■

HIGH VOLTAGE RAIL UP TO 600V

■

BCD OFF LINE TECHNOLOGY

■

INTERNAL BOOTSTRAP DIODE

STRUCTURE

■ 15.6V ZENER CLAMP ON V

■

DRIVER CURRENT CAPABILITY:

S

- SINK CURRENT = 270mA

- SOURCE CURRENT = 170mA

■

VERY LOW START UP CURRENT: 150µA

■ UNDER VOLTAGE LOCKOUT WITH

HYSTERESIS

■

PROGRAMMABLE OSCILLATOR

FREQUENCY

■

DEAD TIME 1.25µs

■ dV/dt IMMUNITY UP TO ±50V/ns

■

ESD PROTECTION

DESCRIPTION

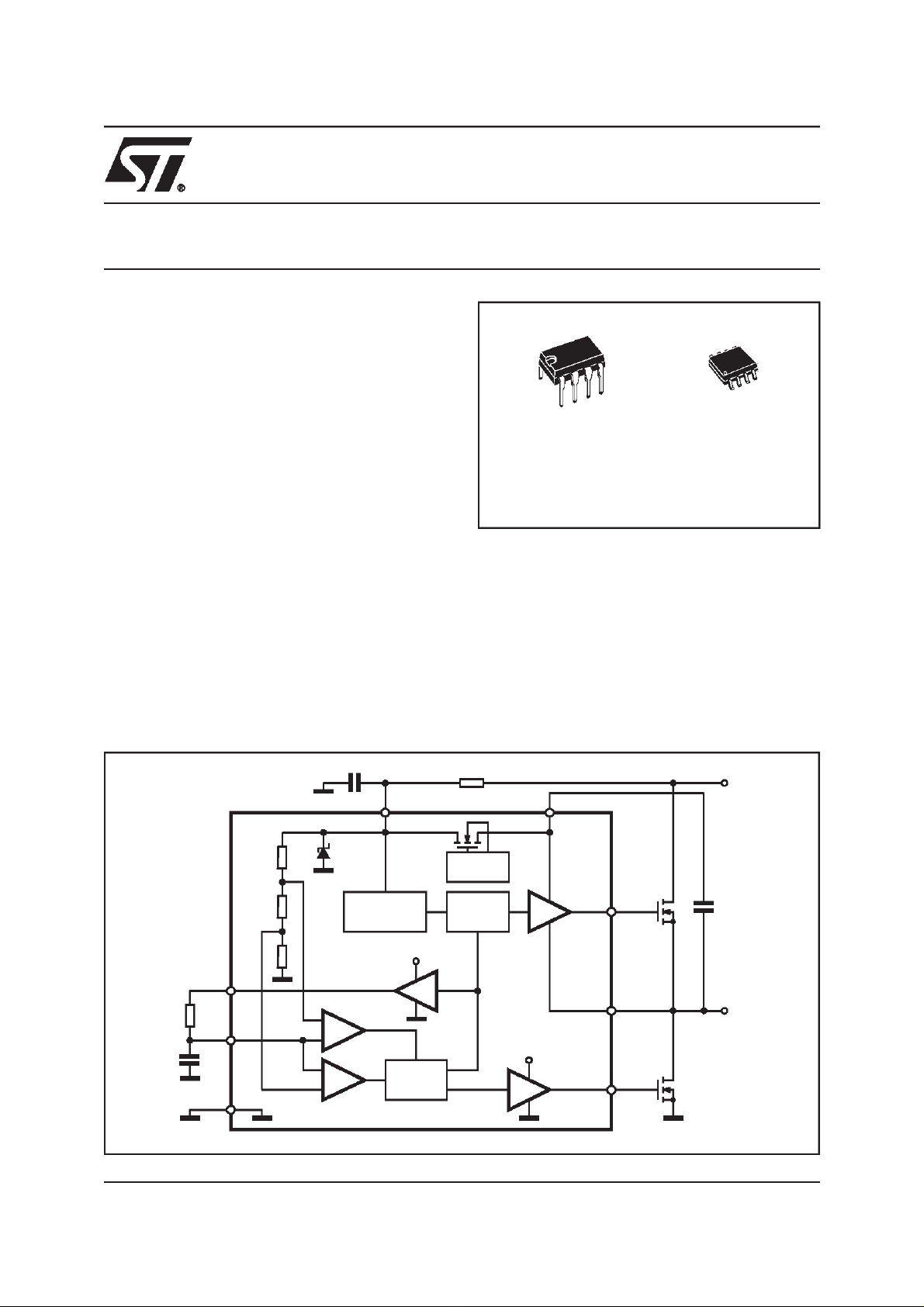

The device is a high voltage half bridge driver with

built in oscillator. The frequency of the oscillator can

L6569

L6569A

HIGH VOLTAGE HALF BRIDGE

DRIVER WITH OSCILLATOR

Minidip SO8

ORDERING NUMBERS:

L6569 L6569D

L6569A L6569AD

be programmed using external resistor and capacitor. The internal circuitry of the device allows it to be

driven also by external logic signal.

The output drivers are designed to drive external nchannel power MOSFET and IGBT. Theinternal log-

µ

ic assures a dead time [typ. 1.25

conduction of the power devices.

Two version are available: L6569 and L6569A. They

differ in the low voltage gate driver start up sequence.

