L6668

Fi

SMART PRIMARY CONTROLLER

1 General Features

■ MULTIPOWER BCD TECHNOLOGY

■ LOAD-DEPENDENT CURRENT-MODE CON-

TROL: FIXED-FREQUENCY (HEAVY LOAD),

FREQUENCY FOLDBACK (LIGHT LOAD),

BURST-MODE (NO-LOAD)

■ ON-BOARD HIGH-VOLTAGE START-UP

■ IMPROVED STANDBY FUNCTION

■ LOW QUIESCENT CURRENT (< 2 mA)

■ SLOPE COMPENSATION

■ PULSE-BY-PULSE & HICCUP-MODE OCP

■ INTERFACE WITH PFC CONTROLLER

■ DISABLE FUNCTION (ON/OFF CONTROL)

■ LATCHED DISABLE FOR OVP/OTP FUNC-

TION

■ PROGRAMMABLE SOFT-START

■ 2% PRECISION REFERENCE VOLTAGE EX-

TERNALLY AVAILABLE

■ ±800 mA TOTEM POLE GATE DRIVER WITH

INTERNAL CLAMP AND UVLO PULL-DOWN

■ BLUE ANGEL, ENERGY STAR, EU CODE OF

CONDUCT COMPLIANT

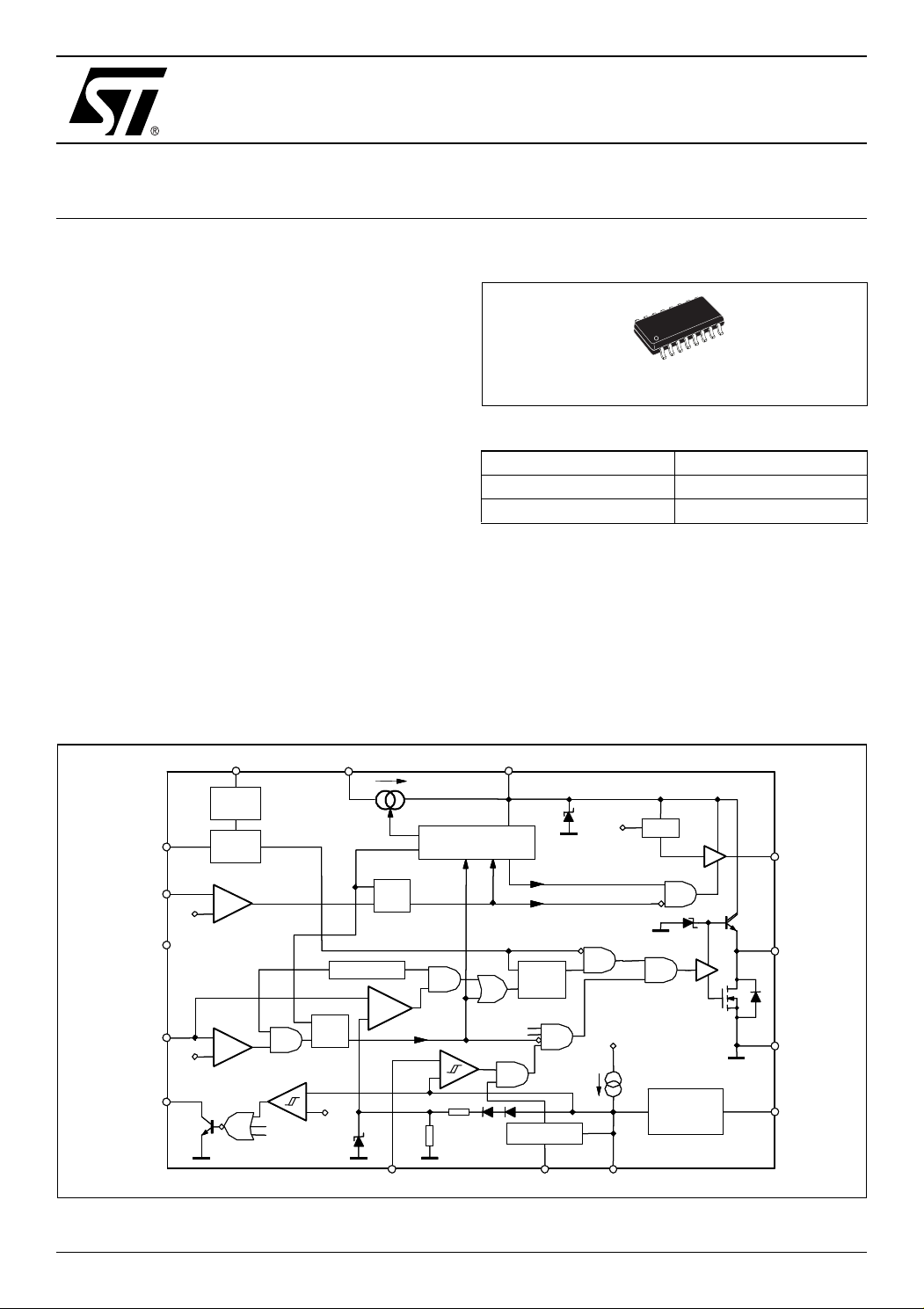

Figure 2. Block Diagram

S-COMP V

RCT

RCT

DIS

DIS

N.C.

N.C.

ISEN

ISEN

PFC_STOP

PFC_STOP

S-COMP V

SLOPE

SLOPE

COMP.

COMP.

16

16

TIMING

TIMING

+

+

7

7

-

-

2.2V

2.2V

6

6

HICCUP

HICCUP

12

12

+

+

-

-

1.5V

1.5V

14

14

DIS

DIS

OCP

OCP

CLK

CLK

-

-

+

+

2.2/2.7V

2.2/2.7V

HV

HV

1

1

BLANKING

BLANKING

R

R

SQ

SQ

and UVLO management

and UVLO management

R

R

SQ

SQ

+

+

PWM

PWM

-

OCP

OCP

0.8V 4R

0.8V 4R

9

9

SKIPADJ

SKIPADJ

gure 1. Package

SO-16 (Narrow)

Table 1. Order Codes

Part Number Package

L6668 SO-16

L6668TR SO-16 in Tape & Reel

■ SO16 PACKAGE ECOPACK

®

1.1 APPLICATIONS

■ HI-END AC-DC ADAPTERS/CHARGERS FOR

NOTEBOOKS.

■ LCD/CRT MONITORS, LCD/CRT TV

■ DIGITAL CONSUMER

CC

CC

515

515

VREG

0.4mA

0.4mA

VREG

VREG

VREG

COMPSS

COMPSS

Vref

Vref

STANDBY

STANDBY

15V

15V

HV generator ON/OFF

HV generator ON/OFF

Vcc_OK

Vcc_OK

HYST. CTRL

HYST. CTRL

-

-

+

+

11R

11R

25V

25V

Vcc_OK

Vcc_OK

DIS

DIS

SQ

SQ

R

R

DIS

DIS

SOFT-START

SOFT-START

11 10

11 10

8

8

VREF

VREF

4

4

OUT

OUT

3

3

GND

GND

13

13

ST-BY

ST-BY

January 2006

Rev. 4

1/23

L6668

2 Description

L6668 is a current-mode primary controller IC, designed to build single-ended converters.

The IC drives the system at fixed frequency at heavy load and an improved Standby function causes a

smooth frequency reduction as the load is progressively reduced. At very light load the device enters a

special operating mode (burst-mode with fixed, externally programmed peak current) that, in addition to

the on-board high-voltage start-up and the very low quiescent current, helps keep low the consumption

from the mains and be compliant with energy saving regulations. To allow meeting compliance with these

standards in power-factor-corrected systems too, an interface with the PFC controller is provided that enables to turn off the pre-regulator when the load level falls below a threshold.

The IC includes also a programmable soft-start, slope compensation for stable operation at duty cycles

greater then 50%, a disable function, a leading edge blanking on current sense to improve noise immunity,

latched disable for OVP or OTP shutdown and an effective two-level OCP able to protect the system even

in case the secondary diode fails short.

