L297

L297A

STEPPER MOTOR CONTROLLERS

NORMAL/WAWEDRIVE

HALF/FULLSTEP MODES

CLOCKWISE/ANTICLOCKWISEDIRECTION

SWITCHMODE LOAD CURRENT REGULA-

TION

PROGRAMMABLE LOAD CURRENT

FEWEXTERNALCOMPONENTS

RESETINPUT& HOME OUTPUT

ENABLEINPUT

STEP-PULSEDOUBLER(L297Aonly)

DESCRIPTION

The L297 Stepper Motor Controller IC generates

fourphase drivesignals for two phase bipolar and

fourphaseunipolar stepmotorsinmicrocomputercontrolledapplications.The motor can be driven in

half step, normal and wawe drive modes and onchip PWM chopper circuits permit switch-mode

control of thecurrent in the windings. A feature of

October 1991

Symbol Parameter Value Unit

V

s

Supply voltage 10 V

V

i

Input signals 7V

P

tot

Totalpower dissipation (T

amb

=70°C)

1W

T

stg,Tj

Storage and junction temperature -40 to + 150 °C

ABSOLUTEMAXIMUM RATINGS

this device is that it requires only clock, direction

and mode input signals. Sincethe phaseare generated internallytheburdenonthemicroprocessor,

and the programmer,is greatly reduced. Mounted

in a 20-pin plastic package, the L297 canbe used

with monolithicbridge drivessuch asthe L298N or

L293E, orwith discretetransistorsanddarlingtons.

The L297Aalso includesa clock pulse doubler.

