现货库存、技术资料、百科信息、热点资讯,精彩尽在鼎好!

G

Advanced transition-mode PFC controller

Features

■ Very precise adjustable output overvoltage

protection

■ Tracking boost function

■ Protection against feedback loop failure

(Latched shutdown)

■ Interface for cascaded converter's PWM

controller

■ Input voltage feedforward (1/V

■ Inductor saturation detection (L6563 only)

■ Remote ON/OFF control

■ Low (≤ 90µA) start-up current

■ 5mA max. quiescent current

■ 1.5% (@ T

= 25°C) internal reference voltage

J

■ -600/+800 mA totem pole gate driver with

active pull-down during UVLO

■ SO14 package

Figure 1. Block diagram

TRACKING

BOOST

6

TBO

V

ZCD

RUN

CC

ND

1:1

CURRENT

MIRROR

1:1

BUFFER

3V

14

12

11

1.4V

0.7V

10

-

+

0.52V

0.6V

ON/OFF CONTROL

(BROWNOUT DETECTION)

2

)

INV COMP MULT

123

-

+

2.5V

VOLT AGE

from

REGULATOR

VFF

ZERO CURRENT

-

+

R2

DETECTOR

(I NTERNA L SU PPLY BUS)

R1

CO MPAR ATOR

+

-

VREF2

9

PWM_STOP

references

Vbi a s

UVLO

Voltage

DISABLE

L6563A

SO-14

Applications

PFC pre-regulators for:

■ HI-END AC-DC adapter/charger

■ Desktop PC, server, WEB server

■ IEC61000-3-2 OR JEIDA-MITI compliant

SMPS, in excess of 350W

Table 1. Device summary

Part number Package Packaging

L6563 SO-14 Tube

L6563TR SO-14 Tape & Reel

L6563A SO-14 Tube

L6563ATR SO-14 Tape & Reel

VFF

MUL TIP LI ER

UVLO

Idea l diod e

+-

INDUCTOR

SATURATION

DETECTION

( not in L6563A )

RSQ

PWM_LATCH

5

LI NE VOLT AGE

FEEDFOR WARD

1.7V

Starter

STARTER

LATCH

Vbi as

8

OFF

1 / V

LEADIN G-EDGE

+-

Q

SAT

15 V

Driver

SAT

FEEDBACK

FAILURE

PROTEC TION

2

BLANKING

+

4

CS

VCC

13

GD

0.2V

0.26V

+

PFC_OK

7

-

2.5V

L6563

March 2007 Rev 4 1/39

www.st.com

39

Contents L6563 - L6563A

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Typical electrical performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2 Feedback Failure Protection (FFP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.3 Voltage Feedforward . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.4 THD optimizer circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.5 Tracking Boost function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.6 Inductor saturation detection (L6563 only) . . . . . . . . . . . . . . . . . . . . . . . . 27

6.7 Power management/housekeeping functions . . . . . . . . . . . . . . . . . . . . . . 28

6.8 Summary of L6563/A idle states . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7 Application examples and ideas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2/39

L6563 - L6563A Description

1 Description

The device is a current-mode PFC controller operating in Transition Mode (TM). Based on

the core of a standard TM PFC controller, it offers improved performance and additional

functions.

The highly linear multiplier, along with a special correction circuit that reduces crossover

distortion of the mains current, allows wide-range-mains operation with an extremely low

THD even over a large load range.

The output voltage is controlled by means of a voltage-mode error amplifier and a precise

(1.5% @T

response to sudden mains voltage changes are improved by the voltage feedforward

function (1/V

Additionally, the IC provides the option for tracking boost operation (where the output

voltage is changed tracking the mains voltage). The device features extremely low

consumption (≤ 90 µA before start-up and ≤ 5 mA running).

In addition to an effective two-step OVP that handles normal operation overvoltages, the IC

provides also a protection against feedback loop failures or erroneous output voltage

setting.

In the L6563 a protection is added to stop the PFC stage in case the boost inductor

saturates. This function is not included in the L6563A. This is the only difference between

the two part numbers.

An interface with the PWM controller of the DC-DC converter supplied by the PFC preregulator is provided: the purpose is to stop the operation of the converter in case of

anomalous conditions for the PFC stage (feedback loop failure, boost inductor's core

saturation) in the L6563 only and to disable the PFC stage in case of light load for the DCDC converter, so as to make it easier to comply with energy saving norms (Blue Angel,

EnergyStar, Energy2000, etc.). The device includes disable functions suitable for remote

ON/OFF control both in systems where the PFC pre-regulator works as a master and in

those where it works as a slave.

The totem-pole output stage, capable of 600 mA source and 800 mA sink current, is suitable

to drive high current MOSFETs or IGBTs. This, combined with the other features and the

possibility to operate with the proprietary Fixed-Off-Time control, makes the device an

excellent low-cost solution for EN61000-3-2 compliant SMPS in excess of 350W.

= 25°C) internal voltage reference. The stability of the loop and the transient

J

2

correction).

Figure 2. Typical system block diagram

PFC PRE-REGULATOR

V

inac

PWM is turned off in case of PFC’s

anomalous operation for safety

L6563

L6563A

PFC can be turned off at light

load to ease compliance with

energy saving regulations.

3/39

DC-DC CONVERTER

PWM or

Resonant

CONTROLLER

V

outdc

Description L6563 - L6563A

1.1 Pin connection

Figure 3. Pin connection (top view)

INV

COMP

MULT

CS

VFF

TBO

PFC_OK

1

2

3

4

5

6

7

14

13

12

11

10

9

8

1.2 Pin description

Table 2. Pin description

Pin N° Name Description

Inverting input of the error amplifier. The information on the output voltage of the PFC preregulator is fed into the pin through a resistor divider.

1INV

2COMP

3MULT

4CS

5VFF

The pin normally features high impedance but, if the tracking boost function is used, an

internal current generator programmed by TBO (pin 6) is activated. It sinks current from the

pin to change the output voltage so that it tracks the mains voltage.

Output of the error amplifier. A compensation network is placed between this pin and INV

(pin 1) to achieve stability of the voltage control loop and ensure high power factor and low

THD.

Main input to the multiplier. This pin is connected to the rectified mains voltage via a

resistor divider and provides the sinusoidal reference to the current loop. The voltage on

this pin is used also to derive the information on the RMS mains voltage.

Input to the PWM comparator. The current flowing in the MOSFET is sensed through a

resistor, the resulting voltage is applied to this pin and compared with an internal reference

to determine MOSFET’s turn-off.

A second comparison level at 1.7V detects abnormal currents (e.g. due to boost inductor

saturation) and, on this occurrence, shuts down the IC, reduces its consumption almost to

the start-up level and asserts PWM_LATCH (pin 8) high. This function is not present in the

L6563A.

2

Second input to the multiplier for 1/V

connected from the pin to GND. They complete the internal peak-holding circuit that

derives the information on the RMS mains voltage. The voltage at this pin, a DC level equal

to the peak voltage at pin MULT (pin 3), compensates the control loop gain dependence on

the mains voltage. Never connect the pin directly to GND.

function. A capacitor and a parallel resistor must be

Vcc

GD

GND

ZCD

RUN

PWM_STOP

PWM_LATCH

4/39

L6563 - L6563A Description

Table 2. Pin description (continued)

Pin N° Name Description

Tracking Boost function. This pin provides a buffered VFF voltage. A resistor connected

6TBO

7PFC_OK

8PWM_LATCH

9PWM_STOP

between this pin and GND defines a current that is sunk from pin INV (pin 1). In this way,

the output voltage is changed proportionally to the mains voltage (tracking boost). If this

function is not used leave this pin open.

PFC pre-regulator output voltage monitoring/disable function. This pin senses the output

voltage of the PFC pre-regulator through a resistor divider and is used for protection

purposes. If the voltage at the pin exceeds 2.5V the IC is shut down, its consumption goes

almost to the start-up level and this condition is latched. PWM_LATCH pin is asserted high.

Normal operation can be resumed only by cycling the Vcc. This function is used for

protection in case the feedback loop fails.

If the voltage on this pin is brought below 0.2V the IC is shut down and its consumption is

considerably reduced. To restart the IC the voltage on the pin must go above 0.26V. If these

functions are not needed, tie the pin to a voltage between 0.26 and 2.5 V.

Output pin for fault signaling. During normal operation this pin features high impedance. If

either a voltage above 2.5V at PFC_OK (pin 7) or a voltage above 1.7V on CS (pin 4) of

L6563 is detected the pin is asserted high. Normally, this pin is used to stop the operation

of the DC-DC converter supplied by the PFC pre-regulator by invoking a latched disable of

its PWM controller. If not used, the pin will be left floating.

Output pin for fault signaling. During normal operation this pin features high impedance. If

the IC is disabled by a voltage below 0.5V on RUN (pin 10) the voltage at the pin is pulled

to ground. Normally, this pin is used to temporarily stop the operation of the DC-DC

converter supplied by the PFC pre-regulator by disabling its PWM controller. If not used,

the pin will be left floating.

Remote ON/OFF control. A voltage below 0.52V shuts down (not latched) the IC and

brings its consumption to a considerably lower level. PWM_STOP is asserted low. The IC

10 RUN

11 ZCD

12 GND Ground. Current return for both the signal part of the IC and the gate driver.

13 GD

14 VCC Supply Voltage of both the signal part of the IC and the gate driver.

restarts as the voltage at the pin goes above 0.6V. Connect this pin to VFF (pin 5) either

directly or through a resistor divider to use this function as brownout (AC mains

undervoltage) protection, tie to INV (pin 1) if the function is not used.

Boost inductor’s demagnetization sensing input for transition-mode operation. A negativegoing edge triggers MOSFET’s turn-on.

Gate driver output. The totem pole output stage is able to drive power MOSFET’s and

IGBT’s with a peak current of 600 mA source and 800 mA sink. The high-level voltage of

this pin is clamped at about 12V to avoid excessive gate voltages.