s] to avoid cross-

BLOCK DIAGRAM

R

C

VS

REGULATOR

2

F

R

F

C

3

F

C

F

GND

BUFFERR

COMP

COMP

S

18

Source

BIAS

V

S

LOGIC

June 2000

This ispreliminary information ona new product now in development. Details are subject to change without notice.

HV

CHARGE

PUMP

LEVEL

SHIFTER

BOOTV

HVG

7

HIGH

SIDE

DRIVER

OUT

6

V

S

LOW SIDE

DRIVER

LVG

54

D94IN058D

C

BOOT

H.V.

LOAD

1/13

L6569 L6569A

ABSOLUTEMAXIMUM RATINGS

Symbol Parameter Value Unit

(*) Supply Current 25 mA

I

S

V

CF

V

LVG

V

OUT

V

HVG

V

BOOT

V

BOOT/OUT

dV

BOOT

dV

OUT

T

stg

T

T

amb

(*)The device has an internal zener clamp between GND and VS (typical 15.6V).Therefore the circuit should not be driven by a DC low im-

pedance power source.

Note:

ESD immunity for pins 6, 7 and 8 is guaranteed up to 900 V (Human Body Model)

Oscillator Resistor Voltage 18 V

Low Side Switch Gate Output 14.6 V

High Side Switch Source Output -1 toV

High Side Switch Gate Output -1 to V

-18 V

BOOT

BOOT

Floating Supply Voltage 618 V

Floating Supply vs OUT Voltage 18 V

/dt VBOOT Slew Rate (Repetitive)

