ST L6566BH User Manual

Features

■ Selectable multimode operation: fixed

frequency or quasi-resonant

■ On-board 840 V high voltage startup

■ Advanced light load management

■ Low quiescent current (< 3 mA)

■ Adaptive UVLO

■ Line feedforward for constant power capability

vs. mains voltage

■ Pulse-by-pulse OCP, shutdown on overload

(latched or auto-restart)

■ Transformer saturation detection

■ Programmable frequency modulation for EMI

reduction

■ Latched or auto-restart OVP

■ Brownout protection

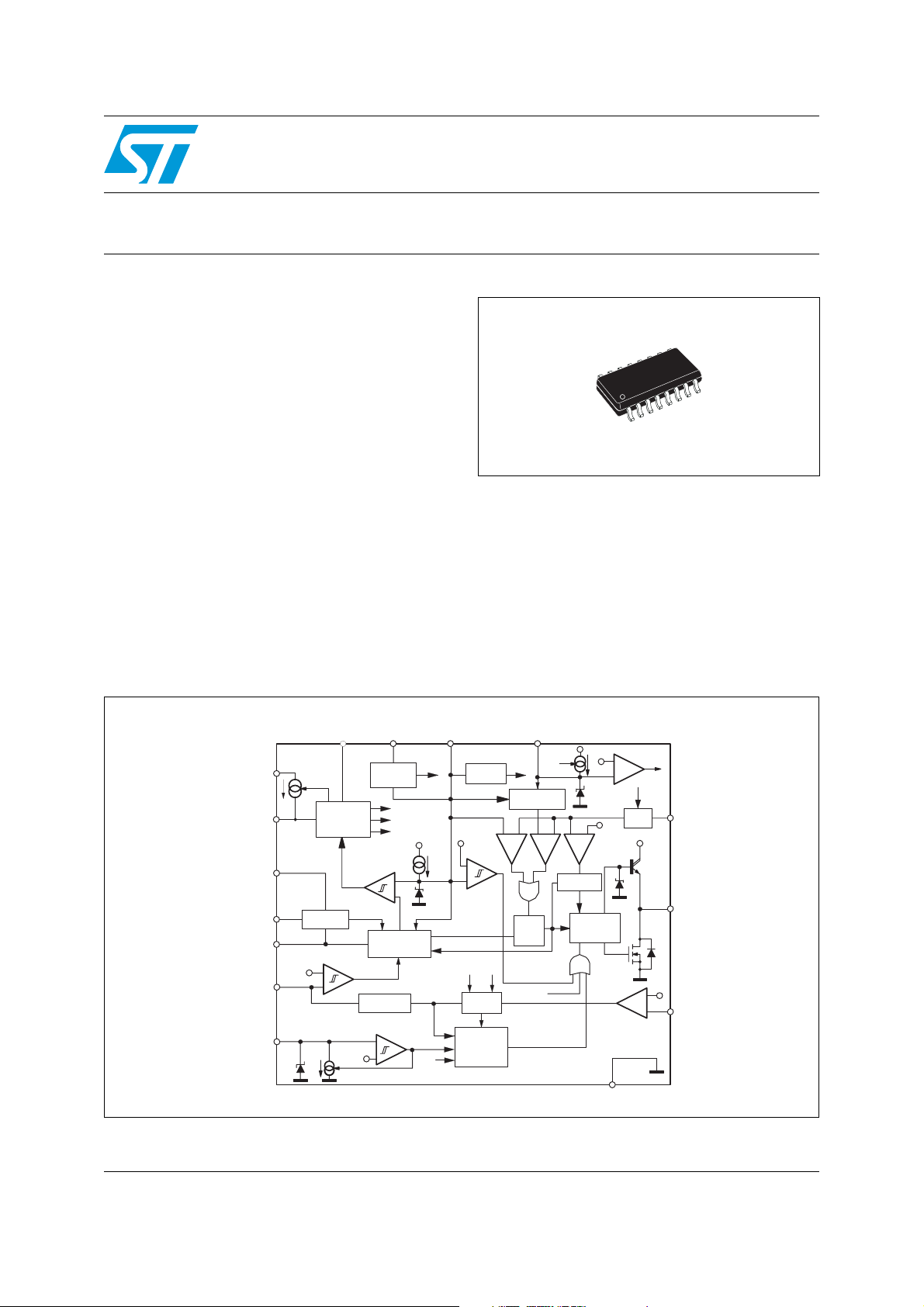

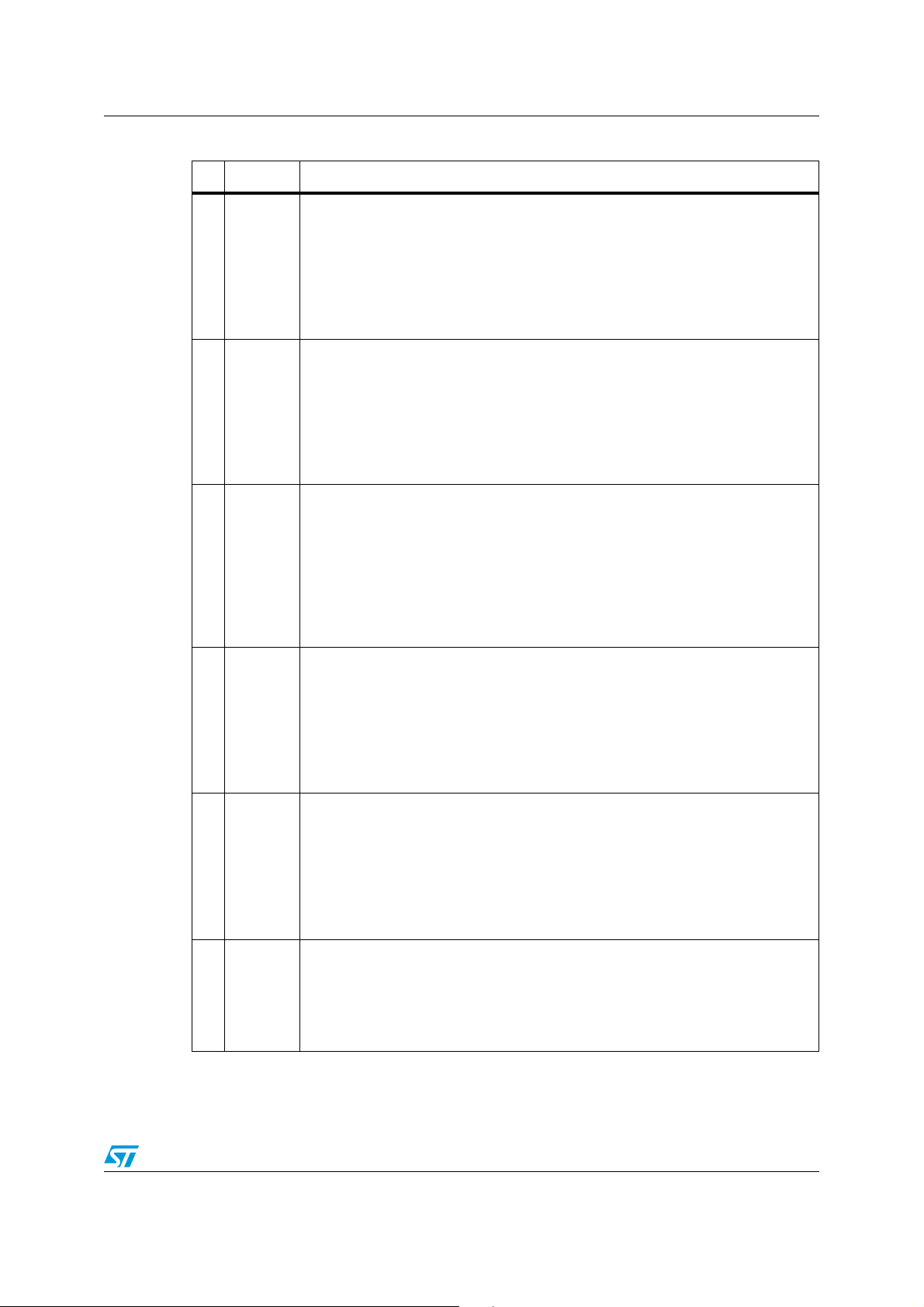

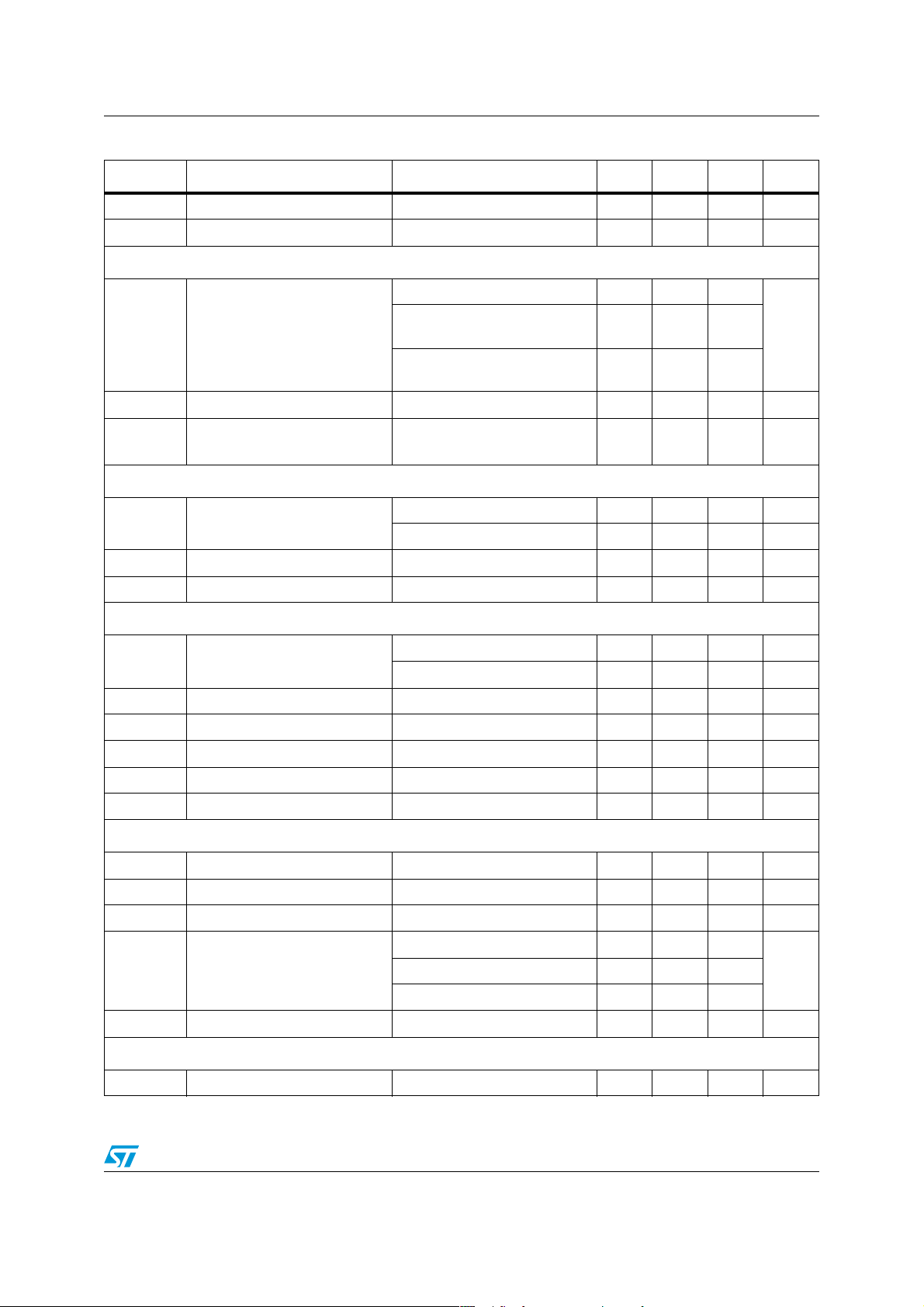

Figure 1. Block diagram

L6566BH

Multimode controller for SMPS

Datasheet — production data

SO16N

■ -600/+800 mA totem pole gate driver with

active pull-down during UVLO

■ SO16N package

Applications

■ Industrial SMPS

■ SMPS running off rectified 3-phase input line

COMP

915

TIME

OUT

LOW CLAMP

& DISABLE

Vth

V

CC

400 uA

+

-

5.7V

BURST-MODE

TIME

OVPL

OUT

OVP

LATCH

IC_LATCH

AC_ FAI L

UVLO

DISABLE

VFF

OFF2

LINE VOLTAGE

FEEDFORWARD

+-

OCPPWM

R

Q

S

OFF2

OVP

+-

V

CC

+-

Hiccup-mode

OCP logic

OCP2

DRIVER

7.7V

I

charge

6.4V

3

1.5 V

OVPL

+

Q

V

CC

14V

LEB

CS

7

4

GD

4.5V

-

+

DIS

8

FMOD

OSC

MOD E/S C

ZCD

AC_O K

VRE F

10

1

HV

I

HV

V

CC

5

6

13

12

100 mV

11

16

50 mV

3 V

VOLTAG E

REGULATOR

ADAP TIVE UVL O

OSCILL ATOR

-

+

15 µA

&

UVLO_ SHF

ZERO CURRENT

DETECTOR

OVERVOLTAGE

0.450V

0.485V

SS

14

SOFT-START

&

FAULT MNGT

Ref er e nc e

voltages

Internal supply

UVL O

-

+

MODE SELECTION

&

TURN -ON LO GIC

PROTECTION

-

+

April 2012 Doc ID 16610 Rev 2 1/51

This is information on a product in full production.

www.st.com

51

Contents L6566BH

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 High voltage startup generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Zero-current detection and triggering block; oscillator block . . . . . . . . . . 19

5.3 Burst-mode operation at no load or very light load . . . . . . . . . . . . . . . . . . 22

5.4 Adaptive UVLO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5 PWM control block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.6 PWM comparator, PWM latch and voltage feedforward blocks . . . . . . . . 25

5.7 Hiccup-mode OCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.8 Frequency modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

5.9 Latched disable function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.10 Soft-start and delayed latched shutdown upon overcurrent . . . . . . . . . . . 32

5.11 OVP block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.12 Brownout protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.13 Slope compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.14 Summary of L6566BH power management functions . . . . . . . . . . . . . . . 39

6 Application examples and ideas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2/51 Doc ID 16610 Rev 2

L6566BH Contents

7 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8 Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Doc ID 16610 Rev 2 3/51

List of tables L6566BH

List of tables

Table 1. Pin functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 2. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 3. Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4. Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 5. L6566BH light load management features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 6. L6566BH protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Table 7. External circuits that determine IC behavior upon OVP and OCP . . . . . . . . . . . . . . . . . . . 44

Table 8. SO16N mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Table 9. Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 10. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4/51 Doc ID 16610 Rev 2

L6566BH List of figures

List of figures

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Typical system block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Pin connection (through top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. Multimode operation with QR option active . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 5. High voltage startup generator: internal schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 6. Timing diagram: normal power-up and power-down sequences . . . . . . . . . . . . . . . . . . . . 18

Figure 7. Timing diagram showing short-circuit behavior (SS pin clamped at 5 V) . . . . . . . . . . . . . . 19

Figure 8. V