5/39

Absolute maximum ratings L6563 - L6563A

2 Absolute maximum ratings

Table 3. Absolute maximum ratings

Symbol Pin Parameter Value Unit

V

CC

---

--- 1, 3, 7

I

PWM_STOP

I

ZCD

P

TOT

T

J

T

STG

14 IC supply voltage (Icc = 20mA) self-limited V

2, 4 to 6, 8

to 10

10 Max. sink current 3 mA

Analog inputs & outputs -0.3 to 8 V

Max. pin voltage (I

9 Zero current detector max. current

Power dissipation @TA = 50°C

Junction temperature operating range -25 to 150 °C

Storage temperature -55 to 150 °C

= 1 mA)

pin

Self-limited V

-10 (source)

10 (sink)

0.75 W

mA

3 Thermal data

Table 4. Thermal data

Symbol Parameter Value Unit

R

thJA

Maximum thermal resistance junction-ambient 120 °C/W

6/39

L6563 - L6563A Electrical characteristics

4 Electrical characteristics

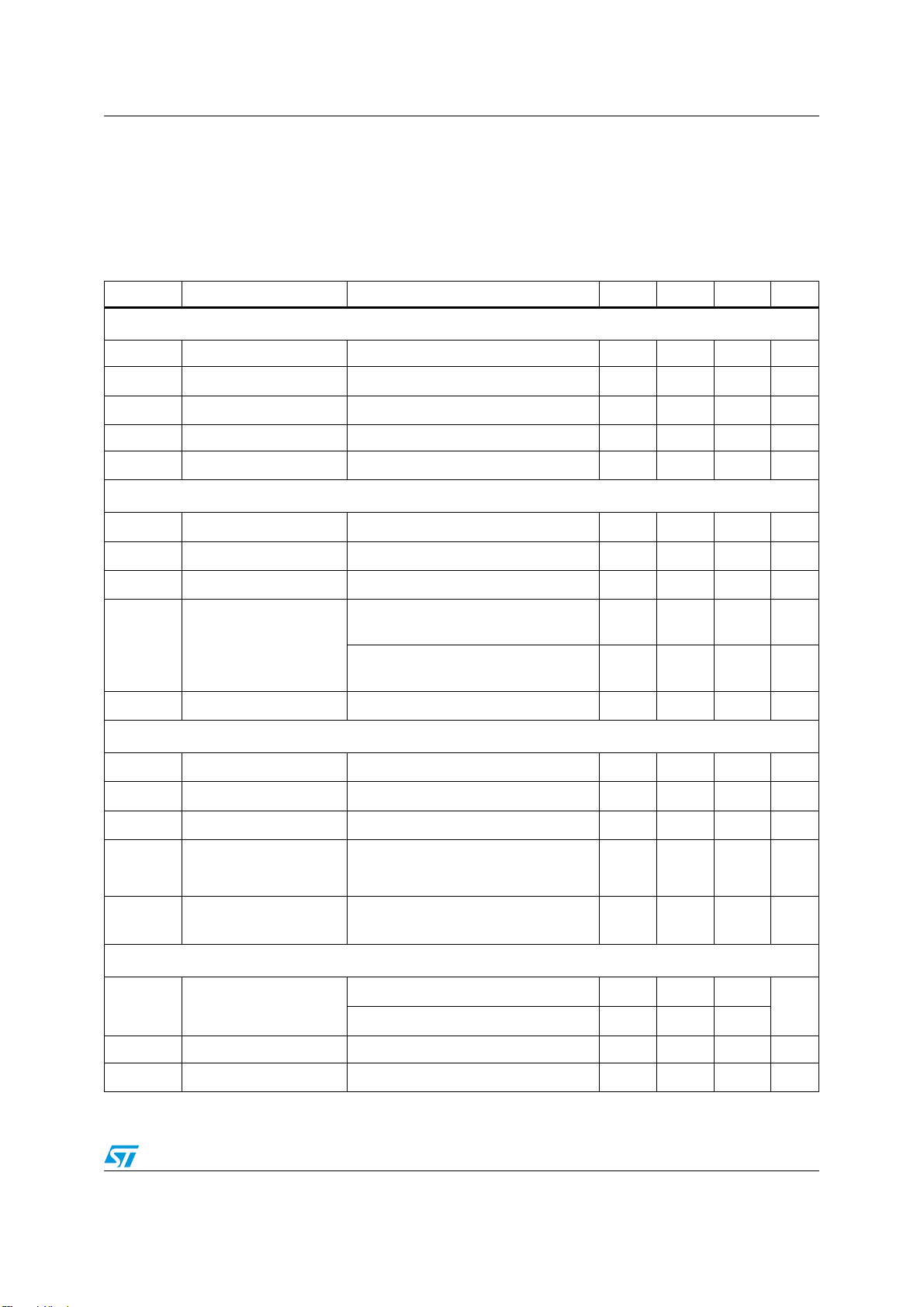

Table 5. Electrical characteristics

( -25°C < T

and GND; unless otherwise specified)

Symbol Parameter Test condition Min Typ Max Unit

Supply voltage

Vcc Operating range After turn-on 10.3 22 V

Vcc

Vcc

Hys Hysteresis 2.3 2.7 V

V

Supply current

< +125°C, VCC = 12V, Co = 1nF between pin GD and GND, CFF =1µF between pin VFF

J

Turn-on threshold

On

Turn-off threshold

Off

Zener Voltage Icc = 20 mA 22 25 28 V

Z

(1)

(1)

11 12 13 V

8.7 9.5 10.3 V

I

start-up

I

I

CC

I

qdis

I

Start-up current Before turn-on, Vcc = 10V 50 90 µA

Quiescent current After turn-on 3 5 mA

q

Operating supply current @ 70kHz 3.8 5.5 mA

Idle state quiescent

Current

Quiescent current During static/dynamic OVP 2 3 mA

q

Multiplier input

I

MULT

V

MULT

V

CLAMP

Vcs∆

---------------------

V

∆

MULT

K

Input bias current

Linear operation range 0 to 3 V

Internal clamp level

Output max. slope

Gain

M

Error amplifier

(3)

Latched by PFC_OK > Vthl or

Vcs > V

CSdis

Disabled by PFC_OK < Vth or

RUN < V

V

I

MULT

V

V

V

V

DIS

= 0 to 3 V

MULT

= 1 mA

=0 to 0.5V, VFF=0.8V

MULT

= Upper clamp

COMP

= 1 V, V

MULT

VFF

= V

COMP

MULT

= 4 V,

180 250 µA

1.5 2.2 mA

-0.2 -1 µA

99.5 V

2.2 2.34 V/V

0.375 0.45 0.525 V

V

I

INV

INV

Voltage feedback input

threshold

TJ = 25 °C

10.3 V < Vcc < 22 V

(2)

2.465 2.5 2.535

V

2.44 2.56

Line regulation Vcc = 10.3 V to 22V 2 5 mV

Input bias current

TBO open, V

= 0 to 4 V

INV

-0.2 -1 µA

7/39

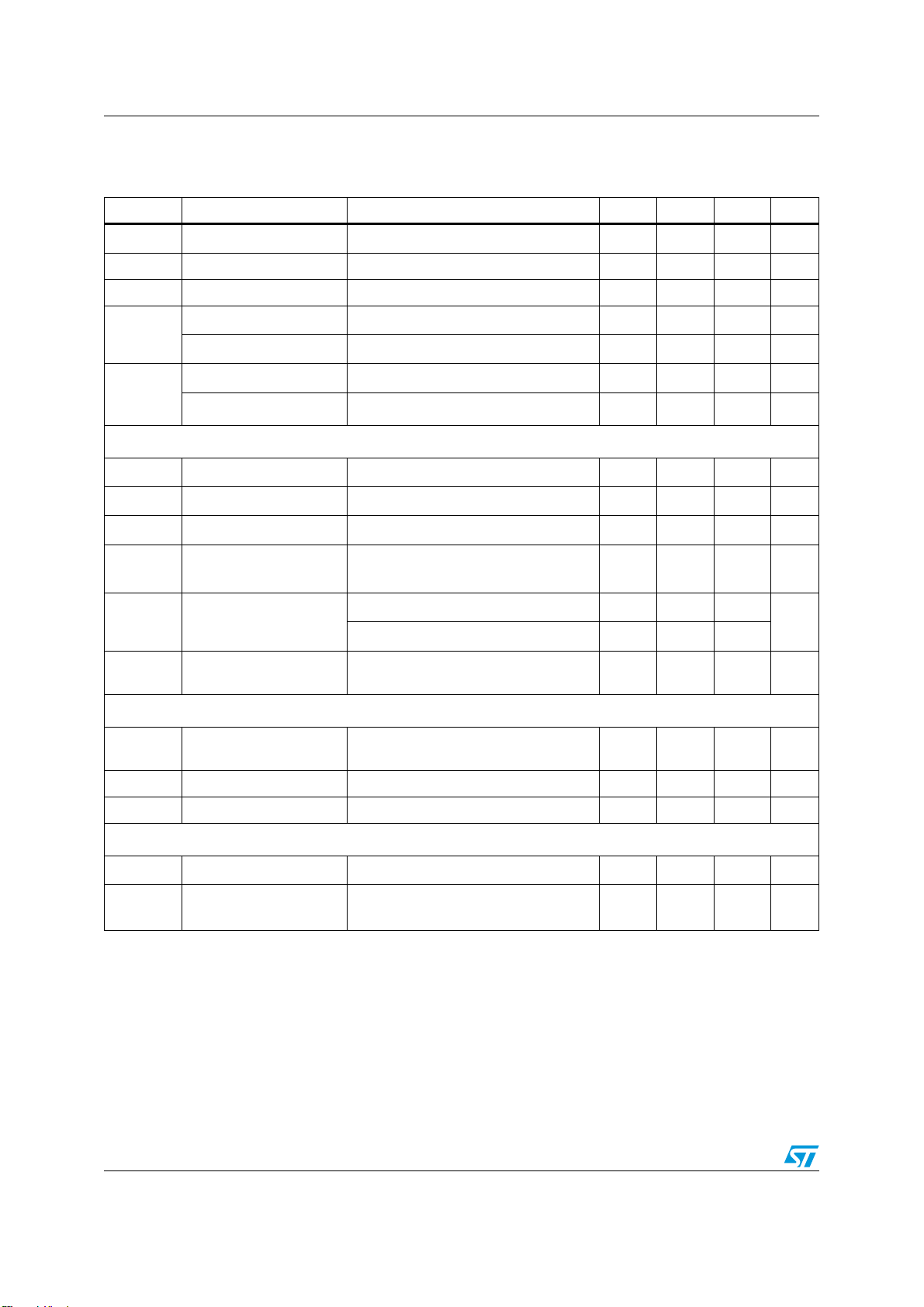

Electrical characteristics L6563 - L6563A

Table 5. Electrical characteristics (continued)

( -25°C < T

< +125°C, VCC = 12V, Co = 1nF between pin GD and GND, CFF =1µF between pin VFF

J

and GND; unless otherwise specified)

Symbol Parameter Test condition Min Typ Max Unit

V

INVCLAMP

Internal clamp level

I

INV

= 1 mA

99.5 V

Gv Voltage gain Open loop 60 80 dB

GB Gain-bandwidth product 1 MHz

I

COMP

V

COMP

Source current

Sink current

Upper clamp voltage

Lower clamp voltage

V

COMP

V

COMP

I

SOURCE

I

= 0.5 mA

SINK

= 4V, V

= 4V, V

= 0.5 mA

INV

INV

(2)

= 2.4 V

= 2.6 V

-2 -3.5 -5 mA

2.5 4.5 mA

5.7 6.2 6.7 V

2.12.252.4 V

Current sense comparator

I

CS

t

LEB

td

(H-L)

V

CSclamp

Vcs

V

CSdis

Input bias current

Leading edge blanking 100 200 300 ns

Delay to output 120 ns

Current sense reference

clamp

Current sense offset

offset

Ic latch-off level (L6563

only)

V

= 0

CS

V

= Upper clamp,

COMP

= V

V

VFF

V

= 0, V

MULT

V

= 3V, V

MULT

(2)

MULT

=0.5V

= 3V

VFF

VFF

= 3V

-1 µA

1.0 1.08 1.16 V

25

5

1.6 1.7 1.8 V

mV

Output overvoltage

I

OVP

Dynamic OVP triggering

current

Hys Hysteresis

Static OVP threshold

Voltage feedforward

V

VFF

∆V

Linear operation range

Dropout

V

MULTpk-VVFF

(4)

(2)

