Offline LED driver with primary-sensing and

Features

■ High power factor capability (> 0.9)

■ 800 V, avalanche rugged internal 11 Ω power

MOSFET

■ Internal high-voltage startup

■ Primary sensing regulation (PSR)

■ +/- 5% accuracy on constant LED output

current

■ Quasi-resonant (QR) operation

■ Optocoupler not needed

■ Open or short LED string management

■ Automatic self supply

Applications

HVLED807PF

high power factor up to 7 W

Datasheet − preliminary data

SO16N

Table 1. Device summary

Order code Package Packaging

■ AC-DC LED driver bulb replacement lamps up

to 7 W, with high power factor

■ AC-DC LED drivers up to 7 W

Description

The HVLED807PF is a high-voltage primary

switcher intended to operate directly from the

rectified mains with minimum external parts and

enabling high power factor (> 0.90) to provide an

efficient, compact and cost effective solution for

LED driving. It combines a high-performance lowvoltage PWM controller chip and an 800 V,

avalanche-rugged Power MOSFET, in the same

package. There is no need for an optocoupler

thanks to the patented primary sensing regulation

(PSR) technique. The device assures protection

against LED string fault (open or short).

HVLED807PF

SO16N

Tu be

HVLED807PFTR Tape & Reel

July 2012 Doc ID 023464 Rev 1 1/17

This is preliminar y information on a new product now in development or undergoing evaluation. Details are subject to

change without notice.

www.st.com

17

Contents HVLED807PF

Contents

1 Principle application circuit and block diagram . . . . . . . . . . . . . . . . . . . 3

1.1 Principle application circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Pin description and connection diagrams . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Thermal data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Device description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 Package information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2/17 Doc ID 023464 Rev 1