Figure 9. Drain ringing cycle skipping as the load is gradually reduced . . . . . . . . . . . . . . . . . . . . . . 20

Figure 10. Operation of ZCD, triggering and oscillator blocks (QR option active) . . . . . . . . . . . . . . . . 22

Figure 11. Load-dependent operating modes: timing diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 12. Addition of an offset to the current sense lowers the burst-mode operation threshold . . . . 23

Figure 13. Adaptive UVLO block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 14. Possible feedback configurations that can be used with the L6566BH . . . . . . . . . . . . . . . 24

Figure 15. Externally controlled burst-mode operation by driving the COMP pin: timing diagram. . . . 25

Figure 16. Typical power capability change vs. input voltage in QR flyback converters . . . . . . . . . . . 26

Figure 17. Left: overcurrent setpoint vs. VFF voltage; right: line feedforward function block. . . . . . . . 27

Figure 18. Hiccup-mode OCP: timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 19. Frequency modulation circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 20. Operation after latched disable activation: timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 21. Soft-start pin operation under different operating conditions and settings . . . . . . . . . . . . . 33

Figure 22. OVP function: internal block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 23. OVP function: timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 24. Maximum allowed duty cycle vs. switching frequency for correct OVP detection. . . . . . . . 36

Figure 25. Brownout protection: internal block diagram and timing diagram . . . . . . . . . . . . . . . . . . . . 37

Figure 26. Voltage sensing techniques to implement brownout protection with the L6566BH . . . . . . 38

Figure 27. Slope compensation waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 28. Typical low-cost application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 29. Typical full-feature application schematic (QR operation) . . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 30. Typical full-feature application schematic (FF operation) . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 31. Frequency foldback at light load (FF operation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 32. Latched shutdown upon mains overvoltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 33. SO16N package drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Figure 34. Recommended footprint (dimensions are in mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

rating vs. temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

HV

Doc ID 16610 Rev 2 5/51

Description L6566BH

1 Description

The L6566BH is an extremely versatile current-mode primary controller IC, specifically

designed for high-performance offline flyback converters running off rectified 3-phase input

lines. It is also suited to single-stage, single-switch, input-current-shaping converters

(single-stage PFC) for applications that must comply with EN61000-3-2 or JEITA-MITI

regulations.

Both fixed-frequency (FF) and quasi-resonant (QR) operation are supported. The user can

choose either of the two depending on application needs. The device features an externally

programmable oscillator: it defines the converter switching frequency in FF mode and the

maximum allowed switching frequency in QR mode.

When FF operation is selected, the ICs work as a standard current-mode controller with a

maximum duty cycle limited to 70% min. The oscillator frequency can be modulated to

mitigate EMI emissions.

QR operation, when selected, occurs at heavy load and is achieved through a transformer

demagnetization sensing input that triggers MOSFET turn-on. Under some conditions, ZVS

(zero-voltage switching) can be achieved. The converter’s power capability rise with the

mains voltage is compensated by line voltage feedforward. At medium and light load, as the

QR operating frequency equals the oscillator frequency, a function (valley skipping) is

activated to prevent further frequency rise and keep the operation as close to ZVS as

possible.

With either FF or QR operation, at very light load the ICs enter a controlled burst-mode

operation that, along with the built-in, non-dissipative, high-voltage startup circuit and the

low quiescent current, helps keep the consumption from the mains low and meet energy

saving recommendations.

An innovative adaptive UVLO helps minimize the issues related to the fluctuations of the

self-supply voltage due to transformer parasites.

