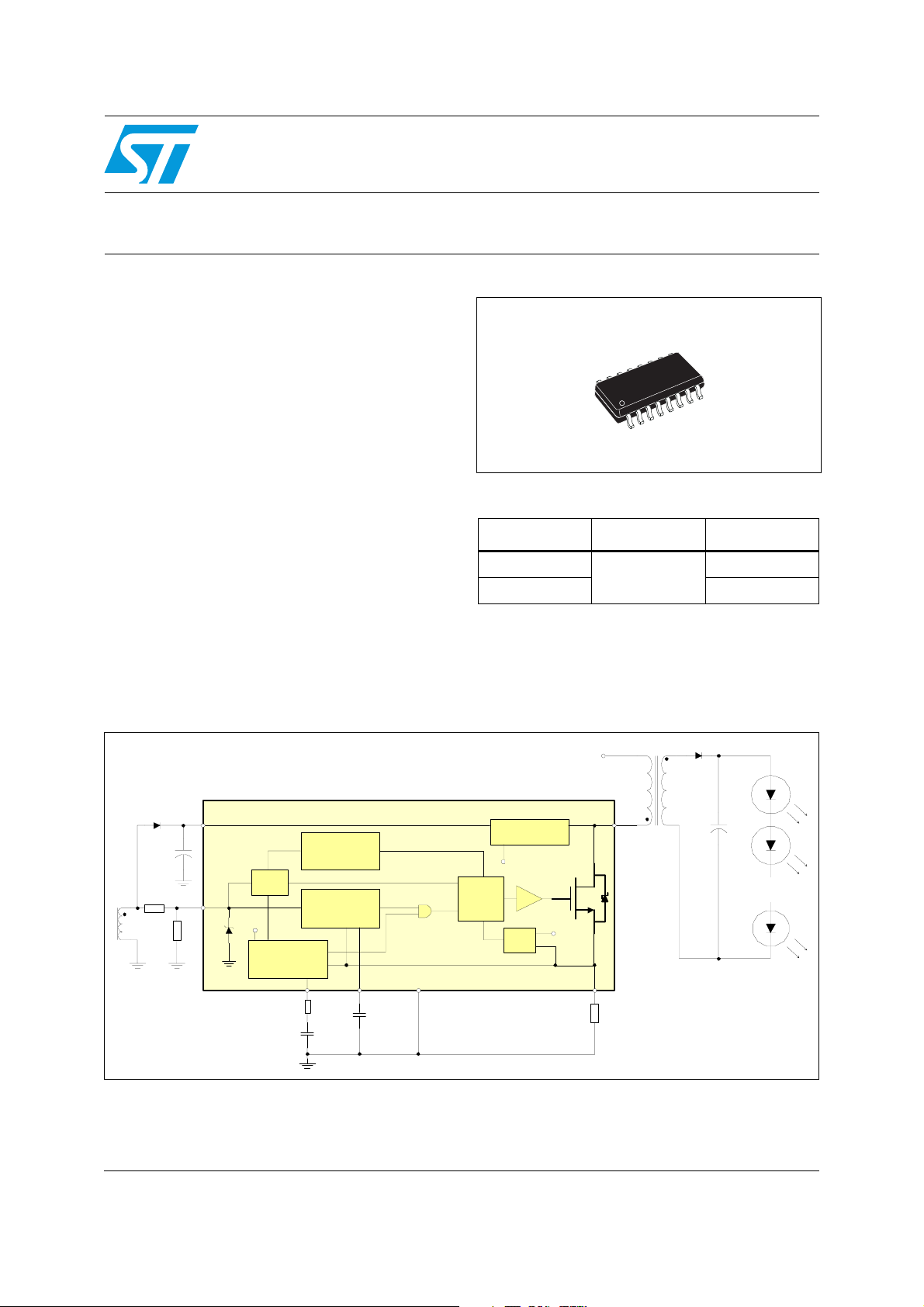

Off-line LED driver with primary-sensing

Features

■ 800 V, avalanche rugged internal power

MOSFET

■ 5% accuracy on constant LED output current

with primary control

■ Optocoupler not needed

■ Quasi-resonant (QR) zero voltage switching

(ZVS) operation

■ Internal HV start-up circuit

■ Open or short LED string management

■ Automatic self supply

■ Input voltage feed-forward for mains

independent cc regulation

HVLED805

SO16N

Table 1. Device summary

Order codes Package Packaging

HVLED805

SO16N

HVLED805TR Tape and reel

Tube

Applications

■ AC-DC led driver applications

■ LED retrofit lamps (i.e. E27, GU10)

Figure 1. Application diagram

VCC

PROTECTION &

FEEDFORWARD

LOGIC

DE MAG

Rdmg

DMG

Rfb

3.3V

LOG IC

Vref

CONSTANT

VOLT AGE

REGULATION

CONSTANT

CURRENT

REGULATION

Vc

COMP ILED GND SOURCE

Rcomp

Ccomp

CLED

DRIVING

LOGIC

HV start-u p &

SUPPLY LOGIC

Vref

1V

OCP

Vin

DRAIN

LED

...

Rsens e

October 2010 Doc ID 18077 Rev 1 1/29

www.st.com

29

Contents HVLED805

Contents

1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Electrical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Pin connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Application information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 Power section and gate driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 High voltage startup generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.3 Secondary side demagnetization detection and triggering block . . . . . . . 15

5.4 Constant voltage operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.5 Constant current operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.6 Voltage feedforward block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.7 Burst-mode operation at no load or very light load . . . . . . . . . . . . . . . . . . 22

5.8 Soft-start and starter block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.9 Hiccup mode OCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.10 Layout recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6 Package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2/29 Doc ID 18077 Rev 1

HVLED805 Description

1 Description

The HVLED805 is a high-voltage primary switcher intended for operating directly from the

rectified mains with minimum external parts to provide an efficient, compact and cost

effective solution for LED driving. It combines a high-performance low-voltage PWM

controller chip and an 800V, avalanche-rugged power MOSFET, in the same package.

The PWM is a current-mode controller IC specifically designed for ZVS (zero voltage

switching) fly-back LED drivers, with constant output current (CC) regulation using primarysensing feedback. This eliminates the need for the opto-coupler, the secondary voltage

reference, as well as the current sense on the secondary side, still maintaining a good LED

current accuracy. Moreover it guarantees a safe operation when short circuit of one or more

LEDs occurs.

In addition, the device can also provide a constant output voltage regulation (CV): it makes

the application able to work safely when the LED string opens due to a failure.

