Page 1

®

.

OPERATING SUPPLY VOLTAGE UP TO 46 V

.

TOTAL DC CURREN T UP TO 4 A

.

LOW SATURATION VO LTAGE

.

OVERTEMPERATU RE P ROT ECTION

.

LOGICAL "0" INPUT VOLTAGE UP TO 1.5 V

(HIGH NOISE IMMUNITY)

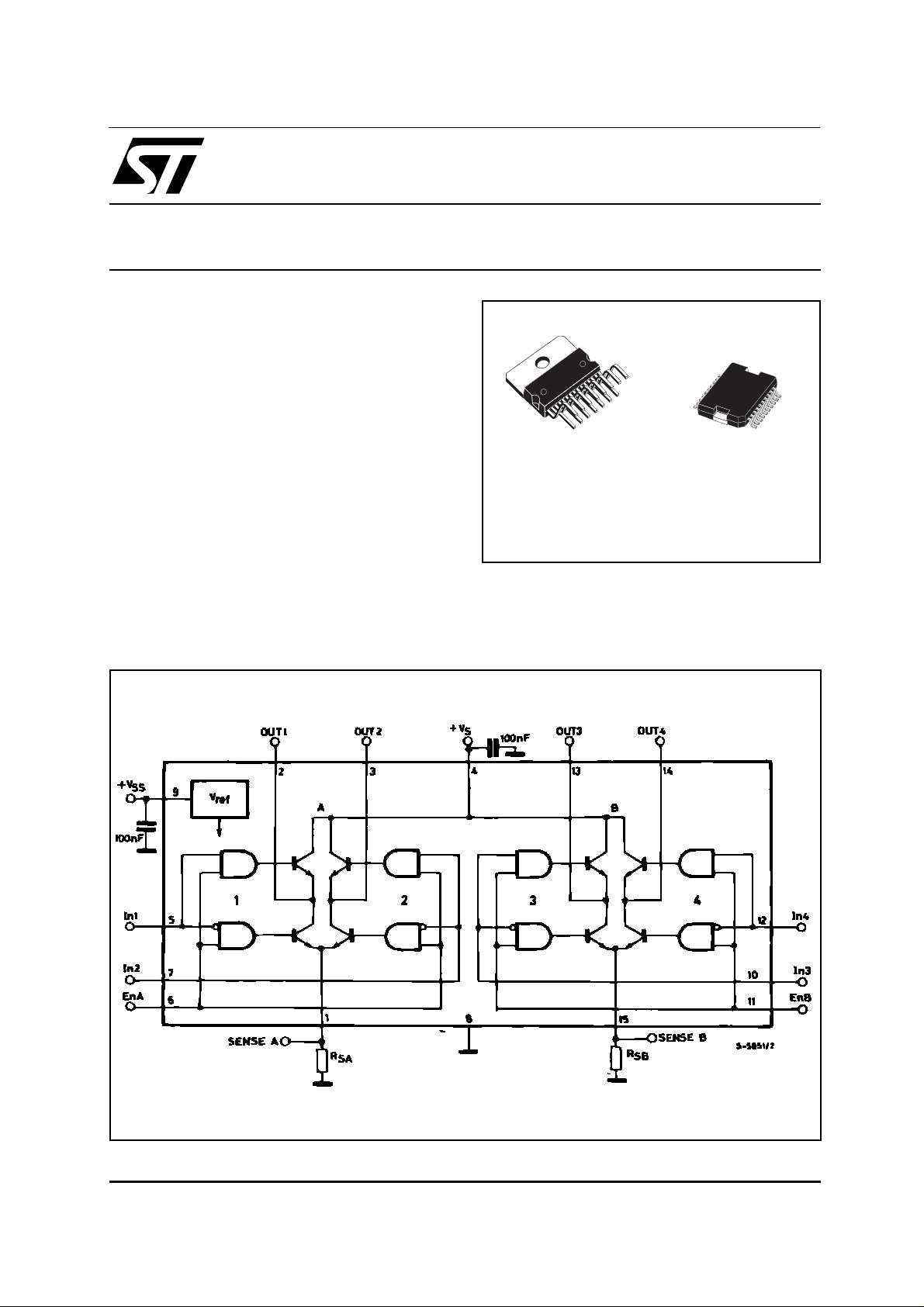

L298

DUAL FULL-BRIDGE DRIVER

DESCRIPTION

The L298 is an integrat ed m onolithic c irc uit in a 15 lead Multiwatt and PowerSO20 packages. It is a

high volt age , hig h c urrent dual f ul l-b ri dge driver designed to acc ept standard T TL logic lev els and drive

inductive loads such as relays, solenoids, DC and

stepping mot ors. Two enab le inputs are provided to

enable or di sable the d evice indepen dently of th e input signals. The emitters of the lower transistors of

each bridge are connected together and the corresponding e xte rnal termi nal c an b e us ed f or the co n-

