6-line IPAD™, EMI filter and ESD protection

Features

■ High design flexibility

■ Lead free package

■ Very low PCB space consumption:

3.5 mm x 1.2 mm

■ Very thin package: 0.5 mm

■ High efficiency in ESD suppression

■ IEC 61000-4-2 level 4

■ High reliability offered by monolithic integration

■ High reduction of parasitic elements through

integration and µQFN packaging

Complies with following standards:

■ IEC 61000-4-2 level 4 external pins

Applications

■ Mobile telephones,

■ Navigation systems

■ Digital still cameras

■ Portable devices.

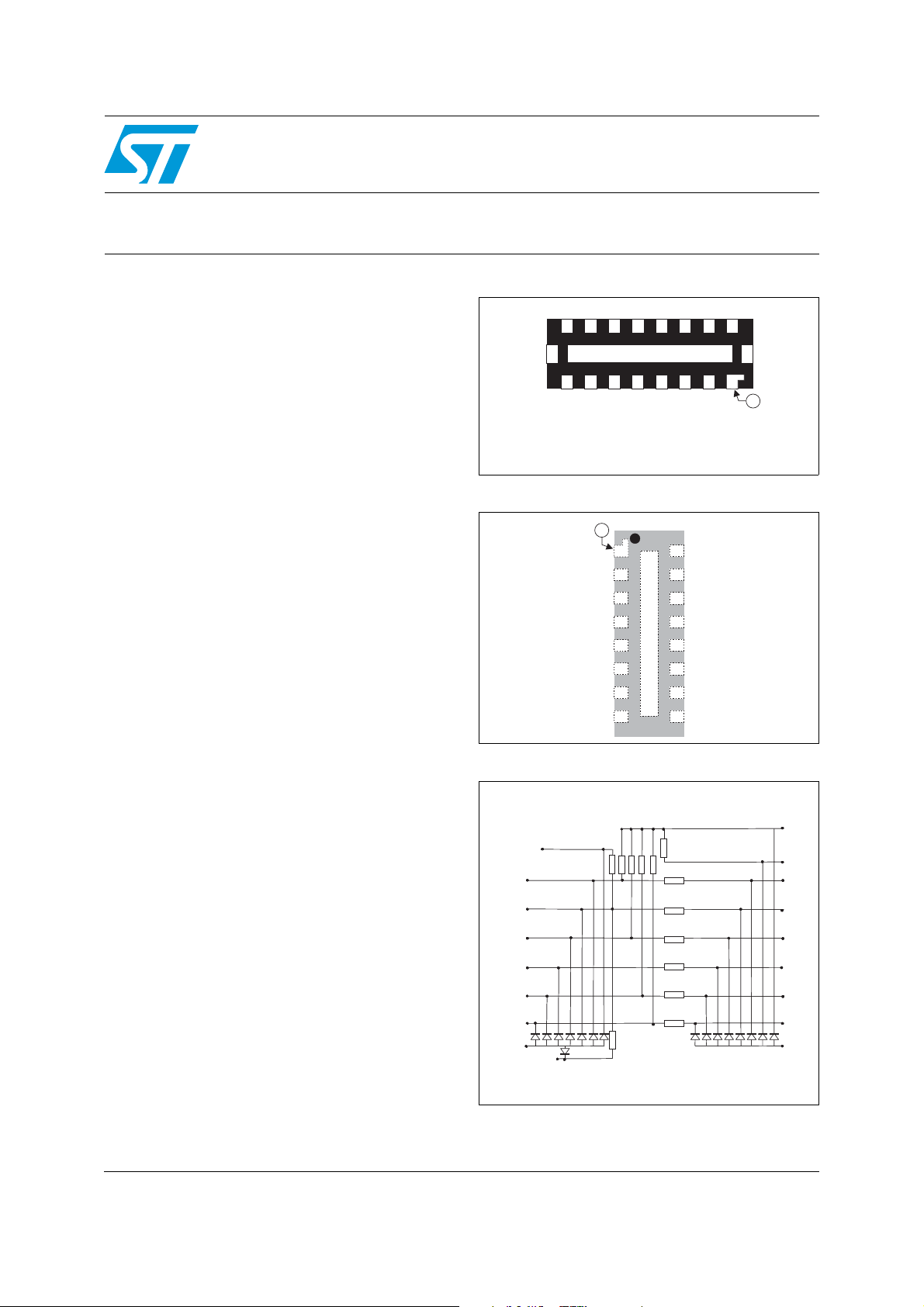

EMIF06-MSD02N16

Micro QFN 16L 3.5 mm x 1.2 mm

(bottom view)

