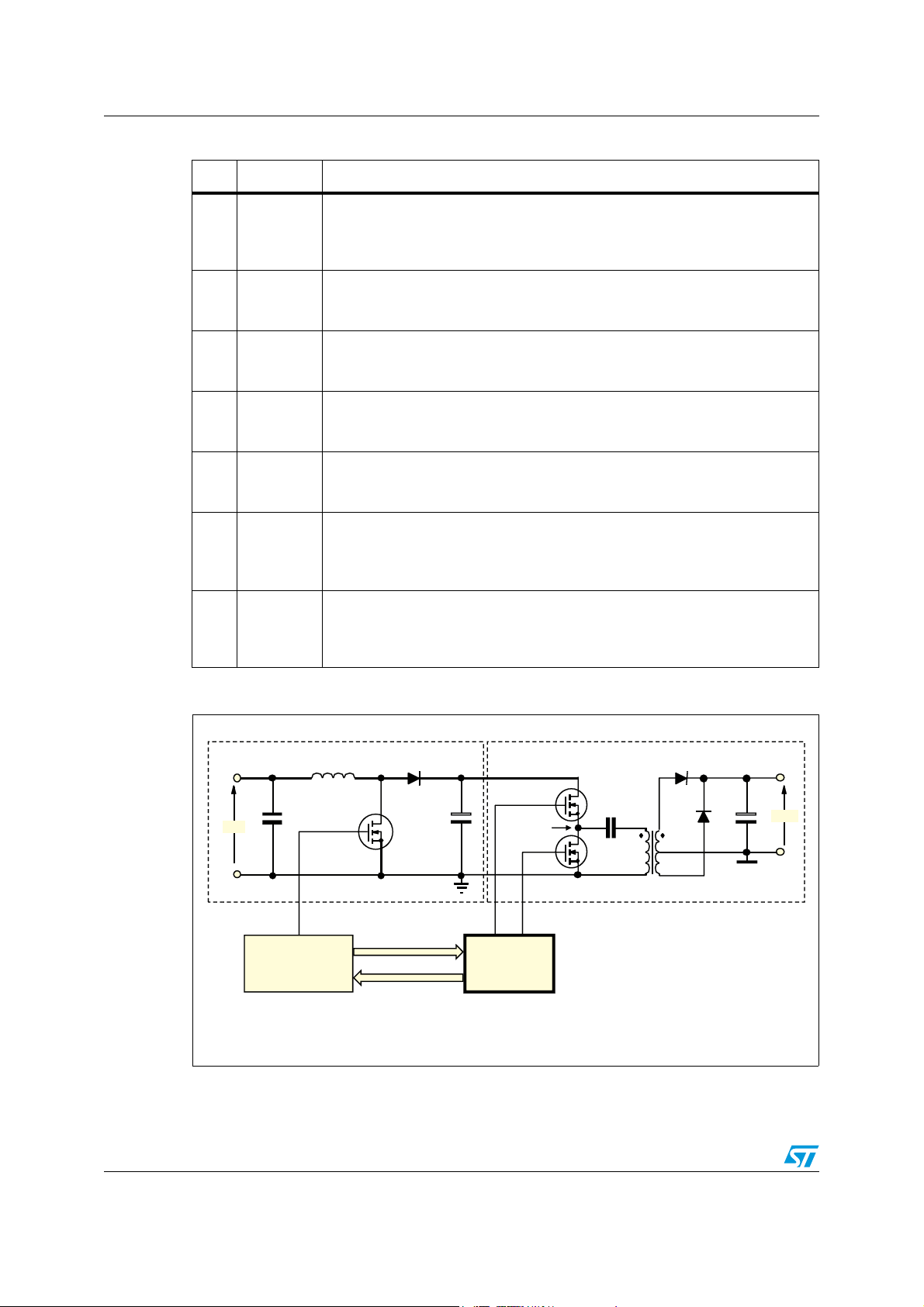

Figure 1. Block diagram

9FF

',

67%<

5)PLQ

&VV

&)

',6$%/(

6

64

9

9

,IPLQ

5

89/2

67$1'%<

9

9&2

',6

&21752/

&$3$&,7,9(

'(7(&7,21

67$57 83

/2*

02'(

6$)(

9

,&

'(/$<

89

'(7(&7,21

89/2

,6(1B',6

=(52&5266,1*'(7(&7,21

2&3

/,1(B2.

9

9

$

%22

('*(

6(16,1*

'5,9,1 *

/2*,&

$'$37,9(

'($'7,0(

46

/,1(

6<1&+5

7675 $3 ' ,2 '(

:, 7+

5

21286

89/2

'5,9(5

6+,)7(5

/9*

,6(1B',6

67$1'%<

+9*

/(9(/

'5,9(5

',6

9FF

9

9

April 2012 Doc ID 022835 Rev 1 1/38

This is information on a product in full production.

9

%227

+9*

287

/9*

*1'

,6(1

3)&B6723

+9

&

%227

/&7$1.

&,5&8, 7

!-V

www.st.com

38

Contents L6699

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Electrical ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Pin connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.1 Oscillator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.2 Adaptive deadtime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.3 Safe-start procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7 Operation at no load or very light load . . . . . . . . . . . . . . . . . . . . . . . . . 21

8 Current sensing, OCP and OLP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9 Capacitive-mode detection function . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10 Line sensing function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

11 Latched shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

12 Bootstrap section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

13 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

14 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2/38 Doc ID 022835 Rev 1

L6699 List of figures

List of figures

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Pin connections (top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Typical system block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. Multimode operation of the L6699 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 5. Oscillator's internal block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 6. Oscillator waveforms and their relationship with gate-driving signals. . . . . . . . . . . . . . . . . 14

Figure 7. Adaptive deadtime: principle schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 8. Relevant timing diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 9. Detailed view of deadtime during low-to-high transition of half bridge midpoint . . . . . . . . . 16

Figure 10. Comparison startup behavior: traditional controller (left), with L6699 (right) . . . . . . . . . . . 18

Figure 11. Comparison of initial cycles after startup: traditional controller (left), with L6699 (right). . . 19

Figure 12. Soft-start circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 13. Input impedance vs. frequency curve in an LLC resonant half bridge . . . . . . . . . . . . . . . . 20

Figure 14. Narrow input voltage range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 15. Wide input voltage range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 16. Load-dependent operating modes: timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 17. How the L6699 can switch off a PFC controller at light load . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 18. Current sensing techniques with sense resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 19. Current sensing techniques “lossless”, with capacitive shunt. . . . . . . . . . . . . . . . . . . . . . . 24

Figure 20. Soft-start and delayed shutdown upon overcurrent timing diagram

(safe-start details are not shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 21. Details of hard-switching transition during capacitive-mode operation. . . . . . . . . . . . . . . . 28

Figure 22. Line sensing function: internal block diagram and timing diagram . . . . . . . . . . . . . . . . . . . 31

Figure 23. Bootstrap supply: standard circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 24. Bootstrap supply: internal bootstrap synchronous diode . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 25. SO16N dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 26. Package drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 27. Recommended footprint (dimensions are in mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Doc ID 022835 Rev 1 3/38

Description L6699

1 Description

The L6699 is a double-ended controller specific to series-resonant half bridge topology.

Both LLC and LCC configurations are supported. It provides symmetrical complementary

duty cycle: the high-side switch and the low-side switch are driven ON/OFF 180° out-of-

phase for exactly the same time. Output voltage regulation is obtained by modulating the

operating frequency. The deadtime inserted between the turn-off of one switch and the turn-

on of the other one is automatically adjusted to best fit the transition times of the half bridge

midpoint. To drive the high-side switch with the bootstrap approach, the IC incorporates a

high voltage floating structure able to withstand more than 600 V with a synchronous-driven

high voltage DMOS that replaces the external fast-recovery bootstrap diode.

The IC enables the user to set the operating frequency range of the converter by means of a

high-accuracy externally programmable oscillator.

At startup, in addition to the traditional frequency-shift soft-start (the switching frequency

starts from a preset maximum value and then decays as far as the steady-state value

determined by the control loop), a proprietary circuit controls the half bridge to prevent hard-

switching from occurring in the initial cycles because of the unbalance in the V·s applied to

the transformer.

At light load the IC can be forced to enter a controlled burst-mode operation that keeps the

converter input consumption as low as possible.

IC protection functions include a current sense input for OCP with frequency shift and

delayed shutdown with automatic restart. Fast shutdown with automatic restart occurs if this

first-level protection cannot control the primary current. Additionally, the IC prevents the

converter from working in or too close to the capacitive mode, to guarantee soft-switching. A

latched disable input (DIS) can be used to implement OTP and/or OVP. The combination of

these protection features offers the highest degree of safety.

Other functions include a not-latched active-low disable input with current hysteresis, useful

for power sequencing or for brownout protection, and an interface with the PFC controller

that enables the switching-off of the pre-regulator during fault conditions or during burst-

mode operation.