Quasi-resonant operation is achieved by means of a transformer demagnetization sensing

input that triggers MOSFET’s turn-on. This input serves also as both output voltage monitor,

to perform CV regulation, and input voltage monitor, to achieve mains-independent CC

regulation (line voltage feed forward).

The maximum switching frequency is top-limited below 166 kHz, so that at medium-light

load a special function automatically lowers the operating frequency still maintaining the

operation as close to ZVS as possible. At very light load, the device enters a controlled

burst-mode operation that, along with the built-in high-voltage start-up circuit and the low

operating current of the device, helps minimize the residual input consumption.

Although an auxiliary winding is required in the transformer to correctly perform CV/CC

regulation, the chip is able to power itself directly from the rectified mains. This is useful

especially during CC regulation, where the fly-back voltage generated by the winding drops.

In addition to these functions that optimize power handling under different operating

conditions, the device offers protection features that considerably increase end-product’s

safety and reliability: auxiliary winding disconnection or brownout detection and shorted

secondary rectifier or transformer’s saturation detection. All of them are auto restart mode.

Doc ID 18077 Rev 1 3/29

Maximum ratings HVLED805

2 Maximum ratings

Table 2. Absolute maximum ratings

Symbol Pin Parameter Value Unit

V

I

V

T

1. Limited by maximum temperature allowed.

1,2, 13-16 Drain-to-source (ground) voltage -1 to 800 V

DS

1,2, 13-16 Drain current

I

D

1,2, 13-16 Single pulse avalanche energy (Tj = 25°C, ID = 0.7A) 50 mJ

E

av

V

cc

DMG

comp

P

tot

T

J

stg

3 Supply voltage (Icc < 25mA) Self limiting V

6 Zero current detector current ±2 mA

7 Analog input -0.3 to 3.6 V

Power dissipation @TA = 50°C 0.9 W

Junction temperature range -40 to 150 °C

Storage temperature -55 to 150 °C

(1)

1A

Table 3. Thermal data

Symbol Parameter Max. value Unit

R

R

Thermal resistance, junction-to-pin 10

thJP

Thermal resistance, junction-to-ambient 110

thJA

°C/W

4/29 Doc ID 18077 Rev 1

HVLED805 Electrical characteristics

3 Electrical characteristics

TJ = -25 to 125 °C, Vcc=14 V; unless otherwise specified.

Table 4. Electrical characteristics

Symbol Parameter Test condition Min. Typ. Max. Unit

Power section

V

(BR)DSS

I

DSS

Drain-source breakdown ID< 100 µA; Tj = 25 °C 800 V

V

= 750V; Tj = 125 °C

Off state drain current

DS

(See Figure 4 and note)

80 µA

Id=250 mA; Tj = 25 °C 11 14

R

DS(on)

C

Drain-source ON-state resistance

Effective (energy-related) output capacitance (See Figure 3)

oss

Id=250 mA; Tj = 125 °C 28

High-voltage start-up generator

V

Start

I

charge

V

CCrestart

Min. drain start voltage I

Vcc startup charge current

Vcc restart voltage

(Vcc falling)

< 100µA 40 50 60 V

charge

> V

> V

; Vcc<Vcc

Start

; Vcc<Vcc

Start

On,

On

45.57

+/-10%

9.5 10.5 11.5

V

DRAIN

Tj = 25 °C

V

DRAIN

(1)

After protection tripping 5

Supply voltage

Vcc Operating range After turn-on 11.5 23 V

Vcc

Vcc

Turn-on threshold

On

Turn-off threshold

Off

V

Zener voltage Icc = 20mA 23 25 27 V

Z

(1)

(1)

12 13 14 V

91011V

Supply current

Ω

mA

V

Icc

start-up

Start-up current (See Figure 5) 200 300 µA

Iq Quiescent current (See Figure 6)11.4mA

Icc Operating supply current @ 50 kHz (See Figure 7)1.41.7mA

Iq

(fault)

Fault quiescent current

During hiccup and brownout

(See Figure 8)

250 350 µA

Start-up timer

T

RESTART

T

START

Start timer period 105 140 175 µs

Restart timer period during burst mode 420 500 700 µs

Demagnetization detector

I

DMGb

Input bias current V

= 0.1 to 3V 0.1 1 µA

DMG

Doc ID 18077 Rev 1 5/29

Electrical characteristics HVLED805

Table 4. Electrical characteristics (continued)

Symbol Parameter Test condition Min. Typ. Max. Unit

V

DMGH

V

DMGL

V

DMGA

V

DMGT

I

DMGON

T

BLANK

Upper clamp voltage I

Lower clamp voltage I

= 1 mA 3.0 3.3 3.6 V

DMG

= - 1 mA -90 -60 -30 mV

DMG

Arming voltage positive-going edge 100 110 120 mV

Triggering voltage negative-going edge 50 60 70 mV

Min. source current during MOSFET ON-time -25 -50 -75 µA

V

≥ 1.3V 6

Trigger blanking time after MOSFET’s turn-off

COMP

= 0.9V 30

V

COMP

Line feedforward

R

Equivalent feedforward resistor I

FF

= 1mA 45 Ω

DMG

Transconductance error amplifier

(1)

= ±10 µA

= 1.65 V

(1)

2.45 2.51 2.57

2.4 2.6

1.3 2.2 3.2 mS

V

REF

Voltage reference

gm Transconductance

Tj = 25 °C

Tj = -25 to 125°C and

Vcc=12V to 23V

ΔI

COMP

V

COMP

Gv Voltage gain Open loop 73 dB

GB Gain-bandwidth product 500 kHz

I

COMP

V

COMPH

V

COMPL

V

COMPBM

Source current V

Sink current V

Upper COMP voltage V

Lower COMP voltage V

Burst-mode threshold 1 V

= 2.3V, V

DMG

= 2.7V, V

DMG

= 2.3V 2.7 V

DMG

= 2.7V 0.7 V

DMG

= 1.65V 70 100 µA

COMP

= 1.65V 400 750 µA

COMP

Hys Burst-mode hysteresis 65 mV

µs

V

Current reference

V

V

ILEDx

CLED

Maximum value

V

COMP

= V

Current reference voltage 0.192 0.2 0.208 V

COMPL

(1)

1.5 1.6 1.7 V

Current sense

t

LEB

d(H-L) Delay-to-output 300 ns

t

V

V

CSdis

1. Parameters tracking each other

Leading-edge blanking 200 250 300 ns

Max. clamp value

CSx

Hiccup-mode OCP level

(1)

dVcs/dt = 200 mV/µs 0.7 0.75 0.8 V

(1)