1 Principle application circuit and block diagram

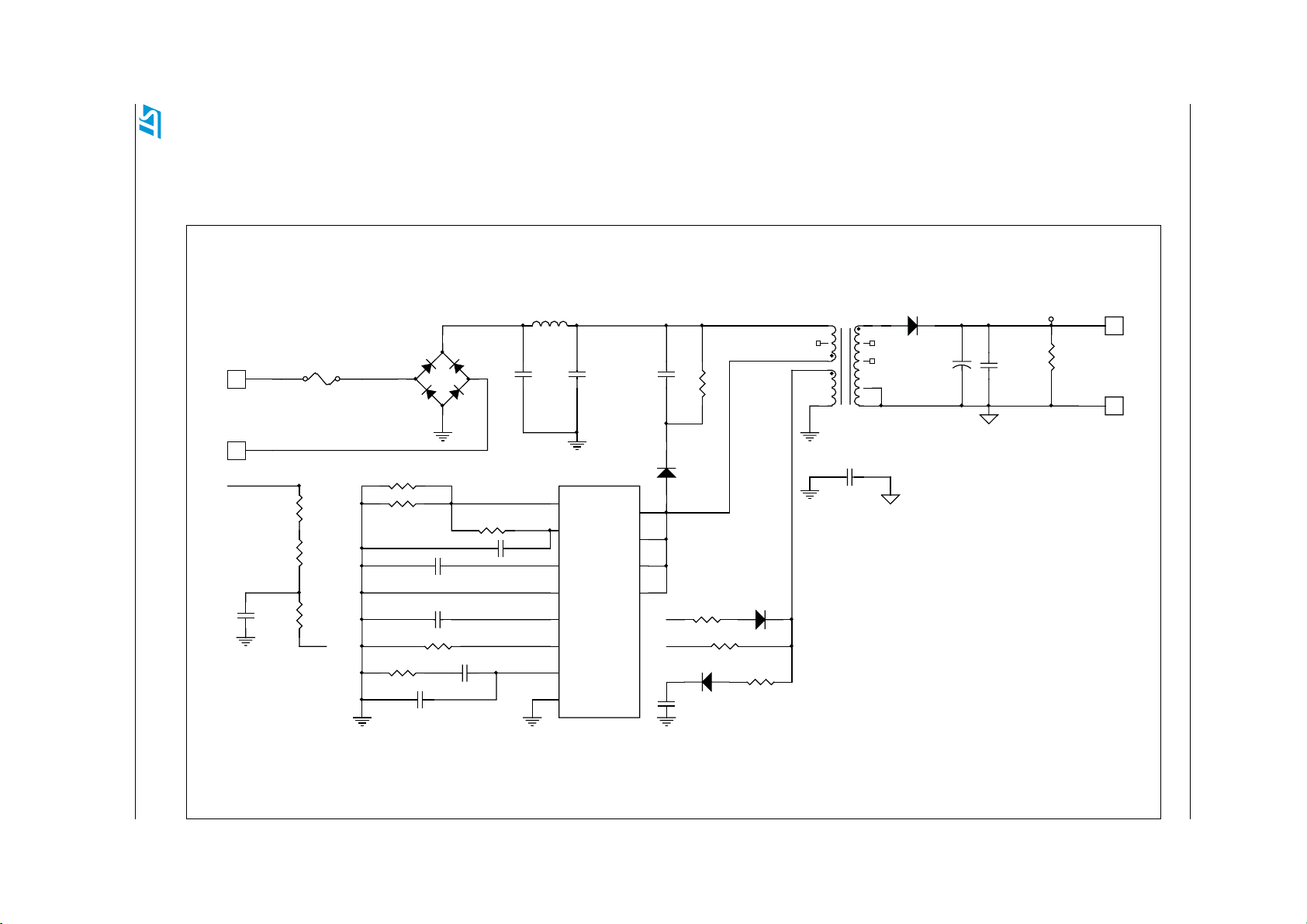

1.1 Principle application circuit

Figure 1. Principle application circuit for high power factor LED driver

HVLED807PF Principle application circuit and block diagram

Doc ID 023464 Rev 1 3/17

J2

CON1

J4

CON1

VIN

COS Filter (1uF)

34

Bridge Diode

F1 1A_DIP

RA

RB

ROS

CS DMG

2 1

C_Vcc (10uF)

C_ILED (10uF)

Rf (8.2k-15k)

+

-

Rsens e

Rsens e

R1 (1k8-2k2)

220pF-330pF

Rfb

Cf (330nF/ 680nF)

Cp (1nF/ 10nF)

Lin (330uH - 820uH)

Cin - (22nF / 47nF)

U1

HVLED8xxPF

1

SOURCE

2

CS

CS

3

VCC

VCC

4

GND

5

ILED

6

DMG

7

COMP

8

NA

N.A.

Cin - (22nF / 47nF)

DRAIN

DRAIN

DRAIN

DRAIN

Csnubber (1nF )

16

15

14

13

VIN

Rsnubber (120k )

S n ubber Diode

CS

RPF

DMG

VCC

C_VCC (470nF)

Rdmg

D2

1N4148

D4

R-VCC (10ohm)

