CFL/TL BALLAST DRIVER PREHEAT AND DIMMING

■ HIGH VOLTAGE RAIL UP TO 600V

■ dV/dt IMMUNITY ± 50 V/ns IN FULL

TEMPERATURE RANGE

■ DRIVER CURRENT CAPABILITY:

250mA SOURCE

450mA SINK

■ SWITCHING TIMES 80/40ns RISE/FALL

■ WITH 1nF LOAD

■ CMOS SHUT DOWN INPUT

■ UNDER VOLTAGE LOCK OUT

■ PREHEAT AND FREQUENCY SHIFTING

TIMING

■ SENSE OP AMP FOR CLOSED LOOP

CONTROL OR PROTECTION FEATURES

■ HIGH ACCURACY CURRENT CONTROLLED

OSCILLATOR

■ INTEGRATED BOOTSTRAP DIODE

■ CLAMPING ON VS.

■ SO16, DIP 16 PACKAGES

DESCRIPTION

In order to ensure voltage ratings in excess of

600V, the L6574 is manufactured with BCD OFF

LINE technology, which makes it well suited for

lamp ballast applications.

L6574

SO16N DIP16

ORDERING NUMBERS:

L6574D L6574

The device is intended to drive two power MOSFETS, in the classical half bridge topology, ensuring all the features needed to drive and properly

control a fluorescent bulb.

A dedicated timing section in the L6574 allows the

user set the necessary parameters for proper preheat and ignition of the lamp.

Also, an OP AMP is available to implement closed

loop control of the lamp current during normal

lamp burning.

An in teg rat ed boo tst r ap s ect io n, e li min ati ng th e no rmally required bo otstra p diode an d the zener clamping on Vs, makes the L6574 well suited for low cost

applica tions where few ad ditional co mponents are

needed to build a high performance ballast.