The protection functions included in this device are: not-latched input undervoltage

(brownout), output OVP (auto-restart or latch-mode selectable), a first-level OCP with

delayed shutdown to protect the system during overload or short-circuit conditions (autorestart or latch-mode selectable), and a second-level OCP that is invoked when the

transformer saturates or there is a short-circuit of the secondary diode. A latched disable

input allows easy implementation of OTP with an external NTC, while an internal shutdown

prevents IC overheating.

Programmable soft-start, leading-edge blanking on the current sense input for greater noise

immunity, slope compensation (in FF mode only), and a shutdown function for externally

controlled burst-mode operation or remote ON/OFF control complete the features of this

device.

6/51 Doc ID 16610 Rev 2

L6566BH Description

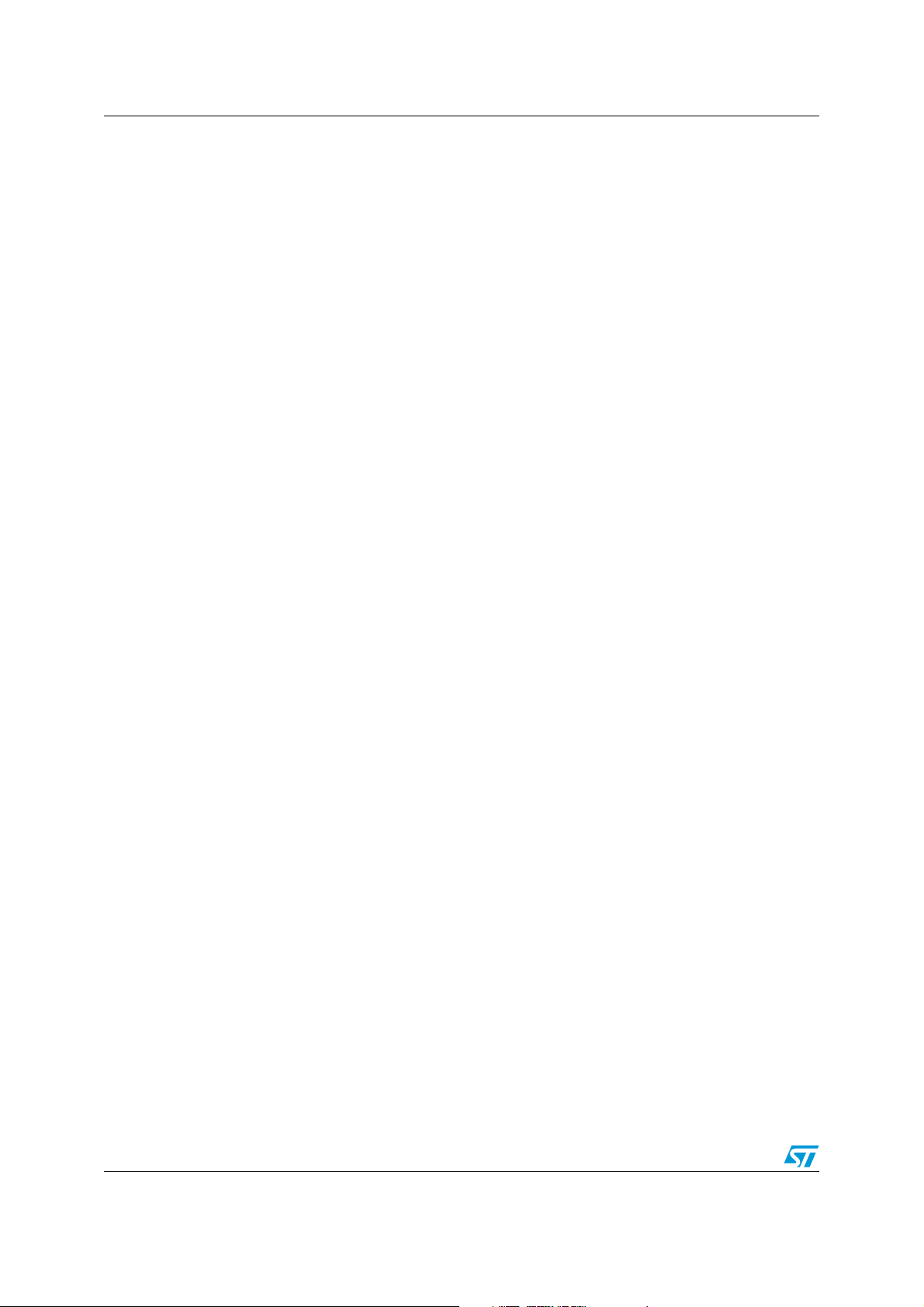

Figure 2. Typical system block diagram

FLYBAC K DC-DC CO NVERTER

Rectified

& Filtered

Mains

Voltage

L6566BH

V

outdc

Doc ID 16610 Rev 2 7/51

Pin settings L6566BH

2 Pin settings

2.1 Connections

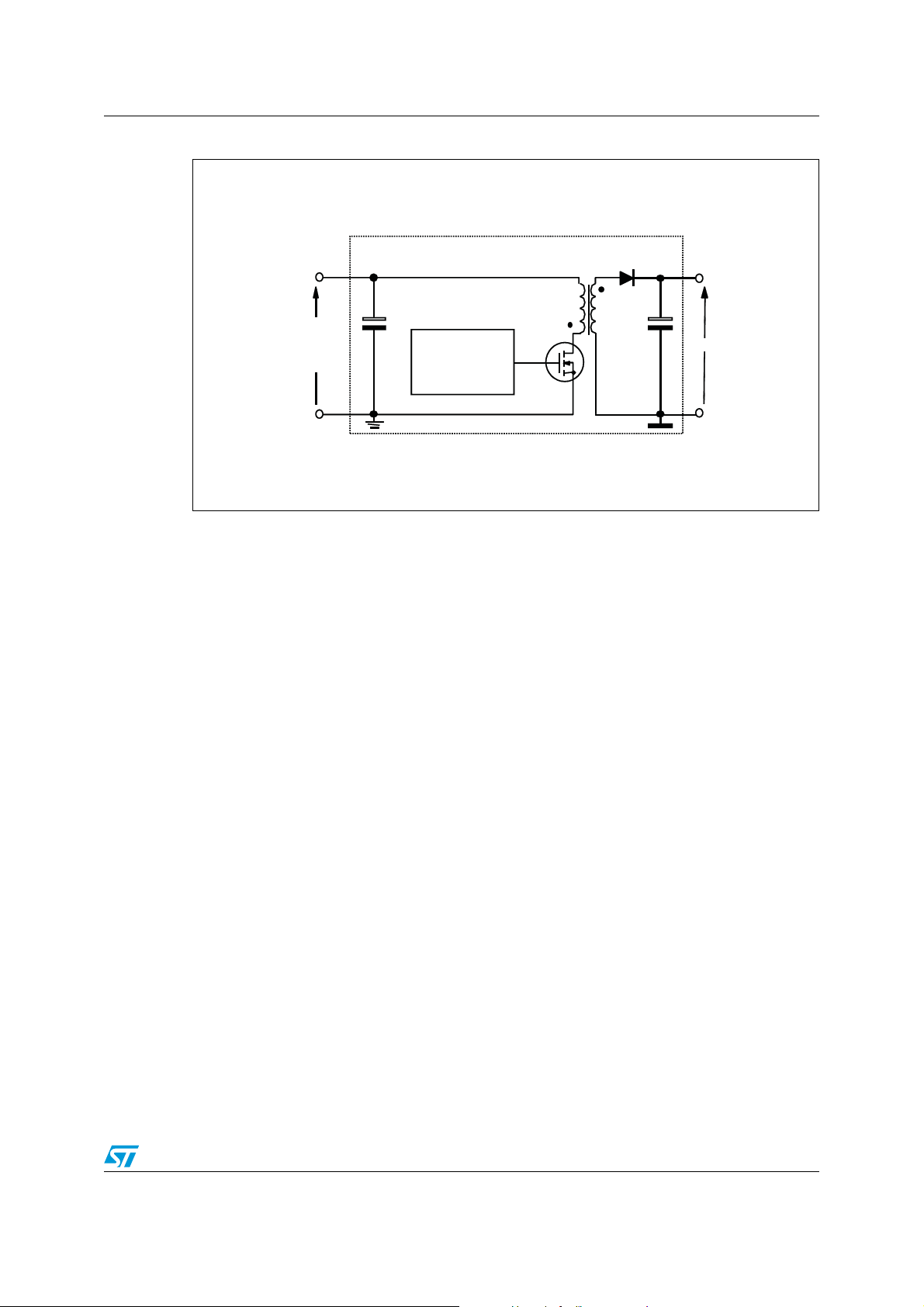

Figure 3. Pin connection (through top view)