0.92 1 1.08 V

6/29 Doc ID 18077 Rev 1

HVLED805 Pin connection

4 Pin connection

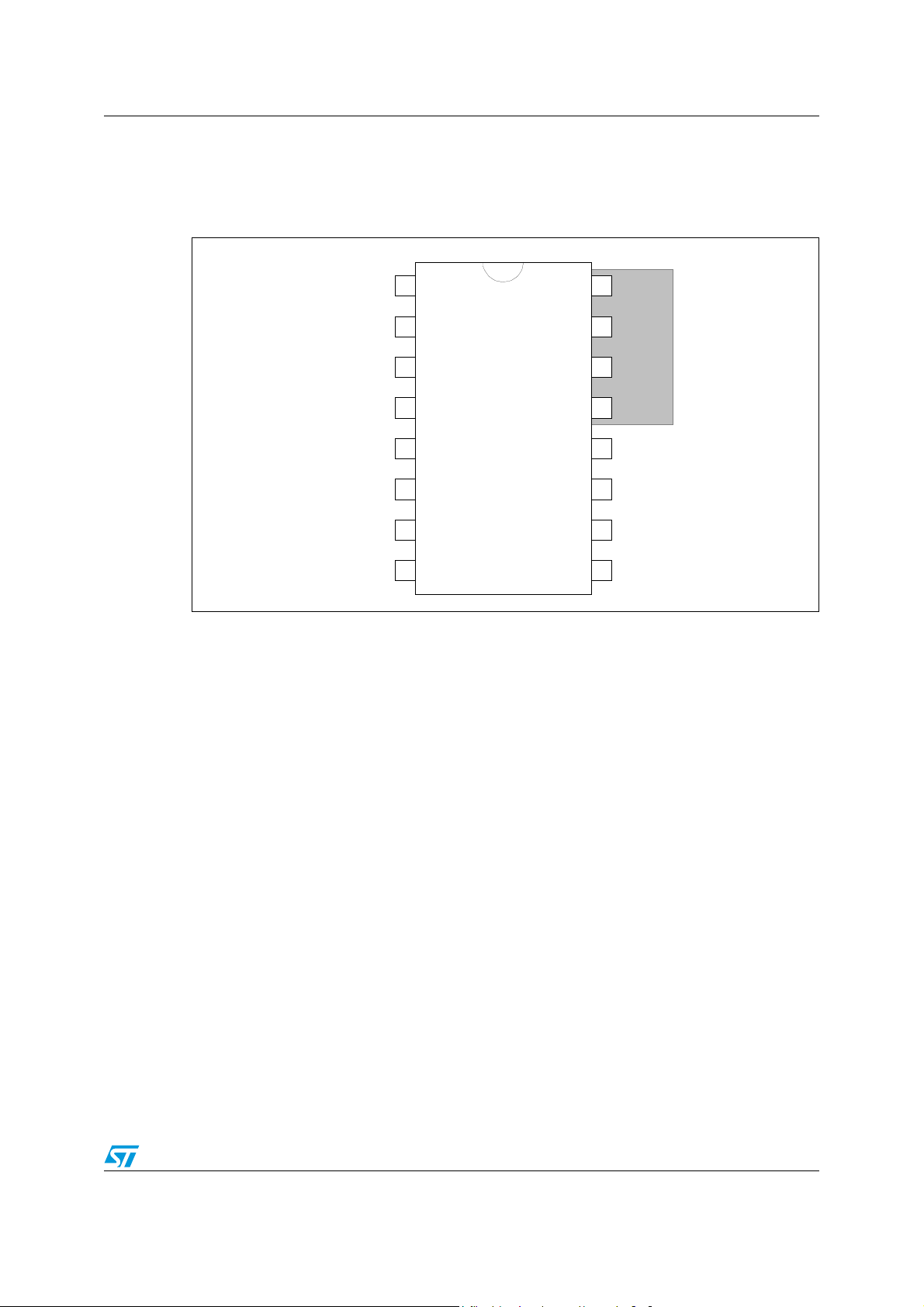

Figure 2. Pin connection (top view)

SOURCE

SOURCE

VCC

GND

ILED

DMG

COMP

N.A. N.A.

2

3

4

5

6

7

8

16

15

14

13

12

11

10

DRAIN1

DRAIN

DRAIN

DRAIN

N.C.

N.A.

N.A.

9

Note: The copper area for heat dissipation has to be designed under the drain pins

Doc ID 18077 Rev 1 7/29

Pin connection HVLED805

Table 5. Pin functions

N. Name Function

Power section source and input to the PWM comparator. The current flowing in the MOSFET

is sensed through a resistor connected between the pin and GND. The resulting voltage is

1, 2 SOURCE

3VCC

4GND

5ILED

6DMG

7COMP

8-11 N.A Not available. These pins must be left not connected

12 N.C Not internally connected. Provision for clearance on the PCB to meet safety requirements.

compared with an internal reference (0.75V typ.) to determine MOSFET’s turn-off. The pin is

equipped with 250 ns blanking time after the gate-drive output goes high for improved noise

immunity. If a second comparison level located at 1V is exceeded the IC is stopped and

restarted after Vcc has dropped below 5V.

Supply Voltage of the device. An electrolytic capacitor, connected between this pin and

ground, is initially charged by the internal high-voltage start-up generator; when the device is

running the same generator will keep it charged in case the voltage supplied by the auxiliary

winding is not sufficient. This feature is disabled in case a protection is tripped. Sometimes a

small bypass capacitor (100nF typ.) to GND might be useful to get a clean bias voltage for the

signal part of the IC.

Ground. Current return for both the signal part of the IC and the gate drive. All of the ground

connections of the bias components should be tied to a trace going to this pin and kept

separate from any pulsed current return.

CC regulation loop reference voltage. An external capacitor will be connected between this

pin and GND. An internal circuit develops a voltage on this capacitor that is used as the

reference for the MOSFET’s peak drain current during CC regulation. The voltage is

automatically adjusted to keep the average output current constant.

Transformer’s demagnetization sensing for quasi-resonant operation. Input/output voltage

monitor. A negative-going edge triggers MOSFET’s turn-on. The current sourced by the pin

during MOSFET’s ON-time is monitored to get an image of the input voltage to the converter,

in order to compensate the internal delay of the current sensing circuit and achieve a CC

regulation independent of the mains voltage. If this current does not exceed 50µA, either a

floating pin or an abnormally low input voltage is assumed, the device is stopped and

restarted after Vcc has dropped below 5V. Still, the pin voltage is sampled-and-held right at

the end of transformer’s demagnetization to get an accurate image of the output voltage to be

fed to the inverting input of the internal, transconductance-type, error amplifier, whose noninverting input is referenced to 2.5V. Please note that the maximum I

current has to not exceed ±2 mA (AMR) in all the Vin range conditions. No capacitor is

allowed between the pin and the auxiliary transformer.