50 V/ns

±

/dt VOUT Slew Rate (Repetitive) ± 50 V/ns

Storage Temperature -40 to 150 °C

Junction Temperature -40 to 150 °C

j

Ambient Temperature (Operative) -40 to 125 °C

V

THERMAL DATA

Symbol Parameter Minidip SO8 Unit

R

th j-amb

Thermal Resistance Junction-Ambient Max 100 150 °C/W

RECOMMENDED OPERATINGCONDITIONS

Symbol Parameter Min. Max. Unit

Supply Voltage 10 V

CL

Floating Supply Voltage - 500 V

High Side Switch Source Output -1 V

BOOT-VCL

Oscillation Frequency 200 kHz

V

BOOT

V

V

S

OUT

f

out

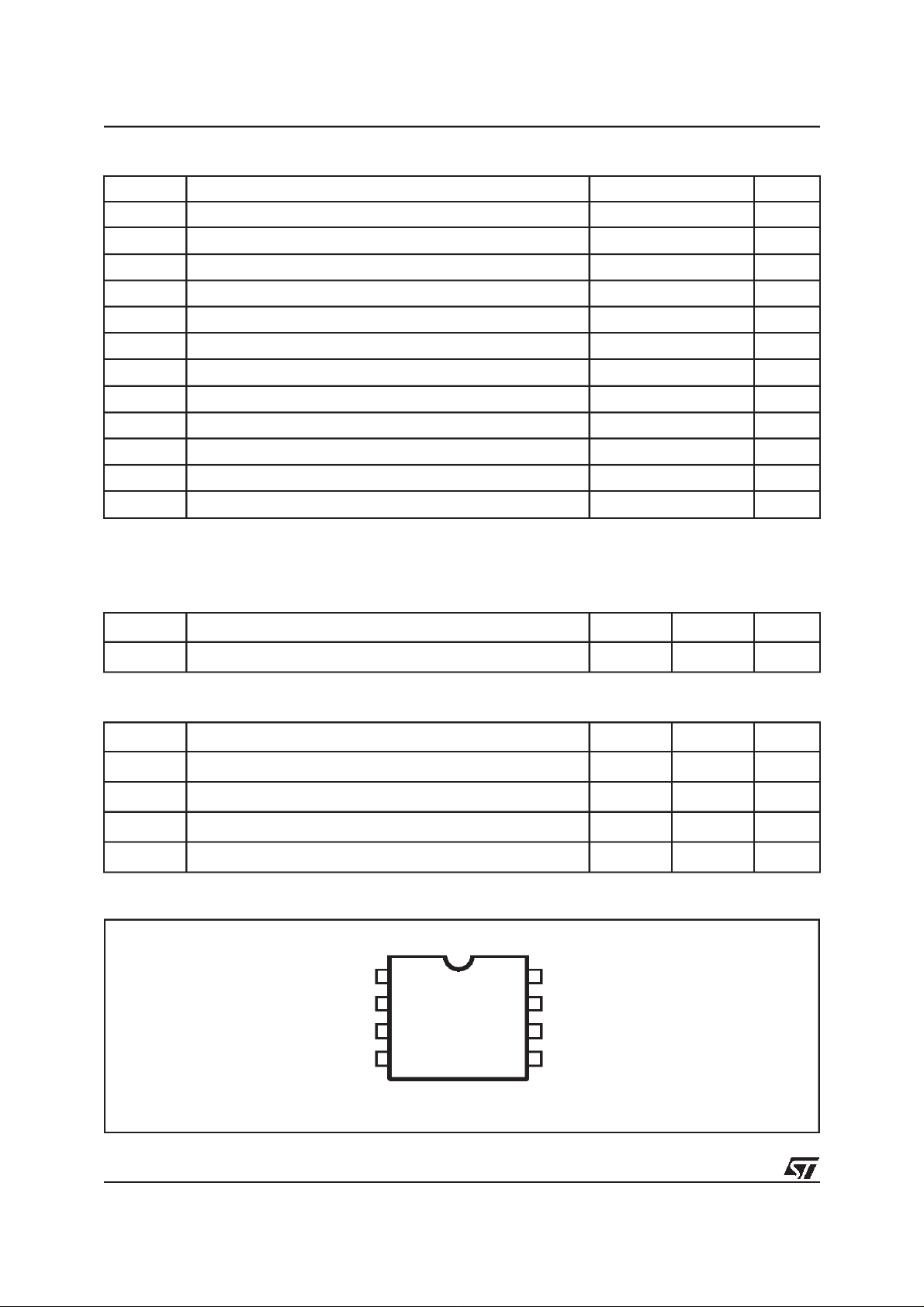

PIN CONNECTION

V

RF

C

GND

S

F

1

2

3

4 LVG

7

6

5

BOOT8

HVG

OUT

V

V

2/13

D94IN059

PIN FUNCTION

N° Pin Description

1 VS Supply input voltage with internal clamp [typ.15.6V]

L6569 L6569A

2 RF Oscillator timing resistor pin.

A buffer set alternatively to V

and GND can provide current to the external resistor RF

S

connected between pin 2 and 3.

Alternatively, the signal on pin 2 can be used also to driveanother IC (i.e. another L6569 to drive

a full H-bridge)

3 CF Oscillator timing capacitor pin.

A capacitor connected between this pin and GND fixes (together with R

) the oscillating

F

frequency

Alternatively an external logic signal can be applied to the pin to drive the IC.

4 GND Ground

5 LVG Low side driver output.

The output stage can deliver 170mA source and 270mA sink [typ.values].

6 OUT Upper driver floating reference

7 HVG High side driver output.

The output stage can deliver 170mA source and 270mA sink [typ.values].