1

16

KO_CASVH

2.2 Pin description

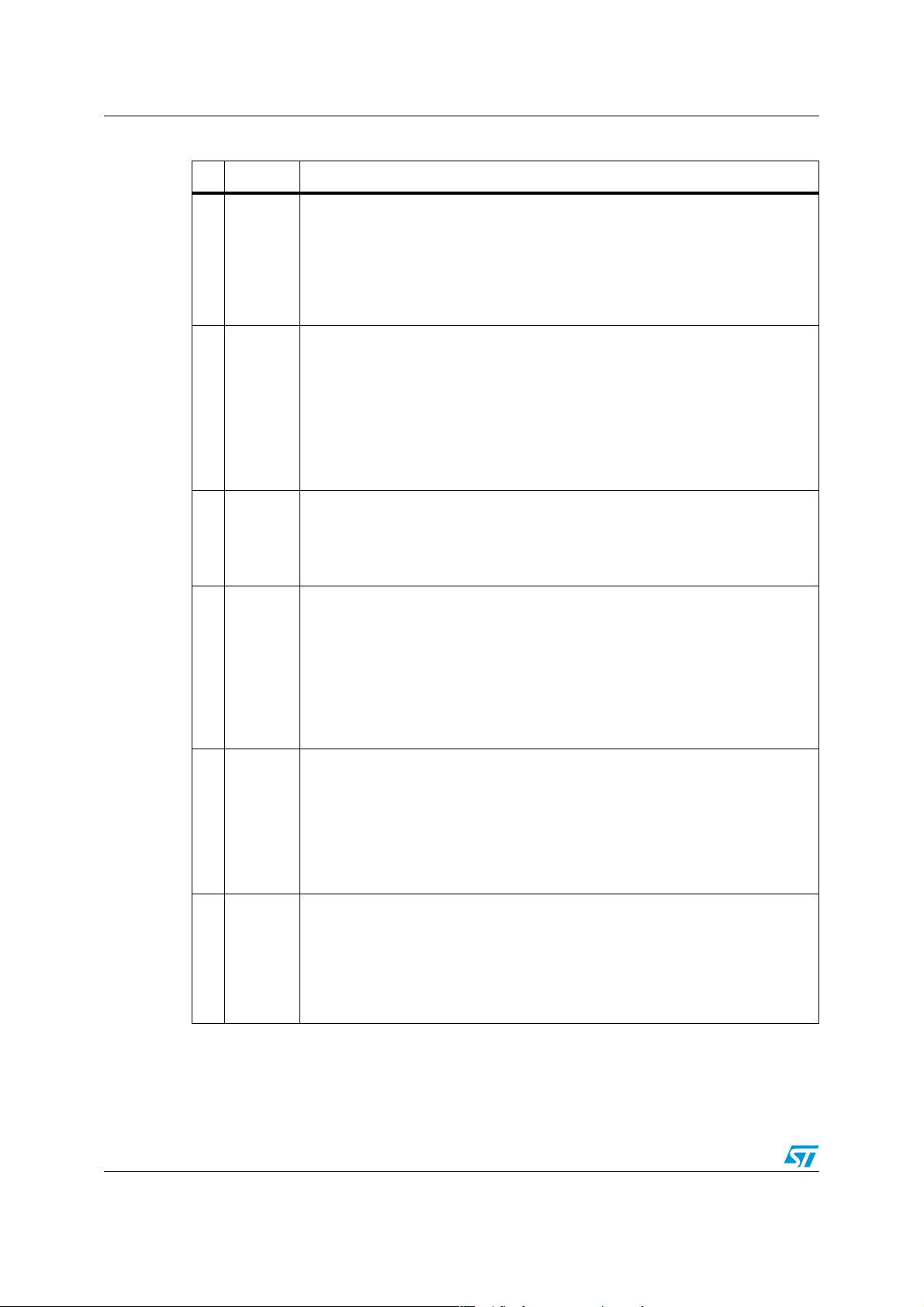

Table 1. Pin functions

N° Pin Function

High voltage startup. The pin, able to withstand 840 V, is to be tied directly to the

rectified mains voltage. A 1 mA internal current source charges the capacitor

connected between the Vcc pin (5) and GND pin (3) until the voltage on the Vcc pin

reaches the turn-on threshold, it is then shut down. Normally, the generator is re-

1HVS

2N.C.

enabled when the Vcc voltage falls below 5 V to ensure a low power throughput

during short-circuit. Otherwise, when a latched protection is tripped the generator is

re-enabled 0.5 V below the turn-on threshold, to keep the latch supplied; or, when

the IC is turned off by the COMP pin (9) pulled low, the generator is active just

below the UVLO threshold to allow a faster restart.

Not internally connected. Provision for clearance on the PCB to meet safety

requirements.

N. C.

GND

GD

Vcc

FMOD

DIS

2

3

4

5

6

7

8

15

14

13

12

11

10

9

VFF

SS

OSC

MODE /S C

ZCD

FERVSC

COMP

AM11479v1

Ground. Current return for both the signal part of the IC and the gate drive. All of

3GND

4GD

8/51 Doc ID 16610 Rev 2

the ground connections of the bias components should be tied to a track going to

this pin and kept separate from any pulsed current return.

Gate driver output. The totem pole output stage is able to drive Power MOSFETs

and IGBTs with a peak current capability of 800 mA source/sink.

L6566BH Pin settings

Table 1. Pin functions (continued)

N° Pin Function

Supply voltage of both the signal part of the IC and the gate driver. The internal

high voltage generator charges an electrolytic capacitor connected between this

pin and GND (pin 3) as long as the voltage on the pin is below the turn-on threshold

5Vcc

6FMOD

7CS

of the IC, after that it is disabled and the chip is turned on. The IC is disabled as the

voltage on the pin falls below the UVLO threshold. This threshold is reduced at light

load to counteract the natural reduction of the self-supply voltage. Sometimes a

small bypass capacitor (0.1 µF typ.) to GND might be useful to obtain a clean bias

voltage for the signal part of the IC.

Frequency modulation input. When FF mode operation is selected, a capacitor

connected from this pin to GND (pin 3) is alternately charged and discharged by

internal current sources. As a result, the voltage on the pin is a symmetrical

triangular waveform with the frequency related to the capacitance value. By

connecting a resistor from this pin to pin 13 (OSC) it is possible to modulate the

current sourced by the OSC pin and then the oscillator frequency. This modulation

is to reduce the peak value of EMI emissions by means of a spread-spectrum

action. If the function is not used, the pin is left open.

Input to the PWM comparator. The current flowing in the MOSFET is sensed

through a resistor, the resulting voltage is applied to this pin and compared with an

internal reference to determine MOSFET turn-off. The pin is equipped with 150 ns

min. blanking time after the gate-drive output goes high for improved noise

immunity. A second comparison level located at 1.5 V latches the device OFF and

reduces its consumption in the case of transformer saturation or secondary diode

short-circuit. The information is latched until the voltage on the Vcc pin (5) goes

below the UVLO threshold, therefore resulting in intermittent operation. A logic

circuit improves sensitivity to temporary disturbances.

8DIS

9COMP

10 VREF

IC latched disable input. Internally, the pin connects a comparator that, when the

voltage on the pin exceeds 4.5 V, latches OFF the IC and brings its consumption to

a lower value. The latch is cleared as the voltage on the Vcc pin (5) goes below the

UVLO threshold, but the HV generator keeps the Vcc voltage high (see pin 1

description). It is then necessary to recycle the input power to restart the IC. For a

quick restart, pull pin 16 (AC_OK) below the disable threshold (see pin 16

description). Bypass the pin with a capacitor to GND (pin 3) to reduce noise pickup. Ground the pin if the function is not used.

Control input for loop regulation. The pin is driven by the phototransistor (emittergrounded) of an optocoupler to modulate its voltage by modulating the current

sunk. A capacitor placed between the pin and GND (3), as close to the IC as

possible to reduce noise pick-up, sets a pole in the output-to-control transfer

function. The dynamics of the pin are in the 2.5 to 5 V range. A voltage below an

internally defined threshold activates burst-mode operation. The voltage at the pin

is bottom-clamped at about 2 V. If the clamp is externally overridden and the

voltage is pulled below 1.4 V, the IC shuts down.

An internal generator furnishes an accurate voltage reference (5 V ± 2%) that can

be used to supply few mA to an external circuit. A small film capacitor (0.1 µF typ.),

connected between this pin and GND (3), is recommended to ensure the stability of

the generator and to prevent noise from affecting the reference. This reference is

internally monitored by a separate auxiliary reference and any failure or drift causes

the IC to latch OFF.

Doc ID 16610 Rev 2 9/51

Pin settings L6566BH

Table 1. Pin functions (continued)

N° Pin Function

Transformer demagnetization sensing input for quasi-resonant operation and OVP

input. The pin is externally connected to the transformer’s auxiliary winding through

a resistor divider. A negative-going edge triggers MOSFET turn-on if QR mode is

11 ZCD

12 MODE/SC

13 OSC

14 SS

15 VFF

selected.

A voltage exceeding 5 V shuts the IC down and brings its consumption to a lower

value (OVP). Latch OFF or auto-restart mode is selectable externally. This function

is strobed and digitally filtered to increase noise immunity.

Operating mode selection. If the pin is connected to the VREF pin (7), quasiresonant operation is selected, the oscillator (pin 13, OSC) determines the

maximum allowed operating frequency.

Fixed-frequency operation is selected if the pin is not tied to VREF, in which case

the oscillator determines the actual operating frequency, the maximum allowed

duty cycle is set at 70% min. and the pin delivers a voltage ramp synchronized to

the oscillator when the gate-drive output is high; the voltage delivered is zero while

the gate-drive output is low. The pin is to be connected to pin CS (7) via a resistor

for slope compensation.

Oscillator pin. The pin is an accurate 1 V voltage source, and a resistor connected

from the pin to GND (pin 3) defines a current. This current is internally used to set

the oscillator frequency that defines the maximum allowed switching frequency of

the L6566BH, if working in QR mode, or the operating switching frequency if

working in FF mode.