Output of the internal transconductance error amplifier. The compensation network will be

placed between this pin and GND to achieve stability and good dynamic performance of the

voltage control loop.

sunk/sourced

DMG

Drain connection of the internal power section. The internal high-voltage start-up generator

13 to 16 DRAIN

8/29 Doc ID 18077 Rev 1

sinks current from this pin as well. Pins connected to the internal metal frame to facilitate heat

dissipation.

HVLED805 Pin connection

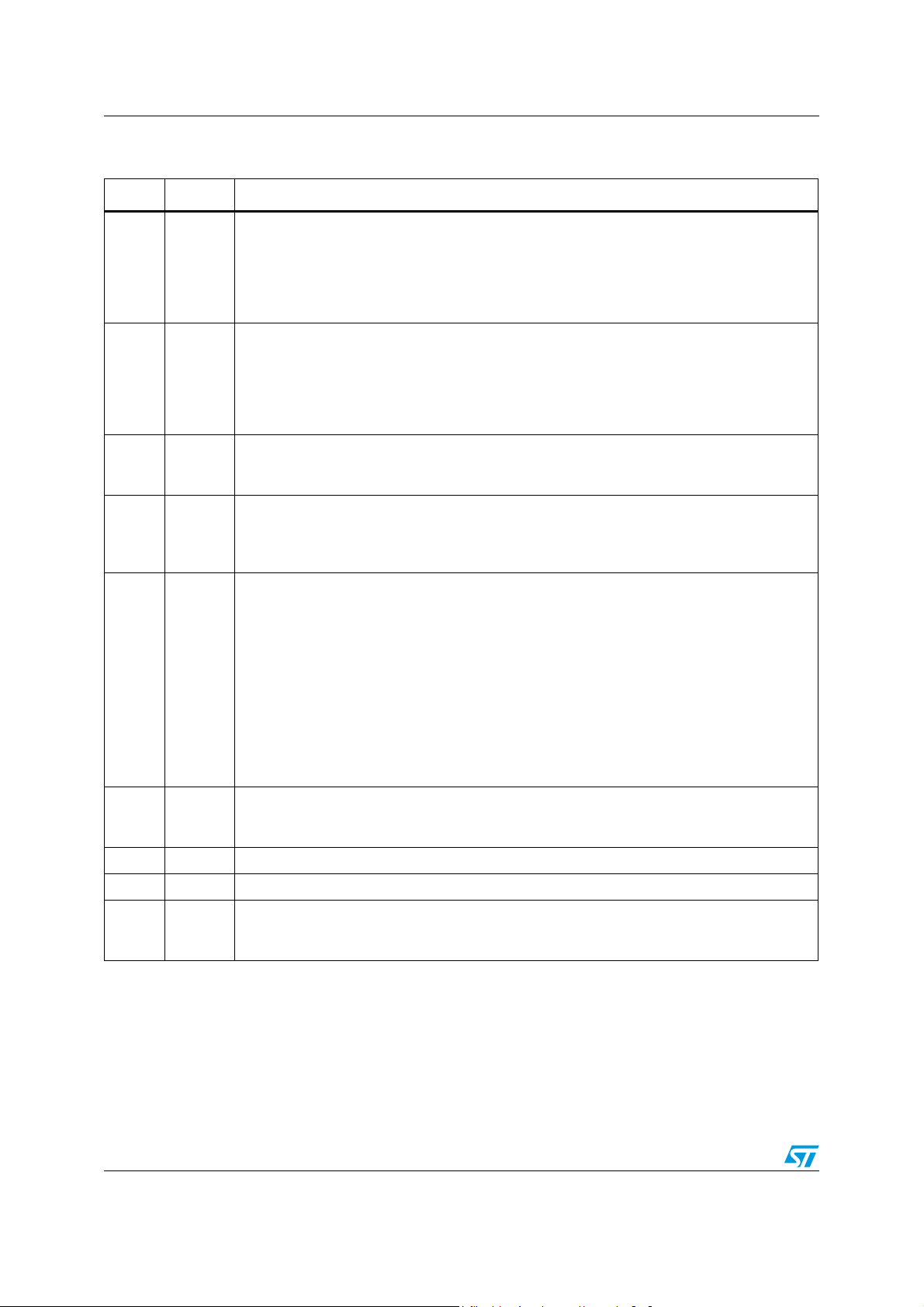

Figure 3. C

output capacitance variation

OSS

C

(pF)

OSS

500

400

300

200

100

0

0 25 50 75 100 125 150

(V)

