Page 1

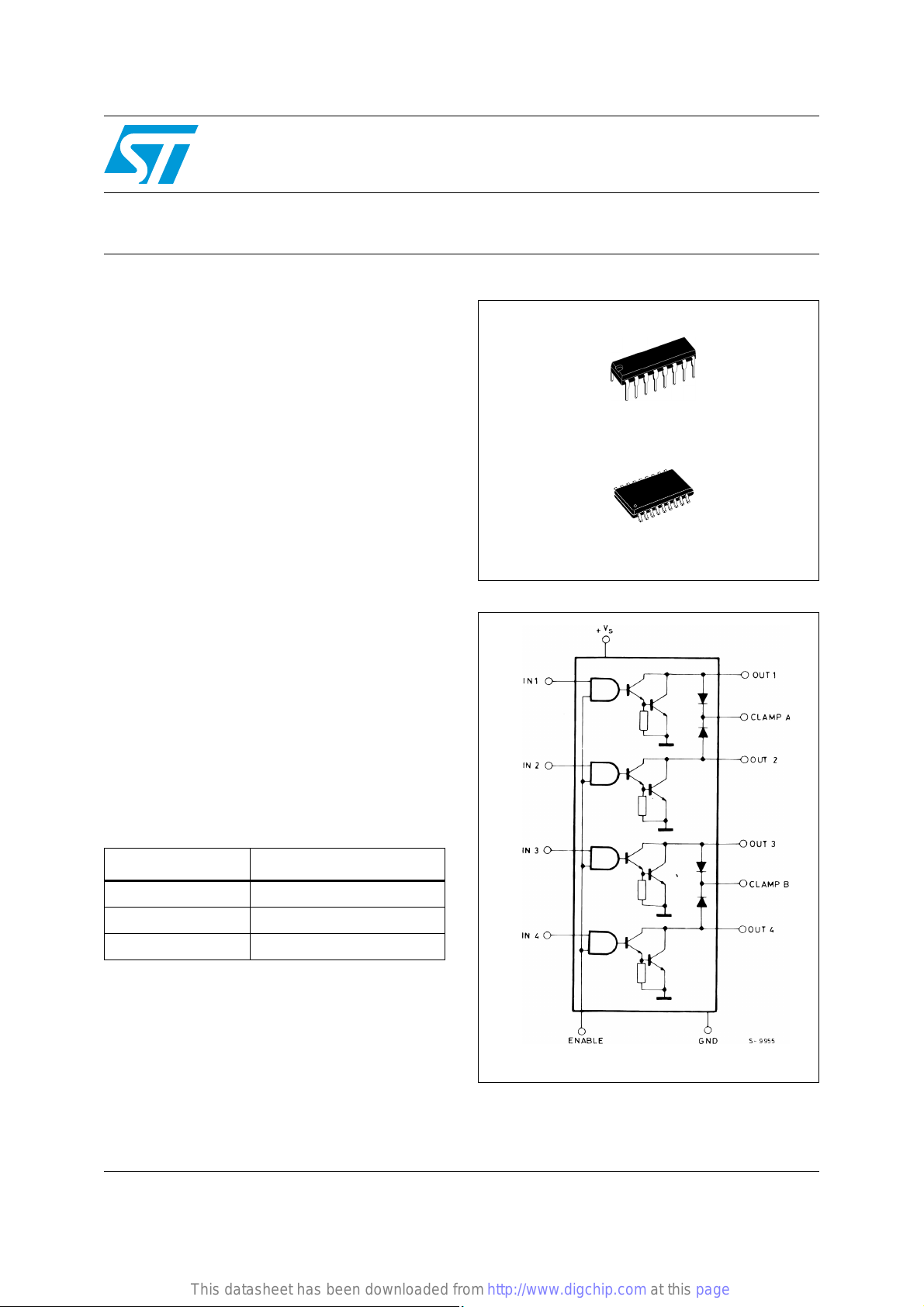

L6221

Quad Darlington switch

Features

■ Four non-inverting inputs with enable

■ Output voltage up to 50 V

■ Output current up to 1.8 A

■ Very low saturation voltage

■ TTL compatible inputs

■ Integral fast recirculation diodes

Applications

The L6221 monolithic quad Darlington switch is

designed for high current, high voltage switching

applications.