Soft-start current source. At startup, a capacitor Css between this pin and GND

(pin 3) is charged with an internal current generator. During the ramp, the internal

reference clamp on the current sense pin (7, CS) rises linearly starting from zero to

its final value, therefore causing the duty cycle to increase progressively starting

from zero as well. During soft-start the adaptive UVLO function and all functions

monitoring the COMP pin are disabled. The soft-start capacitor is discharged

whenever the supply voltage of the IC falls below the UVLO threshold. The same

capacitor is used to delay IC shutdown (latch OFF or auto-restart mode selectable)

after detecting an overload condition (OLP).

Line voltage feedforward input. The information on the converter’s input voltage is

fed into the pin through a resistor divider and is used to change the setpoint of the

pulse-by-pulse current limitation (the higher the voltage, the lower the setpoint).

The linear dynamics of the pin ranges from 0 to 3 V. A voltage higher than 3 V

makes the IC stop switching. If feedforward is not desired, tie the pin to GND (pin 3)

directly if a latch-mode OVP is not required (see pin 11, ZCD) or through a 10 kΩ

min. resistor if a latch-mode OVP is required. Bypass the pin with a capacitor to

GND (pin 3) to reduce noise pick-up.

Brownout protection input. A voltage below 0.45 V shuts down (not latched) the IC,

lowers its consumption and clears the latch set by latched protection (DIS > 4.5 V,

SS > 6.4 V, VFF > 6.4 V). IC operation is re-enabled as the voltage exceeds 0.45 V.

16 AC_OK

10/51 Doc ID 16610 Rev 2

The comparator is provided with current hysteresis: an internal 15 µA current

generator is ON as long as the voltage on the pin is below 0.45 V and is OFF if this

value is exceeded. Bypass the pin with a capacitor to GND (pin 3) to reduce noise

pick-up. Tie to Vcc with a 220 to 680 kW resistor if the function is not used.

L6566BH Electrical data

3 Electrical data

3.1 Maximum rating

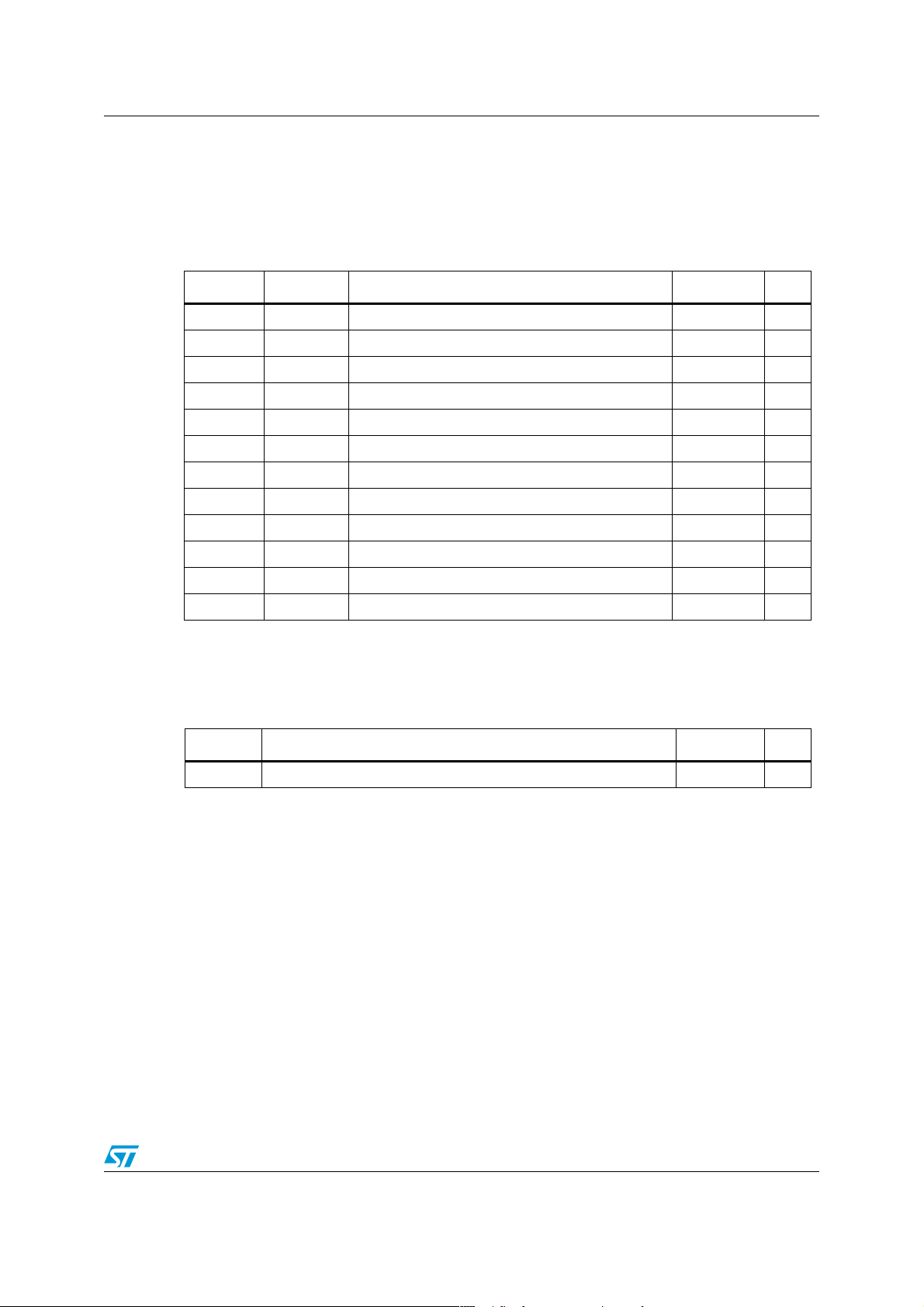

Table 2. Absolute maximum ratings

Symbol Pin Parameter Value Unit

V

HVS

I

HVS

V

CC

V

FMOD

V

max

V

max

I

ZCD

V

MODE/SC

V

OSC

P

TOT

T

STG

T

J

1 Voltage range (referred to ground) @ 25 °C -0.3 to 840 V

1 Output current Self-limited

5 IC supply voltage (Icc = 20 mA) Self-limited

6 Voltage range -0.3 to 2 V

7, 8, 10, 14 Analog inputs and outputs -0.3 to 7 V

9, 15, 16 Maximum pin voltage (Ipin ≤ 1 mA) Self-limited

11 Zero-current detector max. current ±5 mA

12 Voltage range -0.3 to 5.3 V

13 Voltage range -0.3 to 3.3 V

3.2 Thermal data

Table 3. Thermal data

Symbol Parameter Value Unit

Power dissipation @ TA = 50 °C 0.75 W

Storage temperature -55 to 150 °C

Junction operating temperature range -40 to 150 °C

R

thJA

Thermal resistance junction to ambient 120 °C/W

Doc ID 16610 Rev 2 11/51

Electrical characteristics L6566BH

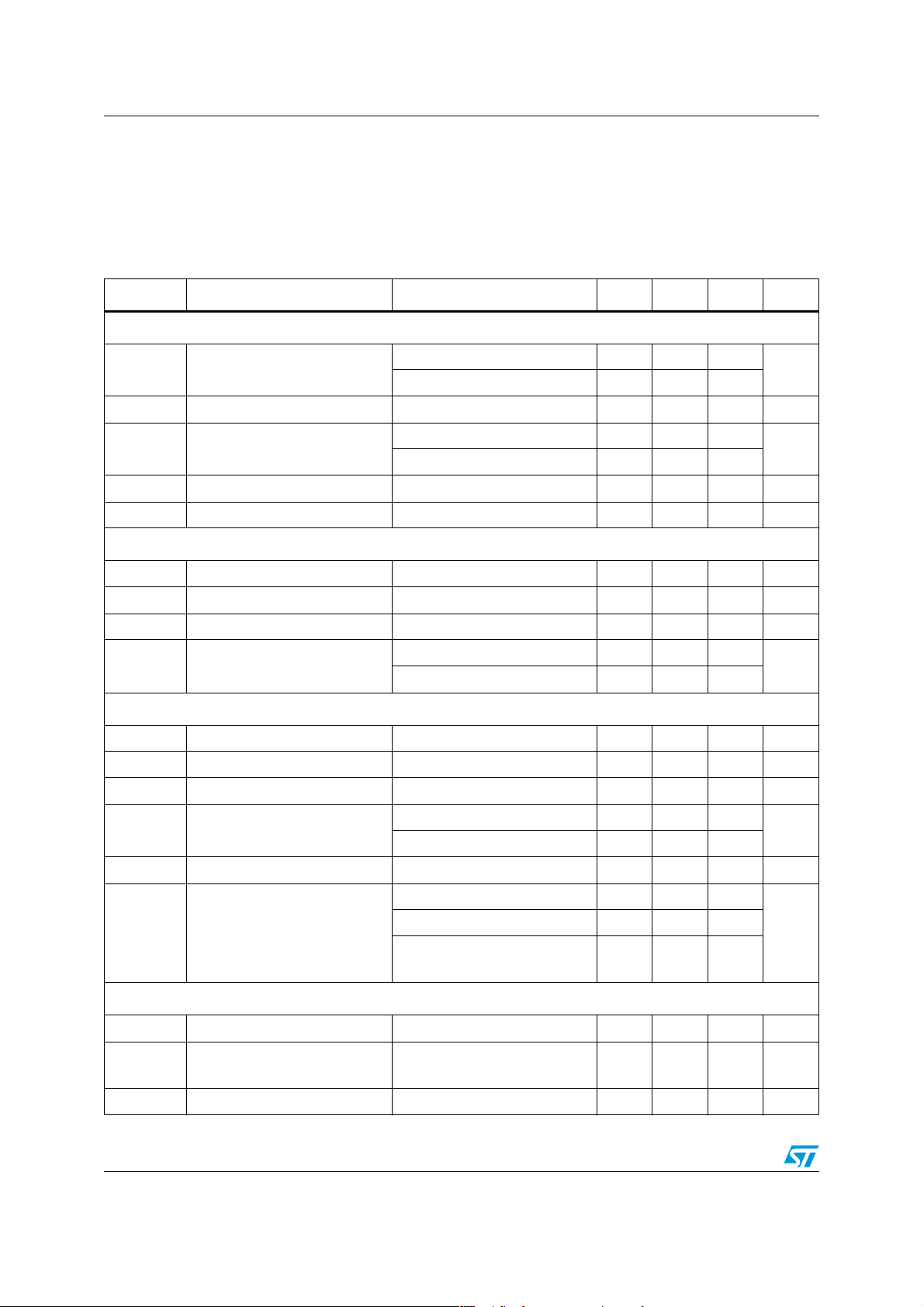

4 Electrical characteristics

(TJ = -25 to 125 °C, VCC = 12, CO = 1 nF; MODE/SC = V

, RT = 20 kΩ from OSC to GND,

REF

unless otherwise specified.)