8 BOOT Bootstrap voltage supply.

It is theupper driver floating supply. The bootstrap capacitor connected between this pin and pin

6 can be fed by an internal structure named “bootstrap driver” (a patented structure). This

structure can replace the external bootstrap diode.

ELECTRICAL CHARACTERISTCS

(VS=12V;V

BOOT-VOUT

=12V;Tj=25°C; unless otherwise specified.)

Symbol Pin Parameter Test Condition Min. Typ. Max. Unit

V

SUVP

V

SUVN

V

SUVH

V

CL

I

SU

I

q

I

BOOTLK

1 VS TurnOn Threshold 8.3 9 9.7 V

VS TurnOffThreshold 7.3 8 8.7 V

VS Hysteresis 0.7 1 1.3 V

VS Clamping Voltage IS= 5mA 14.6 15.6 16.6 V

Start Up Current VS<V

Quiescent Current VS>V

8 Leakage Current BOOT pin vs

GND

I

OUTLK

6 Leakage Current OUT pin vs

GND

I

HVGSO

I

HVG SI

I

LVG SO

I

LVG S

7 High Side Driver Source Current V

High Side Driver Sink Current V

5 Low Side Driver Source Current V

I Low Side Driver SinkCurrent V

SUVN

SUVP

V

= 580V 5

BOOT

V

= 562V 5

OUT

= 6V 110 175 mA

HVG

= 6V 190 275 mA

HVG

= 6V 110 175 mA

LVG

= 6V 190 275 mA

LVG

150 250

500 700

A

µ

A

µ

A

µ

A

µ

3/13

L6569 L6569A

ELECTRICAL CHARACTERISTCS (continued)