BLOCK DIAGRAM

Multiwatt15

ORDERING NUMBERS :

L298HN (Multiwatt Horiz.)

L298P (PowerSO20)

nection of an external sensing r esistor. An ad ditional

supply in put is p ro vi ded so that the logic wor k s at a

lower voltage.

PowerSO20

L298N (Multiwatt Vert.)

Jenuary 2000

1/13

Page 2

L298

ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Value Unit

V

V

SS

V

I,Ven

I

O

V

sens

P

T

op

T

stg

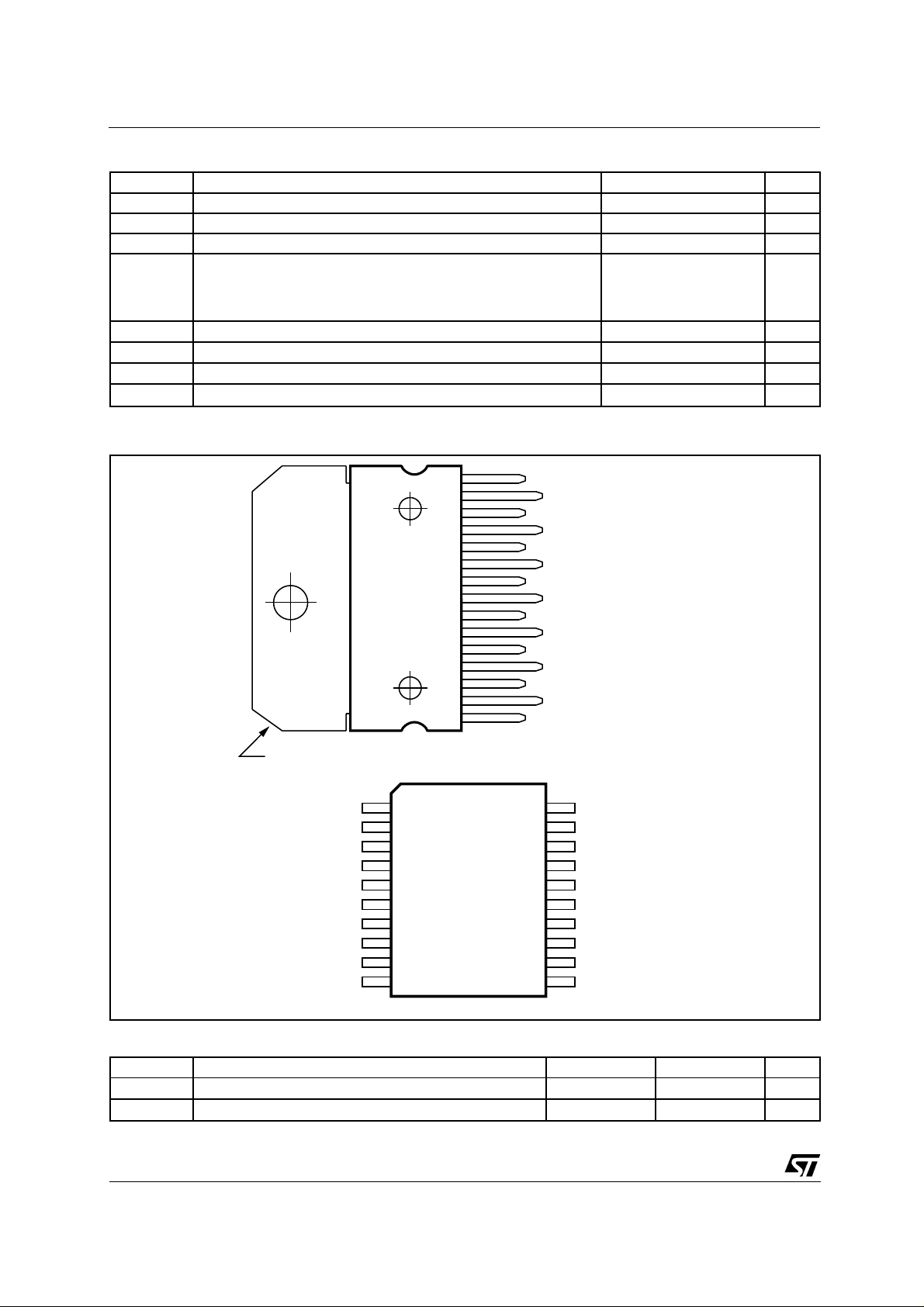

PIN CONNECTIONS (top view)

Power Supply 50 V

S

Logic Supply Voltage 7 V

Input and Enable Voltage –0.3 to 7 V

Peak Output Current (each Channel)

– Non Repetitive (t = 100µs)

–Repetitive (80% on –20% off; t

–DC Opera tio n

= 10ms)

on

3

2.5

2

Sensing Voltage –1 to 2.3 V

Total Power Dissipation (T

tot

case

= 75°C)

25 W

Juncti on Op era ting Temper at ur e –25 to 130

, TjStorag e and Junctio n Temp er atu re –40 to 150

A

A

A

C

°

C

°

Multiwatt15

TAB CONNECTED TO PIN 8

GND

Sense A

N.C.

Out 1

Out 2

V

S

Input 1

Enable A

Input 2

GND 10

1

2

3

4

PowerSO20

5

6

7

8

9

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

D95IN239

D95IN240A

20

19

18

17

16

15

14

13

12

11

CURRENT SENSING B

OUTPUT 4

OUTPUT 3

INPUT 4

ENABLE B

INPUT 3

LOGIC SUPPLY VOLTAGE V

GND

INPUT 2

ENABLE A

INPUT 1

SUPPLY VOLTAGE V

OUTPUT 2

OUTPUT 1

CURRENT SENSING A

GND

Sense B

N.C.

