Features

■ Proprietary multiplier design for minimum THD

■ Very accurate adjustable output overvoltage

protection

■ Ultra-low (30µA) Start-up current

■ Low (2.5mA) quiescent current

■ Digital leading-edge blanking on current sense

■ Disable function on E/A input

■ 1% (@ T

■ -600/+800mA totem pole gate driver with active

pull-down during UVLO and voltage clamp

■ DIP-8/SO-8 packages

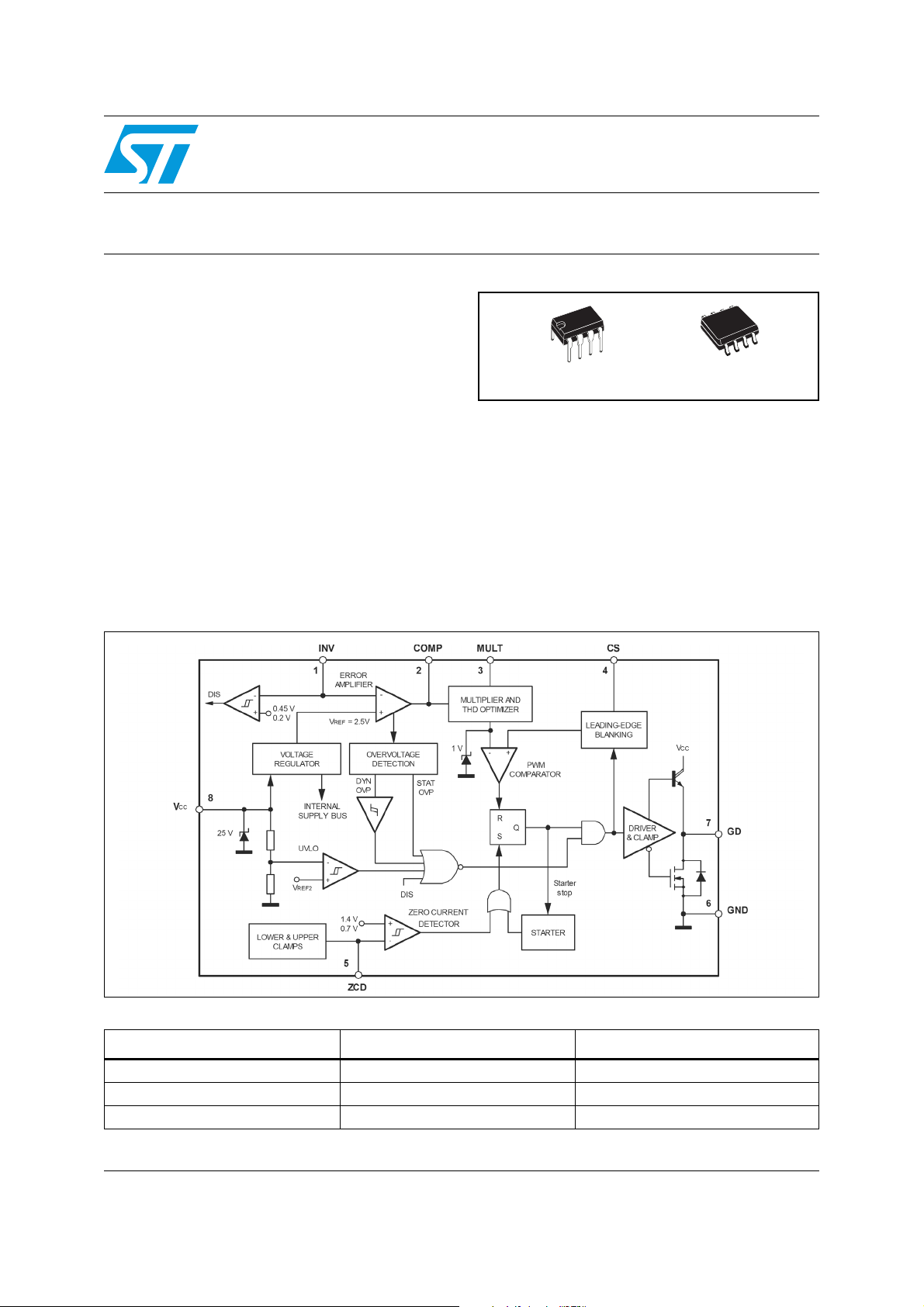

Figure 1. Block diagram

= 25 °C) internal reference voltage

J

L6562A

Transition-mode PFC controller

SO-8DIP-8

Applications

PFC pre-regulators for:

■ IEC61000-3-2 compliant SMPS (Flat TV,

monitors, desktop PC, games)

■ HI-END AC-DC adapter/charger up to 400W

■ Electronic ballast

■ Entry level server & web server

Table 1. Device summary

Order codes Package Packaging

L6562AN DIP-8 Tube

L6562AD SO-8 Tube

L6562ADTR SO-8 Tape & Reel

August 2007 Rev 3 1/26

www.st.com

26

Contents L6562A

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Pin description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6 Typical electrical characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.1 Overvoltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.2 Disable function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.3 THD optimizer circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.4 Operating with no auxiliary winding on the boost inductor . . . . . . . . . . . . 16

7.5 Comparison between the L6562A and the L6562 . . . . . . . . . . . . . . . . . . 17

8 Application examples and ideas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

10 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2/26

L6562A Description

1 Description

The L6562A is a current-mode PFC controller operating in Transition Mode (TM). Coming

with the same pin-out as its predecessors L6561 and L6562, it offers improved performance.

The highly linear multiplier includes a special circuit, able to reduce AC input current

distortion, that allows wide-range-mains operation with an extremely low THD, even over a

large load range.

The output voltage is controlled by means of a voltage-mode error amplifier and an accurate

(1% @T

The device features extremely low consumption (60µA max. before start-up and <5 mA

operating) and includes a disable function suitable for IC remote ON/OFF, which makes it

easier to comply with energy saving requirements (Blue Angel, EnergyStar, Energy2000,

etc.).

An effective two-step OVP enables to safely handle overvoltages either occurring at start-up

or resulting from load disconnection.

The totem-pole output stage, capable of 600 mA source and 800 mA sink current, is suitable

to drive high current MOSFETs or IGBTs. This, combined with the other features and the

possibility to operate with the proprietary Fixed-Off-Time control, makes the device an

excellent low-cost solution for EN61000-3-2 compliant SMPS in excess of 350W.

= 25°C) internal voltage reference.