Symbol Pin Parameter Test Condition Min. Typ. Max. Unit

V

N 2 RF High Level Output Voltage IRF=1mA V

RFO

-0.05 V

S

-0.2 V

S

V

RF OFF

V

CFU

V

CFL

t

d

DC Duty Cycle, Ratio Between Dead

R

ON

V

BC

I

AVE

f

out

RF Low Level Output Voltage IRF= -1mA 50 200 mV

3 CF Upper Threshold 7.7 8 8.2 V

CF Lower Threshold 3.80 4 4.3 V

Internal Dead Time 0.85 1.25 1.65

0.45 0.5 0.55

Time + Conduction Time of High

Side and Low Side Drivers

On resistance of Boostrap

LDMOS

Boostrap Voltage before UVLO VS= 8.2 2.5 3.6 V

1 Average Current from Vs No Load, fs = 60KHz 1.2 1.5 mA

6 Oscillation Frequency RT= 12K; CT= 1nF 57 60 63 kHz

120

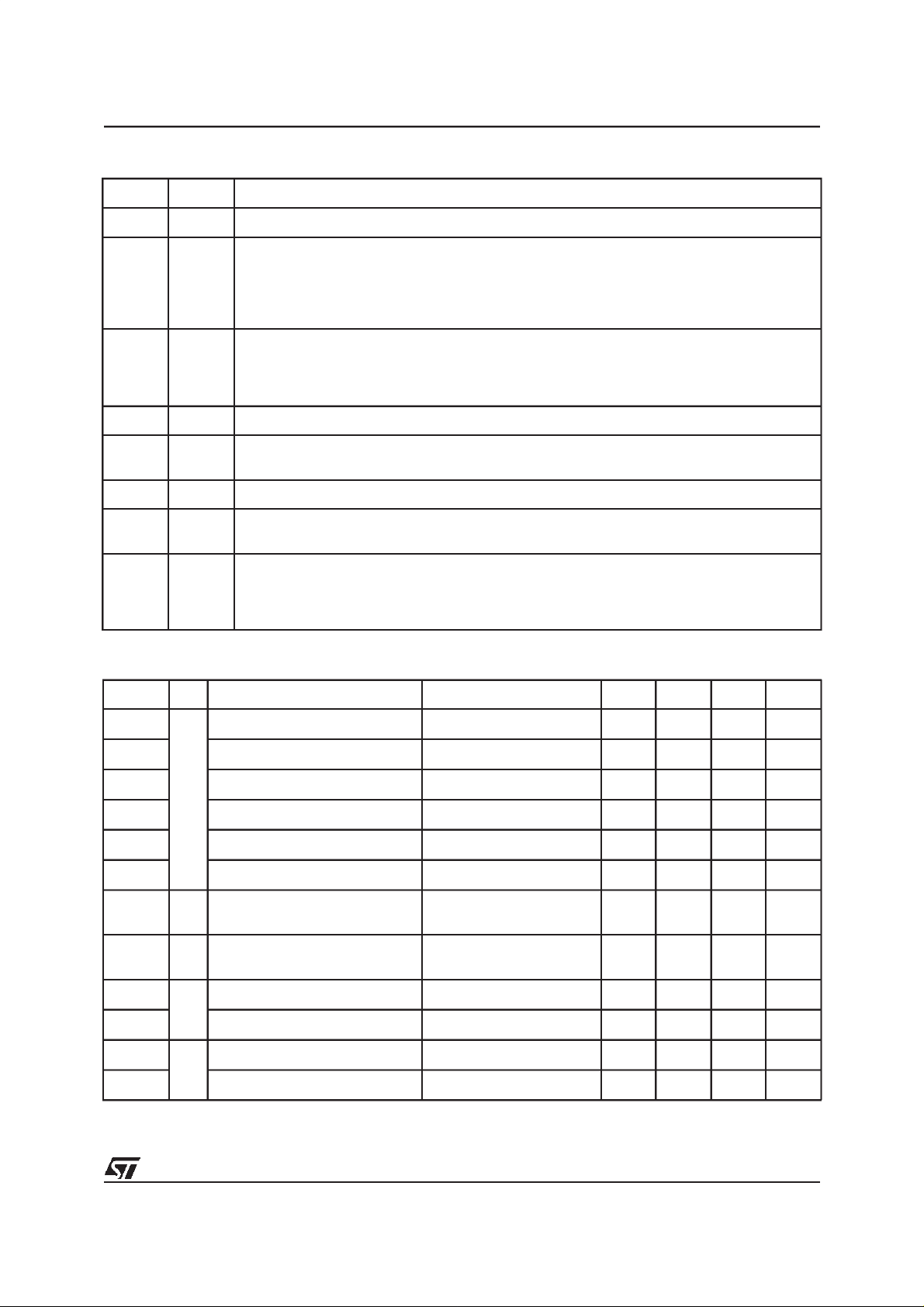

OSCILLATORFREQUENCY

The frequency of the internal oscillator can be programmed using external resistor and capacitor.

The nominal oscillator frequency can be calculated using the following equation:

f

OSC

------------- ------- ---------------------

2RFCFIn2

1

⋅⋅⋅

------------- --------- ------------------ --==

1.3863 RFC

1

⋅⋅

F

s

µ

Ω

Where R

and CFare the external resistor and capacitor.

F

The device can be driven in ”shut down” condition keeping the C

taken:

1. When C

2. The forced discharge of the oscillator capacitor C

is to GND the high side driver is off and the low side is on

F

must not be shorter than 1us: a simple way to do this is to

F

limit the current discharge with a resistive path imposing R · C

Figure 1.

F

R

F

fault signal

R

C

GNDM

4/13

pin close to GND, but some cares have to be

F

>1µs (see fig.1)

F

1

2

3

4

8

7

6

5

L6569 L6569A

BootstrapFunction

The L6569 has an internal Bootstrap structure that enables the user to avoid the external diode needed, in similar devices, to perform the charge of the bootstrap capacitor that, in turns, provide an appropriate driving to the

Upper External Mosfet.

The operation is achieved with an unique structure (patented) that uses a High Voltage Lateral DMOS driven

by an internal charge pump (see Block Diagram) and synchronized, with a 50 nsec delay, with the Low Side

Gate driver (LVG pin), actually working as a synchronous rectifier .

The charging path for the Bootstrap capacitor isclosed via the Lower External Mosfet that is drivenON (i.e.LVG

High) for a time interval:

T

C=RF·CF

starting from the time the Supply Voltage VShas reached the Turn On Voltage (V

After time T

(see waveform Diagram) the LDMOSthatchargesthe Bootstrap Capacitor, is on with a RON=120Ω

1

(typical value).