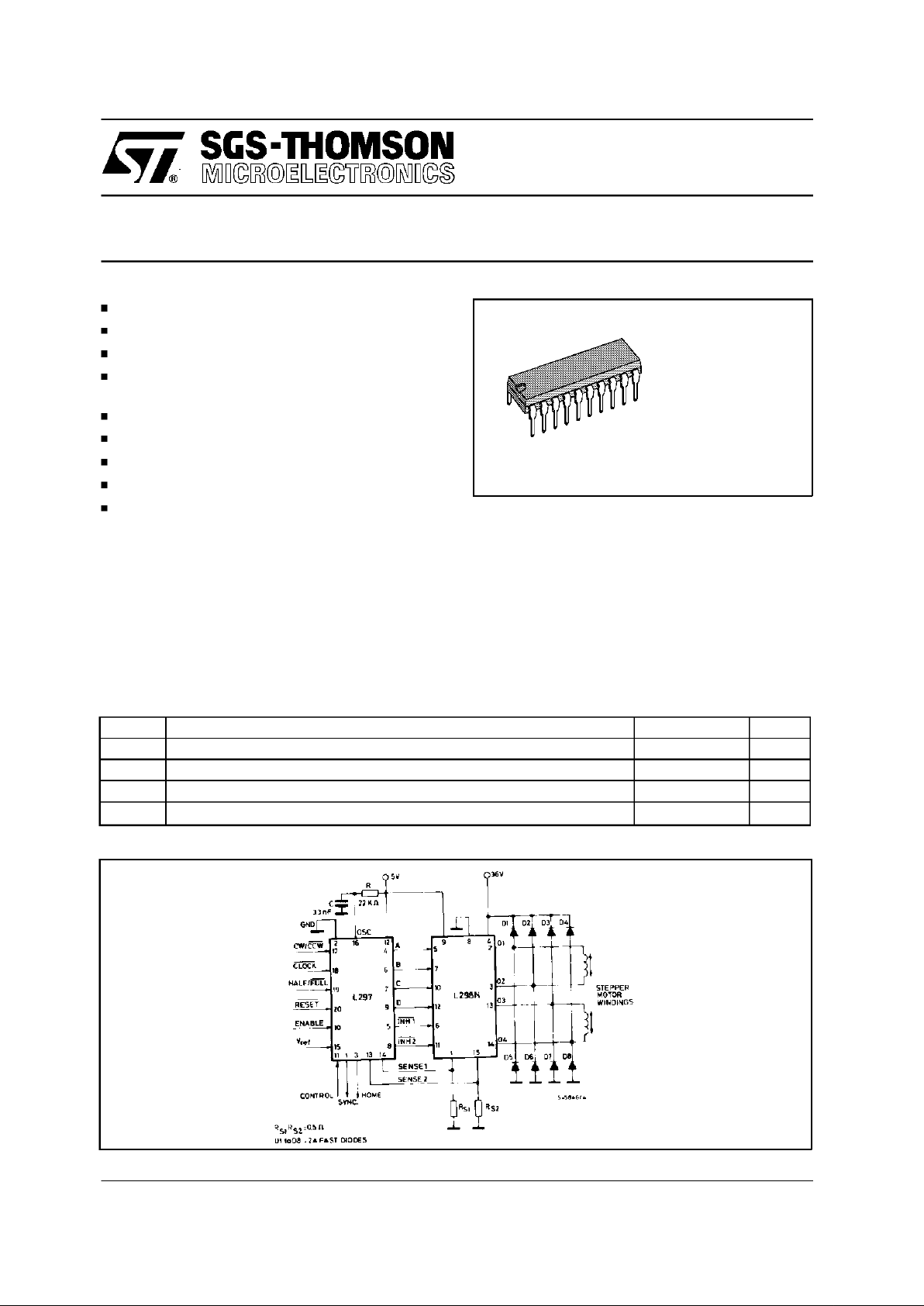

TWOPHASE BIPOLAR STEPPER MOTOR CONTROL CIRCUIT

DIP-20 Plastic

(0.25)