Description

Each of the four switches is controlled by a logic

input and all four are controlled by a common

enable input. All inputs are TTL-compatible for

direct connection to logic circuits.

Each switch consists of an open-collector

Darlington transistor plus a fast diode for

switching applications with inductive device loads.

The emitters of the four switches are commoned.

Any number of inputs and outputs of the same

device may be paralleled.

Table 1. Device summary

Power DIP 12+2+2

SO16+2+2

Figure 1. Block diagram

Order code Package

E-L6221AS Power DIP

E-L6221AD SO16+2+2

E-L6221AD013TR SO16+2+2 (tape and reel)

January 2009 Rev 3 1/22

www.st.com

This datasheet has been downloaded fromhttp://www.digchip.com at this page

22

Page 2

Contents

Contents

1 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Pin information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Test circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 Mounting instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

8 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2/22

Page 3

Thermal data

1 Thermal data

Table 2. Thermal data

Symbol Parameter SO20 Power DIP Unit

R

th j-pins

R

th j-amb

Thermal resistance junction-pins max. 17 14 °C/W

Thermal resistance junction-ambient max. 80 80 °C/W

3/22

Page 4

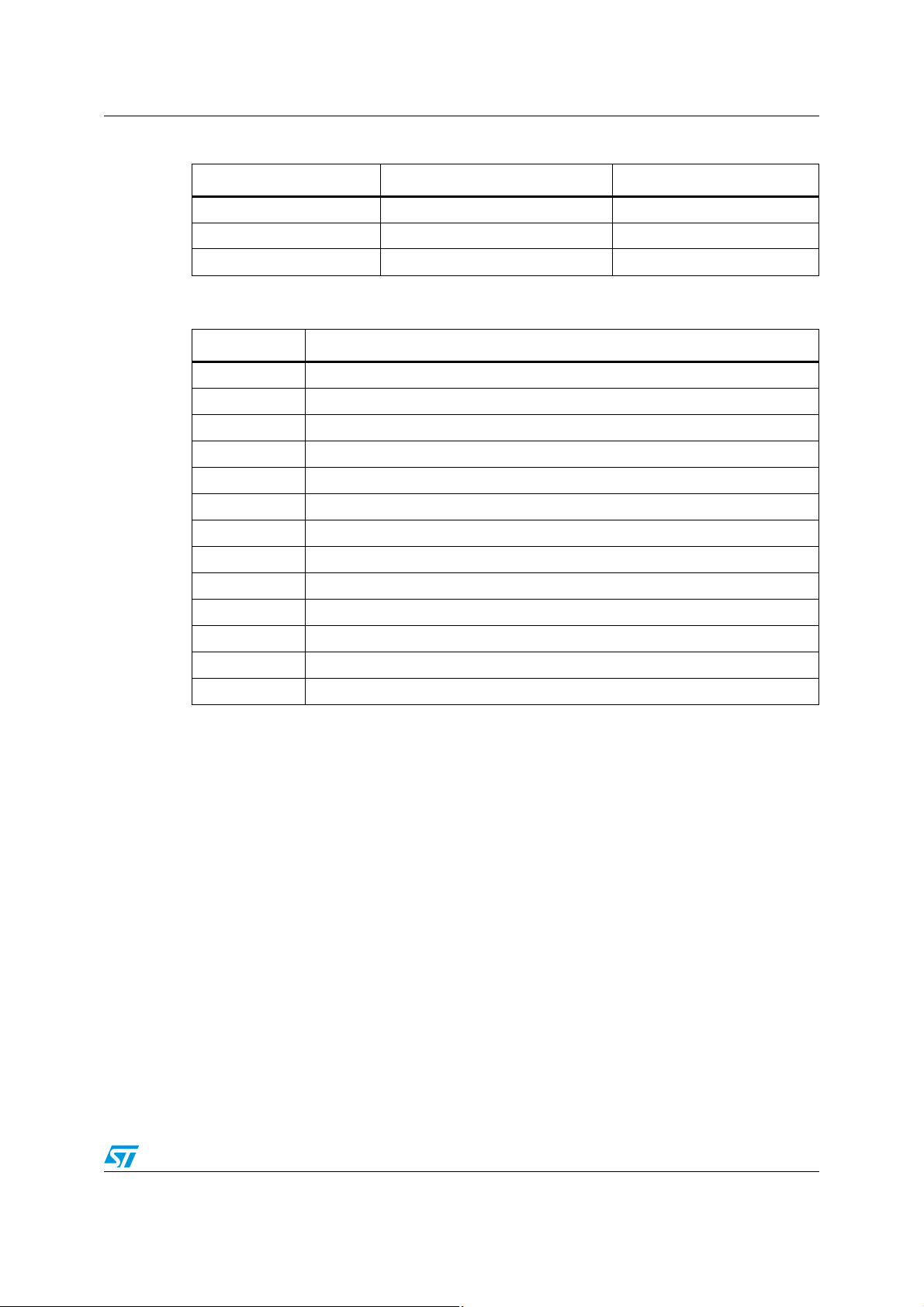

Pin information

2 Pin information

Figure 2. Pin connections (top views)

E-L6221AS (Power DIP)

E-L6221AD (SO16+2+2)

4/22

Page 5

Pin information

Table 3 . Truth t able

(1)

Enable Input Power out

HH ON

HLOFF

LXOFF

1. For each input: H = High level, L = Low level

Table 4. Pin description

(1)