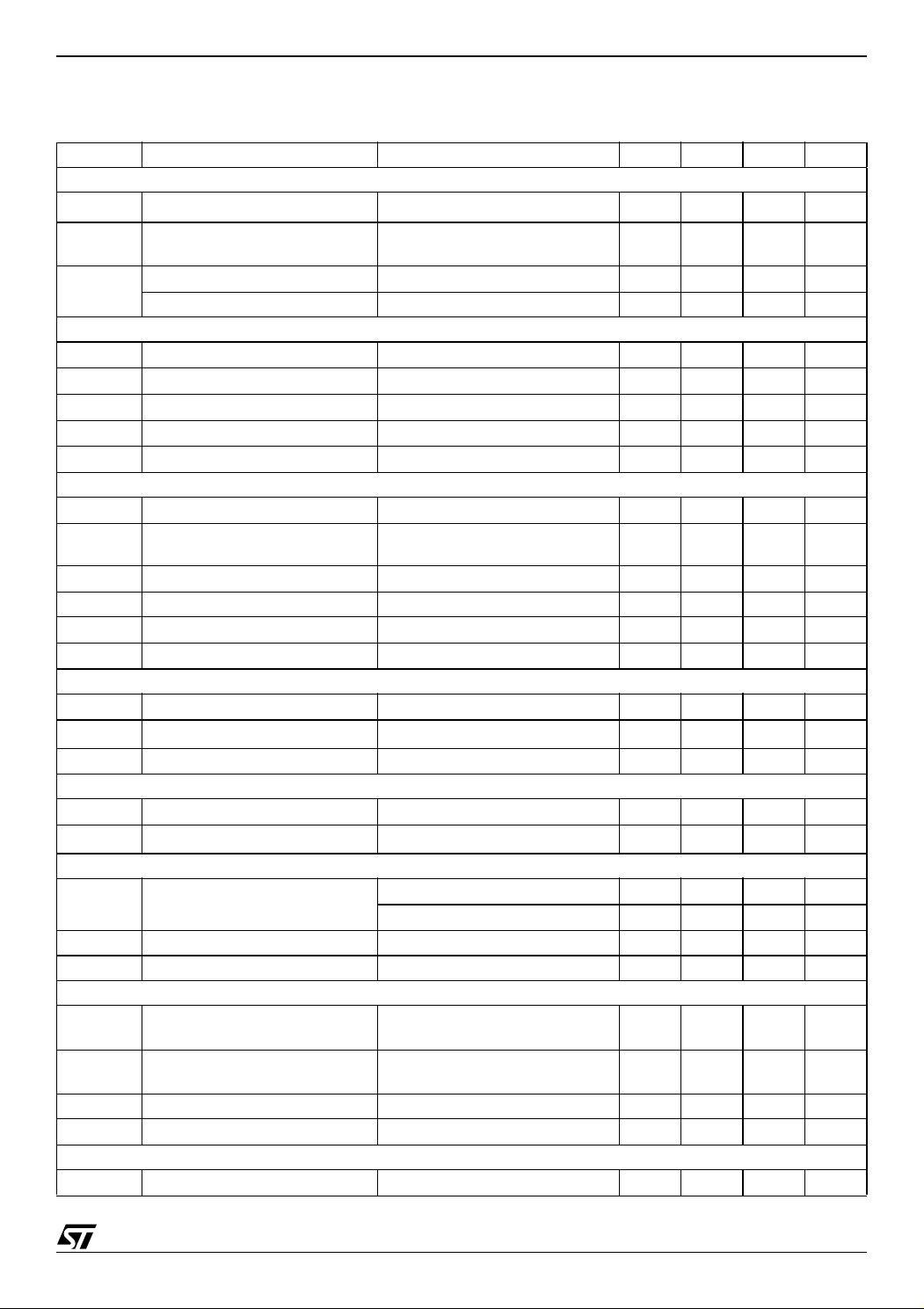

Table 2. Absolute Maximum Ratings

Symbol Pin Parameter Value Unit

V

cc

V

HV

I

HV

--- Analog Inputs & Outputs, except pin 14 -0.3 to 8 V

I

PFC_STOP

V

PFC_STOP

P

tot

T

j

T

stg

Note: 1. ESD immunity for pin 1 is guaranteed up to 900V (Human Body Model).

5 IC Supply voltage (Icc = 20 mA) Self-limited V

1 High-voltage start-up generator voltage range -0.3 to 700 V

1 High-voltage start-up generator current Self-limited A

14 Max. sink current (low state) 2 mA

14 Max. voltage (open state) 16 V

Power Dissipation @Tamb = 50°C 0.75 W

Junction Temperature Operating range -25 to 150 °C

Storage Temperature -55 to 150 °C

1

Table 3. Thermal Data

Symbol Parameter Value Unit

R

th j-amb

Thermal Resistance Junction to AmbientMax 120 °C/W

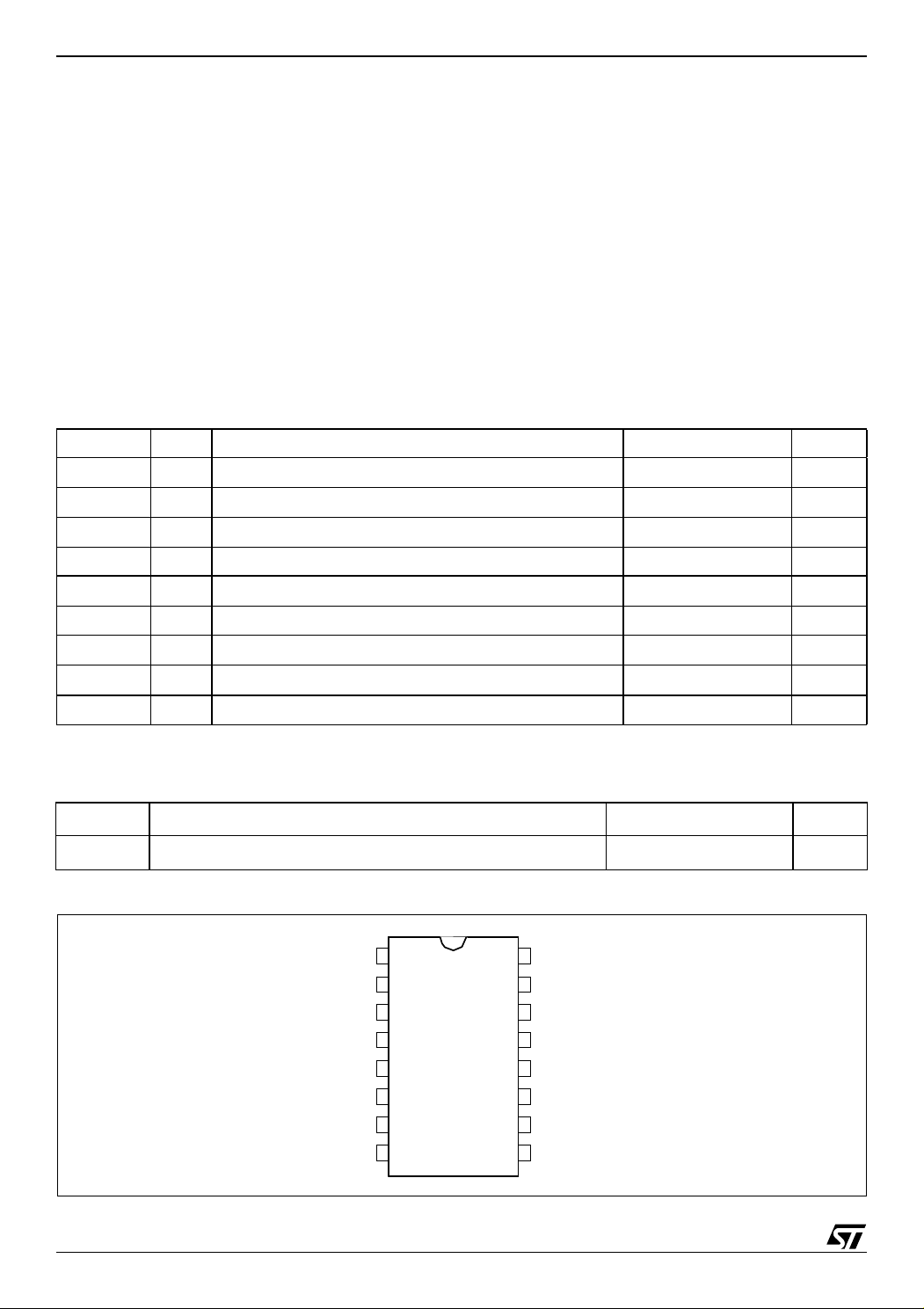

Figure 3. Pin Connection (Top view)

2/23

HV

HV

HVS

HVS

GND

GND

OUT

OUT

Vcc

Vcc

N.C.

N.C.

DIS

DIS

VREF

VREF

RCT

RCT

S-COMP

S-COMP

PFC_STOP

PFC_STOP

STBY

STBY

ISEN

ISEN

SS

SS

COMP

COMP

SKIPADJ

SKIPADJ

Table 4. Pin Description

L6668

Pin

Number

1 HV High-voltage start-up. The pin is to be connected directly to the rectified mains voltage. A

2 HVS High-voltage spacer. The pin is not connected internally to isolate the high-voltage pin and

3 GND Chip ground. Current return for both the gate-drive current and the bias current of the IC. All

4 OUT Gate-drive output. The driver is capable of 0.8A min. source/sink peak current to drive

5 Vcc Supply Voltage of both the signal part of the IC and the gate driver. The internal high volt-

6 N.C. Connect the pin to GND.

7 DIS Latched device shutdown. Internally the pin connects a comparator that, when the voltage

8 VREF Voltage reference. An internal generator furnishes an accurate voltage reference (5V±4%,

9 SKIPADJ Burst-mode control threshold. A voltage is applied to this pin, derived from the reference

10 COMP Control input for PWM regulation. The pin is to be driven by the phototransistor (emitter-

11 SS Soft start. An internal 20µA generator charges an external capacitor connected between

12 ISEN Current sense (PWM comparator) input. The voltage on this pin is internally compared with

Pin Name Function

0.8 mA internal current source charges the capacitor connected between pin Vcc and GND

to start up the IC. When the voltage on the Vcc pin reaches the start-up threshold the generator is shut down. Normally it is re-enabled when the voltage on the Vcc pin falls below

5V, except under latched shutdown conditions, when it is re-enabled as the Vcc voltage falls

0.5V below the start-up threshold.

comply with safety regulations (creepage distance) on the PCB.

of the ground connections of the bias components should be tied to a track going to this pin

and kept separate from any pulsed current return.