J

3/26

Pin settings L6562A

2 Pin settings

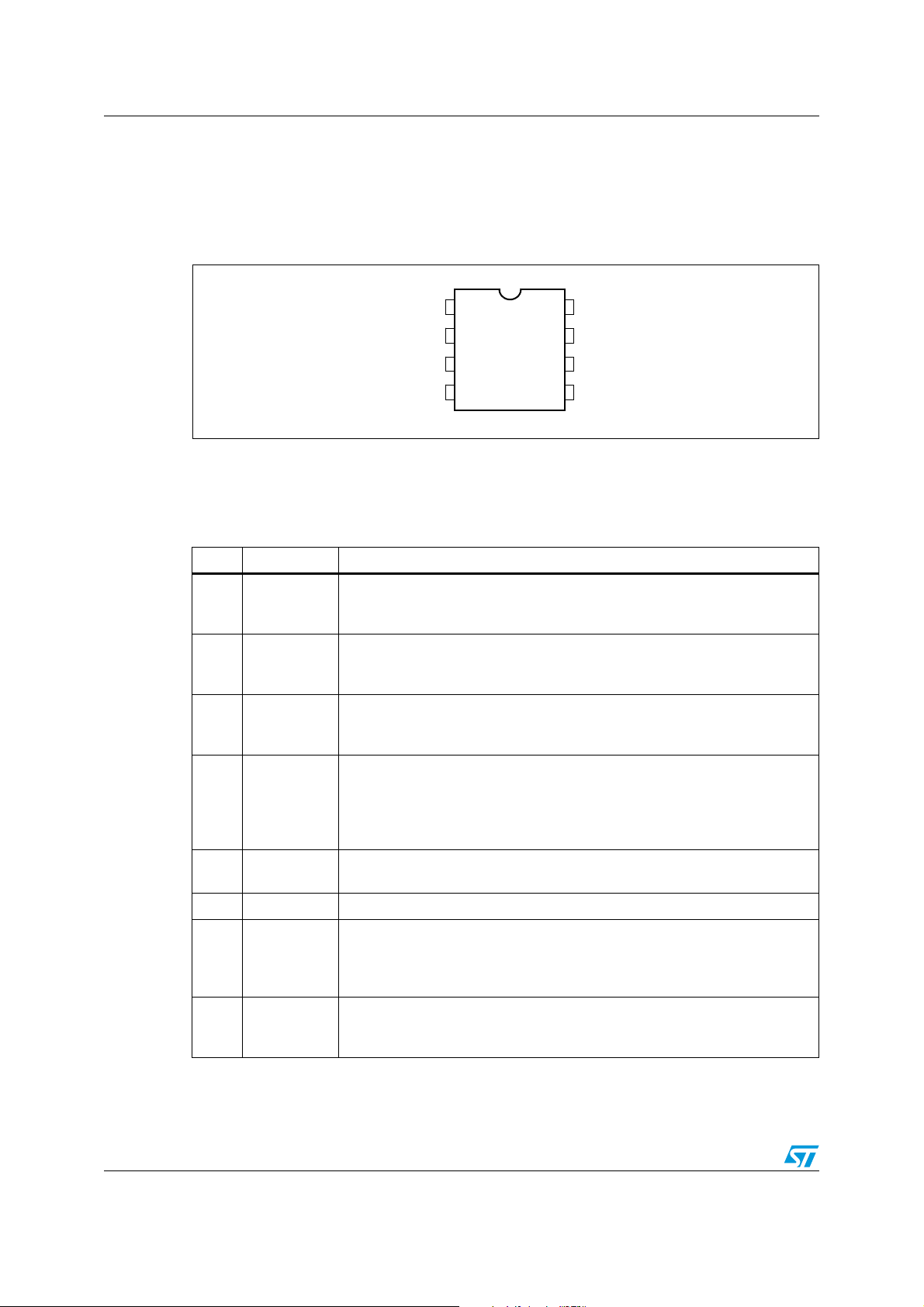

2.1 Pin connection

Figure 2. Pin connection (top view)

2.2 Pin description

Table 2. Pin description

Pin N° Name Description

Inverting input of the error amplifier. The information on the output voltage of

1INV

2COMP

3MULT

the PFC pre-regulator is fed into this pin through a resistor divider. The pin

doubles as an ON/OFF control input.

Output of the error amplifier. A compensation network is placed between this

pin and INV to achieve stability of the voltage control loop and ensure high

power factor and low THD.

Main input to the multiplier. This pin is connected to the rectified mains

voltage via a resistor divider and provides the sinusoidal reference to the

current loop.

INV

COMP

MULT

CS

1

2

3

4

Vcc

8

GD

7

GND

6

ZCD

5

Input to the PWM comparator. The current flowing in the MOSFET is sensed

through a resistor, the resulting voltage is applied to this pin and compared

4CS

5ZCD

6 GND Ground. Current return for both the signal part of the IC and the gate driver.

7GD

8Vcc

4/26

with an internal sinusoidal-shaped reference, generated by the multiplier, to

determine MOSFET’s turn-off. The pin is equipped with 200 ns leading-edge

blanking for improved noise immunity.

Boost inductor’s demagnetization sensing input for transition-mode

operation. A negative-going edge triggers MOSFET’s turn-on.

Gate driver output. The totem pole output stage is able to drive power

MOSFET’s and IGBT’s with a peak current of 600 mA source and 800 mA

sink. The high-level voltage of this pin is clamped at about 12V to avoid

excessive gate voltages in case the pin is supplied with a high Vcc.

Supply Voltage of both the signal part of the IC and the gate driver. The

supply voltage upper limit is extended to 22V min. to provide more headroom

for supply voltage changes.