4/38 Doc ID 022835 Rev 1

L6699 Electrical ratings

2 Electrical ratings

Table 2. Absolute maximum ratings

Symbol Pin Parameter Value Unit

V

BOOT

V

OUT

dV

OUT

V

CC

V

PFC_STOP

I

PFC_STOP

V

LINEmax

I

RFmin

V

ISEN

/dt 14 Floating ground max. slew rate 50 V/ns

16 Floating supply voltage (I

14 Floating ground voltage -3 to V

12 IC supply voltage (Icc ≤ 25 mA) Self-limited V

9 Maximum voltage (pin open) -0.3 to V

9 Maximum sink current (pin low) Self-limited A

7 Maximum pin voltage (Ipin ≤ 1 mA) Self-limited V

4 Maximum source current 2 mA

6 Current sense voltage -3 to 5 V

--- 1 to 5, 8 Analog inputs & outputs voltage -0.3 to 5 V

T

j

T

stg

--- Junction temperature operating range -40 to 150 °C

--- Storage temperature -55 to 150 °C

3 Thermal data

Table 3. Thermal data

≤ 5µA) -1 to 618 V

leak

BOOT

CC

V

V

Symbol Parameter Value Unit

R

th j-amb

P

tot

Max. thermal resistance, junction-to-ambient (SO16N) 120 °C/W

Power dissipation @tamb = 50 °C (SO16N) 0.83 W

Doc ID 022835 Rev 1 5/38

Pin connections L6699

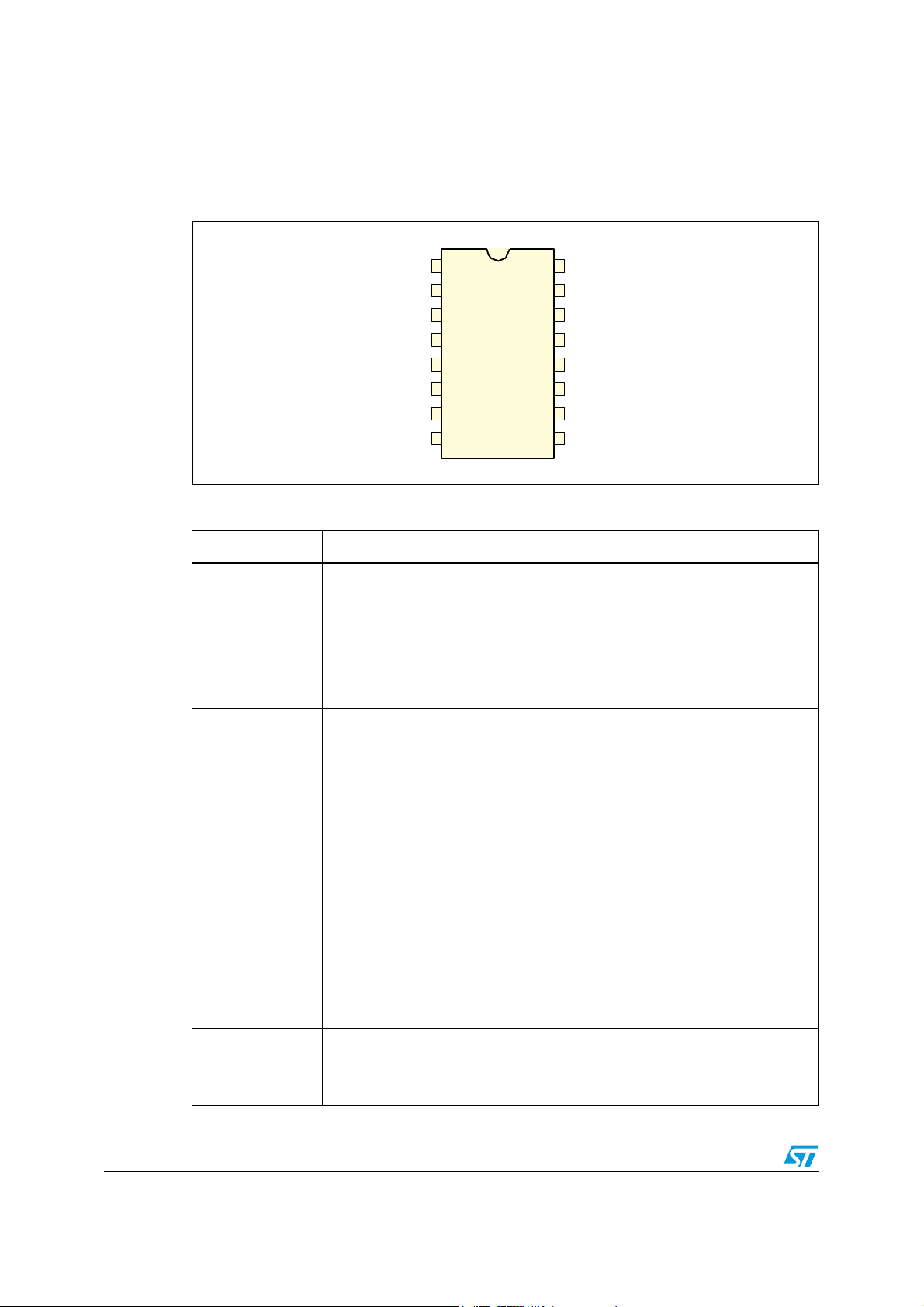

4 Pin connections

Figure 2. Pin connections (top view)

&VV

'(/$<

&)

5)PLQ

67%<

,6(1

/,1(

',6

Table 4. Pin functions

N. Name Function

Soft-start. This pin connects an external capacitor to GND and a resistor to

(pin 4) that set both the initial oscillator frequency and the time constant

RF

min

for the frequency shift that occurs as the chip starts up (soft-start). An internal

1

2DELAY

C

SS

switch discharges this capacitor every time the chip turns off (VCC < UVLO,

LINE < 1.25 V, DIS > 1.85 V, ISEN > 1.5 V, DELAY > 2 V) to make sure it is softstarted next. Additionally the switch is activated when the voltage on the current

sense pin (ISEN) exceeds 0.8 V or when the converter is working too close to,

or in, the capacitive-mode operation.

Delayed shutdown upon overcurrent. A capacitor and a resistor are connected

from this pin to GND to set both the maximum duration of an overcurrent

condition before the IC stops switching and the delay after which the IC restarts

switching. Every time the voltage on the ISEN pin exceeds 0.8 V the capacitor

is charged by 350 µA current pulses and is slowly discharged by the external

resistor. If the voltage on the DELAY pin reaches 2 V, the soft-start capacitor is

completely discharged so that the switching frequency is pushed to its

maximum value and the 350 µA current source is kept always on. As the

voltage on the DELAY pin exceeds 3.5 V the IC stops switching and the internal

generator is turned off, so that the voltage on the pin decays because of the

external resistor. The IC is soft-restarted as the voltage drops below 0.3 V. In

this way, under short-circuit conditions, the converter works intermittently with

very low input average power.

If the voltage on the ISEN pin exceeds 1.5 V, the L6699 is immediately stopped

and the 350 µA current source is kept on until the voltage on the DELAY pin

reaches 3.5 V. Then, the generator is turned off and the voltage on the pin

decays because of the external resistor. Also in this case the IC is soft-restarted

as the voltage drops below 0.3 V.

9%227

+9*

287

1&

9FF

/9*

*1'

3)&B6723

!-V

Timing capacitor. A capacitor connected from this pin to GND is charged and

3CF

6/38 Doc ID 022835 Rev 1

discharged by internal current generators programmed by the external network

connected to pin 4 (RF

converter.

) and determines the switching frequency of the

min

L6699 Pin connections

Table 4. Pin functions (continued)

N. Name Function

Minimum oscillator frequency setting. This pin provides an accurate 2 V

reference, and a resistor connected from this pin to GND defines a current that

is used to set the minimum oscillator frequency. To close the feedback loop that

regulates the converter output voltage by modulating the oscillator frequency,

4RF

min

5STBY

6 ISEN

the phototransistor of an optocoupler is connected to this pin through a resistor.

The value of this resistor sets the maximum operating frequency. Initial

operating frequency should be set below 300 kHz; it is recommended not to

exceed such limit. An R-C series connected from this pin to GND sets

frequency shift at startup to prevent excessive energy inrush (soft-start).

Burst-mode operation threshold. The pin senses some voltage related to the

feedback control, which is compared to an internal reference (1.26 V). If the

voltage on the pin is lower than the reference, the IC enters an idle state and its

quiescent current is reduced. The chip restarts switching as the voltage

exceeds the reference by 30 mV. Soft-start is not invoked. This function realizes

burst-mode operation when the load falls below a level that can be programmed

by properly choosing the resistor connecting the optocoupler to the RF

Figure 1: Block diagram

(see

). Tie the pin to RF

if burst-mode is not used.

min

min

pin

Current sense input. The pin senses the instantaneous primary current though

a sense resistor or a capacitive divider for lossless sensing. If the voltage

exceeds a 0.8 V threshold the soft-start capacitor connected to pin 1 is

internally discharged: the frequency increases and so limits the power

throughput. Under output short-circuit, this normally results in a nearly constant

peak primary current. This condition is allowed for a maximum time set at pin 2.

If the current keeps on building up despite this frequency increase, a second

comparator referenced to 1.5 V disables switching immediately and activates a

restart delay procedure (see DELAY pin description for more information).

This pin is used also for capacitive-mode operation detection and for hardswitching prevention at startup. Do not short the pin to ground; this would

prevent the device from operating correctly.

Line sensing input. The pin is to be connected to the high voltage input bus with

a resistor divider to perform either AC or DC (in systems with PFC) brownout

protection. A voltage below 1.25 V shuts down the IC, lowers its consumption

and discharges the soft-start capacitor. IC operation is enabled as the voltage

7LINE

exceeds 1.25 V. The comparator is provided with current hysteresis: an internal

13 µA current generator is ON as long as the voltage applied at the pin is below

1.25 V, and is OFF if this value is exceeded. Bypass the pin with a capacitor to

GND to reduce noise pick-up. The voltage on the pin is top-limited by an

internal Zener. Tie the pin to V

Latched device shutdown. Internally, the pin connects a comparator that, when

the voltage on the pin exceeds 1.85 V, shuts the IC down and brings its

8DIS

consumption almost to a “before startup” level. The information is latched and it

is necessary to recycle the supply voltage of the IC to enable it to restart: the

latch is removed as the voltage on the V

Tie the pin to GND if the function is not used.

Open-drain ON/OFF control of PFC controller. This pin, normally open, is

intended for stopping the PFC controller, for protection purposes or during

burst-mode operation. It goes low when the IC is shut down by DIS > 1.85 V,

9PFC_STOP

ISEN > 1.5 V and STBY < 1.25 V. The pin is pulled low also when capacitive

mode operation is detected and when the voltage on the DELAY pin exceeds 2

V. In this latter case it goes back open as the voltage falls below 0.3 V. During

UVLO, it is open. Leave the pin unconnected if not used.

with a =100 kΩ resistor if not used.

CC

pin goes below the UVLO threshold.

CC

Doc ID 022835 Rev 1 7/38

Pin connections L6699

Table 4. Pin functions (continued)

N. Name Function

Chip ground. Current return for both the low-side gate-drive current and the

10 GND

11 LVG

12 V

CC

13 N.C.

14 OUT

15 HVG

16 V

BOOT

bias current of the IC. All of the ground connections of the bias components

should be tied to a track going to this pin and kept separate from any pulsed

current return.

Low-side gate-drive output. The driver is capable of 0.3 A min. source and 0.8 A

min. sink peak current to drive the lower MOSFET of the half bridge leg. The pin

is actively pulled to GND during UVLO.

Supply voltage of both the signal part of the IC and the low-side gate driver.

Sometimes a small bypass capacitor (0.1 µF typ.) to GND may be useful to

obtain a clean bias voltage for the signal part of the IC.

High voltage spacer. The pin is not internally connected to isolate the high

voltage pin and ease compliance with safety regulations (creepage distance) on

the PCB.