ORDER CODES : L297 - L297A

1/11

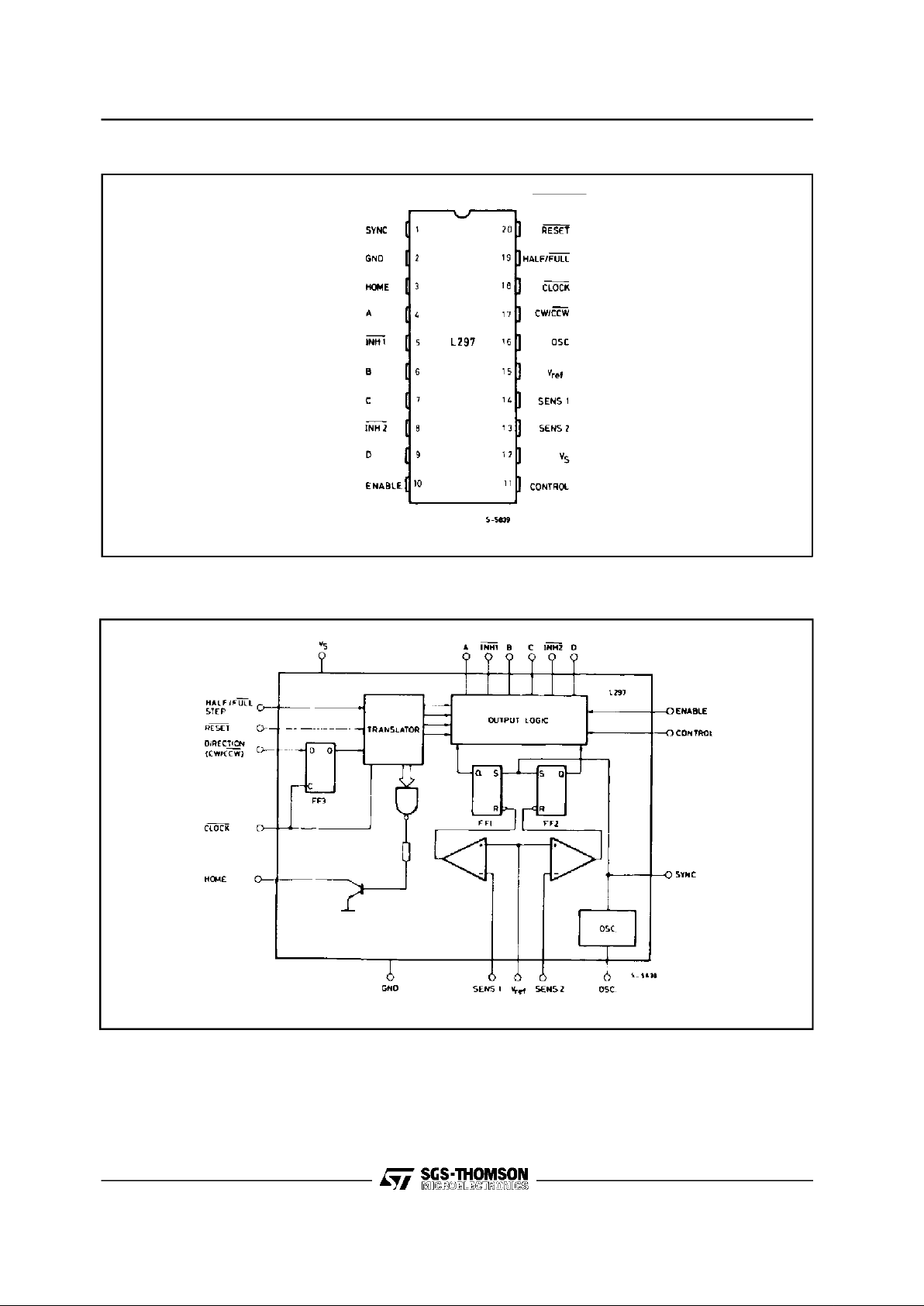

PIN CONNECTION (L297)

BLOCK DIAGRAM (L297)

