现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

Multi-mode controller for SMPS with PFC front-end

Features

■ Selectable multi-mode operation:

fixed frequency or quasi-resonant

■ On-board 700 V high-voltage start-up

■ Advanced light load management

■ Low quiescent current (< 3 mA)

■ Adaptive UVLO

■ Line feedforward for constant power capability

vs. mains voltage

■ Pulse-by-pulse OCP, shutdown on overload

(latched or autorestart)

■ Transformer saturation detection

■ Switched supply rail for PFC controller

■ Latched or autorestart OVP

■ Brownout protection

■ -600/+800 mA totem pole gate driver with

active pull-down during UVLO

■ SO16N package

L6566A

SO16N

Applications

■ Notebook, TV &LCD monitors adapters

■ High power chargers

■ PDP/LCD TV

■ Consumer appliances, like DVD, VCR, set-top

box

■ IT equipment, games, aux. power supplies

■ Power supplies in excess of 150 W

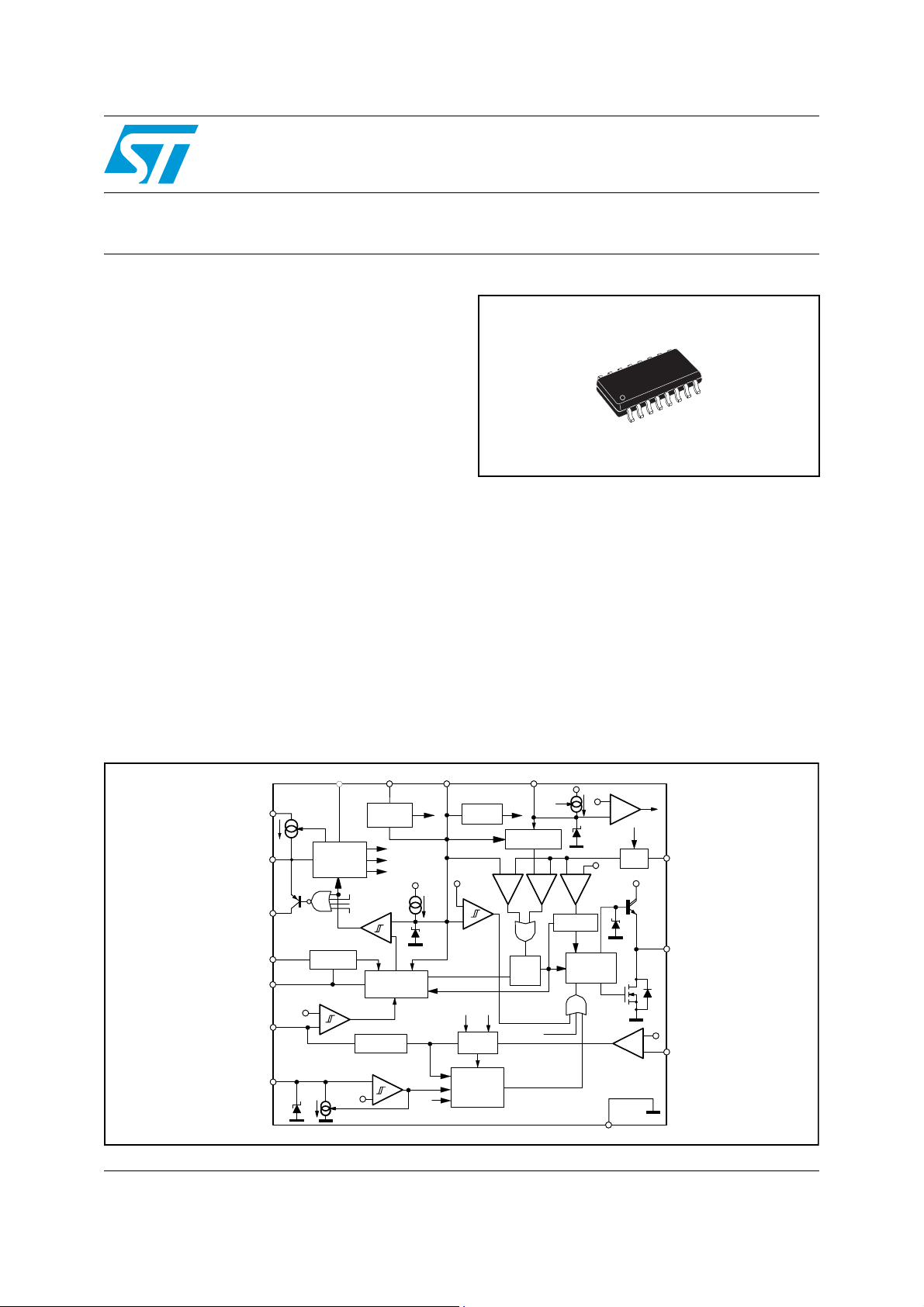

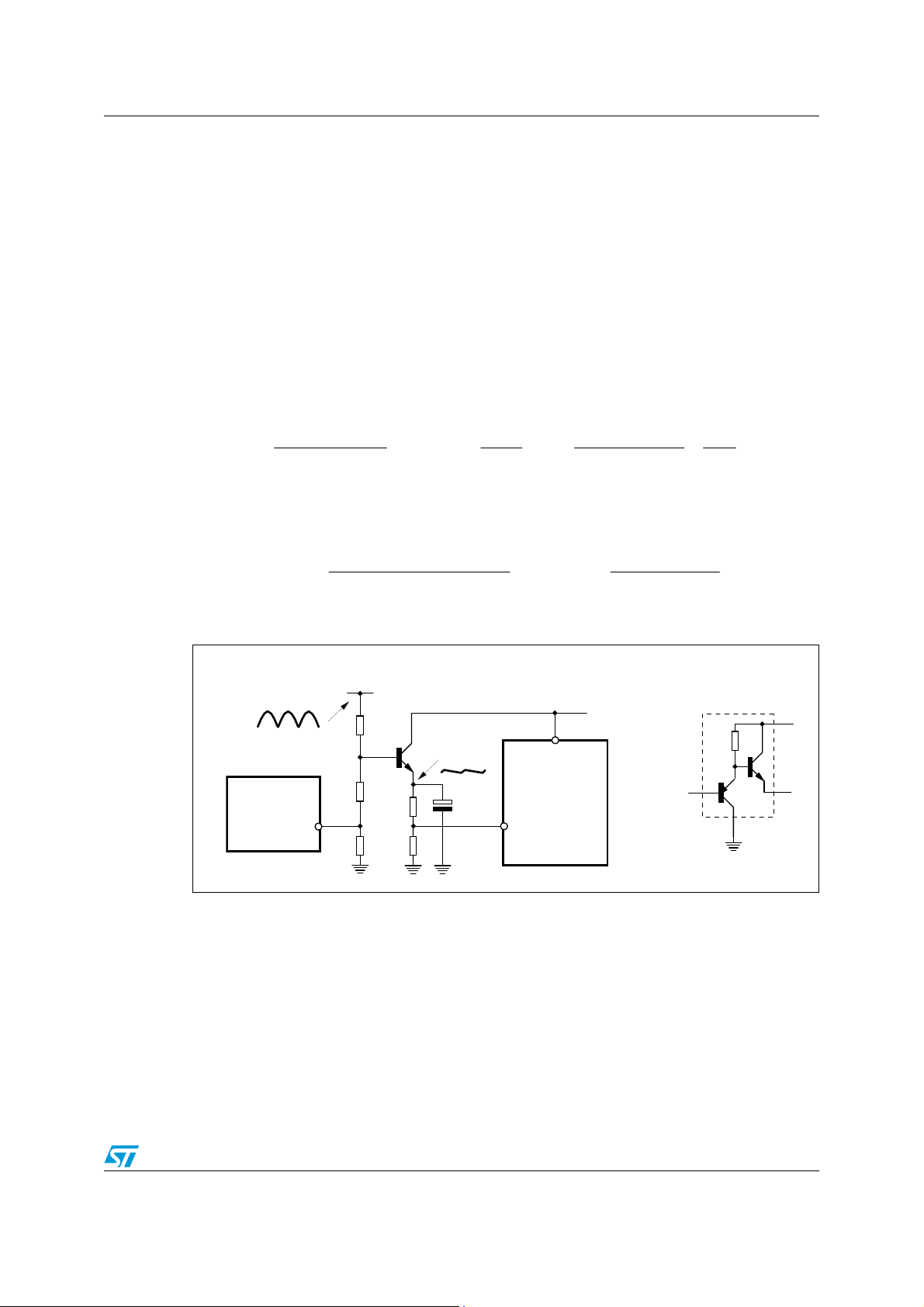

Figure 1. Block diagram

Vcc_PFC

OSC

MODE/S C

ZCD

AC_OK

VREF

10

1

HV

I

charge

V

CC

5

6

13

12

100 mV

11

16

50 mV

3 V

VOLTAGE

REGULATOR

ADAPTIVE UVLO

UVLO_SHF

OSCILLATOR

+

15 µA

&

OCP2

IC_LATCH

AC_ FAIL

ZERO CURRENT

DETECTOR

OVERVOLTAGE

0.450V

0.485V

SS

14

SOFT-START

&

FAULT MNGT

Ref er ence

voltages

Internal supply

UVL O

+

MODE SELECTIO N

&

TURN-ON LOGIC

PROTECTION

-

+

August 2007 Rev 1 1/51

COMP

915

TIME

OUT

LOW CLA MP

& DISABLE

Vth

V

CC

400 uA

+

-

5.7V

BURST-MODE

TIME

OVPL

OUT

OVP

LATCH

IC_LATCH

AC_FAIL

UVLO

DISABLE

VFF

OFF2

LINE VOLTAGE

FEEDFORWARD

+-

OCPPWM

R

Q

S

OFF2

OVP

+-

V

CC

+-

Hiccup-mode

OCP logic

OCP2

DRIVER

7.7V

1 mA

GND

6.4V

3

1.5 V

OVPL

+

Q

V

CC

14V

LEB

CS

7

4

GD

4.5V

+

DIS

8

www.st.com

51

Contents L6566A

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 Electrical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 High-voltage start-up generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Zero current detection and triggering block; oscillator block . . . . . . . . . . 21

5.3 Burst-mode operation at no load or very light load . . . . . . . . . . . . . . . . . . 24

5.4 Adaptive UVLO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.5 PWM control block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.6 PWM comparator, PWM latch and voltage feedforward blocks . . . . . . . . 27

5.7 Hiccup-mode OCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.8 PFC interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.9 Latched disable function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.10 Soft-start and delayed latched shutdown upon overcurrent . . . . . . . . . . . 33

5.11 OVP block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.12 Brownout protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.13 Slope compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.14 Summary of L6566A power management functions . . . . . . . . . . . . . . . . 41

2/51

L6566A Contents

6 Application examples and ideas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8 Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3/51