Out 4

Out 3

Input 4

Enable B

Input 3

VSS

GND

S

SS

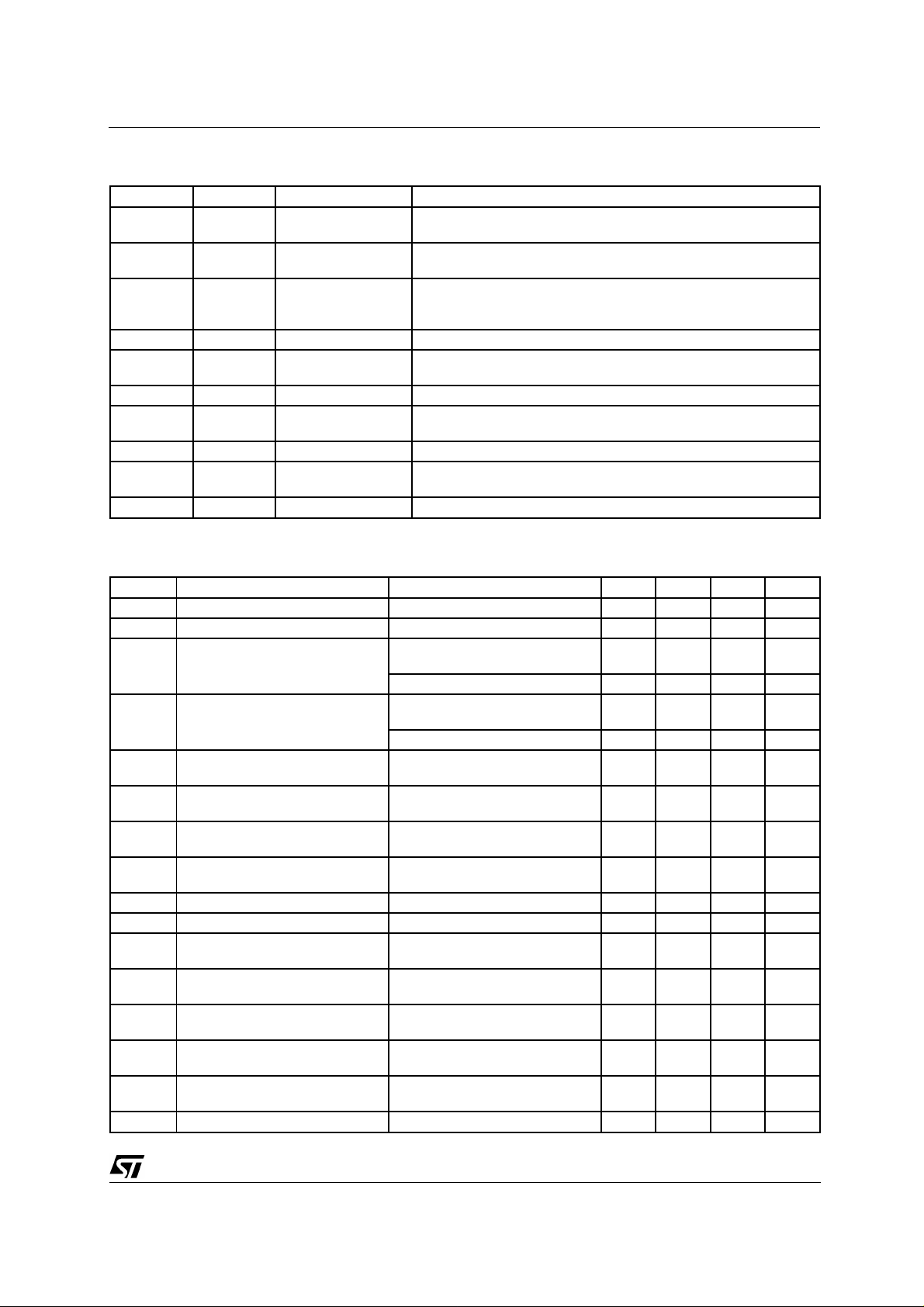

THERMAL DATA

Symbol Parameter PowerSO20 Multiwatt15 Unit

R

th j-case

R

th j-amb

(*) Mounted on aluminum s ubst rate

2/13

Thermal Resistance Junction-case Max. – 3

Thermal Resistance Junction-ambient Max. 13 (*) 35

C/W

°

C/W

°

Page 3

PIN FUNCTIONS (refer t o the block diagram )

MW.15 PowerSO Name Function

1;15 2;19 Sense A; Sense B Between this pin and ground is connected the sense resistor to

control the current of the load.

2;3 4;5 Out 1; Out 2 Outputs of the Bridge A; the current that flows through the load

connected betw een these two pi ns is mon it or ed at pi n 1.

46 V

S

5;7 7;9 Input 1; Input 2 TTL Compatible Inputs of the Bridge A.

6;11 8;14 Enable A; Enable B TTL Compatible Enable Input: the L state disables the bridge A

8 1,10,11,20 GND Ground.

9 12 VSS Supply Voltage for the Logic Blocks. A100nF capacitor must be