2/11

L297-L297A

Symbol Parameter Value Unit

Rth-j-amb Thermal resistance junction-ambient max 80 °C/W

THERMALDATA

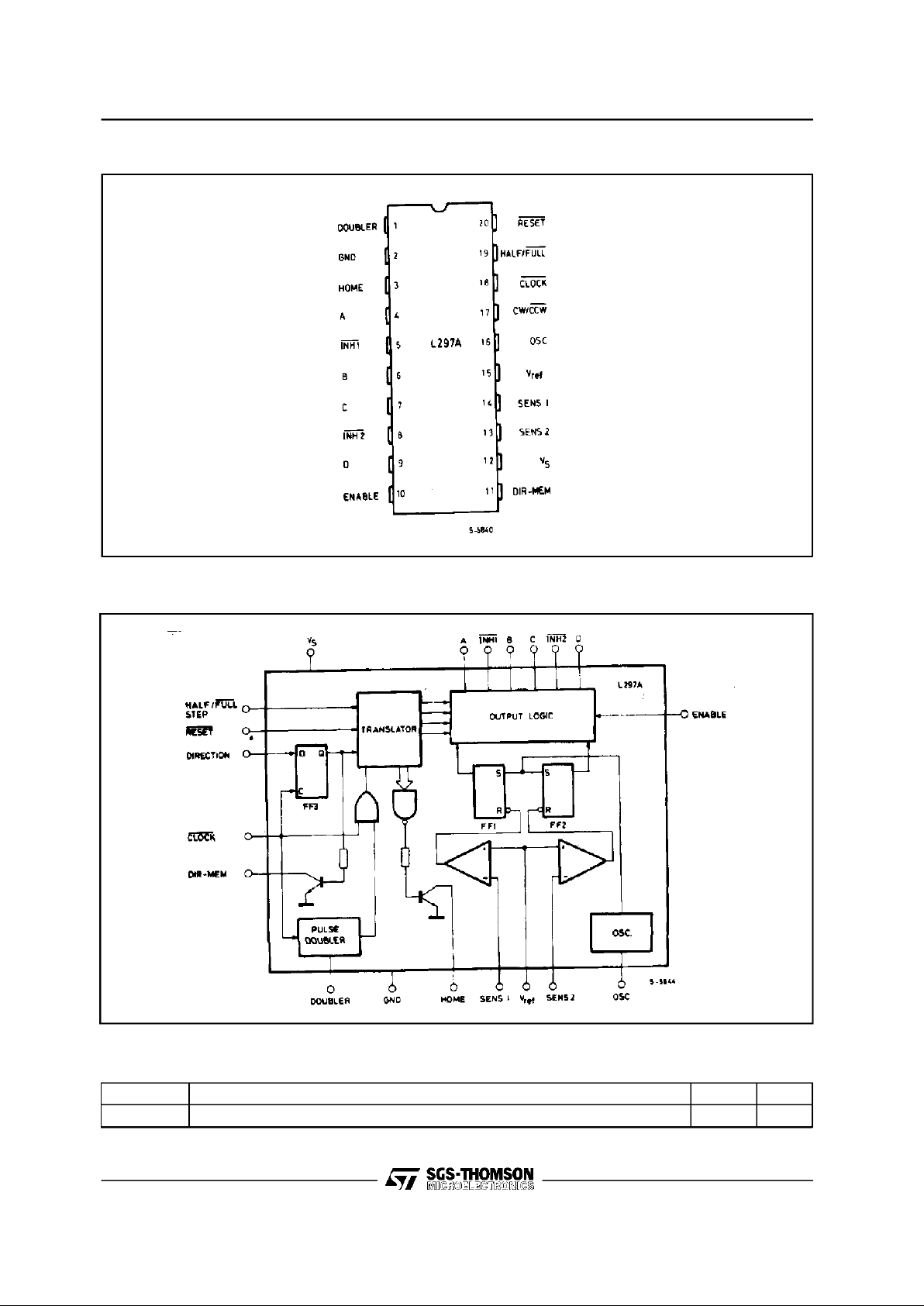

BLOCK DIAGRAM (L297A)

PIN CONNECTION (L297A)