R

= 47 kΩ to GND

FF

17 20 23 µA

15 µA

2 2.15 2.3 V

0.5 3 V

20 mV

8/39

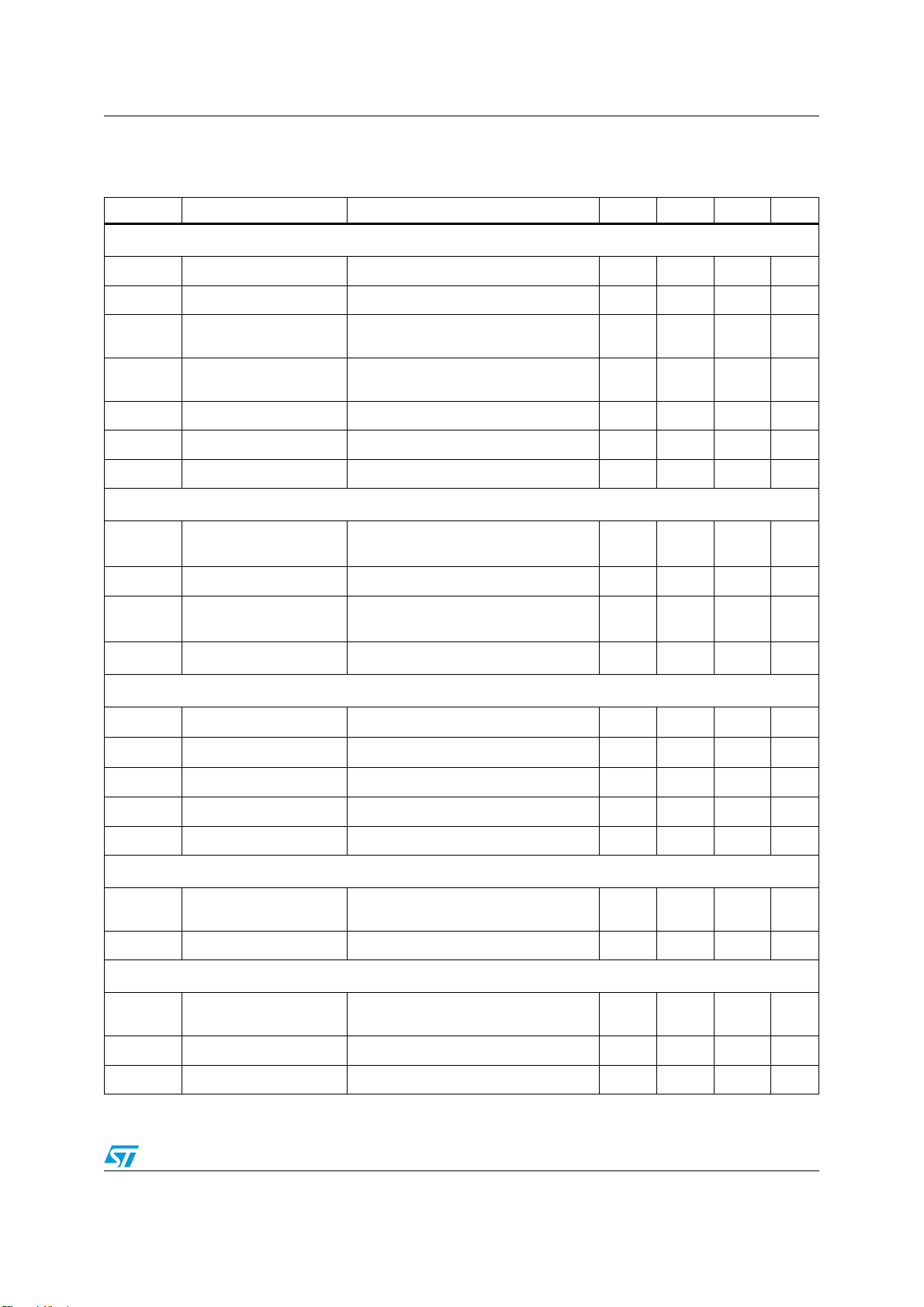

L6563 - L6563A Electrical characteristics

Table 5. Electrical characteristics (continued)

( -25°C < T

< +125°C, VCC = 12V, Co = 1nF between pin GD and GND, CFF =1µF between pin VFF

J

and GND; unless otherwise specified)

Symbol Parameter Test condition Min Typ Max Unit

Zero current detector

V

ZCDH

V

ZCDL

V

ZCDA

V

ZCDT

I

ZCDb

I

ZCDsrc

I

ZCDsnk

Upper clamp voltage

Lower clamp voltage

Arming voltage

(positive-going edge)

Triggering voltage

(negative-going edge)

Input bias current

Source current capability -2.5 mA

Sink current capability 2.5 mA

Tracking boost function

∆V

I

TBO

Dropout voltage

V

- V

VFF

TBO

Linear operation 0 0.25 mA

I

- I

TBO

current

INV

mismatch

V

TBOclamp

Clamp voltage

PFC_OK

V

V

V

EN

I

PFC_OK

V

clamp

Latch-off threshold

thl

Disable threshold

th

Enable threshold

Input bias current

Clamp voltage

I

= 2.5 mA

ZCD

I

= - 2.5 mA

ZCD

(4)

(4)

= 1 to 4.5 V

V

ZCD

I

= 0.25 mA

TBO

= 25 µA to 0.25 mA

I

TBO

(2)

= 4V

V

VFF

Voltage rising

Voltage falling

Voltage rising

V

PFC_OK

I

PFC_OK

(2)

= 0 to 2.5V

= 1 mA

(2)

(2)

5.0 5.7 V

-0.3 0 0.3 V

1.4 V

0.7 V

1µA

20 mV

-3.5 3.5 %

2.9 3 3.1 V

2.4 2.5 2.6 V

0.2 V

0.26 V

-0.1 -1 µA

99.5 V

PWM_LATCH

I

leak

V

H

PWM_STOP

I

leak

V

L

V

clamp

Low level leakage

current

High level

High level leakage

current

Low level

Clamp voltage

V

PWM_LATCH

I

PWM_LATCH

V

PWM_STOP

I

PWM_STOP

PFC_OK

= 2 mA

I

=0

= -0.5 mA

3.7 V

= 6V

= 0.5 mA

99.5 V

9/39

-1 µA

1µA

1V

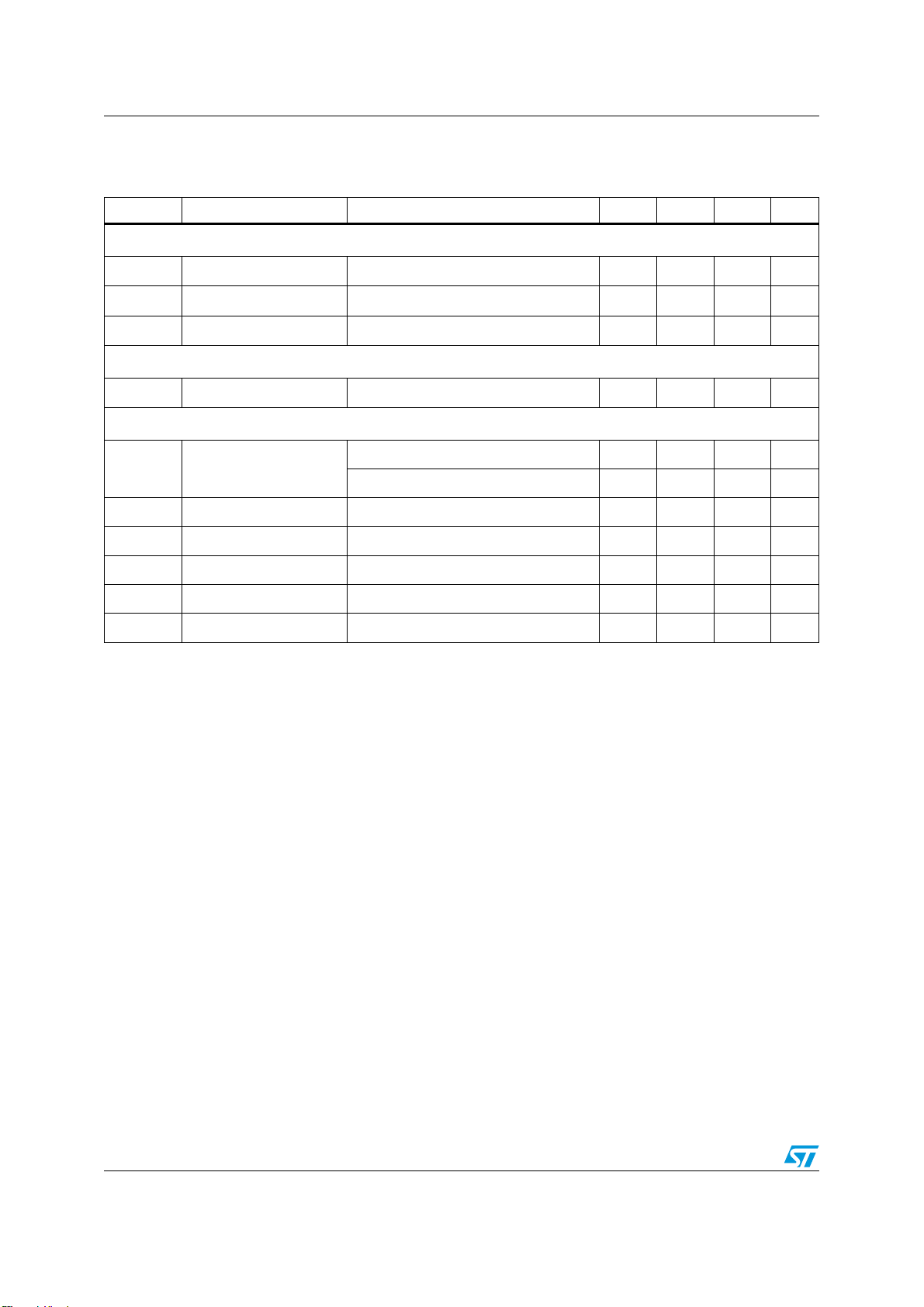

Electrical characteristics L6563 - L6563A

Table 5. Electrical characteristics (continued)

( -25°C < T

< +125°C, VCC = 12V, Co = 1nF between pin GD and GND, CFF =1µF between pin VFF

J

and GND; unless otherwise specified)

Symbol Parameter Test condition Min Typ Max Unit

Run function

I

RUN

V

DIS

V

EN

Start timer

t

START

Gate driver

V

OHdrop

V

OLdrop

t

f

t

r

V

Oclamp

V

Input bias current

Disable threshold

Enable threshold

= 0 to 3 V

RUN

Voltage falling

Voltage rising

(2)

(2)

-1 µA

0.5 0.52 0.54 V

0.56 0.6 0.64 V

Start timer period 75 150 300 µs

Dropout voltage

I

GDsource

I

GDsource

I

GDsink

= 20 mA

= 200 mA

= 200 mA

22.6V

2.5 3 V

12V

Current fall time 30 70 ns

Current rise time 40 80 ns

Output clamp voltage

UVLO saturation

(1), (2) Parameters tracking each other

(3) The multiplier output is given by:

(4) Parameters guaranteed by design, functionality tested in production.