Name Function

IN 1 Input to driver 1

IN 2 Input to driver 2

OUT 1 Output of driver 1

OUT 2 Output of driver 2

CLAMP A Diode clamp to driver 1 and driver 2

IN 3 Input to driver 3

IN 4 Input to driver 4

OUT 3 Output of driver 3

OUT 4 Output of driver 4

CLAMP B Diode clamp to driver 3 and driver 4

ENABLE Enable input to all drivers

V

S Logic supply voltage

GND Common ground

1. See

Figure 1: Block diagram

5/22

Page 6

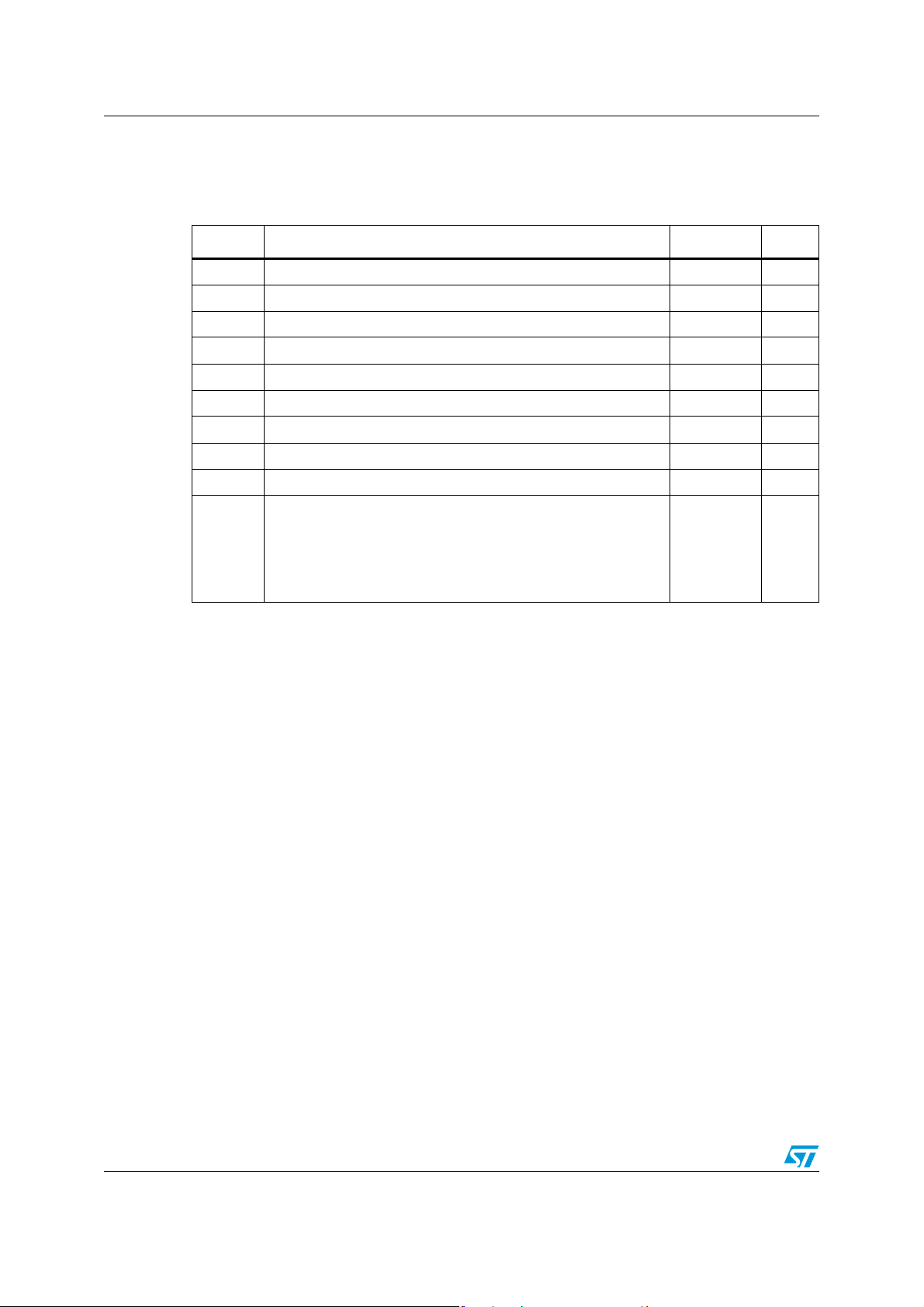

Absolute maximum ratings

3 Absolute maximum ratings

Table 5. Absolute maximum ratings

Symbol Parameter Value Unit

V

o

V

s

VIN, V

I

C

I

C

I

C

T

op

T

stg

I

sub

P

tot

Output voltage 50 V

Logic supply voltage 7 V

Input voltage, enable voltage V

EN

Continuous collector current (for each channel) 1.8 A

Collector peak current (repetitive, duty cycle = 10% ton = 5 ms) 2.5 A

Collector peak current (non repetitive, t = 10 μ s) 3.2 A

Operating temperature range (junction) -40 to +150 °C

Storage temperature range -55 to +150 °C

Output substrate current 350 mA

Total power dissipation at:

T

= 90 ° C (Power DIP)

pins

T

= 90°C (SO20)

case

T

= 70 ° C (Power DIP)

amb

T

= 70°C (SO20)

amb

4.3

3.5

1

1

S

W

W

W

W

6/22

Page 7

Electrical characteristics

4 Electrical characteristics

Note: Refer to the test circuits Figure 3 to Figure 10 (VS = 5 V, T