T1

1 10

2

3

4

5 6

TRA NSFORMER

C10

Y1 - SAFETY

O utpo ut Diode

9

8

7

C12

Cout Bulk

C13

Cout SMD

Vout

R12

Mini mum Load

J1

CON1

J3

CON1

AM13207v1

4/17 Doc ID 023464 Rev 1

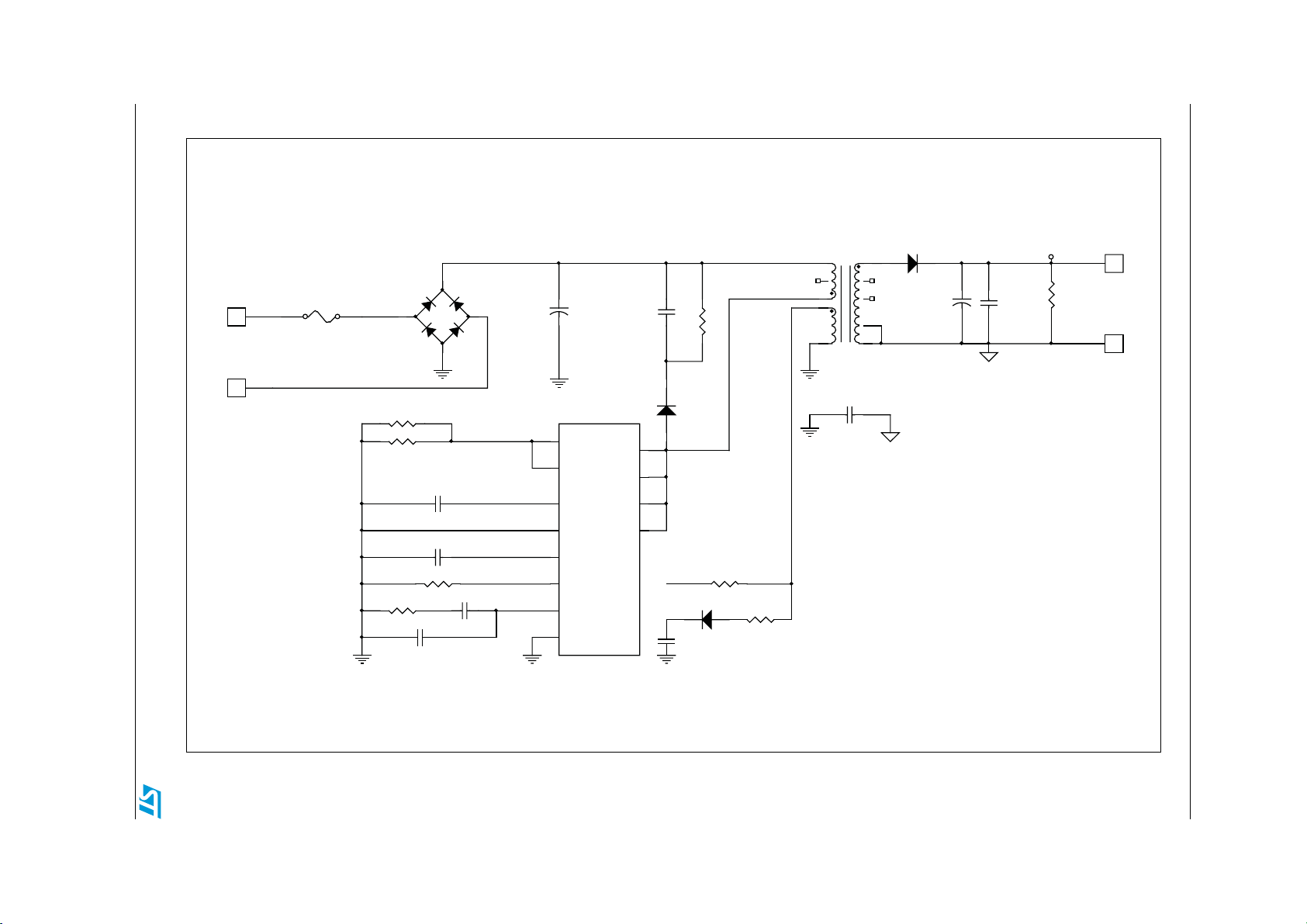

Figure 2. Principle application circuit for standard LED driver

Principle application circuit and block diagram HVLED807PF

J7

CON1

J8

CON1

F2 1A_DIP

Bridge Diode

2 1

Rsens e

Rsens e

C_Vcc (10uF)

C_ILED (10uF)

Rfb

Rf (8.2k -15k)

Cp (1nF/ 10nF)

34

+

-

Cf (330nF/ 680nF)

VCC

DMG

1

2

3

4

5

6

7

8

NA

C22

Cin

U2

HVLED8xxPF

SOURC E

CS

VCC

GND

ILED

DMG

COMP

N.A.