List of tables L6566A

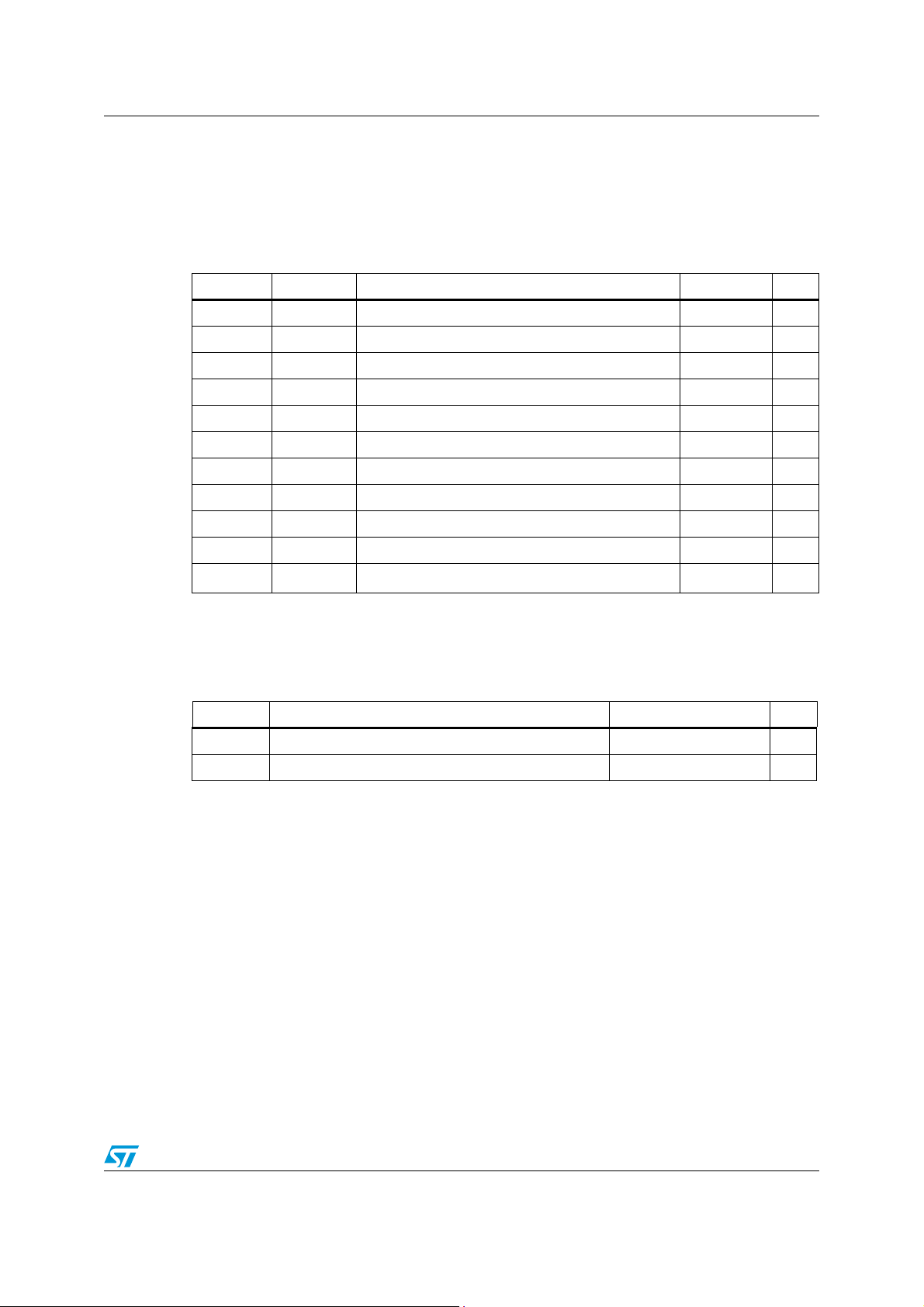

List of tables

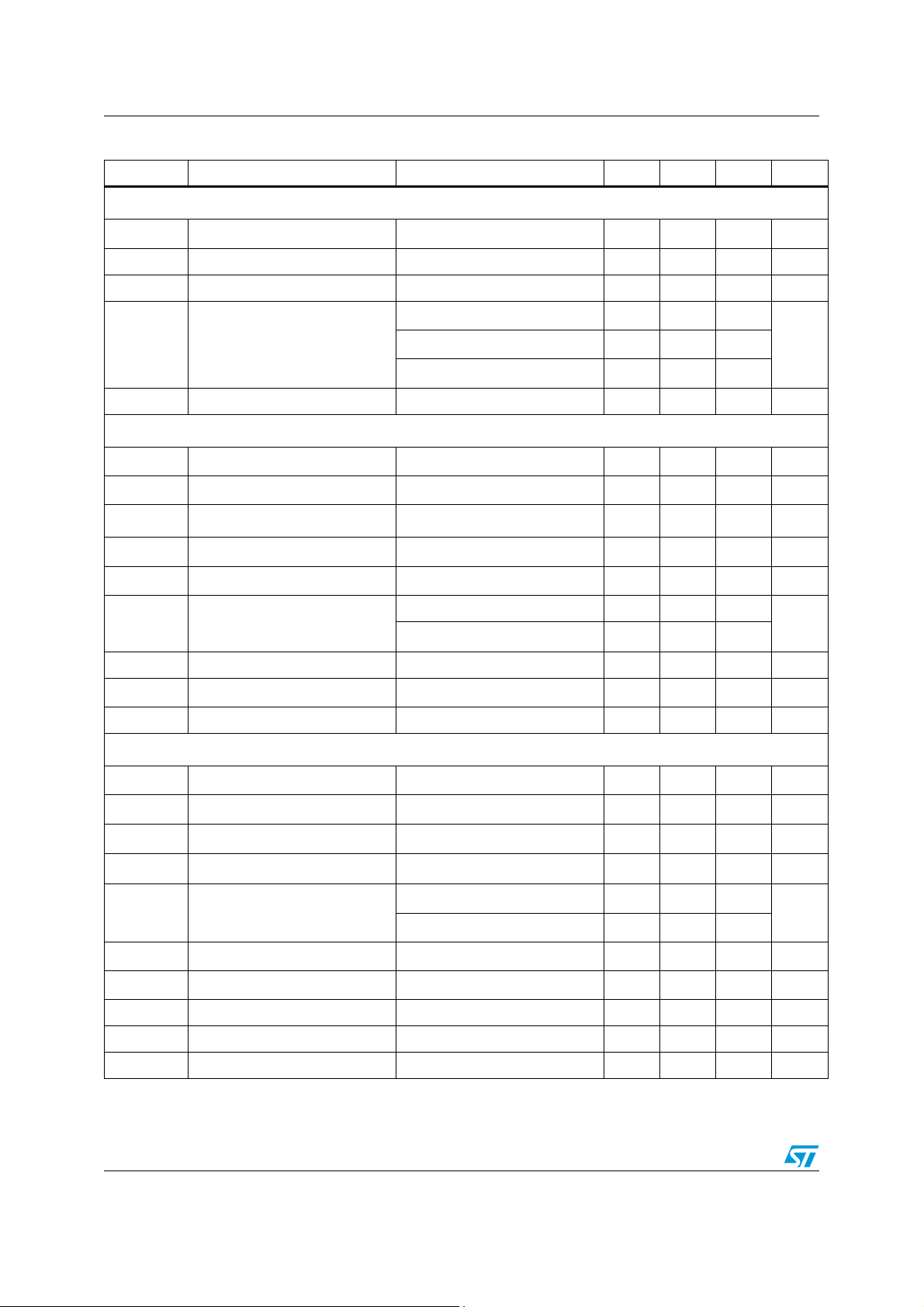

Table 2. Pin functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 3. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 4. Thermal data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Table 5. Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 6. L6566A light load management features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Table 7. L6566A protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 8. External circuits that determine IC behavior upon OVP and OCP . . . . . . . . . . . . . . . . . . . 45

Table 9. SO16N mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Table 10. Order codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Table 11. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4/51

L6566A List of figures

List of figures

Figure 1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

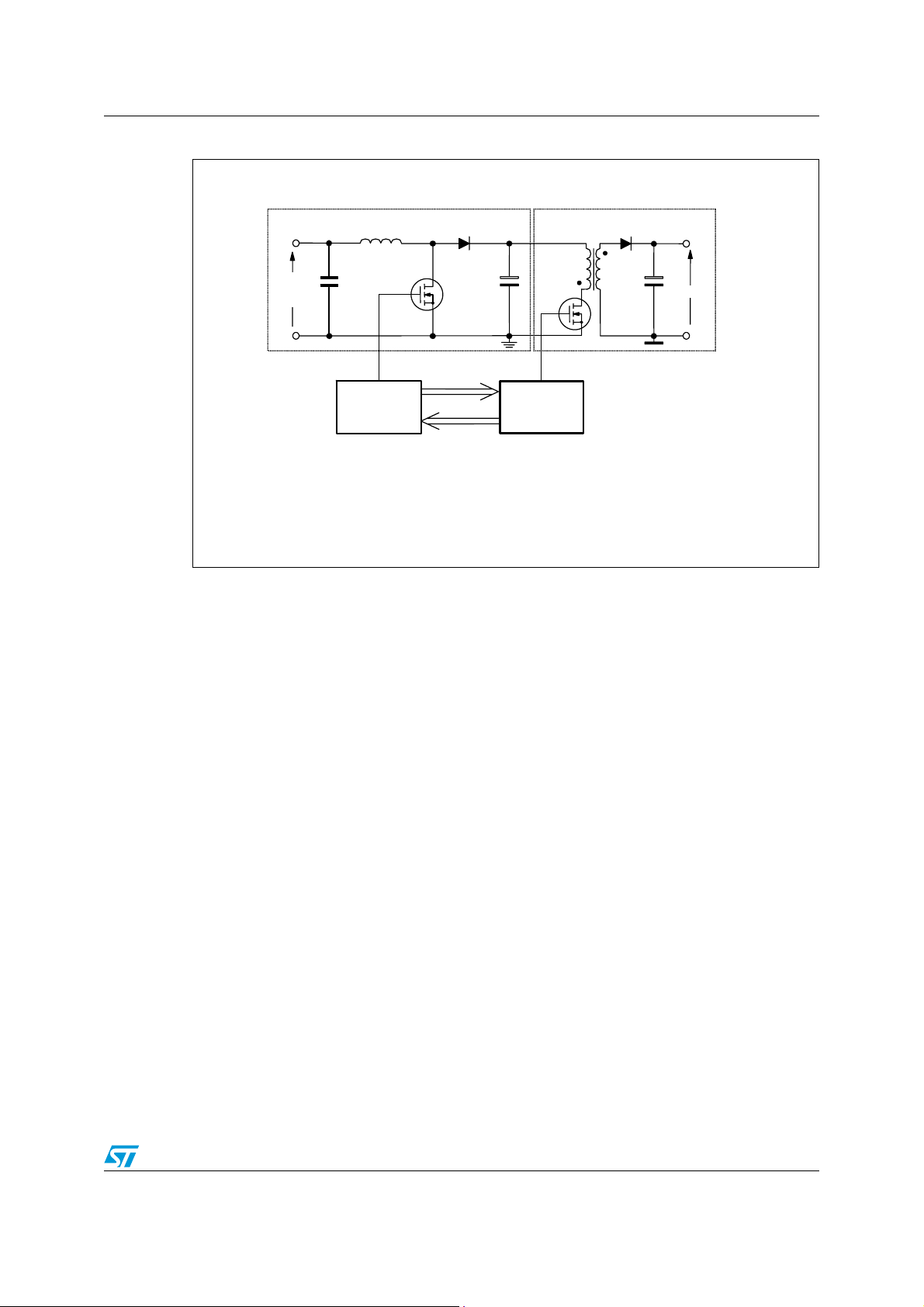

Figure 2. Typical system block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

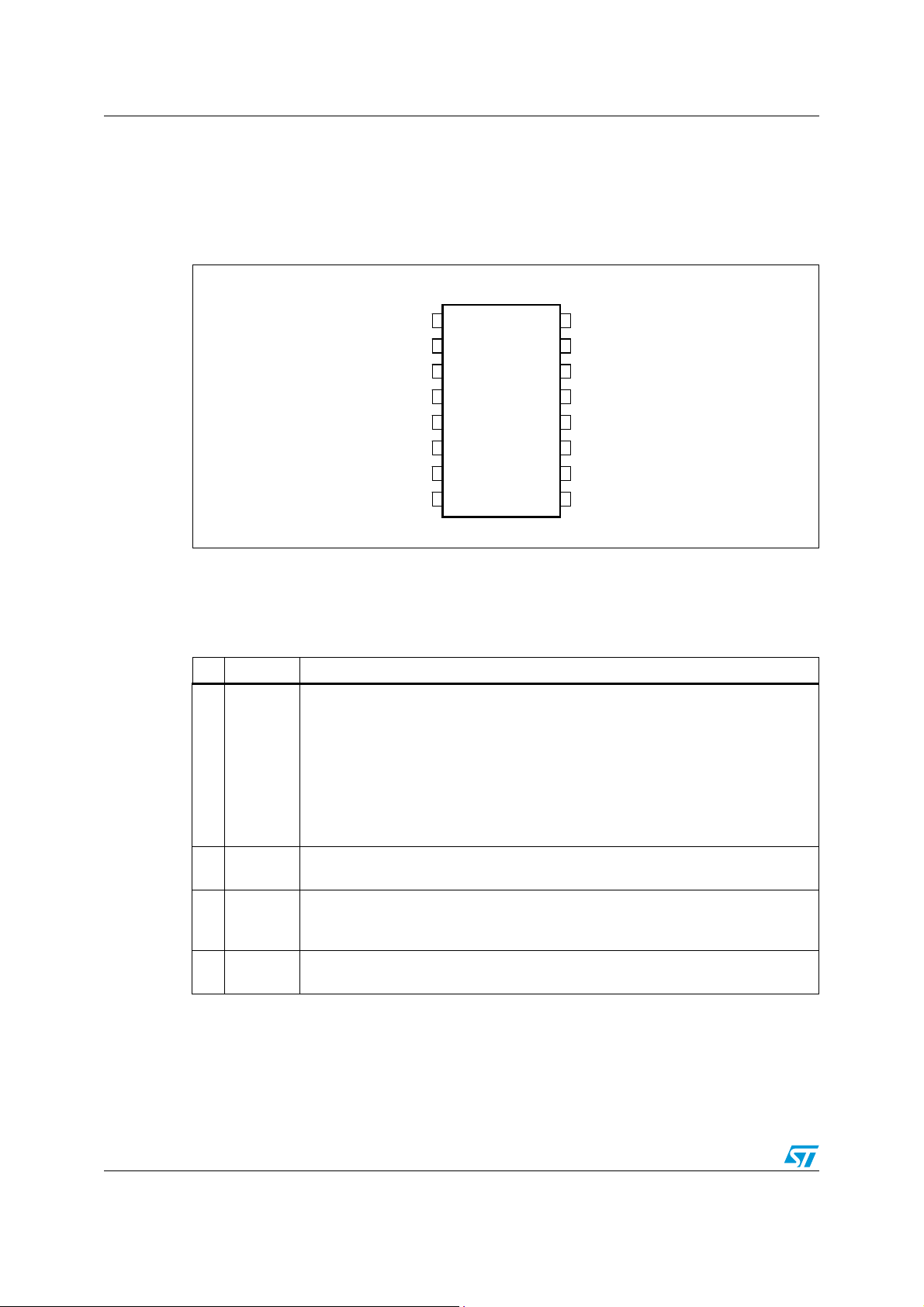

Figure 3. Pin connection (through top view) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 4. Multi-mode operation with QR option active . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 5. High-voltage start-up generator: internal schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 6. Timing diagram: normal power-up and power-down sequences . . . . . . . . . . . . . . . . . . . . 19

Figure 7. Timing diagram showing short-circuit behavior (SS pin clamped at 5V). . . . . . . . . . . . . . . 20