= 25 °C unless otherwise

amb

specified).

Table 6. Electrical characteristics

Symbol Parameter Test condition Min. Typ. Max. Unit

V

S

I

s

V

CE(sus)

I

CEX

V

CE(sat)

VINL, VENL Input low voltage - - - 0.8 V

I

L, IENL Input low current VIN = V

IN

V

L, VENH Input high voltage - 2.0 - - V

IN

IINH, IENH Input high current VIN = VINH, VEN = VENH--10μA

Logic supply voltage - 4.5 - 5.5 V

Logic supply current

All outputs ON, I

= 0.7A - - 20 mA

C

All outputs OFF - - 20 mA

= VINL, VEN = VENH

V

Output sustaining voltage

Output leakage current

Collector emitter saturation

voltage (one input on, all others

inputs off.)

IN

I

= 100 mA

C

VCE = 50V

V

= VINL, VEN = VENH

IN

= 4.5 V

V

s

V

= VINH, VEN = VENH

IN

IC = 0.6 A

IC = 1 A

I

= 1.8 A

C

, VEN = V

INL

ENL

46 - - V

--1mA

-

-

-

-

-

-

1

1.2

1.6

---100 μA

V

I

R

V

F

t

d (on)

t

d (off)

ΔI

Clamp diode leakage current

Clamp diode forward voltage

VR = 50 V, VEN = VENH

VIN = VINL

IF = 1A

IF = 1.8A

- - 100 μA

-

-

-

1.6

-

2.0VV

Tu r n- o n d e l a y t i m e Vp = 5V, RL = 10Ω --2μs

Turn-off delay time Vp = 5V, RL = 10Ω --5μs

= 5V, VEN = 5V

V

s

Logic supply current variation

IN

I

= -300 mA for each

out

channe

l

- - 120 mA

7/22

Page 8

Test circuits

5 Test circuits

Note: Pin numbers without parentheses apply to the Power DIP package.