Figure 1. Pin configuration

1

GND

RDATA_VCC

VCC

DAT2_Ex

DAT3_Ex

CMD_Ex

CLK_Ex

DAT0_Ex

DAT1_Ex

WP/CD

RDAT3_GND

DAT2_In

DAT3_In

CMD_In

CLK_In

DAT0_In

DAT1_In

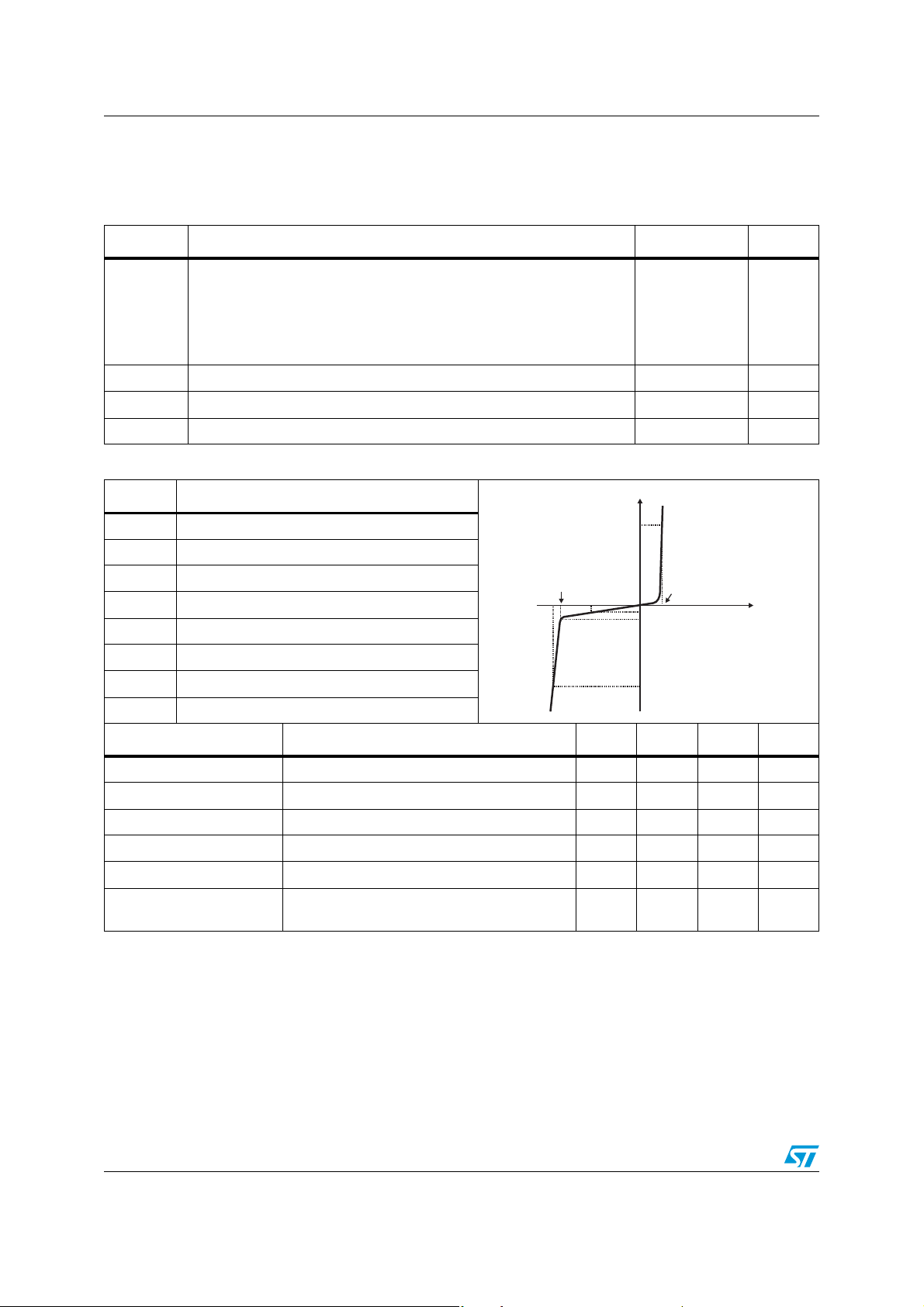

Figure 2. Schematic circuit diagram

1

Description

Vcc

R12

The EMIF06-MSD02N16 is a highly integrated

device designed to suppress EMI/RFI noise for

interface line filtering. It is packaged in

micro QFN.