Figure 8. Zero current detection block, triggering block, oscillator block and related logic . . . . . . . . 20

Figure 9. Drain ringing cycle skipping as the load is gradually reduced . . . . . . . . . . . . . . . . . . . . . . 21

Figure 10. Operation of ZCD, triggering and Oscillator blocks (QR option active). . . . . . . . . . . . . . . . 23

Figure 11. Load-dependent operating modes: timing diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 12. Addition of an offset to the current sense lowers the burst-mode operation threshold. . . . 25

Figure 13. Adaptive UVLO block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 14. Possible feedback configurations that can be used with the L6566A. . . . . . . . . . . . . . . . . 26

Figure 15. Externally controlled burst-mode operation by driving pin COMP: timing diagram. . . . . . . 27

Figure 16. Typical power capability change vs input voltage in QR flyback converters . . . . . . . . . . . 28

Figure 17. Left: Overcurrent setpoint vs. VFF voltage; right: Line Feedforward function block . . . . . . 29

Figure 18. Hiccup-mode OCP: timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 19. Possible interfaces between the L6566A and a PFC controller . . . . . . . . . . . . . . . . . . . . . 32

Figure 20. Operation after latched disable activation: timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 21. Soft-start pin operation under different operating conditions and settings . . . . . . . . . . . . . 34

Figure 22. OVP Function: internal block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 23. OVP function: timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 24. Maximum allowed duty cycle vs. switching frequency for correct OVP detection. . . . . . . . 37

Figure 25. Brownout protection: internal block diagram and timing diagram . . . . . . . . . . . . . . . . . . . . 38

Figure 26. Ac voltage sensing with the L6566A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 27. Slope compensation waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 28. Typical low-cost application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 29. Typical full-feature application schematic (QR operation) . . . . . . . . . . . . . . . . . . . . . . . . . 44

Figure 30. Typical full-feature application schematic (FF operation) . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Figure 31. Frequency foldback at light load (FF operation) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Figure 32. Latched shutdown upon mains overvoltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5/51

Description L6566A

1 Description

The L6566A is an extremely versatile current-mode primary controller IC specifically

designed for high-performance offline flyback converters operated from front-end Power

Factor Correction (PFC) stages in applications supposed to comply with EN61000-3-2 or

JEITA-MITI regulations.

Both Fixed-frequency (FF) and Quasi-resonant (QR) operation are supported. The user can

pick either of the two depending on application needs.

The device features an externally programmable oscillator: it defines converter's switching

frequency in FF mode and the maximum allowed switching frequency in QR mode.

When FF operation is selected, the IC works like a standard current-mode controller with a

maximum duty cycle limited at 70% min.

QR operation, when selected, occurs and is achieved through a transformer

demagnetization sensing input that triggers MOSFET's turn-on. Under some conditions,

ZVS (Zero-voltage Switching) can be achieved. Converter's power capability rise with the

input voltage is compensated by line voltage feedforward. At medium and light load, as the

QR operating frequency equals the oscillator frequency, a function (valley skipping) is

activated to prevent further frequency rise and keep the operation as close to ZVS as

possible.

With either FF or QR operation, at very light load the IC enters a controlled burst-mode

operation that, along with the built-in non-dissipative high-voltage start-up circuit and a

reduced quiescent current, helps keep low the consumption from the mains and meet

energy saving recommendations.

To allow meeting them in two-stage power-factor-corrected systems as well, the L6566A

provides an interface with the PFC controller that enables to turn off the pre-regulator at light

load.

An innovative adaptive UVLO helps minimize the issues related to the fluctuations of the

self-supply voltage due to transformer's parasitics.

The protection functions included in this device are: not-latched input undervoltage

(brownout), output OVP (auto-restart or latch-mode selectable), a first-level OCP with

delayed shutdown to protect the system during overload or short circuit conditions (autorestart or latch-mode selectable) and a second-level OCP that is invoked when the

transformer saturates or the secondary diode fails short. A latched disable input allows easy

implementation of OTP with an external NTC, while an internal thermal shutdown prevents

IC overheating.

Programmable soft-start, leading-edge blanking on the current sense input for greater noise

immunity, slope compensation (in FF mode only), and a shutdown function for externally

controlled burst-mode operation or remote ON/OFF control complete the equipment of this

device.

6/51

L6566A Description

Figure 2. Typical system block diagram

PFC PRE-REGULATOR

Rectified

Mains

Voltage

L6563/A

PFC

FLYBACK DC-DC CONVERTER

PWM/QR controller is turned off in case of PFC's

anomalous operation, for safety

L6566A

PFC is automatically turned off at light

load to ease compliance with

energy saving specifications.

V outdc

7/51

Pin settings L6566A

2 Pin settings

2.1 Connections

Figure 3. Pin connection (through top view)

1

HVS AC_OK

HVS AC_OK

N.C.

N.C.

GND

GND

GD

GD

Vcc

Vcc

Vcc_PFC

Vcc_PFC

CS

CS

DIS

DIS

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

16

16

15

15

14

14

13

13

12

12

11

11

10

10

9

9

VFF

VFF

SS

SS

OSC

OSC

MODE/SC

MODE/SC

ZCD

ZCD

VREF

VREF

COMP

COMP

2.2 Pin description

Table 2. Pin functions

N° Pin Function

High-voltage start-up. The pin, able to withstand 700V, is to be tied directly to the

rectified mains voltage. A 1 mA internal current source charges the capacitor

connected between Vcc pin (5) and GND pin (3) until the voltage on the Vcc pin

reaches the turn-on threshold, then it is shut down. Normally, the generator is re-

1HVS

2N.C.

3GND

4GD

enabled when the Vcc voltage falls below 5V to ensure a low power throughput

during short circuit. Otherwise, when a latched protection is tripped the generator is

re-enabled 0.5V below the turn-on threshold, to keep the latch supplied; or, when

the IC is turned off by pin COMP (9) pulled low the generator is active just below

the UVLO threshold to allow a faster restart.

Not internally connected. Provision for clearance on the PCB to meet safety

requirements.

Ground. Current return for both the signal part of the IC and the gate drive. All of

the ground connections of the bias components should be tied to a track going to

this pin and kept separate from any pulsed current return.

Gate driver output. The totem pole output stage is able to drive power MOSFET’s

and IGBT’s with a peak current capability of 800 mA source/sink.

8/51

L6566A Pin settings

Table 2. Pin functions (continued)

N° Pin Function

Supply Voltage of both the signal part of the IC and the gate driver. The internal

high voltage generator charges an electrolytic capacitor connected between this

pin and GND (pin 3) as long as the voltage on the pin is below the turn-on threshold

5Vcc

6Vcc_PFC

7CS

of the IC, after that it is disabled and the chip is turned on. The IC is disabled as the

voltage on the pin falls below the UVLO threshold. This threshold is reduced at light

load to counteract the natural reduction of the self-supply voltage. Sometimes a

small bypass capacitor (0.1 µF typ.) to GND might be useful to get a clean bias

voltage for the signal part of the IC.

Supply pin output. This pin is intended for supplying the PFC controller IC in

systems comprising a PFC pre-regulator or other compatible circuitry. It is internally

connected to the Vcc pin (5) via a controlled switch. The switch is closed as the IC

starts up and opens when the voltage at pin COMP is lower than a threshold (light

load), whenever the IC is shut down (either latched or not) and during UVLO. If not

used, the pin will be left floating.

Input to the PWM comparator. The current flowing in the MOSFET is sensed

through a resistor, the resulting voltage is applied to this pin and compared with an

internal reference to determine MOSFET’s turn-off. The pin is equipped with 150 ns

min. blanking time after the gate-drive output goes high for improved noise

immunity. A second comparison level located at 1.5V latches the device off and

reduces its consumption in case of transformer saturation or secondary diode short

circuit. The information is latched until the voltage on the Vcc pin (5) goes below

the UVLO threshold, hence resulting in intermittent operation. A logic circuit

improves sensitivity to temporary disturbances.

8DIS

9COMP

10 VREF

IC’s latched disable input. Internally the pin connects a comparator that, when the

voltage on the pin exceeds 4.5V, latches off the IC and brings its consumption to a

lower value. The latch is cleared as the voltage on the Vcc pin (5) goes below the

UVLO threshold, but the HV generator keeps the Vcc voltage high (see pin 1

description). It is then necessary to recycle the input power to restart the IC. For a

quick restart pull pin 16 (AC_OK) below the disable threshold (see pin 16

description).Bypass the pin with a capacitor to GND (pin 3) to reduce noise pick-up.

Ground the pin if the function is not used.

Control input for loop regulation. The pin will be driven by the phototransistor

(emitter-grounded) of an optocoupler to modulate its voltage by modulating the

current sunk. A capacitor placed between the pin and GND (3), as close to the IC

as possible to reduce noise pick-up, sets a pole in the output-to-control transfer

function. The dynamics of the pin is in the 2.5 to 5V range. A voltage below an

internally defined threshold activates burst-mode operation. The voltage at the pin

is bottom-clamped at about 2V. If the clamp is externally overridden and the voltage

is pulled below 1.4V the IC will shut down.

An internal generator furnishes an accurate voltage reference (5V±2%) that can be

used to supply few mA to an external circuit. A small film capacitor (0.1 µF typ.),

connected between this pin and GND (3), is recommended to ensure the stability of

the generator and to prevent noise from affecting the reference. This reference is

internally monitored by a separate auxiliary reference and any failure or drift will

cause the IC to latch off.

9/51

Pin settings L6566A

Table 2. Pin functions (continued)

N° Pin Function

Transformer demagnetization sensing input for quasi-resonant operation and OVP

input. The pin is externally connected to the transformer’s auxiliary winding through

a resistor divider. A negative-going edge triggers MOSFET’s turn-on if QR mode is

11 ZCD

12 MODE/SC

13 OSC

14 SS

15 VFF

selected.

A voltage exceeding 5V shuts the IC down and brings its consumption to a lower

value (OVP). Latch-off or auto-restart mode is selectable externally. This function is

strobed and digitally filtered to increase noise immunity.

Operating mode selection. If the pin is connected to the VREF pin (7) Quasiresonant operation is selected and the oscillator (pin 13, OSC) determines the

maximum allowed operating frequency.

Fixed-frequency operation is selected if the pin is not tied to VREF, in which case

the oscillator determines the actual operating frequency, the maximum allowed

duty cycle is set at 70% min. and the pin delivers a voltage ramp synchronized to

the oscillator when the gate-drive output is high; the voltage delivered is zero while

the gate-drive output is low. The pin is to be connected to pin CS (7) via a resistor

for slope compensation.

Oscillator pin. The pin is an accurate 1 V voltage source, and a resistor connected

from the pin to GND (pin 3) defines a current. This current is internally used to set

the oscillator frequency that defines the maximum allowed switching frequency of

the L6566A, if working in QR mode, or the operating switching frequency if working

in FF mode.

Soft-start current source. At start-up a capacitor Css between this pin and GND

(pin 3) is charged with an internal current generator. During the ramp, the internal

reference clamp on the current sense pin (7, CS) rises linearly starting from zero to

its final value, thus causing the duty cycle to increase progressively starting from

zero as well. During soft-start the Adaptive UVLO function and all functions

monitoring pin COMP are disabled. The soft-start capacitor is discharged whenever

the supply voltage of the IC falls below the UVLO threshold. The same capacitor is

used to delay IC’s shutdown (latch-off or auto-restart mode selectable) after

detecting an overload condition (OLP).

Line voltage feedforward input. The information on the converter’s input voltage is

fed into the pin through a resistor divider and is used to change the setpoint of the

pulse-by-pulse current limitation (the higher the voltage, the lower the setpoint).

The linear dynamics of the pin ranges from 0 to 3V. A voltage higher than 3V makes

the IC stop switching. If feedforward is not desired, tie the pin to GND (pin 3)

directly if a latch-mode OVP is not required (see pin 11, ZCD) or through a resistor

if a latch-mode OVP is required. Bypass the pin with a capacitor to GND (pin 3) to

reduce noise pick-up.

Brownout protection input. A voltage below 0.45V shuts down (not latched) the IC,

lowers its consumption, opens the Vcc_PFC pin (6), and clears the latch set by

latched protections (DIS>4.5V, SS>6.4V, VFF>6.4V). IC’s operation is re-enabled

16 AC_OK

10/51

as the voltage exceeds 0.45V. The comparator is provided with current hysteresis:

an internal 15 µA current generator is ON as long as the voltage on the pin is below

0.45V and is OFF if this value is exceeded. Bypass the pin with a capacitor to GND

(pin 3) to reduce noise pick-up. Tie to Vcc with a 220 to 680 kΩ resistor if the

function is not used.