High-side gate-drive floating ground. Current return for the high-side gate-drive

current. Lay out the connection of this pin carefully to avoid too large spikes

below ground.

High-side floating gate-drive output. The driver is capable of 0.3 A min. source

and 0.8 A min. sink peak current to drive the upper MOSFET of the half bridge

leg. A resistor internally connected to pin 14 (OUT) ensures that the pin is not

floating during UVLO.

High-side gate-drive floating supply voltage. The bootstrap capacitor connected

between this pin and pin 14 (OUT) is fed by an internal synchronous bootstrap

diode driven in-phase with the low-side gate-drive. This patented structure

replaces the normally used external diode.

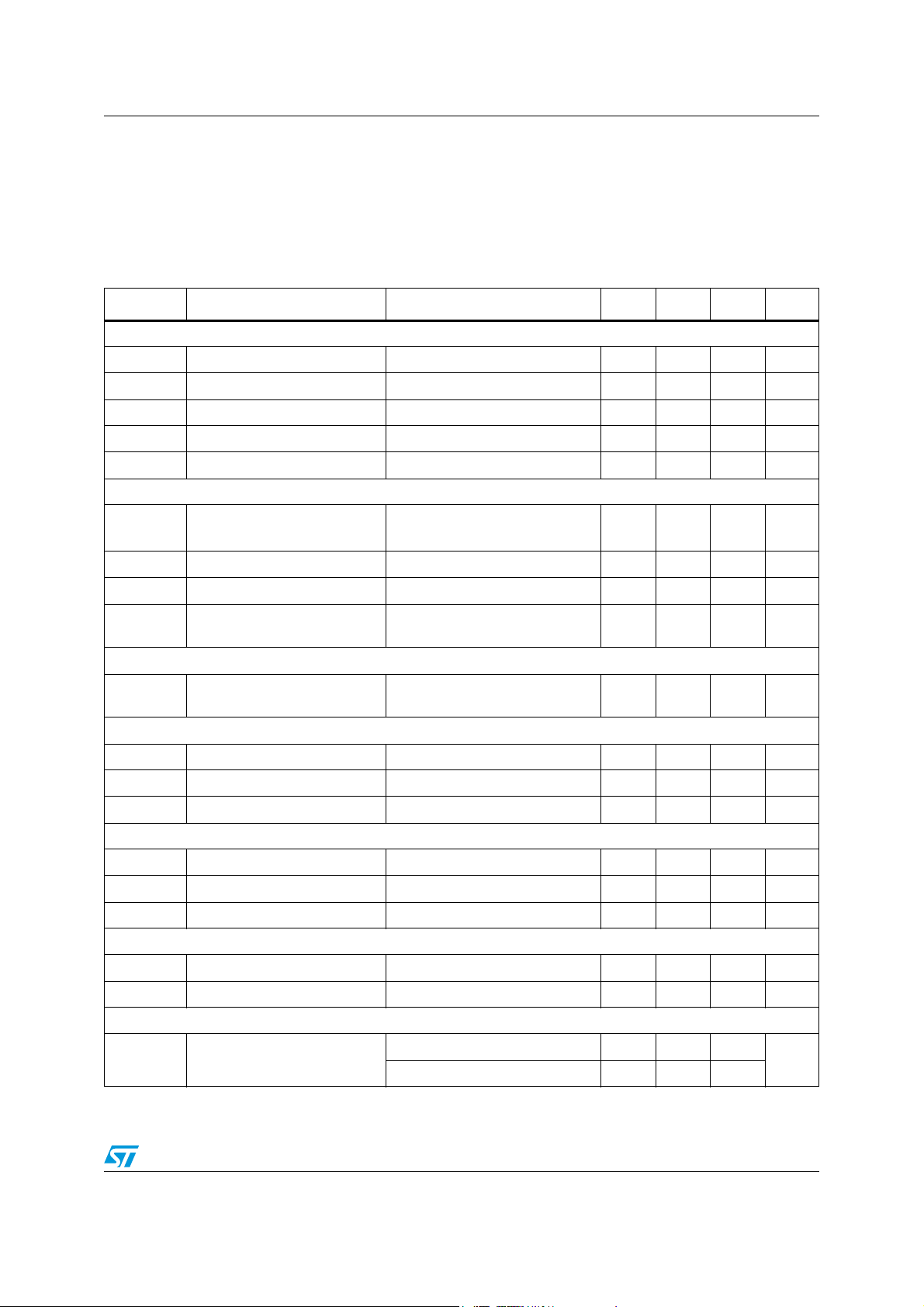

Figure 3. Typical system block diagram

0%2%'5,!4/2/04)/.!, 2%3/.!.4(!,&"2)$' %

INAC

6

, !,

, ,

2ES ON A N T ( "I S T UR N E D O FF I NC A S EO F

0&#gSANO MALOUSOPERATIONFORSAFETY

3(

4(

,

0&#CANBETURNEDOFFATLIGHT

L O AD TO EAS EC O MPLIAN C EW I T H

ENER GYSAVINGREGULATIONS

(!,&"2)$'%

-)$0/).4

,

TDC

OU

6

!-V

8/38 Doc ID 022835 Rev 1

L6699 Electrical data

5 Electrical data

Tj = -25 to +125 °C, VCC = 15 V, V

= 12 KΩ; unless otherwise specified.

RF

min

BOOT

= 15 V, C

HVG

= C

= 1 nF; CF = 470 pF;

LVG

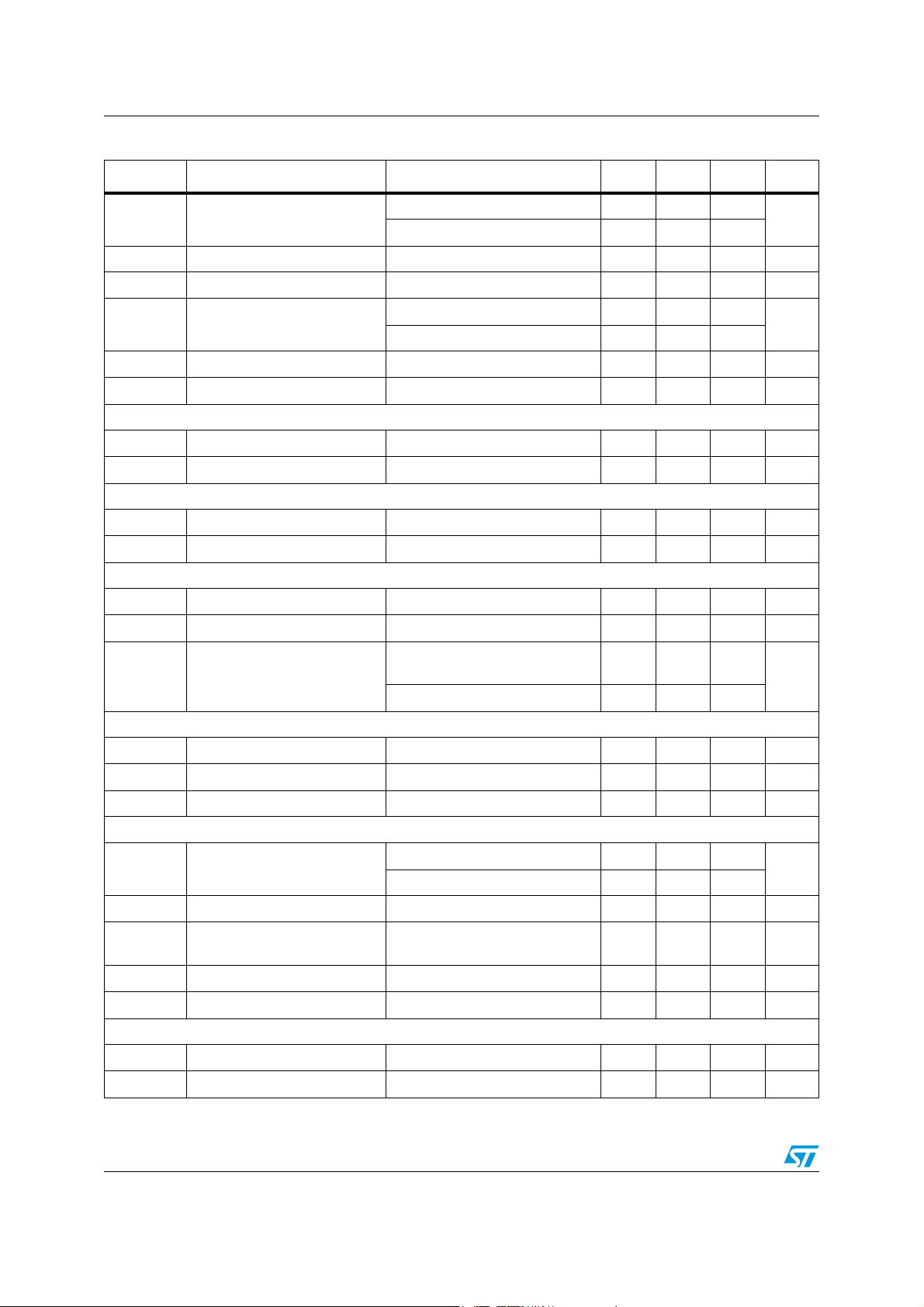

Table 5. Electrical characteristics

Symbol Parameter Test condition Min. Typ. Max. Unit

Ic supply voltage

V

CC

V

CCOn

V

CCOff

Hys Hysteresis 2.55 V

V

Supply current

I

start-up

I

q

I

op

I

q

High-side floating gate-drive supply

R

DS(on)

Operating range After device turn-on 8.85 16 V

Turn-on threshold Voltage rising 10 10.7 11.4 V

Turn-off threshold Voltage falling 7.45 8.15 8.85 V

VCC clamp voltage Iclamp = 15 mA 16 17 17.9 V

Z

Startup current

Quiescent current Device on, V

Operating current Device on, V

Residual consumption

Synchronous bootstrap diode

ON-resistance

Before device turn-on

VCC = V

>1.92 V or V

V

DIS

<1.2 V

V

LINE

= high 150

V

LVG

CCOn

- 0.2 V

= 1 V 1 1.3 mA

STBY

= V

STBY

DELAY

RFmin

>3.65 V or

250 300 µA

34.1mA

400 500 µA

Overcurrent comparator

I

ISEN

V

ISENx

V

ISENdis

Input bias current V

Frequency shift threshold Voltage rising

Immediate stop threshold Voltage rising

Line sensing

V

V

LINE

I

Hys

clamp

Threshold voltage Voltage rising or falling

Current hysteresis V

Clamp level I

Latched disable function

V

I

DIS

DIS

Input bias current V

Disable threshold Voltage rising

Oscillator

f

osc

Oscillation frequency

= 0 to V

ISEN

= 1.2 V 101316µA

LINE

= 1 mA 6 V

LINE

= 0 to 1.92 V -1 µA

DIS

ISENdis

(1)