This filter includes ESD protection circuitry, which

prevents damage to the protected device when

subjected to ESD surges.

DAT2_In

DAT2_In

DAT3_In

DAT3_In

CMD_In

CMD_In

CLK_In

CLK_In

DAT0_In

DAT0_In

DAT1_In

DAT1_In

DAT3 pull-up

DAT3 pull-up

GND

GND

DAT3 pull-down

DAT3 pull-down

R7

R7

R13

R13

R8 R9

R8 R9

R10 R11

R10 R11

R12

R1

R1

R2

R2

R3

R3

R4

R4

R5

R5

R6

R6

TM: IPAD is a trademark of STMicroelectronics

November 2008 Rev 1 1/12

Vcc

WP/CD

WP/CD

DAT2_Ex

DAT2_Ex

DAT3_Ex

DAT3_Ex

CMD_Ex

CMD_Ex

CLK_Ex

CLK_Ex

DAT0_Ex

DAT0_Ex

DAT1_Ex

DAT1_Ex

GND

GND

www.st.com

Characteristics EMIF06-MSD02N16

1 Characteristics

Table 1. Absolute ratings (limiting values)

Symbol Parameter Value Unit

ESD IEC 61000-4-2

Contact discharge on DATx_In, CMD_In and CLK_In pins

V

PP

On all other pins

Contact discharge

Air discharge

T

T

op

T

stg

Table 2. Electrical characteristics (T

Maximum junction temperature 125 °C

j

Operating temperature range - 30 to + 85 °C

Storage temperature range - 55 to + 150 °C

Symbol Parameter

C

V

I

V

V

R

I

R

LINE

Breakdown voltage

BR

Leakage current @ V

RM

Stand-off voltage

RM

Clamping voltage

CL

Dynamic resistance

d

Peak pulse current

PP

Series resistance between Input & Output

I/O

RM

Input capacitance per line

amb

= 25 °C)

I

I

F

V

BR

V

V

RM

CL

2

8

12

V

F

I

RM

I

R

I

PP

Symbol Test conditions Min. Typ. Max. Unit

kV

V

V

BR

I

RM

R1, R2, R3, R4, R5, R

R

, R8, R9, R10, R11, R12Pull-up resistors 80 90 100 kΩ

7

IR = 1 mA 5 8 V

VRM = 3 V 200 nA

Series resistors - tolerance ±20% 36 45 54 Ω

6

R13 Pull-down resistor - tolerance ±20% 375 470 565 kΩ

V

= 0 V, V

C

line

LINE

(under zero light conditions)