L6566A Electrical data

3 Electrical data

3.1 Maximum rating

Table 3. Absolute maximum ratings

Symbol Pin Parameter Value Unit

V

HVS

I

HVS

V

CC

V

Vcc_PFC

I

Vcc_PFC

V

max

V

max

I

ZCD

V

MODE/SC

V

OSC

P

TOT

1 Voltage range (referred to ground) -0.3 to 700 V

1 Start-up current Self-limited

5 IC supply voltage (Icc = 20 mA) Self-limited

6 Voltage range -0.3 to Vcc V

6 Max. source current (continuous) 30 mA

7, 8, 10, 14 Analog inputs & outputs -0.3 to 7 V

9, 15, 16 Maximum pin voltage (Ipin ≤ 1mA) Self-limited

11 Zero current detector max. current ±5 mA

12 Voltage range -0.3 to 5 V

13 Voltage range -0.3 to 3.3 V

Power dissipation @TA = 50°C

0.75 W

3.2 Thermal data

Table 4. Thermal data

Symbol Parameter Value Unit

R

thJA

T

Thermal resistance junction to ambient 120 °C/W

Junction operating temperature range -40 to 150 °C

J

11/51

Electrical characteristics L6566A

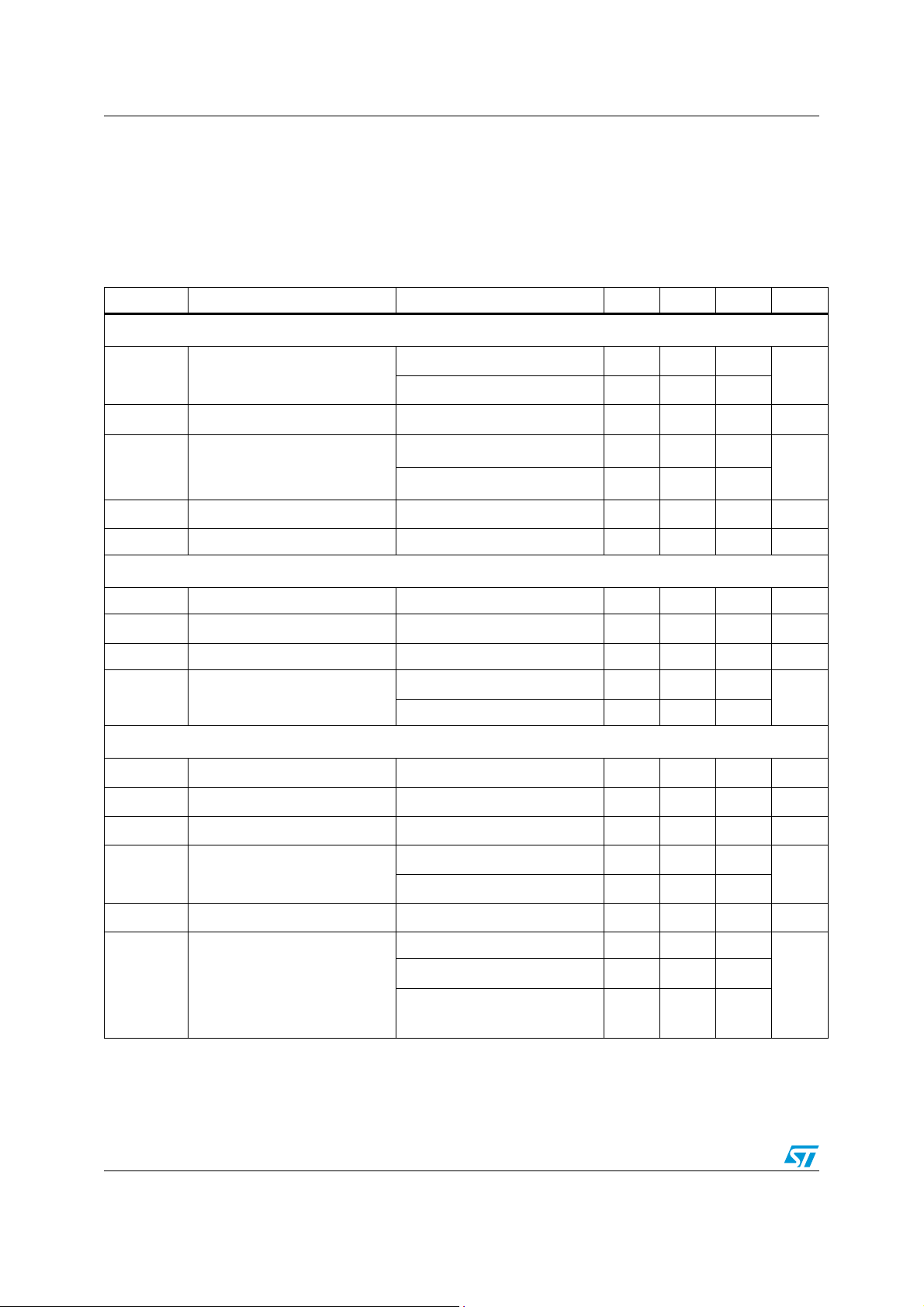

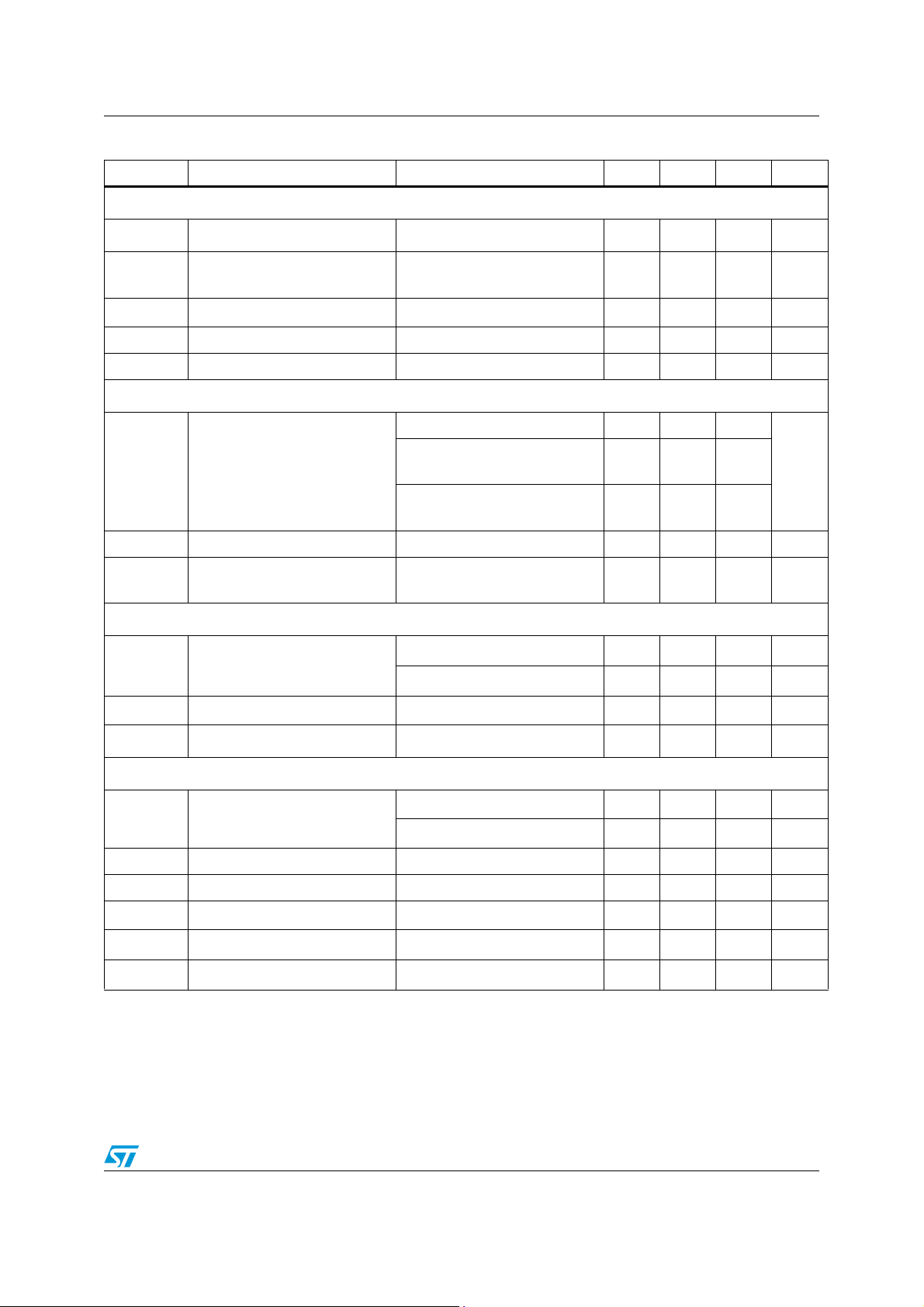

4 Electrical characteristics

(TJ = -25 to 125°C, VCC = 12, CO = 1 nF; MODE/SC=V

, RT = 20 kΩ from OSC to GND,

REF

unless otherwise specified).

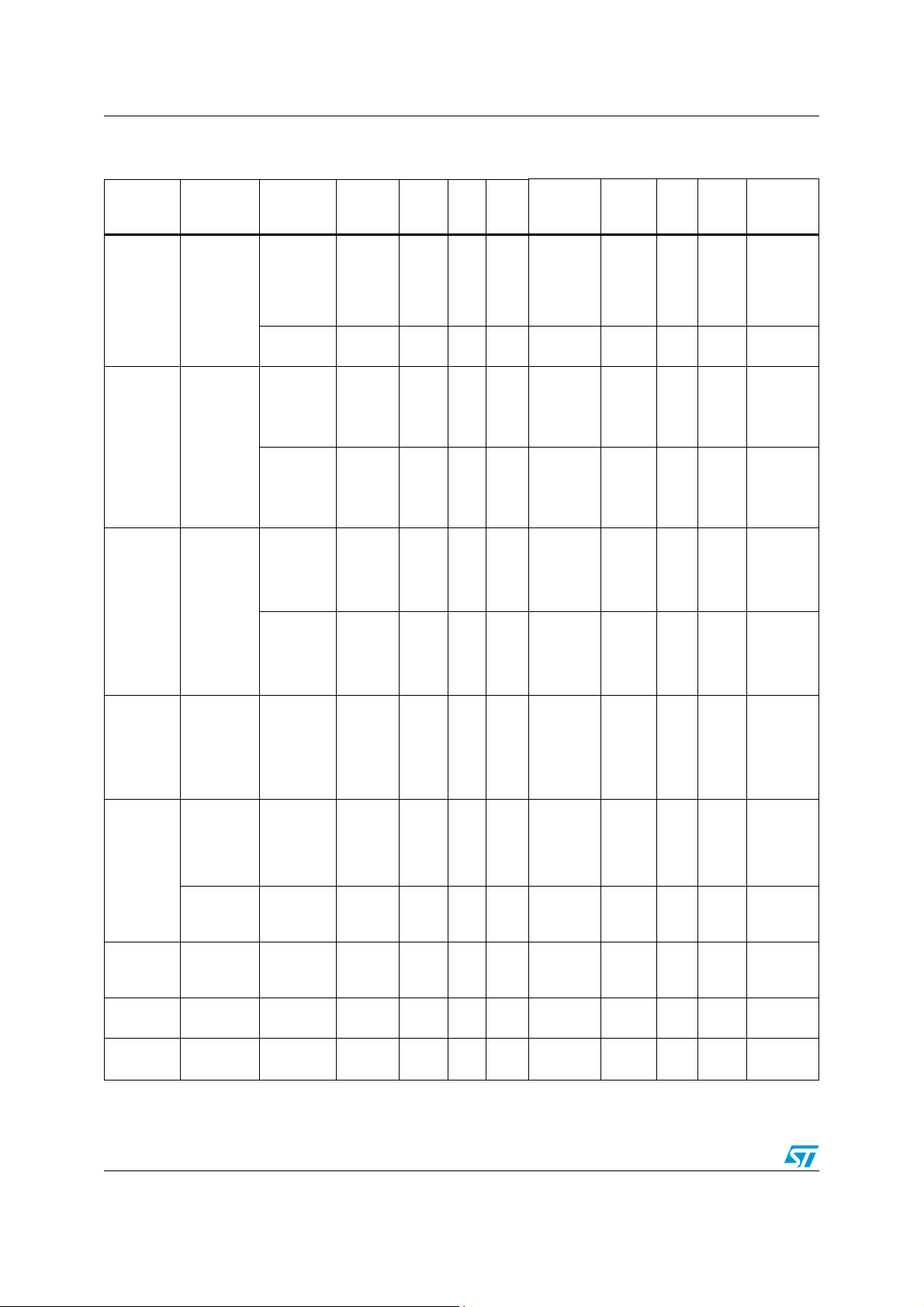

Table 5. Electrical characteristics

Symbol Parameter Test condition Min. Typ. Max. Unit

Supply voltage

V

Vcc Operating range after turn-on

V

Vcc

Vcc

Turn-on threshold

On

Turn-off threshold

Off

Hys Hysteresis

V

Zener voltage Icc = 20 mA, IC disabled 23 25 27 V

Z

(1)

(1)

(1)

V

Supply current

I

start-up

I

q

Start-up current Before turn-on, Vcc = 13 V 200 250 µA

Quiescent current

After turn-on, V

Icc Operating supply current MODE/SC open 4 4.6 mA

I

qdis

Quiescent current

IC disabled

IC latched off 440 500

COMP

COMP

V

COMP

V

COMP

COMP

> V

= V

> V

COMPL

COMPO

> V

= V

COMPL

(2)

COMPL

COMPO

ZCD

= V

CS

= 1V

10.6 23

823

13 14 15 V

9.4 10 10.6

7.2 7.6 8.0

4V

2.6 2.8 mA

330 2500

V

V

µA

High-voltage start-up generator

I

V

HV

V

HVstart

I

charge

I

HV, ON

I

HV, OFF

Breakdown voltage

Start voltage

Vcc charge current

ON-state current

OFF-state leakage current

< 100 µA

HV

< 100 µA

I

Vcc

V

HV

V

HV

V

HV

V

HV

> V

Hvstart

> V

Hvstart

> V

Hvstart

= 400 V

Vcc falling 4.4 5 5.6

(1)