10; 12 13;15 Input 3; Input 4 TTL Compatible Inputs of the Bridge B.

13; 14 16;17 Out 3; Out 4 Outputs of the Bridge B. The current that flows through the load

– 3;18 N.C. Not Connected

Supply Voltage for the Power Output Stages.

A non-inductive 100nF capacitor must be connected between this

pin and grou nd.

(enable A) and/or the bridge B (enable B).

connected between this pin and ground.

connected betw een these two pi ns is mon it or ed at pi n 15.

L298

ELECT RICAL CHARA CTE RISTICS (V

= 42V; VSS = 5V, Tj = 25°C; unless otherwise spec if ie d)

S

Symbol Parameter Test Conditions Min. Typ. Max. Unit

Supply Voltage (pin 4) Operative Condition VIH +2.5 46 V

V

S

V

Logic Supply Voltage (pin 9) 4.5 5 7 V

SS

I

Quiescent Supply Current (pin 4) Ven = H; IL = 0 Vi = L

S

V

= H

i

13

50

22

70

Ven = L Vi = X 4 mA

I

Quiescent Current from VSS (pin 9) Ven = H; IL = 0 Vi = L

SS

V

= H

i

24

7

36

12

Ven = L Vi = X 6 mA

V

Input Low Voltage

iL

–0.3 1.5 V

(pins 5, 7, 10, 12)