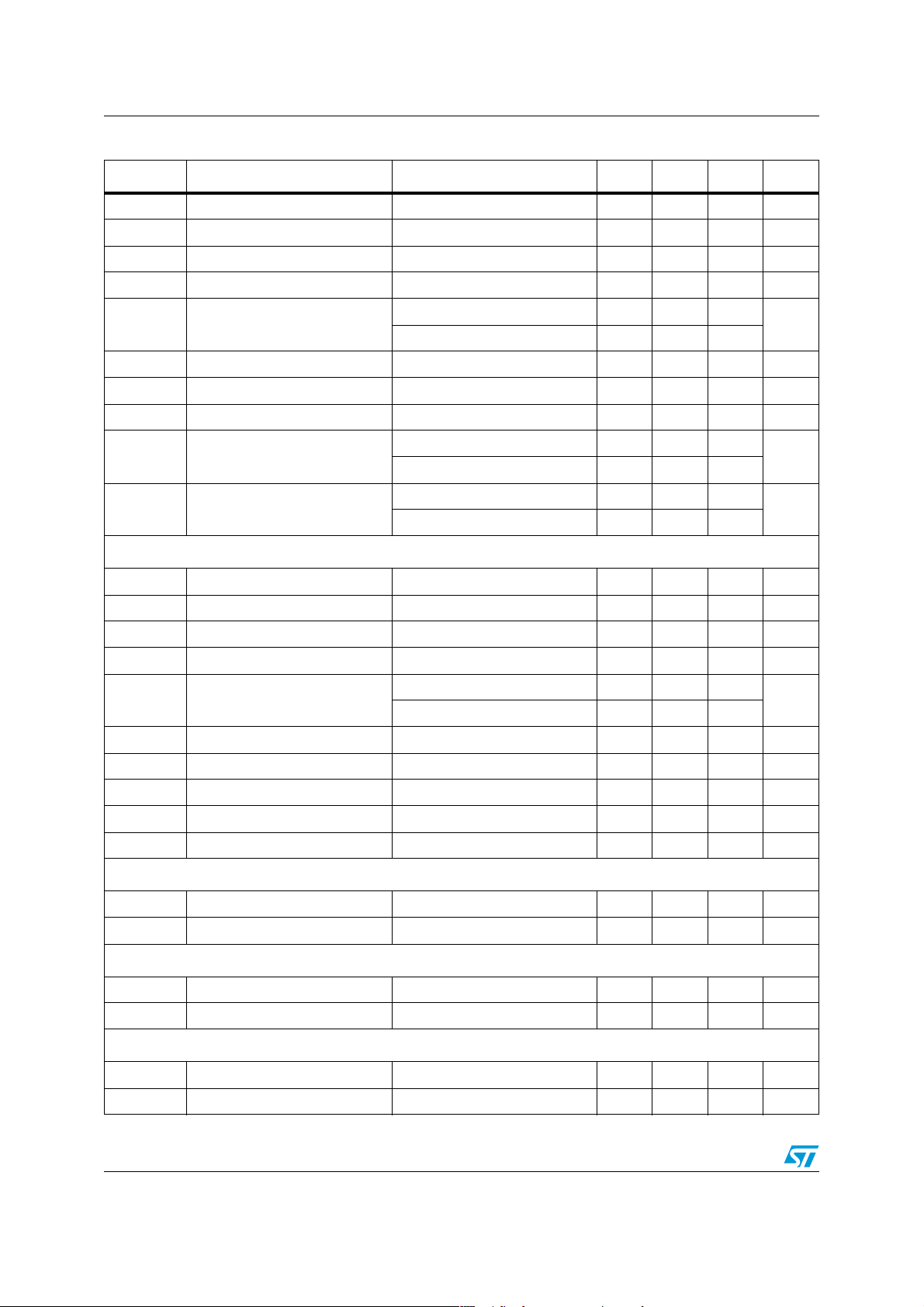

Table 4. Electrical characteristics

Symbol Parameter Test condition Min. Typ. Max. Unit

Supply voltage

Vcc Operating range after turn-on

Vcc

Vcc

Hys Hysteresis V

V

Supply current

I

start-up

I

q

Icc Operating supply current MODE/SC open 4 4.6 mA

I

qdis

V

> V

COMP

V

COMP

Turn-on threshold

On

Turn-off threshold

Off

Zener voltage Icc = 20 mA, IC disabled 23 25 27 V

Z

(1)

(1)

(1)

COMP

V

V

= V

COMP

COMP

> V

COMPL

COMPO

> V

= V

COMPL

COMPL

COMPO

10.6 23

823

13 14 15 V

9.4 10 10.6

7.2 7.6 8.0

4V

Startup current Before turn-on, Vcc = 13 V 200 250 µA

Quiescent current After turn-on, V

IC disabled

(2)

ZCD

= V

= 1 V 2.6 2.8 mA

CS

330 2500

Quiescent current

IC latched OFF 440 500

V

V

µA

High voltage startup generator

V

HV

V

HVstart

I

charge

I

HV, ON

I

HV, OFF

V

CCrestart

Breakdown voltage

Start voltage I

Vcc charge current VHV > V

ON-state current

OFF-state leakage current VHV = 400 V 40 µA

Vcc restart voltage

Reference voltage

V

V

I

REF

REF

REF

Output voltage

To t a l va r ia ti on

Short-circuit current V

(3)

I

< 100 µA @ 25 °C 840 V

HV

< 100 µA 65 80 100 V

Vcc

, Vcc > 3 V 0.55 0.85 1 mA

Hvstart

V

> V

HV

> V

V

HV

, Vcc > 3 V 1.6

Hvstart

, Vcc = 0 0.8

Hvstart

Vcc falling 4.4 5 5.6

(1)

IC latched OFF 12.5 13.5 14.5

(1)

Disabled by

V

< V

COMP

(1)