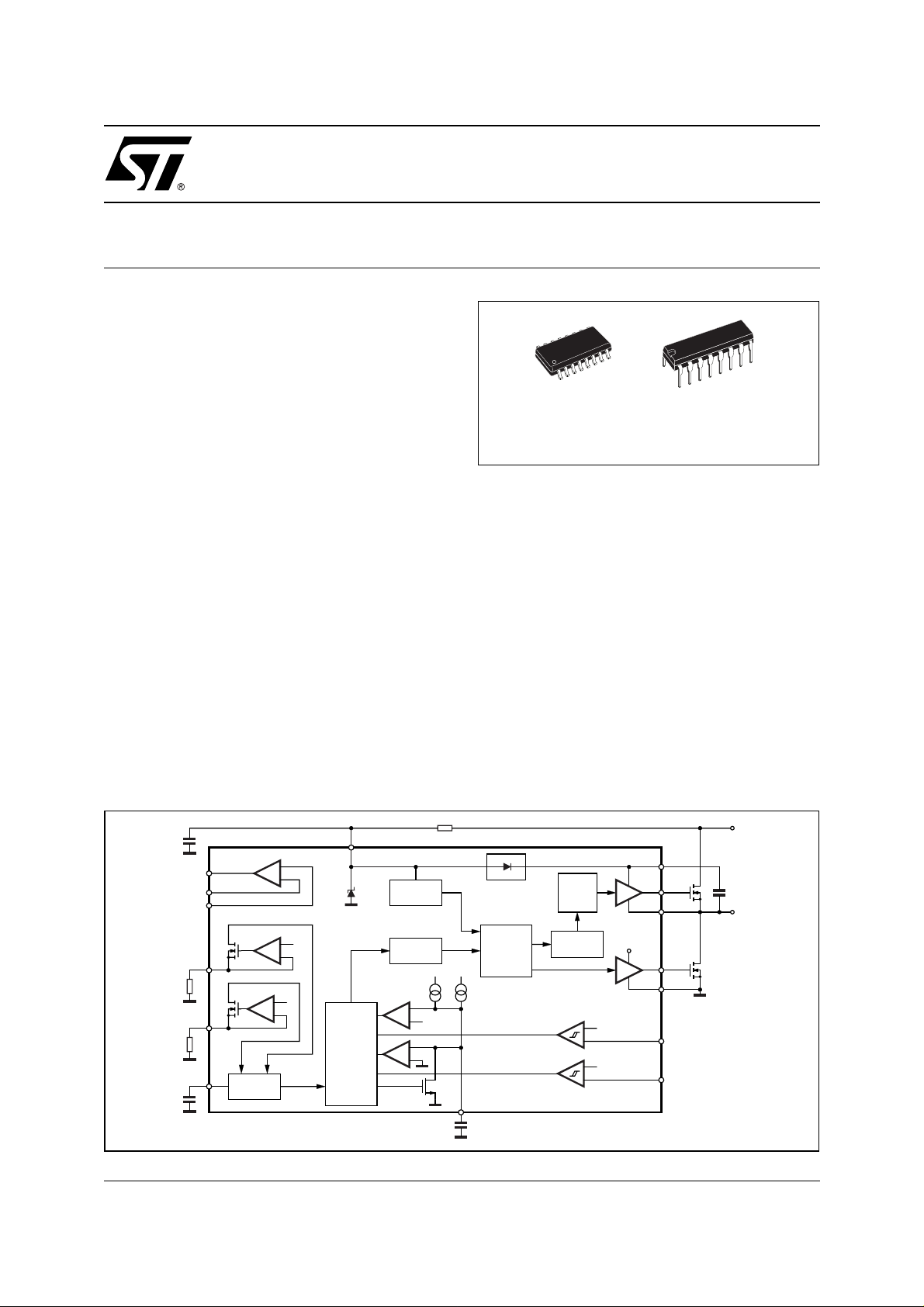

BLOCK DIAGRAM

OPOUT

OPIN-

OPIN+

R

ING

R

PRE

Cf

September 2003

OP AMP

Imin

Imax

VCO

V

S

V

+

-

V

REF

V

REF

CONTROL

LOGIC

UV

DETECTION

DEAD

TIME

Ifs

+

Vthpre

-

+

-

Ipre

DRIVER

DRIVING

LOGIC

C

PRE

HVG

DRIVER

LEVEL

SHIFTER

LVG DRIVER

+

-

+

-

V

V

THE

V

THE

D97IN493A

BOOT

HVGBOOTSTRAP

OUT

S

LVG

GND

EN1

EN2

H.V.