Input High Vol ta ge

V

iH

2.3 VSS V

(pins 5, 7, 10, 12)

Low Voltage Input Current

I

iL

Vi = L –10

(pins 5, 7, 10, 12)

High Voltage Input Current

I

iH

Vi = H ≤ V

–0.6V

SS

30 100

(pins 5, 7, 10, 12)

V

= L Enable Low Voltage (pins 6, 11) –0.3 1.5 V

en

= H Enable High Voltage (pins 6, 11) 2.3 V

V

en

Ien = L Low Voltage Enable Current

Ven = L –10

SS

(pins 6, 11)

= H High Voltage Enable Current

I

en

= H ≤ VSS –0.6V

V

en

30 100

(pins 6, 11)

V

CEsat (H)

V

CEsat (L )

V

CEsat

V

sens

Source Saturation Voltage IL = 1A

= 2A

I

L

Sink Saturation Voltage IL = 1A (5)

= 2A (5)

I

L

Total Drop IL = 1A (5)

= 2A (5)

I

L

Sensing Voltage (pins 1, 15) –1 (1) 2 V

0.95 1.35

2

0.85 1.2

1.7

1.7

2.7

1.6

2.3

1.80 3.2

4.9

mA

mA

mA

mA

µ

µ

V

µ

µ

V

V

V

V

V

V

A

A

A

A

3/13

Page 4

L298

ELECT RICAL CHARA CTE RISTICS (continued)

Symbol Parameter Test Conditions Min. Typ. Max. Unit

T

(Vi) Source Current Turn-off Delay 0.5 Vi to 0.9 IL (2); (4) 1.5

1

(Vi) Source Current Fall Time 0.9 IL to 0.1 IL (2); (4) 0.2

T

2

(Vi) Source Current Turn-on Delay 0.5 Vi to 0.1 IL (2); (4) 2

T

3

(Vi) Source Current Rise Time 0.1 IL to 0.9 IL (2); (4) 0.7

T

4

(Vi) Sink Current Turn-off Delay 0.5 Vi to 0.9 IL (3); (4) 0.7

T

5

(Vi) Sink Current Fall Time 0.9 IL to 0.1 IL (3); (4) 0.25

T

6

(Vi) Sink Current Turn-on Delay 0.5 Vi to 0.9 IL (3); (4) 1.6

T

7

(Vi) Sink Current Rise Time 0.1 IL to 0.9 IL (3); (4) 0.2

T

8

) Commutation Fre qu enc y IL = 2A 25 40 KHz

fc (V

i

T

(Ven) Source Current Turn-off Delay 0.5 Ven to 0.9 IL (2); (4) 3

1

(Ven) Source Current Fall Time 0.9 IL to 0.1 IL (2); (4) 1

T

2

(Ven) Source Current Turn-on Delay 0.5 Ven to 0.1 IL (2); (4) 0.3

T

3

(Ven) Source Current Rise Time 0.1 IL to 0.9 IL (2); (4) 0.4

T

4

(Ven) Sink Current Turn-off Delay 0.5 Ven to 0.9 IL (3); (4) 2.2

T

5

(Ven) Sink Current Fall Time 0.9 IL to 0.1 IL (3); (4) 0.35

T

6

(Ven) Sink Current Turn-on Delay 0.5 Ven to 0.9 IL (3); (4) 0.25

T

7

(Ven) Sink Current Rise Time 0.1 IL to 0.9 IL (3); (4) 0.1

T

8

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

s

µ

1) 1)Sensing voltage c an be – 1 V for t ≤ 50 µsec; in stead y state V

2) See fig. 2.

3) See fig. 4.

4) The load must be a pure resistor.