Pin numbers in parentheses are not applicable.

Figure 3. Logic supply current

Set VIN = 4.5 V, VEN = 0.8 V, or VIN = 0.8 V, VEN = 4.5 V, for IS (all outputs off)

Set V

= 2 V, VEN = 2 V, for IS (all outputs on)

IN

Figure 4. Output sustaining voltage

Figure 5. Output leakage current

8/22

Page 9

Test circuits

Figure 6. Collector-emitter saturation voltage

Figure 7. Logic input characteristics

Set S1, S2 open, VIN, VEN = 0.8 V for IIN L, IEN L

, S2 open, VIN, VEN = 2 V for IIN H, IEN H

Set S

1

Set S

, S2 closed, VIN, VEN = 0.8 V for VIN L, VEN L

1

, S2 closed, VIN, VEN = 2 V for VIN H, VEN H

Set S

1

Figure 8. Clamp-diode leakage current

9/22

Page 10

Test circuits

Figure 9. Clamp-diode forward voltage

Figure 10. Switching time test circuit

Figure 11. Switching time waveforms

10/22

Page 11

Test circuits

Figure 12. Allowed peak collector current versus duty cycle for 1, 2, 3 or 4

contemporary working outputs (L6221AS)

Figure 13. Collector saturation voltage versus collector current

Figure 14. Free-wheeling diode forward voltage versus diode current

11/22

Page 12

Test circuits

Figure 15. Collector saturation voltage versus junction temperature at IC = 1 A

Figure 16. Free-wheeling diode forward voltage versus junction temperature

at I

= 1 A

F

Figure 17. Saturation voltage against junction temperature

12/22

Page 13

Test circuits

Figure 18. Free-wheeling diode forward voltage against junction temperature

13/22

Page 14

Application information

6 Application information

When inductive loads are driven by the L6221, a Zener diode in series with the integral freewheeling diodes increases the voltage across which energy stored in the load is discharged

and therefore speeds the current decay (

For reliability it is suggested that the Zener is chosen so that

There are two reasons for this:

● The Zener voltage changes in temperature and current.

● The instantaneous power must be limited to avoid the reverse second breakdown.

