FULLY INTEGRATED POWER SUPPL Y

■ WIDE-RANGE MAINS OPERATION

■ "ON-CHIP" 700V V (BR)DSS POWER MOS

■ 65 kHz INTERNAL OSCILLA TOR

■ 2.5V ± 2% INTERNAL REFERENCE

■ STANDBY MODEFOR HIGH EFFICIENCY AT

LIGHT LOAD

■ OVERCURRENT AND LATCHED

OVERVOLTAGE PROTECTION

■

NON DISSIPATIVE BUILT-IN START-UP CIRCUIT

■ THERMAL SHUTDOWN WITH HYSTERESIS

■ BROWNOUTPROTECTION (SMD PACKAGE

ONLY)

L6590

MINIDIP SO16W

ORDERING NUMBERS:

L6590N L6590D

- HOME APPLIANCES/LIGHTING

■ LINE CARD, DC-DC CONVERTERS

MAIN APPLICATIONS

■ WALL PLUG POWER SUPPLIES UP TO 15 W

■ AC-DC ADAPTERS

■ AUXILIARYPOWER SUPPLIES FOR:

- CRT AND LCD MONITOR (BLUE ANG EL)

- DESKTOP PC/SERVER

- FAX, TV, LASER PRINTER

TYPICAL APPLICATION CIRCUIT

AC line

88 to 264 Vac

GND

DRAIN

L6590

1

Vcc

3

56, 7,8

4

VFBCOMP

Pout

up to 15W

DESCRIPTION

The L6590 is a monolithic switching regulator designed in BCD OFF-LINEtechnology, able to operate

with wide range input voltage and to deliver up to

15Woutput power. The internal power switch is a lateral power MOSFET with a typical R

and a V

AC line

88 to 264 Vac

(BR)DSS

of 700V minimum.

DRAIN

1

GND

L6590

VFB COMP

3

56, 7, 8

4

Vcc

DS(on)

of 13

Pout

up to 15W

Ω

October 2000

Primary Feedback

Secondary Feedback

1/23

L6590

D

DESCRIPTION

(continued)

The MOSFET is source-grounded, thus it is possible

to build flyback, boost and forward converters.

The device can work with secondary feedback and a

2.5V±2%internal reference,in addition to a high gain

error amplifier, makes possible also the use in applications either with primary feedback or not isolated.

Theinternalfixedoscillator frequencyandthe integrated

non dissipative start-up generator minimize the external

component count and power consumption.

The device is equipped with a standby function that

automatically reduces the oscillator frequency from

65 to 22 kHz under light load conditions to enhance

BLOCK DIAGRAM

DRAIN

(1)

[1]

START-UP

THERMAL

SHUTDOWN

+

-

GND

(6,7,8)

PGND

[9, ..., 16]

OCP

STANDBY

65/22kHz

efficiency (P

<1W@P

in

= 0.5W with wide range

out

mains).

Internal protections like cycle-by-cycle current limiting,

latched output overvoltage protection, mains undervoltage protection (SMD version only) and thermal shutdown generate a 'robust' design solution.

TheIC usesa special leadframe with the ground pins

(6, 7 and 8 in minidip, 9 to16 in SO16W package) internally connected in order for heat to be easily removed from the silicon die. An heatsink can then be

realized by simply making provision of few cm

copper on the PCB. Furthermore, the pin(s) close to

the high-voltage one are not connected to ease compliance with safety distances on the PCB.

[x] : L6590D (SO16W)

CC

V

(3)

SGN

[5]

BOK

[6]

VFB

(5)

[4]

[8]

OSC

SUPPLY

&UVLO

PWM

VREF

+

-

OVP

BROWNOUT

VREF

+

-

+

2.5V

2.5V

2

of

PIN CONNECTIONS

DRAIN

COMP

2/23

(Top view)

N.C.

Vcc

MINIDIP

L6590

GND

GND

GND

VFB

DRAIN

N.C.

N.C.

Vcc

SGND

BOK

COMP

VFB

COMP

[7]

(4)

PGND

PGND

PGND

PGND

PGND

PGND

PGND

PGND

SO16W

L6590D

L6590

PIN FUNCTIONS

Pin#

L6590 L6590D

1 1 DRAIN Drain connection of the internal power MOSFET. The internal high voltage start-up

2 2, 3 N.C. Not internally connected. Provision for clearance on the PCB.

34V

47

5 8 VFB Inverting input of the Error Amplifier.The non-inverting one is internally connected to a

6 to 8 - GND Connection of both the source of the internal MOSFET and the return of the bias current

- 6 BOK Brownout Protection. If the voltage applied to this pin is lower than 2.5V the PWM is

- 5 SGND Current return for the bias current of the IC.

- 9 to 16 PGND Connection of the source of the internal MOSFET. Pins connected to the metal frame to

Name Description

generator sinks current from this pin.

Supply pin of the IC. An electrolytic capacitor is connected between this pin and ground.

CC

The internal start-up generator charges the capacitor until the voltage reaches the startup threshold. The PWM is stopped if the voltage at the pin exceeds a certain value.

COMP

Output of the Error Amplifier. Used for control loop compensation or to directly control

PWM with an optocoupler.

2.5V± 2% reference. This pin can be grounded in some feedback schemes.

of the IC. Pins connected to the metal frame to facilitate heat dissipation.

disabled. This pin is typically used for sensing the input voltage of the converter through

a resistor divider. If not used, the pin can be either left floating or connected to Vcc

through a 15 kΩ resistor.

facilitate heat dissipation.

THERMAL DATA

Symbol Parameter Minidip SO16W Unit

R

thj-amb

R

thj-pins

(*) Value depending on PCB copper area and thickness

Thermal Resistance Junction to ambient (*) 35 to 60 40 to 65 °C/W

Thermal Resistance Junction to pins 15 20 °C/W

.