I

GDsource

Vcc=0 to Vcc

= 5mA; Vcc = 20V

, I

=10mA

On

sink

V

------------------------------------------------------------ -

V

CSKM

⋅=

MULTVCOMP

V

2

VFF

10 12 15 V

1.1 V

2.5–()⋅

10/39

L6563 - L6563A Typical electrical performance

5 Typical electrical performance

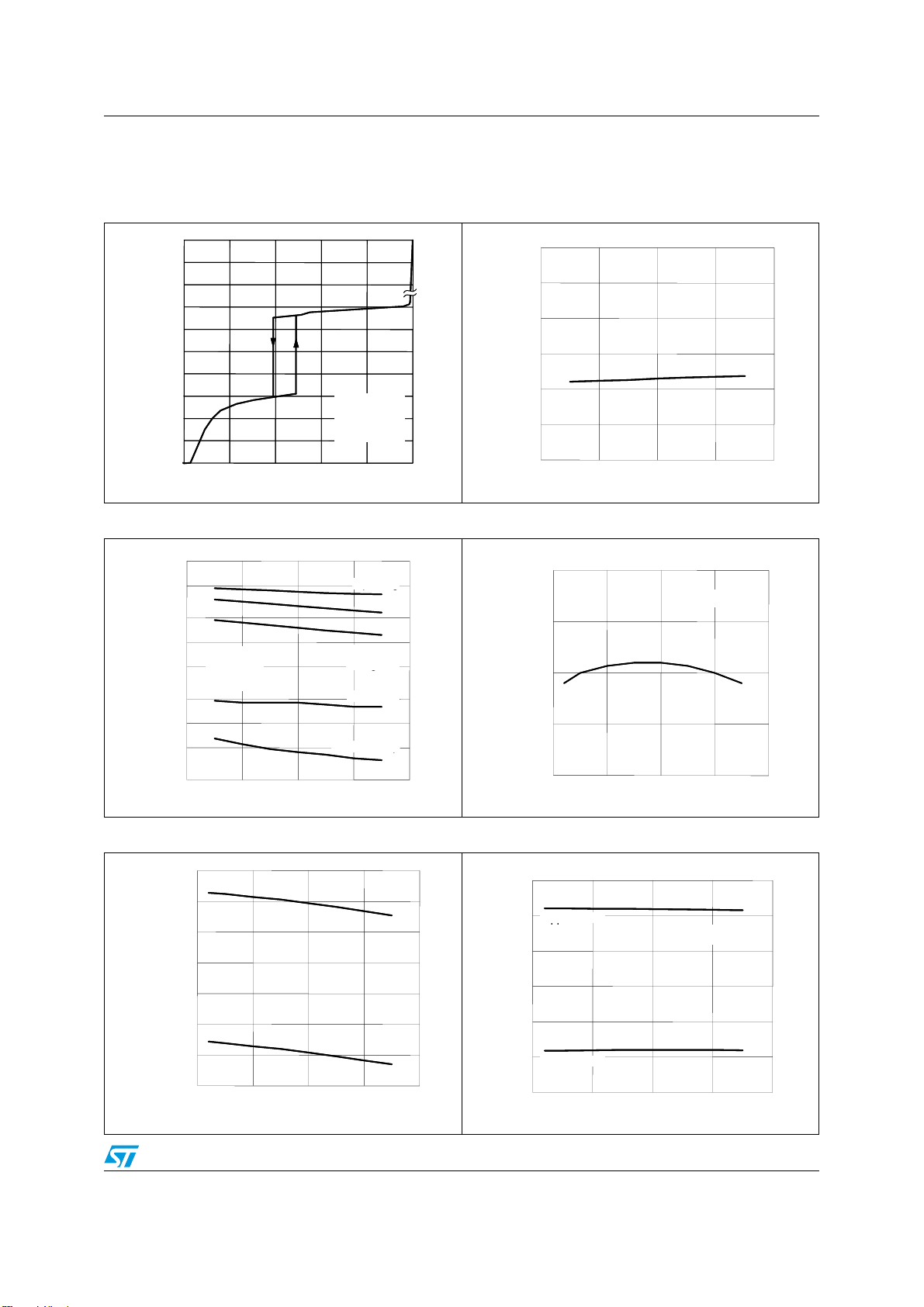

Figure 4. Supply current vs supply voltage Figure 5. V

z (pin 14)

z (pin 14)

Vcc

Icc

Icc

(mA)

(mA)

10

10

5

5

1

1

0.5

0.5

0.1

0.1

0.05

0.05

0.01

0.01

0.005

0.005

0

0

0 5 10 15 20

0 5 10 15 20

Vcc(V)

Vcc(V)

Figure 6. IC consumption vs T

Icc

Icc

10

10

(mA)

(mA)

5

5

2

2

1

1

Vcc = 12 V

Vcc = 12 V

0.5

0.5

Co = 1 nF

Co = 1 nF

f = 70 kHz

f = 70 kHz

0.2

0.2

0.1

0.1

0.05

0.05

Co = 1nF

Co = 1nF

f = 70 kHz

f = 70 kHz

j

j

= 25°C

= 25°C

T

T

J

Operating

Operating

Quiescent

Quiescent

Disabled or

Disabled or

during OVP

during OVP

Latched off

Latched off

Before start-up

Before start-up

25

25

Vcc

(V)

(V)

28

28

27

27

26

26

25

25

24

24

23

23

22

22

-50 0 50 100 150

-50 0 50 100 150

Figure 7. Feedback reference vs T

V

V

REF

REF

(pin 1)

(pin 1)

(V)

(V)

2.6

2.6

2.55

2.55

2.5

2.5

2.45

2.45

Zener voltage vs T

CC

Tj (°C)

Tj (°C)

J

J

Vcc = 12 V

Vcc = 12 V

0.02

0.02

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

Figure 8. Start-up & UVLO vs T

12.5

12.5

CC-ON

CC-ON

V

V

(V)

(V)

12

12

11.5

11.5

11

11

10.5

10.5

10

10

CC-OFF

CC-OFF

V

V

9.5

9.5

(V)

(V)

9

9

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

2.4

2.4

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

J

Figure 9. E/A output clamp levels vs T

V

V

COMP

COMP

(pin 2)

(pin 2)

7

7

(V)

(V)

6

6

Upper clamp

Upper clamp

Vcc = 12 V

Vcc = 12 V

5

5

4

4

3

3

2

2

Lower clamp

Lower clamp

1

1

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

J

11/39

Typical electrical performance L6563 - L6563A

Figure 10. Static OVP level vs T

V

V

COMP

COMP

(pin 2)

(pin 2)

2.5

2.5

(V)

(V)

2.4

2.4

2.3

2.3

2.2

2.2

2.1

2.1

2

2

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

J

Vcc = 12 V

Vcc = 12 V

Figure 12. Dynamic OVP current vs TJ

(normalized value)

I

I

OVP

OVP

120%

120%

Vcc = 12 V

Vcc = 12 V

110%

110%

Figure 11. Vcs clamp vs T

V

V

CSx (pin 4)

CSx (pin 4)

(V)

(V)

1.5

1.5

1.4

1.4

1.3

1.3

1.2

1.2

1.1

1.1

1

1

-50 0 50 100 150

-50 0 50 100 150

V

V

COMP

COMP

Tj (°C)

Tj (°C)

J

Vcc = 12 V

Vcc = 12 V

= Upper clamp

= Upper clamp

Figure 13. Current-sense offset vs

mains voltage phase angle

V

V

CSoffset (pin 4)

CSoffset (pin 4)

30

30

(mV)

(mV)

25

25

20

20

Vcc = 12 V

Vcc = 12 V

Tj = 25 °

Tj = 25 °

V

V

MULT

MULT

V

V

FF

FF

= 0 to 3V

= 0 to 3V

= 3V

= 3V

100%

100%

90%

90%

80%

80%

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

Figure 14. Delay-to-output vs T

t

t

D(H-L)

D(H-L)

300

300

(ns)

(ns)

250

250

200

200

150

150

100

100

50

50

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

J

Vcc = 12 V

Vcc = 12 V

15

15

10

10

5

5

0

0

0 0.628 1.256 1.884 2.512 3.14

0 0.628 1.256 1.884 2.512 3.14

V

V

MULT

MULT

V

V

= 0 to 0.7V

= 0 to 0.7V

= 0.7V

= 0.7V

FF

FF

θ(

θ(

°)

°)

Figure 15. Ic latch-off level on current sense vs

T

(L6563 only)

J

Vpin4

Vpin4

2.0

2.0

(V)

(V)

1.8

1.8

1.6

1.6

1.4

1.4

1.2

1.2

1.0

1.0

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

Vcc = 12 V

Vcc = 12 V

12/39

L6563 - L6563A Typical electrical performance

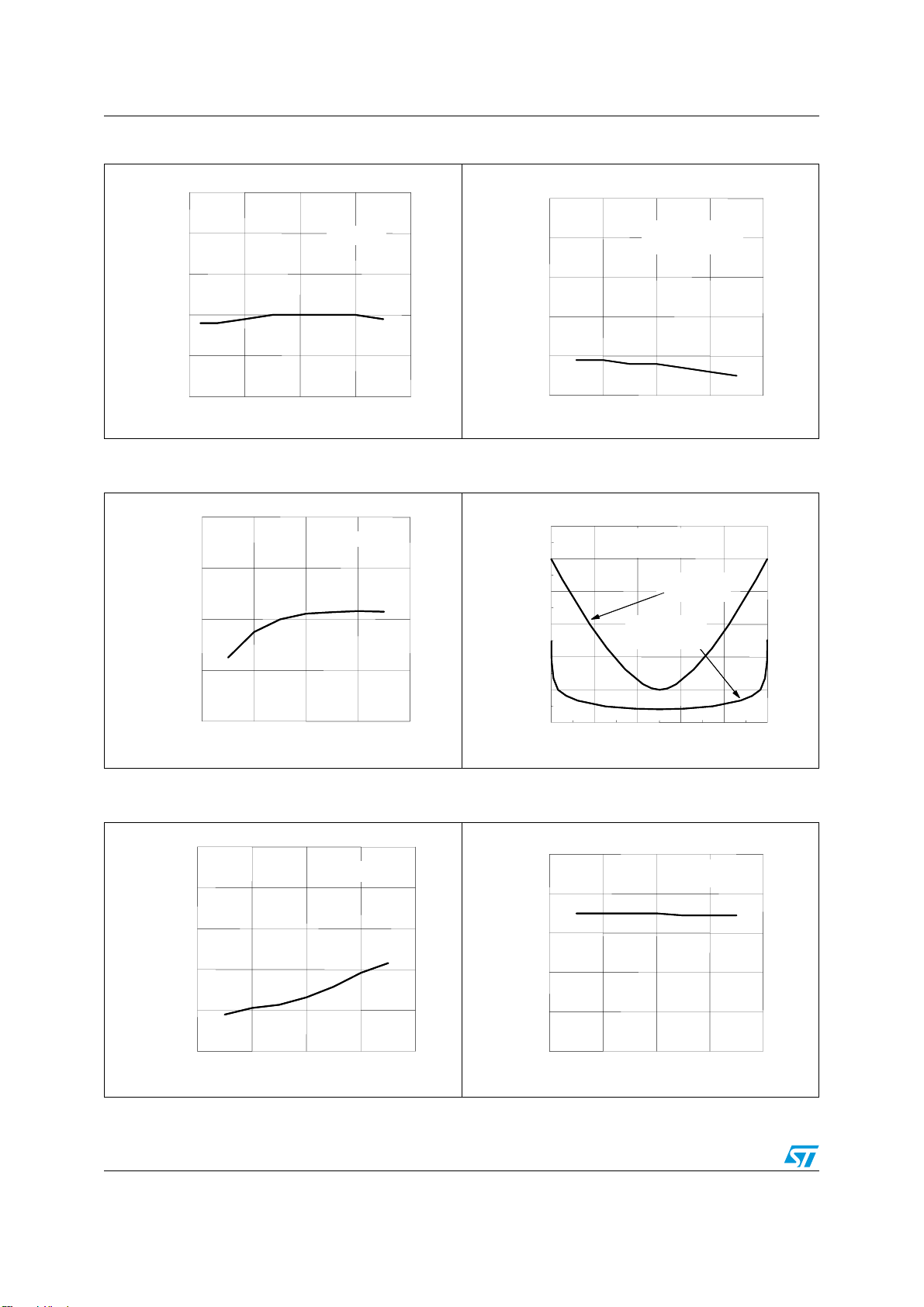

Figure 16. Multiplier characteristics @ V

V

V

CS

CS

(pin 4)