3/11

L297-L297A

4/11

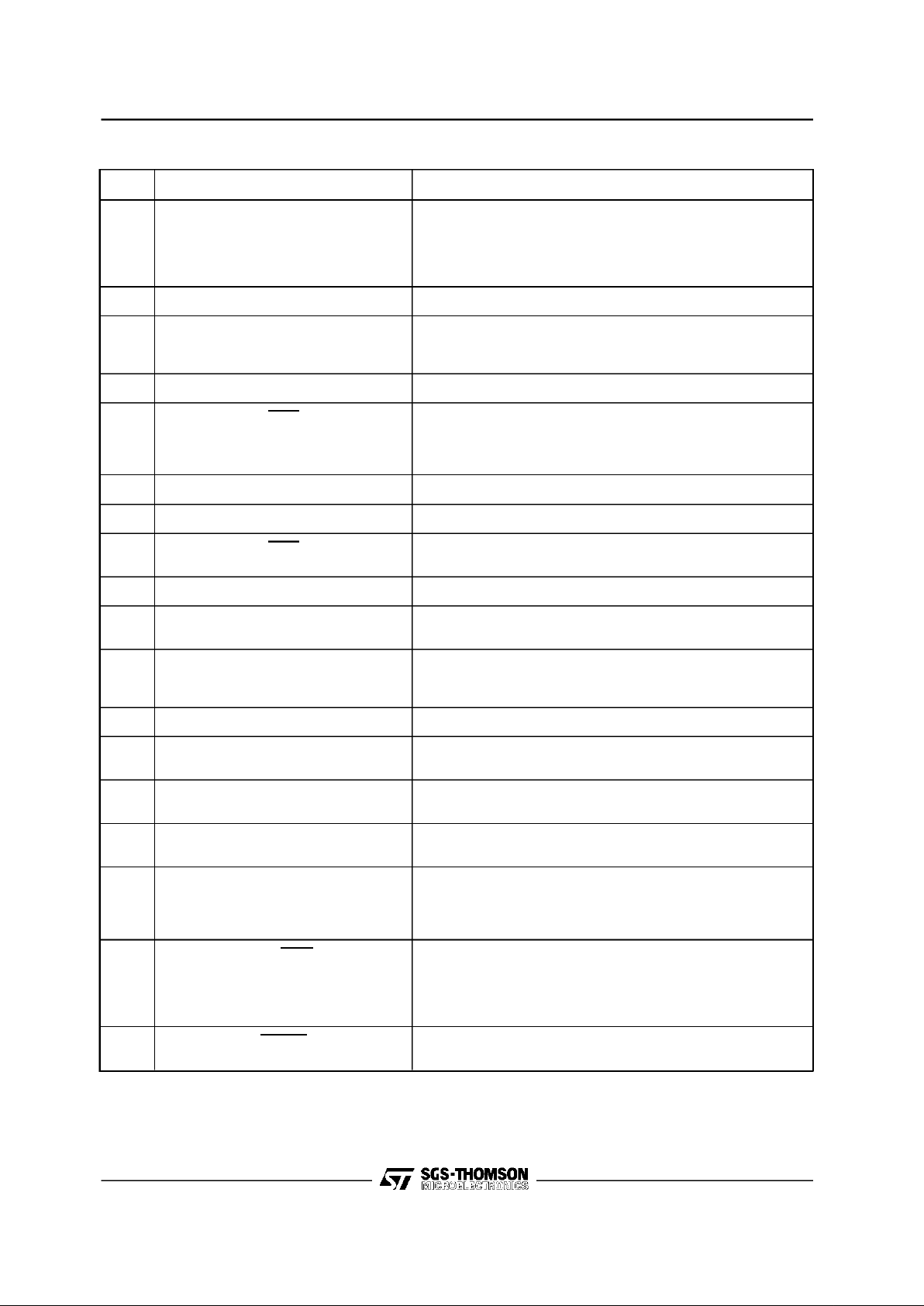

N°

NAME FUNCTION

1 SYNC Output of the on-chip chopper oscillator.

TheSYNC connections The SYNC connections of all L297s to be

synchronized are connected together and the oscillator

componentsare omitted on all but one. If an external clock

source is used it is injected at this terminal.

2 GND Ground connection.

3 HOME Open collector output that indicates when the L297 is in itsinitial

state (ABCD = 0101).

Thetransistor is open when this signal is active.

4 A Motor phase Adrive signal for power stage.

5 INH1 Activelow inhibit control for driverstage of Aand B phases.

When a bipolar bridge isused this signal can be used to ensure

fast decay of load current when a winding is de-energized. Also

used by chopper to regulate load current if CONTROL input is low.

6 B Motor phase B drive signal for power stage.

7 C Motorphase C drive signal for power stage.

8 INH2 Activelow inhibit control for drive stages of C and D phases.

Same functions as INH1.

9 D Motorphase D drive signal for power stage.

10 ENABLE Chipenable input. When low (inactive) INH1, INH2, A, B,C and D

are brought low.

11 CONTROL Controlinput that defines action of chopper.

When low chopper acts on INH1 and INH2;when high chopper

acts on phase lines ABCD.

12 V

s

5Vsupply input.

13 SENS

2

Inputfor load current sense voltage from power stagesof phases

C and D.

14 SENS

1

Inputfor load current sense voltage from power stagesof phases

Aand B.

15 V

ref

Reference voltage for chopper circuit. Avoltage applied to this pin

determinesthe peak load current.

16 OSC

AnRC network (R to V

CC

, C to ground) connected to this terminal

determinesthe chopper rate. This terminal is connected to

groundon all but one device in synchronized multi - L297

configurations. f ≅ 1/0.69 RC

17 CW/CCW Clockwise/counterclockwise direction control input.

Physical direction of motor rotation also depends on connection

of windings.

Synchronized internally therefore direction can be changed at any

time.

18 CLOCK Stepclock. An activelow pulse on this input advances the motor

one increment. The step occurs on the rising edge of this signal.

PIN FUNCTIONS - L297

L297-L297A

N°

NAME FUNCTION

19 HALF/FULL Half/full step select input. When high selects halfstep operation,

whenlow selects fullstep operation. One-phase-on full step

mode is obtained by selecting FULL when the L297’s translator is

at an even-numbered state.