MOSFET’s. The voltage delivered to the gate is clamped at about 15V so as to prevent too

high values when the IC is supplied with a voltage close to or exceeding 20V.

age generator charges an electrolytic capacitor connected between this pin and GND as

long as the voltage on the pin is below the start-up threshold of the IC, after that it is disabled. Sometimes a small bypass capacitor (0.1µF typ.) to GND might be useful to get a

clean bias voltage for the signal part of the IC.

on the pin exceeds 2.2V, shuts the IC down and brings its consumption to a value barely

higher than before start-up. The information is latched and it is necessary to recycle the

input power to restart the IC: the latch is removed as the voltage on the Vcc pin goes below

the UVLO threshold. Connect the pin to GND if the function is not used.

all inclusive) that can be used to supply up to 5 mA to an external circuit. A small film

capacitor (0.1µF typ.), connected between this pin and GND is recommended to ensure the

stability of the generator and to prevent noise from affecting the reference.

voltage VREF via a resistor divider. When the control voltage at pin COMP falls 50 mV

below the voltage on this pin the IC is shutdown and the consumption is reduced. The chip

is re-enabled as the voltage on pin COMP exceeds the voltage on the pin. The high-voltage

start-up generator is not invoked. The function is disabled during the soft-start ramp. The

pin must always be biased between 0.8 and 2.5V. A voltage between 0.8 and 1.4V disables

the function, if the pin is pulled below 0.8V the IC is shut down.

grounded) of an optocoupler to modulate the voltage by modulating the current sunk from

(sourced by) the pin (0.4 mA typ.). It is recommended to place a small filter capacitor

between the pin and GND, as close to the IC as possible to reduce switching noise pick up,

to set a pole in the output-to-control transfer function. A voltage 50 mV lower than that on

pin SKIPADJ shuts down the IC and reduces its current consumption.

the pin and GND generating a voltage ramp across it. This ramp clamps the voltage at pin

COMP during start-up, thus the duty cycle of the power switch starts from zero. During the

ramp all functions monitoring the voltage at pin COMP are disabled. The SS capacitor is

quickly discharged as the chip goes into UVLO.

an internal reference derived from the voltage on pin COMP and when they are equal the

gate drive output (previously asserted high by the clock signal generated by the oscillator)

is driven low to turn off the power MOSFET. The pin is equipped with 200 ns. min. blanking

time for improved noise immunity. A second comparison level located at 1.5V shuts the

device down and brings its consumption almost to a “before start-up” level.

3/23

L6668

Table 4. Pin Description (continued)

Pin

Number

Pin Name Function

13 STBY Standby function. This pin is a high-impedance one as long as the voltage on pin COMP is

higher than 3V. When the voltage on pin COMP falls below 3V, the voltage on the pin tracks

that on pin COMP and is capable of sinking current. A resistor connected from the pin to the

oscillator allows programming frequency foldback at light load.

14 PFC_STOP Open-drain ON/OFF control of PFC controller. This pin is intended for driving the base of a

PNP transistor in systems comprising a PFC pre-regulator, to stop the PFC controller at

light load by cutting its supply. The pin, normally low, opens if the voltage on COMP is lower

than 2.2V and goes back low when the voltage on pin COMP exceeds 2.7V. Whenever the

IC is shutdown, either latched (DIS >2.2V, ISEN >1.5V) or not (UVLO, SKIPADJ<0.8), the

pin is open as well.

15 S-COMP Voltage ramp for slope compensation. When the gate-drive output is high the pin delivers a

voltage tracking the oscillator ramp (shifted down by one V

); when the gate-drive output

BE

is low the voltage delivered is zero. The pin is to be connected to pin ISEN via a resistor to

make slope compensation and allow stable operation at duty cycles close to and greater

than 50%.

16 RCT Oscillator pin. A resistor to VREF and a capacitor to GND define the oscillator frequency (at

full load). A resistor connect to STBY modifies the oscillator frequency when the voltage on

pin COMP is lower than 3V.

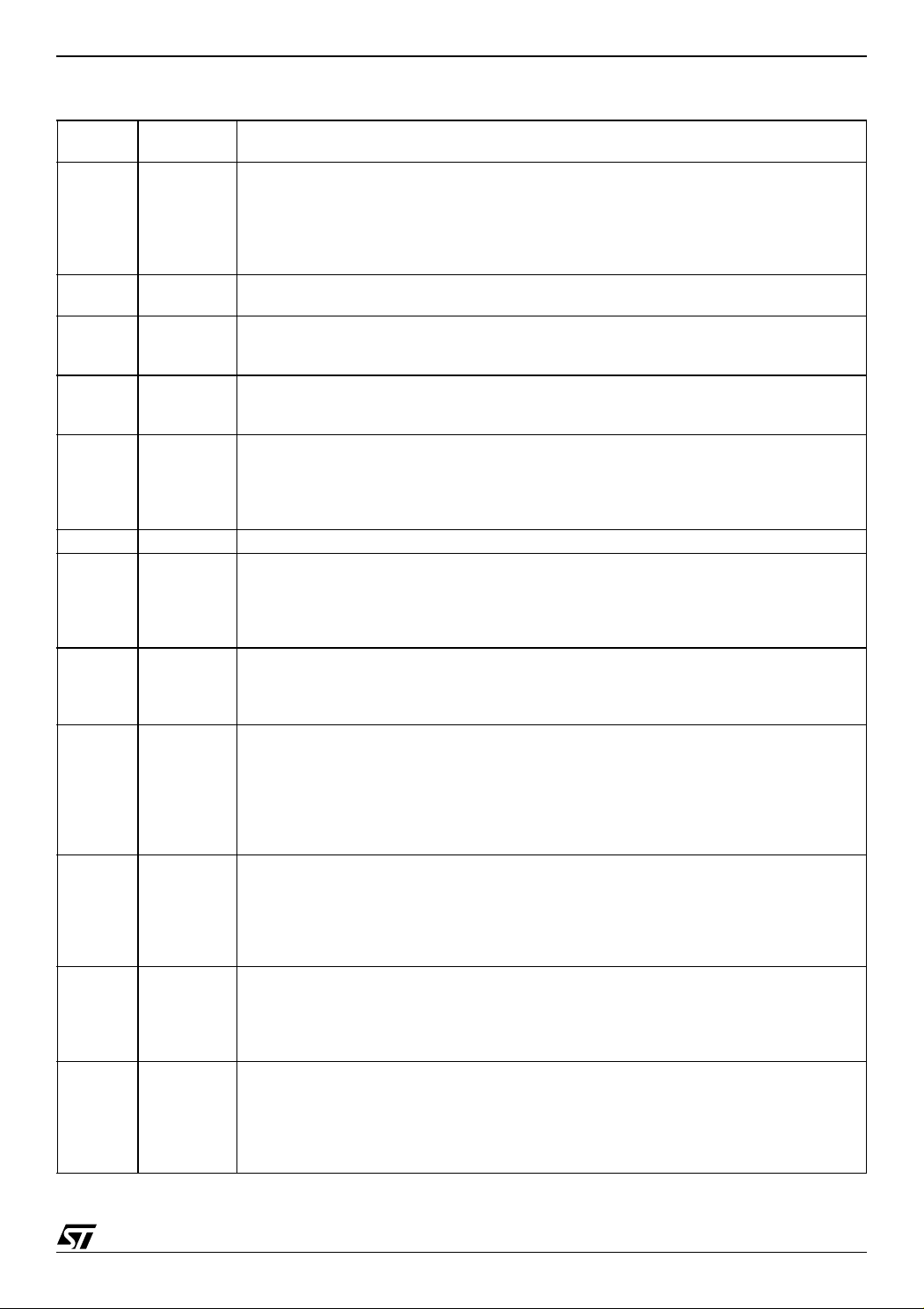

Table 5. Electrical Characteristcs

(T

= 0 to 105°C, Vcc=15V, Co=1nF; RT =13.3k , CT =1nF; unless otherwise specified)

j

Symbol Parameter Test Condition Min. Typ. Max. Unit

SUPPLY VOLTAGE

Vcc Operating range After turn-on 9.4 22 V

V

CCOn

V

CCOff

Turn-on threshold

Turn-off threshold

Hys Hysteresis 4.0 V

V

Zener Voltage Icc = 20 mA 22 24 28 V

Z

SUPPLY CURRENT

I

start-up

I

I

CC

I

qdis

Start-up Current Before turn-on,

Quiescent Current After turn-on 2 2.5 mA

q

Operating Supply Current 4 mA

Shutdown quiescent

current

HIGH-VOLTAGE START-UP GENERATOR

V

V

HVstart

I

charge

I

HV, ON

I

HV, OFF

V

CCrestart

Breakdown voltage I

HV

Start voltage I

Vcc charge current VHV > V

ON-state current VHV > V

Leakage current (OFF state) VHV = 400 V 40 µA

HV generator restart voltage 4.4 5 5.6 V

(1)

(1)

After turn-on

12.5 13.5 14.5 V

8.0 8.7 9.4 V

150 µA

Vcc=Vcc

V

DIS

V

SKIPADJ

0.8 <V

< 100 µA 700 V

HV

< 100 µA 60 80 105 V

Vcc

V

HV

(1)