(pin 4)

(V)

(V)

Vcc = 12 V

Vcc = 12 V

Tj = 25 °C

Tj = 25 °C

1

1

0.8

0.8

0.6

0.6

0.4

0.4

0.2

0.2

0

0

0 0.2 0.4 0.6 0.8 1 1.2

0 0.2 0.4 0.6 0.8 1 1.2

V

V

MULT

MULT

upper voltag e

upper voltag e

clamp

clamp

(pin 3) (V)

(pin 3) (V)

3.5

3.5

3.0

3.0

2.6

2.6

5.5

5.5

5.0

5.0

4.5

4.5

4.0

4.0

V

V

COMP

COMP

= 1V Figure 17. ZCD clamp levels vs T

FF

V

(pin 2)

(pin 2)

(V)

(V)

V

ZCD (pin 11)

ZCD (pin 11)

7

7

(V)

(V)

6

6

5

5

4

4

3

3

2

2

1

1

0

0

-1

-1

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

J

Upper clamp

Upper clamp

Vcc = 12 V

Vcc = 12 V

= ±2.5 mA

= ±2.5 mA

I

I

ZCD

ZCD

Lower clamp

Lower clamp

Figure 18. Multiplier characteristics @ VFF = 3V Figure 19. ZCD source capability vs T

V

V

CS

CS

(pin 4)

(pin 4)

(V)

(V)

0.5

0.5

0.4

0.4

Vcc = 12 V

Vcc = 12 V

Tj = 25 °C

Tj = 25 °C

upper voltag e

upper voltag e

clamp

clamp

V

V

5.5

5.5

5.0

5.0

COMP

COMP

(pin 2)

(pin 2)

(V)

(V)

I

I

ZCDsrc

ZCDsrc

(mA)

(mA)

0

0

-2

-2

V

V

ZCD

ZCD

Vcc = 12 V

Vcc = 12 V

= lower clamp

= lower clamp

J

0.3

0.3

0.2

0.2

0.1

0.1

0

0

0 0.5 1 1.5 2 2.5 3 3.5

0 0.5 1 1.5 2 2.5 3 3.5

V

V

MULT

MULT

(pin 3) (V)

(pin 3) (V)

Figure 20. Multiplier gain vs T

K

K

M

M

1

1

V

Tj (°C)

Tj (°C)

V

V

V

MULT

MULT

0.8

0.8

0.6

0.6

0.4

0.4

0.2

0.2

0

0

-50 0 50 100 150

-50 0 50 100 150

J

Vcc = 12 V

Vcc = 12 V

=4 V

=4 V

COMP

COMP

= VFF=1V

= VFF=1V

3.5

3.5

3.0

3.0

2.6

2.6

4.5

4.5

4.0

4.0

-4

-4

-6

-6

-8

-8

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

Figure 21. VFF & TBO dropouts vs T

(mV)

(mV)

6

6

Vpin6 - Vpin5

Vpin6 - Vpin5

4

4

Vcc = 12 V

2

2

Vpin5 - Vpin3

Vpin5 - Vpin3

0

0

-2

-2

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

Vcc = 12 V

Vpin3 = 2.9 V

Vpin3 = 2.9 V

J

13/39

Typical electrical performance L6563 - L6563A

Figure 22. TBO current mismatch vs T

I(INV)-I(TBO)

I(INV)-I(TBO)

100·

100·

I(INV)

I(INV)

-0.8

-0.8

-1.0

-1.0

-1.2

-1.2

-1.4

-1.4

ITBO = 250 µA

ITBO = 250 µA

-1.6

-1.6

-1.8

-1.8

-2.0

-2.0

-2.2

-2.2

-2.4

-2.4

ITBO = 25 µA

ITBO = 25 µA

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

Vcc = 12 V

Vcc = 12 V

J

Figure 24. TBO-INV current mismatch vs

TBO currents

I(INV)-I(TBO)

I(INV)-I(TBO)

100·

100·

I(INV)

I(INV)

-1.6

-1.6

Vcc = 12 V

-1.7

-1.7

-1.8

-1.8

-1.9

-1.9

-2.0

-2.0

-2.1

-2.1

-2.2

-2.2

-2.3

-2.3

0 100 200 300 400 500 600

0 100 200 300 400 500 600

I(TBO)

I(TBO)

Vcc = 12 V

Tj = 25 °C

Tj = 25 °C

Figure 23. RUN thresholds vs T

Vpin10

Vpin10

1.0

1.0

(V)

(V)

0.8

0.8

ON

ON

0.6

0.6

OFF

OFF

0.4

0.4

0.2

0.2

0.0

0.0

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

J

Vcc = 12 V

Vcc = 12 V

Figure 25. PWM_LATCH high saturation vs T

Vpin8

Vpin8

5.3

5.3

(V)

(V)

5.2

5.2

5.1

5.1

5.0

5.0

4.9

4.9

4.8

4.8

4.7

4.7

4.6

4.6

4.5

4.5

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

Vcc = 12 V

Vcc = 12 V

Isource = 50 µA

Isource = 50 µA

Isource = 500 µA

Isource = 500 µA

J

Figure 26. TBO clamp vs T

Vpin6

Vpin6

3.5

3.5

(V)

(V)

3.25

3.25

3

3

2.75

2.75

2.5

2.5

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

J

Vcc = 12 V

Vcc = 12 V

Vpin3= 4 V

Vpin3= 4 V

14/39

Figure 27. PWM_STOP low saturation vs T

Vpin9

Vpin9

5.0

5.0

0.50

0.50

(V)

(V)

Vcc = 12 V

0.40

0.40

4.0

4.0

3.0

3.0

0.30

0.30

2.0

2.0

0.20

0.20

1.0

1.0

0.10

0.10

0

0

0.0

0.0

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

Vcc = 12 V

Isink = 0.5 mA

Isink = 0.5 mA

J

L6563 - L6563A Typical electrical performance

Figure 28. PFC_OK thresholds vs T

Vpin7

Vpin7

3.0

3.0

(V)

(V)

Latch-off

2.0

2.0

1.0

1.0

0.5

0.5

0.3

0.3

0.2

0.2

0.1

0.1

Figure 30. Start-up timer vs T

Tstart

Tstart

150

150

(µs)

(µs)

140

140

130

130

Latch-off

ON

ON

OFF

OFF

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

Vcc = 12 V

Vcc = 12 V

J

Vcc = 12 V

Vcc = 12 V

J

Figure 29. UVLO saturation vs T

Vpin15

Vpin15

1.1

1.1

(V)

(V)

1

1

0.9

0.9

0.8

0.8

0.7

0.7

0.6

0.6

0.5

0.5

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

J

Vcc = 0 V

Vcc = 0 V

Figure 31. Gate-drive output low saturation

Vpin15 (V)

Vpin15 (V)

4

4

3

3

Tj = 25 °C

Tj = 25 °C

Vcc = 11 V

Vcc = 11 V

SINK

SINK

120

120

110

110

100

100

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

Figure 32. Gate-drive clamp vs T

Vpin15

Vpin15

clamp

clamp

(V)

(V)

12

12

11.5

11.5

11

11

10.5

10.5

10

10

-50 0 50 100 150

-50 0 50 100 150

Tj (°C)

Tj (°C)

J

Vcc = 20 V

Vcc = 20 V

2

2

1

1

0

0

0 200 400 600 800 1,000

0 200 400 600 800 1,000

IGD(mA)

IGD(mA)

Figure 33. Gate-drive output high saturation

V

(V)

V

(V)

pin15

pin15

-1.5

-1.5

Tj = 25 °C

-2

-2

Vcc - 2.0

Vcc - 2.0

-2.5

-2.5

Vcc - 2.5

Vcc - 2.5

-3

-3

Vcc - 3.0

Vcc - 3.0

-3.5

-3.5

Vcc - 3.5

Vcc - 3.5

-4

-4

Vcc - 4.0

Vcc - 4.0

-4.5

-4.5

0 100 200 300 400 500 600 700

0 100 200 300 400 500 600 700

IGD(mA)

IGD(mA)

Tj = 25 °C

Vcc = 11 V

Vcc = 11 V

SOURCE

SOURCE

15/39

Application information L6563 - L6563A

6 Application information

6.1 Overvoltage protection

Normally, the voltage control loop keeps the output voltage VO of the PFC pre-regulator

close to its nominal value, set by the ratio of the resistors R1 and R2 of the output divider.

Neglecting the ripple components, under steady state conditions the current through R1

equals that through R2. Considering that the non-inverting input of the error amplifier is

internally biased at 2.5V, the voltage at pin INV will be 2.5V as well, then:

Equation 1

V

I

R2IR1

2.5

------- -

R2

If the output voltage experiences an abrupt change ∆Vo the voltage at pin INV is kept at 2.5V

by the local feedback of the error amplifier, a network connected between pins INV and

COMP that introduces a long time constant. Then the current through R2 remains equal to

2.5/R2 but that through R1 becomes:

O

--------------------- -===

2.5–

R1

Equation 2

VO2.5– VO∆+

I'

--------------------------------------- -=

The difference current ∆I

R1

= I’R1 - I’R1 = ∆VO/R1 will flow through the compensation network

R1

R1

and enter the error amplifier (pin COMP). This current is monitored inside the IC and when it

reaches about 18 µA the output voltage of the multiplier is forced to decrease, thus reducing

the energy drawn from the mains. If the current exceeds 20 µA, the OVP is triggered

(Dynamic OVP), and the external power transistor is switched off until the current falls

approximately below 5 µA. However, if the overvoltage persists (e.g. in case the load is

completely disconnected), the error amplifier will eventually saturate low hence triggering an

internal comparator (Static OVP) that will keep the external power switch turned off until the

output voltage comes back close to the regulated value. The output overvoltage that is able

to trigger the OVP function is then:

Equation 3

∆

VO = R1 · 20 · 10

-6

16/39

L6563 - L6563A Application information

An important advantage of this technique is that the overvoltage level can be set

independently of the regulated output voltage: the latter depends on the ratio of R1 to R2,

the former on the individual value of R1. Another advantage is the precision: the tolerance of

the detection current is 15%, which means 15% tolerance on the ∆V

. Since it is usually

O

much smaller than Vo, the tolerance on the absolute value will be proportionally reduced.