(1)

(1)

(1)

0.76 0.80 0.84 V

1.43 1.5 1.55 V

1.18 1.22 1.26 V

1.78 1.85 1.92 V

-1 µA

58.2 60 61.8

kHz

R

= 2.7 kΩ 225 235 245

RFmin

Doc ID 022835 Rev 1 9/38

Electrical data L6699

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

T

V

V

V

RF

D

CFp

CFv

REF

K

Deadtime self-adjustment

(2)

range

Peak value 3.9 V

Valley value 0.9 V

Voltage reference on pin 4

Current mirroring ratio 1 A/A

M

Timing resistor range 1 100 kΩ

min

Minimum value 0.23

Maximum

(1)

I

REF

value 0.7

= -2 mA

(1)

1.93 2 2.07

1.8 2 2.07

Zero-current comparator

V

ZCD neg

V

ZCD pos

Threshold voltage (-) -10 mV

Threshold voltage (+) +10 mV

Pfc_stop function

I

leak

R

PFC_STOP

High level leakage current V

ON-state resistance I

PFC_STOP

PFC_STOP

= VCC, V

= 1 mA, V

= 0 V 1 µA

DIS

> 1.92 V 130 200 Ω

DIS

Soft-start function

I

leak

Open-state current V(CSS) = 2 V 0.5 µA

R Discharge resistance 120 Ω

V

T

DISCH

CSS discharge duration

> V

ISEN

capacitive-mode

or approaching

ISENx

5

Capacitive-mode detected 50

Standby function

µs

V

µs

I

STBY

V

STBY

Input bias current V

Disable threshold Voltage falling

= 0 to 1.3 V -1 µA

STBY

(1)

1.22 1.26 1.3 V

Hys Hysteresis Voltage rising 30 mV

Delayed shutdown function

V

= 1 V 1

I

leak

I

CHARGE

Vth

1

Vth

2

Vth

3

Open-state current

Charge current V

Threshold for forced operation

at max. frequency

Shutdown threshold Voltage rising

Restart threshold Voltage falling

DELAY

= 1 V, after shutdown -0.1 -0.5

V

DELAY

= 2.5 V, V

DELAY

Voltage rising

(1)

(1)

(1)

= 0.85 V 250 350 450 µA

ISEN

1.92 2.0 2.08 V

3.35 3.5 3.65 V

0.27 0.3 0.33 V

Low-side gate driver (voltages referred to GND)

V

V

LVG L

LVG H

Output low voltage I

Output high voltage I

= 200 mA 1.5 V

sink

= 5 mA 12.8 13.3 V

source

10/38 Doc ID 022835 Rev 1

µA

L6699 Electrical data

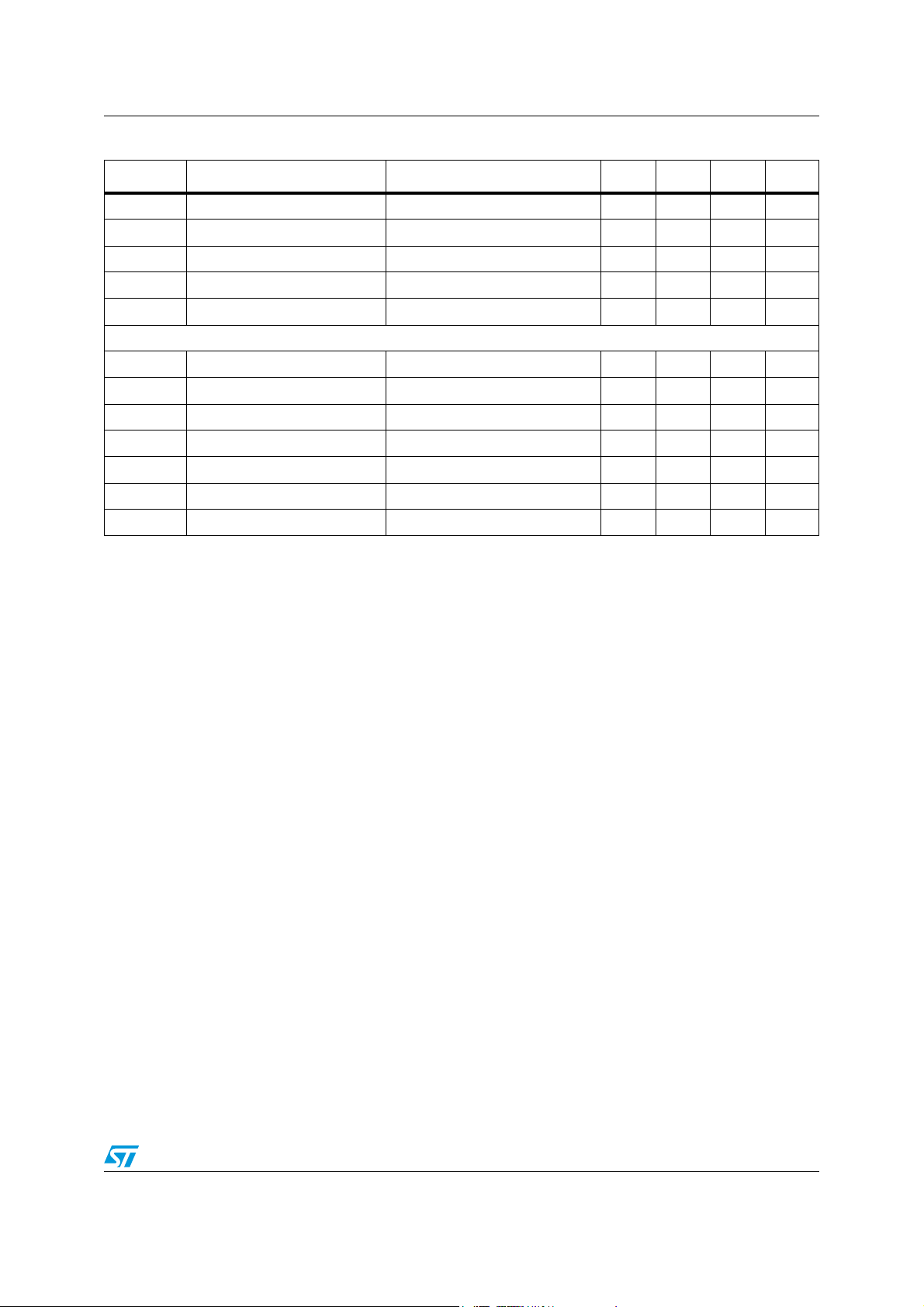

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

I

sourcepk

I

sinkpk

t

t

Peak source current -0.3 A

Peak sink current 0.8 A

Fall time 30 ns

f

Rise time 60 ns

r

UVLO saturation V

High-side gate driver (voltages referred to out)

V

LVG L

V

LVG H

I

sourcepk

I

sinkpk

t

t

Output low voltage I

Output high voltage I

Peak source current -0.3 A

Peak sink current 0.8 A

Fall time 30 ns

f

Rise time 60 ns

r

HVG-OUT pull-down 22 kΩ

1. Values tracking each other.

Figure 9

2. Refer to adaptive deadtime section,

.

= 0 to V

CC

= 200 mA 1.5 V

sink

= 5 mA 12.8 13.3 V

source

CCOn

, I

= 2 mA 1.1 V

sink

Doc ID 022835 Rev 1 11/38

Application information L6699

6 Application information

The L6699 is an advanced double-ended controller specific to resonant half bridge topology.

In these converters the MOSFETs of the half bridge leg are alternately switched on and off

(180° out-of-phase) for exactly the same time. This is commonly referred to as symmetrical

operation at “50% duty cycle”, although the real duty cycle, i.e. the ratio of the ON-time of

either switch to the switching period, is actually less than 50%. The reason is that there is a

deadtime T

one, where both MOSFETs are off. This deadtime is essential in order for the converter to

work correctly: it enables soft-switching and, then, high-frequency operation with high

efficiency and low EMI emissions.

inserted between the turn-off of either MOSFET and the turn-on of the other

D

A special feature of this IC is that it is able to automatically adjust T

within a range so that it

D

best fits the transition times of the half bridge midpoint (adaptive deadtime). This allows the

user to optimize the design of the resonant tank so that soft-switching can be achieved with

a lower level of reactive energy (i.e. magnetizing current), therefore optimizing efficiency

under a broader load range, from full to light load.

To perform converter output voltage regulation the device is able to operate in different

modes (

Figure 1

), depending on the load conditions:

1. Variable frequency at heavy and medium/light load. A relaxation oscillator (see

Section 6.1: Oscillator

for more details) generates a symmetrical triangular waveform,

which MOSFET switching is locked to. The frequency of this waveform is related to a

current that is modulated by the feedback circuitry. As a result, the tank circuit driven by

the half bridge is stimulated at a frequency dictated by the feedback loop to keep the

output voltage regulated, therefore exploiting its frequency-dependent transfer

characteristics.

2. Burst-mode control with no or very light load. When the load falls below a value, the

converter enters a controlled intermittent operation, where a series of a few switching

cycles at a nearly fixed frequency are spaced out by long idle periods where both

MOSFETs are in the OFF-state. A further load decrease is translated into longer idle

periods and then in a reduction of the average switching frequency. When the converter

is completely unloaded, the average switching frequency can go down even to few

hundred hertz, therefore minimizing magnetizing current losses as well as all

frequency-related losses and making it easier to comply with energy saving

specifications.