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

I

V

I

clamp

P

T

T

stg

ds

d

cc

tot

Drain Source Voltage -0.3 to 700 V

Drain Current 0.7 A

IC Supply Voltage 18 V

VccZener Current 20 mA

Error Amplifier Ouput Sink Current 3 mA

Voltage on Feedback Input 5 V

BOK pin Sink Current 1 mA

Power Dissipation at T

2

, 2 oz copper dissipating area on PCB

3cm

Operating Junction Temperature -40 to 150 °C

j

< 50°C (Minidip and SO16W)

amb

1.5 W

Storage Temperature -40 to 150 °C

3/23

L6590

ELECTRICAL CHARACTERISTCS

(Tj= -25 to 125°C, Vcc= 10V; unless otherwise specified)

Symbol Parameter Test Condition Min. Typ. Max. Unit

POWER SECTION

V

(BR)DSS

I

R

DS(on)

Drain Source Voltage Id< 200 µA; Tj= 25 °C 700 V

Off state drain current Vds= 560V; Tj= 125 °C 200 µA

dss

Drain-to-Source on resistance

R

vs. Tj: see fig. 20

DS(on)

I

= 120mA; Tj=25°C 13 16 Ω

d

= 120mA; Tj= 125 °C 23 28

I

d

ERROR AMP SECTION

V

Input Voltage Tj= 25 °C 2.45 2.5 2.55 V

FB

= 125°C 2.4 2.5 2.6

T

j

Ib E/A Input Bias Current V

= 0 to 2.5 V 0.3 5 µA

FB

Avol DC Gain open loop 60 70 dB

B Unity Gain Bandwidth 0.7 1 MHz

SVR Supply voltage Rejection f = 120 Hz 70 dB

I

I

source

Output Sink Current V

sink

Output Source Current V

=1V 1 mA

COMP

= 3.5V; VFB = 2V -0.5 -1 -2.5 mA

COMP

V

COMPH

V

COMPL

Vout High I

Vout Low I

OSCILLATOR SECTION

F

D

D

Oscillator Frequency Tj=25°C 58 65 72 kHz

osc

Min. Duty Cycle V

min

Max. Duty Cycle V

max

DEVICE OPERATION SECTION

I

I

chargeVCC

V

CCclampVCC

V

Operating Supply Current fsw = Fosc 4.5 7 mA

op

I

Quiescent Current MOS disabled 3.5 6 mA

Q

charge Current Vcc=0VtoV

clamp Voltage I

Start Threshold

ccon

voltage

= -0.5mA; VFB=2V 3.8 4.50 V

source

= 1mA ; VFB=3V 1 V

sink

52 65 74

=1V 0 %

COMP

=4V 67 70 73 %

COMP

- 0.5V;

V

= 100 to 400V; Tj=25°C

ds

=0VtoV

V

cc

ccon

ccon

- 0.5V;

-3 -4.5 -7 mA

-2.5 -4.5 -7.5 mA

Vds= 100 to 400V

= 10mA (*) 16.5 17 17.5 V

clamp

(*) 14 14.5 15 V

V

4/23

V

ccoff

dsmin

Min operating voltage after Turnon(*) 6 6.5 7 V

Drain start voltage 40 V

L6590

ELECTRICAL CHARACTERISTICS

(continued)

Symbol Parameter Test Condition Min. Typ. Max. Unit

CIRCUIT PROTECTIONS

I

pklim

OVP Overvoltage Protection I

Pulse-by-pulse Current Limit di/dt = 120 mA/ µs 550 625 700 mA

= 10 mA (*) 16 16.5 17 V

cc

LEB Masking Time After MOSFET turn-on (**) 120 ns

STANDBY SECTION

F

I

pksb

Oscillator Frequency 19 22 25 kHz

SB

Peak switch current for Standby

Transition from F

osc

to F

SB

80 mA

Operation

I

pkno

Peak switch current for Normal

Transition from FSBto F

osc

190 mA

Operation

BROWNOUT PROTECTION (L6590D only)

V

I

V

Threshold Voltage Voltage either rising or falling 2.4 2.5 2.6 V

th

Current Hysteresis V

Hys

Clamp Voltage I

CL

= 3V -30 -50 -70 µA

pin

= 0.5 mA 5.6 6.4 7.2 V

pin

THERMAL SHUTDOWN (***)

Threshold 150 165 °C

Hysteresis 40 °C

(*) Parameters tracking one the other

(**) Parameter guaranteed by design, not tested in production

(***) Parameters guaranteed by design, functionality tested in production

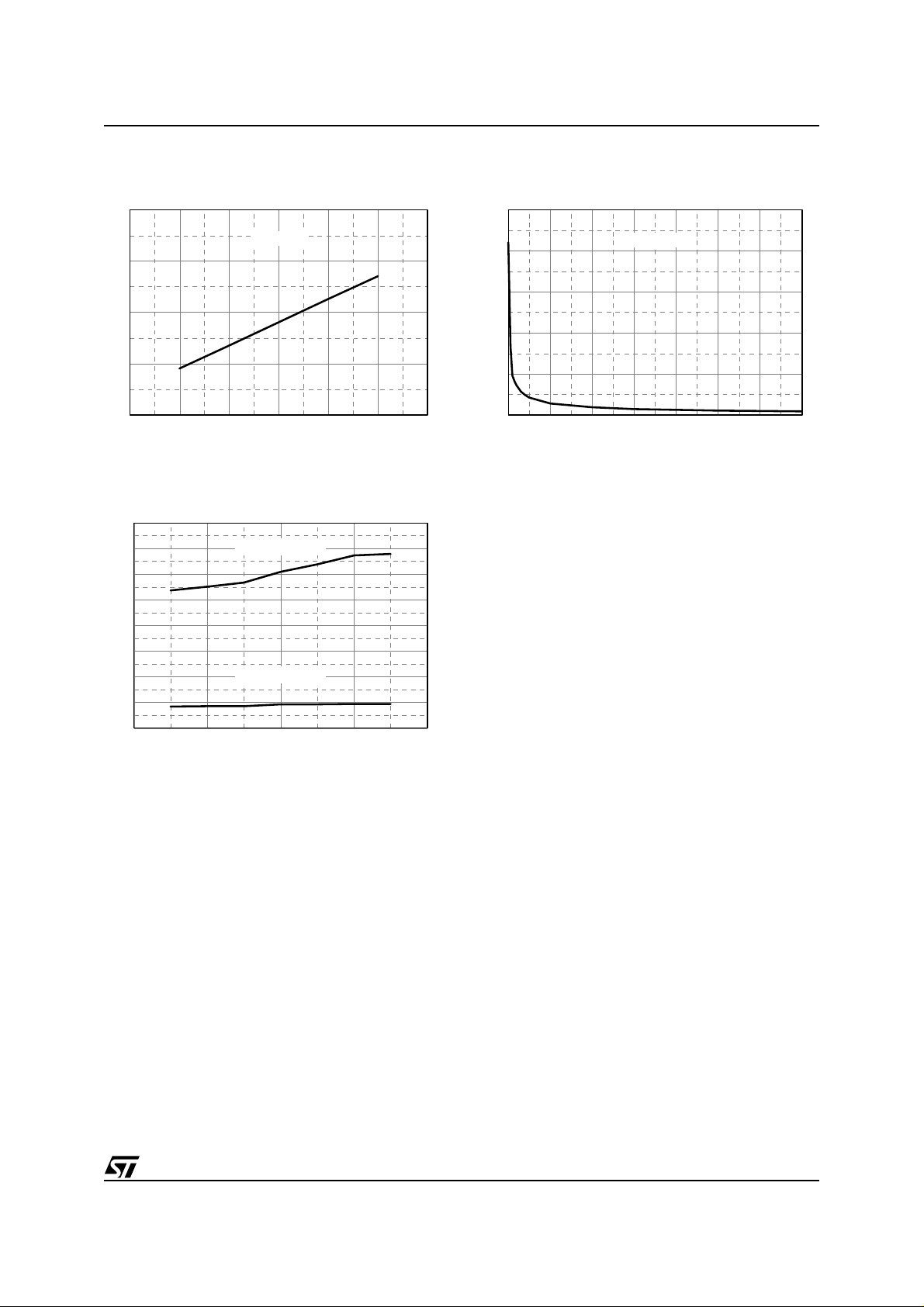

Figure 1. Start-up & UVLO Thresholds Figure 2. Start-up Current Generator

Vcc [V]