After DIS tripping

-0.5

ON

> 2.2, or V

> 1.5 180 µA

ISEN

<0.8 1 1.8 mA

> V

< V

COMP

Hvstart

Hvstart

Hvstart

SKIPADJ

, Vcc > 3V 0.55 0.85 1 mA

, Vcc > 3V 1.6 mA

, Vcc = 0 0.8

1.3 mA

12 13 14 V

4/23

Table 5. Electrical Characteristcs (continued)

(T

= 0 to 105°C, Vcc=15V, Co=1nF; RT =13.3k , CT =1nF; unless otherwise specified)

j

Symbol Parameter Test Condition Min. Typ. Max. Unit

REFERENCE VOLTAGE

V

V

REF

REF

I

REF

Output voltage

Total variation Vcc= 9.4 to 22 V,

Short circuit current V

Sink capability in UVLO Vcc = 6V; Isink = 0.5 mA 0.2 0.5 V

PWM CONTROL

V

COMP

I

COMP

R

D

D

COMP

max

min

Maximum level I

H

Max. source current V

Dynamic resistance V

Maximum duty cycle V

Minimum duty cycle V

CURRENT SENSE COMPARATOR

I

ISEN

t

LEB

t

d(H-L)

Input Bias Current V

Leading Edge Blanking After gate drive low-to-high

Delay to Output 100 ns

Gain 3.56 3.75 3.94 V/V

V

ISENx

V

ISENdis

Maximum signal V

Hiccup-mode OCP level

STANDBY FUNCTION

V

drop

V

th

V

- V

COMP

STBY

Threshold on V

COMP

Hysteresis 50 mV

LATCHED DISABLE FUNCTION

I

DIS

Input Bias Current V

Vth Disable threshold

OSCILLATOR

fsw Oscillation Frequency Tj = 25°C, V

Vpk Oscillator peak voltage

Vvy Oscillator valley voltage

SLOPE COMPENSATION

S-COMP

S-COMP

Ramp peak R

pk

Ramp starting value R

vy

Ramp voltage OUT pin low 0

Source capability V

SOFT-START

I

SSC

Charge current Tj = 25 °C 14 20 26 µA

(2)

Tj = 25 °C; I

REF

= 1 mA

4.925 5 5.075 V

4.8 5.13 V

I

= 1 to 5 mA

REF

= 0 10 30 mA

REF

=0 5.5 V

COMP

= 1 V 320 400 480 µA

COMP

= 2 to 4 V 22 kΩ

COMP

= 5 V 70 75 %

COMP

= 1 V 0 %

COMP

= 0 -1 µA

ISEN

160 225 290 ns

transition

= 5 V 0.725 0.8 0.875 V

COMP

(2)

I

= 0.8 mA, V

STBY

(2)

Voltage falling

= 0 to Vth -1 µA

DIS

(2)

voltage rising

COMP

Vcc = 9.4 to 22V, V

(2)

(2)

= 3 kΩ to GND,

S-COMP

OUT pin high, V

= 3 kΩ to GND,

S-COMP

<3V 35 mV

COMP

= 5 V 95 100 105 kHz

= 5 V 93 100 107 kHz

COMP

= 5V

COMP

1.35 1.5 1.65 V

3V

2.1 2.2 2.3 V

2.85 3 3.15 V

0.8 0.95 1.1 V

1.6 1.75 1.9 V

0.15 0.35 0.55 V

OUT pin high

S-COMP = VS-COMPpk

0.8 mA

L6668

5/23

L6668

Table 5. Electrical Characteristcs (continued)

(T

= 0 to 105°C, Vcc=15V, Co=1nF; RT =13.3k , CT =1nF; unless otherwise specified)

j

Symbol Parameter Test Condition Min. Typ. Max. Unit

V

SSsat

V

SSclamp

SKIPADJ FUNCTION

I

bias

V

SKIP

Hys Hysteresis Below V

V

OFF

PFC_STOP FUNCTION

I

leak

V

Vth Threshold for high level

Vth Threshold for high level

GATE DRIVER

V

V

OH

I

sourcepk

I

sinkpk

t

t

V

Oclamp

(1), (2)

Parameters in tracking each other

Low saturation voltage Duty cycle = 0 0.6 V

High saturation voltage 7 V

Input Bias Current V

= 0 to 4.5 V -1 µA

SKIP

Operating range 1.4 2.5 V

SKIP

25 85 mV

Shutdown threshold Voltage falling 0.8 V

High level leakage current V

Low saturation level I

L

Output Low Voltage I

OL

Output High voltage I

PFC_STOP

PFC_STOP

V

COMP

V

COMP

= 200 mA 1.0 V

sink

source

= 1mA, V

falling

rising

< 16V, V

(2)

(2)

= 2V 1 µA

COMP

= 4V 0.1 V

COMP

2.1 2.2 2.3 V

2.55 2.7 2.85 V

= 5 mA, Vcc = 12V 9.8 10.3 V

Peak source current -0.8 A

Peak sink current 0.8 A

Current Fall Time 30 ns

f

Current Rise Time 55 ns

r

Output clamp voltage I

UVLO saturation Vcc= 0 to Vccon, I

= 5mA; Vcc = 20V 10 12 15 V

source

= 2mA 1.1 V

sink

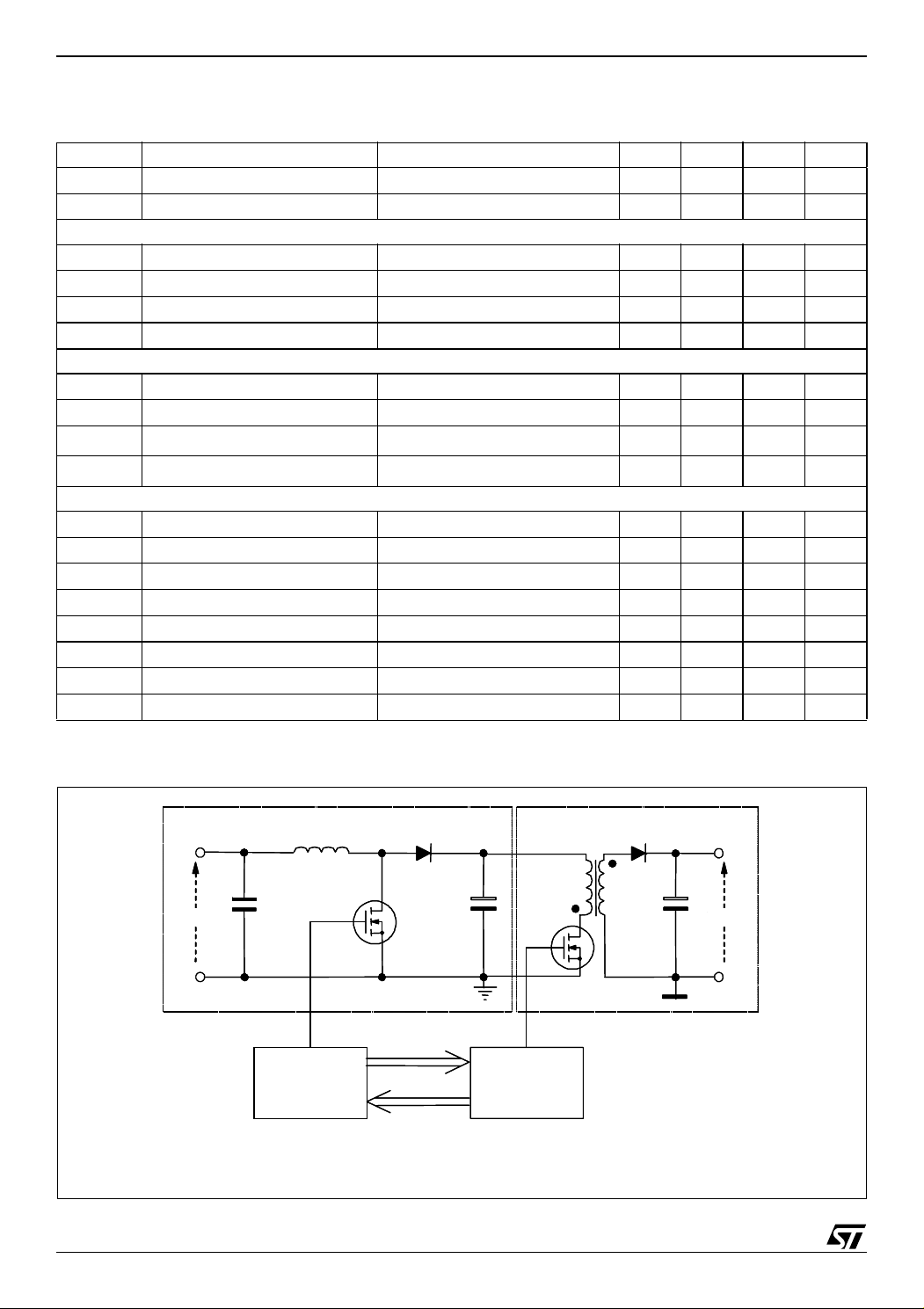

Figure 4. Typical System Block Diagram

PFC PRE-REGULATOR DC-DC CONVERTER

PFC PRE-REGULATOR DC-DC CONVERTER

V

V

inac

inac

PWM is turned off in case of PFC's

PWM is turned off in case of PFC's

anomalous operation, for safety

anomalous operation, for safety

L6561/2

L6561/2

or

or

L6563

L6563

PFC can be turned off at light

PFC can be turned off at light

load to ease compliance with

load to ease compliance with

energy saving regulations.

energy saving regulations.