V

DS

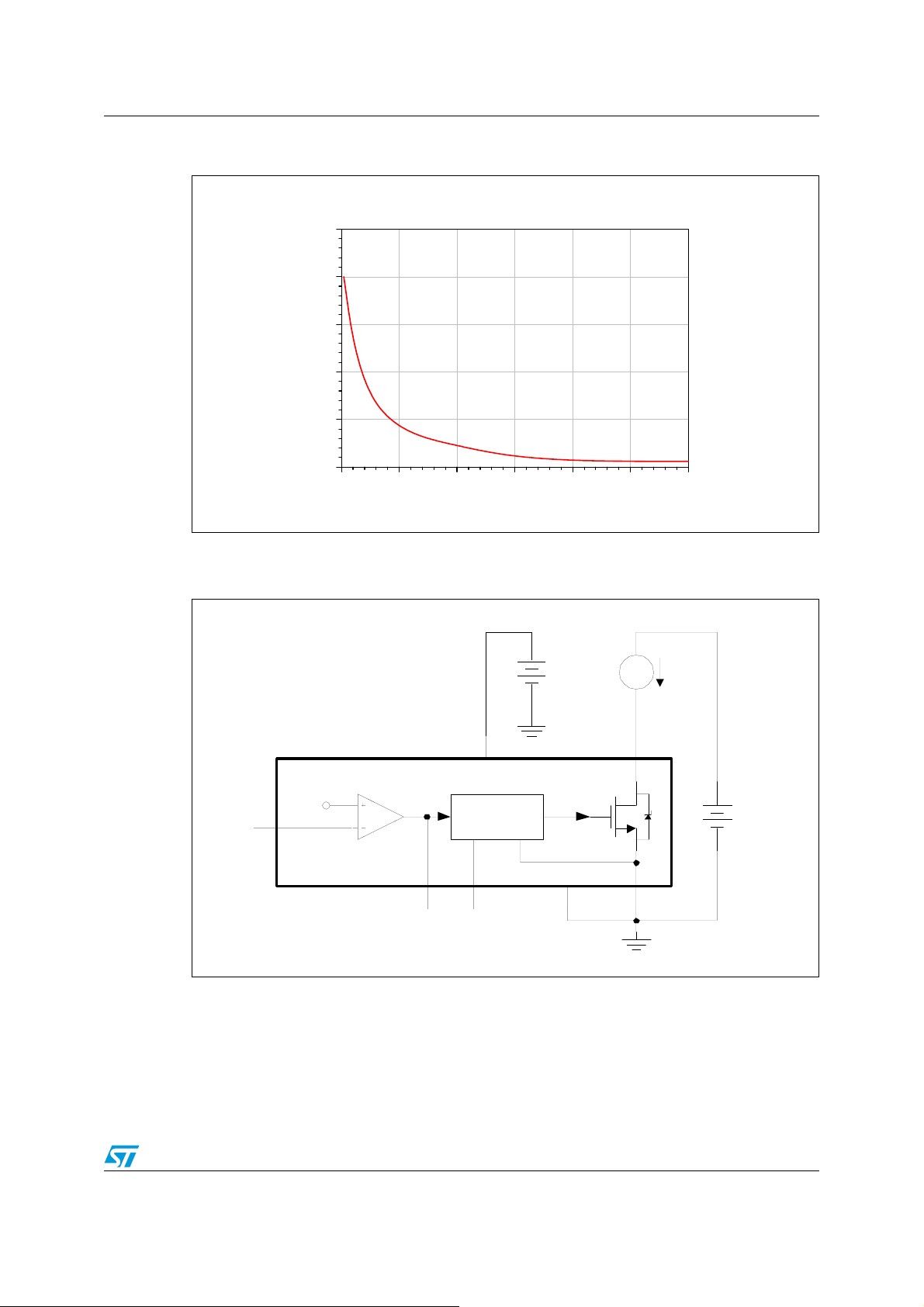

Figure 4. Off state drain and source current test circuit

DMG

Note: The measured I

µA typ. @ 750 V) and the effective MOSFET’s off state drain current

+

14V

-

VCC DRAIN

2.5V

is the sum between the current across the 12 MΩ start-up resistor (62.5

DSS

CUR RE NT

CONTROL

GND

S OUR CEIL EDCOM P

Idss

A

+

Vin

75 0V

Doc ID 18077 Rev 1 9/29

Pin connection HVLED805

μ

Figure 5. Start-up current test circuit

Icc start-up

2.5V

DMG

Figure 6. Quiescent current test circuit

+

A

11.8V

-

VCC DRAIN

CUR RE NT

CONTROL

S OUR CEIL EDCOM P

GND

Iq _m ea s

2.5V

DM G

33 k

3V

-

+

+

-

Iq = Iq_meas - - 100 A

A

VCC DRAIN

CUR RENT

CONTROL

0.1 1 3V

⋅

3.3kΩ

+

-

GND

14 V

SO URCEILE DCOMP

10k

+

-

0.2V0.8 V

10/29 Doc ID 18077 Rev 1

HVLED805 Pin connection

Figure 7. Operating supply current test circuit

+

15V

GND

10

50kHz

10k

A

27 k

220k

2.5V

DMG

10 k

+

-

-5V

Icc

VCC DRAIN

CU RRENT

CO NTRO L

2.8V

+

-

Note: The circuit across the DMG pin is used for switch-on synchronization

Figure 8. Quiescent current during fault test circuit

1.5k

2W

+

150V

-

S OU RCEIL EDCO MP

5.6

DMG

2.5V

Iq ( fa u l t )

+

A

14V

-

VCC DRAIN

CUR RE NT

CONTROL

S OUR CEIL EDCOM P

GND

Doc ID 18077 Rev 1 11/29

Application information HVLED805

5 Application information

The HVLED805 is an off-line all-primary sensing switching regulator, specific for offline LED

drivers based on quasi-resonant ZVS (zero voltage switching at switch turn-on) flyback

topology.

Depending on converter’s load condition, the device is able to work in different modes

(Figure 9 for constant voltage operation):

1. QR mode at heavy load. Quasi-resonant operation lies in synchronizing MOSFET's

turn-on to the transformer’s demagnetization by detecting the resulting negative-going

edge of the voltage across any winding of the transformer. Then the system works

close to the boundary between discontinuous (DCM) and continuous conduction

(CCM) of the transformer. As a result, the switching frequency will be different for

different line/load conditions (see the hyperbolic-like portion of the curves in Figure 9).

Minimum turn-on losses, low EMI emission and safe behavior in short circuit are the

main benefits of this kind of operation. The resulting constant current mode fixes the

average current also in case of a short-circuit failure of one or more LEDs.

2. Valley-skipping mode at medium/ light load. Depending on voltage on COMP pin, the

device defines the maximum operating frequency of the converter. As the load is

reduced MOSFET’s turn-on will not any more occur on the first valley but on the second

one, the third one and so on. In this way the switching frequency will no longer increase

(piecewise linear portion in Figure 9).

3. Burst-mode with no or very light load. When the load is extremely light or disconnected,

the converter will enter a controlled on/off operation with constant peak current.

Decreasing the load will then result in frequency reduction, which can go down even to

few hundred hertz, thus minimizing all frequency-related losses and making it easier to

comply with energy saving regulations or recommendations. Being the peak current

very low, no issue of audible noise arises. Thanks to this feature, the application is able

to safely manage the open circuit caused by an LED failure.

Figure 9. Multi-mode operation of HVLED805 (Constant voltage operation)

f

f

f

osc

osc

osc

f

f

f

sw

sw

sw

0

0

0

12/29 Doc ID 18077 Rev 1

Valley-skipping

Valley-skipping

Valley-skipping

mode

mode

mode

Burst-mode

Burst-mode

Burst-mode

Quasi-resonant mode

Quasi-resonant mode

Quasi-resonant mode

P

P

P

in

in

in

Input voltage

Input voltage

Input voltage

Pinmax

Pinmax

Pinmax

HVLED805 Application information

5.1 Power section and gate driver

The power section guarantees safe avalanche operation within the specified energy rating

as well as high dv/dt capability. The Power MOSFET has a V(BR)DSS of 800V min. and a

typical R

DSon

of 11 Ω.