16

14

Start-up

12

10

8

6

-50 0 50 100 150

Tj [°C]

UVLO

Icc [mA]

5.5

5

Vdrain = 40 V

4.5

4

3.5

3

024681012

Vcc [V]

Tj = -25°C

Tj = 25 °C

Tj = 125 °C

5/23

L6590

Figure 3 . Start-up Current Generator

Icc [mA]

5.5

Vdrain = 60 V

Tj = -25 °C

5

Tj = 25°C

4.5

4

Tj = 125°C

3.5

3

024681012

Vcc [V]

Figure 4. IC Consumption Before Start-up

Icc [µA]

700

600

500

400

300

200

Tj = 125°C

Tj = -25 °C

Tj = 25 °C

Figure 6. IC Operating Current

Icc [mA]

5

VFB = 2.3 V

fsw = 65 kHz

4.5

4

Tj = 125°C

Tj = 25 °C

Tj = -25°C

3.5

3

7 8 9 10 11 12 13 14 15

Vcc [V]

Figure 7. IC Operating Current

Icc [mA]

4.4

VFB = 2.3 V

4.2

4

3.8

3.6

3.4

3.2

fsw = 22 kHz

Tj = 125 °C

Tj = 25 °C

Tj = -25°C

100

7 8 9 101112131415

Vcc [V]

Figure 5. IC Quiescent Current

Icc [mA]

4

VFB = 2.7 V

3.8

3.6

3.4

Tj = 125°C

Tj = -25°C

3.2

3

6 8 10 12 14 16 18

Vcc [V]

6/23

Tj = 25°C

3

7 8 9 10 11 12 13 14 15

Vcc [V]

Figure 8. S witching Frequency vs.

Temperature

fsw [kHz]

80

70

60

50

40

30

20

10

-50 0 50 100 150

Normal operation

Standby

Tj [°C]

L6590

Figure 9 . Vcc clamp vs. Temperature

VCCclamp [V]

18

17.8

17.6

I

clamp

=20mA

17.4

Iclamp =10mA

17.2

17

-50 0 50 100 150

Tj [°C]

Figure 10. OV P Threshold vs. Temperature

Vth [V]

16

15.8

15.6

15.4

Figure 12. OCP threshold vs. Temperat ure

Ipklim / (Ipklim@ Tj = 25°C)

1.1

1.08

di/dt = 120 mA/µs

1.06

1.04

1.02

1

0.98

-50 0 50 100 150

Tj [°C]

Figure 13. Internal E/A Referenc e Voltage

Vref [V]

2.6

2.55

2.5

15.2

15

-50 0 50 100 150

Tj [°C]

Figure 11. OCP Threshold vs. Current Slope

Ipklim / (Ipklim @ di/dt = 120 mA/µs)

1.06

1.04

1.02

1

0.98

0.96

50 100 150 200 250

Tj = 25°C

dI/dt[mA/µs]

2.45

2.4

-50 0 50 100 150

Tj [°C]

Figure 14. Error Amplifier Slew Rate

VCOMP [V]

5

= 100 pF

L

open loop

Ω

4

3

VCOMP

V

FB

RL =10k

C

2

1

0

0 2 4 6 8 10121416

t[µs]

7/23

L6590

Figure 15. COMP pin Characteristic

VCOMP [V]

6

VFB =0

5

Tj = 25 °C

4

3

2

1

0

0 0.2 0.4 0.6 0.8 1 1 .2 1.4

ICOMP [mA]

Figure 16. COM P pin Dynamic Resistance vs.

Temperature

RCOMP[kOhm]

10.5

10

VFB =0

Figure 18. Breakdown Voltage vs. Temperature

BVDSS / (BVDSS @ Tj = 25°C)

1.08

1.06

Idrain = 200 µA

1.04

1.02

1

0.98

0.96

0.94

0.92

-50 0 50 100 150

Tj [°C]

Figure 19. Drain Leakage vs. Drain Voltage

Idrain [µA]

50

40

Tj = 125 °C

Tj = 25 °C

9.5

9

8.5

8

-50 0 50 100 150

Tj [°C]

Figure 17. Error Amplifier Gain and Phase

dB

100

50

0

Phase

Gain

1 10 100 1k 10k 100k

1M

f[Hz]

m

φ

90

180

30

Tj = -25°C

20

10

100 200 300 400 500 600 700

Vdrain [V]

Figure 20. Rds(ON) vs. Tempe rature

Rds(ON) / (Rds(ON) @ Tj=25°C)

1.8

°

0

1.6

Idrain = 120 mA

1.4

1.2

1

0.8

0.6

-50 0 50 100 150

Tj [°C]

8/23

Figure 21. Rds(ON) vs. Idrain Figure 22. Coss vs. Drain Voltage

L6590

Rds(ON) / (Rds(ON) @ Idrain=120 mA)

1.3

Tj = 25 °C

1.2

1.1

1

0.9

0 100 200 300 400 500 600

Idrain [mA]

Figure 23. Standby Function Thresholds

DrainPeak Current[mA]

220

200

180

160

140

120

100

80

60

-50 0 50 100 150

22 kHz → 65 kHz

65 kHz→22 kHz

Tj [°C]

Coss [pF]

250

200

Tj = 25 °C

150

100

50

0

0 100 200 300 400 500 600 700

Vdrain [V]

9/23

L6590

)