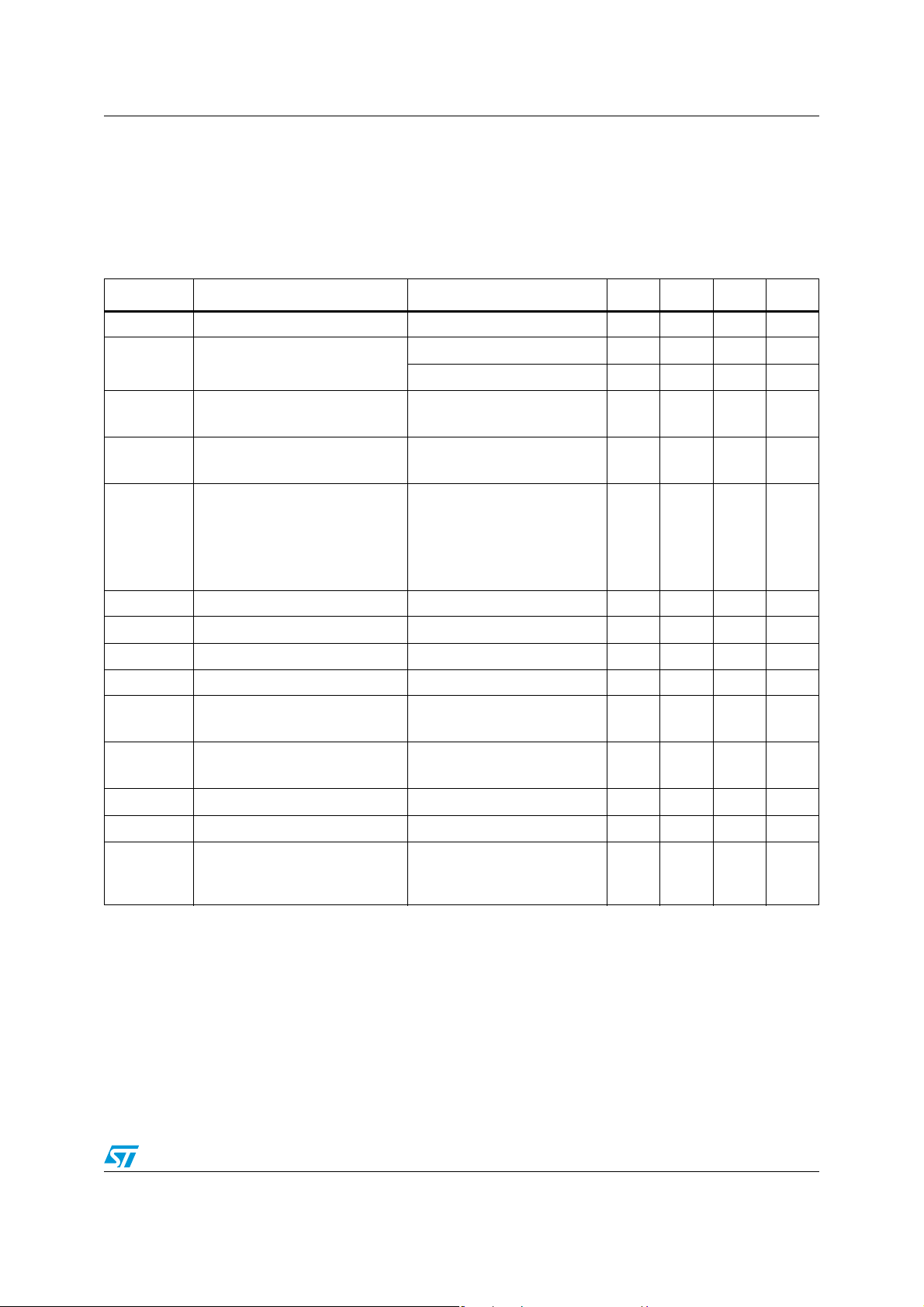

Figure 19. Free-wheeling diode connection when driving inductive loads

Figure 19

VpVz35 V<+

).

Care must be taken to ensure that the collectors are placed close together to avoid different

current partitioning at turn-off.