L6562A Maximum ratings

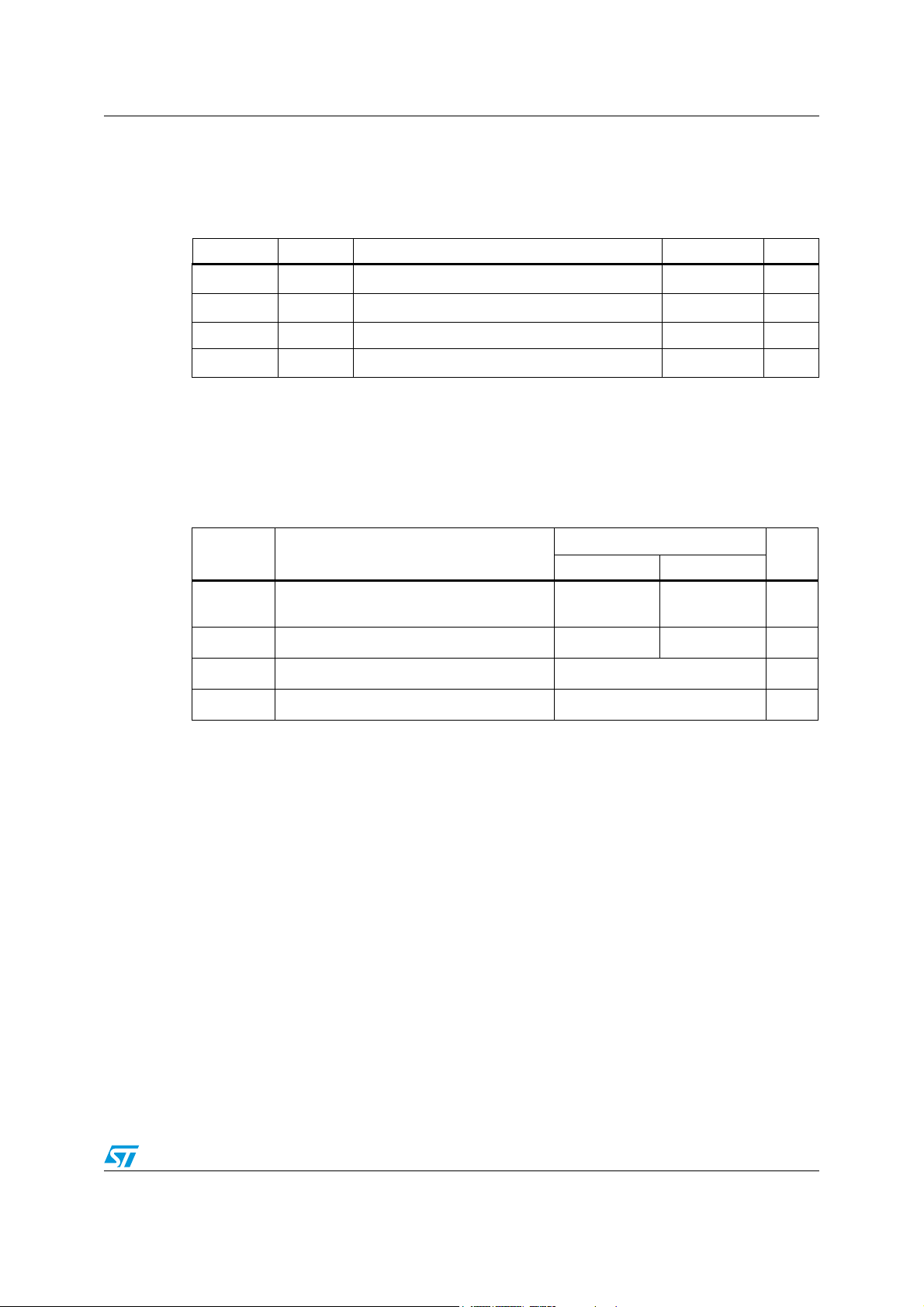

3 Maximum ratings

Table 3. Absolute maximum ratings

Symbol Pin Parameter Value Unit

V

CC

I

GD

--- 1 to 4 Analog inputs & outputs -0.3 to 8 V

I

ZCD

8 IC supply voltage (ICC ≤ 20mA) Self-limited V

7 Output totem pole peak current Self-limited A

5 Zero current detector max. current ±10 mA

4 Thermal data

Table 4. Thermal data

Symbol Parameter

SO8 DIP8

Val ue

Unit

R

P

T

thJA

TOT

T

J

STG

Max. Thermal Resistance, Junction-toambient

Power Dissipation @TA = 50°C 0.65 1 W

Junction Temperature Operating range -40 to 150 °C

Storage Temperature -55 to 150 °C

150 100 °C/W

5/26

Electrical characteristics L6562A

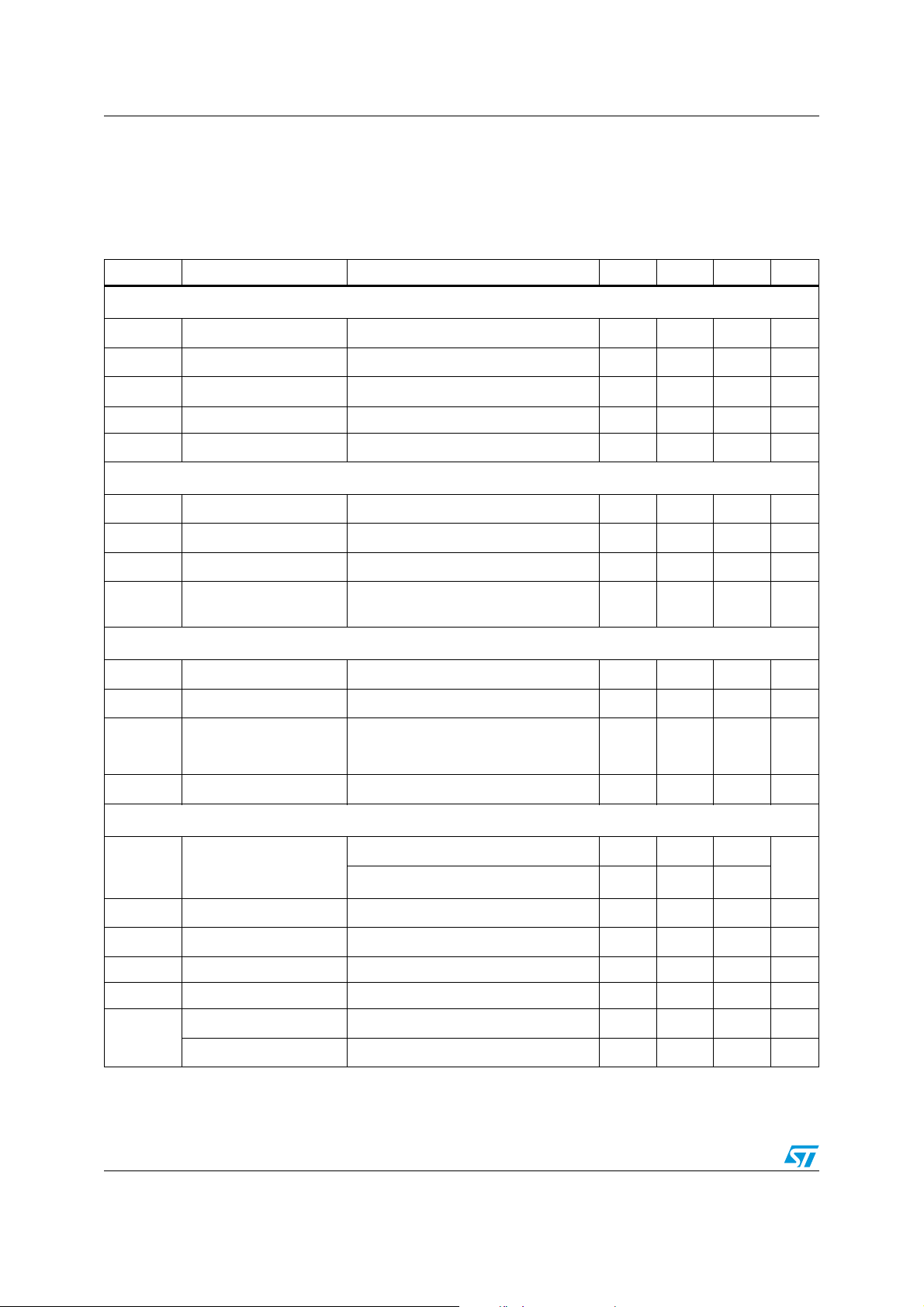

5 Electrical characteristics

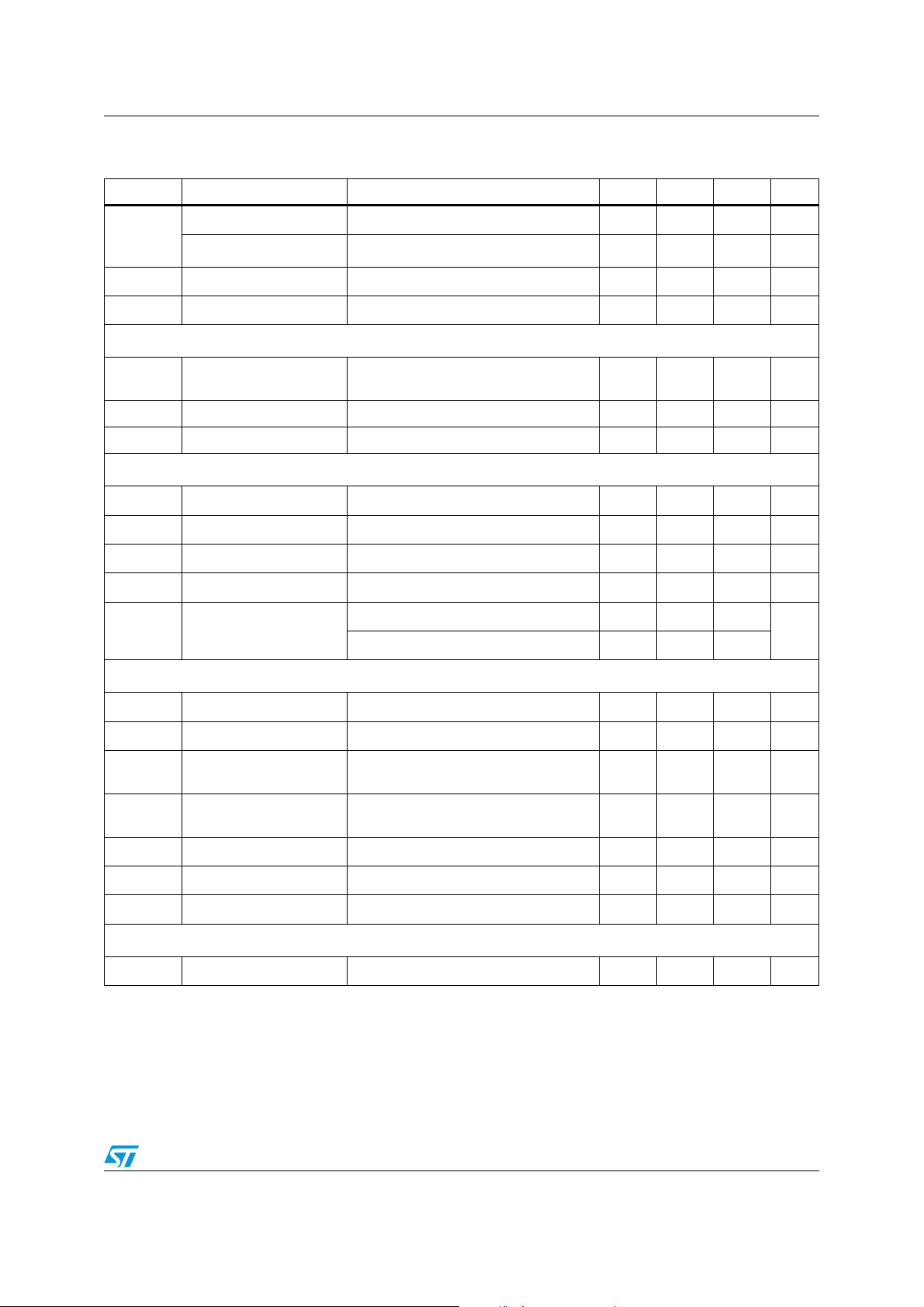

Table 5. Electrical characteristics

( -25°C < T

Symbol Parameter Test condition Min Typ Max Unit

Supply voltage

< +125°C, VCC = 12V, Co = 1nF; unless otherwise specified)

J

V

Vcc

Vcc

CC

Operating range After turn-on 10.5 22.5 V

Turn-on threshold

On

Turn-off threshold

Off

(1)

(1)

11.7 12.5 13.3 V

9.5 10 10.5 V

Hys Hysteresis 2.2 2.8 V

V

Z

Zener Voltage

= 20mA

I

CC

22.5 25 28 V

Supply current

I

start-up

I

q

I

CC

I

q

Start-up current

Quiescent current After turn-on 2.5 3.75 mA

Operating supply current @ 70kHz 3.5 5 mA

Quiescent current

Before turn-on, V

CC

= 11V

During OVP (either static or dynamic)

or V

≤150mV

INV

30 60 µA

1.7 2.2 mA

Multiplier input