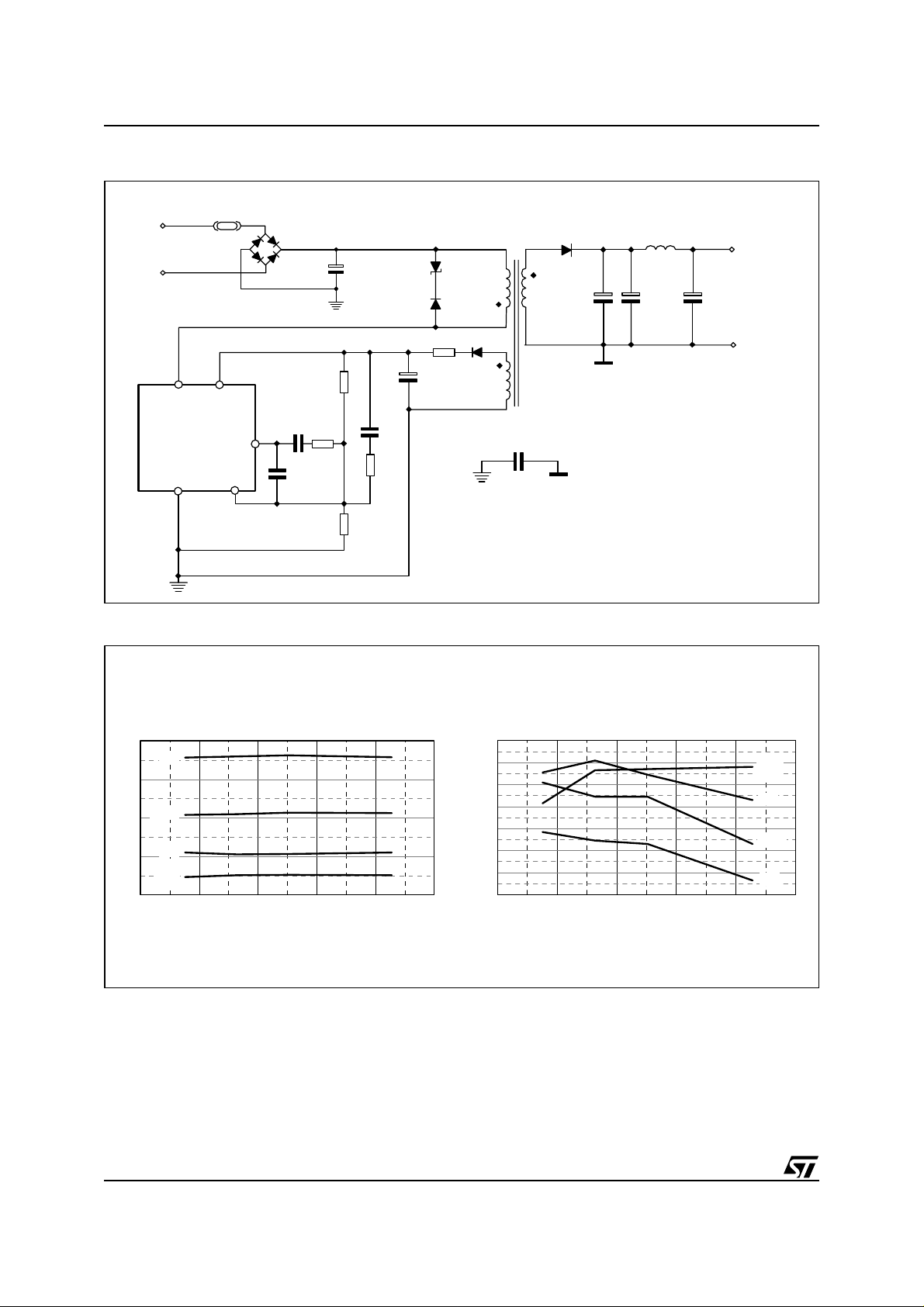

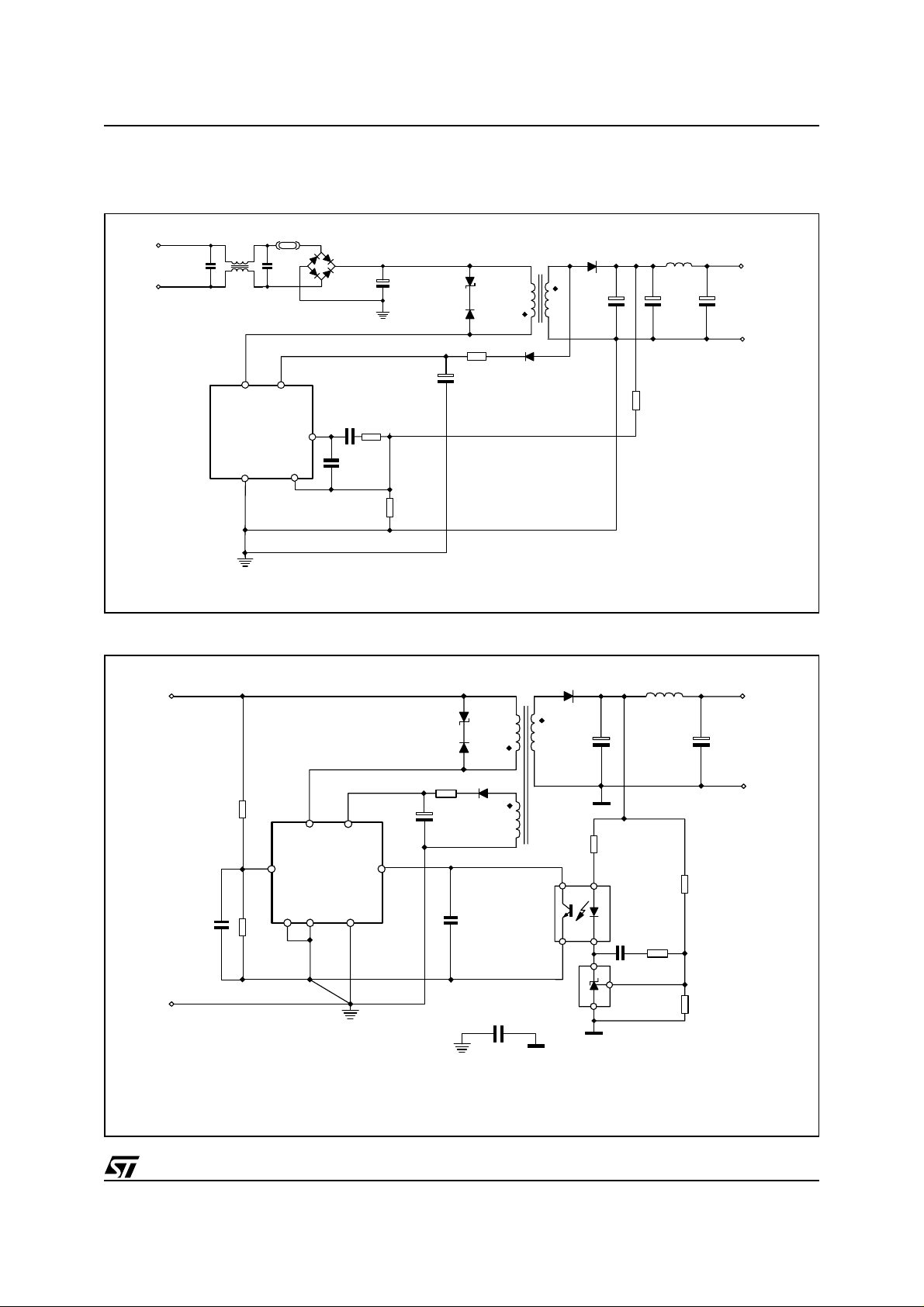

Figure 24. Test Board (1) with Primary Feedback: Electri cal Schematic

F1

Vin

88 to 264 Vac

L6590

6, 7, 8

2A/250V

IC1

31

4

5

BD1

DF06M

C5

680 nF

C1

22 µF

400 V

5.6 kΩ

1.1 kΩ

C6

10 nF

R2

R3

BZW06-154

STTA106

100 nF

110

R4

1.5 kΩ

C4

R5

D1

D2

Ω

T1

D4 BYW100-100

C7, C8

330 µF

16 V

R1 68 Ω

D3

C2

1N4148

22 µF

25 V

C7

2.2 nF

Y

T1 specification

Core E20/10/6, ferrite 3C85 or N67 or equivalent

≈

0.5 mm gap for a primary inductance of 2.9 mH

leakage

<90 µH

L

Primary : 180 T, 2 series windings 90T each, AWG33(∅0.22 mm

Sec : 19 T, AWG30 (∅0.3 mm)

Aux : 19 T, AWG33

L1

4.7 µH

C9

100 µF

16 V

Vo =12 V ± 10%

Po= 1 to 10 W

Figure 25. Test Board (1) Evaluation Data

Output Voltage [V]

13.5

1W

13

2.5 W

12.5

5W

12

out =

P

10 W

11.5

50 100 150 200 250 300

Load & Line regulation

Input Voltage[Vac]

Efficiency [%]

Efficiency

86

out =

84

82

80

P

10 W

5W

78

76

74

72