In the L6569A a different start up procedure is followed (see waveform Diagram). The Lower External Mosfet is

driveOFF until V

hasreached the TurnOn Threshold(V

S

Being the LDMOS used to implement the bootstrap operation a ”bi-directional” switch the current flowing into

the BOOT pin (pin 8) can lead an undue stress to the LDMOS itself if a ZERO VOLTAGE SWITCHING operations is not ensured, and then an high voltage is applied to the BOOT pin. This condition can occur, for example,

when the load is removed and an high resistive value is placed in series with the gate of the external Power

Mos. To help the user to secure his design a SAFE OPERATING AREA for the Bootstrap LDMOS is provided

(fig. 7).

Let’s consider the steps that should be taken.

1) Calculate the Turn on delay ( td ) of your Lower Power MOS:

· In2 → 1.1 · RF·C

), then againthe TCtimeinterval starts asabove.

SUVPp

F

= 9 V typical value).

SUVP

d

id

+

=

t

RgR

()C

⋅⋅

iss

1

------------- ------ -ln

V

TH

-----------–

1

V

S

2) Calculate the Fall time ( tf ) of your Lower Power MOS:

R

R

+

g

-------------- -------- -- Q

=

t

f

VSV

id

⋅

TH

gd

–

where:

= External gate resistor

R

g

R

=50Ω, typical equivalent output resistance of the driving buffer (when sourcing current)

id

V

TH,Ciss

V

S

and Qgdare Power MOS parameters

= Low Voltage Supply.

3) Sketch the VBOOT waveform (using log-log scales) starting from the Drain Voltage of the Lower Power MOS

(remember to add the Vs, your Low Voltage Supply, value) on the Bootstrap LDMOS SOA . On fig. 8 an example

is given where:

= Low Voltage Supply

V

S

= High Voltage Supply Rail

V

HV

The V

voltage swing must fall below the curve identified by the actual operating frequency of your applica-

BOOT

tion.