V

CCrestart

Vcc restart voltage

IC latched off

(1)

Disabled by

COMP

< V

V

12/51

, Vcc > 3V

, Vcc > 3V

, Vcc = 0

COMPOFF

700 V

65 80 100 V

0.55 0.85 1 mA

1.6

mA

0.8

40 µA

12.5 13.5 14.5

V

9.4 10 10.6

L6566A Electrical characteristics

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

Reference voltage

V

V

I

REF

REF

REF

Output voltage

To t al va r i at io n

Short circuit current

Sink capability in UVLO Vcc = 6V; Isink = 0.5 mA 0.2 0.5 V

V

OV

Overvoltage threshold 5.3 5.7 V

Internal oscillator

V

D

f

sw

OSC

max

Oscillation frequency

Voltage reference

Maximum duty cycle

Brownout protection

Vth Threshold voltage

I

Hys

V

AC_OK_CL

Current Hysteresis

Clamp level

(1)

TJ = 25 °C; I

I

= 1 to 5 mA,

REF

REF

Vcc= 10.6 to 23 V

= 0

V

REF

= 1 mA

4.95 5 5.05 V

4.9 5.1 V

10 30 mA

Operating range 10 300

TJ = 25°C, V

MODE/SC = Open

Vcc=12 to 23 V, V

MODE/SC = Open

(3)

MODE/SC = Open,

V

= 5 V

COMP

Voltage falling (turn-off)

Voltage rising (turn-on)

Vcc > 5V, V

(1)

I

AC_OK

ZCD

= 0.3V

VFF

= 100µA

= 0,

ZCD

= 0,

95 100 105

93 100 107

0.97 1 1.03 V

70 75 %

0.432 0.450 0.468 V

0.452 0.458 0.518 V

12 15 18 µA

33.153.3 V

kHz

Line voltage feedforward

I

VFF

V

VFF

V

OFF

V

VFFlatch

Kc

K

FF

Input bias current

Linear operation range 0 to 3 V

IC disable voltage 3 3.15 3.3 V

Latch-off/clamp level

Control voltage gain

Feedforward gain

(3)

(3)

V

V

V

V

V

VFF

ZCD

ZCD

VFF

VFF

= 0 to 3 V, V

> V

ZCDth

> V

ZCDth

= 1 V, V

= 1 V, V

COMP

COMP

ZCD

< V

= 4 V

= 4 V

ZCDth

-1 µA

-0.7 -1 mA

6.4 V

0.4 V/V

0.04 V/V

13/51

Electrical characteristics L6566A

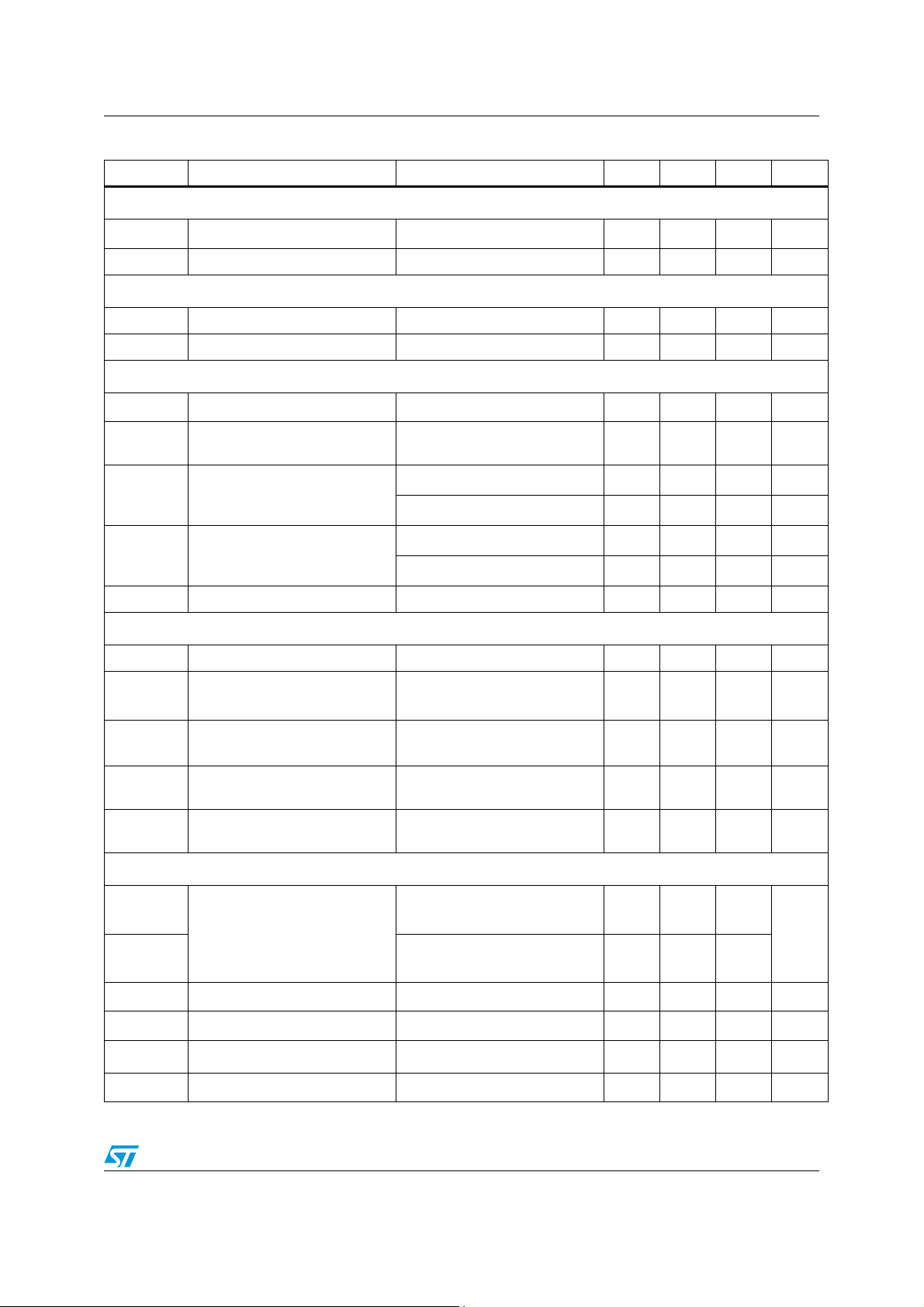

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

Current sense comparator

V

= 0

CS

V

V

V

(1)

I

I

(1)

V

(1)

(1)

V

= V

COMP

COMP

COMP

COMP

SOURCE

V

COMP

COMP

COMPHI

= V

COMPHI

= V

COMPHI

= 0

= -1mA

= 0V

VFF

= 3.3 V

= 2.6 to 4.8 V

MODE/SC = Open

= 2V

COMP

, V

, V

, V

VFF

VFF

VFF

= 0V

= 1.5V

= 3.0V

-1 µA

0.92 1 1.08

0.45 0.5 0.55

00.1

1.4 1.5 1.6 V

5.7 V

2.0 V

4.8 5 5.2 V

320 400 480 µA

25 kΩ

2.52 2.65 2.78

2.7 2.85 3

-3.5 -1.5 mA

V

V

td

V

V

I

CS

t

LEB

(H-L)

CSx

CSdis

Input bias current

Leading edge blanking 150 250 300 ns

Delay to output 100 ns

Overcurrent setpoint

Hiccup-mode OCP level

PWM control

V

COMPHI

V

COMPLO

V

COMPSH

I

COMP

R

COMP

V

COMPBM

Upper clamp voltage

Lower clamp voltage

Linear dynamics upper limit

Max. source current V

Dynamic resistance

Burst-mode threshold

Hys Burst-mode hysteresis 20 mV

I

CLAMPL

V

COMPOFF

Lower clamp capability

Disable threshold Voltage falling 1.4 V

Zero current detector/ overvoltage protection

I

V

ZCDH

V

ZCDL

V

ZCDA

V

ZCDT

I

ZCD

I

ZCDsrc

I

ZCDsnk

T

BLANK1

V

ZCDth

T

BLANK2

Upper clamp voltage

Lower clamp voltage

Arming voltage

Triggering voltage

Internal pull-up

Source current capability

Sink current capability

Turn-on inhibit time After gate-drive going low 2.5 µs

OVP threshold 4.85 5 5.15 V

OVP strobe delay After gate-drive going low 2 µs

= 3 mA

ZCD

= - 3 mA

I

ZCD

(1)

positive-going edge

(1)

negative-going edge

V

V

V

V

< V

COMP

ZCD < 2 V, V

= V

ZCD

= V

ZCD

14/51

COMPSH

ZCDL

ZCDH

COMP

= V

COMPHI

5.4 5.7 6 V

-0.4 V

85 100 115 mV

30 50 70 mV

-1

µA

-130 -100 -70

-3 mA

3mA

L6566A Electrical characteristics

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

Latched shutdown function

V

I

V

OTP

OTP

Input bias current

Disable threshold

Thermal shutdown

Vth Shutdown threshold 180 °C

Hys Hysteresis 40 °C

VCC_PFC function

DIS

(1)

= 0 to V

OTP

-1 µA

4.32 4.5 4.68 V

I

leak

V

Vcc

V

Vcc_PFC

OFF-state leakage current V

-

ON-state voltage dropout V

Level for pin 6 open and lower

V

COMPO

UVLO off threshold (COMP

voltage falling)

Level for pin 6 closed and higher

V

COMPL

UVLO off threshold (COMP

voltage rising)

T

delay

Pin 6 change of state delay Closed-to-open 10 ms

Mode selection / slope compensation

MODE

SC

SC

Threshold for QR operation 3 V

th

Ramp peak

pk

(MODE/SC = Open)

Ramp starting value

vy

(MODE/SC = Open)

Ramp voltage

(MODE/SC = Open)

Source capability

(MODE/SC = Open)

= 2.5V, V

COMP

= 4V, I

COMP

(3)

(3)

MODE/SC = Open

(3)

(3)

MODE/SC = Open

R

S-COMP

pin high, V

R

S-COMP

VCC_PFC

= 3 kΩ to GND, GD

COMP

= 3 kΩ to GND,

GD pin high

Vcc_PFC

= 5 V

= 0

= 10mA

1µA

0.15 0.3 V

2.61 2.75 2.89 V

3.02 3.15 3.28

2.93.053.2 V

3.41 3.55 3.69

1.7 V

0.3 V

GD pin low 0 V

V

S-COMP = VS-COMPpk

0.8 mA

Soft-start

I

SS1

I

SS2

I

SSdis

V

SSclamp

V

SSDIS

V

SSLAT

Charge current

Discharge current

High saturation voltage

Disable level

Latch-off level

= 25 °C, VSS < 2 V,

T

J

= 4 V

V

COMP

TJ = 25 °C, VSS > 2 V,

=V

V

COMP

V

SS

V

COMP

(1)