6/23

L6668

L6668

V

V

outdc

outdc

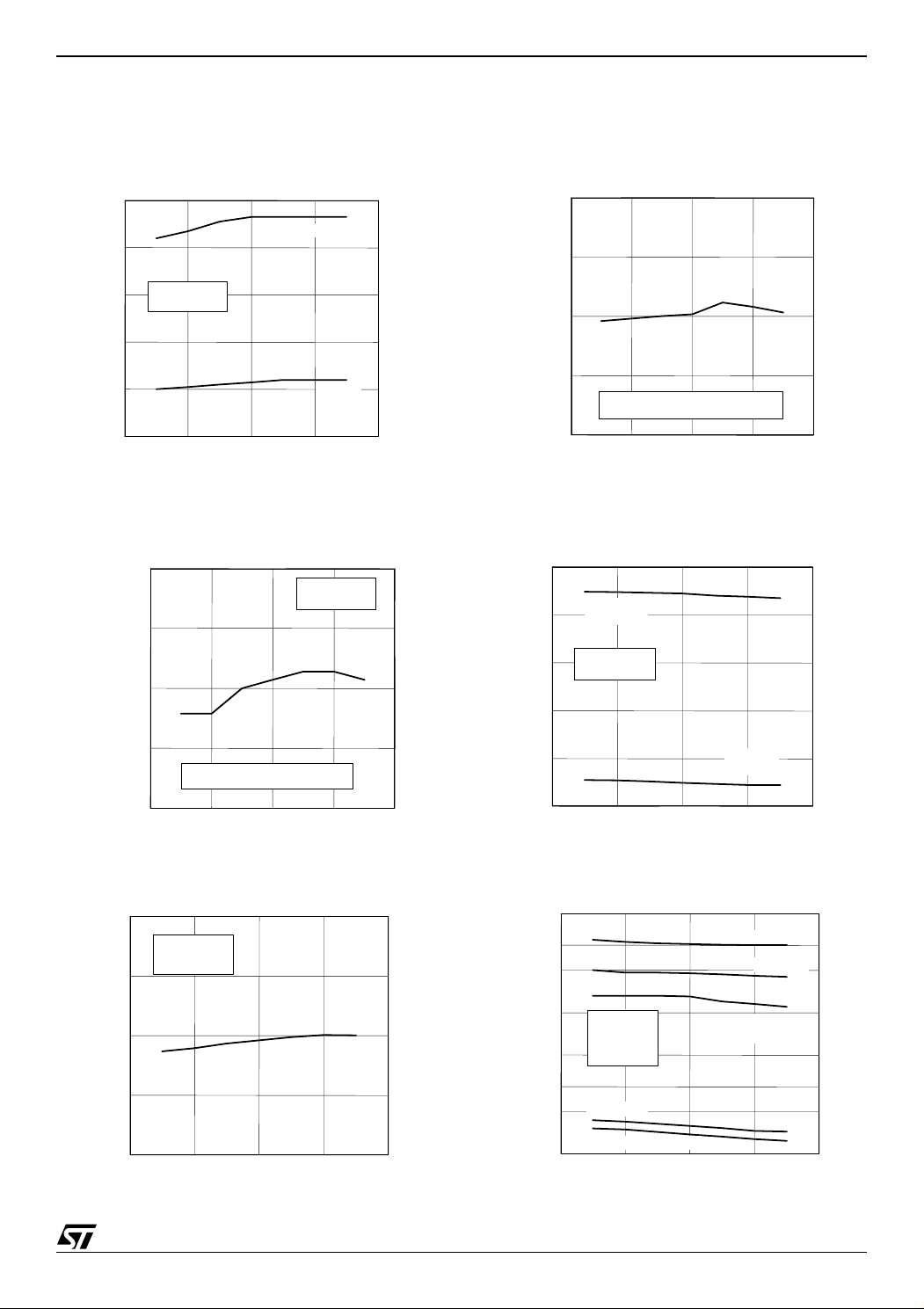

3 Typical Electrical Performance

L6668

Figure 5. High-voltage generator ON-state sink current vs. Tj

HV

I

(pin 1)

1.2

[mA]

1

0.8

VHV = 100 V

0.6

0.4

0.2

-50 0 50 100 150

Vcc≥3V

Vcc = 0

Tj (°C)

Figure 6. High-voltage generator output (Vcc charge current) vs. Tj

Icc (pin 5)

120%

VHV = 100 V

110%

Figure 8. High-voltage generator start voltage vs. Tj

HV

120%

110%

100%

90%

Values normalized to VHV@ 25°C

80%

-50 0 50 100 150

Tj (°C)

Figure 9. High-voltage generator Vcc restart voltage vs. Tj

Vcc (pin 5)

14

[V]

12

while

latched off

100%

90%

Values normalized to Icc @ 25°C

80%

-50 0 50 100 150

Tj (°C)

Figure 7. High-voltage pin leakage vs. Tj

HV

I

(pin 1)

40

[µA]

VHV = 400 V

30

20

10

Vcc = 15V

0

-50 0 50 100 150

Tj (°C)

10

VHV = 100 V

8

6

4

-50 0 50 100 150

normal

operation

Tj (°C)

Figure 10. IC consumption vs. Tj

Icc (pin 5)

5

[mA]

3

2

1

Vcc = 15 V

Co = 1 nF

0.5

0.3

0.2

0.1

f = 100 kHz

Latched off

Before start-up (Vcc=12V)

-50 0 50 100 150

during burst-mode

Tj (°C)

Operating

Quiescent

Disa bled or

7/23

L6668

Figure 11. Start-up & UVLO vs. Tj

V

CC (pin 5)

(V)

14

ON

13

12

OFF while

latched off

11

10

9

8

OFF

-50 0 50 100 150

Tj (°C)

Figure 12. Vcc Zener voltage vs. Tj

Vcc

Z (pin 5)

(V)

26

25

24

23

22

21

Figure 14. COMP source current vs. Tj

(pin 10)

I

COMP

140%

120%

100%

80%

Values normalized to I

60%

-50 0 50 100 150

Tj (°C)

Vcc = 15 V

V

COMP

COMP

= 1 V

@ 25°C

Figure 15. COMP dynamic resistance vs. Tj

R

R

COMP (pin 1 0)

COMP (pin 1 0)

32

32

(kΩ)

(kΩ)

30

30

28

28

26

26

24

24

22

22

20

20

Vcc = 15 V

Vcc = 15 V

20

-50 0 50 100 150

Tj (°C)

Figure 13. COMP voltage upper clamp level vs. Tj

V

(pin 10)

COMP

7

8/23

(V)

6.5

6

5.5

5

-50 0 50 100 150

Tj (°C)

Vcc = 15 V

18

18

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

Figure 16. Max. duty-cycle vs. Tj

(%)

75

74

73

72

71

70

-50 0 50 100 150

Tj (°C)

Vcc = 15 V

L6668

Figure 17. Oscillator frequency vs. Tj

fsw

102%

101.5%

101%

100.5%

RT= 13.3 k

C

T = 1 nF

Ω

Vcc = 22V

Vcc = 15V

Vcc = 9.4V

100%

99.5%

Values normalized to fsw @ Tj=25°C, Vcc=15V

99%

-50 0 50 100 150

Tj (°C)

Figure 18. Oscillator ramp vs. Tj

Vpin14

3.5

(V)

3.0

2.5

Peak

Vcc = 15 V

Figure 20. Disable level on current sense vs. Tj

Vpin12

(V)

2.0

Vcc = 15 V

1.8

1.6

1.4

1.2

1.0

-50 0 50 100 150

Tj (°C)

Figure 21. Reference voltage vs. Tj

V

REF

(pin 8 )

(V)

5.1

Vcc = 15 V

5.05

2.0

1.5

Valley

1.0

0.5

-50 0 50 100 150

Tj (°C)

Figure 19. Current sense clamp vs. Tj

V

ISENx ( pin 12)

(V)

1

Vcc = 15 V

V

= Upper clamp

0.9

0.8

0.7

0.6

-50 0 50 100 150

COMP

Tj (°C)

5

4.95

4.9

-50 0 50 100 150

Tj (°C)

Figure 22. PFC_STOP open/low thresholds on

V

vs. Tj

COMP

V

COMP

(pin 10)

2.8

(V)

PFC_STOP low (voltage rising)

2.7

2.6

2.5

2.4

2.3

PFC_STOP open (voltage falling)

2.2

2.1

-50 0 50 100 150

Tj (°C)

Vcc = 15 V

9/23

L6668

Figure 23. Standby thresholds vs. Tj

V

COMP

(pin 10)

3.6

(V)

3.4

3.2

2.8

2.6

2.4

Disa ble (vo ltage risi ng)

3

Enable (voltage falling)

-50 0 50 100 150

Tj (°C)

Vcc = 15 V

Figure 24. Standby pin dropout vs. Tj

Vpin13 - Vpin10

0

(mV)