The gate driver of the power MOSFET is designed to supply a controlled gate current during

both turn-on and turn-off in order to minimize common mode EMI. Under UVLO conditions

an internal pull-down circuit holds the gate low in order to ensure that the power MOSFET

cannot be turned on accidentally.

5.2 High voltage startup generator

Figure 10 shows the internal schematic of the high-voltage start-up generator (HV

generator). It includes an 800 V-rated N-channel MOSFET, whose gate is biased through

the series of a 12 MΩ resistor and a 14 V zener diode, with a controlled, temperaturecompensated current generator connected to its source. The HV generator input is in

common with the DRAIN pin, while its output is the supply pin of the device (Vcc). A mains

“UVLO” circuit (separated from the UVLO of the device that sense Vcc) keeps the HV

generator off if the drain voltage is below V

(50 V typical value).

START

Figure 10. High-voltage start-up generator: internal schematic

DR AI N

12 M14 V

Vcc_OK

Mai ns UV LO

CO NT RO L

HV_EN

IHV

Icharge

S OURCE

Vcc

With reference to the timing diagram of Figure 11, when power is applied to the circuit and

the voltage on the input bulk capacitor is high enough, the HV generator is sufficiently

biased to start operating, thus it will draw about 5.5 mA (typical) from the bulk capacitor.

Doc ID 18077 Rev 1 13/29

Application information HVLED805

Most of this current will charge the bypass capacitor connected between the Vcc pin and

ground and make its voltage rise linearly.

As the Vcc voltage reaches the start-up threshold (13 V typ.) the chip starts operating, the

internal power MOSFET is enabled to switch and the HV generator is cut off by the Vcc_OK

signal asserted high. The IC is powered by the energy stored in the Vcc capacitor.

The chip is able to power itself directly from the rectified mains: when the voltage on the V

pin falls below Vcc

generator is turned on and charges the supply capacitor until it reaches the V

(10.5V typ.), during each MOSFET’s off-time the HV current

restart

CCOn

CC

threshold.

In this way, the self-supply circuit develops a voltage high enough to sustain the operation of

the device. This feature is useful especially during CC regulation, when the flyback voltage

generated by the auxiliary winding alone may not be able to keep Vcc above V

CCrestart

.

At converter power-down the system will lose regulation as soon as the input voltage falls

below V

. This prevents converter’s restart attempts and ensures monotonic output

Start

voltage decay at system power-down.

Figure 11. Timing diagram: normal power-up and power-down sequences

Vin

Vin

Start

Start

V

V

Vcc

Vcc

VccON

VccON

Vccrestart

Vccrestart

DRAIN

DRAIN

t

t

t

t

Icharge

Icharge

5.5 mA

5.5 mA

Normal operation

Power-on

Power-on

Normal operation

CV mode

CV mode

14/29 Doc ID 18077 Rev 1

Normal operation

Normal operation

CC mode

CC mode

Power-o ff

Power-o ff

t

t

t

t

t

t

t

t

HVLED805 Application information

5.3 Secondary side demagnetization detection and triggering block

The demagnetization detection (DMG) and Triggering blocks switch on the power MOSFET

if a negative-going edge falling below 50 mV is applied to the DMG pin. To do so, the

triggering block must be previously armed by a positive-going edge exceeding 100 mV.

This feature is used to detect transformer demagnetization for QR operation, where the

signal for the DMG input is obtained from the transformer’s auxiliary winding used also to

supply the IC.

Figure 12. DMG block, triggering block

Rdmg

Aux

DMG

Rfb

110mV

60 mV

DMG

CLAMP

-

+

BLAN KI N G

TIME

Fr om C C/ CV Bl ock

TURN-ON

LO GI C

LE B

ST AR TE R

Fr om OCP

S

Q

R

To Dr iver

The triggering block is blanked after MOSFET’s turn-off to prevent any negative-going edge

that follows leakage inductance demagnetization from triggering the DMG circuit

erroneously.

This blanking time is dependent on the voltage on COMP pin: it is T

= 0.9 V, and decreases almost linearly down to T

BLANK

= 6 µs for V

BLANK

COMP

= 30 µs for V

= 1.3 V

COMP

The voltage on the pin is both top and bottom limited by a double clamp, as illustrated in the

internal diagram of the DMG block of Figure 12. The upper clamp is typically located at 3.3

V, while the lower clamp is located at -60mV. The interface between the pin and the auxiliary

winding will be a resistor divider. Its resistance ratio as well as the individual resistance

values will be properly chosen (see “Section 5.5: Constant current operation on page 18”

and “Section 5.6: Voltage feedforward block on page 20”.

Please note that the maximum I

sunk/sourced current has to not exceed ±2 mA (AMR)

DMG

in all the Vin range conditions. No capacitor is allowed between DMG pin and the auxiliary

transformer.

The switching frequency is top-limited below 166 kHz, as the converter’s operating

frequency tends to increase excessively at light load and high input voltage.

A Starter block is also used to start-up the system, that is, to turn on the MOSFET during

converter power-up, when no or a too small signal is available on the DMG pin.

The starter frequency is 2 kHz if COMP pin is below burst mode threshold, i.e. 1 V, while it

becomes 8 kHz if this voltage exceed this value.

Doc ID 18077 Rev 1 15/29

Application information HVLED805

V

After the first few cycles initiated by the starter, as the voltage developed across the auxiliary

winding becomes large enough to arm the DMG circuit, MOSFET’s turn-on will start to be

locked to transformer demagnetization, hence setting up QR operation.

The starter is activated also when the IC is in CC regulation and the output voltage is not

high enough to allow the DMG triggering.

If the demagnetization completes – hence a negative-going edge appears on the DMG pin –

after a time exceeding time T

from the previous turn-on, the MOSFET will be turned

BLANK

on again, with some delay to ensure minimum voltage at turn-on. If, instead, the negativegoing edge appears before T

going edge after T

will turn-on the MOSFET. In this way one or more drain ringing

BLANK

has elapsed, it will be ignored and only the first negative-

BLANK

cycles will be skipped (“valley-skipping mode”, Figure 13) and the switching frequency will

be prevented from exceeding 1/T

BLANK

.

Figure 13. Drain ringing cycle skipping as the load is progressively reduced

DS

V

DS

V

DS

T

T

FW

osc

T

V

Pin = Pin'

(limit condition)

T

ON

t

T

osc

in''

< P

in'

Pin= P

t

T

osc

in'''

Pin= P

< P

in''

Note: That when the system operates in valley skipping-mode, uneven switching cycles may be

observed under some line/load conditions, due to the fact that the OFF-time of the MOSFET

is allowed to change with discrete steps of one ringing cycle, while the OFF-time needed for

cycle-by-cycle energy balance may fall in between. Thus one or more longer switching

cycles will be compensated by one or more shorter cycles and vice versa. However, this

mechanism is absolutely normal and there is no appreciable effect on the performance of

the converter or on its output voltage.