C

BOOT

LOAD

1/10

L6574

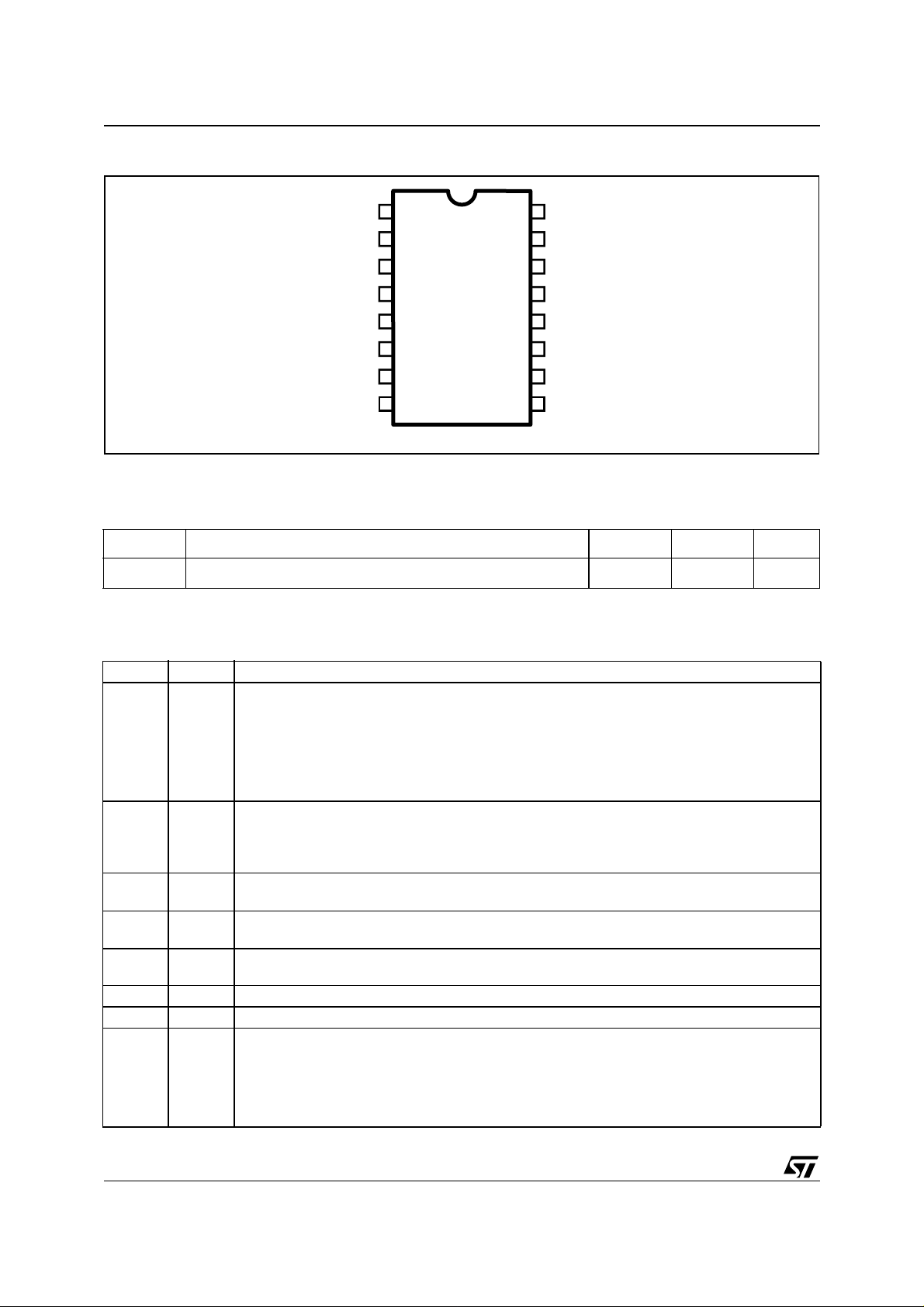

PIN CONNECTION (top view)

CPRE

RPRE

CF

RING

OPOUT

OPIN-

OPIN+

1

2

3

4

5

6

7 GND

15

14

13

12

11

10

VBOOT16

HVG

OUT

N.C.

V

S

LVG

EN1 8 EN29

D97IN492

THERMA L D ATA

Symbol Parameter DIP16 SO16N Unit

R

th j-amb

Thermal Resistance Junction to ambient Max. 80 120 °C/W

PIN DESCRIPTION

N° Pin Function

1 CPRE Preheat Timing Capacitor. The capacitor C

according to the relations: t

PRE

= K

PRE

· C

0.15s/µF). This feat ure is obtained by chargin g CPRE with two different cu rrents. During tPRE

this current is independent of the external components, so CPRE is charged up to 3.5V (preheat

timing comparato r threshol d). During t

ence between f

PRE

and f

). In this way tSH is always set at 0.1t

IGN

SH

at pin 1 is 5V.

2 RPRE Maximum Oscillation Frequency Setting. The resistance connected between this pin and ground

sets the fPRE value, fixing the difference betwe en f

Start-up procedure, the effect current drown from R

V

=2V.

REF

3 CF Oscillator Frequency Setting. The capacitor C

In normal operation this pin shows a triangular wave.