5/13

L6569 L6569A

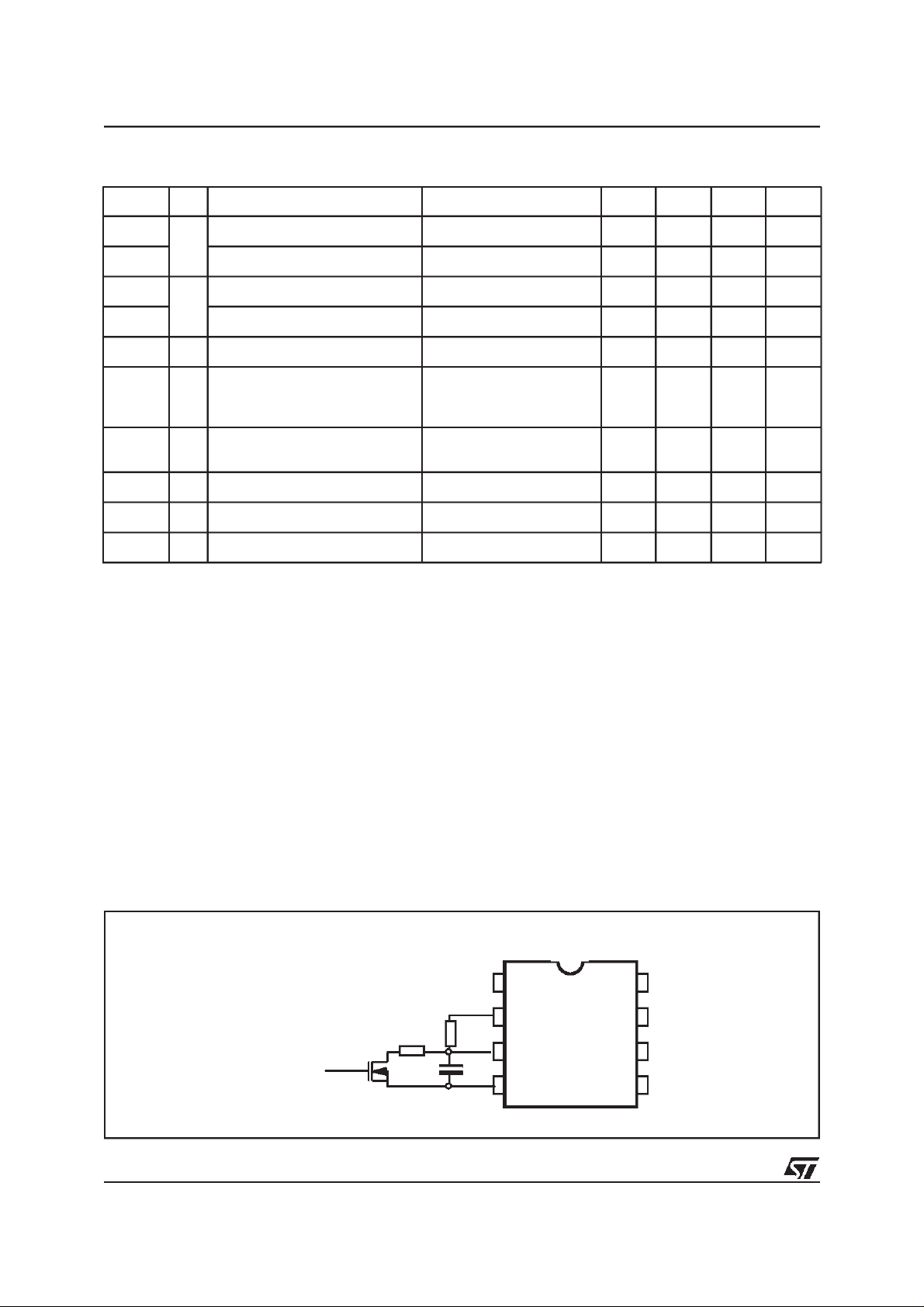

DEMOBOARD

To allow an easy evaluation of the device, a P.C. board dedicated to lamp ballast application has been designed.

Fig.11 shows the electrical schematic of a typical ballast application, while the PC and component layout isgiven in Fig12.This application has been designed to work with both the 110+/-20%V and the 220 +/- 20%V mains

by means of a voltage doubler configuration at the bulk capacitor. The ballast inductance and the operating frequency are especially designed for a 18 W Sylvania De-luxe T/E type bulb. The PTC for preheat at the start up

and the two back to back synchronization diodes, makes this application easy to implement and safe in operation.

part value

R1 15ohm 1W

R2, R3 22 ohm

R4 27K

R5 100K 1/2W

R6 47ohm

R7, R9 180K

R8 120K 1/2W

D1 18V zener

D2, D3 BYW100-100

D4,D5,D6,D7 1N4007

D8 1N4148

C1 560pF 50V

C2,C5 47µF 250V

C3 4.7µF 25V

C4 100nF 50V

C6 100nF 250V

C7-C8 8.2nF 630V

C9 470pF 630V

RV1 PTC 150ohm

Q1, Q2 STD2NB50-1

L1 2.4mH

6/13

Figure 2. Waveforms (L6569)

V

S

V

BOOT-VOUT

L6569 L6569A

V

SUVP

V

S

V

CF

LVG

Figure 3. Waveforms (L6569A)

V

S

V

BOOT-VOUT

τ=Ron*C

BOOT

T1

T

C

4.6V(typ)

D95IN250B

V

SUVP

V

S

V

CF

LVG

4.6V(typ)

τ=Ron*C

BOOT

T1

T

C

D95IN251B

7/13

L6569 L6569A

Figure 4. Typical Dead Time vs. Temperature

Dependency

Dead time [µsec]

1.7

1.6

1.5

1.4

1.3

1.2

1.1

1

0.9

-50 0 50 100 150

Temperature [C]

D96IN378A

Figure 5. Typical Frequency vs Temperature

Dependency

Frequency [KHz]

65

64

63

62

61

60

59

58

57

56

55

-50 -25 0 25 50 75 100 125

Temperature [C]

D96IN379A

Figure 6. Typical and Theoretical Oscillator

Frequency vs Resistor Value

f (KHz)

150

100

90

80

70

60

50

C=1nF

C=560pF

C=330pF

D96IN380

Theoretical

Figure 7. V

pin SOA for different Operating

boot

Frequency @ Tj=125°C

VBOOT

(V)

500

300

200

100

50

30

20

10

20 50 100 200 500 1,000 2,000 5,000 10,000

Figure 8. V

VBOOT

(V)