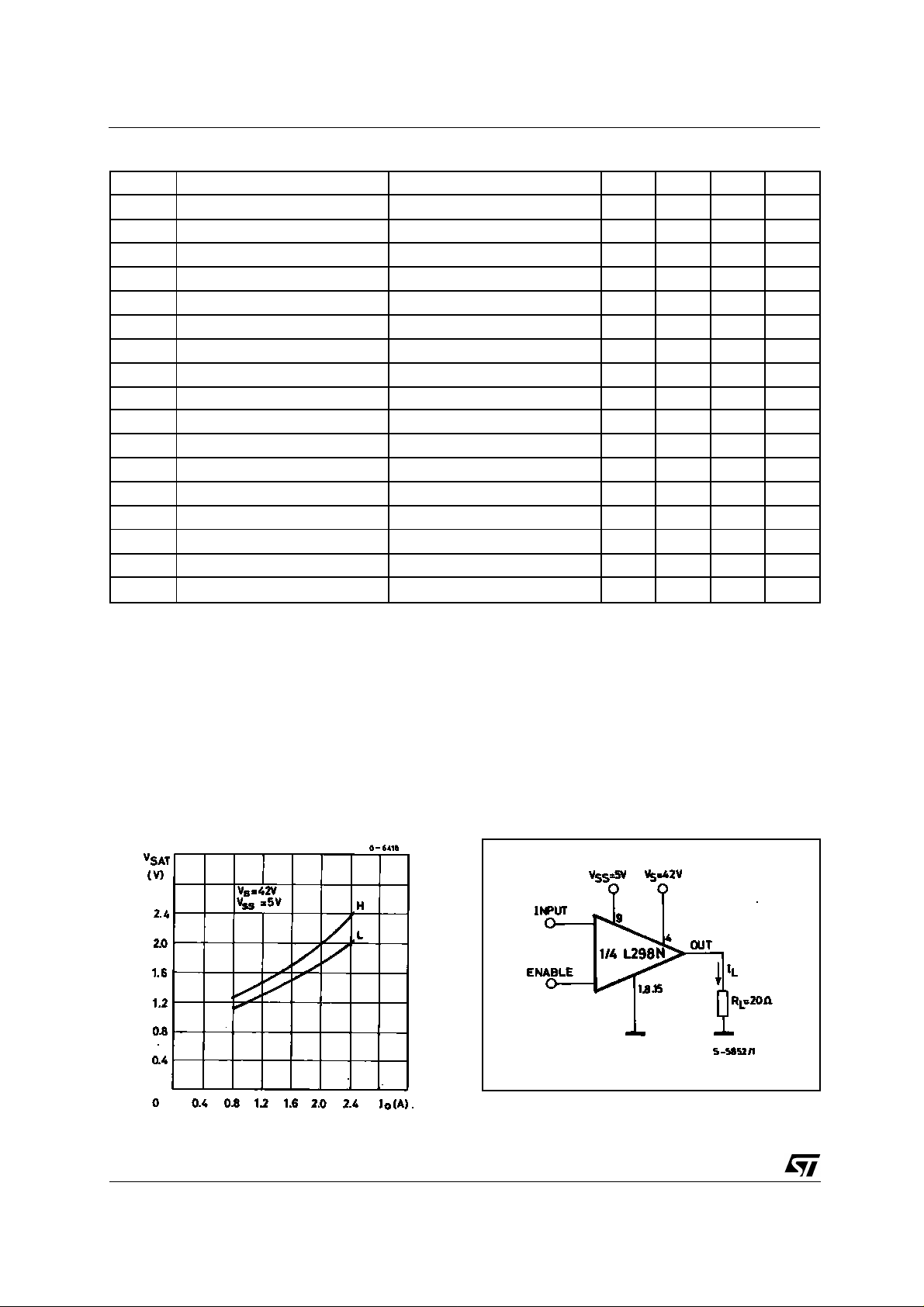

Figure 1 : Typical Sat ur ation Voltage vs . O utput

Current.

min ≥ – 0.5 V.

sens

Figure 2 : Switchin g Tim es T es t Cir c uit s .

4/13

Note :

For INPUT Switching, set EN = H

For ENABLE Switching, set IN = H

Page 5

Figure 3 : Source Cur ren t Delay Times vs. Input or En abl e S wit c hi ng.

Figure 4 : Switchin g Tim es T es t Cir c uit s .

L298

Note :

For INPUT Switching, set EN = H

For ENABLE Switching, set IN = L

5/13

Page 6

L298

Figure 5 : Sink Curre nt Delay Times vs. Input 0 V E nab le S witching.

Figure 6 : Bidirectional DC Motor C ont r ol.

Inputs Function

= H C = H ; D = L Forward

V

en

C = L ; D = H Reverse

C = D Fast Motor Stop

Ven = L C = X ; D = X Free Running

L = Low H = High X = Don’t care

Motor Stop

6/13

Page 7

L298

Figure 7 : For higher cur ren t s, ou tp uts can be par alleled. Tak e c ar e to par al lel c hannel 1 with cha nnel 4

and channel 2 wit h cha nnel 3.