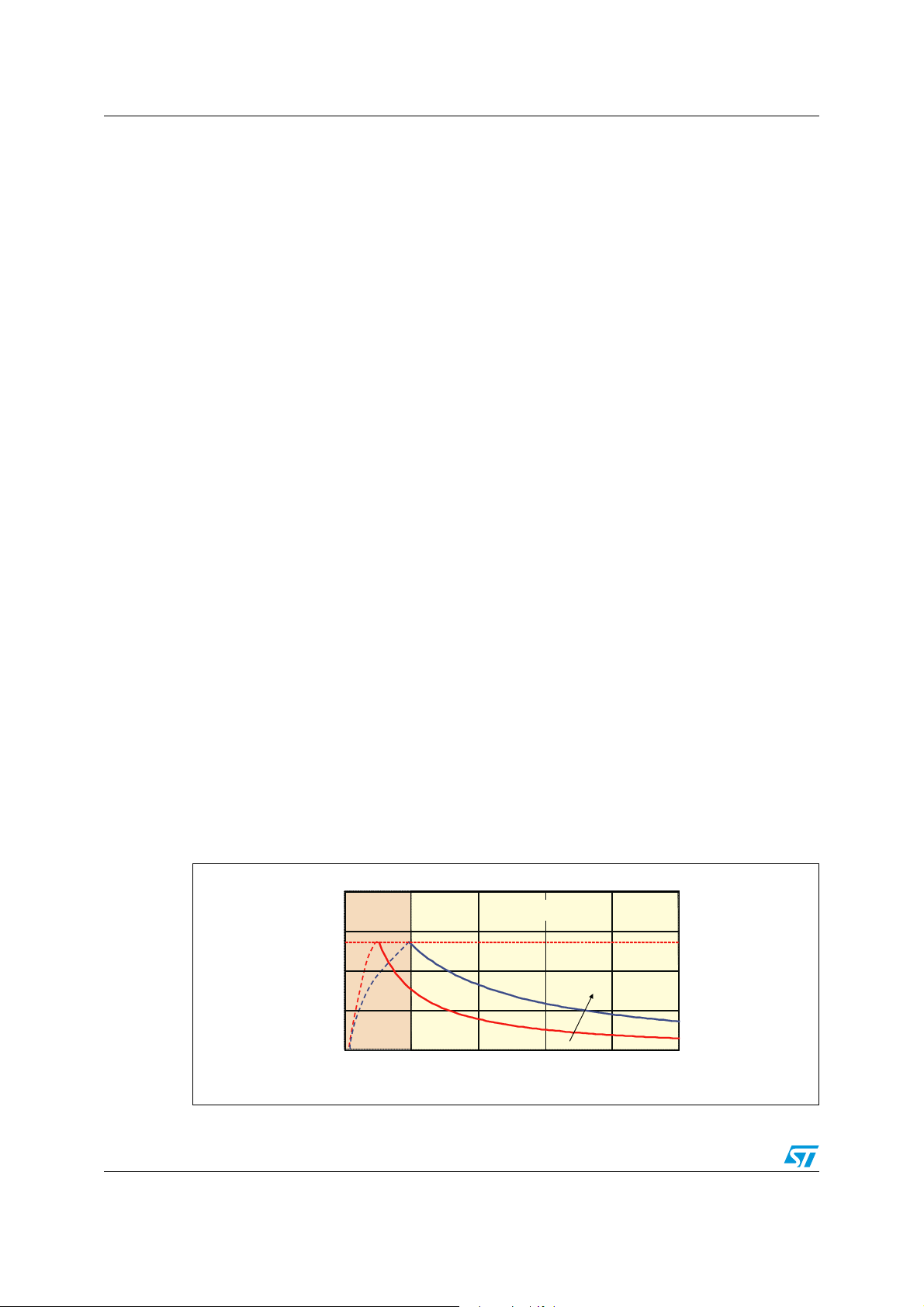

Figure 4. Multimode operation of the L6699

%XUVWPRGH

%XUVWPR GH

IUHTXHQF\

I

VZ

12/38 Doc ID 022835 Rev 1

5HVRQDQWPRGH

YDULDEOH IUHTXHQ F\

3

LQ

LQ

9

3LQPD[

!-V

L6699 Application information

6.1 Oscillator

The oscillator is programmed externally by means of a capacitor (CF), connected from pin 3

(CF) to ground, that is alternately charged and discharged by the current defined with the

network connected to pin 4 (

2 mA source capability; the higher the current sourced by the pin, the higher the oscillator

frequency. The block diagram of

operation.

RF

). The pin provides an accurate 2 V reference with about

min

Figure 5

shows a simplified internal circuit that explains the

The network that loads the

1. a resistor

RF

connected between the pin and ground that determines the minimum

min

RF

pin generally comprises three branches:

min

operating frequency.

2. a resistor RFmax connected between the pin and the collector of the (emittergrounded) phototransistor that transfers the feedback signal from the secondary side

back to the primary side; while in operation, the phototransistor modulates the current

through this branch - therefore modulating the oscillator frequency - to perform output

voltage regulation; the value of RFmax determines the maximum frequency the half

bridge is operated at when the phototransistor is fully saturated.

3. an R-C series circuit (C

the setting up of a frequency shift at startup (see

+ RSS) connected between the pin and ground that enables

SS

Section 6.3: Safe-start procedure

Note that the contribution of this branch is zero during steady-state operation.

Figure 5. Oscillator's internal block diagram

,

6

2&MIN

2

&MIN

2

#

33

2

33

&MAX

6

6

)

2

3

1

2

+-q)

2

q+-q)

+-q)

2

#&

2

#&

).

!-V

The following approximate relationships hold for the minimum and the maximum oscillator

frequency respectively:

Equation 1

min

=f

1

RF · CF · 3

min

max

=f;

Doc ID 022835 Rev 1 13/38

1

()

RF//RF · CF · 3

maxmin

Application information L6699

After fixing CF according to

Table 6. Recommended values for CF as a function of the startup frequency f

f

[kHz] CF [pF] f

start

Ta bl e 6

:

[kHz] CF [pF]

start

150 680 230 - 240 180

160 560 250 150

170 470 260 120

180 390 270 100

190 – 200 330 280 82

210 270 290 68

220 220 300 56

Value of RF

entire range needed for regulation, from the minimum value f

and maximum load) to the maximum value f

and RF

min

is selected so that the oscillator frequency is able to cover the

max

(at maximum input voltage and minimum

max

(at minimum input voltage

min

load):

Equation 2

RF

min

=RF;

f

max

1

-

f

min

mi n

=RF

1

f · CF · 3

min

max

start

Figure 6. Oscillator waveforms and their relationship with gate-driving signals

CF

D

HVG

LVG

HB

T

A different selection criterion is given for RF

Section 7: Operation at no load or very light load

In

Figure 6

the timing relationship between the oscillator waveform and the gate-drive

D

T

if burst-mode operation is to be used (see

max

t

t

t

t

).

AM11380v1

signal, as well as the midpoint of the half bridge leg (HB) is shown. Note that the low-side

gate-drive is turned on while the oscillator's triangle is ramping up and the high-side gatedrive is turned on while the triangle is ramping down. In this way, at startup, or as the IC

resumes switching during burst-mode operation, the low-side MOSFET is switched on first

to charge the bootstrap capacitor. As a result, the bootstrap capacitor is always charged and

ready to supply the high-side floating driver (see

Section 12: Bootstrap section

).

14/38 Doc ID 022835 Rev 1

L6699 Application information

6.2 Adaptive deadtime

A deadtime TD inserted between the turn-off of either switch and the turn-on of the

complementary one, where both switches are in the OFF-state, is essential to achieve softswitching. Its value must be larger than the time T

half bridge midpoint. This duration T

depends on the total parasitic capacitance of the half

T

bridge midpoint, which must be completely charged or depleted and the value of the

resonant tank current during the transition.

needed for the rail-to-rail swing of the

T

With good approximation, the tank current during the transition time T

constant and equal to the “switched current” I

transition begins. If C

denotes the total parasitic capacitance of the half bridge midpoint (it

HB

, i.e. the value of the tank current as the

S

can be considered

T

includes the Coss of the MOSFETs, the transformer's primary winding parasitic

capacitance, plus other stray contributors), the condition for soft-switching is:

Equation 3

C

HB

=T ≤

T

I

S

which should be met under all operating conditions. This formula suggests that T

large enough to always exceed T

at a minimum and T

at a maximum. However, a too long deadtime may lead to the loss of

T

, especially with maximum Vin and at no load, where IS is

T

TVin

D

should be

D

soft-switching too: in fact, the tank current must not change its sign within the deadtime,

which could lead to the turn-on of either MOSFET with a non-zero drain-to-source voltage

or, even worse, with the body diode of the other MOSFET conducting (capacitive mode

operation - see

Section 9: Capacitive-mode detection function

for more details). This may

occur at maximum load and minimum Vin, especially when the tank circuit is designed for a

low magnetizing current to optimize light load efficiency. Additionally, a too long deadtime

may increase conduction losses in the body diodes and significantly limit the operating

frequency of the half bridge.

A good approach is to automatically adjust T

so that it tracks TT, keeping TT ≤ TD under all

D

operating conditions. This is the objective of the adaptive deadtime function in the L6699.

Figure 7

and

Figure 8

show the principle schematic and its key waveforms. An edge

detector (the |d/dt| block) senses that the half bridge midpoint (connected to the OUT pin) is

swinging from B+ to GND or vice versa through the

V

pin, which moves exactly following

BOOT

the OUT pin (due to Cboot there is a DC voltage difference between them). The output of

the |d/dt| block is high as long as the OUT pin is swinging and, as the transition is

completed, the output goes low. A monostable circuit, sensitive to negative-going edges,

releases a pulse that marks the end of the deadtime.

Doc ID 022835 Rev 1 15/38

Application information L6699

Figure 7. Adaptive deadtime: principle

$4END

$2)6).'

,/')#7)4(

!$!04)6%

$%!$4)-%

schematic

MON O

(3

3()&4 %2

,3

,%6%,

\DDT\

6BOOT

(6'

/54

,6'

"

#BOO T

!-V

Figure 8. Relevant timing diagrams

Note that the “Driving logic…” block sets a minimum deadtime T

which T

switch, and also a maximum deadtime T

bridge. T

cannot go, to prevent simultaneous conduction of the high-side and the low-side

D

D_MAX

is internally set at either 700 ns or one fourth of the oscillator cycle,

to guarantee proper operation of the half

D_MAX

(≈ 230 ns) below

D_MIN

whichever is shorter.

Figure 9. Detailed view of deadtime during low-to-high transition of half bridge

midpoint

The actual deadtime T

adjustment circuit of

image shown in

Figure 9

that can be observed during operation does not depend only on the

D

Figure 7

. This fact can be explained with the aid of the oscilloscope

.

It illustrates a detailed view of the low-to-high transition of the half bridge midpoint

(waveform labeled HB) along with the high-side gate-drive (HVG), the low-side gate-drive

(LVG) and the oscillator voltage on pin CF (OSC). Obviously, the information that follows

applies to the high-to-low transition as well.