50 100 150 200 250 300

InputVoltage [Vac]

2.5 W

1W

10/23

Figure 26. Test Board (1) Main Waveforms

Ch3: Idrain

L6590

Ch3: Idrain

Vin=100V

DC

Pout = 10 W

Ch2: Vdrain

Ch3: Idrain

Ch2: Vdrain

Vin = 100 V

Pout = 1 W

DC

Ch2: Vdrain

Ch3: Idrain

Ch2: Vdrain

Figure 27. Test Board (2) with Secondary Feedback: Electrical Schematic

F1

2A/250V

Vin

88 to 264

Vac

Cx

100 nF

L

A

22 mH

CxB

100 nF

6, 7, 8

IC1

L6590

BD1

DF06M

31

5

C1

22 µF

400 V

4

STT A106

C2

22 µF

25V

D2

R1 10

D1

BZW06-154

Ω

D3

1N4148

C3

22 nF

6.8 k

T1

OP1

PC817

R6

Ω

C4

2.2 nF

Y1

class

D4 1N5822

C5, C6, C7

470 µF

16V

RubyconZL

4

3

1

2

560

1

2

3

R2

100 nF

TL431

Ω

C9

IC2

2k

R5

L1

4.7 µH

C8

220 µF

10V

Rubycon

ZL

Ω

Vin=400V

Pout = 10 W

Vin=400V

Pout = 1 W

5Vdc/2A

R3

Ω

2.43 k

R4

Ω

2.43 k

DC

DC

Core E20/10/6,ferrite 3C85 or N67 or equivalent

T1 specification

≈

0.6 mm gap for a primary inductance of 1.4 mH

leakage

<30 µH

L

Primary : 128 T, 2 series windings64T each, AWG32(∅0.22mm)

