Page 1

Introduction

The EVALSP820-XS is an easy to use evaluation board for the STSPIN820, providing a compact solution to evaluate the

performance of the STSPIN820 stepper motor driver with minimal external equipment and without the need for extra

components.

The hardware is fully compatible with RepRAp Arduino Mega Poloulo Shield (RAMPS) or other similar Fused Filament

Fabrication (FFF) 3D Printing platforms, representing a very fast drop-in replacement of similar solutions. Contrary to most other

competitor solutions, the EVALSP820-XS helps customers to really exploit the benefits of working at high microstepping

resolution.

Getting started with the EVALSP820-XS evaluation board

UM2434

User manual

UM2434 - Rev 1 - June 2018

For further information contact your local STMicroelectronics sales office.

www.st.com

Page 2

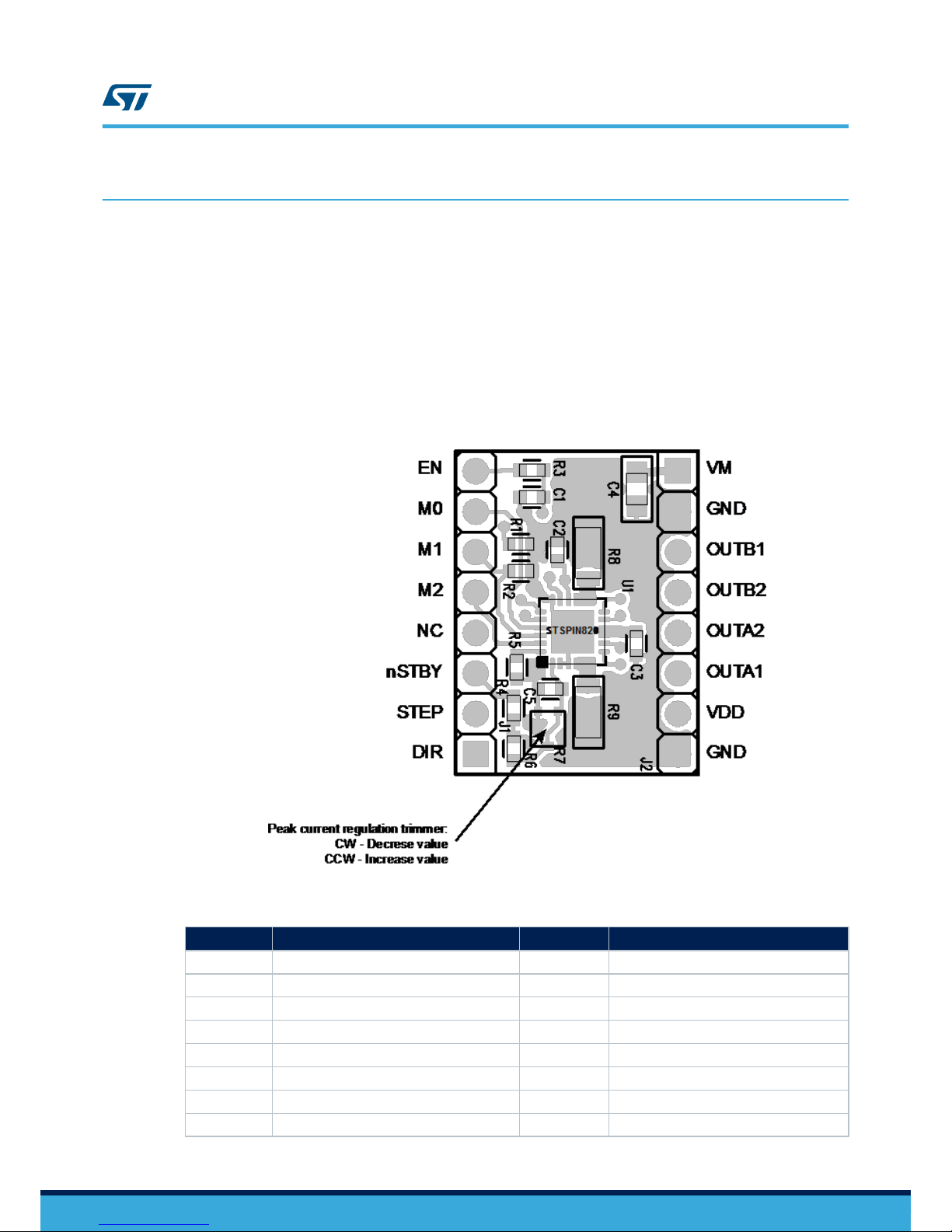

1 Board overview

The main characteristics of the board are:

• Supply voltage from 7 V to 45 V

• Output current up to 1.5 A rms for each motor phase

• Peak current regulation through trimmer

• Form factor and connectivity compatible with RAMPS (RepRap Arduino Mega Pololu Shield) or similar

boards

• Based on STSPIN820 driver featuring:

–

Stepper motor driving with a microstepping resolution up to 1/256th of step

– Overcurrent, short-circuit and overtemperature protections

Figure 1. Board overview

Table 1. Board pinout

J1

Signal J2 Signal

8 Enable (EN) 1 Motor supply voltage (VM)

7 Step mode selection input (M0) 2 Ground

6 Step mode selection input (M1) 3 Phase B out 1 (OUTB1)

5 Step mode selection input (M2) 4 Phase B out 2 (OUTB2)

4 NC 5 Phase A out 2 (OUTA2)

3 Active low standby (nSTBY) 6 Phase A out 1 (OUTA1)

2 Step-clock input (STEP) 7 Logic supply voltage (VDD)

1 Direction input (DIR) 8 Ground

UM2434

Board overview

UM2434 - Rev 1

page 2/11

Page 3

2 Quick start

2.1 Safety precautions

Note: Warning! Some of the components mounted on the board could reach hazardous temperatures during

operation.

While using the board, please adhere to the following precautions

• Do not touch the components

• Do not cover the board

• Do not put the board in contact with flammable materials of with materials releasing smoke when heated

After operation, allow the board to cool down before touching it.

2.2 Adjusting motor peak current

The R7 trimmer adjusts the reference voltage of the STSPIN820 PWM current controller setting the peak current

input to the motor phases.

The R7 trimmer controls the current level. Rotating clockwise increases and rotating counter clockwise decrease

the current level.

The range depends on the VDD logic supply voltage (pin 6 of J2) as listed in the table below.

Table 2. Peak current ranges

VDD Minimum Maximum

3.3 V V

REF

= 0 V

I

peak

= 0 A

(1)

V

REF

= 0.67 V

I

peak

= 4.5 A

(2)

5 V V

REF

= 0 V

I

peak

= 0 A

(1)

V

REF

= 1 V

I

peak

= 6.8 A

(2)

(1)

Minimum current could be present due to the PWM current control operation

(2)

The overcurrent protection of the STSPIN820 could limit the actual peak current

2.2.1 Modify the peak current range

The trimmer can be adjusted by modifying some board components.

In particular the components contributing to the definition of the peak current are:

• Both the sensing resistors

• Pull-up resistor (R6)

• Sensing resistor (R8 and R9)

The detailed formula is the following:

Changing the sensing resistors requires particular attention:

• Bust the sensing resistors must have the same value

•

Power dissipation on the resistors is equal to I

peak

2

× R

sense

. The power rating must be selected accordingly.