I

MULT

V

MULT

Vcs∆

---------------------

V

∆

MULT

K

Input bias current

Linear operation range 0 to 3 V

Output max. slope

(2)

Gain

V

MULT

V

MULT

V

COMP

V

MULT

= 1V, V

= 0 to 4V

= 0 to 1V,

= Upper clamp

= 4V,

COMP

-1 µA

11.1 V/V

0.32 0.38 0.44 V

Error amplifier

= 25 °C

V

I

INV

INV

Voltage feedback input

threshold

Line regulation

Input bias current

T

J

10.5V < V

V

CC

V

INV

CC

= 10.5V to 22.5V

= 0 to 3V

< 22.5V

(1)

2.475 2.5 2.525

2.455 2.545

25mV

-1 µA

Gv Voltage gain Open loop 60 80 dB

GB Gain-bandwidth product 1 MHz

I

COMP

Source current

Sink current

V

COMP

V

COMP

= 4V, V

= 4V, V

INV

INV

= 2.4V

= 2.6V

-2 -3.5 -5 mA

2.5 4.5 mA

6/26

V

L6562A Electrical characteristics

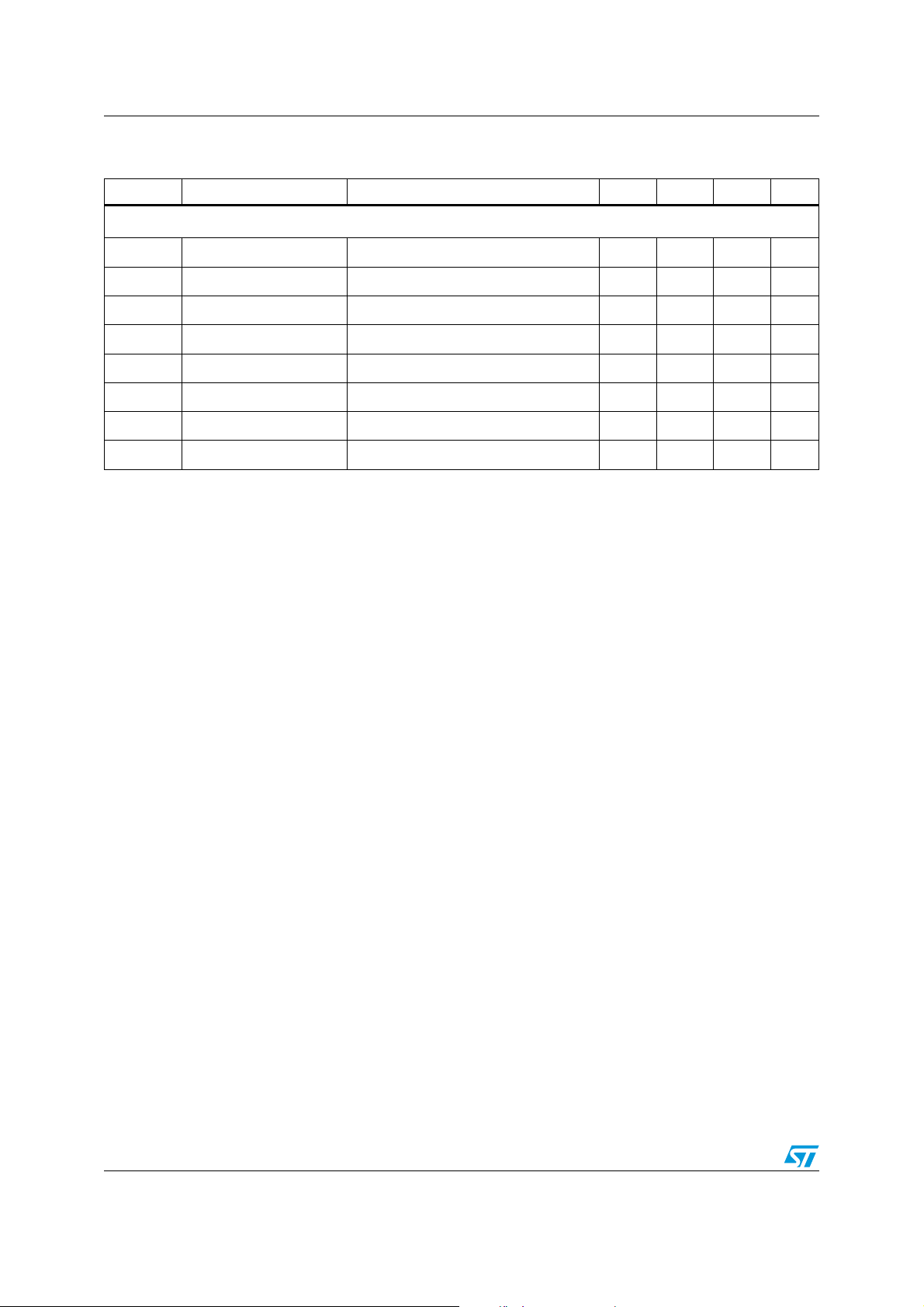

Table 5. Electrical characteristics (continued)

( -25°C < T

Symbol Parameter Test condition Min Typ Max Unit

< +125°C, VCC = 12V, Co = 1nF; unless otherwise specified)

J

V

COMP

V

INVdis

V

INVen

Lower clamp voltage

Disable threshold 150 200 250 mV

Restart threshold 380 450 520 mV

Output overvoltage

Upper clamp voltage

I

OVP

Dynamic OVP triggering

current

Hys Hysteresis

Static OVP threshold

Current sense comparator

td

Vcs

I

t

V

LEB

CS

(H-L)

CS

Input bias current

Leading edge blanking 100 200 300 ns

Delay to output 175 ns

Current sense clamp

Current sense offset

offset

I

SOURCE

I

SINK

(3)

(1)

V

V

V

V

= 0.5mA

= 0.5mA

= 0

CS

COMP

MULT

MULT

= 0

= 2.5V

(1)