16/38 Doc ID 022835 Rev 1

L6699 Application information

There are three contributors to TD:

● The turn-off delay t

of the Power MOSFET, which depends on the input

OFF

characteristics of the specific MOSFET and the speed its gate is driven

● The transition time T

● The detection time t

the half bridge midpoint takes for a rail-to-rail swing

T

that elapses from the end of the half bridge midpoint swing to

det

the gate-drive signal of the other MOSFET going high; this includes the detection time

as well as the propagation delay along the downstream logic circuitry up to the driver

output.

It is important to point out that the value of T

is essentially tdet: therefore the minimum observable T

other hand, is counted starting from the negative-going edge of the gate-drive signal, so it

actually fixes a maximum limit for T

Finally, it is worth stating that the adaptive deadtime function does not significantly increase

efficiency by itself. It is a degree of freedom that must be exploited for this purpose when

designing the resonant tank. Essentially, it allows the use of a higher magnetizing

inductance in the transformer, which minimizes the magnetizing current and, then, the

conduction losses associated to it. Additionally, this may reduce the switched current I

the minimum required to achieve soft-switching, therefore reducing turn-off switching losses

in MOSFETs. Efficiency at medium and light load greatly benefits from this optimization.

6.3 Safe-start procedure

In the L6699 a new startup procedure, termed “safe-start”, has been implemented to

prevent loss of soft-switching during the initial switching cycles, which is not 100%

guaranteed by the usual soft-start procedure.

Sweeping the operating frequency from an initial high value, that should not exceed

300 kHz, down to the point where the control loop takes over, which is commonly referred to

as soft-start, has a twofold benefit. On the one hand, since the deliverable power depends

inversely on frequency, it progressively increases the converter's power capability, therefore

avoiding excessive inrush current. On the other hand, it makes the converter initially work at

frequencies higher than the upper resonance frequency of the LLC tank circuit, which

ensures inductive-mode operation (i.e. with the tank current lagging the square wave

voltage generated by the half bridge) and, therefore, soft-switching.

: TD ≤ T

D

specified in the electrical characteristics

D_MIN

D_MAX

is always longer. T

D

.

D_MAX

, on the

to

S

However, the last statement is true under a quasi-static approximation, i.e. when the

operating point of the resonant tank is slowly varying around a steady-state condition. This

approximation is not correct during the very first switching cycles of the half bridge, where

the initial conditions of the tank circuit can be away from those under steady-state.

Therefore, hard-switching is possible during the transient period needed to reach the slowly

varying steady-state condition dictated by the soft-start action. A non-zero initial voltage on

the resonant capacitor Cr and transformer flux imbalance during the previously mentioned

transient period are the possible causes of hard-switching in the initial cycles.

In high voltage half bridge controllers it is customary to start the switching activity by turning

on the low-side MOSFET for a preset time to pre-charge the bootstrap capacitor (see

Section 12: Bootstrap section

) and ensure proper driving of the high-side MOSFET from the

first cycle. In traditional controllers, normal switching starts right at the end of the pre-charge

time, as shown in the left-hand image in

Doc ID 022835 Rev 1 17/38

Figure 10

.

Application information L6699

Figure 10. Comparison startup behavior: traditional controller (left), with L6699

(right)

A non-zero initial voltage on the resonant capacitor may cause the very first turn-on of the

high-side MOSFET to occur with non-zero drain-to-source voltage while the body diode of

the low-side MOSFET is conducting, therefore invoking its reverse recovery. More hardswitching cycles may follow (see the left-hand image in

Figure 10

). These events are few but

potentially hazardous: they could cause the destruction of both MOSFETs, should the

resulting dv/dt across the low-side MOSFET exceed its maximum rating (see

Capacitive-mode detection function

for more details).

Section 9:

To prevent this hard-switching cycle(s) with body diode reverse recovery, the L6699 waits

about 50

Figure 10

µs after the pre-charge time before starting switching (see the right-hand image in

). This idle time is normally long enough to let the tank current decay to essentially

zero in case of an initially charged resonant capacitor. On the other hand, it is too short for

the bootstrap capacitor to be significantly discharged.

To understand the origin of transformer flux imbalance it is worth remembering that the half

bridge is driven with 50% duty cycle, so that under steady-state conditions the voltage

across the resonant capacitor Cr has a DC component equal to Vin/2. Consequently, the

transformer's primary winding is symmetrically driven by a ± Vin/2 square wave.

At startup, however, the voltage across Cr is often quite different from Vin/2, so it takes

some time for its DC component to reach the steady-state value Vin/2. During this transient,

the transformer is not driven symmetrically and, then, there is a significant V·s imbalance in

two consecutive half-cycles. If this imbalance is large, there is a significant difference in the

up and down slopes of the tank current and, the duration of the two half-cycles being the

same, the current may not reverse in a switching half-cycle, as shown in the left-hand image

in

Figure 11

. Once again, one MOSFET can be turned on while the body diode of the other

is conducting and this may happen for a few cycles.

To prevent this, the L6699 is provided with a proprietary circuit that modifies the normal

operation of the oscillator during the initial switching cycles, so that the initial V·s unbalance

is nearly eliminated. Its operation is such that current reversal in every switching half-cycle

and, then, soft-switching is ensured.

18/38 Doc ID 022835 Rev 1

L6699 Application information

Figure 11. Comparison of initial cycles after startup: traditional controller (left), with

L6699 (right)

It goes without saying that when either MOSFET is turned on for the very first time, this

occurs with a non-zero drain-to-source voltage. Therefore, strictly speaking, hard-switching

is still there. However, this type of one-shot hard-switching, where the body diode of the

other MOSFET is not reverse recovered, is of little concern. In fact, the related capacitive

power loss is thermally insignificant and, with a proper gate-drive circuit, spurious turn-on of

the other MOSFET through Cgd injection is easily prevented.

The timing diagrams of

Figure 11

compare the startup behavior of a resonant converter

driven by a traditional resonant controller with that of a converter driven by the L6699.

During the initial phase, the ramps of the oscillator are synchronized to the zero-crossings of

the tank current, so that a trapezoidal waveform appears across CF. As a result, the duty

cycle of the half bridge is initially considerably less than 50% and the tank current changes

its sign every half-cycle. The device goes to normal operation after approximately 50 µs

from the first switching cycle. If the timing capacitor CF is selected according to

Ta b le 6

, this

transition is nearly seamless and just a small perturbation of the tank current can be

observed.

Using capacitor values significantly different from those provided in

Ta bl e 6

might cause

large perturbations during the transition. This might bring the half bridge close to losing softswitching with a consequent activation of the capacitive-mode detection function.

With the L6699 the soft-start function is easily realized with the addition of an R-C series

circuit from pin 4 (

Initially, the capacitor C

parallel with RF

RF

) to ground (see

min

is totally discharged, so that the series resistor RSS is effectively

SS

and the resulting initial frequency is determined by RSS and RF

min

Figure 13

).

min

only,

as the optocoupler's phototransistor is cut off (as long as the output voltage is not too far

away from the regulated value):

Equation 4

star t

=f

1

()

R//RF· CF ·3

SSmin

The C

V) and, consequently, the current through R

times the constants R

capacitor is progressively charged until its voltage reaches the reference voltage (2

SS

SS·CSS

, however, the soft-start phase really ends when the output

goes to zero. This conventionally takes 5

SS

voltage has got close to the regulated value and the feedback loop has taken over, so that

Doc ID 022835 Rev 1 19/38

Application information L6699

the operating frequency is essentially determined by the current sunk by the optocoupler's

phototransistor.

During this frequency sweep phase the operating frequency decays following the

exponential charge of C

: then, it initially changes relatively quickly but the rate of change

SS

gets slower and slower. This counteracts the non-linear frequency dependence of the tank

circuit that makes the converter's input impedance change little as frequency is away from

resonance and change very quickly as frequency approaches resonance frequency (see

Figure 13

).

Figure 12. Soft-start circuit Figure 13. Input impedance vs.

frequency curve in an LLC

resonant half bridge

500%22% 3/.!. #%

&2%15%. #9

3TEADY STATE

EQUENCY

FR

)NITIAL

FR

EQUENCY

!-V

F

2&M IN

,/7% 22%3/.!. #%

\:F\

2&M IN

2

33

#SS

#

33

,

!-V

&2%15%. #9

As a result, the DC input current smoothly increases, without the peaking that occurs with

linear frequency sweep, and the output voltage reaches the regulated value with almost no

overshoot.

Ty p ic al ly, R

and CSS is selected based on the following relationships:

SS

Equation 5

-

3

10 ·3

R

SS

SS

RF

min

=R

f

start

1

-

f

min

SS

=C;

where f

Figure 20

is recommended to not be over 300 kHz. Please refer to the timing diagram of

start

to see some significant signals during the soft-start phase.

20/38 Doc ID 022835 Rev 1

L6699 Operation at no load or very light load

!-V

,

34"9

2&M IN

2

&MI N

2

&MAX

,).%

2

!

"

2

"

2

,

2

(

2!2"2

,

7 Operation at no load or very light load

When the resonant half bridge is lightly loaded or totally unloaded, its switching frequency

reaches its maximum value. To keep the output voltage under control and avoid losing softswitching in these conditions, there must be some current flowing through the transformer's

magnetizing inductance. This current can be kept relatively low because of the adaptive

deadtime function; however, it produces power losses that prevent the converter's no load

consumption from achieving very low values anyhow.

To overcome this issue, the L6699 enables the user to make the converter operate

intermittently (burst-mode operation), with a series of a few switching cycles spaced out by

long idle periods where both MOSFETs are in the OFF-state, so that the average switching

frequency can be substantially reduced. As a result, the average value of the residual

magnetizing current and the associated losses is considerably cut down, therefore

facilitating the converter to comply with energy saving specifications.

The L6699 can be operated in burst-mode by using pin 5 (STBY): if the voltage applied to

this pin falls below 1.26 V, the IC enters an idle state where both gate-drive outputs are low,

the oscillator is stopped, the soft-start capacitor C

reference at the

RF

pin stays alive to minimize IC consumption and VCC capacitor

min

discharge. The IC resumes normal operation as the voltage on the pin exceeds 1.26 V by 30

mV.

keeps its charge and only the 2V

SS

In the L6699, the half bridge stops and restarts during burst-mode are more accurately

controlled with respect to its predecessors: the last cycle before stopping and the first cycle

after restarting are such that the DC voltage across the resonant capacitor Cr always stays

close to its steady-state value Vin/2. In this way, the anomalous current peaks due to V·s

unbalance in the transformer are minimized.