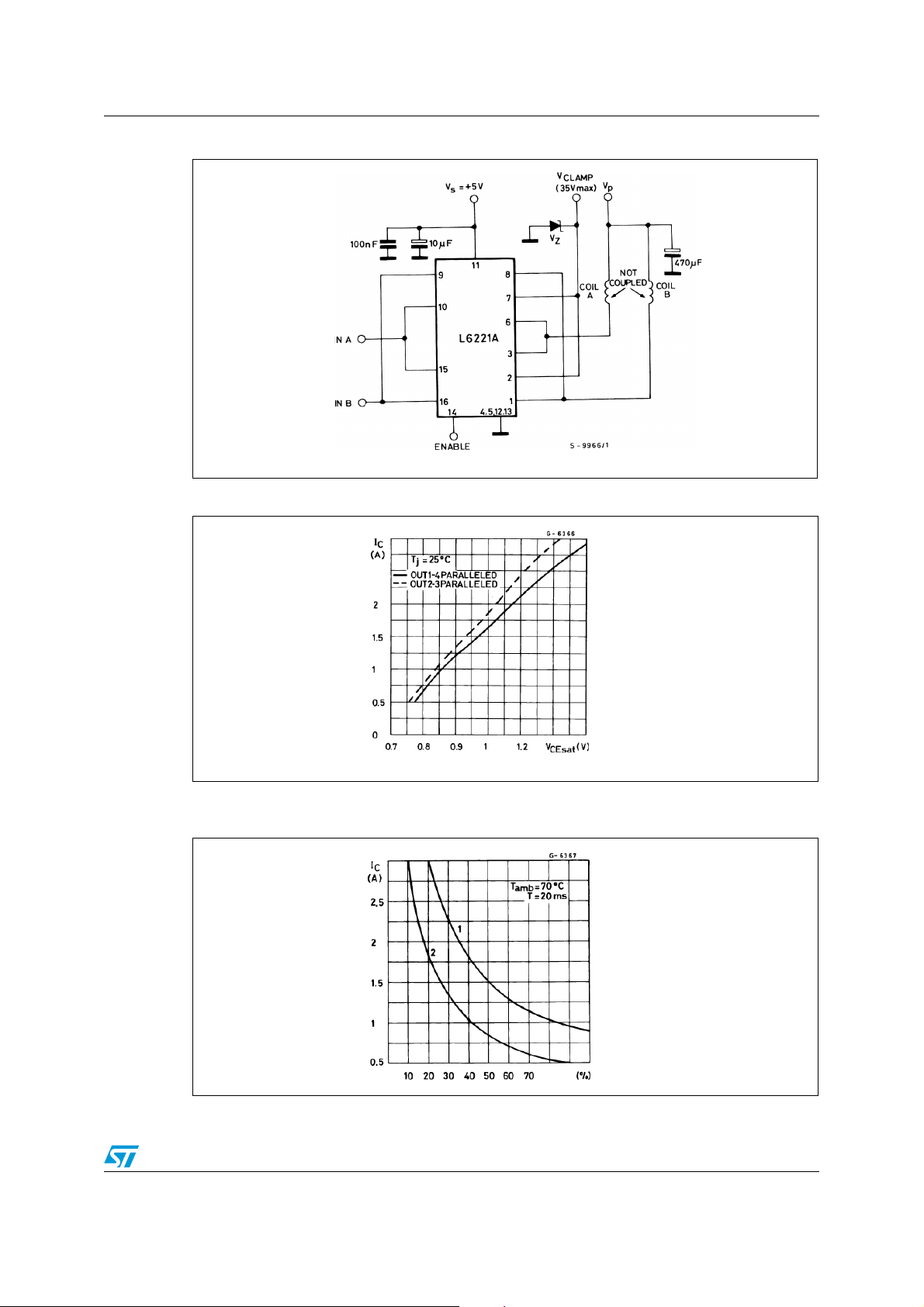

It is suggested to put in parallel channel 1 and 4 and channel 2 and 3 as shown in

for the similar electrical characteristics of the logic section (turn-on and turn-off delay time)

and the power stages (collector saturation voltage, free-wheeling diode forward voltage).

Figure 20

14/22

Page 15

Application information

Figure 20. Driver for solenoids up to 3 A

Figure 21. Saturation voltage versus collector current

Figure 22. L6221AS peak collector current versus duty cycle for 1 or 2 paralleled

outputs driven

15/22

Page 16

Mounting instructions

7 Mounting instructions

The R

copper area of the printed circuit board (

Figure 23. Example of PCB copper area used as heat sink

Figure 24. External heat sink mounting example

of the E-L6221AS can be reduced by soldering the GND pins to a suitable

th j-amb

Figure 23

) or to an external heat sink (

Figure 24

).

16/22

Page 17

Mounting instructions

Figure 25

shows the maximum dissipable power P

and the R

tot

as a function of the

th j-amb

side "α" of two equal square copper areas having a thickness of 35 µm (1.4 mils). During

soldering the pins temperature must not exceed 260 °C and the soldering time must not be

longer than 12 seconds.

The external heat sink or printed circuit copper area must be connected to electrical ground.

Figure 25. Maximum dissipable power and junction-to-ambient thermal resistance

versus side "α"