-5

-10

-15

-20

-25

Vcc = 15 V

V

= 2V

COMP

I

STBY = 0.8 mA

Figure 26. SKIPADJ hysteresis vs. Tj

Vpin9

100.0

(mV)

80.0

Vcc = 15 V

60.0

Vskipadj = 2.5 V

40.0

20.0

0.0

-50 0 50 100 150

Vskipadj = 1.4 V

Tj (°C)

Figure 27. SKIPADJ disable threshold vs. Tj

Vpin9

1.0

(V)

0.9

0.8

0.7

0.6

Vcc = 15 V

-30

-50 0 50 100 150

Tj (°C)

Figure 25. DIS threshold vs. Tj

V pin 7

2.5

(V)

2.4

2.3

2.2

2.1

2.0

-50 0 50 100 150

Tj (°C)

Vcc = 15 V

0.5

-50 0 50 100 150

Tj (°C)

Figure 28. Soft-start charge current vs. Tj

( pin11)

Iss

40.0

(µA)

30.0

20.0

10.0

Vcc = 15 V

0.0

-50 0 50 100 150

Tj (°C)

10/23

L6668

Figure 29. S-COMP ramp vs. Tj

Vpin15

2.0

(V)

Peak

1.5

Vcc = 15 V

R

S-SCOMP = 3 k

1.0

0.5

Valley

0.0

-50 0 50 100 150

Tj (°C)

Figure 30. UVLO saturation vs. Tj

Vpin4

1

(V)

0.9

0.8

Vcc = 0 V

Figure 32. Gate-drive output low saturation

V

pin4

[V]

5

4

Ω

3

2

1

0

0 200 400 600 800 1,000 1,200

Tj = 25 °C

Vcc = 12 V

SINK

IGD[mA]

Figure 33. Gate-drive output high saturation

V

pin4

[V]

Vcc - 2.0

Vcc - 3.0

Vcc - 4.0

Tj = 25 °C

Vcc = 12 V

SOURCE

0.7

0.6

0.5

-50 0 50 100 150

Tj (°C)

Figure 31. Gate-drive clamp vs. Tj

clamp

Vpin4

13

(V)

Vcc = 20 V

12.8

12.6

12.4

12.2

12

-50 0 50 100 150

Tj (°C)

Vcc - 5.0

Vcc - 6.0

0 200 400 600 800 1,000

IGD[mA]

11/23

L6668

4 Application Information

The L6668 is a versatile current-mode PWM controller specific for offline fixed-frequency, peak-currentmode-controlled flyback converters.

The device is able to operate in different modes (fig. 34), depending on the converter's load conditions:

1) Fixed frequency at heavy load. In this region the IC operates exactly like a standard current mode control

chip: a relaxation oscillator, externally programmable with a capacitor and a resistor, generates a sawtooth

and releases a clock pulse during the falling edge of the sawtooth; the power switch is turned on by the clock

pulses and is turned off by the control loop.

2) Frequency-foldback mode at medium and light load. As the load is reduced the oscillator frequency is reduced as well by slowing down the charge of the timing capacitor proportionally to the load itself.

3) Burst-mode control with no or very light load. When the load is extremely light or disconnected, the converter

will enter a controlled on/off operation with constant peak current. A load decrease will be then translated

into a frequency reduction, which can go down even to few hundred hertz, thus minimizing all frequencyrelated losses and making it easier to comply with energy saving regulations. Being the peak current very

low, no issue of audible noise arises.

Figure 34. Multi-mode operation of the L6668

Frequency foldback mode

Burs t mode

sw

f

0

0

in

P

Fixed-frequency mode

Pinmax

4.1 High-voltage start-up generator

Figure 35 shows the internal schematic of the high-voltage start-up generator (HV generator). It is made

up of a high-voltage N-channel FET, whose gate is biased by a 15 M

Ω resistor, with a temperature-com-

pensated current generator connected to its source.

Figure 35. High-voltage start-up generator: internal schematic

HV

3

GND

1

I

HV

Vcc

5

I

charge

L6668 15 M

Vcc_OK

Ω

HV_EN

CONTR OL

The HV generator is physically located on a separate chip, made with BCD off-line technology able to withstand 700V, controlled by a low-voltage chip, where all of the control functions reside.

12/23

L6668

With reference to the timing diagram of figure 36, when power is first applied to the converter the voltage

on the bulk capacitor (Vin) builds up and, as it reaches about 80V, the HV generator is enabled to operate (HV_EN is pulled high) so that it draws about 1 mA. This current, diminished by the IC consumption,

charges the bypass capacitor connected between pin Vcc (5) and ground and makes its voltage rise almost linearly.

Figure 36. Timing diagram: normal power-up and power-down sequences

Vin

Vin

V

V

HVstar t

HVstar t

regulation is lost here

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc

ON

OFF

OFF

restart

restart

OUT

OUT

HV_EN

HV_EN

Vcc_OK

Vcc_OK

regulation is lost here

ON

t

t

t

t

t

t

t

t

I

1 mA

1 mA

I

HV

HV

Normal

Power-up Power-down

Power-up Power-down

Normal

operation

operation

t

t

t

t

As the Vcc voltage reaches the start-up threshold (13.5V typ.) the low-voltage chip starts operating and

the HV generator is cut off by the Vcc_OK signal asserted high. The IC is powered by the energy stored

in the Vcc capacitor until the self-supply circuit (typically an auxiliary winding of the transformer and a

steering diode) develops a voltage high enough to sustain the operation.

The residual consumption of this circuit is just the one on the 15M

Ω resistor (≈10 mW at 400 Vdc), typically

50-70 times lower, under the same conditions, as compared to a standard start-up circuit made with an

external dropping resistor.

Figure 37. Timing diagram showing short-circuit behavior

Short circuit occurs here

Short circuit occurs here

t

t

t

t

VccON

VccON

VccOFF

VccOFF

Vccrest

Vccrest

OUT

OUT

Vcc_OK

Vcc_OK

Vcc

Vcc

1 mA

1 mA

HV

HV

I

I

t

t

t

t

13/23

L6668

At converter power-down the system will lose regulation as soon as the input voltage is so low that either

peak current or maximum duty cycle limitation is tripped. Vcc will then drop and stop IC activity as it falls

below the UVLO threshold (8.7V typ.).

The Vcc_OK signal is de-asserted as the Vcc voltage goes below a threshold Vcc

5V. The HV generator can now restart but, if Vin < V

, as shown in figure 36, HV_EN is de-asserted

instart

too and the HV generator is disabled.

This prevents converter's re-start attempts and ensures monotonic output voltage decay at power-down.

The low restart threshold Vcc

ensures that, during short circuits, the restart attempts of the L6668 will

restart

have a very low repetition rate, as shown in the timing diagram of figure 37, and that the converter will

work safely with extremely low power throughput.

4.2 Frequency Foldback Block and operation at medium/light load

At heavy load, namely as the voltage on pin COMP (V

) is higher than 3V, the device works at a fixed

COMP

frequency like a standard current mode PWM controller.

As the load is reduced, and the V

voltage falls below 3V (approximately corresponding to 50% of the

COMP

maximum load in a fully DCM system), the oscillator frequency can be made dependent on converter's

load conditions - the lower the load, the lower the frequency and vice versa.

Figure 38. Frequency foldback function: oscillator frequency is a function of COMP voltage

located at about

restart

f

f

osc

STBY

STBY

T

T

osc

L6668

L6668

COMP

COMP

3.0V

3.0V

-

-

+

+

OSCILLATOR

OSCILLATOR

13

13

8

8

16

16

This is done by adding an external resistor R

STBY

STBY

Vref

Vref

R

R

R

R

T

T

RCT

RCT

C

C

between pins RCT (#16) and STBY (#13), which acti-

STBY

vates the circuit shown in figure 38.

When V

nected to a current sink, tracks V

is below 3 V (oscillator's peak voltage) the voltage on the STBY pin, which is internally con-

COMP

and then some of the current that charges CT is diverted to ground

COMP

through the STBY pin.

In this way the rate of rise of the voltage across C

the lower V

the lower the frequency. Instead, when V

COMP

high impedance and the oscillator frequency f

is slowed down and the oscillator frequency decreased,

T

will be determined by RT and CT. These components can

osc

is greater than 3 V the STBY pin features

COMP

be then calculated as it is usually done with this type of oscillator:

RTC

1.4

---------=

T

f

osc

R

R

STBY

STBY

1.4 3.0 4.4

1.4 3.0 4.4

V

V

COMP

COMP

14/23

Figure 39. Standby function: frequency shift vs. timing resistors (normalized quantities)

1

1

0.9

0.9

0.8

0.8

0.7

0.7

f

f

min

min

0.6

0.6

f

f

osc

osc

0.5

0.5

0.4

0.4

0.3

0.3

0.2

0.2

0. 1 10

0. 1 10

2.5V

2.5V

2.2V

2.2V

2V

2V

1.8V

1.8V

V(SKIPADJ) = 1.6V

V(SKIPADJ) = 1.6V

V(SKIPADJ) = 1.5V

V(SKIPADJ) = 1.5V

V(SKIPADJ) = 1.4V

V(SKIPADJ) = 1.4V

R

R

STBY

STBY

R

R

T

T

L6668

The determination of R

mode operation takes place (f

can be done assuming that the minimum switching frequency before burst-

STBY

) is specified. This value will be above the audible range to ensure a

min

noise-free operation. With the aid of the diagrams in figure 39, which show the relationship between the

frequency shift obtained and the ratio of R

possible to determine R

. Draw an horizontal line corresponding to the desired f

STBY

to RT for different values of the burst-mode threshold, it is

STBY

ratio as long as

min/fosc

it intercepts the characteristic corresponding to the voltage set at the pin SKIPADJ (#9). From there, draw

a vertical line: on the horizontal axis it is possible to read the required R

STBY/RT

ratio.