TJ = 25 °C; I

I

REF

COMPOFF

REF

= 1 to 5 mA,

= 1 mA 4.95 5 5.05 V

Vcc = 10.6 to 23 V

= 0 10 30 mA

REF

9.4 10 10.6

4.9 5.1 V

mA

V

12/51 Doc ID 16610 Rev 2

L6566BH Electrical characteristics

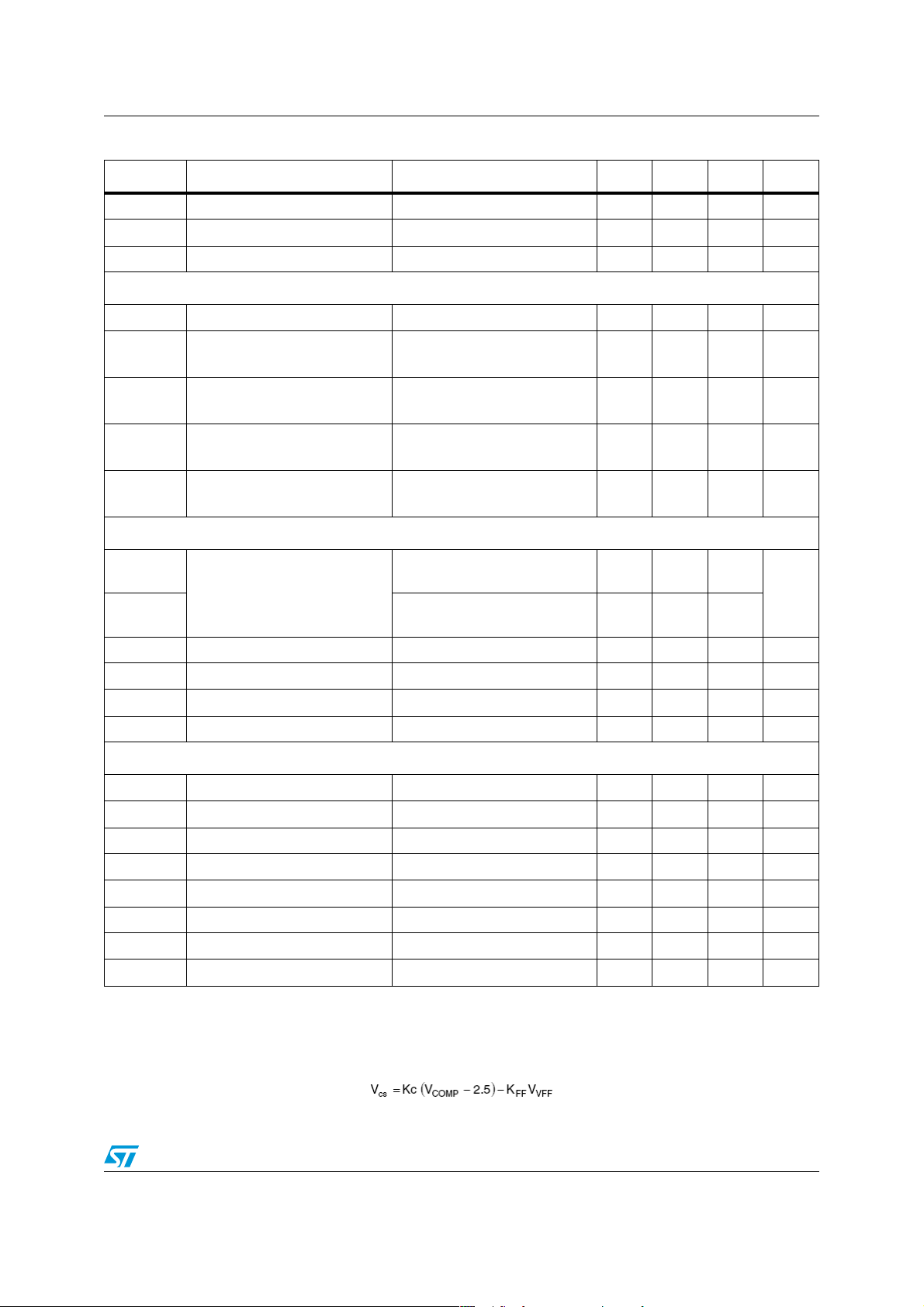

Table 4. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

Sink capability in UVLO Vcc = 6 V; Isink = 0.5 mA 0.2 0.5 V

V

OV

Overvoltage threshold 5.3 5.7 V

Internal oscillator

Oscillation frequency

Voltage reference

Maximum duty cycle

V

D

f

sw

OSC

max

Brownout protection

Vth Threshold voltage

I

Hys

V

AC_OK_CL

Current hysteresis Vcc > 5 V, V

Clamp level

Line voltage feedforward

I

VFF

V

VFF

V

OFF

V

VFFlatch

Input bias current

Linear operation range 0 to 3 V

IC disable voltage 3 3.15 3.3 V

Latch OFF/clamp level V

Kc Control voltage gain

K

FF

Feedforward gain

Current sense comparator

(3)

(4)

Operating range 10 300

T

= 25 °C, V

J

MODE/SC = open

Vcc =12 to 23 V, V

MODE/SC = open

(4)

MODE/SC = open,

V

= 5 V

COMP

ZCD

= 0,

ZCD

= 0,

95 100 105

kHz

93 100 107

0.9711.03V

70 75 %

Voltage falling (turn-off) 0.432 0.450 0.468 V

Voltage rising (turn-on) 0.452 0.485 0.518 V

= 0.3 V 121518µA

VFF

(1)

V

V

V

V

I

VFF

ZCD

ZCD

VFF

VFF

= 100 µA 3 3.15 3.3 V

AC_OK

= 0 to 3 V, V

> V

ZCDth

> V

ZCDth

= 1 V, V

= 1 V, V

COMP

COMP

< V

ZCD

ZCDth

-0.7 -1 mA

6.4 V

= 4 V 0.4 V/V

= 4 V 0.04 V/V

-1 µA

I

CS

t

LEB

td

(H-L)

V

CSx

V

CSdis

PWM control

V

COMPHI

Input bias current VCS = 0 -1 µA

Leading edge blanking 150 250 300 ns

Delay to output 100 ns

V

Overcurrent setpoint

Hiccup-mode OCP level

Upper clamp voltage I

= V

COMP

= V

COMP

V

= V

COMP

(1)

= 0 5.7 V

COMP

COMPHI

COMPHI

COMPHI

, V

= 0 V 0.92 1 1.08

VFF

, V

= 1.5 V 0.45 0.5 0.55

VFF

, V

= 3.0 V 0 0.1

VFF

1.4 1.5 1.6 V

VV

Doc ID 16610 Rev 2 13/51

Electrical characteristics L6566BH

Table 4. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

V

COMPLO

V

COMPSH

I

COMP

R

COMP

V

COMPBM

Lower clamp voltage I

Linear dynamics upper limit

Max. source current V

Dynamic resistance V

Burst-mode threshold

SOURCE

(1)

(1)

(1)

= -1 mA 2.0 V

V

= 0 V 4.855.2V

VFF

= 3.3 V 320 400 480 µA

COMP

= 2.6 to 4.8 V 25 kΩ

COMP

2.52 2.65 2.78

MODE/SC = open 2.7 2.85 3

Hys Burst-mode hysteresis 20 mV

I

CLAMPL

V

COMPOFF

V

COMPO

V

COMPL

Lower clamp capability V

= 2 V -3.5 -1.5 mA

COMP

Disable threshold Voltage falling 1.4 V

(4)

Level for lower UVLO OFF

threshold (voltage falling)

Level for higher UVLO OFF

threshold (voltage rising)

2.61 2.75 2.89

(4)

MODE/SC = open 3.02 3.15 3.28

(4)

(4)

MODE/SC = open 3.41 3.55 3.69

2.93.053.2

Zero-current detector/overvoltage protection

V

ZCDH

V

ZCDL

V

ZCDA

V

ZCDT

I

ZCD

I

ZCDsrc

I

ZCDsnk

T

BLANK1

V

ZCDth

T

BLANK2

Upper clamp voltage I

Lower clamp voltage I

Arming voltage

Triggering voltage

Internal pull-up

Source current capability V

Sink current capability V

Turn-on inhibit time After gate-drive going low 2.5 µs

OVP threshold 4.85 5 5.15 V

OVP strobe delay After gate-drive going low 2 µs

= 3 mA 5.4 5.7 6 V

ZCD

= - 3 mA -0.4 V

ZCD

(1)

Positive-going edge 85 100 115 mV

(1)

Negative-going edge 30 50 70 mV

V

COMP

V

ZCD

ZCD

ZCD

< V

COMPSH

< 2 V, V

= V

ZCDL

= V

ZCDH

COMP

= V

COMPHI

-130 -100 -70

-3 mA

3mA

-1

Latched shutdown function

V

V

V

µA

I

V

OTP

OTP

Input bias current V

Disable threshold

DIS

(1)

= 0 to V

OTP

4.32 4.5 4.68 V

Thermal shutdown

Vth Shutdown threshold 160 °C

Hys Hysteresis 50 °C

External oscillator (frequency modulation)

f

FMOD

Oscillation frequency C

= 0.1 µF 600 750 900 Hz

MOD

--- Usable frequency range 0.05 15 kHz

14/51 Doc ID 16610 Rev 2

-1 µA

L6566BH Electrical characteristics

Table 4. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

V

V

I

FMOD

pk

vy

Peak voltage

Valley voltage 0.5 V

Charge/discharge current 150 µA

Mode selection / slope compensation

(4)

1.5 V

MODE

th

SC

pk

SC

vy

Soft-start

I

SS1

I

SS2

I

SSdis

V

SSclamp

V

SSDIS

V

SSLAT

Gate driver

Threshold for QR operation 3 V

Ramp peak

(MODE/SC = open)

Ramp starting value

(MODE/SC = open)

Ramp voltage

(MODE/SC = open)

Source capability

(MODE/SC = open)

Charge current

R

pin HIGH, V

R

GD pin HIGH

GD pin LOW 0 V

V

TJ = 25 °C, VSS < 2 V,

V

TJ = 25 °C, VSS > 2 V,

V

= 3 kΩ to GND, GD

S-COMP

= 3 kΩ to GND,

S-COMP

S-COMP = VS-COMPpk

= 4 V

COMP

= V

COMP

COMP

COMPHi

= 5 V

1.7 V

0.3 V

0.8 mA

14 20 26

µA

3.556.5

Discharge current VSS > 2 V 3.556.5µA

High saturation voltage V

Disable level

Latch OFF level V

= 4 V 2 V

COMP

(1)

V

COMP

COMP

= V

= V

COMPHi

COMPHi

4.8555.15V

6.4 V

V

GDH

V

GDL

I

sourcepk

I

sinkpk

t

t

V

GDclamp

Output high voltage I

Output low voltage I

Output source peak current -0.6 A

Output sink peak current 0.8 A

Fall time 40 ns

f

Rise time 50 ns

r

Output clamp voltage I

UVLO saturation Vcc = 0 to V

1. Parameters tracking one another.

2. See

3. For the thermal behavior, refer to

4. The voltage feedforward block output is given by:

Table 6 on page 18

and

Table 7 on page 44

Figure 8

.

GDsource

GDsink

GDsource

.