500

V

HV+VS

300

200

100

50

30

20

t

d

10

20 50 100 200 500 1,000 2,000 5,000 10,000

110KHz

70KHz

50KHz

20KHz

150KHz

Time (ns),from LVG Transition High

pin SOA @ Tj= 125°C

boot

ACTUAL OPERTATING

FREQUENCY

VBOOT

t

f

Time (ns),from LVG Transition High

V

S

D96IN381

D96IN416

Figure 9. Typical Rise and Fall Times vs. Load

Capacitance

time [nsec]

300

250

200

150

100

D96IN417

Tr

Tf

8/13

30

20

5678910 15 20 30 4050

Resistor Value (Kohm)

50

0

0123456

C [nF]

For both high and low side buffers @25°C Tamb

Figure 10. Quiescent Current vs. Supply Voltage.

L6569 L6569A

Iq (µA)

4

10

3

10

2

10

D96IN418

10

02468101214VS(V)

Figure 11. CFL Demoboard 110/220V Inputs.

4 x1N4006

220V

N

110V

R8

120K

1/2W

D7 D4

D5D6

R1 15 1W

L1=2.4mH core THLCC E2006-B4 Ref also VOGH 5750409200 2.4mH

C7-C8=PS8n2J H3 630-2ATH

C5

47µ

250V

C2

47µ

F

250V

R5 100K

1/2W

C3

F

4.7µ

25V

R4

27K

1/4W

D8

1N4148

F

ZPD 18V

V

S

RF

L6569

CF

C1

560pF

50V

D1

C9 470pF630V

R6 471/4W

BOOT

HVG

OUT

LVG

GND

C4100nF 50V

R2 22 1/4W

R3 22 1/4W

D96IN419B

R10 10K

1/4W

Q1

STD2NB50-1

Q2

STD2NB50-1

180K

1/4W

BYW100-100

D2

D3 BYW100-100

R9

180K

1/4W

R7

C6

100nF

250V

L1=2.4mH

C7

8.2nF

630V

C8

8.2nF

630V

CFL

SYLVANIA DELUXT/E18W

LAMP

RV1

PTC 150

350V

9/13

L6569 L6569A

Figure 12. PC Board and Components Layout.

Component Side

Copper Side

10/13

L6569 L6569A

DIM.

D (1) 4.8 5.0 0.189 0.197

F (1) 3.8 4.0 0.15 0.157

(1) D and F donot include mold flash or protrusions. Mold flashor

MIN. TYP. MAX. MIN. TYP. MAX.

A 1.75 0.069

a1 0.1 0.25 0.004 0.010

a2 1.65

a3 0.65 0.85 0.026 0.033

b 0.35 0.48 0.014 0.019

b1 0.19 0.25 0.007 0.010

C 0.25 0.5 0.010 0.020

c1 45° (typ.)

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 3.81 0.150

L 0.4 1.27 0.016 0.050

M 0.6 0.024

S8°(max.)

potrusions shall not exceed 0.15mm (.006inch).

mm inch

0.065

OUTLINE AND

MECHANICAL DATA

SO8

11/13

L6569 L6569A

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 3.32 0.131

a1 0.51 0.020

B 1.15 1.65 0.045 0.065

b 0.356 0.55 0.014 0.022

b1 0.204 0.304 0.008 0.012

D 10.92 0.430

E 7.95 9.75 0.313 0.384

e 2.54 0.100

e3 7.62 0.300

e4 7.62 0.300

F 6.6 0.260

I 5.08 0.200

L 3.18 3.81 0.125 0.150

Z 1.52 0.060

mm inch

OUTLINE AND

MECHANICAL DATA

Minidip

12/13

L6569 L6569A

Information furnished isbelieved to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of useof suchinformation nor for any infringement of patents or otherrightsofthird parties whichmay result from its use.No license is granted

by implicationor otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

2000 STMicroelectronics - All Rights Reserved

Australia - Brazil - China - Finland - France - Germany - Hong Kong - India- Italy - Japan - Malaysia -Malta- Morocco - Singapore - Spain

STMicroelectronics GROUP OF COMPANIES

- Sweden - Switzerland - United Kingdom - U.S.A.

http://www.st.com

13/13

Loading...

Loading...