Two-phase-on full step mode is set by selecting FULL when the

translator is at an odd numbered position. (The home position is

designate state 1).

20 RESET Reset input. An active low pulse on this input restores the

translator to the home position (state 1, ABCD = 0101).

PIN FUNCTIONS - L297 (continued)

N° NAME FUNCTION

1 DOUBLER An RC network connected to this pin determines the delay

betweenan input clock pulse and thecorresponding ghost pulse.

11 DIR-MEM Direction Memory. Inverted output of the direction flip flop. Open

collector output.

PIN FUNCTIONS - L297A

Pin functionof the L297Aare identicalto those of the L297 except for pins 1 and 11.

CIRCUIT OPERATION

The L297(A)is intendedfor use with a dual bridge

driver,quad darlington array or discrete power devices in step motor driving applications.It receives

step clock, direction and mode signals from the

systems controller (usually a microcomputer chip)

and generates control signals for the powerstage.

The principalfunctions are a translator, which generates the motor phase sequences, and a dual

PW/M chopper circuit which regulates the current

in the motor windings. The translator generates

t hr ee d iffer en t sequen ce s, sele cted by t h e

HALF/FULLinput. These are normal (two phases

energised),wave drive (one phase energised)and

half-step (alternately one phase energised/two

phases energised). Two inhibit signals are also

generatedby the L297 in half step andwave drive

modes.Thesesignals,whichconnectdirectlytothe

L298’senableinputs,areintendedtospeedcurrent

decay when a winding is de-energised.When the

L297 is used to drivea unipolarmotor the chopper

acts onthese lines.

An inputcalledCONTROLdetermineswhetherthe

chopper will act on the phase lines ABCD or the

inhibitlines INH1 and INH2. When the phase lines

are choppedthe non-activephase line of eachpair

(AB or CD) isactivated(rather than interruptingthe

line then active).In L297 + L298 configurationsthis

technique reduces dissipation in the load current

sense resistors.

A common on-chip oscillator drives the dual chopper.It suppliespulses atthe chopperrate which set

the twoflip-flops FF1 andFF2. When the currentin

a windingreaches the programmedpeak valuethe

voltageacrossthe senseresistor(connectedtoone

of the sense inputs SENS

1

or SENS2) equalsV

ref

and the corresponding comparator resets its flip

flop, interrupting the drive current until the next

oscillator pulse arrives. The peak current for both

windingsis programmedbya voltagedivideron the

V

ref

input.

Ground noise problems in multiple configurations

can be avoidedby synchronisingthechopperoscillators.This isdoneby connectingallthe SYNCpins

together, mounting the oscillator RC network on

one deviceonly and grounding the OSC pin on all

other devices.

The L297A includes a pulse doubler on the step

clock line which is intendedto simplify the implementation of multiple stepping. A ghost pulse is

generatedautomaticallyaftereachinputpulse, delayed by the time 0.75 R

dCd

.

The RC network should be dimensioned to place

the ghost pulse roughly halfway between clock

pulses.Ifpin1 (DOUBLER)is groundedthedoubler

functionis disabled.

5/11

L297-L297A

6/11

MOTORDRIVINGPHASE SEQUENCES

The L297’s translator generatesphase sequences

for normal drive, wave drive and half step modes.

The state sequences and output waveforms for

these three modes are shown below. In all cases

the translator advances on the low to high transistion of CLOCK.

Clockwise rotation is indicate;for anticlockwiserotation the sequences are simply reversed RESET

restores the translator to state 1, where ABCD =

0101.

HALF STEP MODE

Half stepmode is selected by a high level on the HALF/FULLinput.

NORMALDRIVE MODE

Normal drive mode (also called ”two-phase-on” drive) is selected by a low level on the HALF/FULL input

when the translator is at an odd numbered state (1, 3, 5 or 7). In this mode the INH1 and INH2 outputs

remain high throughout.