DRAIN

DRAIN

DRAIN

DRAIN

Csnubber (1nF )

16

15

14

13

VIN

Rsnubber (120k )

S n ubber Diode

DMG

VCC

C_VCC (470nF)

Rdmg

D6

1N4148

R-VCC (10ohm)

T2

1 10

2

3

4

5 6

TRA NSFORMER

C21

Y1 - SAFETY

O utpo ut Diode1

9

8

7

C15

Cout Bulk

C23

Cout SMD

Vout

R16

Minimum Load

J5

CON1

J6

CON1

AM13208v1

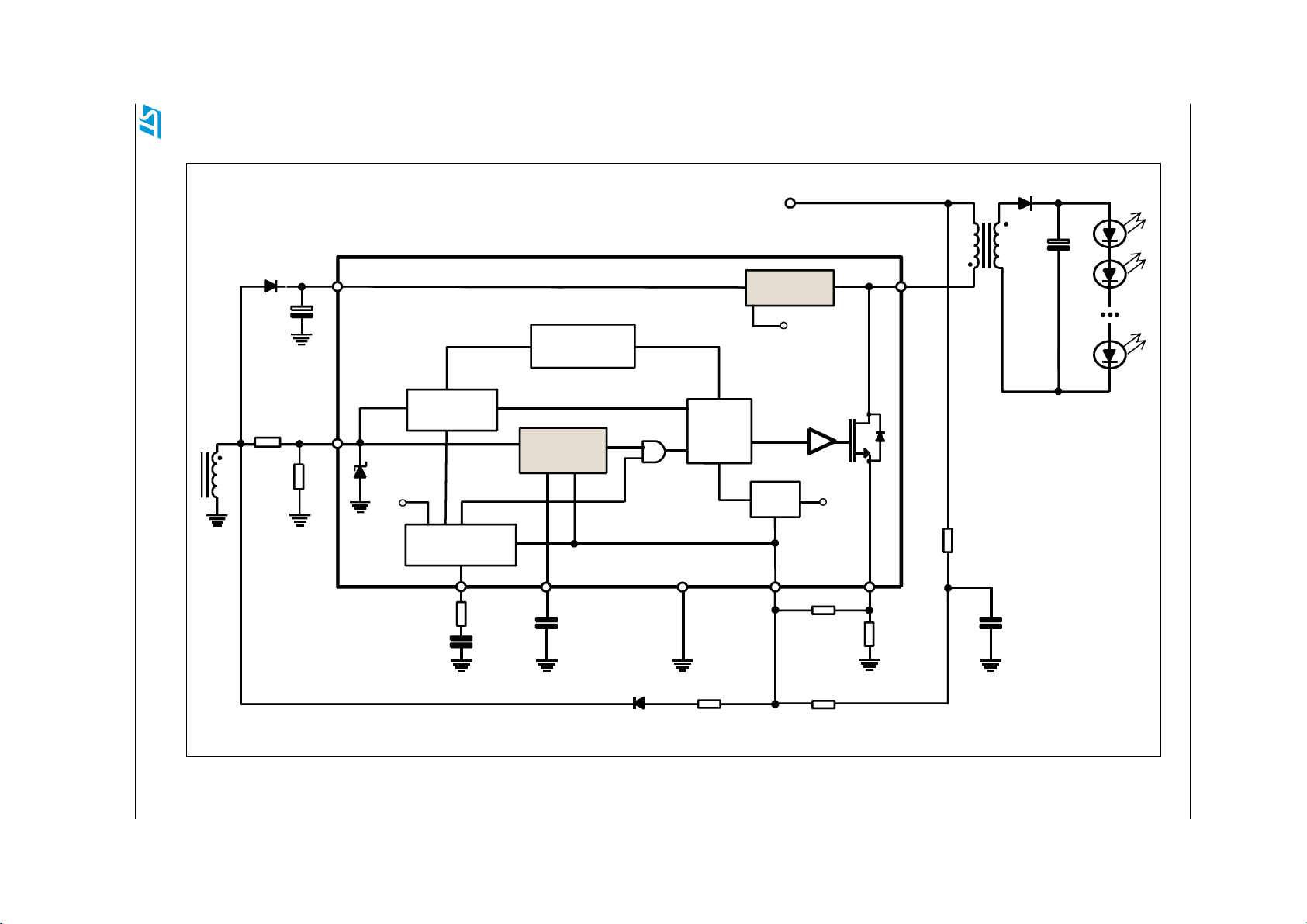

1.2 Block diagram

Figure 3. Block diagram

HVLED807PF Principle application circuit and block diagram

+ VIN

Doc ID 023464 Rev 1 5/17

VCC

PROTECTION &

FEEDFORWARD

LOGIC

DEMAG

R

DMG

DMG

R

FB

3.3 V

LOGIC

Vref

Constant Voltage

Regulation

COMP

R

COMP

C

COMP

CONSTANT

CURRENT

REGULATION

VILED

ILED

C

VCS

LED

GND

DRIVING

LOGIC

R

PF

HV start-up &

Supply Logic

Vref

OCP

CS

DRAIN

1 V

R

A

R

1

R

OS

SOURCE

R

SENSE

LED

AM13209v1

Pin description and connection diagrams HVLED807PF

A

A

A

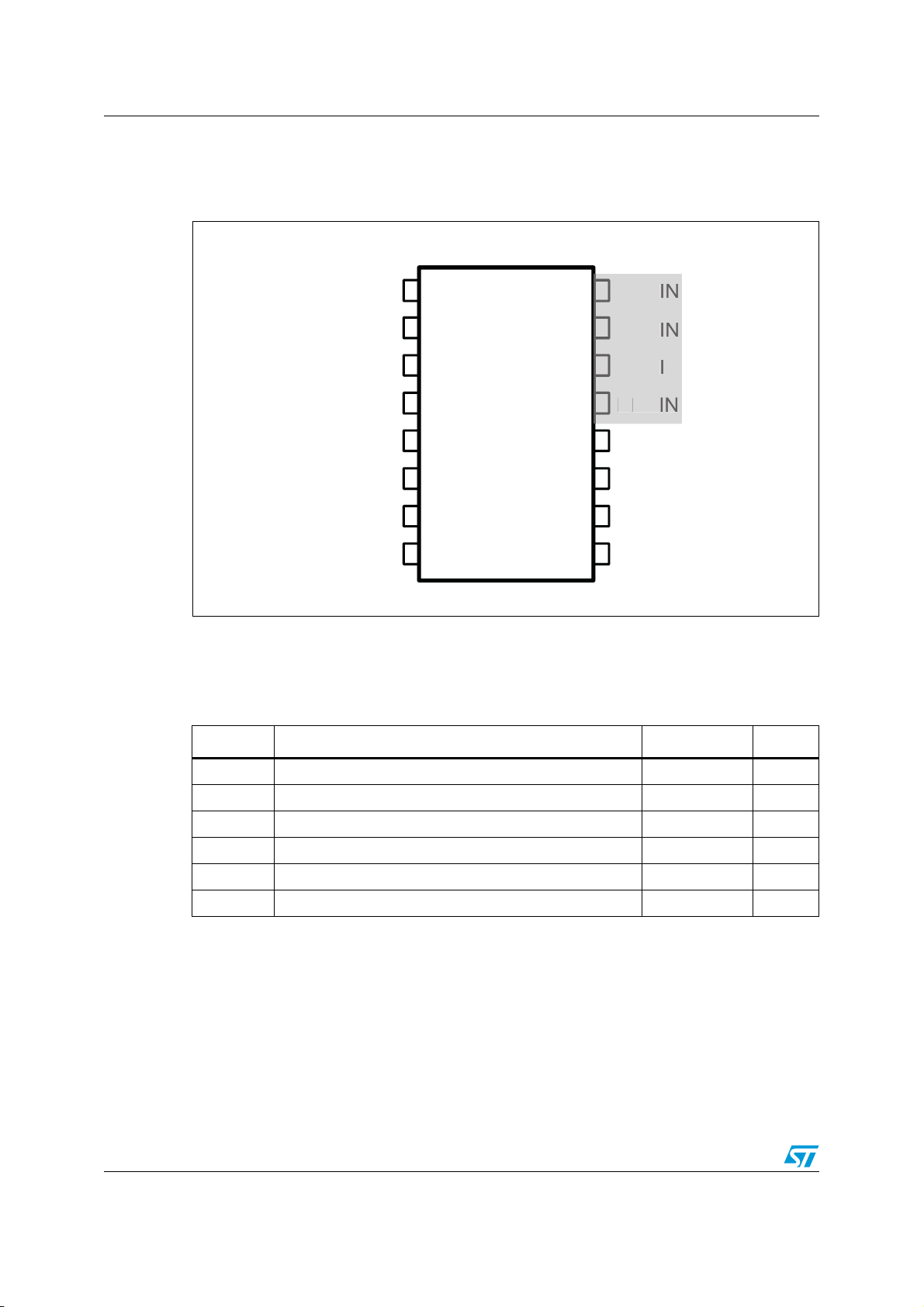

2 Pin description and connection diagrams

Figure 4. Pin connection (top view)

SOURCE

2.1 Thermal data

Table 2. Thermal data

Symbol Parameter Max. value Unit

CS

VCC

GND

ILED

DMG

COMP

N.A.

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