Sec : 6 T, 4xAWG32

Aux : 14 T, AWG32

11/23

L6590

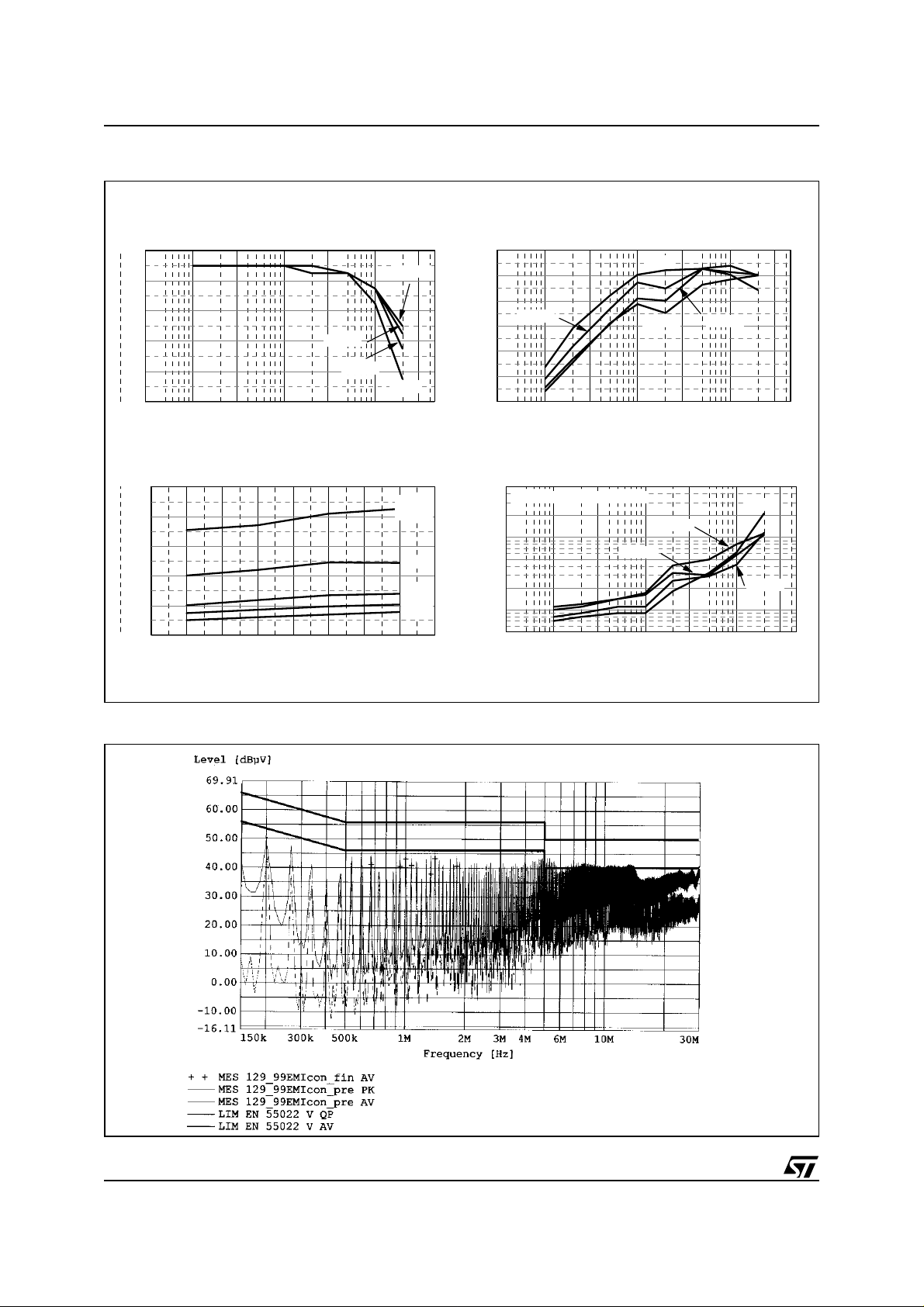

Figure 28. Te st B oard (2) evaluation data

Output Voltage [V]

Load & Line regulation

5

4.98

4.96

AC

4.94

4.92

4.9

0.003 0.01 0.03 0.1 0.3 1 3

Input Power [mW]

Light-load Consumption

Load Current [A]

220 V

110 V

AC

1,000

800

600

400

200

0

50 100 150 200 250 300 350 400 450

DC InputVoltage [V]

264 V

88 V

AC

AC

out

P

0.5W

0.25W

0.1W

0.05W

0W

Efficiency [%]

80

Efficiency

88 VAC

70

60

AC

110 V

50

264 V

AC

220V

AC

40

30

20

0.003 0.01 0.03 0.1 0.3 1 3

Pdiss [W]

5

Rthj-amb= 58 °C/W @ 1.5W

2

Load Current [A]

Device Power Dissipation

AC

264 V

88 V

1

AC

0.5

0.2

220 V

110 V

0.1

0.05

0.003 0.01 0.03 0.1 0.3 1 3

Load Current [A]

AC

AC

Figure 29. Te st B oard (2) EMI Characterization

12/23

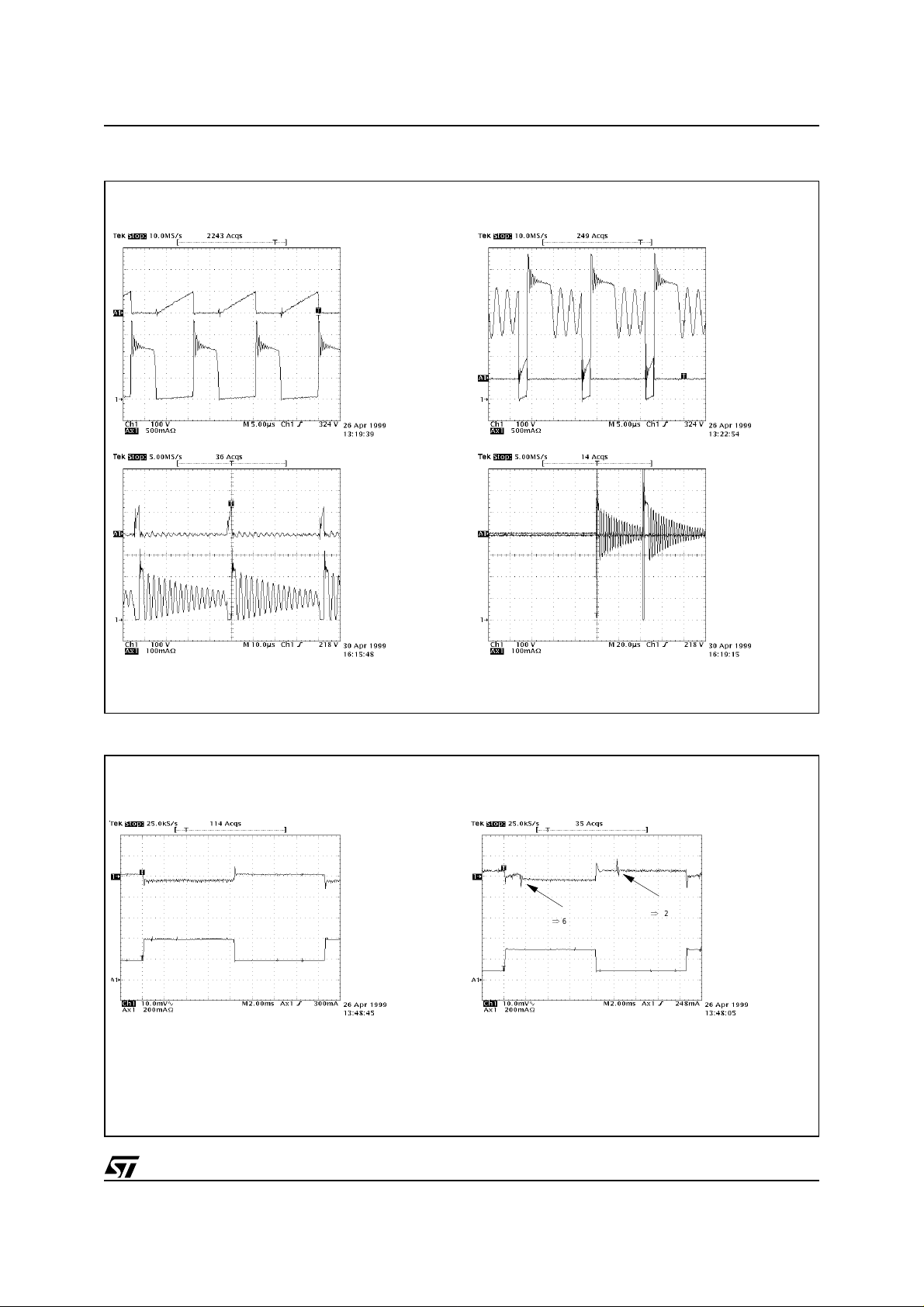

Figure 30. Test Board (2) Main Waveforms

A1: Idrain

L6590

Ch1: Vdrain

Vin=100V

DC

Iout = 2 A

Ch1: Vdrain

A1: Idrain

Vin=100V

DC

Iout = 50 mA

Ch1: Vdrain

Figure 31. Test Board (2) Load Transient Response

A1: Idrain

A1: Idrain

Ch1: Vdrain

Vin = 400 V

Iout = 2 A

Vin = 400 V

Iout = 50 mA

DC

DC

Vout

Standby Function

is not tripped

Iout

Vin = 200 V

DC

Iout = 0.2↔0.4 A

transition

⇒

22

65 kHz

Standby Function

is tripped

Vout

65

Iout

transition

⇒

22 kHz

Vin=200V

DC

Iout= 0.1↔0.3 A

13/23

L6590

APPLICATION INFORMATION

In the following sections the functional blocks as well as the most important internal functions of the device will

be described.