Example: V

= 400V, ∆VO = 40V.

O

Then: R1 = 40V/20µA = 2MΩ ; R2 = 2.5·2MΩ·/(400-2.5) = 12.58kΩ.

The tolerance on the OVP level due to the L6563/A will be 40·0.15 = 6 V, that is ± 1.36%.

When either OVP is activated the quiescent consumption is reduced to minimize the

discharge of the Vcc capacitor.

Figure 34. Output voltage setting, OVP and FFP functions: internal block diagram

Vout

R4

R1

{

R1a

R1b

PFC_OK

INV

R2

0.26V

7

9.5V

1

9.5V

I

TBO

Frequency

Compensation

2.5V

+

-

+

-

+

E/A

-

TBO

FUNCTION

FAULT (not latched)

FAULT (latched)

2.25V

-

+

20 µA

2

COMP

Static OVP

Dynamic OVP

L6563

L6563A

R3

{

R3a

R3b

17/39

Application information L6563 - L6563A

6.2 Feedback Failure Protection (FFP)

The OVP function above described is able to handle "normal" overvoltage conditions, i.e.

those resulting from an abrupt load/line change or occurring at start-up. It cannot handle the

overvoltage generated, for instance, when the upper resistor of the output divider (R1) fails

open: the voltage loop can no longer read the information on the output voltage and will

force the PFC pre-regulator to work at maximum ON-time, causing the output voltage to rise

with no control.

A pin of the device (PFC_OK) has been dedicated to provide an additional monitoring of the

output voltage with a separate resistor divider (R3 high, R4 low, see Figure 34). This divider

is selected so that the voltage at the pin reaches 2.5V if the output voltage exceeds a preset

value, usually larger than the maximum Vo that can be expected, also including worst-case

load/line transients.

Example: V

= 400 V, Vox = 475V. Select: R3 = 3MΩ;

O

then: R4 = 3MΩ ·2.5/(475-2.5) = 15.87kΩ.

When this function is triggered, the gate drive activity is immediately stopped, the device is

shut down, its quiescent consumption is reduced below 250 µA and the condition is latched

as long as the supply voltage of the IC is above the UVLO threshold. At the same time the

pin PWM_LATCH is asserted high. PWM_LATCH is an open source output able to deliver

3.7V min. with 0.5 mA load, intended for tripping a latched shutdown function of the PWM

controller IC in the cascaded DC-DC converter, so that the entire unit is latched off. To

restart the system it is necessary to recycle the input power, so that the Vcc voltages of both

the L6563/A and the PWM controller go below their respective UVLO thresholds.

The PFC_OK pin doubles its function as a not-latched IC disable: a voltage below 0.2V will

shut down the IC, reducing its consumption below 1 mA. In this case both PWM_STOP and

PWM_LATCH keep their high impedance status. To restart the IC simply let the voltage at

the pin go above 0.26 V.

Note that this function offers a complete protection against not only feedback loop failures or

erroneous settings, but also against a failure of the protection itself. Either resistor of the

PFC_OK divider failing short or open or a PFC_OK pin floating will result in shutting down

the IC and stopping the pre-regulator.

6.3 Voltage Feedforward

The power stage gain of PFC pre-regulators varies with the square of the RMS input

voltage. So does the crossover frequency f

has a single pole characteristic. This leads to large trade-offs in the design.

For example, setting the gain of the error amplifier to get f

having f

control loop causes large transient current flow during rapid line or load changes that are

limited by the dynamics of the multiplier output. This limit is considered when selecting the

sense resistor to let the full load power pass under minimum line voltage conditions, with

some margin. But a fixed current limit allows excessive power input at high line, whereas a

fixed power limit requires the current limit to vary inversely with the line voltage.

Voltage Feedforward can compensate for the gain variation with the line voltage and allow

overcoming all of the above-mentioned issues. It consists of deriving a voltage proportional

to the input RMS voltage, feeding this voltage into a squarer/divider circuit (1/V

and providing the resulting signal to the multiplier that generates the current reference for

the inner current control loop (see Figure 35).

≅ 4 Hz @ 88 Vac, resulting in a sluggish control dynamics. Additionally, the slow

c

of the overall open-loop gain because the gain

c

= 20 Hz @ 264 Vac means

c

2

corrector)

18/39

L6563 - L6563A Application information

Figure 35. Voltage feedforward: squarer-divider (1/V2) block diagram and transfer

characteristic

Vcsx

2

V

=4V

1.5

1

0.5

0

0.5

01234

V

FF=VMULT

COMP

Actual

Ideal

current

reference

(Vcsx)

L6563

L6563A

MULTI PL IER

E/ A o ut put

COMP

(V

1/V

C

VFF

FF

Rectif ied mains

)

"ideal" diode

2

5

-

+

9.5V

R

FF

R5

3

MULT

R6

In this way a change of the line voltage will cause an inversely proportional change of the

half sine amplitude at the output of the multiplier (if the line voltage doubles the amplitude of

the multiplier output will be halved and vice versa) so that the current reference is adapted to

the new operating conditions with (ideally) no need for invoking the slow dynamics of the

error amplifier. Additionally, the loop gain will be constant throughout the input voltage

range, which improves significantly dynamic behavior at low line and simplifies loop design.

Actually, deriving a voltage proportional to the RMS line voltage implies a form of integration,

which has its own time constant. If it is too small the voltage generated will be affected by a

considerable amount of ripple at twice the mains frequency that will cause distortion of the

current reference (resulting in high THD and poor PF); if it is too large there will be a

considerable delay in setting the right amount of feedforward, resulting in excessive

overshoot and undershoot of the pre-regulator's output voltage in response to large line

voltage changes. Clearly a trade-off is required.

The device realizes Voltage Feedforward with a technique that makes use of just two

external parts and that limits the feedforward time constant trade-off issue to only one

direction. A capacitor C

and a resistor RFF , both connected from the VFF (pin 5) pin to

FF

ground, complete an internal peak-holding circuit that provides a DC voltage equal to the

peak of the rectified sine wave applied on pin MULT (pin 3). R

discharge C

sudden line voltage rise, C

when the line voltage decreases (see Figure 35). In this way, in case of

FF

will be rapidly charged through the low impedance of the

FF

provides a means to

FF

internal diode and no appreciable overshoot will be visible at the pre-regulator's output; in

case of line voltage drop C

will be discharged with the time constant RFF·CFF, which can

FF

be in the hundred ms to achieve an acceptably low steady-state ripple and have low current

distortion; consequently the output voltage can experience a considerable undershoot, like

in systems with no feedforward compensation.

19/39

Application information L6563 - L6563A

The twice-mains-frequency (2·fL) ripple appearing across CFF is triangular with a peak-topeak amplitude that, with good approximation, is given by:

Equation 4

2V

MULTpk

---------------------------------------=

VFF∆

14fLRFFC

+

FF

where f

ripple, related to the amplitude of its 2·f

is the line frequency. The amount of 3rd harmonic distortion introduced by this

L

component, will be:

L

Equation 5

D

%

3

Figure 36 shows a diagram that helps choose the time constant R

amount of maximum desired 3

rd

harmonic distortion. Always connect RFF and CFF to the

---------------------------------=

2πf

LRFFCFF

100

FF·CFF

based on the

pin, the IC will not work properly if the pin is either left floating or connected directly to

ground.

Figure 36. R

as a function of 3rd harmonic distortion introduced in the input

FF·CFF

current

10

R · C [s]

FFFF

0.1

1

f = 60 Hz

L

f = 50 Hz

L

0.01

0.1 1 10

The dynamics of the voltage feedforward input is limited downwards at 0.5V (see Figure 35),

that is the output of the multiplier will not increase any more if the voltage on the V

below 0.5V. This helps to prevent excessive power flow when the line voltage is lower than

the minimum specified value (brownout conditions).

20/39

D %

3

pin is

FF

L6563 - L6563A Application information

6.4 THD optimizer circuit

The L6563/A is provided with a special circuit that reduces the conduction dead-angle

occurring to the AC input current near the zero-crossings of the line voltage (crossover

distortion). In this way the THD (Total Harmonic Distortion) of the current is considerably

reduced.

A major cause of this distortion is the inability of the system to transfer energy effectively

when the instantaneous line voltage is very low. This effect is magnified by the highfrequency filter capacitor placed after the bridge rectifier, which retains some residual

voltage that causes the diodes of the bridge rectifier to be reverse-biased and the input

current flow to temporarily stop.

To overcome this issue the device forces the PFC pre-regulator to process more energy

near the line voltage zero-crossings as compared to that commanded by the control loop.

This will result in both minimizing the time interval where energy transfer is lacking and fully

discharging the high-frequency filter capacitor after the bridge.

Figure 37 shows the internal block diagram of the THD optimizer circuit.

Figure 37. THD optimizer circuit

t

t

VFF

VFF

MULT

MULT

t

t

@ Vac1

@ Vac1

@ Vac2 > Vac1

@ Vac2 > Vac1

2

2

1 / V

1 / V21 / V

MULTIPLIER

MULTIPLIERMULTIPLIER

OFFSET

OFFSET

OFFSET

GENERATOR

GENERATOR

GENERATOR

COMP

COMP

t

t

+

+

+

+

t

t

to PWM

to PWM

comparator

comparator

t

t

t

t

21/39

Application information L6563 - L6563A

Figure 38. THD optimization: standard TM PFC controller (left side) and L6563/A

(right side)

Input current Input current

Rectified mains voltage Rectified mains voltage

Imains

Input current

MOSFET's drain voltage

Vdrain

Imains

Input current

MOSFET's drain voltage

Vdrain

Essentially, the circuit artificially increases the ON-time of the power switch with a positive

offset added to the output of the multiplier in the proximity of the line voltage zero-crossings.

This offset is reduced as the instantaneous line voltage increases, so that it becomes

negligible as the line voltage moves toward the top of the sinusoid. Furthermore the offset is

modulated by the voltage on the V

pin (see Section 6.3 on page 18 section) so as to have

FF

little offset at low line, where energy transfer at zero crossings is typically quite good, and a

larger offset at high line where the energy transfer gets worse.

The effect of the circuit is shown in Figure 38, where the key waveforms of a standard TM

PFC controller are compared to those of this chip.

To take maximum benefit from the THD optimizer circuit, the high-frequency filter capacitor

after the bridge rectifier should be minimized, compatibly with EMI filtering needs. A large

capacitance, in fact, introduces a conduction dead-angle of the AC input current in itself even with an ideal energy transfer by the PFC pre-regulator - thus reducing the effectiveness

of the optimizer circuit.

22/39

L6563 - L6563A Application information

6.5 Tracking Boost function

In some applications it may be advantageous to regulate the output voltage of the PFC preregulator so that it tracks the RMS input voltage rather than at a fixed value like in

conventional boost pre-regulators. This is commonly referred to as "tracking boost" or

"follower boost" approach.

With this IC the function can be realized by connecting a resistor (R

) between the TBO pin

T

and ground. The TBO pin presents a DC level equal to the peak of the MULT pin voltage and

is then representative of the mains RMS voltage. The resistor defines a current, equal to

V(TBO)/R

, that is internally 1:1 mirrored and sunk from pin INV (pin 1) input of the error

T

amplifier. In this way, when the mains voltage increases the voltage at TBO pin will increase

as well and so will do the current flowing through the resistor connected between TBO and

GND. Then a larger current will be sunk by INV pin and the output voltage of the PFC preregulator will be forced to get higher. Obviously, the output voltage will move in the opposite

direction if the input voltage decreases.