Figure 26. Maximum allowable power dissipation versus ambient temperature

17/22

Page 18

Package mechanical data

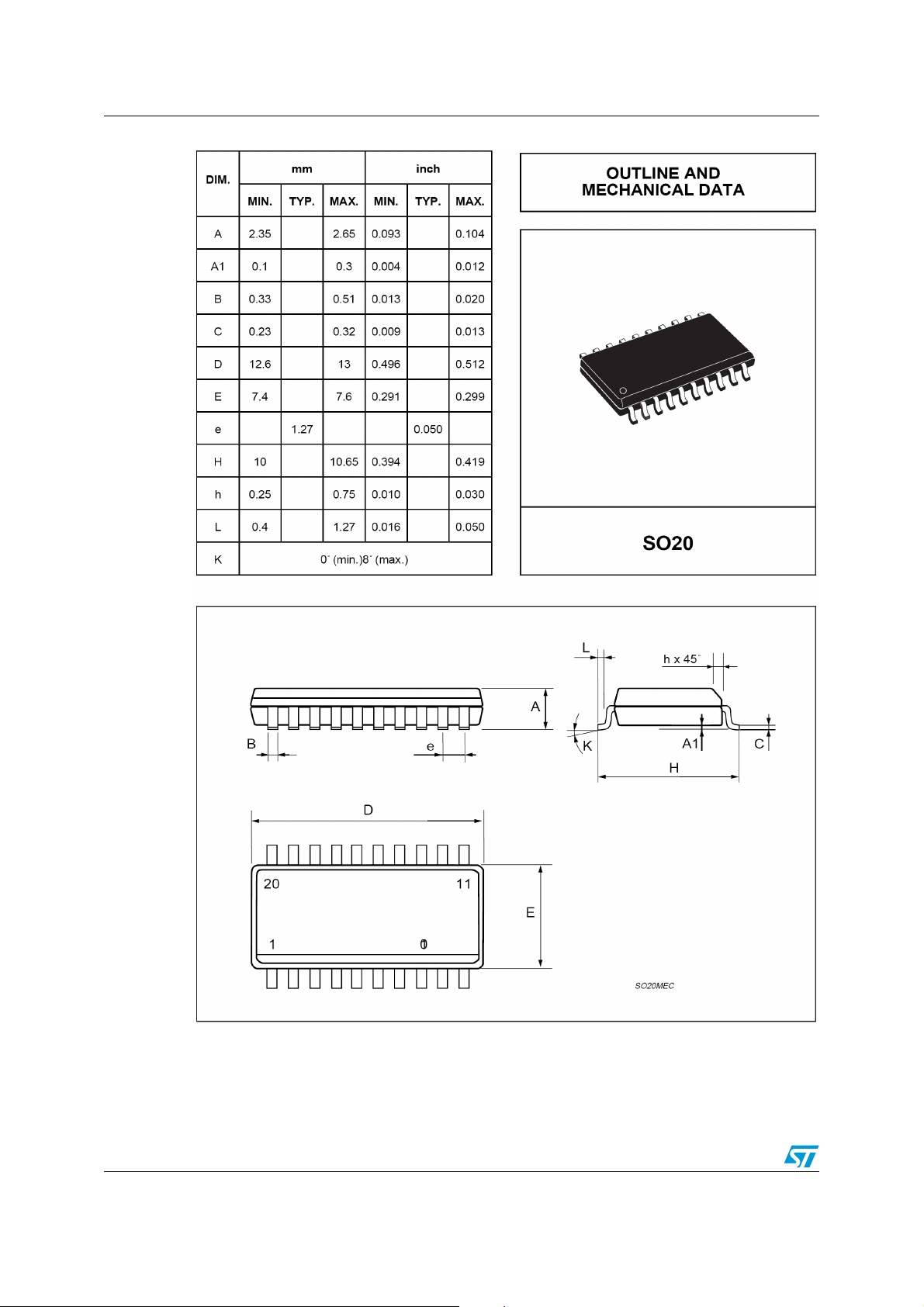

8 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK® packages, depending on their level of environmental compliance. ECOPACK®

specifications, grade definitions and product status are available at:

ECOPACK® is an ST trademark.

www.st.com

.

18/22

Page 19

Package mechanical data

DIM.

a1 0.51 0.020

B 0.85 1.40 0.033 0.055

b 0.50 0.020

b1 0.38 0.50 0.015 0.020

D 20.0 0.787

E 8.80 0.346

e 2.54 0.100

e3 17.78 0.700

F 7.10 0.280

I 5.10 0.201

L 3.30 0.130

Z 1.27 0.050

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

OUTLINE AND

MECHANICAL DATA

Power DIP 16

Powerdip 16

19/22

Page 20

Package mechanical data

20/22

Page 21

Revision history

9 Revision history

Table 7. Document revision history

Date Revision Changes

14-Jan-2004 2 Released in EDOCS

Document reformatted.

19-Jan-2009 3

Inserted title for

Removed reference to obsolete product L6221N and the associated

package (multiwatt-15).

Figure 19

.

21/22

Page 22

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

22/22

Loading...

Loading...