= Upper clamp, Vmult = 1.5V

5.3 5.7 6 V

2.12.252.4 V

23.5 27 30.5 µA

20 µA

2.12.252.4 V

-1 µA

1.0 1.08 1.16 V

25

mV

5

Zero current detector

V

ZCDH

V

ZCDL

V

ZCDA

V

ZCDT

I

ZCDb

I

ZCDsrc

I

ZCDsnk

Upper clamp voltage

Lower clamp voltage

Arming voltage

(positive-going edge)

Triggering voltage

(negative-going edge)

Input bias current

Source current capability -2.5 mA

Sink current capability 2.5 mA

Starter

t

START

Start timer period 75 190 300 µs

I

ZCD

I

ZCD

(3)

(3)

V

ZCD

= 2.5mA

= - 2.5mA

= 1 to 4.5V

5.0 5.7 6.5 V

-0.3 0 0.3 V

1.4 V

0.7 V

2µA

7/26

Electrical characteristics L6562A

(

−

⋅

Table 5. Electrical characteristics (continued)

( -25°C < T

Symbol Parameter Test condition Min Typ Max Unit

Gate driver

< +125°C, VCC = 12V, Co = 1nF; unless otherwise specified)

J

V

OL

V

OH

I

srcpk

I

snkpk

t

t

V

Oclamp

1. All the parameters are in tracking

2. The multiplier output is given by:

3. Parameters guaranteed by design, functionality tested in production.

Output low voltage I

Output high voltage I

= 100mA 0.6 1.2 V

sink

= 5mA 9.8 10.3 V

source

Peak source current -0.6 A

Peak sink current 0.8 A

Voltage fall time 30 70 ns

f

Voltage rise time 60 110 ns

r

Output clamp voltage I

UVLO saturation Vcc = 0 to V

= ⋅

= 5mA; Vcc = 20 V 10 12 15 V

source

, I

CCon

sink

COMPMULTcs

= 2 mA 1.1 V

)

5.2VVK V

8/26

L6562A Typical electrical characteristic

pj

pj

6 Typical electrical characteristic

Figure 3. Supply current vs supply

10.00

1.00

0.10

Icc (mA)

0.01

0.00

0.00 5. 00 10.00 15.00 20.00 25.00

Figure 5. IC consumption vs T

10

1

voltage

Vcc (V)

Co = 1 nF

f = 70 kHz

Tj = 25°C

J

Ope rat ing

Quiescent

Disabled or during OVP

Figure 4. Start-up & UVLO vs TJ

13

Vcc-ON

12

11

(V)

10

Vcc-OFF

9

-50 0 50 100 150

Tj (°C)

Figure 6. Vcc Zener voltage vs T

28

27

26

J

Icc (mA)

0.01

0.1

-50 0 50 1 00 150

Tj (°C)

Vcc = 12 V

Co= 1 nF

f = 70 kHz

Before start-up

25

VccZ (V)

24

23

22

-50 0 50 100 150

Tj (°C)

9/26

Typical electrical characteristic L6562A

j

Figure 7. Feedback reference vs T

2.6

2.55

2.5

VREF (V)

2.45

2.4

-50 0 50 100 150

Figure 9. E/A output clamp levels vs TJFigure 10. Delay-to-output vsT

6

5

4

3

V COMP pin2 (V)

2

Tj (°C)

J

Vcc = 12V

Uppe r cl am p

Vcc = 12V

Lower clam p

Figure 8. OVP current vs T

35

34

33

32

31

30

29

Iovp (uA)

28

27

26

25

24

23

-50 0 50 100 150

300

200

tD (H-L) (ns)

100

Tj (°C)

J

Vcc = 12V

J

Vcc = 12V

1

-50 0 50 100 150

Tj (°C)

10/26

0

-50 0 50 100 150

Tj (°C)

L6562A Typical electrical characteristic

p

V

pj

pj

Figure 11. Multiplier characteristic Figure 12. Vcs clamp vs T

1.2

Upper Volt. Clamp

1.1

1.0

0.9

0.8

0.7

0.6

0.5

Vcs (pi n4) (V)

0.4

0.3

0.2

0.1

0.0

-0.1

Figure 13. ZCD clamp levels vs T

7

6

5

4

3

Vzcd (V)

2

5.75 V

5 V

4.5V

0 0.2 0.4 0.6 0.8 1 1.2 1. 4 1.6 1.8 2 2.2 2. 4 2. 6 2.8 3

VMULT (pin3) (V)

V COMP (pin2) (V

4 V

J

Uppe r cl am p

Vcc = 12V

IZCD = ±2. 5 mA

3.5V

3 V

2.5

1.3

)

1.2

Vcsx (V)

1.1

1

-50 0 50 100 150

Tj (°C)

Figure 14. Start-up timer vs T

200

190

180

Tstart (us)

170

J

Vcc = 12V

VCOMP = Upper clamp

J

Vcc = 12V

1

0

-1

-50 0 50 100 150

Tj (°C)

Lower clam p

160

150

-50 0 50 100 150

Tj (°C)

11/26

Typical electrical characteristic L6562A

Figure 15. Gate-driver output low

5.00

4.00

3.00

Vpin7 (V)

2.00

1.00

0.00

0 200 400 600 800 1000

Figure 17. Gate-drive clamp vs T

13.5

13.25

13

Vpin 7 clamp (V)

12.75

saturation

I GD (mA)

Tj = 25 °C

Vcc = 12V

SINK

J

Vcc = 20V

Figure 16. Gate-drive output high

saturation

12.00

11.00

10.00

9.00

Vpin7 (V)

8.00

7.00

6.00

0 200 400 600

I GD (mA)

Figure 18. Output gate drive low

saturation vs T

1.1

1

Vcc = 11V

0.9

Vcc = 0V

0.8

Vpin7 (V)

0.7

0.6

during UVLO

J

Isink = 2 m A

Tj = 25 °C

Vcc = 12V

SOURCE

12.5

-50 0 50 100 150

Tj (°C)

12/26

0.5

-50 0 50 100 150

Tj (°C)

L6562A Application information

7 Application information

7.1 Overvoltage protection

Under steady-state conditions, the voltage control loop keeps the output voltage Vo of a

PFC pre-regulator close to its nominal value, set by the resistors R1 and R2 of the output

divider. Neglecting ripple components, the current through R1, I

I

. Considering that the non-inverting input of the error amplifier is internally referenced at

R2

2.5V, also the voltage at pin INV will be 2.5V, then:

Equation 1

V

I

R2IR1

2.5

------- -

R2

O

--------------------- -===

2.5–

R1

If the output voltage experiences an abrupt change ∆Vo > 0 due to a load drop, the voltage

at pin INV will be kept at 2.5V by the local feedback of the error amplifier, a network

connected between pins INV and COMP that introduces a long time constant to achieve

high PF (this is why ∆Vo can be large). As a result, the current through R2 will remain equal

to 2.5/R2 but that through R1 will become:

, equals that through R2,

R1

Equation 2

VO2.5– VO∆+

I'

--------------------------------------- -=

R1

R1

The difference current ∆IR1=I'R1-IR2=I'R1-IR1= ∆Vo/R1 will flow through the compensation

network and enter the error amplifier output (pin COMP). This current is monitored inside

the device and if it reaches about 24µA the output voltage of the multiplier is forced to

decrease, thus smoothly reducing the energy delivered to the output. As the current

exceeds 27µA, the OVP is triggered (Dynamic OVP): the gate-drive is forced low to switch

off the external power transistor and the IC put in an idle state. This condition is maintained

until the current falls below approximately 7µA, which re-enables the internal starter and

allows switching to restart. The output ∆Vo that is able to trigger the Dynamic OVP function

is then:

Equation 3

∆

VO = R1 · 20 · 10

- 6

An important advantage of this technique is that the OV level can be set independently of

the regulated output voltage: the latter depends on the ratio of R1 to R2, the former on the

individual value of R1. Another advantage is the precision: the tolerance of the detection

current is 13%, i.e. 13% tolerance on ∆Vo. Since ∆Vo << Vo, the tolerance on the absolute

value will be proportionally reduced.