APPLICATION INFORMATION (Re fer to the block diagra m)

1.1. POW ER OUTPUT ST A GE

The L298 in tegrates two pow er output stages (A ; B).

The power output stage is a bridge configuration

and its outputs can drive an inductive load in common or diffe renzial mo de, depend ing on the s tate of

the inputs. The current that flows through the load

comes out from the brid ge at the sen se out put : an

external r esis tor ( R

; RSB.) allows t o dete ct the in-

SA

tensity of this cu rr en t.

1.2. INPUT STAGE

Each bri dge is dri ven b y means of four gate s the in-

put of which ar e In1 ; In2 ; EnA a nd I n3 ; In4 ; E nB .

The In inputs s et the bridge st ate when The En i nput

is high ; a low state of t he En input inhibits the b ridge.

All the inpu ts ar e TT L com pa t ible .

2. SUGGESTIONS

A non inductive capacitor, usually of 100 nF, must

be foreseen between both Vs and Vss, to ground,

as near as pos sibl e to G ND pin. When the lar ge c apacitor of the powe r su ppl y is too f ar from the I C, a

second smaller one must be foreseen near the

L298.

The sense resi sto r, not of a wire wo und type, must

be grounded near t he ne gative pol e of V s that mu st

be near the GN D pin of the I.C.

Each input must be connected to the source of the

driving s ign als by me ans of a v er y shor t path.

Turn-On and Turn-Off : Before to Turn-ON the Supply Voltage and b efore to Turn it OFF, the E nable input must be d riven to the Low state.

3. APPLICATIONS

Fig 6 sho ws a bidirectional DC motor c ontr ol Sche-

matic Dia gram for wh ich o nly o ne bridg e is needed .

The external bridge of diodes D1 to D4 is made by

four fast recovery elements (trr ≤ 200 nsec) that

must be chosen of a VF as low as possible at the

worst cas e of t he lo ad c ur re nt .

The sen se output v oltage can be used to control the

current am plitude by chopp ing the inputs, or to provide ove rcurr ent p rotectio n by switc hing low the enable input.

The brake function (Fast motor stop) requires that

the Absolute Maximum Rating of 2 Amps must

never be ov er co m e.

When the repetitive peak current needed from the

load is higher than 2 Amp s , a p ar all eled configur ation can be chosen (See Fig.7).

An external bridge of diodes are required when inductive loads are dr iv en and whe n the inputs of the

IC are chop ped ; Sho ttky diodes would be preferred.

7/13

Page 8

L298

This solut ion can drive unt il 3 Amps In DC operati on

and until 3.5 Am p s of a r epetitive pea k cur r ent .

On Fig 8 it is shown the d riving of a two pha se bipolar

stepper motor ; the needed signals to drive the inputs of the L298 are generated, in this example,

from the IC L297.

Fig 9 show s an ex am ple of P.C.B . designed for the

applicati on of F ig 8.

Figure 8 : Two Phase Bipolar Stepp er Motor Circuit .

This circ uit dr iv es bipolar steppe r m otor s wit h w inding current s up to 2 A . The diodes are fas t 2 A types .

Fig 10 shows a second two phase bipolar stepper

motor control circuit where the current is controlled

by the I.C. L65 06.

RS1 = RS2 = 0.5

D1 to D8 = 2 A Fast diodes

8/13

Ω

VF ≤ 1.2 V @ I = 2 A

{

trr ≤ 200 ns

Page 9

Figure 9 : Suggested Pr int ed Cir c uit B oar d La y out for the Circuit of fi g. 8 (1 : 1 scale).

L298

Figure 10 : Two Phase Bi polar Stepper Mo tor C ont r ol C ir cu it by Us ing t he Cur re nt Con t rol ler L65 06.