To avoid undesired output voltage rise should the mains voltage exceed the maximum

specified value, the voltage at the TBO pin is clamped at 3V. By properly selecting the

multiplier bias it is possible to set the maximum input voltage above which input-to-output

tracking ends and the output voltage becomes constant. If this function is not used, leave

the pin open: the device will regulate a fixed output voltage.

Starting from the following data:

● Vin

● Vin

● Vo

● Vo

● Vox = absolute maximum limit for the regulated output voltage;

● ∆Vo = OVP threshold,

= minimum specified input RMS voltage;

1

= maximum specified input RMS voltage;

2

= regulated output voltage @ Vin = Vin1;

1

= regulated output voltage @ Vin = Vin2;

2

23/39

Application information L6563 - L6563A

to set the output voltage at the desired values use the following design procedure:

1. Determine the input RMS voltage Vin

that produces Vo = Vox:

clamp

Equation 6

and choose a value Vin

Vox Vo1–

Vin

clamp

such that Vin2 = Vinx < Vin

x

---------------------------

Vo

Vo1–

2

Vin

Vox Vo2–

---------------------------

2

Vo

2

. This will result in a limitation of the

clamp

Vin1⋅–⋅=

Vo1–

output voltage range below Vox (it will equal Vox if one chooses Vin

2. Determine the divider ratio of the MULT pin (pin 3) bias:

Equation 7

k

and check that at minimum mains voltage Vin

3

-----------------------=

2Vin

⋅

x

the peak voltage on pin 3 is greater than

1

0.65V.

3. Determine R1, the upper resistor of the output divider:

Equation 8

Vo∆

---------- -

R1

20

106⋅=

= Vin

x

clamp

)

4. Calculate the lower resistor R

of the output divider and the adjustment resistor RT:

2

Equation 9

R2 2.5 R1

R

T

2kR1

24/39

--------------------------------------------------------------------------------------------------

⋅⋅=

Vo

Vin2Vin

⋅⋅ ⋅=

----------------------------- -

1

Vo

2.5–()Vin2Vo22.5–()Vin1⋅–⋅

–

2

Vin

–

Vin

2

1

1

Vo1–

L6563 - L6563A Application information

5. Check that the maximum current sourced by the TBO pin (pin 6) does not exceed the

maximum specified (0.25mA):

Equation 10

I

TBOmax

3

------ -

R

0.25 10

T

3–

⋅≤=

In the following Mathcad® sheet, as an example, the calculation is shown for the circuit

illustrated in Figure 40. Figure 41 shows the internal block diagram of the tracking boost

function.

Design data

Vin1 := 88V Vo1:= 200V

Vin

:= 264V Vo2:= 385V

2

Vox ;= 400V

∆Vo ;= 40V

Step 1

Vin

clamp

Vox Vo1–

---------------------------

:

Vo

⋅=

Vo1–

2

Vin

Vox Vo2–

---------------------------

2

Vo

Vin

⋅–

Vo1–

2

1

Vin

clamp

= 278.27V

choose: Vinx: = 270V

Step 2

k:

⋅

2Vin

3

-----------------------=

Step 3

Vo∆

---------- -

R1:

20

k = 7.857 x 10

x

106⋅=

25/39

R1 = 2 x 106 Ω

-3

Application information L6563 - L6563A

Step 4

Vin

–

Vin

2

R2: 2.5 R1

RT:k2R1

⋅⋅⋅=

--------------------------------------------------------------------------------------------------

⋅⋅=

Vo

2.5–()Vin2Vo22.5–()Vin1⋅–⋅

1

Vin

–

Vin

2

----------------------------- -

Vo1–

Vo

2

1

1

R2 = 4.762 x 104 Ω

RT = 2.114 x 104 Ω

Step 5

3

I

TBOmax

:

⋅=

10

R

T

3

------ -

I

TBOmax

= 0.142 mA

Vo(Vi) : =

V

MULTpk

V

TBO

2.5 1

k2Vi⋅⋅←

if V

MULTpk

R1

⎛⎞

------- -+

V

⎝⎠

R2

TBO

3,V

⋅+⋅

MULTpk

R1

------- -

R

T

Vo(Vin1) = 200V

Vo(Vin2) = 385V

,3<()←

Vo(VinX) = 391.307V

Figure 39. Output voltage vs. input voltage characteristic with TBO

400

350

Vin

Vo

)

(

300

250

200

100

150

Vin

200

250

Vin

Vin

2

Vo

2

x

300

26/39

L6563 - L6563A Application information

FUSE

4A/250V

BRIDGE

4 x 1N4007

+

-

Vout

D1

MOS

Rectified mains

3

MULT

FF

R5

R6

NTC

R8a

1 M

R8b

1 M

47.5 k

R10a

3.3 M

Ω

Ω

R9

Ω

R10b

3.3 M

Ω

R11

34.8 k

Ω

Ω

STTH1L06

T

R5

62 k

Ω

C6 100 nF

1

13

4

7

10 nF

Ω

C7

C5

1 µF

R6

10

Ω

R7a,b

0.68

1/4 W

STP8NM50

Ω

C1

0.22 µF

400V

R2

51.1 k

Supply Voltage

10.3 to 22V

14

3

12

C4

470 nF

R3

68 k

Ω

11

8

9

2

L6563

5

6

10

R4

R10

21 k

390 k

Ω

R1a

3.3 M

Ω

R1b

3.3 M

Ω

Ω

C2

2.2nF

C3

F

22

m

25V

COMP

I

R1

R1

1

INV

I

R2

R2

9.5V

I

TBO

2.5V

+

E/A

-

1:1 CURRENT

MIRROR

L6563

L6563A

I

TBO

2

current

reference

MULTIPLIER

3V

6

TBO

R

T

1/V

2

"ideal"

-

diode

+

9.5V

5

VFF

C

FF

R

Figure 40. 80W, wide-range-mains PFC pre-regulator with tracking boost function active

Vac

(88V to 264V)

Figure 41. Tracking boost and voltage feedforward blocks

Vo=200 to 385 V

Po=80W

C6

56 µF

400V

6.6 Inductor saturation detection (L6563 only)

Boost inductor's hard saturation may be a fatal event for a PFC pre-regulator: the current

upslope becomes so large (50-100 times steeper, see Figure 42) that during the current

sense propagation delay the current may reach abnormally high values. The voltage drop

caused by this abnormal current on the sense resistor reduces the gate-to-source voltage,

so that the MOSFET may work in the active region and dissipate a huge amount of power,

which leads to a catastrophic failure after few switching cycles.

However, in some applications such as ac-dc adapters, where the PFC pre-regulator is

turned off at light load for energy saving reasons, even a well-designed boost inductor may

occasionally slightly saturate when the PFC stage is restarted because of a larger load

demand. This happens when the restart occurs at an unfavorable line voltage phase, so that

the output voltage may drop significantly below the rectified peak voltage. As a result, in the

27/39

Application information L6563 - L6563A

boost inductor the inrush current coming from the bridge rectifier adds up to the switched

current and, furthermore, there is little or no voltage available for demagnetization.

To cope with a saturated inductor, the L6563 is provided with a second comparator on the

current sense pin (CS, pin 4) that stops and latches off the IC if the voltage, normally limited

within 1.1V, exceeds 1.7V. Also the cascaded DC-DC converter can be stopped via the

PWM_LATCH pin that is asserted high. In this way the entire system is stopped and enabled

to restart only after recycling the input power, that is when the Vcc voltages of the L6563

and the PWM controller go below their respective UVLO thresholds. System safety will be

considerably increased.

To better suit the applications where a certain level of saturation of the boost inductor needs

to be tolerated, the L6563A does not support this protection function.

Figure 42. Effect of boost inductor saturation on the MOSFET current and detection method

6.7 Power management/housekeeping functions

A special feature of this IC is that it facilitates the implementation of the "housekeeping"

circuitry needed to coordinate the operation of the PFC stage to that of the cascaded DCDC converter. The functions realized by the housekeeping circuitry ensure that transient

conditions like power-up or power down sequencing or failures of either power stage be

properly handled.

This device provides some pins to do that. As already mentioned, one communication line

between the IC and the PWM controller of the cascaded DC-DC converter is the

PWM_LATCH pin, which is normally open when the PFC works properly and goes high if it

loses control of the output voltage (because of a failure of the control loop) or if the boost

inductor saturates, with the aim of latching off the PWM controller of the cascaded DC-DC

converter as well (Section 6.2: Feedback Failure Protection (FFP) on page 18 for more

details).

A second communication line can be established via the disable function included in the

PFC_OK pin (Section 6.2 on page 18 for more details ). Typically this line is used to allow

the PWM controller of the cascaded DC-DC converter to shut down the L6563/A in case of

light load, to minimize the no-load input consumption. Should the residual consumption of

the chip be an issue, it is also possible to cut down the supply voltage. Interface circuits like

those shown in Figure 43, where the L6563/A works along with the L5991, PWM controller

with standby function, can be used. Needless to say, this operation assumes that the

cascaded DC-DC converter stage works as the master and the PFC stage as the slave or, in

other words, that the DC-DC stage starts first, it powers both controllers and

enables/disables the operation of the PFC stage.

28/39

L6563 - L6563A Application information

Figure 43. Interface circuits that let DC-DC converter’s controller IC disable the L6563/A at light

Vcc

16

L6668

load

16

4

100 nF

ST-BY

Vref

14

27

k

100

150

k

Ω

k

150

k

10 k

PFC_STOP

Ω

Ω

Ω

Ω

BC557

BC557

8.2 V

2.2 k

Ω

L6563

47

k

Ω

BC547

7

PFC_OK

BC547

Vcc

14

L6563

L6563A

L5991/A

VREF

8

ST-BY

16

4

Vref

100 nF

100 k

L6668

100

k

Ω

Ω

PFC_STOP

14

27

k

Ω

150

k

Ω

150

k

Ω

2.2 k

BC557

Ω

Vcc

PFC_OK

L6563

14

100 nF

(RUN)

BC547

BC557

7

(10)

15

k

Ω

BC547

L6563

L6563A

Supply_Bus

L5991/A

14

PFC_STOP

L6599

PFC_OK

(RUN)

7

(10)

L6563

L6563A

The third communication line is the PWM_STOP pin (pin 9), which works in conjunction with

the RUN pin (pin 10). The purpose of the PWM_STOP pin is to inhibit the PWM activity of

both the PFC stage and the cascaded DC-DC converter. The pin is an open collector,

normally open, that goes low if the device is disabled by a voltage lower than 0.52V on the

RUN pin. It is important to point out that this function works correctly in systems where the

PFC stage is the master and the cascaded DC-DC converter is the slave or, in other words,

where the PFC stage starts first, powers both controllers and enables/disables the operation

of the DC-DC stage.