16

16

15

15

14

14

13

13

12

12

11

11

10

10

DRAIN

DRAIN

DRAIN

N

DRAIN

N.C.

N.A.

N.A.

9

9

N.A.

AM13210v1

R

thJP

R

thJA

P

TOT

T

MAX

T

STG

T

6/17 Doc ID 023464 Rev 1

Thermal resistance, junction-to-pin 10 °C/W

Thermal resistance, junction-to-ambient 110 °C/W

Maximum power dissipation at TA = 50 °C 0.9 W

Maximum junction temperature 150 °C

Storage temperature range -55 to 150 °C

Junction temperature range -40 to 125 °C

J

HVLED807PF Electrical specifications

3 Electrical specifications

3.1 Absolute maximum ratings

Table 3. Absolute maximum ratings

Symbol Pin Parameter Value Unit

V

DS

I

D

Eav 1, 13-16

1, 13-16 Drain-to-source (ground) voltage -1 to 800 V

1, 13-16 Drain current

Single-pulse avalanche energy

(Tj = 25 °C, I

Vcc 3 Supply voltage (Icc < 25 mA) Self limiting V

I

DMG

V

CS

6 Zero current detector current ±2 mA

2 Current sense analog input -0.3 to 3.6 V

Vcomp 7 Analog input -0.3 to 3.6 V

1. Limited by maximum temperature allowed.

3.2 Electrical characteristics

Table 4. Electrical characteristics

Symbol Parameter Test condition Min. Typ. Max. Unit

Power section

V

(BR)DSS