UM2434

Quick start

UM2434 - Rev 1

page 3/11

Page 4

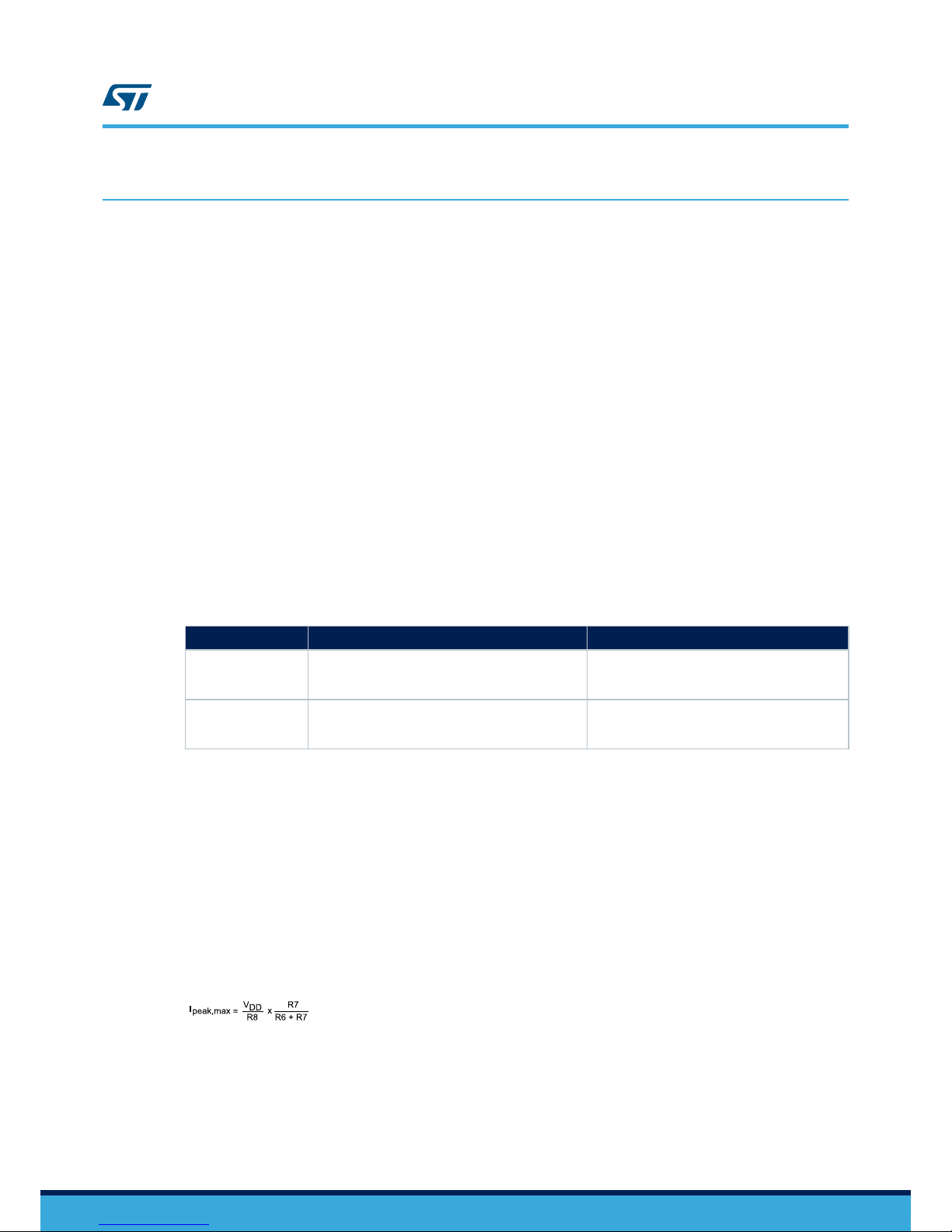

2.3 Setting off time duration

The R5 resistor sets the off time duration for the PWM current control circuitry as indicated in the figure below.

Low resistance value imposes a short off time reducing the current ripple into the motor phases.

The default value is 10 kΩ, corresponding to about 14 µs.

Figure 2. OFF time vs R

OFF

value

0

20

40

60

80

100

120

140

160

OFF time [µs ]

R

OFF

[k ]