Example: Vo = 400V, ∆Vo = 40V. Then: R1 = 40V/27µA

≈ 1.5MΩ ;

R2 = 1.5 MΩ ·2.5/(400-2.5) = 9.43kΩ. The tolerance on the OVP level due to the L6562A will

be 40·0.13 = 5.3V, that is ± 1.2%.

13/26

Application information L6562A

When the load of a PFC pre-regulator is very low, the output voltage tends to stay steadily

above the nominal value, which cannot be handled by the Dynamic OVP. If this occurs,

however, the error amplifier output will saturate low; hence, when this is detected the

external power transistor is switched off and the IC put in an idle state (Static OVP). Normal

operation is resumed as the error amplifier goes back into its linear region. As a result, the

device will work in burst-mode, with a repetition rate that can be very low.

When either OVP is activated the quiescent consumption of the IC is reduced to minimize

the discharge of the Vcc capacitor and increase the hold-up capability of the IC supply

system.

7.2 Disable function

The INV pin doubles its function as a not-latched IC disable: a voltage below 0.2V shuts

down the IC and reduces its consumption at a lower value. To restart the IC, the voltage on

the pin must exceed 0.45 V. The main usage of this function is a remote ON/OFF control

input that can be driven by a PWM controller for power management purposes. However it

also offers a certain degree of additional safety since it will cause the IC to shutdown in case

the lower resistor of the output divider is shorted to ground or if the upper resistor is missing

or fails open.

7.3 THD optimizer circuit

The device is equipped with a special circuit that reduces the conduction dead-angle

occurring to the AC input current near the zero-crossings of the line voltage (crossover

distortion). In this way the THD (Total Harmonic Distortion) of the current is considerably

reduced.

A major cause of this distortion is the inability of the system to transfer energy effectively

when the instantaneous line voltage is very low. This effect is magnified by the highfrequency filter capacitor placed after the bridge rectifier, which retains some residual

voltage that causes the diodes of the bridge rectifier to be reverse-biased and the input

current flow to temporarily stop.

14/26

L6562A Application information

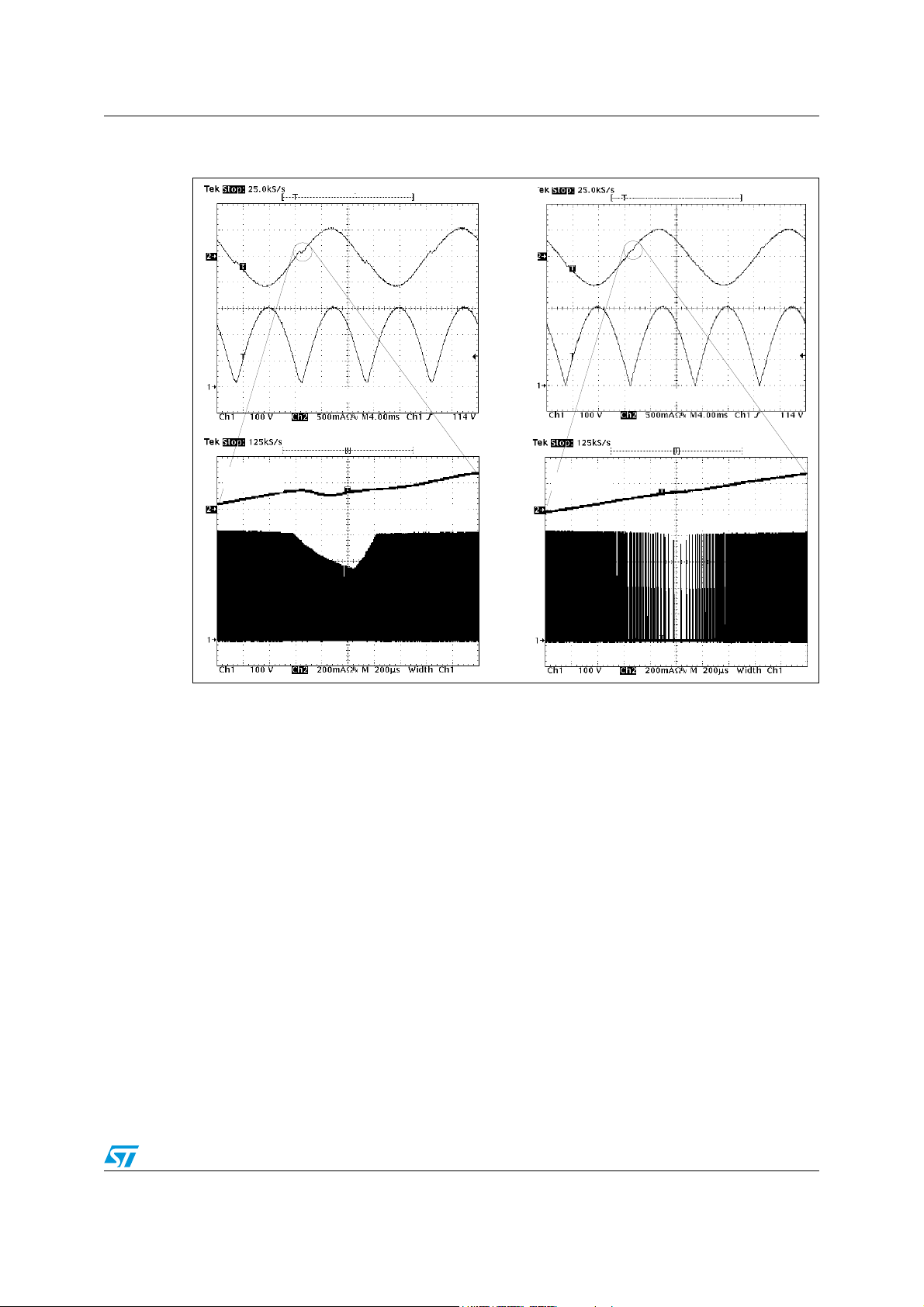

Figure 19. THD optimization: standard TM PFC controller (left side) and L6562A

(right side)

Input current Input current

Rectified mains voltage Rectified mains voltage

Imains

Input current

MOSFET's drain voltage

Vdrain

Imains

Input current

MOSFET's drain voltage

Vdrain

To overcome this issue the circuit embedded in the device forces the PFC pre-regulator to

process more energy near the line voltage zero-crossings as compared to that commanded

by the control loop. This will result in both minimizing the time interval where energy transfer

is lacking and fully discharging the high-frequency filter capacitor after the bridge. The effect

of the circuit is shown in figure 2, where the key waveforms of a standard TM PFC controller

are compared to those of the L6562A.

Essentially, the circuit artificially increases the ON-time of the power switch with a positive

offset added to the output of the multiplier in the proximity of the line voltage zero-crossings.

This offset is reduced as the instantaneous line voltage increases, so that it becomes

negligible as the line voltage moves toward the top of the sinusoid.

To maximally benefit from the THD optimizer circuit, the high-frequency filter capacitor after

the bridge rectifier should be minimized, compatibly with EMI filtering needs. A large

capacitance, in fact, introduces a conduction dead-angle of the AC input current in itself even with an ideal energy transfer by the PFC pre-regulator - thus making the action of the

optimizer circuit little effective.

15/26

Application information L6562A

7.4 Operating with no auxiliary winding on the boost inductor

To generate the synchronization signal on the ZCD pin, the typical approach requires the

connection between the pin and an auxiliary winding of the boost inductor through a limiting

resistor. When the device is supplied by the cascaded DC-DC converter, it is necessary to

introduce a supplementary winding to the PFC choke just to operate the ZCD pin.