Start-up Circuit

When power is first applied to the circuit and the voltage on the bulk capacitor is sufficiently high, an internal

high-voltage current generator is sufficiently biased to start operating and drawing about 4.5 mA through the

primary winding of the transformer and the drainpin. Most of this current charges the bypass capacitor connected between pin Vcc (3) and ground and makes its voltage rise linearly.

As the Vcc voltage reaches the start-up threshold (14.5V typ.) the chip, after resetting all its internal logic, starts

operating, the internal power MOSFET is enabled to switch and the internal high-voltage generator is disconnected. The IC is powered by the energy stored in the Vcc capacitor until the self-supply circuit (typically an

auxiliary windingof the transformer) developsa voltagehighenough to sustain the operation.

As the IC is running, the supply voltage, typically generated by a self-supply winding, can range between 16 V

(Overvoltage protection limit, see the relevant section) and 7 V, threshold of the Undervoltage Lockout. Below

this value the device is switched off (and the internal start-up generator is activated). The two thresholds are in

tracking.

The voltage on the Vcc pin is limited at safe values by a clamp circuit. Its 17V threshold tracks the Overvoltage

protection threshold.

Figure 32. Start-up circu it internal schematic

DRAIN

POWER

MOSFET

GND

Vcc

15 M

UVLO

Ω

17 V

150

Ω

Power MOSFET and Gate Driver

The power switch is implemented with a lateral N-channel MOSFET having a V

ical R

of 13Ω. It has a SenseFET structure to allow a virtually lossless current sensing (used only for pro-

DS(on)

(BR)DSS

of 700V min. and a typ-

tection).

During operation in Discontinuous Conduction Mode at low mains thedrain voltage is likely to go belowground.

Any risk of injecting the substrate of the IC is prevented by an internal structure surrounding the switch.

The gate driver of the power MOSFET is designed to supply a controlled gate current during both turn-on and

turn-off in order to minimize common mode EMI.

Under UVLO conditions an internal pull-down circuit holds the gate low in order to ensure that the power MOS-

FET cannot be turned on accidentally.

14/23

Figure 33. PWM Control internal schematic

L6590

Max.Duty cycle

E/A

+

-

S

R

from OCP

comparator

VFB

to gate

Q

driver

OSCILLATOR

+

PWM

-

COMP

Clock

Oscillator and PWM Control

PWMregulation is accomplished by implementingvoltage modecontrol. As shown in fig. 33, this block includes

an oscillator, a PWM comparator, a PWM latch and an Error Amplifier.

The oscillator operates at a frequency internally fixed at 65 kHz with a precision of ± 10 %. The maximum duty

cycle is limited at 70% typ.

The PWM latch (reset dominant) is set by the clock pulses of theoscillator and is reset by either the PWM comparator or the Overcurrent comparator.

The Error Amplifier (E/A) is an op-amp with a MOS input stage and a class AB output stage. The amplifier is

compensated for closed loop stability at unity gain, has a small-signal DC gain of 70 dB (typ.) and a gain-bandwidth product over 1 MHz.

In case of overcurrent the error amplifier output saturates high and the conduction of the power MOSFET is

stopped by the OCP comparator instead of the PWM comparator.

Under zero load conditions the error amplifier is close to its low saturation and the gate drive delivers as short

pulses as it can, limited by internal delays. They are howevertoo longto maintainthe long-termenergy balance,

thus from time to time some cycles need being skipped and the operation becomes asynchronous. This is automatically done by the control loop.

Standby Function

The standby function, optimized for flyback topology, automatically detects a light load condition for the converter and decreasestheoscillator frequency. The normal oscillationfrequency is automatically resumed when the

output load builds up and exceeds a defined threshold.

This function allows to minimize power losses related to switching frequency, which represent the majority of losses

in a lightly loaded flyback, without giving up the advantages of a higher switching frequency at heavy load.

The Standby function is realizedby monitoringthe peak current in the power switch. If the loadis low that it does

not reach a threshold (80 mA typ.), the oscillator frequency will be set at 22 kHz typ.

When the load demands more power and the peak primary current exceeds a second threshold (190 mA typ.)

theoscillator frequency is reset at 65 kHz. This 110 mA hysteresis prevents undesired frequency change when

power is such that the peak current is close to either threshold.

The signal coming from the sense circuit is digitally filtered to avoid false triggering of this function as a result of

large load changes or noise.

15/23

L6590

Figure 34. Standby Function timing diagram

Pout

Peak

80 mA

190mA

Primary

Current

Load

regulation

Vout

small glitch

STANDBY

(before filter)

STANDBY

2ms 1ms

(filtered)

65 kHz

sw

f

22 kHz

Brownout Protection (L6590D only)

Brownout Protection is basically a not-latched device shutdown functionality. It will typically be used to detect a

mains undervoltage (brownout). This condition may cause overheating of the primary power section due to an

excess of RMS current.

Figure 35. Brownout Protection Function internal schematic an d timing diagram

HV Input bus

ON

V

OFF

V

16/23

HV Input bus

BOK

50 µA

6.4 V

2.5 V

Vcc

+

-

VinOK

L6590D

VinOK

Vcc

PWM

Vout

L6590

Another problem is the spurious restarts that are likely to occur during converter power down if the input voltage

decays slowly (e.g. with a large input bulk capacitor) and that cause the output voltage not to decay to zero

monothonically.

Converter shutdown can be accomplished with the L6590D by means of an internal comparator that can be

used to sense the voltage across the input bulk capacitor. This comparator is internally referenced to 2.5V and

disables the PWM if the voltage applied at its non-inverting input, externally available, is below the reference.

PWM operation is re-enabled as the voltage at the pin is more than 2.5V.

The brownout comparator is provided with current hysteresis instead of a more usual voltage hysteresis: an internal 50 µA current generator is ON as long as the voltage applied at the non-inverting input exceeds 2.5V and

is OFF if the voltage is below 2.5V. This approach provides an additional degree of freedom: it is possible to set

the ON threshold and the OFF threshold separately by properly choosing the resistors of the external divider,

which is not possible with voltage hysteresis.

Overvoltage Protection

The IC incorporatesan Overvoltage Protection (OVP) thatcan be particularly useful to protect the converter and

the load against voltage feedback loop failures. This kind of failure causes the output voltage to rise with no

control and easily leads to the destruction of the load and of the converter itself if not properly handled.