To implement burst-mode operation, the voltage applied to the STBY pin needs to be related

to the feedback loop.

Figure 14

shows the simplest implementation, suitable to a narrow

input voltage range (e.g. when there is a PFC front-end).

Figure 14. Narrow input voltage range Figure 15. Wide input voltage range

2&M IN

2

&MI N

2

&MAX

34"9

,

!-V

Essentially, RF

mode operation. Once f

defines the switching frequency f

max

max is

fixed, RF

is found from the relationship:

max

Doc ID 022835 Rev 1 21/38

above which the L6699 enters burst-

max

Operation at no load or very light load L6699

Equation 6

RF

max

3

=RF

8

min

·

f

max

1

-

f

min

Note that, unlike the f

some load Pout

greater than the minimum one. PoutB is normally such that the

B

considered in the

max

Section 6.1: Oscillator

, here f

is associated to

max

transformer's peak currents are low enough not to cause audible noise.

The resonant converter's switching frequency, however, depends also on the input voltage;

so, in case there is quite a large input voltage range, with the circuit of

Pout

would change considerably. In this case it is recommended to use the arrangement

B

shown in

Figure 15

, where the information on the converter's input voltage is added to the

Figure 14

the value of

voltage applied to the STBY pin. Due to the strongly non-linear relationship between

switching frequency and input voltage, it is more practical to find empirically the right amount

of correction R

the total value R

(see

Section 10: Line sensing function

/ (RA + RB) needed to minimize the change in PoutB. Take care in choosing

A

+ RB much greater than RL to minimize the effect on the LINE pin voltage

A

).

Figure 16. Load-dependent operating modes: timing diagram

34"9

HYSTER

6

F

,6'

(6'

0&#?34 /0

OSC

M6

T

T

T

0&#

'!4%

$2) 6%

2ESONANT-ODE "URST-ODE

Whichever circuit is in use, its operation can be described as follows. As the load falls below

the value Pout

voltage on the STBY pin (

the frequency tries to exceed the maximum programmed value f

B

V

) goes below 1.26 V. The IC then stops with both gate-drive

STBY

outputs low, so that both MOSFETs of the half bridge leg are in the OFF-state. The voltage

V

now increases as a result of the feedback reaction to the energy delivery stop and, as

STBY

it exceeds 1.29 V, the IC restarts switching. After a while,

response to the energy burst and stops the IC. In this way the converter works in a burstmode fashion with a nearly constant switching frequency. A further load decrease then

increases the time between consecutive bursts and/or reduces the duration of each burst.

This reduces the average switching frequency, which can go down even to few hundred

hertz. The timing diagram of

Figure 16

illustrates this kind of operation, showing the most

significant signals. A small capacitor (typically in the hundred pF) from the STBY pin to

ground, placed as close to the IC as possible to reduce switching noise pick-up, helps obtain

clean operation.

22/38 Doc ID 022835 Rev 1

2ESONANT-ODE

V

goes down again in

STBY

!-V

and the

max

L6699 Operation at no load or very light load

Figure 17. How the L6699 can switch off a PFC controller at light load

ZCD ( L6562)

Vcc

12

L6699

PFC_STOP

9

100 k

W

BC547

INV (L6562A)

22 k

W

BC547

L6562/2A

L6699

L6563S/H

L6564, L6564T/H

L4984

PFC_STOP9

PFC_OK

(AC_OK)

AM11388v1

To help the user meet energy saving requirements even in power-factor-corrected systems,

where a PFC pre-regulator precedes the DC-DC converter, the L6699 allows that the PFC

pre-regulator can be turned off during burst-mode operation, therefore eliminating the no

load consumption of this stage (0.5

- 1 W). There is no compliance issue in that, because

EMC regulations on low-frequency harmonic emissions refer to nominal load, no limit is

envisaged when the converter operates with light or no load.

To do so, the L6699 provides pin 8 (PFC_STOP): it is an open drain output, normally open,

that is asserted low when the IC is idle during burst-mode operation. This signal is externally

used for switching off the PFC controller and the pre-regulator as shown in

Figure 17

. When

the L6699 is in UVLO the pin is kept open to allow the PFC controller to start first.

The PFC_STOP pin is also used by some protection functions (OCP, OLP and latched

shutdown). Please refer to the relevant sections for more information.

Doc ID 022835 Rev 1 23/38

Current sensing, OCP and OLP L6699

!-V

,

)3% .

#R

#S

)

#R

2S

/PTIONAL

2

&

#

&

8 Current sensing, OCP and OLP

In the L6699 the current sense input ISEN (pin 6) senses the current flowing in the resonant

tank to perform multiple tasks:

1. Primary overcurrent protection (OCP function).

2. Hard-switching cycles prevention at startup (see

3. Capacitive-mode detection during operation (see

function

).

In this section the discussion is concentrated on the OCP function.

Unlike PWM-controlled converters, where energy flow is controlled by the duty cycle of the

primary switch (or switches), in a resonant half bridge the duty cycle is fixed and energy flow

is controlled by its switching frequency. This has an impact on the way current limitation can

be realized. While in PWM-controlled converters energy flow can be limited simply by

terminating switch conduction in advance when the sensed current exceeds a preset

threshold (cycle-by-cycle limitation), in a resonant half bridge the most efficient way to

reduce an excessive current level is to increase the switching frequency, i.e. the oscillator

frequency.

In

Figure 18

and 19 a couple of current sensing methods are illustrated.

Section 6.3: Safe-start procedure

).

Section 9: Capacitive-mode detection

Figure 18. Current sensing techniques

with sense resistor

)

#R

#R

2S

!-V

,

)3% .

/PTIONAL

2

#

&

&

Figure 19. Current sensing techniques

“lossless”, with capacitive

shunt

Note: The L6699 must sense the instantaneous tank current for proper operation of the smooth

startup function and the capacitive-mode detection circuit. Therefore, if a smoothing RC

circuit (the one shown in the dashed box) is used to reduce the noise level on the ISEN pin,

its time constant RF CF should be in the range of 100 - 200 ns. With slightly longer time

constants it is recommended that converter operation close to the capacitive-mode

boundary and during short-circuit, as well as at the end of the smooth-start phase, be

checked for possible hard-switching cycles. With considerably longer time constants (> 200

ns) hard-switching under the above mentioned conditions becomes very likely.

24/38 Doc ID 022835 Rev 1

L6699 Current sensing, OCP and OLP

The ISEN pin, which is also able to withstand negative voltages, is internally connected to

the input of a first comparator, referenced to

second comparator referenced to 1.5 V. The operation of the second comparator is

described later.

V

(0.8 V typ. 0.76 V min.), and to that of a

ISENx

If the voltage externally applied to the pin by either circuit in

the first comparator is tripped and this causes an internal switch to be turned on for 5 µs and

discharges the soft-start capacitor C

increases the oscillator frequency and thereby limits energy transfer. Under output shortcircuit conditions, this operation results in a peak primary current that periodically oscillates

below the maximum value allowed by the sense resistor Rs.

In the circuit shown in

value can be determined using the equation:

Equation 7

Figure 18

(see

SS

, Rs is placed directly in series to the resonant tank. Its

Section 6.3: Safe-start procedure

Figure 18

and 19 exceeds 0.8 V

). This quickly

76.0

=Rs

I

Crpkx

where I

and the primary winding of the transformer, which is related to the maximum load and the

minimum input voltage. The power dissipation in Rs can be approximately found with:

Equation 8

is the maximum expected peak current flowing through the resonant capacitor

Crpkx

I ·4.0P ≈

CrpkxRs

The circuit shown in

selected equal to Cr/100 or less and is a low-loss type, and the sense resistor Rs is selected

as:

Equation 9

and the associated power dissipation is reduced by a factor (1+Cr/Cs). This circuit is then

recommended when the efficiency target is very high.

This OCP is effective in limiting primary-to-secondary energy flow in case of an overload or

an output short-circuit, but the output current through the secondary winding and rectifiers

under these conditions may be so high that it endangers converter safety if continuously

flowing. To prevent any damage it is customary to force the converter to work intermittently,

which brings the average output current to values such that the thermal stress for the

transformer and the rectifiers can be easily handled.

If intermittent operation upon overload or short-circuit is desired, the designer can program

externally the maximum time T

conditions. Overloads or short-circuits lasting less than T

Figure 19

operates as a capacitive current divider; Cs is typically

77.0

=Rs

I

Crpkx

that the converter is allowed to run under these

SH

C

r

+1 ·

)(

Cs

do not cause any other action,

SH

Doc ID 022835 Rev 1 25/38

Current sensing, OCP and OLP L6699

therefore providing the system with immunity to short duration phenomena. If, instead, TSH

is exceeded, an overload protection (OLP) procedure is activated that shuts down the L6699

and, in case of continuous overload/short-circuit, results in continuous intermittent operation

with a user-defined duty cycle.

This function is realized on pin 2 (DELAY), with a capacitor C

R

connected to ground. As the voltage on the ISEN pin exceeds 0.8 V, the first OCP

Delay

comparator, in addition to turning on the switch that discharges C

generator that sources 350 µA for 50 µs from the DELAY pin and charges C

and a parallel resistor

Delay

, turns on a current

SS

Delay

. During an

overload/short-circuit the OCP comparator and the internal current source is repeatedly

activated and C

is charged with an average current depending essentially on CSS, RSS,

Delay

the characteristics of the resonant circuit, and the short-circuit impedance; the discharge

due to R

This operation continues until the voltage on C

the time T

not a simple relationship that links T

experimentally. As a rough indication, using 1 µF for C

is negligible because the associated time constant is typically much longer.

Delay

, V(DELAY), reaches 2 V, which defines

, or until the overload/short-circuit disappears, whichever occurs first. There is

SH

SH

to C

Delay

, so it is more practical to determine C

Delay

, TSH should be around 100 ms in

Delay

Delay

case of a dead short on the output.