V

COMP

V

> 2 V

= 4 V

COMP

=V

COMPHi

=V

COMPHi

COMPHi

15/51

14 20 26

µA

3.5 5 6.5

3.5 5 6.5 µA

2V

4.85 5 5.15 V

6.4 V

Electrical characteristics L6566A

−

−

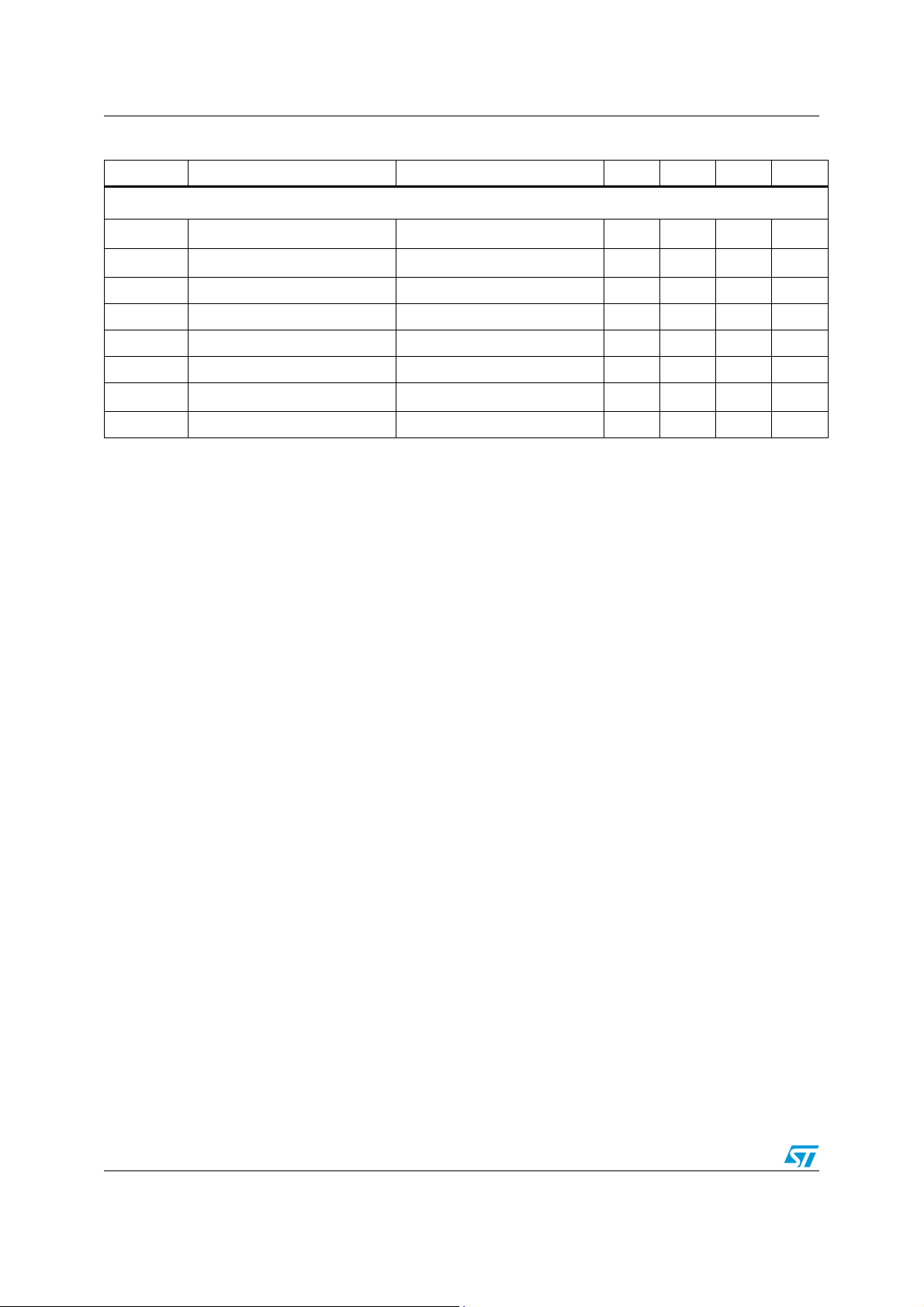

Table 5. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

Gate driver

V

GDH

V

GDL

I

sourcepk

I

sinkpk

t

t

V

GDclamp

Output high voltage

Output low voltage

Output source peak current -0.6 A

Output sink peak current 0.8 A

Fall time 40 ns

f

Rise time 50 ns

r

Output clamp voltage

UVLO saturation Vcc = 0 to V

1. Parameters tracking one another.

2. See Table 6 on page 41 and Table 7 on page 42

3. The Voltage Feedforward block output is given by:

I

GDsource

I

GDsink

I

GDsource

= 5 mA, Vcc = 12V

= 100 mA

= 5mA; Vcc = 20V

ccon, Isink = 1mA 0.9 1.1 V

()

=

9.8 11 V

0.75 V

10 11.3 15 V

VK5.2VKc V

VFFFFCOMPcs

16/51

L6566A Application information

5 Application information

The L6566A is a versatile peak-current-mode PWM controller specific for offline flyback

converters. The device allows either Fixed-Frequency (FF) or Quasi-Resonant (QR)

operation, selectable with the pin MODE/SC (12): forcing the voltage on the pin over 3V (e.g.

by tying it to the 5V reference externally available at pin VREF, 10) will activate QR

operation, otherwise the device will be FF-operated.

Irrespective of the operating option selected by pin 12, the device is able to work in different

modes, depending on the converter's load conditions. If QR operation is selected (see

Figure 4):

1. QR mode at heavy load. Quasi-resonant operation lies in synchronizing MOSFET's

turn-on to the transformer's demagnetization by detecting the resulting negative-going

edge of the voltage across any winding of the transformer. Then the system works

close to the boundary between discontinuous (DCM) and continuous conduction

(CCM) of the transformer. As a result, the switching frequency will be different for

different line/load conditions (see the hyperbolic-like portion of the curves in

Minimum turn-on losses, low EMI emission and safe behavior in short circuit are the

main benefits of this kind of operation.

2. Valley-skipping mode at medium/ light load. The externally programmable oscillator of

the L6566A, synchronized to MOSFET's turn-on, enables the designer to define the

maximum operating frequency of the converter. As the load is reduced MOSFET's turnon will not any more occur on the first valley but on the second one, the third one and

so on. In this way the switching frequency will no longer increase (piecewise linear

portion in

Figure 4).

3. Burst-mode with no or very light load. When the load is extremely light or disconnected,

the converter will enter a controlled on/off operation with constant peak current.

Decreasing the load will then result in frequency reduction, which can go down even to

few hundred hertz, thus minimizing all frequency-related losses and making it easier to

comply with energy saving regulations or recommendations. Being the peak current

very low, no issue of audible noise arises.

Figure 4).

Figure 4. Multi-mode operation with QR option active

f

osc

Valley-skipping

f

sw

0

0

mode

Burst-mode

Quasi-resonant mode

P

in

17/51

Input volta ge

Pinmax

Application information L6566A

K

If FF operation is selected:

1. FF mode from heavy to light load. The system operates exactly like a standard current

mode, at a frequency f

determined by the externally programmable oscillator: both

sw

DCM and CCM transformer operation are possible, depending on whether the power

that it processes is greater or less than:

Equation 1

2

sw

⎞

VVin

R

⎟

⎟

VVin

+

R

⎠

Lpf2

Pin

⎛

⎜

⎜

⎝

=

T

where Vin is the input voltage to the converter, VR the reflected voltage (i.e. the

regulated output voltage times the primary-to-secondary turn ratio) and Lp the

inductance of the primary winding. Pin

is the power level that marks the transition from

T

continuous to discontinuous operation mode of the transformer.

2. Burst-mode with no or very light load. This kind of operation is activated in the same

way and results in the same behavior as previously described for QR operation.

The L6566A is specifically designed for flyback converters operated from front-end Power

Factor Correction (PFC) stages in applications supposed to comply with EN61000-3-2 or

JEITA-MITI regulations. Pin 6 (Vcc_PFC) provides the supply voltage to the PFC control IC.

5.1 High-voltage start-up generator

Figure 5 shows the internal schematic of the high-voltage start-up generator (HV generator).

It is made up of a high-voltage N-channel FET, whose gate is biased by a 15 MΩ resistor,

with a temperature-compensated current generator connected to its source.

Figure 5. High-voltage start-up generator: internal schematic

L6566A

Vcc_O

15 M

Ω

HV_EN

CONTROL

3

GND

HV

1

I

HV

Vcc5

I

charge

18/51

L6566A Application information

With reference to the timing diagram of Figure 6, when power is first applied to the converter

the voltage on the bulk capacitor (Vin) builds up and, at about 80V, the HV generator is

enabled to operate (HV_EN is pulled high) so that it draws about 1 mA. This current, minus

the device’s consumption, charges the bypass capacitor connected from pin Vcc (5) to

ground and makes its voltage rise almost linearly.

Figure 6. Timing diagram: normal power-up and power-down sequences

Vin

V

HVstart

Vcc

(pin 5)

Vcc

Vcc

Vcc

restart

ON

OFF

regulation is lost here

t

Vcc_PFC

(pin 6)

GD

(pin 4)

HV_EN

Vcc_OK

charge

I

0.85 mA

light load

Power-on Power-off

heavy load

Normal

operation

t

t

t

t

t

As the Vcc voltage reaches the start-up threshold (14V typ.) the low-voltage chip starts

operating and the HV generator is cut off by the Vcc_OK signal asserted high. The device is

powered by the energy stored in the Vcc capacitor until the self-supply circuit (typically an

auxiliary winding of the transformer and a steering diode) develops a voltage high enough to

sustain the operation. The residual consumption of this circuit is just the one on the 15 MΩ

resistor (≈ 10 mW at 400 Vdc), typically 50-70 times lower, under the same conditions, as

compared to a standard start-up circuit made with external dropping resistors.

At converter power-down the system will lose regulation as soon as the input voltage is so

low that either peak current or maximum duty cycle limitation is tripped. Vcc will then drop

and stop IC activity as it falls below the UVLO threshold (10V typ.). The Vcc_OK signal is

de-asserted as the Vcc voltage goes below a threshold Vcc

HV generator can now restart. However, if Vin < Vin

, as illustrated in Figure 6, HV_EN is

start

located at about 5V. The

restart

de-asserted too and the HV generator is disabled. This prevents converter’s restart attempts

and ensures monotonic output voltage decay at power-down in systems where brownout

protection (see the relevant section) is not used.

The low restart threshold Vcc

ensures that, during short circuits, the restart attempts of

restart

the device will have a very low repetition rate, as shown in the timing diagram of

page 20

, and that the converter will work safely with extremely low power throughput.

19/51

Figure 7 on

Application information L6566A

Figure 7. Timing diagram showing short-circuit behavior (SS pin clamped at 5V)

Vcc

(pin 5)

Vcc

Vcc

restart

Vcc

GD

(pin 4)

Vcc_OK

charge

I

0.85 mA

ON

OFF

Short circuit occurs here

< 0.03T

T

rep

rep

t

t

t

t

Figure 8. Zero current detection block, triggering block, oscillator block and related

logic

COMP

915

L6566A

line

FFWD

VFF

+Vin

ZCD

11

MONO

STABLE

BLANKING

TIME

Reset

4:1

Counter

R

Z1

R

Z2

100 mV

50 mV

5V

+

Strobe

+

-

5.7V

S/H

blanking

START

TURN-ON

LOGIC

OSCILLATOR

FAULT

PWM

CS

7

GD

R

Q

S

13

OSC

R

T

DRIVER

4

Q

Rs

20/51

L6566A Application information

V

5.2 Zero current detection and triggering block; oscillator block

The Zero Current Detection (ZCD) and Triggering blocks switch on the external MOSFET if

a negative-going edge falling below 50 mV is applied to the input (pin 11, ZCD). To do so the

triggering block must be previously armed by a positive-going edge exceeding 100 mV.

This feature is typically used to detect transformer demagnetization for QR operation, where

the signal for the ZCD input is obtained from the transformer’s auxiliary winding used also to

supply the L6566A. The triggering block is blanked for T

turn-off to prevent any negative-going edge that follows leakage inductance

demagnetization from triggering the ZCD circuit erroneously.

The voltage at the pin is both top and bottom limited by a double clamp, as illustrated in the

internal diagram of the ZCD block of

Figure 8 on page 20. The upper clamp is typically

located at 5.7 V, while the lower clamp is located at -0.4V. The interface between the pin and

the auxiliary winding will be a resistor divider. Its resistance ratio will be properly chosen

Section 5.11: OVP block on page 35”) and the individual resistance values (R

(see “

will be such that the current sourced and sunk by the pin be within the rated capability of the

internal clamps (±3 mA).

At converter power-up, when no signal is coming from the ZCD pin, the oscillator starts up

the system. The oscillator is programmed externally by means of a resistor (R

from pin OSC (13) to ground. With good approximation the oscillation frequency f

= 2.5 µs after MOSFET’s

BLANK

, RZ2)

Z1

) connected

T

will be:

osc

Equation 2

3

102f⋅

≈

(with f

osc

in kHz and RT in kW). As the device is turned on, the oscillator starts immediately;

osc

R

T

at the end of the first oscillator cycle, being zero the voltage on the ZCD pin, the MOSFET

will be turned on, thus starting the first switching cycle right at the beginning of the second

oscillator cycle. At any switching cycle, the MOSFET is turned off as the voltage on the

current sense pin (CS, 7) hits an internal reference set by the Line Feedforward block, and

the transformer starts demagnetization. If this completes (hence a negative-going edge

appears on the ZCD pin) after a time exceeding one oscillation period T

previous turn-on, the MOSFET will be turned on again - with some delay to ensure minimum

voltage at turn-on – and the oscillator ramp will be reset. If, instead, the negative-going edge