Note that the characteristic for V(SKIPADJ)=1.4V corresponds to the burst-mode operation not used (see

next section). Note also that, for a given V(SKIPADJ), there is both a lower limit to the R

STBY/RT

ratio and

a maximum frequency shift allowed. Not observing these limits will result in erratic behavior.

In applications where the switching frequency needs not be tightly fixed for some specific reason there is

no major drawback to this technique. In case this function is not desired, the STBY pin shall be left open.

4.3 Operation at no load or very light load

When the PWM control voltage at pin COMP falls about 50 mV below a threshold externally programmable via pin 9 (SKIPADJ), the IC is disabled with the MOSFET kept in OFF state and its consumption reduced at a very low value to minimize Vcc capacitor discharge. The soft-start capacitor is not discharged.

The control voltage now will increase as a result of the feedback reaction to the energy delivery stop, the

threshold will be exceeded and the IC will restart switching again. In this way the converter will work in

burst-mode with a constant peak current defined by the disable level applied at pin 9. A load decrease will

then cause a frequency reduction, which can go down even to few hundred hertz, thus minimizing all frequency-related losses and maximizing efficiency. This kind of operation is noise-free provided the peak

current, which is user-defined by the bias voltage at pin 9, is very low.

The timing diagram of figure 40 illustrates this kind of operation along with the other ones, showing the

most significant signals.

15/23

L6668

Figure 40. Load-dependent operating modes: timing diagram

COMP

3.0V

V(SKIPADJ)

50 mV

hyster.

f

osc

t

t

OUT

Fix. Fr eq.

Mode

Burst-mode

Frequency Foldback Mode

Fix. Fr eq.

t

Mode

The operating range of the voltage V(SKIPADJ) is practically limited upwards by the onset of audible

noise: typically, with a voltage above 2-2.1V some noise can be heard under some line/load conditions. If,

instead, V(SKIPADJ) is set below the low saturation value of the PWM control voltage (1.4V typ.) burstmode operation will never take place. Always bias the pin at some voltage, a floating pin will result in

anomalous behavior. The SKIPADJ pin doubles its function: if the voltage is pulled below 0.8V the IC is

disabled completely, except for the externally available reference voltage VREF, and its quiescent consumption reduced. The soft-start capacitor is discharged so that, when the voltage on the SKIPADJ pin is

pulled above 0.8V, the chip is soft-started just like exiting from UVLO. This function is useful for some kind

of remote ON/OFF control. The comparator referenced to 0.8V does not have hysteresis; hence make

sure that the voltage on the pin does not linger on the threshold to prevent uncertain behavior.

4.4 PWM control Block

The device is specific for secondary feedback. Typically, there is a TL431 at the secondary side and an

optocoupler that transfers output voltage information to the PWM control at the primary side, crossing the

isolation barrier. The PWM control input (pin #10, COMP) is driven directly by the phototransistor's collector (the emitter is grounded to GND) to modulate the duty cycle.

4.5 Current Comparator, PWM Latch and Hiccup-mode OCP

The current comparator senses the voltage across the current sense resistor (Rs) on pin 12 (ISEN) and,

by comparing it with the programming signal derived form the control voltage on pin 10 (COMP), determines the exact time when the external MOSFET is to be switched off. The PWM latch avoids spurious

switching of the MOSFET, which might result from the noise generated ("double-pulse suppression").

16/23

Figure 41. Hiccup-mode OCP: timing diagram

Secondary diode is shorte d here

Vcc

Vcc

Vcc

Vcc

Vcc

Vcc

OFF

OFF

V

V

OUT

OUT

OCP latch

OCP latch

Vcc_OK

Vcc_OK

ON

ON

re

re

1.5 V

CS

CS

1.5 V

Secondary diode is shorte d here

L6668

t

t

t

t

t

t

t

t

t

t

A second comparator senses the voltage on the current sense input and shuts the IC down if the voltage

at the pin exceeds 1.5 V. Such an anomalous condition is typically generated by either a short circuit of

the secondary rectifier or a shorted secondary winding or a saturated flyback transformer.

This condition is latched as long as the IC is supplied. When the IC is disabled, however, no energy is

coming from the self-supply circuit, then the voltage on the Vcc capacitor will decay and cross the UVLO

threshold after some time, which clears the latch. The internal start-up generator is still off, then the Vcc

voltage still needs to go below its restart voltage before the Vcc capacitor is charged again and the IC restarted.

Ultimately, either of the above mentioned failures will result in a low-frequency intermittent operation (Hiccup-mode operation), with very low stress on the power circuit. The timing diagram of figure 41 illustrates

this operation.

4.6 Power Management

The L6668 is specifically designed to minimize converter's losses under light or no-load conditions, and a

special function has been provided to help the designer meet energy saving requirements even in powerfactor-corrected systems where a PFC pre-regulator precedes the DC-DC converter.

Actually EMC regulations require compliance with low-frequency harmonic emission limits at nominal

load, no limit is envisaged when the converter operates with a light load. Then the PFC pre-regulator can

be turned off, thus saving the no-load consumption of this stage (0.5 to 1W).

To do so, the device provides the PFC_STOP (#14) pin: it is an open collector output, normally low, that

becomes open when the voltage V

falls below 2.2V.

COMP

This signal will be externally used for switching off the PFC controller and the pre-regulator as shown in

figure 42. To prevent intermittent operation of the PFC stage, 0.5V hysteresis is provided: the PFC_STOP

pin is re-asserted low (which will re-enable the PFC pre-regulator) when V

exceeds 2.7 V.

COMP

A capacitor (and a limiting resistor in the hundred ohms), shown in dotted lines, may be used if one wants

to delay PFC turn-off

When the L6668 is in UVLO (Vcc<8.7V) the pin is kept high so as to ensure that the PFC pre-regulator

will start up only after the DC-DC converter governed by the L6668 is activated.

17/23

L6668

Figure 43 shows a timing diagram where the PFC_STOP function operation is illustrated under different

operating conditions.

Figure 42. How the L6668 can switch off a PFC controller at light load

BC557

BC557

Vcc

Vcc

16

16

PFC_STOP14

L6668

L6668

PFC_STOP14

Figure 43. Operation of PFC_STOP function

Vcc

ON

Vcc

OFF

Vcc

10 k

10 k

2.2 k

2.2 k

Ω

Ω

8.2 V

8.2 V

Ω

Ω

Vcc

Vcc

PFC

PFC

controller

controller

PFC_STOP

COMP

2.2V

OUT

PFC

Gate

Drive

Star t-up Full -load Light- load Full- load

Figure 44. Operation after DIS pin activation: timing diagram

DIS

DIS

2.2V

2.2V

Vcc

Vcc

VccON

VccON

HV generator is tur ned on

VccON -0.5

VccON -0.5

VccOFF

VccOFF

Vccrest

Vccrest

OUT

OUT

HV generator is tur ned on

HV generator is disabled here

HV generator is disabled here

2.7V

Disabl e latch is rese t here

Disabl e latch is rese t here

t

t

t

t

t

t

t

t

t

18/23

V

V

Vin

Vin

HVstart

HVstart

Input source is removed here

Input source is removed here

t

t

t

t

L6668

4.7 Disable function

Latched OTP or OVP functions can be easily realized with the L6668: the IC is equipped with a comparator whose non-inverting input is externally available on pin #7 (DIS), and whose inverting input is internally referenced to 2.2V.

As the voltage on the pin exceeds the threshold the IC is immediately shut down and its consumption reduced at a low value. The information is latched and it is necessary to let the voltage on the Vcc pin go

below the UVLO threshold to reset the latch and restart the IC.

To keep the latch supplied as long as the converter is connected to the input source, the HV generator is

activated periodically so that Vcc oscillates between the start-up threshold V

then necessary to disconnect the converter from the input source to restart the IC. This operation is shown

in the timing diagram of figure 44. Activating the HV generator in this way cuts its power dissipation approximately by three and keeps peak silicon temperature close to the average value.

4.8 Slope compensation

A pin of the device (#15, S-COMP) provides a voltage ramp during MOSFET's ON-time which is a repetition of the oscillator sawtooth, buffered (0.8 mA min. capability) and level shifted down by one Vbe.

This ramp is intended for implementing additive slope compensation on current sense. This is needed to

avoid the sub-harmonic oscillation that arises in all peak-current-mode-controlled converters working in

continuous conduction mode with a duty cycle close to or exceeding 50%.

Figure 45. Slope compensation waveforms

ccON

and V

- 0.5V. It is

ccON

RCT

RCT

t

OUT

OUT

S-COMP

S-COMP

t

t

t

t

t

The compensation will be realized by connecting a programming resistor between this pin and the current

sense input (pin 12, ISEN). The pin has to be connected to the sense resistor with another resistor to make

a summing node on the pin.