AM040213

2.4

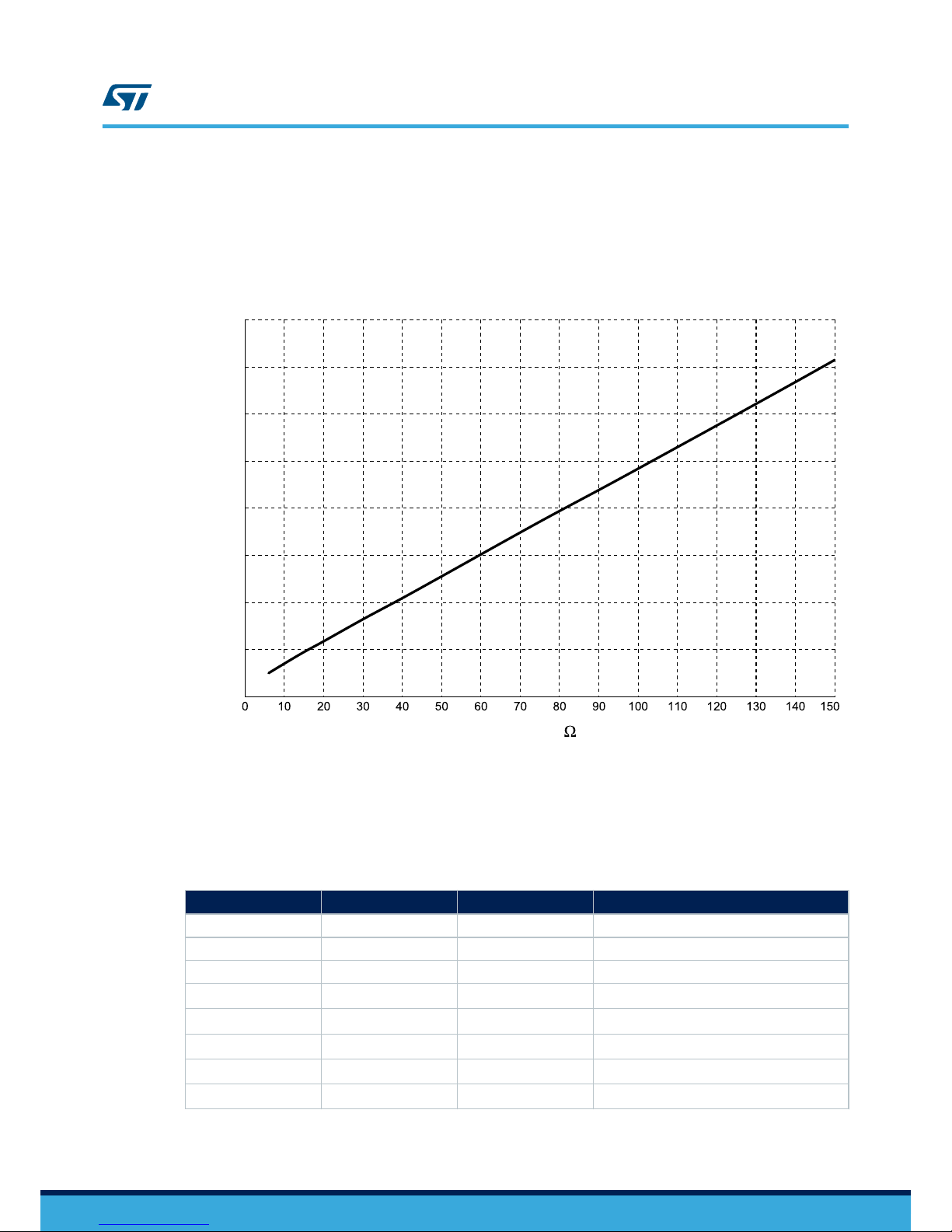

Setting the step mode

The inputs M0, M1 and M2 sets the step mode of the STSPIN820 driver as listed in the table below.