5.4 Constant voltage operation

The IC is specifically designed to work in primary regulation and the output voltage is

sensed through a voltage partition of the auxiliary winding, just before the auxiliary rectifier

diode.

Figure 14 shows the internal schematic of the constant voltage mode and the external

connections.

t

16/29 Doc ID 18077 Rev 1

HVLED805 Application information

Figure 14. Voltage control principle: internal schematic

Rd mg

Aux

DMG

Rf b

S/ H

DEMAG

LO G I C

2.5V

-

EA

+

To PWM Logic

-

CV

+

From Rsense

COMP

R

C

Due to the parasitic wires resistance, the auxiliary voltage is representative of the output just

when the secondary current becomes zero. For this purpose, the signal on DMG pin is

sampled-and-held at the end of transformer’s demagnetization to get an accurate image of

the output voltage and it is compared with the error amplifier internal reference.

During the MOSFET’s OFF-time the leakage inductance resonates with the drain

capacitance and a damped oscillation is superimposed on the reflected voltage. The S/H

logic is able to discriminate such oscillations from the real transformer’s demagnetization.

When the DMG logic detects the transformer’s demagnetization, the sampling process

stops, the information is frozen and compared with the error amplifier internal reference.

The internal error amplifier is a transconductance type and delivers an output current

proportional to the voltage unbalance of the two outputs: the output generates the control

voltage that is compared with the voltage across the sense resistor, thus modulating the

cycle-by-cycle peak drain current.

The COMP pin is used for the frequency compensation: usually, an RC network, which

stabilizes the overall voltage control loop, is connected between this pin and ground.

The output voltage can be defined according the formula:

Equation 1

V

Where n

The R

DMG

AUX

SEC

REF

−⋅

SEC

and n

R ⋅

=

FB

n

n

are the secondary and auxiliary turn’s number respectively.

AUX

value can be defined depending on the application parameters (see “Section 5.6:

R

DMG

VV

REFOUT

Voltage feedforward block on page 20” section).

Doc ID 18077 Rev 1 17/29

Application information HVLED805

⋅

=

5.5 Constant current operation

Figure 15 presents the principle used for controlling the average output current of the

flyback converter.

The output voltage of the auxiliary winding is used by the demagnetization block to generate

the control signal for the mosfet switch Q1. A resistor R in series with it absorbs a current

/R, where VC is the voltage developed across the capacitor C.

V

C

The flip-flop’s output is high as long as the transformer delivers current on secondary side.

This is shown in

Figure 16.

The capacitor C has to be chosen so that its voltage V

Since it is charged and discharged by currents in the range of some ten µA (I

can be considered as a constant.

C

CLED

is

typically 20 µA) at the switching frequency rate, a capacitance value in the range 4.7-10 nF

is suited for switching frequencies in the ten kHz.

The average output current can be expressed as:

Equation 2

I

OUT

Where IS is the secondary peak current, T

⎛

⋅=

⎜

2

⎝

ONSEC

⎞

ONSECS

⎟

T

⎠

is the conduction time of the secondary

T

I

side and T is the switching period.

Taking into account the transformer ratio n between primary and secondary side, I

be expressed is a function of the primary peak current I

:

P

can also

S

Equation 3

InI

PS

As in steady state the average current IC:

Equation 4

()

⎛

ITTI

⎜

CLEDONSECCLED

⎝

Which can be solved for VC:

Equation 5

VV ⋅=

CLEDC

Where V

is fed to the CC comparator, the primary peak current can be expressed as:

As V

C

18/29 Doc ID 18077 Rev 1

CLED

=R • I

and is internally defined.

LED

−+−⋅

T

ONSEC

V

⎞

C

⎟

ONSEC

R

⎠

0T

=⋅

T

HVLED805 Application information

Equation 6

V

R

SENSE

C

I =

P

Combining (2), (3) (5) and (6):

Equation 7

n

I ⋅=

OUT

RV2

CLED

SENSE

This formula shows that the average output current does not depend anymore on the input

or the output voltage, neither on transformer inductance values. The external parameters

defining the output current are the transformer ratio n and the sense resistor R

SENSE

.

Figure 15. Current control principle

.

Iref

To PWM Logic

-

CC

+

R

From Rsense

Q1

Rdmg

DMG

DEMAG

LOGIC

S

Q

R

Aux

Rfb

ILED

CLED

Doc ID 18077 Rev 1 19/29

Application information HVLED805

⋅

Figure 16. Constant current operation: Switching cycle waveforms

T

I

P

t

Is

t

Q

t

I

IC

CLED

5.6 Voltage feedforward block

The current control structure uses the voltage VC to define the output current, according to

(7). Actually, the CC comparator will be affected by an internal propagation delay Td, which

will switch off the MOSFET with a peak current than higher the foreseen value.

This current overshoot will be equal to:

Equation 8

Will introduce an error on the calculated CC setpoint, depending on the input voltage.

The HVLED805 implements a Line Feedforward function, which solves the issue by

introducing an input voltage dependent offset on the current sense signal, in order to adjust

the cycle-by-cycle current limitation.

The internal schematic is shown in

Figure 17.

I −=

CLED

Δ I

P

VT

IN d

=

V

t

C

R

L

P

20/29 Doc ID 18077 Rev 1

HVLED805 Application information

(

Figure 17. Feedforward compensation: internal schematic

DRAIN

Rdmg

Aux

DMG

Rf b

Feedforward

Logi c

.

IF F

CC

Bl oc k

-

CC

+

PW M

LOGIC

RFF

SOURCE

Rs e n s e

During MOSFET’s ON-time the current sourced from DMG pin is mirrored inside the

“

Feedforward Logic” block in order to provide a feedforward current, I

FF

.

Such “feedforward current” is proportional to the input voltage according to the formula:

Equation 9

V

I⋅=

FF

IN

Rm

dmg

Where m is the primary-to-auxiliary turns ratio.