Since no ramp is delivered during MOSFET OFF-time (see figure 45), no external component other than

the programming resistor is needed to ensure a clean operation at light loads. If slope compensation is

not required the pin shall be left floating.

19/23

L6668

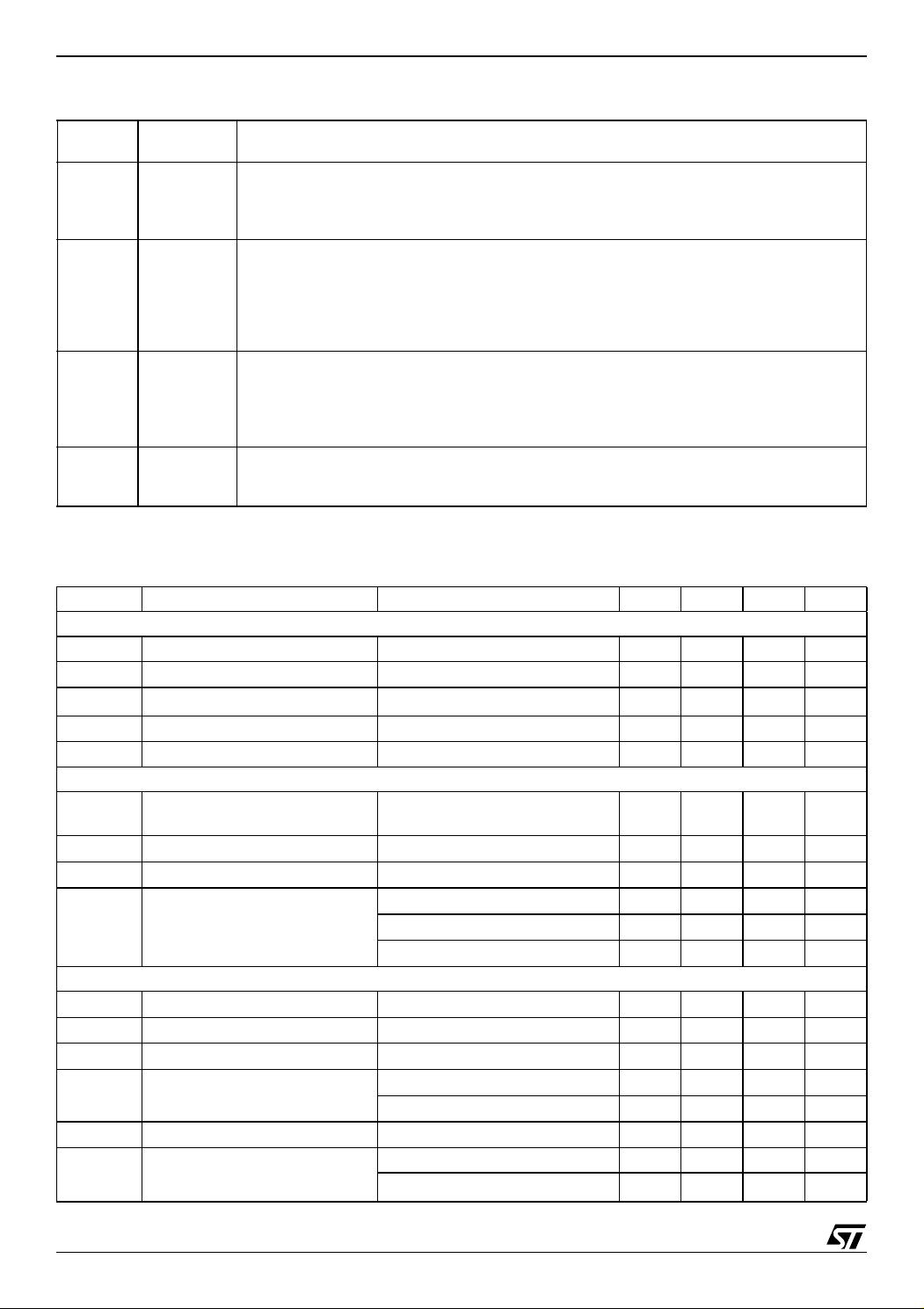

Figure 46. Typical Application: 80W, WRM flyback; Electrical Schematic

T1: CORE E32/16/9, N67

T1: CORE E32/16/9, N67

PRIM. IND. 430µH; lgap = 1mm

PRIM. IND. 430µH; lgap = 1mm

R1

R1

3 MΩ

3 MΩ

R2

R2

3 MΩ

3 MΩ

R3 10Ω

R3 10Ω

R710Ω

R710Ω

R12 1kΩ

R12 1kΩ

D1

D1

1.5KE200

1.5KE200

D2

D2

STTH1L06

STTH1L06

D3 1N4148

D3 1N4148

R13A,B

R13A,B

0.56

0.56

1/2W

1/2W

N1

N1

56T

56T

N3

N3

8T

8T

Q1

Q1

STP9NK65

STP9NK65

T1

T1

C4

C4

100 nF

100 nF

F1 T2A250V

F1 T2A250V

J1

J1

88 to 264

88 to 264

Vac

Vac

4.03 kΩ

4.03 kΩ

R9

R9

6.2 kΩ

6.2 kΩ

3.3 nF

3.3 nF

C3 100 nF

C3 100 nF

R8

R8

C5

C5

STBY

STBY

RCT

RCT

NTC1

NTC1

VREF

VREF

16

16

13

13

N.C.

N.C.

82.5 kΩ

82.5 kΩ

BD1

BD1

DF04M

DF04M

C1

C1

100 µF

100 µF

400 V

400 V

R5 47kΩ

R5 47kΩ

S-COMP

S-COMP

815

815

L6668

L6668

6

R10

R10

6

9

9

47 kΩ

47 kΩ

56 nF

56 nF

R11

R11

R4

R4

330 k

330 k

Ω

Ω

C2

C2

25 V

25 V

47 µF

47 µF

R6

R6

9.1 kΩ

9.1 kΩ

VCC

VCC

DIS

DIS

11

11

SS

SS

C6

C6

HV

HV

OUT

OUT

57

57

4

4

1

1

ISEN

ISEN

12

12

10

10

3

3

COMPSKIPADJ

COMPSKIPADJ

GND

GND

OC1

OC1

PC817A

PC817A

C7

C7

2.2 nF

2.2 nF

D4

D4

STPS20150CT

STPS20150CT

N2

N2

10T

10T

C12

C12

2.2 nF

2.2 nF

Y1

Y1

R14

R14

4.3 kΩ

4.3 kΩ

OC1

OC1

PC817A

PC817A

TL431

TL431

1

1

2

2

3

3

C8A,B,C

C8A,B,C

680 µF

680 µF

25 V

25 V

1.2 kΩ

1.2 kΩ

R15

R15

C10

C10

100 nF

100 nF

R16

R16

47 kΩ

47 kΩ

R18

R18

1.3 kΩ

1.3 kΩ

C9

C9

100 nF

100 nF

8.06 kΩ

8.06 kΩ

R17

R17

18V/4.5A

18V/4.5A

GND

GND

J2

J2

Table 6. Light load measurements on the circuit of figure 46

Output power Test condition Input power

Pout = 0.5 W Vin= 110 Vac 0.71 W

Vin= 230 Vac 0.86 W

Pout = 0 W Vin= 110 Vac 0.09 W

Vin= 230 Vac 0.17 W

20/23

L6668

5 Package information

In order to meet environmental requirements, STMicroelectronics offers this device in ECOPACK® package. This package has a Lead-free second level interconnect. The category of second level Interconnect

is marked on the package and on the inner box label, in compliance with JEDEC Standard JESD97.

The maximum ratings related to soldering conditions are also marked on the inner box label. ECOPACK

is an STMicroelectronics trademark.

ECOPACK specifications are available at: www.st.com.

Figure 47. SO16 (Narrow) Mechanical Data & Package Dimensions

DIM.

A 1.75 0.069

a1 0.1 0.25 0.004 0.009

a2 1.6 0.063

b 0.35 0.46 0.014 0.018

b1 0.19 0.25 0.007 0.010

C 0.5 0 .020

c1 45° (typ.)

(1)

D

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 8.89 0.350

(1)

F

G 4 .60 5.30 0.181 0.208

L 0.4 1.27 0.150 0.050

M 0.62 0.024

S8° (max.)

(1) "D" an d "F" do not i nclude mold f lash or protru sions - Mold

flash or protr usions shall not ex ceed 0.15mm (.006 inc.)

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

9.8 10 0.386 0.394

3.8 4.0 0.150 0.157

OUTLINE AND

MECHANICAL DATA

SO16 (Narrow)

0016020 D

21/23

L6668

6 Revision History

Table 7. Revision History

Date Revision Description of Changes

20-May-2005 1 First Issue.

15-July-2005 2 Modify values in Electrical Characteristics

28-July-2005 3 Changed the maturity from “Preliminary Data” to “Datasheet”.

13-Jan-2006 4 Absolute Maximum Rating Update (added ESD note for pin 1).

Modified value “DIS >2.2V” in the table 4 pin 14.

22/23

L6668

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2006 STMicroelectronics - All rights reserved

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

STMicroelectronics group of companies

www.st.com

23/23

Loading...

Loading...