appears before T

after T

will turn-on the MOSFET and synchronize the oscillator. In this way one or more

osc

drain ringing cycles will be skipped (“valley-skipping mode”,

frequency will be prevented from exceeding f

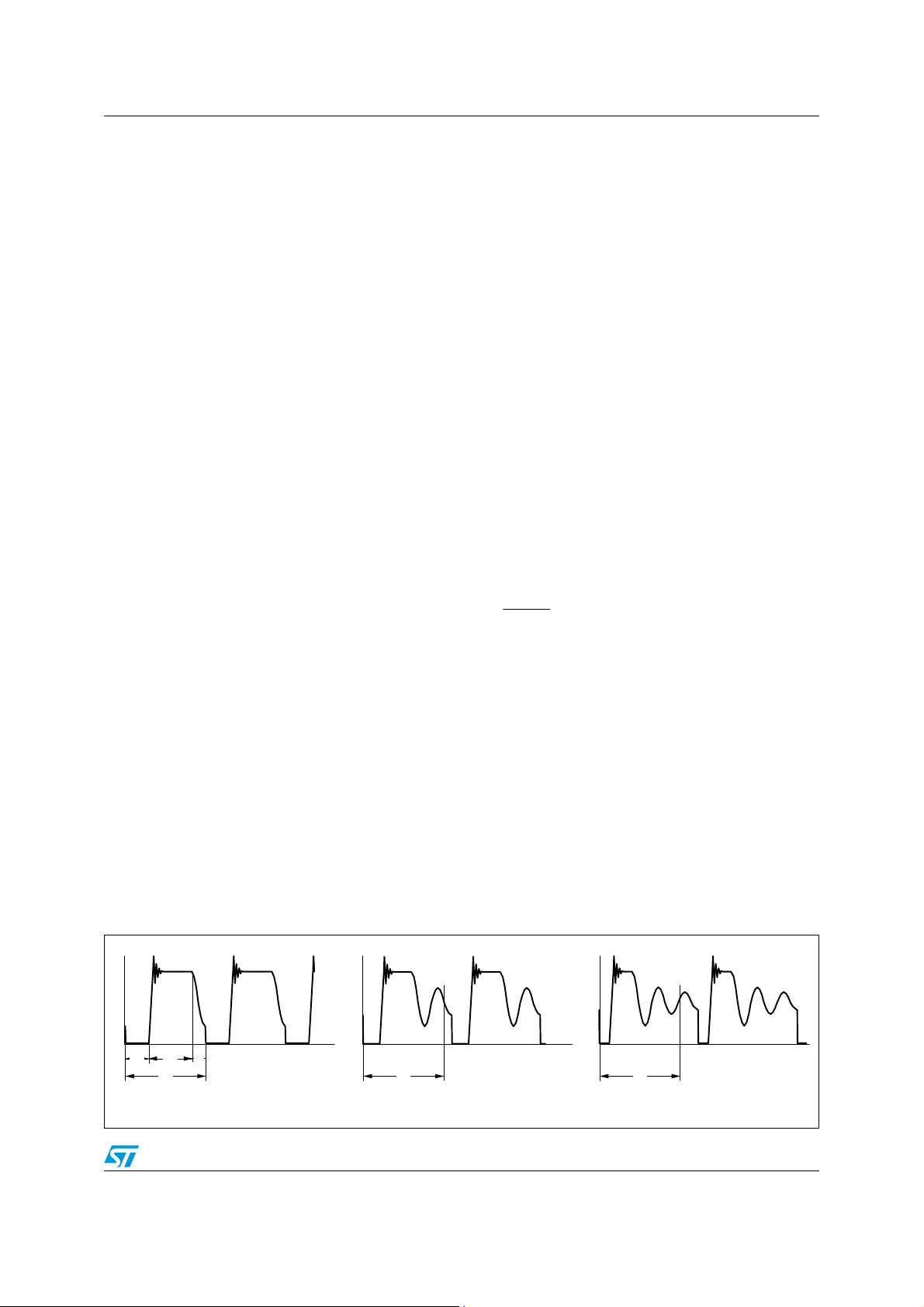

Figure 9. Drain ringing cycle skipping as the load is gradually reduced

DS

has elapsed, it will be ignored and only the first negative-going edge

osc

Figure 9) and the switching

.

osc

V

DS

V

DS

osc

=1/f

from the

osc

T

T

FW

osc

T

V

Pin = Pin'

(limit condition)

T

ON

t

T

osc

in''

< P

in'

Pin= P

t

T

osc

in'''

Pin= P

< P

in''

t

21/51

Application information L6566A

Note: When the system operates in valley skipping-mode, uneven switching cycles may be

observed under some line/load conditions, due to the fact that the OFF-time of the MOSFET

is allowed to change with discrete steps of one ringing cycle, while the OFF-time needed for

cycle-by-cycle energy balance may fall in between. Thus one or more longer switching

cycles will be compensated by one or more shorter cycles and vice versa. However, this

mechanism is absolutely normal and there is no appreciable effect on the performance of

the converter or on its output voltage.

If the MOSFET is enabled to turn on but the amplitude of the signal on the ZCD pin is

smaller than the arming threshold for some reason (e.g. a heavy damping of drain

oscillations, like in some single-stage PFC topologies, or when a turn-off snubber is used),

MOSFET’s turn-on cannot be triggered. This case is identical to what happens at start-up:

at the end of the next oscillator cycle the MOSFET will be turned on, and a new switching

cycle will take place after skipping no more than one oscillator cycle.

The operation described so far does not consider the blanking time T

turn off, and actually T

does not come into play as long as the following condition is

BLANK

after MOSFET’s

BLANK

met:

Equation 3

T

BLANK

1D −≤

T

osc

where D is the MOSFET duty cycle. If this condition is not met, things do not change

substantially: the time during which MOSFET’s turn-on is inhibited is extended beyond T

by a fraction of T

lower than the programmed value f

earlier than expected. However this is quite unusual: setting f

phenomenon can be observed at duty cycles higher than 60%. See

on page 35

for further implications of T

. As a consequence, the maximum switching frequency will be a little

BLANK

and valley-skipping mode may take place slightly

osc

= 150 kHz, the

osc

Section 5.11: OVP block

.

BLANK

osc

If the voltage on the COMP pin (9) saturates high, which reveals an open control loop, an

internal pull-up keeps the ZCD pin close to 2V during MOSFET's OFF-time to prevent noise

from false triggering the detection block. When this pull-up is active, the ZCD pin might not

be able to go below the triggering threshold, which would stop the converter. To allow autorestart operation, however ensuring minimum operating frequency in these conditions, the

oscillator frequency that retriggers MOSFET's turn-on is that of the external oscillator

divided by 128. Additionally, to prevent malfunction at converter's start-up, the pull-up is

disabled during the initial soft-start (see the relevant section). However, to ensure a correct

start-up, at the end of the soft-start phase the output voltage of the converter must meet the

condition:

Equation 4

Vout >

where Ns is the turn number of the secondary winding, Naux the turn number of the

auxiliary winding and I

22/51

the maximum pull-up current (130 µA).

ZCD

Ns

Naux

IR

ZCD1Z

L6566A Application information

The operation described so far under different operating conditions for the converter is

illustrated in the timing diagrams of

Figure 10.

If the FF option is selected the operation will be exactly equal to that of a standard currentmode PWM controller. It will work at a frequency fsw = fosc; both DCM and CCM

transformer's operation are possible, depending on the operating conditions (input voltage

and output load) and on the design of the power stage. The MOSFET is turned on at the

beginning of each oscillator cycle and is turned off as the voltage on the current sense pin

reaches an internal reference set by the Line Feedforward block. The maximum duty cycle is

limited at 70% minimum. The signal on the ZCD pin in this case is used only for detecting

feedback loop failures (see

Figure 10. Operation of ZCD, triggering and Oscillator blocks (QR option active)

ZCD

(pin 11)

100 mV

50 mV

Oscillator

ramp

Section 5.11: OVP block on page 35).

ZCD

(pin 11)

100 mV

50 mV

Oscillator

ramp

ZCD

(pin 11)

100 mV

50 mV

Oscillator

ramp

ZCD

blanking

time

Arm /Trigger

ON-enable

PWM latch

Set

PWM latch

Reset

GD

(pin 4)

armed trigger

a) full load

ZCD

blanking

time

Arm/Trigger

ON-enable

PWM latch

Set

PWM latch

Reset

GD

(pin 4)

b) light load

ZCD

blanking

time

Arm /Trigger

ON-enable

PWM latch

Set

PWM latch

Reset

GD

(pin 4)

c) start - up

23/51

Application information L6566A

5.3 Burst-mode operation at no load or very light load

When the voltage at the COMP pin (9) falls 20 mV below a threshold fixed internally at a

value, V

COMPBM

the MOSFET kept in OFF state and its consumption reduced at a lower value to minimize

Vcc capacitor discharge.

The control voltage now will increase as a result of the feedback reaction to the energy

delivery stop (the output voltage will be slowly decaying), the threshold will be exceeded and

the device will restart switching again. In this way the converter will work in burst-mode with

a nearly constant peak current defined by the internal disable level. A load decrease will

then cause a frequency reduction, which can go down even to few hundred hertz, thus

minimizing all frequency-related losses and making it easier to comply with energy saving

regulations. This kind of operation, shown in the timing diagrams of

others previously described, is noise-free since the peak current is low.

If it is necessary to decrease the intervention threshold of the burst-mode operation, this can

be done by adding a small DC offset on the current sense pin as shown in

page 25

.

Note: The offset reduces the available dynamics of the current signal; thereby, the value of the

sense resistor must be determined taking this offset into account.

Figure 11. Load-dependent operating modes: timing diagrams

, depending on the selected operating mode, the L6566A is disabled with

Figure 11 along with the

Figure 12 on

COMP

(pin 9)

V

COMPBM

f

osc

sw

f

GD

(pin 4)

MODE/SC=Open

MODE/SC=VREF

FF Mode Burst-mode FF Mode

QR Mode

Burst-mode

V alley-skipping Mode

20 mV

hyster.

t

MODE/SC=Open

MODE/SC=VREF

t

t

QR Mode

24/51

L6566A Application information

COMP

Figure 12. Addition of an offset to the current sense lowers the burst-mode operation

threshold

5.4 Adaptive UVLO

A major problem when optimizing a converter for minimum no-load consumption is that the

voltage generated by the auxiliary winding under these conditions falls considerably as

compared even to a few mA load. This very often causes the supply voltage Vcc of the

control IC to drop and go below the UVLO threshold so that the operation becomes

intermittent, which is undesired. Furthermore, this must be traded off against the need of

generating a voltage not exceeding the maximum allowed by the control IC at full load.

To help the designer overcome this problem, the device, besides reducing its own

consumption during burst-mode operation, also features a proprietary adaptive UVLO

function. It consists of shifting the UVLO threshold downwards at light load, namely when

the voltage at pin COMP falls below a threshold V

Interface"), so as to have more headroom. To prevent any malfunction during transients from

minimum to maximum load the normal (higher) UVLO threshold is re-established when the

voltage at pin COMP exceeds V

Vcc has exceeded the normal UVLO threshold (see

ensures that at full load the MOSFET will be driven with a proper gate-to-source voltage.

Figure 13. Adaptive UVLO block

9

V

COMPL

V

COMPO

(*) Vc c

OFF2

Vcc_PFC

Vcc_PFC

-

+

< Vcc

is selected when Q is high

OFF1

6

logic

R

S Q

Vcso= V ref

R

R + Rc

Vref

10

L6566A

4

Rc

R

7

3

Rs

internally fixed (see "PFC

COMPO

(see "Chapter 5.8: PFC interface on page 31") and

COMPL

Figure 13). The normal UVLO threshold

VCOMP

Vcc

5

+

-

UVLO

+

SW

-

Vcc

Vcc

OFF1

OFF2

(*)

L6566A

(pin 9)

V

COMPL

V

COMPO

Vcc

(pin 5)

VccOFF 1

Vcc

Vcc_PFC

(pin 6)

t

OFF2

Q

Tdelay

t

t

t

25/51

Application information L6566A

5.5 PWM control block

The device is specific for secondary feedback. Typically, there is a TL431 on the secondary

side and an optocoupler that transfers output voltage information to the PWM control on the

primary side, crossing the isolation barrier. The PWM control input (pin 9, COMP) is driven

directly by the phototransistor's collector (the emitter is grounded to GND) to modulate the

duty cycle (

In applications where a tight output regulation is not required, it is possible to use a primarysensing feedback technique. In this approach the voltage generated by the self-supply

winding is sensed and regulated. This solution, shown in

is cheaper because no optocoupler or secondary reference is needed, but output voltage

regulation, especially as a result of load changes, is quite poor. Ideally, the voltage

generated by the self-supply winding and the output voltage should be related by the

Naux/Ns turn ratio only. Actually, numerous non-idealities, mainly transformer's parasitics,

cause the actual ratio to deviate from the ideal one. Line regulation is quite good, in the

range of ± 2%, whereas load regulation is about ±5% and output voltage tolerance is in the

range of ±10%.

The dynamics of the pin is in the 2.5 to 5V range. The voltage at the pin is clamped

downwards at about 2 V. If the clamp is externally overridden and the voltage on the pin is

pulled below 1.4V the L6566A will shut down. This condition is latched as long as the device

is supplied. While the device is disabled, however, no energy is coming from the self-supply

circuit, thus the voltage on the Vcc capacitor will decay and cross the UVLO threshold after

some time, which clears the latch and lets the HV generator restart. This function is

intended for an externally controlled burst-mode operation at light load with a reduced

output voltage, a technique typically used in multi-output SMPS, such as those for CRT TVs

or monitors (see the timing diagram

Figure 14, left-hand side circuit).

Figure 14, right-hand side circuit,

Figure 15 on page 27).

Figure 14. Possible feedback configurations that can be used with the L6566A

L6566A

9

COMP

TL431

Secondary feedback Primary feedback

Vout

L6566A

COMP

5 Vcc

9

Cs

N

aux

26/51

L6566A Application information

Figure 15. Externally controlled burst-mode operation by driving pin COMP: timing

diagram

Vcc

(pin 5)

Vcc

Vcc

restart

Vcc

COMP

(pin 9)

GD

(pin 4)

Vcc_OK

charge

I

0.85 mA

Vcc_PFC

(pin 6)

Vout

Standby is commanded here

ON

OFF

t

t

t

t

t

t

t

5.6 PWM comparator, PWM latch and voltage feedforward blocks

The PWM comparator senses the voltage across the current sense resistor Rs and, by

comparing it to the programming signal delivered by the feedforward block, determines the

exact time when the external MOSFET is to be switched off. Its output resets the PWM

latch, previously set by the oscillator or the ZCD triggering block, which will assert the gate

driver output low. The use of PWM latch avoids spurious switching of the MOSFET that

might result from the noise generated ("double-pulse suppression").

Cycle-by-cycle current limitation is realized with a second comparator (OCP comparator)

that senses the voltage across the current sense resistor Rs as well and compares this

voltage to a reference value V

the circuit schematic in

Figure 17 on page 29). In this way, if the programming signal

delivered by the feedforward block and sent to the PWM comparator exceeds V

the OCP comparator to reset first the PWM latch instead of the PWM comparator. The value

of Vcsx, thereby, determines the overcurrent setpoint along with the sense resistor Rs.