L297-L297A

MOTORDRIVINGPHASE SEQUENCES (continued)

WAVEDRIVE MODE

Wave drive mode (also called ”one-phase-on” drive) is selected by a low level on the HALF/FULL input

when the translator is at an even numbered state (2, 4, 6 or 8).

Symbol Parameter Testconditions Min. Typ Max. Unit

V

s

Supply voltage (pin 12) 4.75 7 V

I

s

Quiescent supply current (pin 12) Outputs floating 50 80 mA

V

i

Input voltage

(pin 11, 17, 18,19, 20)

Low 0.8 V

High 2 V

s

V

I

i

Input current

(pin 11, 17, 18,19, 20)

Vi= L 100 µ

A

V

i

=H 10 µA

V

en

Enable input voltage (pin 10) Low 1.5 V

High 2 V

s

V

I

en

Enable input current (pin 10)

V

en

= L 100 µ

A

V

en

=H 10 µA

V

o

Phase output voltage

(pins 4, 6, 7, 9)

Io= 10mA V

OL

0.4 V

I

o

= 5mA V

OH

3.9 V

V

inh

Inhibit output voltage (pins 5, 8) Io= 10mA V

inh L

0.4 V

I

o

= 5mA V

inh H

3.9 V

V

SYNC

Sync Output Voltage Io= 5mA V

SYNC H

3.3 V

I

o

= 5mA V

SYNC V

0.8

ELECTRICAL CHARACTERISTICS (Refer to the block diagram T

amb

=25°C, Vs= 5V unless otherwise

specified)

7/11

L297-L297A

8/11

Symbol Parameter Test conditions Min. Typ Max. Unit

I

leak

Leakage current (pin 3, 11*) VCE=7V 1

µA

V

sat

Saturation voltage (pins 3, 11*) I = 5 mA 0.4 V

V

off

Comparators offset voltage

(pins 13, 14, 15)

V

ref

=1V 5 mV

I

o

Comparator bias current

(pins 13, 14, 15)

-100 10

µA

V

ref

Input reference voltage(pin 15) 0 3 V

t

CLK

Clock time 0.5 µ

s

t

S

Set up time 1

µs

t

H

Hold time 4

µs

t

R

Reset time 1 µs

t

RCLK

Reset to clock delay 1 µs

ELECTRICALCHARACTERISTICS (continued)

* L297Aonly

Figure 1.

L297-L297A

APPLICATIONINFORMATION

TWOPHASE BIPOLARSTEPPER MOTORCONTROLCIRCUIT

This circuit drives bipolar stepper motors with winding currents up to 2A. The diodes are fast 2A types.

Figure2.

Figure3 : SynchronisingL297s Figure4 : Pulse doubler (L297A)

9/11

L297-L297A

10/11

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

a1 0.254 0.010

B 1.39 1.65 0.055 0.065

b 0.45 0.018

b1 0.25 0.010

D 25.4 1.000

E 8.5 0.335

e 2.54 0.100

e3 22.86 0.900

F 7.1 0.280

I 3.93 0.155

L 3.3 0.130

Z 1.34 0.053

DIP20 PACKAGE MECHANICALDATA

L297-L297A

Information furnished is believed to be accurate and reliable. However, SGS-THOMSON Microelectronics assumes no responsibility for the

consequences of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No

licenseis granted by implication or otherwise under any patent or patent rights of SGS-THOMSON Microelectronics. Specifications mentioned

in this publication are subject to change without notice. This publication supersedes and replaces all information previously supplied.

SGS-THOMSON Microelectronics products are not authorized foruse as critical componentsin life supportdevices or systems without express

written approval of SGS-THOMSON Microelectronics.

1994 SGS-THOMSON Microelectronics - AllRights Reserved

SGS-THOMSON Microelectronics GROUP OF COMPANIES

Australia - Brazil -France - Germany - Hong Kong - Italy - Japan - Korea - Malaysia -Malta - Morocco - The Netherlands - Singapore -

Spain - Sweden - Switzerland - Taiwan- Thaliand - United Kingdom - U.S.A.

11/11

L297-L297A

Loading...

Loading...