If such an event occurs, the voltage generated by the auxiliary winding that supplies the IC will fly up tracking

the output voltage. An internal comparator continuously monitors the Vcc voltage and stops the operation of the

IC if the voltage exceeds 16.5 V. This condition is latched and maintained until the Vcc voltage falls below the

UVLO threshold. The converter will then operate intermittently.

Figure 36. OVP internal schematic

Vcc DRAIN

to

MOSFET

to OVP

+

OVP

-

latch

GND

Overcurrent Protection

Thedevice uses pulse-by-pulse current limiting for Overcurrent Protection (OCP), in order to prevent overstress

of the internal MOSFET: its current during the ON-time is monitored and, if it exceeds a determined value, the

conductionis terminated immediately. TheMOSFETwillbe turned on again in the subsequentswitchingcycle.

As previously mentioned, the internal powerMOSFET has a SenseFET structure: the source of a few cells are

connectedtogether and kept separate from the othersourceconnections so as to realize a 1:100 current divider.

The "sense" portion is connected to a ground referenced, sense resistor having a low thermal coefficient. The

OCP comparator senses the voltage drop across the sense resistor and resets the PWM latch if the drop exceeds a threshold, thus turning off the MOSFET. In this way the overcurrent threshold is set at about 0.65 A

(typical value).

17/23

L6590

At turn-on, there are large current spikes due to the discharge of parasitic capacitances and, in case of Continuos Conduction Mode operation, to secondary diode reverse recovery as well, which could falsely trigger the

OCP comparator. To increase noise immunity the output of the OCP comparator is blanked for a short time

(about120 ns) just after the MOSFETis turnedon, so that any disturbancewithin this time slotis rejected(Leading Edge Blanking).

Figure 37. OCP internal schem atic

DRAIN

Max. Duty cycle

OSCILLATOR

+

PWM

-

Clock

Clock

S

R

Q

OCP

LEB

Driver

1

1/100

+

Rsense

-

0.5 V

GND

Thermal Shutdown

Overheating of the device due to an excessive power throughput or insufficient heatsinking is avoided by the

Thermal Shutdown function. A thermal sensor monitors the junction temperature close to the power MOSFET

and, when the temperature exceeds 150 °C (min.), sets an alarm signal that stops the operation of the device.

This is a not-latched function and the power MOSFET is re-enabled as the temperature falls about 40 °C.

18/23

APPLICATION IDEAS

Figure 38. 10W AC-DC adapter with no isolation

F1

2A/250V

Vin

88 to 264 Vac

Cx

100 nF

A

L

22 mH

100 nF

3(4)1

L6590

(L6590D)

6, 7, 8

(9 to16)

CxB

5(8)

BD1

DF06M

C1

22 µF

400 V

IC1

C4

R3

100 nF

4

(7)

27 k Ω

C5

2.2 nF

BZW06-154

STTA106

R4

1kΩ

D1

D2

R1 10 Ω

C2

22 µF

25 V

T1

D3

1N4148

D4 S TPS3L60S

C7, C8

330 µF

16 V

R2

3.9 kΩ

L1

4.7 µH

C9

100 µF

16 V

Vo =12 V ± 3%

Io= 0 to 0.8 A

L6590

Figure 39. 15W Auxiliary SMPS for PC

Vin = 200 to 375 Vdc

R2

Ω

1.8 M

41

IC1

67

L6590D

9,..., 16

5

R3

20 k

8

Ω

C1

10 nF

BZW06-154

STTA106

C2

22 µF

25 V

D1

D2

R1 10

Ω

1N4148

C3

47 nF

Core E20/10/6, ferrite 3C85 or N67 or equivalent

≈

0.5 mm gap for a primary inductance of 1.6 mH

leakage

L

<30 µH

Primary : 130 T, 2series windings65T each, AWG33(∅0.22 mm)

T1 specification

Sec : 14 T,AWG26(∅0.4 mm)

T1

D4 STPS10L25D

C5, C6, C7

470 µF

10 V

L1

4.7 µH

C8

100 µF

10V

5Vdc/3A

D3

R4

Ω

560

R5

Ω

2.43 k

1

4

470 nF

IC2

TL431

C9

240

R7

Ω

R6

2.43 k

3

2

1

3

2

C4

2.2 nF

Y

OP1

PC817

Ω

CoreE20/10/6, ferrite 3C85or N67 or equivalent

≈

0.9 mm gap for a primary inductance of 2 mH

leakage

<50 µH

L

T1 specification

Primary : 200 T, 2 serieswindings 100T each, AWG33(∅0.22 mm)

Sec : 9 T, 2 xAWG23 (∅0.64 mm)

Aux : 21 T,AWG33

19/23

L6590

,

Figure 40. 7.2V/7W Battery Charger

Vin

88 to 264 Vac

A

Cx

100 nF

L6590

(L6590D)

6, 7, 8

(9 to 16)

F1

2A/250V

L

22 mH

CxB

100 nF

R2

Ω

5.6 k

3(4)1

5

(8)

4(7)

R4 10 kΩ

C3 10 nF

Core E20/10/6, ferrite 3C85 or N67 or equivalent

≈

1 mm gap for a primary inductance of 2.6 mH

leakage

L

<60 µH

Primary : 230 T, 2 series windings 115T each, AWG36(∅0.16 mm)

Sec : 13 T, AWG23 (∅0.64 mm)

Aux : 60 T

AWG36

BD1

DF06M

22 µF

400 V

R1

39

Ω

C3

10 µF

25V

R3

Ω

1.5 k

T1 specification

C1

D2

STTA106

34

C2

220 nF

BZW06-154

OP1

PC817

C4

2.2 nF

Y1 class

D1

D3 BAV21

T1

16:1

R12

1k

D4 1N5821

1

2

Ω

1N4148

C5, C6

330 µF

16V

R7

620

1N4148

1N4148

D6

D7

D5

Ω

R5

4.7 k

D8

BZX79C12

R6

Ω

0.1

R8

560

C8 680 nF

R11

11.8 k

5

7

Ω

Ω

Ω

6

IC2

TSM103

421

C9 330 nF

Q1

BC337

22.6 k

R10

Ω

6.8 k

8

3

C7

10 µF

25V

R9

Ω

7.2 Vdc / 1 A

R13

12 k

Ω

REFERENCES

[1] “Getting Familiar with the L6590 Family, High-voltage Fully Integrated Power Supply” (AN1261)

[2] “Offline Flyback Converters Design Methodology with the L6590 Family” (AN1262)

20/23

L6590

21/23

L6590

22/23

L6590

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may resultfrom its use. No licenseisgranted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2000 STMicroelectronics - All Rights Reserved

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malta - Morocco - Singapore - Spain

STMicroelectronics GROUP OF COMPANIES

- Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

23/23

Loading...

Loading...