According to the schematic, the voltage on the non-inverting comparator will be:

Equation 10

(-)

V=R I+I R+R⋅⋅

SENSE D FF FF SENSE

)

The offset introduced by feedforward compensation will be:

Equation 11

V

IN

()

RR

SENSEFF

As RFF>>R

V +⋅

OFFSET

, the previous one can be simplified as:

SENSE

=

Rm

⋅

dmg

Equation 12

RV

⋅

V

OFFSET

=

FFIN

Rm

⋅

dmg

Doc ID 18077 Rev 1 21/29

Application information HVLED805

This offset is proportional to VIN and is used to compensate the current overshoot,

according to the formula:

Equation 13

TV

⋅

dIN

R

L

SENSE

p

RV

⋅

=⋅

FFIN

Rm

⋅

dmg

Finally, the R

resistor can be calculated as follows:

dmg

Equation 14

RL

N

R

dmg

N

AUX

PRI

⋅

⋅=

FFp

RT

⋅

SENSEd

In this case the peak drain current does not depend on input voltage anymore.

One more consideration concerns the R

sourced by the DMG pin, I

, is compared with an internal reference current I

DMG

value: during MOSFET’s ON-time, the current

dmg

µA typical).

If I

DMG

< I

DMGON

, the brownout function is activated and the IC is shut-down.

This feature is especially important when the auxiliary winding is accidentally disconnected

and considerably increases the end-product’s safety and reliability.

5.7 Burst-mode operation at no load or very light load

When the voltage at the COMP pin falls 65 mV below a threshold fixed internally at a value,

V

COMPBM

reduced at a lower value to minimize Vcc capacitor discharge.

In this condition the converter operates in burst-mode (one pulse train every T

µs), with minimum energy transfer.

, the IC is disabled with the MOSFET kept in OFF state and its consumption

DMGON

START

(-50

=500

As a result of the energy delivery stop, the output voltage decreases: after 500 µs the

controller switches-on the MOSFET again and the sampled voltage on the DMG pin is

compared with the internal reference. If the voltage on the EA output, as a result of the

comparison, exceeds the V

threshold, the device restarts switching, otherwise it stays

COMPL

OFF for another 500 µs period.

In this way the converter will work in burst-mode with a nearly constant peak current defined

by the internal disable level. A load decrease will then cause a frequency reduction, which

can go down even to few hundred hertz, thus minimizing all frequency-related losses and

making it easier to comply with energy saving regulations. This kind of operation, shown in

the timing diagrams of

Figure 19 along with the others previously described, is noise-free

since the peak current is low

22/29 Doc ID 18077 Rev 1

HVLED805 Application information

Figure 18. Load-dependent operating modes: timing diagrams

COMP

65 mV

hyster.

V

COMPL

DS

I

TSTART TSTART TSTART TSTART

5.8 Soft-start and starter block

The soft start feature is automatically implemented by the constant current block, as the

primary peak current will be limited from the voltage on the C

During start-up, as the output voltage is zero, the IC will start in CC mode with no high peak

current operations. In this way the voltage on the output capacitor will increase slowly and

the soft-start feature will be ensured.

Actually the C

value is not important to define the soft-start time, as its duration depends

LED

on others circuit parameters, like transformer ratio, sense resistor, output capacitors and

load. The user will define the best appropriate value by experiments.

5.9 Hiccup mode OCP

The device is also protected against short circuit of the secondary rectifier, short circuit on

the secondary winding or a hard-saturated flyback transformer. A comparator monitors

continuously the voltage on the R

exceeds 1 V.

SENSE

Normal-modeBurst-modeNormal-mode

capacitor.

LED

and activates a protection circuitry if this voltage

To distinguish an actual malfunction from a disturbance (e.g. induced during ESD tests), the

first time the comparator is tripped the protection circuit enters a “warning state”. If in the

subsequent switching cycle the comparator is not tripped, a temporary disturbance is

assumed and the protection logic will be reset in its idle state; if the comparator will be

tripped again a real malfunction is assumed and the device will be stopped.

This condition is latched as long as the device is supplied. While it is disabled, however, no

energy is coming from the self-supply circuit; hence the voltage on the V

capacitor will

CC

decay and cross the UVLO threshold after some time, which clears the latch. The internal

start-up generator is still off, then the V

Doc ID 18077 Rev 1 23/29

voltage still needs to go below its restart voltage

CC

Application information HVLED805

before the VCC capacitor is charged again and the device restarted. Ultimately, this will

result in a low-frequency intermittent operation (Hiccup-mode operation), with very low

stress on the power circuit. This special condition is illustrated in the timing diagram of

Figure 18.

Figure 19. Hiccup-mode OCP: timing diagram

VCC

VccON

VccOFF

Vccrest

VSOURC E

Vcsdis

VDS

1 V

Secondary diode is shorted here

5.10 Layout recommendations

A proper printed circuit board layout is essential for correct operation of any switch-mode

converter and this is true for the HVLED805 as well. Careful component placing, correct

traces routing, appropriate traces widths and compliance with isolation distances are the

major issues. In particular:

● The compensation network should be connected as close as possible to the COMP

pin, maintaining the trace for the GND as short as possible

● Signal ground should be routed separately from power ground, as well from the sense

resistor trace.

t

t

Two switching cycles

t

24/29 Doc ID 18077 Rev 1

HVLED805 Application information

Figure 20. Suggested routing for converter

ACIN

ACIN

VDD

DMG

COMP S OURCE

HVLED805

ILEDGND

DR AI N

LED

...

Doc ID 18077 Rev 1 25/29

Package mechanical data HVLED805

6 Package mechanical data

In order to meet environmental requirements, ST offers these devices in different grades of

ECOPACK

specifications, grade definitions and product status are available at: www.st.com.

ECOPACK

®

packages, depending on their level of environmental compliance. ECOPACK®

®

is an ST trademark.

Table 6. SO16N mechanical data

mm inch

Dim.

Min Typ Max Min Typ Max

A 1.75 0.069

a1 0.1 0.25 0.004 0.009

a2 1.6 0.063

b 0.35 0.46 0.014 0.018

b1 0.19 0.25 0.007 0.010

C 0.5 0.020

c1 45° (typ.)

D (1) 9.8 10 0.386 0.394

E 5.8 6.2 0.228 0.244

e 1.27 0.050

e3 8.89 0.350

F

(1) 3.8 4.0 0.150 0.157

G 4.60 5.30 0.181 0.208

L 0.4 1.27 0.150 0.050

M 0.62 0.024

S 8 °(max.)

26/29 Doc ID 18077 Rev 1

HVLED805 Package mechanical data

Figure 21. Package dimensions

Doc ID 18077 Rev 1 27/29

Revision history HVLED805

7 Revision history

Table 7. Document revision history

Date Revision Changes

14-Oct-2010 1 Initial release

28/29 Doc ID 18077 Rev 1

HVLED805

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 18077 Rev 1 29/29

Loading...

Loading...