Table 3. Step mode selection

M2 M1 M0 Mode

LOW LOW LOW Full step

LOW LOW HIGH ½ step

LOW HIGH LOW ¼ of step

LOW HIGH HIGH

1/8th of step

HIGH LOW LOW

1/16

th

of step

HIGH LOW HIGH

1/32

nd

of step

HIGH HIGH 0

1/128

th

of step

HIGH HIGH HIGH

1/256

th

of step

UM2434

Setting off time duration

UM2434 - Rev 1

page 4/11

Page 5

3 Schematic, layout and bill of material

Figure 3. Schematic

VDD

VMOT

B1

B2

A2

A1

GND

GND

Connected on

RAMP 1.4

VCC

VCC

VCC

C1

10NF

C5

1NF

U1

STSPIN820

STBY/RESET

16

EN/FAULT

17

DIR

20

STCK

19

MODE3

23

MODE1

21

REF

1

TOFF

24

VS

9

OUTA1

7

OUTA2

8

SENSEA1

5

OUTB1

12

OUTB2

11

SENSEB1

14

GND2EPAD

25

DECAY

18

MODE2

22

VS

10

SENSEA2

6

SENSEB2

13

SNSA

4

SNSB

15

GND

3

R9

0.15R

R7

10K

ST2TA103

1 3

2

R8

0.15R

C2

1NF

R2

100K

C4

4.7UF

50V

R3 39K

J2

1

2

3

4

5

6

7

8

R6

39K

R4

18K

J1

1

2

3

4

5

6

7

8

R5

10K

R1

100K

C3

100NF

OUTB1

OUTB2

DIR

M2

M1

M0

EN

VMM

STEP

OUTA1

OUTA2

AM040394

Figure 4. Layout top

AM040395

Figure 5. Layout bottom

AM040396

UM2434

Schematic, layout and bill of material

UM2434 - Rev 1

page 5/11

Page 6

Table 4. Bill of material

Item Qty. Ref. Part/ value Voltage/ watt/

ampere

Tolerance Package Manufacturer Orderable part

number

1 1 C1 10 NF 50 V 0.15 0603

2 2 C2, C5 1 NF 50 V 0.15 0603

3 1 C3 100 NF 100 V 0.15 0603

4 1 C4 4.7 UF 50 V 0.15 0805

5 2 J1, J2 61300811121 WURTH

ELECTRONIK

61300811121

6 2 R1, R2 100 K 1/10 W 0.05 0603

7 2 R3, R6 39 K 1/10 W 0.05 0603

8 1 R4 18 K 1/10 W 0.05 0603

9 1 R5 10 K 1/10 W 0.05 0603

10 1 R7 10 K 1/10 W 0.2 L2.75_W2.2_H0.8 BOURNS TC42X-2-103

11 2 R8, R9 0.15 R 1/2 W 0.01 1206

12 1 U1 STSPIN820 QFN24_L4_W4_P0.5 ST STSPIN820

UM2434

Schematic, layout and bill of material

UM2434 - Rev 1

page 6/11

Page 7

Revision history

Table 5. Document revision history

Date Version Changes

28-Jun-2018 1 Initial release.

UM2434

UM2434 - Rev 1

page 7/11

Page 8

Contents

1 Board overview ...................................................................2

2 Quick start ........................................................................3

2.1 Safety precautions .............................................................3

2.2 Adjusting motor peak current.....................................................3

2.2.1 Modify the peak current range...............................................3

2.3 Setting off time duration .........................................................3

2.4 Setting the step mode...........................................................4

3 Schematic, layout and bill of material ..............................................5

Revision history ........................................................................7

UM2434

Contents

UM2434 - Rev 1

page 8/11

Page 9

List of tables

Table 1. Board pinout .......................................................................2

Table 2. Peak current ranges.................................................................. 3

Table 3. Step mode selection..................................................................4

Table 4. Bill of material ......................................................................6

Table 5. Document revision history..............................................................7

UM2434

List of tables

UM2434 - Rev 1

page 9/11

Page 10

List of figures

Figure 1. Board overview....................................................................2

Figure 2. OFF time vs R

OFF

value .............................................................4

Figure 3. Schematic .......................................................................5

Figure 4. Layout top .......................................................................5

Figure 5. Layout bottom ....................................................................5

UM2434

List of figures

UM2434 - Rev 1

page 10/11

Page 11

IMPORTANT NOTICE – PLEASE READ CAREFULLY

STMicroelectronics NV and its subsidiaries (“ST”) reserve the right to make changes, corrections, enhancements, modifications, and improvements to ST

products and/or to this document at any time without notice. Purchasers should obtain the latest relevant information on ST products before placing orders. ST

products are sold pursuant to ST’s terms and conditions of sale in place at the time of order acknowledgement.

Purchasers are solely responsible for the choice, selection, and use of ST products and ST assumes no liability for application assistance or the design of

Purchasers’ products.

No license, express or implied, to any intellectual property right is granted by ST herein.

Resale of ST products with provisions different from the information set forth herein shall void any warranty granted by ST for such product.

ST and the ST logo are trademarks of ST. All other product or service names are the property of their respective owners.

Information in this document supersedes and replaces information previously supplied in any prior versions of this document.

© 2018 STMicroelectronics – All rights reserved

UM2434

UM2434 - Rev 1

page 11/11

Loading...

Loading...