4 RIGN Minimum Oscilla tion Fre quen cy Set ting. Th e resis tance connect ed betw een th is pin a nd grou nd

sets the f

value. The voltage at this pin is fixed at V

IGN

5 OPout Out of the operational amplifier. To implement a feedback control loop this pin can be connected

to the RIGN pin by means an appropriate circuitry.

6 OPin- Inverting Input of the operational amplifier.

7 OPin+ Non Inverting Input of the operational amplifier.

8 EN1 Enable 1. This pin (active high), forces the device in a latched shutdown state (like in the under

voltage conditions). There are two ways to resume normal operation:

– the first is to reduce the supply voltage below the undervoltage threshold and then

increase it again until the valid supply is recognised.

– the second is activating EN2 input.

The enable 1 is especially designed for strong fault (e.g. in case of lamp disconnection).

sets the preheating a nd the frequ ency shift tim e,

PRE

and tSH = KFS · C

PRE

the curren t depends on R

and f

PRE

is over. The voltage at this pin is fixed at

PRE

, along with to R

F

=2V.

REF

(typ. K

PRE

PRE

. In steady state the voltage

PRE

(f

PRE

> f

PRE

and R

IGN

= 1.5s/µF, KFS =

PRE

value (i.e. on the differ-

). At the end of the

IGN

, sets f

IGN

PRE

and f

ING

.

2/10

PIN DESCRIPTION (continued)

N° Pin Function

9 EN2 Enable 2. EN2 input (active high) restarts the start-up procedure (preheating and ignition

sequence). This features is useful if the lamp does not turn-on after the first ignition sequence .

10 GND Ground.

11 LVG Low Side Driver Output. This pin must be connected to the low side power MOSFET gate of the

half bridge. A resistor connected b etween this pin and the p ower MOS gate can be used to

reduce the peak current.

12 VS Supply Voltage. This pin, connected to the supply filter capacitor, is internally clamped (15.6V

typical).

13 N.C. Non Connected. This pin set a distance between the pins related to the HV and those rela ted to

the LV side.

14 OUT High Side Driver Floating Reference. This pin must be connected close to the source of the high

side power MOS or IGBT.

15 HVG High Side Driver Output. This pin must be connected to the high side power MOSFET gate of the

half bridge. A resistor connected b etween this pin and the p ower MOS gate can be used to

reduce the peak current.

16 VBOOT Bootstrapped Supply Voltage. Between this pin and VS must be connected the bootstrap capac-

itor. A patented integrated cir cuitry replaces the exte rnal bootstrap diode, by m eans of a high

voltage DMOS, synchronously driven with the low side power MOSFET.