This function is quite flexible and can be used in different ways. In systems comprising an

auxiliary converter and a main converter (e.g. desktop PC's silver box or hi-end LCD-TV),

where the auxiliary converter also powers the controllers of the main converter, the pin RUN

can be used to start and stop the main converter. In the simplest case, to enable/disable the

PWM controller the PWM_STOP pin can be connected to either the output of the error

amplifier (Figure 44 a) or, if the chip is provided with it, to its soft-start pin (Figure 44 b). The

use of the soft-start pin allows the designer to delay the start-up of the DC-DC stage with

respect to that of the PFC stage, which is often desired. An underlying assumption in order

for that to work properly is that the UVLO thresholds of the PWM controller are certainly

higher than those of the L6563/A.

29/39

Application information L6563 - L6563A

Figure 44. Interface circuits that let the L6563/A switch on or off a PWM controller

If this is not the case or it is not possible to achieve a start-up delay long enough (because

this prevents the DC-DC stage from starting up correctly) or, simply, the PWM controller is

devoid of soft start, the arrangement of Figure 45 lets the DC-DC converter start-up when

the voltage generated by the PFC stage reaches a preset value. The technique relies on the

UVLO thresholds of the PWM controller.

Figure 45. Interface circuits for actual power-up sequencing (master PFC)

Another possible use of the RUN and PWM_STOP pins (again, in systems where the PFC

stage is the master) is brownout protection, thanks to the hysteresis provided.

Brownout protection is basically a not-latched device shutdown function that must be

activated when a condition of mains undervoltage is detected. This condition may cause

overheating of the primary power section due to an excess of RMS current. Brownout can

also cause the PFC pre-regulator to work open loop and this could be dangerous to the PFC

stage itself and the downstream converter, should the input voltage return abruptly to its

rated value. Another problem is the spurious restarts that may occur during converter power

down and that cause the output voltage of the converter not to decay to zero monotonically.

For these reasons it is usually preferable to shutdown the unit in case of brownout.

30/39

L6563 - L6563A Application information

IC shutdown upon brownout can be easily realized as shown in Figure 46 The scheme on

the left is of general use, the one on the right can be used if the bias levels of the multiplier

and the R

time constant are compatible with the specified brownout level and with the

FF·CFF

specified holdup time respectively.

In Ta bl e 6 it is possible to find a summary of all of the above mentioned working conditions

that cause the device to stop operating.

Figure 46. Brownout protection (master PFC)

AC mains

L6563

L6563A

RUN

10

5

VFF

10

RUN

L6563

L6563A

R

FF

C

FF

6.8 Summary of L6563/A idle states

.

Table 6. Summary of L6563/A idle states

Condition

UVLO Vcc < 8.7 V Open Open 50 µA Auto-restart

Feedback

disconnected

Saturated

Boost Inductor

AC Brownout RUN < 0.52 V Open Active (low) 1.5 mA Auto-restart

Standby PFC_OK < 0.2 V Open Open 1.5 mA Auto-restart

Caused or

revealed by

PFC_OK > 2.5 V Active (high) Open 180 µA Latched

Vcs > 1.7 V

(L6563 only)

PWM_LATCH

(pin 8)

Active (high)

(L6563 only)

PWM_STOP

(pin 9)

Open 180 µA

consumption

(L6563 only)

Typical IC

IC behavior

Latched

(L6563 only)

31/39

Application examples and ideas L6563 - L6563A

7 Application examples and ideas

Figure 47. Demo board (EVAL6563-80W) 80W, Wide-range, Tracking Boost: Electrical schematic

NTC

R3A

120 k

C1

FUSE

4A/250V

Vac

(88V to 264V)

P1

1W08G

+

-

0.47 µF

400V

R11A

1 M

R11B

1 M

R10

15.8 k

4.7 nF

Boost inductor spec:

E25x13x7 core, 3C85 ferrite or equivalent

1.6 mm gap for 0.43 mH primary inductance

Primary: 80 turns 20 x 0.1 mm

Secondary: 9 turns 0.1 mm

Daux

1N4007

C9

470 nF

R14

R1

47 k

11

L6563

5

Ω

Ω

390 k

R17

T

C8

R4

1 µF

39 k

Ω

C12 220 nF

1

2

13

10

4

Ω

R6

22

7

R15

0

Ω

R7A

0.68

Ω

C10

1/2 W

N.A.

D3

47 k

20 V

R18

C6

R2

33

Ω

15 nF

D2

TP1

Ω

TP2

47 k

R20

9

8

14

3

12

6

Ω

22.1 k

1N4148

R3B

120 k

Ω

Ω

Ω

Ω

C7

C4

100 nF

Ω

C2

33 µF

25V

D1

2.5

R9A

1 M

R9B

1 M

Q1

STP8NM50

C11

4.7 nF

R8

37.4 k

Ω

Ω

Ω

Ω

STTH2L06

Ω

R7B

0.68

Ω

1/2 W

R12A

1 M

R12A

1 M

Vo=220 to 390 V

Ω

Ω

10.5 k

Po = 80 W

R13

Ω

C5

56 µF

400 V

Figure 48. EVAL6563-80W: PCB and component layout (Top view, real size: 64 x 94 mm)

32/39

L6563 - L6563A Application examples and ideas

Figure 49. EVAL6563-80W: PCB layout, soldering side (Top view)

Table 7. EVAL6563-80W: Evaluation results at full load

Vin (VAC)

90 85.3 219.4 16.6 79.64 93.4 0.999 3.7

115 84.9 244.1 15.0 80.80 95.2 0.998 4.3

Pin (W)

Vo (VDC)

(V

∆Vo

pk-pk

Po (W) η (%) PF THD (%)

)

135 83.7 263.7 13.9 80.16 95.8 0.997 4.8

180 83.5 307.6 14.5 80.28 96.1 0.993 6.0

230 85.2 356.7 13.0 81.33 95.5 0.984 7.7

265 85.0 390.6 12.1 80.85 95.1 0.974 9.5

Note: Measurements done with the line filter shown in Figure 51.

Table 8. EVAL6563-80W: Evaluation results at half load

Vin (VAC)

90 43.4 219.9 8.6 40.90 94.2 0.997 4.8

115 42.6 244.5 7.7 40.10 94.1 0.994 5.7

135 43.1 264.0 7.3 40.39 93.7 0.989 6.5

180 43.8 307.7 7.7 40.31 92.0 0.978 8.4

230 45.6 356.8 6.8 41.03 90.0 0.951 9.6

265 46.0 390.7 6.7 40.63 88.3 0.920 14.2

Pin (W)

Vo (VDC)

(V

∆Vo

pk-pk

Po (W) η (%) PF THD (%)

)

Note: Measurements done with the line filter shown in Figure 51.

33/39

Application examples and ideas L6563 - L6563A

Figure 50. EVAL6563-80W: Vout vs. Vin relationship (tracking boost)

Figure 51. Line filter (not tested for EMI compliance) used for EVAL6563-80W

evaluation

34/39

L6563 - L6563A Application examples and ideas

Figure 52. 250W, wide-range-mains PFC pre-regulator with fixed output voltage

FUSE

8A/250V

Vac

88V

to

264V

Figure 53. 350W, wide-range-mains PFC pre-regulator with fixed output voltage and FOT control

B1

KBU8M

+

-

Boost Inductor (L1) Spec

Vcc

R1A

10.3 to 22 V

820 k

R2

10 k

R1B

820 k

C3

10nF

C2

1

R7

390 k

C5

470nF

µ

F

C1

1 µF

400V

ETD29x16x10 core, 3C85 ferrite or equivalent

1.5 mm gap for 150 µH prim ary inductance

Primary: 74 turns 20xAWG30 ( 0.3 mm)

Secondary: 8 turns 0 .1 mm

47 k

L1

R3

11

14

3

5

10

D1

1N5406

R4

1 M

R5

C4

6.8 k

1 µF

21

L6563

8 9

7

6

13

4

12

D3 1N4148

R6 33

STTH5L06

M1

STP12NM50

R8A,B

0.22

1 W

NTC1

D2

2.5

R9A

1 M

R9B

1 M

C6

470 nF

630 V

R10

12.7 k

C7

10 nF

Vout = 400V

Pout = 250 W

R11A

1.87 M

R11B

1.87 M

C8

150 µF

450 V

R12

20 k

FUSE

8A/250V

Vac

88V

to

264V

B1

KBU8M

C1

1 µF

+

400V

-

R2

10 k

L1: core E42*21*15, B2 material

1.9 mm ai r gap on c entre l eg, mai n winding

induct ance 0.55 m H

58 T of 20 x AWG32 ( 0.2 mm)

R1A

620 k

R1B

620 k

10.3 to 22 V

C3

10nF

Vcc

C2

1

R3

390 k

C4

470nF

D1

1N5406

L1

R4

1 M

R5

C5

6.8 k

1 µF

21

98 9

14

µ

F

1.5 k

BC557

3

10

5

TR1

12 k

L6563

11

R6

R7

R8

1.5 k

C6 330 pF

C7

560 pF

7

D3 1N4148

6

R9 6.8

C8

D4

1N4148

R10 6.8

R11 330

R12A,B,C

0.33

1 W

13

12

4

D5

1N4148

330 pF

D2

STTH806DTI

M1A

STP12 NM50

M1B

STP12 NM50

NTC1

2.5

R13A

1 M

R13B

1 M

C9

470 nF

630 V

R14

12.7 k

C10

10 nF

Vout = 400V

Pout = 350W

R15A

1.87 M

R15B

1.87 M

C11

220 µF

450 V

R16

20 k

35/39

Application examples and ideas L6563 - L6563A

Figure 54. Demagnetization sensing without auxiliary winding

C

ZCD

R

ZCD

V

inac

ZCD

9

L6563

L6563A

Figure 55. Enhanced turn-off for big MOSFET driving

V

cc

14

GD

DRIVER

L6563

L6563A

GND

13

BC327

12

Rs

V

out

R

load

Q

36/39

L6563 - L6563A Package mechanical data

8 Package mechanical data

In order to meet environmental requirements, ST offers these devices in ECOPACK®

packages. These packages have a Lead-free second level interconnect . The category of

second level interconnect is marked on the package and on the inner box label, in

compliance with JEDEC Standard JESD97. The maximum ratings related to soldering

conditions are also marked on the inner box label. ECOPACK is an ST trademark.

ECOPACK specifications are available at: www.st.com

Table 9. SO-14 Mechanical data

Dim.

Min Typ Max Min Typ Max

A 1.35 1.75 0.053 0.069

A1 0.10 0.30 0.004 0.012

A2 1.10 1.65 0.043 0.065

B 0.33 0.51 0.013 0.020

C 0.19 0.25 0.007 0.01

D (1)

8.55 8.75 0.337 0.344

E 3.80 4.0 0.150 0.157

e 1.27 0.050

H 5.8 6.20 0.228 0.244

h 0.25 0.50 0.01 0.02

L 0.40 1.27 0.016 0.050

k 0° (min.), 8° (max.)

ddd 0.10 0.004

mm. inch

Figure 56. Package dimensions

0016019D

37/39

Revision history L6563 - L6563A

9 Revision history

Table 10. Revision history

Date Revision Changes

13-Nov-2004 1 First issue

24-Sep-2005 2 Changed the maturity from “Preliminary data” to “Datasheet”

Added new part number L6563A (Table 2)

17-Nov-2006 3

12-Mar-2007 4

Updated the Section 4 on page 7 & Section 7 on page 32 the

document has been reformatted

Replaced block diagram, added Figure 37 on page 21 and minor

editor changes.

38/39

L6563 - L6563A

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the