I

DSS

Drain-source breakdown ID < 100 µA; Tj = 25 °C 800 V

OFF-state drain current

(1)

= 0.7 A)

D

(1) (2)

= 750 V; Tj = 125 °C

V

DS

(3)

, see

Figure 5

1A

50 mJ

80 µA

R

DS(on)

C

OSS

Drain-source ON-state

resistance

Effective (energy-related)

output capacitance

High-voltage startup generator

V

START

I

CHARGE

V

CC_RESTART

Min. drain start voltage I

Vcc startup charge current

Vcc restart voltage

(Vcc falling)

Id=250 mA; Tj = 25 °C 6 7.4

Id=250 mA; Tj = 125 °C

(3)

(3)

See

Figure 6

< 100 µA 40 50 60 V

charge

> V

V

DRAIN

Vcc < Vcc

Start

On

;

45.57

Tj = 25 °C

> V

V

DRAIN

Vcc < Vcc

(4)

Start

On

;

+/- 10%

9.5 10.5 11.5 V

14.8

Ω

mA

After protection tripping 5

Doc ID 023464 Rev 1 7/17

Electrical specifications HVLED807PF

Table 4. Electrical characteristics

(1) (2)

(continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

Supply voltage

Vcc Operating range After turn-on 11.5 23

V

CC_ON

V

CC_OFF

V

Turn-on threshold

Turn-off threshold

Z

Internal Zener voltage Icc = 20 mA 23 25 27 V

(4)

(4)

12 13 14 V

91011V

Supply current

I

CC_START-UP

Iq Quiescent current See

I

CC

Iq

(fault)