RR and R

depend from the load current

sense

9/13

Page 10

L298

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 5 0.197

B 2.65 0.104

C 1.6 0.063

D 1 0.039

E 0.49 0.55 0.019 0.022

F 0.66 0.75 0.026 0.030

G 1.02 1.27 1.52 0.040 0.050 0.060

G1 17.53 17.78 18.03 0.690 0.700 0.710

H1 19.6 0.772

H2 20.2 0.795

L 21.9 22.2 22.5 0.862 0.874 0.886

L1 21.7 22.1 22.5 0.854 0.870 0.886

L2 17.65 18.1 0.695 0.713

L3 17.25 17.5 17.75 0.679 0.689 0.699

L4 10.3 10.7 10.9 0.406 0.421 0.429

L7 2.65 2.9 0.104 0.114

M 4.25 4.55 4.85 0.167 0.179 0.191

M1 4.63 5.08 5.53 0.182 0.200 0.218

S 1.9 2.6 0.075 0.102

S1 1.9 2.6 0.075 0.102

Dia1 3.65 3 .85 0.144 0.152

mm inch

OUTLINE AND

MECHANICAL DATA

Multiwatt15 V

10/13

Page 11

L298

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

A 5 0.197

B 2.65 0.104

C 1.6 0.063

E 0.49 0.55 0.019 0.022

F 0.66 0.75 0.026 0.030

G 1.14 1.27 1.4 0.045 0.050 0.055

G1 17.57 17.78 17.91 0.692 0.700 0.705

H1 19.6 0.772

H2 20.2 0.795

L 20.57 0.810

L1 18.03 0.710

L2 2.54 0.100

L3 17.25 17.5 17.75 0.679 0.689 0.699

L4 10.3 10.7 10.9 0.406 0.421 0.429

L5 5.28 0.208

L6 2.38 0.094

L7 2.65 2.9 0.104 0.114

S 1.9 2.6 0.075 0.102

S1 1.9 2.6 0.075 0.102

Dia1 3.65 3.85 0.144 0.152

mm inch

OUTLINE AND

MECHANICAL DATA

Multiwatt15 H

11/13

Page 12

L298

DIM.

MIN. TYP. MAX. MIN. TYP. MAX.

mm inch

A 3.6 0.142

a1 0.1 0.3 0.004 0.012

a2 3.3 0.130

a3 0 0.1 0.000 0.004

b 0.4 0.53 0.016 0.021

c 0.23 0.32 0.009 0.013

D (1) 15.8 16 0.622 0.630

D1 9.4 9.8 0.370 0.386

E 13.9 14.5 0.547 0.570

e 1.27 0.050

e3 11.43 0.450

E1 (1) 10.9 11.1 0.429 0.437

E2 2.9 0.114

E3 5.8 6.2 0.228 0.244

G 0 0.1 0.000 0.004

H 15.5 15.9 0.610 0.626

h 1.1 0.043

L 0.8 1.1 0.031 0.043

N 10˚ (max.)

S

8˚ (max.)

T10 0.394

(1) "D and F" do not include mold flash or protrusions.

- Mold flash or protrusions shall not exceed 0.15 mm (0.006").

- Critical dimensions: "E", "G" and "a3"

OUTLINE AND

MECHANICAL DATA

JEDEC MO-166

PowerSO20

E2

h x 45

DETAIL B

BOTTOM VIEW

R

lead

a3

Gage Plane

E

DETAIL B

0.35

S

D1

L

c

a1

DETAIL A

slug

- C -

SEATING PLANE

GC

(COPLANARITY)

E3

NN

a2

A

b

DETAIL A

e3

H

D

T

1

e

1120

E1

10

PSO20MEC

12/13

Page 13

L298

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences of us e of such inform ation nor for any infringement of patent s or other right s of third parties whic h may result from its use. No

license is granted by implication or otherwise under any patent or patent rights of STMicroelectronics. Specification mentioned in this

publication are subject to change without notice. This publication supersedes and replaces all information pr eviously supplied. STMicroelectronics products are not authorized for use as critical components in life support devices or systems without express wr itten

approval of STMicr oelectronic s.

Australia - Brazil - Chin a - Finl and - France - Ger many - H ong Kong - In dia - Ital y - Japan - Mal aysia - Malta - M orocco -

The ST logo is a regis tered tradem ark of STMic roelec tronics

© 2000 STMicroelec tronics – Printed in Ital y – All Ri ghts Reserv ed

STMicroelectronic s GROUP OF COM PANIES

Singapore - Spain - Swede n - Swi tzerland - U nited K ingdom - U. S.A.

http://www.st.co m

13/13

Loading...

Loading...