= 5 mA, Vcc = 12 V 9.8 11 V

= 100 mA 0.75 V

= 5 mA; Vcc = 20 V 10 11.3 15 V

ccon, Isink = 1 mA 0.9 1.1 V

Doc ID 16610 Rev 2 15/51

Application information L6566BH

5 Application information

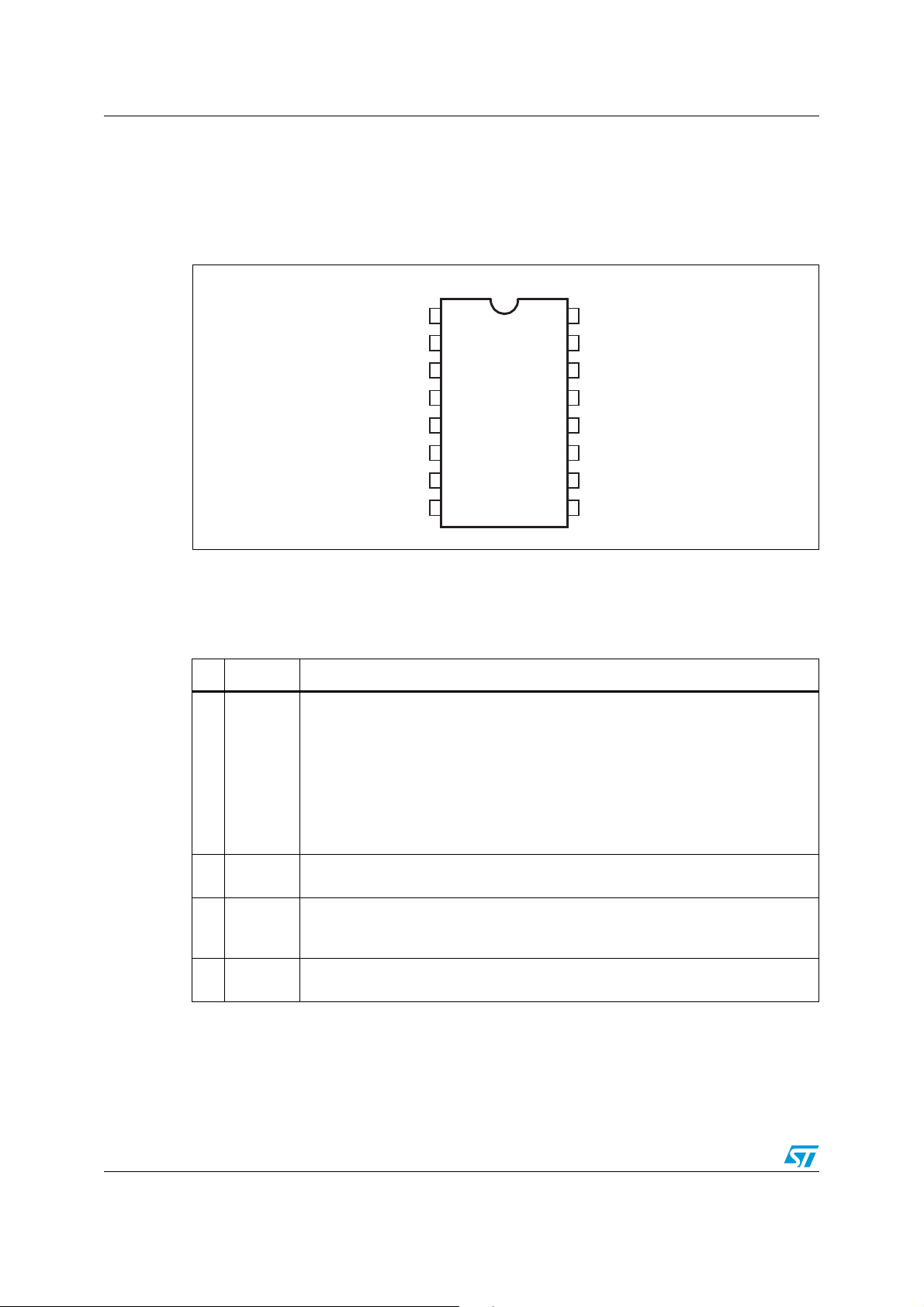

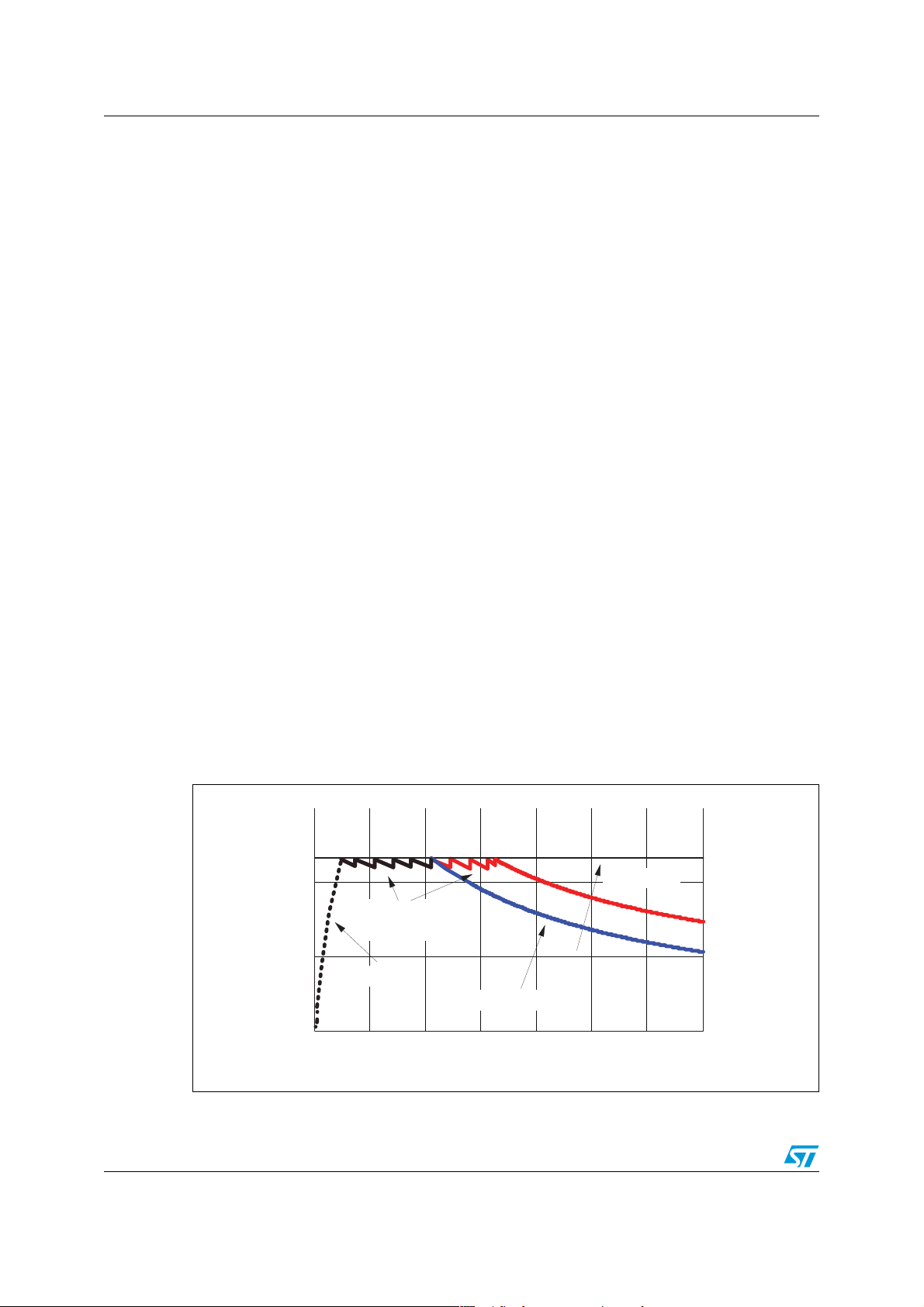

The L6566BH is a versatile peak-current-mode PWM controller specific to offline flyback

converters. The device allows either fixed-frequency (FF) or quasi-resonant (QR) operation,

selectable with the MODE/SC pin (12): forcing the voltage on the pin over 3 V (e.g. by tying

it to the 5 V reference externally available at the VREF pin, 10) activates QR operation,

otherwise the device is FF-operated.

Irrespective of the operating option selected by pin 12, the device is able to work in different

modes, depending on the converter’s load conditions. If QR operation is selected (see

Figure 4

1. QR mode at heavy load. Quasi-resonant operation lies in synchronizing MOSFET turn-

2. Valley-skipping mode at medium/ light load. The externally programmable oscillator of

3. Burst-mode with no or very light load. When the load is extremely light or disconnected,

):

on to the transformer’s demagnetization by detecting the resulting negative-going edge

of the voltage across any winding of the transformer. Then, the system works close to

the boundary between discontinuous (DCM) and continuous conduction (CCM) of the

transformer. As a result, the switching frequency is different for different line/load

conditions (see the hyperbolic-like portion of the curves in

Figure 4

). Minimum turn-on

losses, low EMI emission and safe behavior in short-circuit are the main benefits of this

kind of operation.

the L6566BH, synchronized to MOSFET turn-on, enables the user to define the

maximum operating frequency of the converter. As the load is reduced, MOSFET turnon no longer occurs on the first valley but on the second one, the third one and so on.

In this way the switching frequency no longer increases (piecewise linear portion in

Figure 4

).

the converter enters a controlled on/off operation with constant peak current.

Decreasing the load then results in frequency reduction, which can go down even to

few hundred hertz, therefore minimizing all frequency-related losses and making it

easier to comply with energy saving regulations or recommendations. With the peak

current very low, no issue of audible noise arises.

Figure 4. Multimode operation with QR option active

f

osc

Valley-skipping

f

sw

0

0

16/51 Doc ID 16610 Rev 2

mode

Burst- m ode

Quasi-resonant mode

P

in

Input voltage

Pinmax

AM11480v1

Loading...

Loading...