Startup current See

Operating supply current

at 50 kHz

See

Fault quiescent current See

Figure 7

Figure 8

Figure 9

Figure 10

200 300 µA

11.4mA

1.4 1.7 mA

250 350 µA

Startup timer

T

START

T

RESTART

Start timer period 105 140 175 µs

Restart timer period

during burst mode

420 500 700 µs

Demagnetization detector

I

Dmgb

V

DMGH

V

DMGL

V

DMGA

V

DMGT

T

BLANK

Input bias current V

Upper clamp voltage I

Lower clamp voltage I

Arming voltage Positive-going edge 100 110 120 mV

Triggering voltage Negative-going edge 50 60 70 mV

Trigger blanking time after

MOSFET turn-off

= 0.1 to 3 V 0.1 1 µA

DMG

= 1 mA 3.0 3.3 3.6 V

DMG

= - 1 mA -90 -60 -30 mV

DMG

V

≥ 1.3 V 6

COMP

= 0.9 V 30

V

COMP

Line feedforward

µs

R

FF

Equivalent feedforward

resistor

I

= 1 mA 45 Ω

DMG

Transconductance error amplifier

T

j = 25 °C 2.45 2.51 2.57

V

REF

Voltage reference

(3)

Tj = -25 to 125 °C and

Vcc = 12 V to 23 V

= ± 10 µA

∆I

gm Transconductance

Gv Voltage gain

GB Gain-bandwidth product

COMP

V

= 1.65 V

COMP

(5)

Open loop 73 dB

(5)

8/17 Doc ID 023464 Rev 1

2.4 2.6

V

1.3 2.2 3.2 ms

500 KHz

HVLED807PF Electrical specifications

Table 4. Electrical characteristics

(1) (2)

(continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

= 2.3 V,

V

DMG

= 1.65 V

V

COMP

= 2.7 V,

V

DMG

= 1.65 V

V

COMP

= 2.3 V 2.7 V

DMG

= 2.7 V 0.7 V

DMG

70 100 µA

400 750 µA

I

COMP

V

COMPH

V

COMPL

V

COMPBM

Source current

Sink current

Upper COMP voltage V

Lower COMP voltage V

Burst-mode threshold 1 V

Hys Burst-mode hysteresis 65 mV

Current reference

V

V

ILEDx

CLED

Maximum value V

COMP

= V

COMPL

1.5 1.6 1.7 V

Current reference voltage 0.192 0.2 0.208 V

Current sense

t

LEB

T

D

V

CSx

V

CSdis

1. Vcc=14 V (unless otherwise specified).

2. Limits are production tested at Tj=Ta=25 °C, and are guaranteed by statistical characterization in the range

Tj 25-125

3. Not production tested, guaranteed statistical characterization only.

4. Parameters tracking each other (in the same section).

5. Guaranteed by design.

Leading-edge blanking

Delay-to-output (H-L) 90 200 ns

Max. clamp value

Hiccup-mode OCP level

°C.

(5)

(4)

dVcs/dt = 200 mV/µs 0.7 0.75 0.8 V

(4)

0.92 1 1.08 V

330 ns

Figure 5. OFF-state drain and source current test circuit

DM G

2.5V

14V

VDD

+

-

COMP SOURCE

ILED

CU RRE NT

CONTROL

GND

CS

DR AIN

Idss

A

AM13211v1

Note: The measured IDSS is the sum between the current across the startup resistor and the

effective

MOSFET’s

OFF-state drain current.

Doc ID 023464 Rev 1 9/17

Vin

750V

Electrical specifications HVLED807PF

Figure 6. COSS output capacitance variation

600

500

400

300

Coss [pF]

200

100

0

0 25 50 75 100 125 150

Vds [ V]