Another solution could be implemented by simply connecting the ZCD pin to the drain of the

power MOSFET through an R-C network as shown in figure 3: in this way the highfrequency edges experienced by the drain will be transferred to the ZCD pin, hence arming

and triggering the ZCD comparator.

Also in this case the resistance value must be properly chosen to limit the current

sourced/sunk by the ZCD pin. In typical applications with output voltages around 400V,

recommended values for these components are 22pF (or 33pF) for C

R

. With these values proper operation is guaranteed even with few volts difference

ZCD

between the regulated output voltage and the peak input voltage

Figure 20. ZCD pin synchronization without auxiliary winding

ZCD

C

ZCD

R

and 330k for

ZCD

ZCD

5

L6562A

16/26

L6562A Application information

7.5 Comparison between the L6562A and the L6562

The L6562A is not a direct drop-in replacement of the L6562, even if both have the same

pin-out. One function (Disable) has been relocated.

Table 2 compares the two devices, i.e. those parameters that may result in different values

of the external components. The parameters that have the most significant impact on the

design, i.e. that definitely require external component changes when converting an L6562based design to the L6562A, are highlighted in bold.

Table 6. L6562A vs. L6562

Parameter L6562 L6562A

IC turn-on & turn-off thresholds (typ.) 12/9.5 V 12.5/10 V

Turn-off threshold spread (max.) ±0.8 V ±0.5 V

IC consumption before start-up (max.) 70 uA 60 uA

Multiplier gain (typ.) 0.6 0.38

Current sense reference clamp (typ.) 1.7 V 1.08 V

Current sense propagation delay (delay-to-output) (typ.) 200 ns 175 ns

Dynamic OVP triggering current (typ.) 40 uA 27 uA

ZCD arm/trigger/clamp thresholds (typ.) 2.1/1.4/0.7 V 1.4/0.7/0 V

Enable threshold (typ.)

Gate-driver internal drop (max.) 2.6 V 2.2 V

Leading-edge blanking on current sense No Yes

Reference voltage accuracy ( overall) 2.4% 1.8%

1. Function located on pin 5 (ZCD)

2. Function located on pin 1 (INV)

0.3 V

(1)

0.45 V

(2)

The lower value (-36%) for the clamp level of the current sense reference voltage allows the

use of a lower sense resistor for the same peak current, with a proportional reduction of the

associated power dissipation. Essentially, the advantage is the reduction of the power

dissipated in a single point (hotspot), which is a considerable benefit in applications where

heat removal is critical, e.g. in adapters enclosed in a sealed plastic case. The lower value

for the Dynamic OVP triggering current allows the use of a higher resistance value (+48%)

for the upper resistor of the divider sensing the output voltage of the PFC stage (keeping the

same overvoltage level) with no significant increase of noise sensitivity. This reduction goes

in favor of standby consumption in applications required to comply with energy saving

regulations.

17/26

Application examples and ideas L6562A

8 Application examples and ideas

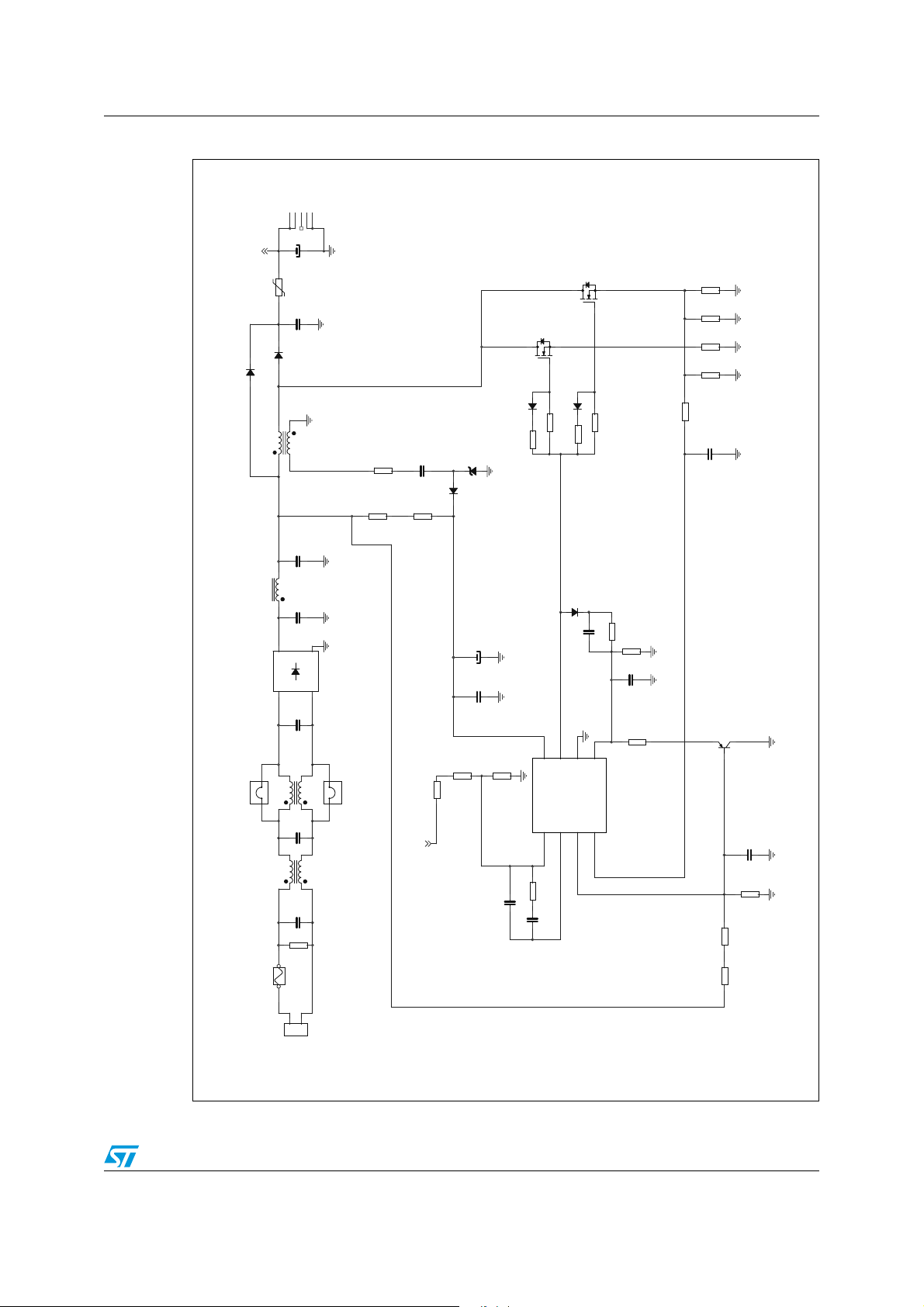

Figure 21. Demo board EVL6562A-TM-80W, wide-range mains : electrical schematic

Vo=400V

Vo=400V

Po=80W

Po=80W

R11

R11

Ω

Ω

1M

1M

R12

R12

1M

1M

Ω

Ω

C6

C6

47 µF

47 µF

450V

450V

R13B

R13B

82 k

82 k

Ω

Ω

Ω

Ω

F1

F1

4A/250V

4A/250V

Vac

Vac

88V

88V

to

to

264V

264V

R4

R4

Ω

Ω

270 k

270 k

270 k

270 k

R1

R1

1 M

1 M

Ω

Ω

C1

P1

P1

+

+

W08

W08

-

-

Boost Inductor Spec (ITACOIL E2543/E)

Boost Inductor Spec (ITACOIL E2543/E)