In the case of an overload lasting less than T

decays with the time constant C

is shorter if this occurs before C

Delay·RDelay

is totally discharged. If, on the other hand, it is charged

Delay

up to 2 V, the internal switch that discharges C

SH

, C

is no longer charged, so its voltage

Delay

. Note that the value of TSH for the next overload

is continuously turned on, the PFC_STOP

SS

pin is pulled low, and the 350 µA current source is forced continuously on until V(DELAY)

reaches 3.5 V. This phase lasts:

Equation 10

C ·3.4T ≈

De layMP

with T

close to f

expressed in ms and C

MP

(see

start

Section 6.3: Safe-start procedure

in µF. During this time the L6699 runs at a frequency

Delay

resonant circuit. As V(DELAY) equals 3.5 V, the L6699 stops switching and the internal 350

µA generator is turned off, so that C

is slowly discharged by R

Delay

when V(DELAY) falls below 0.3 V, which takes:

Equation 11

33.0

The timing diagram of

voltage of the L6699 (V

does not restart immediately after V

Figure 20

CC

shows this operation. Note that if during TSTOP the supply

) falls below the UVLO threshold the IC records the event and

exceeds the startup threshold, if V(DELAY) is still

CC

higher than 0.3 V. Also the PFC_STOP pin stays low as long as V(DELAY) is greater than

0.3 V.

26/38 Doc ID 022835 Rev 1

) to minimize the energy inside the

. The IC restarts

Delay

5.3

≈

C ·R · 4.2ln ·C ·R=T

DelayDelayDelayDelaySTOP

L6699 Current sensing, OCP and OLP

Figure 20. Soft-start and delayed shutdown upon overcurrent timing diagram (safe-

start details are not shown)

).#!3%,)33%,&3500,)%$

4

-0

-).0/7%2

4

34/0

3(5 4$/ 7.

T

T

T

T

T

T

!-V

)3%.

$%,!9

6OUT

0&#?34 /0

6CC

#SS

6

34!2450

4

3(

4

6

6

6

6

6

SS

3/&4 34!2 4 3/&4 34!2 4

./2-!,

/0%2!4)/.

/6%2

,/!$

./2-!,

/0%2!4)/.

/6%2,/!$

In applications where continuous operation of the converter is needed even under overload

conditions, the delayed shutdown function can be disabled by simply grounding the DELAY

pin.

If the voltage on the ISEN pin reaches 1.5 V, the second comparator is triggered. Switching

is stopped immediately and both the internal switch that discharges C

and the 350 µA

SS

current source on the DELAY pin are forced continuously on. As V(DELAY) equals 3.5 V the

350 µA generator is turned off, so that C

is slowly discharged by R

Delay

. The L6699

Delay

restarts when V(DELAY) falls below 0.3 V.

Doc ID 022835 Rev 1 27/38

Capacitive-mode detection function L6699

9 Capacitive-mode detection function

Normally, the resonant half bridge converter operates with the resonant tank current lagging

behind the square-wave voltage applied by the half bridge leg, like a circuit having a

reactance of an inductive nature. In this way the applied voltage and the resonant current

have the same sign at every transition of the half bridge, which is a necessary condition in

order for soft-switching to occur (zero-voltage switching, ZVS at turn-on for both MOSFETs).

Therefore, should the phase relationship reverse, i.e. the resonant tank current anticipates

the applied voltage, like in circuits having a capacitive reactance, soft-switching would be

lost. This is termed capacitive-mode operation and must be avoided because of its

significant drawbacks:

1. Both MOSFETs feature hard-switching at turn-on, like in conventional PWM-controlled

converters (see

higher than the total power normally dissipated under “soft-switching” conditions and

this may easily lead to their overheating, since heatsinking is not usually sized to

handle this abnormal condition.

2. The body diode of the MOSFET just switched off conducts current during deadtime and

its voltage is abruptly reversed by the other MOSFET turned on (see

Therefore, once reverse-biased, the conducting body diode keeps its low impedance

until it recovers, therefore creating a condition equivalent to a shoot-through of the half

bridge leg. This is a potentially destructive condition (see next point) and causes

additional power dissipation due to the current and voltage of the conducting body

diode simultaneously high during part of its recovery.

3. There is an extremely high reverse dv/dt (many tens of V/ns!) experienced by the

conducting body diode at the end of its recovery with the other MOSFET turned on.

This dv/dt may exceed the rating of the MOSFET and lead to an immediate failure

because of the second breakdown of the parasitic BJT intrinsic in its structure. If a

MOSFET is hot, the turn-on threshold of its parasitic BJT is lower, and dv/dt-induced

failure is much more likely. The L6699 may be also damaged if its OUT pin is subject to

a dv/dt exceeding the AMR (50 V/ns).

Figure 21

). The associated capacitive losses may be considerably

Figure 21

).

Figure 21. Details of hard-switching transition during capacitive-mode operation

28/38 Doc ID 022835 Rev 1

L6699 Capacitive-mode detection function

4. When either MOSFET is turned on, the other one can be parasitically turned on too, if

the current injected through its Cgd and flowing through the gate driver's pull-down is

large enough to raise the gate voltage close to the turn-on threshold This would be a

lethal shoot-through condition for the half bridge leg.

5. The recovery of the body diodes generates large and energetic negative voltage spikes

because of the unavoidable parasitic inductance of the PCB subject to its di/dt. These

are coupled to the OUT pin and may damage the L6699.

6. There is a large common-mode EMI generation that adversely affects EMC.

Resonant converters work in capacitive mode when their switching frequency falls below a

critical value that depends on the loading conditions and the input-to-output voltage ratio.

They are especially prone to enter capacitive-mode when the input voltage is lower than the

minimum specified and/or the output is overloaded or short-circuited. Designing a converter

so that it never works in capacitive-mode, even under abnormal operating conditions, is

definitely possible but this may pose unacceptable design constraints in some cases.

To prevent the severe drawbacks of capacitive-mode operation, while enabling a design that

needs to ensure inductive-mode operation only in the specified operating range, neglecting

abnormal operating conditions, the L6699 provides the capacitive-mode detection function.

The IC monitors the phase relationship between the tank current circuit sensed on the ISEN

pin and the voltage applied to the tank circuit by the half bridge, checking that the former

lags behind the latter (inductive-mode operation). If the phase-shift approaches zero, which

is indicative of impending capacitive-mode operation, the monitoring circuit activates the

OCP procedure (see

Section 8: Current sensing, OCP and OLP

) so that the resulting

frequency rise keeps the converter away from that dangerous condition. Also in this case

the DELAY pin is activated, so that the OLP function, if used, is eventually tripped after a

time T

causing intermittent operation and reducing thermal stress.

SH

If the phase relationship reverses abruptly (which may happen in case of dead short at the

converter's output), the L6699 is stopped immediately, the soft-start capacitor C

discharged and a new soft-start cycle is initiated after 50

µs idle time. During this idle period

is totally

SS

the PFC_STOP pin is pulled low to stop the PFC stage as well.

Doc ID 022835 Rev 1 29/38

Line sensing function L6699

10 Line sensing function

This function basically stops the IC as the input voltage to the converter falls below the

specified range and lets it restart as the voltage goes back within the range. The sensed

voltage can be either the rectified and filtered mains voltage, in which case the function acts

as a brownout protection, or, in systems with a PFC pre-regulator front-end, the output

voltage of the PFC stage, in which case the function serves as a power-on and power-off

sequencing.

L6699 shutdown upon input undervoltage is accomplished by means of an internal

comparator, as shown in the block diagram of

available at pin 7 (LINE). The comparator is internally referenced to 1.22 V and disables the

IC if the voltage applied at the LINE pin is below the internal reference. Under these

conditions the soft-start is discharged, the PFC_STOP pin is open and the consumption of

the IC is reduced. PWM operation is re-enabled as the voltage on the pin is above the

reference. The comparator is provided with current hysteresis instead of a more usual

voltage hysteresis: an internal 13 µA current sink is ON as long as the voltage applied at the

LINE pin is below the reference and is OFF if the voltage is above the reference.

This approach provides an additional degree of freedom: it is possible to set the ON

threshold and the OFF threshold separately by properly choosing the resistors of the

external divider (see below). With voltage hysteresis, on the other hand, fixing one threshold

automatically fixes the other one depending on the built-in hysteresis of the comparator.

Figure 22

, whose non-inverting input is

With reference to

(Vin

) and OFF (Vin

ON

Equation 12

which, solved for R

Equation 13

Figure 22

ON

R

and RL, yields:

H

, the following relationships can be established for the ON

) thresholds of the input voltage:

OFF

25.1Vin -

-

H

=R

H

R

OFF

25.1Vin

25.1

=

R

LH

25.1

25.1Vin

-

25.1

-

6

+10 ·13=

R

VinVin

-

OFFON

6

10 · 13

;

L

OFF

R=R;

HL

30/38 Doc ID 022835 Rev 1

L6699 Line sensing function

Figure 22. Line sensing function: internal block diagram and timing diagram

(6)NP UTBUS

6IN

/.

6IN

/&&

,).%

(6 ) NP U TB U S

2

(

,).%

2

,

6CC

!

6

6

6IN/+

,

6

6IN / +

)

(93

!

6CC

,6'

(6'

6OU T

While the line undervoltage is active there is no switching activity, therefore the V

T

T

T

T

T

T

T

!-V

voltage

CC

(if not supplied by another source) continuously oscillates between the startup and the

UVLO thresholds, as shown in the timing diagram of

Figure 22

.

The LINE pin, while the device is operating, is a high impedance input connected to high

value resistors, so it is prone to pick-up noise,. This might alter Vin

or give rise to

OFF

undesired switch-off of the IC during ESD tests. It is possible to bypass the pin to ground

with a small film capacitor (e.g. 1-10 nF) to prevent any malfunctioning of this kind.

If the function is not used the pin can be pulled high by connecting it to V

resistor in the hundred k

Ω.

through a

CC

Doc ID 022835 Rev 1 31/38

Latched shutdown L6699

11 Latched shutdown

The L6699 is equipped with a comparator having the non-inverting input externally available

on pin 8 (DIS) and with the inverting input internally referenced to 1.85 V. As the voltage on

the pin exceeds the internal threshold, the IC is immediately shut down, the PFC_STOP pin

is asserted low and the quiescent consumption reduced to a low value. The information is

latched and it is necessary to let the voltage on the V

pin go below the UVLO threshold to

CC

reset the latch, de-assert the pin PFC_STOP, and restart the IC.

This function is useful to implement a latched overtemperature protection very easily by

biasing the pin with a divider from an external reference voltage (e.g. pin 4,

RF

), where

min

the upper resistor is an NTC physically located close to a heating element like the MOSFET,

or a secondary diode or the transformer.

An OVP can be implemented as well, e.g. by sensing the output voltage and transferring an

overvoltage condition via an optocoupler. A latch-mode OCP protection can be implemented

by connecting this pin to DELAY (pin 2).

12 Bootstrap section

The supply of the floating high-side section is obtained by means of a bootstrap circuitry.

This solution normally requires a high voltage fast-recovery diode (D

charge the bootstrap capacitor C