L6574

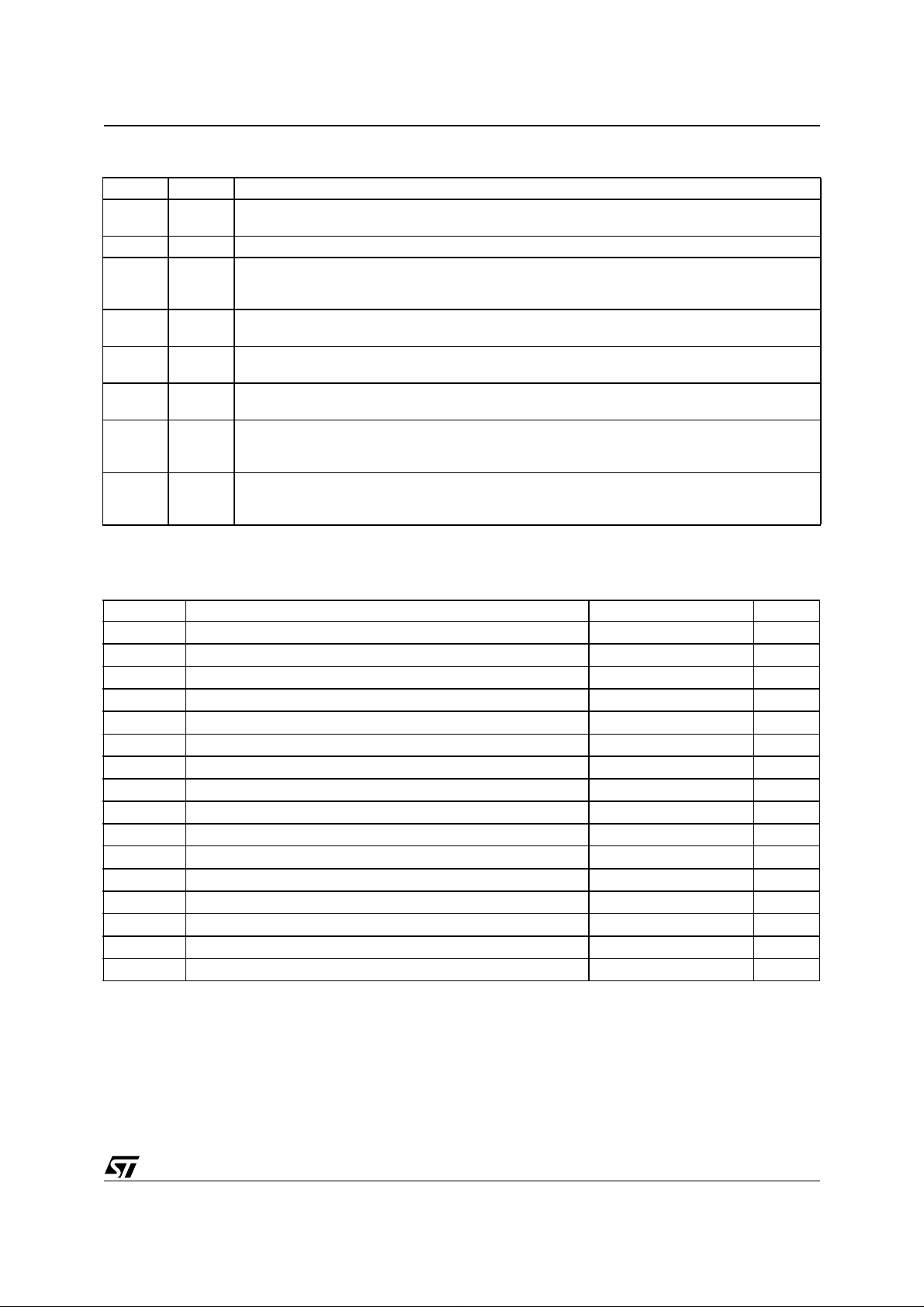

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

I

S

V

LVG

V

OUT

V

HVG

V

BOOT

dV

BOOT

dV

OUT

V

V

, V

V

EN1

, I

I

EN1

V

opc

V

opd

V

opo

T

stg

T

amb

(*) The device has an internal Clamping Zener between GND and the V

Supply Current (*) 25 mA

Low Side Output -0.3 to Vs +0.3 V

High Side Reference -1 to VBOOT -18 V

High Side Output -1 to VBOOT V

Floating Supply Voltage -1 to 618 V

/dt V

pin Slew rate (repetitive) ±50 V/ns

BOOT

/dt OUT pin Slew Rate (repetitive) ±50 V/ns

Forced Input Voltage (pins Ring, Rpre) -0.3 to 5 V

ir

Forced Input Voltage (pins Cpre, Cf) -0.3 to 5 V

ic

Enable Input Voltage -0.3 to 5 V

EN2

Enable Input Current ±3mA

EN2

Sense Op Amp Common Mode Range -0.3 to 5 V

Sense Op Amp Differential Mode Range ±5V

Sense Op Amp Output Voltage (forced) 4.6 V

, TjStorage Temperature -40 to +150 °C

Ambient Temperature -40 to +125 °C

pin, it must not be supplied by

CC

a Low Impedance Voltage Source.

Note: ESD immunity for pins 14, 15 and 16 is guaranteed up to 900V (Human Body Model)

3/10

Loading...

Loading...