The power that QR flyback converters with a fixed overcurrent setpoint (like fixed-frequency

systems) are able to deliver changes with the input voltage considerably. Obviously, this is

not a problem if the flyback converter runs off a fixed voltage bus generated by the PFC preregulator; however, with a tracking boost PFC (a "boost follower" PFC), the regulated output

voltage at maximum mains voltage can be even twice the value at minimum mains voltage.

In this case the issue is still there, although not as big as without PFC and wide-range

mains. With a 1:2 voltage change, the maximum transferable power at maximum line can be

50% higher than at minimum line, as shown by the upper curve in the diagram of

The L6566A has the Line Feedforward function available to solve this issue.

. Its output is or-ed with that of the PWM comparator (see

CSX

, it will be

CSX

Figure 16.

27/51

Application information L6566A

Figure 16. Typical power capability change vs input voltage in QR flyback converters

2.5

2

in

inmin

@ V

1.5

@ V

inlim

P

inlim

P

1

0.5

11.522.5 33.54

system not

compensated

system optimally

compensated

in

V

inmin

V

k = 0

k = k

k

opt

It acts on the overcurrent setpoint Vcsx, so that it is a function of the converter’s input voltage

Vin (output of the PFC pre-regulator) sensed through a dedicated pin (15, VFF): the higher

the input voltage, the lower the setpoint. This is illustrated in the diagram on the left-hand

side of

and V

Figure 17 on page 29: it shows the relationship between the voltage on the pin VFF

csx (with the error amplifier saturated high in the attempt of keeping output voltage

regulation):

Equation 5

csx

V

VFF

1V

3

k

1

Vin

−=−=

3

Note: If the voltage on the pin exceeds 3V switching ceases but the soft-start capacitor is not

discharged. The schematic in Figure 17 on page 29 shows also how the function is included

in the control loop.

With a proper selection of the external divider R1-R2, i.e. of the ratio k = R2 / (R1+R2), it is

possible to achieve the optimum compensation described by the lower curve in the diagram

of

Figure 16.

The optimum value of k, k

, which minimizes the power capability variation over the input

opt

voltage range, is the one that provides equal power capability at the extremes of the range.

The exact calculation is complex, and non-idealities shift the real-world optimum value from

the theoretical one. It is therefore more practical to provide a first cut value, simple to be

calculated, and then to fine tune experimentally.

Assuming that the system operates exactly at the boundary between DCM and CCM, and

neglecting propagation delays, the following expression for k

can be found:

opt

Equation 6

V

opt

3k

⋅=

R

()

⋅++⋅

VVVVV

Rmaxinmininmaxinminin

Experience shows that this value is typically lower than the real one. Once the maximum

peak primary current, I

PKpmax

, occurring at minimum input voltage Vinmin has been found,

the value of Rs can be determined from (2):

28/51

L6566A Application information

V

Equation 7

k

opt

1Rs−

=

V

minin

3

I

maxPKp

The converter is then tested on the bench to find the output power level Pout

regulation is lost (because overcurrent is being tripped) both at Vin = Vin

Vin = Vin

Figure 17. Left: Overcurrent setpoint vs. VFF voltage; right: Line Feedforward function block

[V]

csx

1.2

1

0.8

0.6

0.4

0.2

0

00.511.522.533.5

If Pout

increasing; if Pout

V

@ Vin

lim

max

VFF

[V]

.

V

COMP

= Upper clamp

> Pout

max

lim

@ Vin

@ Vin

lim

max

min

< Pout

PFC Outp ut Bus

To PFC's OV

sensi ng

COMP

R1B

R2

9

R1A

15

L6566A

Optional for

OVP settings

VFF CS

VOLTAGE

FEED

FORWARD

Vcsx

1.5 V

Rs

7

+

PWM

+

OCP

+

Hiccup

-

Clock/ZCD

the system is still undercompensated and k needs

@ Vin

lim

the system is overcompensated and k

min

min

R

S

lim

and

Q

DISABLE

where

DRIVER

needs decreasing. This will go on until the difference between the two values is acceptably

low. Once found the true k

in this way, it is possible that Pout

opt

turns out slightly different

lim

from the target; to correct this, the sense resistor Rs needs adjusting and the above tuning

process will be repeated with the new Rs value. Typically a satisfactory setting is achieved in

no more than a couple of iterations.

4

GD

In applications where this function is not wanted, e.g. because the PFC stage regulates at a

fixed voltage, the VFF pin can be simply grounded, directly or through a resistor (see

“

Chapter 5.11: OVP block on page 35”). The overcurrent setpoint will be then fixed at the

maximum value of 1V. If a lower setpoint is desired to reduce the power dissipation on Rs,

the pin can be also biased at a fixed voltage using a divider from VREF (pin 10).

If the FF option is selected the Line Feedforward function can be still used to compensate for

the total propagation delay Td of the current sense chain (internal propagation delay td

(H-L)

plus the turn-off delay of the external MOSFET), which in standard current mode PWM

controllers is done by adding an offset on the current sense pin proportional to the input

voltage. In that case the divider ratio k, which will be much smaller as compared to that used

with the QR option selected, can be calculated with the following equation:

Equation 8

Td

3k

=

opt

29/51

LpRs

Application information L6566A

where Lp is the inductance of the primary winding. In case a constant maximum power

capability vs. the input voltage is not required, the VFF pin can be grounded, directly or

through a resistor (see

setpoint at 1V, or biased at a fixed voltage through a divider from VREF to get a lower

setpoint.

It is possible to bypass the pin to ground with a small film capacitor (e.g. 1-10 nF) to ensure

a clean operation of the IC even in a noisy environment.

The pin is internally forced to ground during UVLO, after activating any latched protection

and when pin COMP is pulled below its low clamp voltage (see

block on page 26

Section 5.11: OVP block on page 35 ), hence fixing the overcurrent

Section 5.5: PWM control

).

5.7 Hiccup-mode OCP

A third comparator senses the voltage on the current sense input and shuts down the device

if the voltage on the pin exceeds 1.5 V, a level well above that of the maximum overcurrent

setpoint (1V). Such an anomalous condition is typically generated by either a short circuit of

the secondary rectifier or a shorted secondary winding or a hard-saturated flyback

transformer.

To distinguish an actual malfunction from a disturbance (e.g. induced during ESD tests), the

first time the comparator is tripped the protection circuit enters a “warning state”. If in the

next switching cycle the comparator is not tripped, a temporary disturbance is assumed and

the protection logic will be reset in its idle state; if the comparator will be tripped again a real

malfunction is assumed and the L6566A will be stopped. Depending on the time relationship

between the detected event and the oscillator, occasionally the device could stop after the

third detection.

This condition is latched as long as the device is supplied. While it is disabled, however, no

energy is coming from the self-supply circuit; hence the voltage on the Vcc capacitor will

decay and cross the UVLO threshold after some time, which clears the latch. The internal

start-up generator is still off, then the Vcc voltage still needs to go below its restart voltage

before the Vcc capacitor is charged again and the device restarted. Ultimately, this will result

in a low-frequency intermittent operation (Hiccup-mode operation), with very low stress on

the power circuit. This special condition is illustrated in the timing diagram of

Figure 18.

30/51

L6566A Application information

t

Figure 18. Hiccup-mode OCP: timing diagram

Vcc

(pin 5)

Vcc

Vcc

restart

Vcc

ON

OFF

Secondary diode is shorted here

CS

V

(pin 7)

GD

(pin 4)

OCP latch

Vcc_OK

Vcc_PFC

(pin 6)

1.5 V

5.8 PFC interface

The device is specifically designed to minimize converter’s losses under light or no-load

conditions, and a special function has been provided to help the designer meet energy

saving requirements even in power-factor-corrected systems where a PFC pre-regulator

precedes the isolated DC-DC converter.

Actually EMC regulations require compliance with low-frequency harmonic emission limits

at nominal load; no limit is envisaged when the converter operates with a light load. Then

the PFC pre-regulator can be turned off, thus saving the no-load consumption of this stage

(0.5÷1W).

t

t

t

t

t

To do so, the L6566A provides the Vcc_PFC pin (6): this pin is internally connected to the

Vcc pin (5) via a PNP transistor, normally closed, that opens when the voltage V

below V

COMPO

, a threshold internally set at a value depending on whether QR operation or

COMP

falls

FF operation is selected. This pin is intended for supplying the PFC controller of the preregulator as shown in

Figure 16 on page 28. The switch is thermally protected, so that the

IC will stop if an external failure causes the pin to be overloaded for too long time or shorted

to ground.

31/51

Application information L6566A

Figure 19. Possible interfaces between the L6566A and a PFC controller

Vcc

5

Vcc_PFC6

L6566A

Vcc

5

22 k

Vcc_PFC6

L6566A

Ω

4.7k

Vcc

L6561

L6562

L6563

RUN

10

Ω

L6563

To prevent intermittent operation of the PFC stage, some hysteresis is provided: if the

internal switch is open, it will be closed (which will re-enable the PFC pre-regulator) when

COMP

exceeds V

COMP

must stay below V

V

transients V

the Vcc_PFC pin to open. Entering burst-mode (V

COMPL

> V

. Additionally, to reject V

COMPO

for more than 1024 oscillator cycles in order for

COMPO

COMP

< V

undershoots during

COMP

COMPBM

) will open Vcc_PFC

immediately.

Besides pin 6 going open, when V

COMP

below to compensate for the drop of the voltage delivered by the self-supply circuit that

occurs at light load (see

Section 5.4: Adaptive UVLO on page 25).

5.9 Latched disable function

The device is equipped with a comparator having the non-inverting input externally available

at the pin DIS (8) and with the inverting input internally referenced to 4.5V. As the voltage on

the pin exceeds the internal threshold, the device is immediately shut down and its

consumption reduced to a low value.

The information is latched and it is necessary to let the voltage on the Vcc pin go below the

UVLO threshold to reset the latch and restart the device. To keep the latch supplied as long

as the converter is connected to the input source, the HV generator is activated periodically

so that Vcc oscillates between the start-up threshold V

HV generator in this way cuts its power dissipation approximately by three (as compared to

the case of continuous conduction) and keeps peak silicon temperature close to the average

value.

To let the L6566A restart it is then necessary to disconnect the converter from the input

source. Pulling pin 16 (AC_OK) below the disable threshold (see

protection on page 38

latch can be cleared and a quicker restart is allowed as the input source is removed. This

operation is shown in the timing diagram of

) will stop the HV generator until Vcc falls below Vcc

falls below V

Figure 20.

COMPO

ccON

the UVLO threshold is set 2.4 V

and V

- 0.5V. Activating the

ccON

Section 5.12: Brownout

, so that the

restart

This function is useful to implement a latched overtemperature protection very easily by

biasing the pin with a divider from VREF, where the upper resistor is an NTC physically

located close to a heating element like the MOSFET, or the transformer. The DIS pin is a

high impedance input, thus it is prone to pick up noise, which might give origin to undesired

latch-off of the device. It is possible to bypass the pin to ground with a small film capacitor

(e.g. 1-10 nF) to prevent any malfunctioning of this kind.

32/51

L6566A Application information

Figure 20. Operation after latched disable activation: timing diagram

DIS

(pin 8)

4.5V

Vcc

Vcc

(pin 5)

Vcc

ON

-0.5

Vcc

restart

Vcc

GD

(pin 4)

HV generator is turned on

ON

OFF

Restart is quicker

Disable latch is reset here

HV generator turn-on is di sabled here

t

t

Vcc_PFC

(pin 6)

Vin

HVstart

V

AC_OK

(pin 16)

Vth

Input s o urce is removed here

t

t

t

t

5.10 Soft-start and delayed latched shutdown upon overcurrent

At device start-up, a capacitor (Css) connected between the SS pin (14) and ground is

charged by an internal current generator, I

During this ramp, the overcurrent setpoint progressively rises from zero to the value

imposed by the voltage on the VFF pin (15, see “

Feedforward blocks

”); MOSFET’s conduction time increases gradually, hence controlling the

start-up inrush current. The time needed for the overcurrent setpoint to reach its steady

state value, referred to as soft-start time, is approximately:

Equation 9

, from zero up to about 2V where it is clamped.

SS1

PWM Comparator, PWM Latch and Voltage

V

VFF

3

⎞

⎟

⎟

⎠

During the ramp (i.e. until V

⎛

Css

T

SS

I

1SS

= 2 V) all the functions that monitor the voltage on pin COMP

SS

VFFcsx

Css

⎜

−==

)V(V

1

⎜

I

⎝

1SS

are disabled.

The soft-start pin is also invoked whenever the control voltage (COMP) saturates high,

which reveals an open-loop condition for the feedback system. This condition very often

occurs at start-up, but may be also caused by either a control loop failure or a converter

overload/short circuit. A control loop failure results in an output overvoltage that is handled

by the OVP function of the L6566A (see next section). In case of QR operation, a short

circuit causes the converter to run at a very low frequency, then with very low power

capability. This makes the self-supply system that powers the device unable to keep it

33/51

Application information L6566A

V

operating, so that the converter will work intermittently, which is very safe. In case of

overload the system has a power capability lower than that at nominal load but the output

current may be quite high and overstress the output rectifier. In case of FF operation the

capability is almost unchanged and both short circuit and overload conditions are more

critical to handle.

The L6566A, regardless of the operating option selected, makes it easier to handle such

conditions: the 2V clamp on the SS pin is removed and a second internal current generator

I

= I

SS2

allowed to reach 2 V

resulting behavior will be identical to that under short circuit illustrated in

page 19

See

/4 keeps on charging Css. As the voltage reaches 5V the device is disabled, if it is

SS1