AM13212v1

Figure 7. Startup current test circuit

DMG

2.5V

11.8 V

+

Iccstart-up

A

VDD

CURRENT

CONTROL

-

COM P SOURCE

ILED

GND

CS

DRAIN

AM13213v1

10/17 Doc ID 023464 Rev 1

HVLED807PF Electrical specifications

Figure 8. Quiescent current test circuit

Iq_meas

VDD

2.5V

+

DMG

33k

3V

-

COM P SOURCE

ILED

0.8V

Figure 9. Operating supply current test circuit

Icc

27k

220k

10k

10k

DMG

2.5V

+

-

COM P SOURCE

A

VDD

CURR ENT

CONTROL

GND

ILED

CS

CURR ENT

CON TROL

GND

14VA

DRAIN

10k

15V

DRAIN

CS

0.2V

AM13214v1

1.5K 2W

150V

50 kHz

10

-5V

2.8V

Note: The circuit across the DMG pin is used for switch-on synchronization.

Figure 10. Quiescent current during fault test circuit

DMG

2.5V

Iq(fault)

A

VDD

+

-

COM P SOURCE

ILED

CURRENT

CON TROL

GND

14V

CS

5.6

AM13215v1

DRAIN

AM13216v1

Doc ID 023464 Rev 1 11/17

Device description HVLED807PF

4 Device description

The HVLED807PF is a high-voltage primary switcher intended to operate directly from the

rectified mains with minimum external parts to provide high power factor (> 0.90) and an

efficient, compact and cost effective solution for LED driving. It combines a highperformance low-voltage PWM controller chip and an 800 V, avalanche-rugged Power

MOSFET, in the same package.

The PWM is a current-mode controller IC specifically designed for ZVS (zero voltage

switching) flyback LED drivers, with constant output current (CC) regulation using primary

sensing feedback (PSR). This eliminates the need for the optocoupler, the secondary

voltage reference, as well as the current sense on the secondary side, while still maintaining

a good LED current accuracy. Moreover, it guarantees a safe operation when short-circuit of

one or more LEDs occurs.

The device can also provide a constant output voltage regulation (CV): it allows the

application to be able to work safely when the LED string opens due to a failure.

In addition, the device offers the shorted secondary rectifier (i.e. LED string shorted due to a

failure) or transformer saturation detection.

Quasi-resonant operation is achieved by means of a transformer demagnetization sensing

input that triggers MOSFET turn-on. This input serves also as both output voltage monitor,

to perform CV regulation, and input voltage monitor, to achieve mains-independent CC

regulation (line voltage feedforward).

The maximum switching frequency is top-limited below 166 kHz, so that at medium-light

load a special function automatically lowers the operating frequency still maintaining the

operation as close to ZVS as possible. At very light load, the device enters a controlled

burst-mode operation that, along with the built-in high-voltage startup circuit and the low

operating current of the device, helps minimize the residual input consumption.

Although an auxiliary winding is required in the transformer to correctly perform CV/CC

regulation, the chip is able to power itself directly from the rectified mains. This is useful

especially during CC regulation, where the flyback voltage generated by the winding drops.

12/17 Doc ID 023464 Rev 1

HVLED807PF Package information

5 Package information

In order to meet environmental requirements, ST offers these devices in different grades of

®

ECOPACK

specifications, grade definitions and product status are available at:

packages, depending on their level of environmental compliance. ECOPACK

www.st.com

.

ECOPACK is an ST trademark.

Figure 11. SO16N mechanical data

mm

Dim.

Min. Typ. Max.

A 1.75

A1 0.10 0.25

A2 1.25

b0.31 0.51

c0.17 0.25

D 9.80 9.90 10.00

E5.806.006.20

E1 3.80 3.90 4.00

e1.27

h0.25 0.50

L0.40 1.27

k0 8°

ccc 0.10

Doc ID 023464 Rev 1 13/17

Package information HVLED807PF

Figure 12. SO16N drawing

14/17 Doc ID 023464 Rev 1

0016020_F

HVLED807PF Package information

Figure 13. SO16N recommended footprint (dimensions are in mm)

Doc ID 023464 Rev 1 15/17

Revision history HVLED807PF

6 Revision history

Table 5. Document revision history

Date Revision Changes

26-Jul-2012 1 Initial release.

16/17 Doc ID 023464 Rev 1

HVLED807PF

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2012 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 023464 Rev 1 17/17

Loading...

Loading...