C1

0.22 µF

0.22 µF

630V

630V

R2

R2

1 M

1 M

Ω

Ω

C2

C2

10nF

10nF

R3

R3

15 k

15 k

Ω

Ω

E25x13x7 core, N67 ferrite

E25x13x7 core, N67 ferrite

1.5 mm gap for 0. 7 mH primary induct ance

1.5 mm gap for 0. 7 mH primary induct ance

Primary: 102 turns 20x0.1 mm

Primary: 102 turns 20x0.1 mm

Secondary: 10 turns 0.1 mm

Secondary: 10 turns 0.1 mm

R5

R5

C29

C29

22 µF

22 µF

25V

25V

Ω

Ω

D8

D8

1N4148

1N4148

D2

D2

1N5248B

1N5248B

C5

C5

10 nF

10 nF

VCC

VCC

MULT

MULT

100 nF

100 nF

R14

R14

100

100

Ω

Ω

R6

R6

47 k

47 k

Ω

Ω

ZCD COMP INV

ZCD COMP INV

8

8

3

3

GND

GND

C4

C4

T1

T1

C3 - 2200 nF

C3 - 2200 nF

5

21

5

21

L6562A

L6562A

6

6

C23

C23

150 nF

150 nF

CS

CS

R50 - 22 kΩ

R50 - 22 kΩ

GD

GD

7

7

4

4

R15

R15

SHORTED

SHORTED

R8

R8

47k

47k

D1

D1

NTC

STP8NM50FP

STP8NM50FP

R10

R10

0.68 Ω

0.68 Ω

0.25W

0.25W

NTC

2.5

2.5

Ω

Ω

Q1

Q1

R13

R13

15 k

15 k

STTH1L06

STTH1L06

R7

R7

33

33

Ω

Ω

Ω

Ω

R9

R9

0.68 Ω

0.68 Ω

0.25W

0.25W

18/26

L6562A Application examples and ideas

Figure 22. L6562A 80W TM PFC evaluation

Figure 23. L6562A 80W TM PFC evaluation

board: compliance to EN61000-3-2

0.0 1

0.001

Harmonic current (A)

0. 0001

Vin = 230 Vac - 50 Hz, Pout = 80 W

THD = 10.48 %, PF = 0.973

standard

Mea sur ements @ 230V ac Ful l load EN61000-3 -2 cl ass D li mit s

1

0. 1

1 3 5 7 9 11131517192123252729313335 37 39

Harmonic Order (n)

Vin = 100 Vac - 50 Hz, Pout = 80 W

THD = 3.18 %, PF = 0.997

Figure 24. Figure 3 - L6562A 80W TM PFC

Evaluation board: Input Current

waveform @230V-50Hz – 80W load

board: compliance to JEIDA-MITI

standard

Meas ure ment s @ 10 0Vac Full lo ad JEIDA-MITI class D limits

1

0. 1

0.0 1

0.001

Harm onic current (A)

0. 0001

1 3 5 7 9 1113151719 212325 272931 3335 37 39

Harmonic Order (n)

Figure 25. Figure 4- L6562A 80W TM PFC

Evaluation board: Input Current

waveform @100V-50Hz – 80W load

19/26

Application examples and ideas L6562A

)

Figure 26. L6562A 80W TM PFC evaluation

1.00

0.95

0.90

PF

0.85

0.80

80 100 120 140 160 180 200 220 240 26 0

board: Power Factor vs Vin

Pout = 80W

Vin (Vac)

Figure 28. L6562A 80W TM PFC evaluation

board: efficiency vs Vin

100

95

90

85

EFFICIENCY (%)

80

75

80 100 120 140 160 180 200 220 240 260

Pout = 80W

Vin (Vac)

Figure 27. L6562A 80W TM PFC evaluation

board: THD vs Vin

12

10

8

6

THD (%

4

2

0

80 100 120 140 160 180 200 220 240 260

Vin (V ac)

Pout = 80W

Figure 29. L6562A 80W TM PFC Evaluation

board: Static Vout regulation vs

Vin

404

403.5

403

402.5

402

Vout (Vdc)

401.5

401

400.5

400

80 100 120 140 160 180 200 220 240 260

Pout = 80W

Vin (V ac)

20/26

L6562A Application examples and ideas

+

Figure 30. Demo board EVL6562A-400W, wide-range mains, FOT: electrical schematic

12345

+400 Vdc

C7

330uF-450V

R2

NTC 2R5-S237

C6

470nF-630V

D3

STTH8R06

D1

1N5406

D7

1-25-6

118

L4

PQ40-500uH

C10

33N

R5

47R

R3

180K

R4

D5

D4

LL4148

180K

LL4148

R36

3R9

BZX85- C15

Q2

STP12NM50FP

Q1

STP12NM50FP

D8

LL4148

R17

6R8

R18

6R8

R35

3R9

R23

0R68W

R22

0R39-1W

R21

0R39-1W

R20

0R39-1W

R19

1K0

C20

330pF

C5

470nF-630V

L3

DM-51uH-6A

C4

470nF-630V

C12

+

-

D2

D15X B60

~

~

C3

680nF-X2

L2

RES

JP101

JUMPER

1 2

C2

L1

CM-1.5 mH-5A

C1

R1

F1

8A/250V

JP102

JUMPER

1 2

470nF-X2

470nF-X2

1M5

R10

+400 Vdc

47uF/50V

C11

470nF/50V

R12

R11

750k

9.1k

680k

220nF

R14

39k

C13

C14

3.3uF

8

VCCGDGND

INV

123

COMP

D6

LL4148

R15

820

R16

C15

100pF

657

15K

C16

220pF

Q3

R31

1K5

BC857C

ZCD

L6562A

MULT

CS

4

C21

10nF

R34

10k

R33

620k

R32

620k

1

2

J1

90 - 265Vac

21/26

Package mechanical data L6562A

9 Package mechanical data

In order to meet environmental requirements, ST offers these devices in ECOPACK®

packages. These packages have a Lead-free second level interconnect . The category of

second level interconnect is marked on the package and on the inner box label, in

compliance with JEDEC Standard JESD97. The maximum ratings related to soldering

conditions are also marked on the inner box label. ECOPACK is an ST trademark.

ECOPACK specifications are available at: www.st.com

22/26

L6562A Package mechanical data

Table 7. DIP-8 mechanical data

mm Inch

Dim.

Min Typ Max Min Typ Max

A 3.32 0.131

a1 0.51 0.020

B 1.15 1.65 0.045 0.065

b 0.356 0.55 0.014 0.022

b1 0.204 0.304 0.008 0.012

D 10.92 0.430

E 7.95 9.75 0.313 0.384

e 2.54 0.100

e3 7.62 0.300

e4 7.62 0.300

F 6.6 0.260

I 5.08 0.200

L 3.18 3.81 0.125 0.150

Z 1.52 0.060

Figure 31. Package dimensions

23/26

Package mechanical data L6562A

Table 8. SO-8 mechanical data

Dim.

Min Typ Max Min Typ Max

A 1.35 1.75 0.053 0.069

A1 0.10 0.25 0.004 0.010

A2 1.10 1.65 0.043 0.065

B 0.33 0.51 0.013 0.020

C 0.19 0.25 0.007 0.010

(1)

D

4.80 5.00 0.189 0.197

E 3.80 4.00 0.15 0.157

e 1.27 0.050

H 5.80 6.20 0.228 0.244

h 0.25 0.50 0.010 0.020

L 0.40 1.27 0.016 0.050

k 0° (min.), 8° (max.)

ddd 0.10 0.004

1. Dimensions D does not include mold flash, protru-sions or gate burrs. Mold flash, potrusions or gate burrs

shall not exceed 0.15mm (.006inch) in total (both side).

mm. inch

Figure 32. Package dimensions

24/26

L6562A Revision history

10 Revision history

Table 9. Revision history

Date Revision Changes

03-Mar-2007 1 First release

28-Jun-2007 2 Updated electrical characteristics

07-Aug-2007 3 Added Chapter 6: Typical electrical characteristic on page 9

25/26

L6562A

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2007 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

26/26

Loading...

Loading...