= 30 mV, F = 1 MHz

OSC

20 pF

2/12

EMIF06-MSD02N16 Characteristics

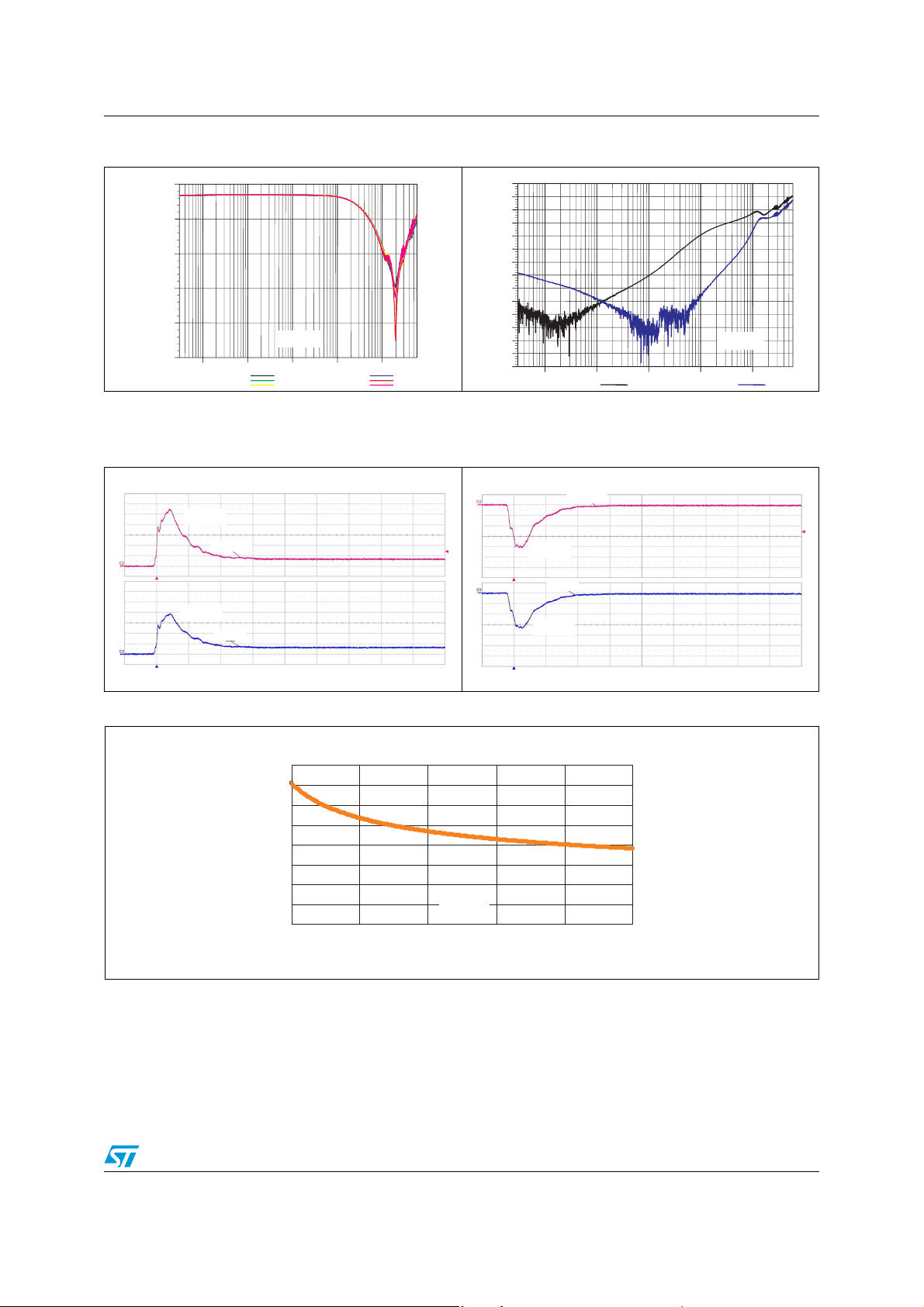

Figure 3. S21 attenuation measurement Figure 4. Analog cross talk measurements

dB

0.00

-10.00

-20.00

-30.00

-40.00

F (Hz)

-50.00

100.0k 1.0M 10.0M 100.0M 1.0G

DAT0 DAT1

DAT2 DAT3

CLK CMD

Figure 5. ESD response to IEC 61000-4-2

(+12 kV air discharge) on one input

(V

) and on one output (V

in

55 V Max

IN

out

)

Figure 6. ESD response to IEC 61000-4-2

0.00

-10.00

-20.00

-30.00

-40.00

-50.00

-60.00

-70.00

-80.00

-90.00

-100.00

-110.00

-120.00

-130.00

-140.00

dB

F (Hz)

100.0k 1.0M 10.0M 100.0M 1.0G

-DAT3

DAT2

DAT2

-DAT1

(- 12 kV air discharge) on one input

(Vin) and on one output (V

IN

-41 V Max

OUT

out

)

39 V Max

OUT

-34 V Max

Figure 7. Line capacitance versus reverse voltage applied on DATx and CMD line

C

(pF)

LINE

16

14

12

10

8

6

4

V

(V)

2

0

0.0 1.0 2.0 3.0 4.0 5.0

LINE

3/12

Application information EMIF06-MSD02N16

2 Application information

The EMIF06-mSD02N16 is a dedicated interface device for micro SD card/T-Flash card in

mobile phones. The device provides:

● ESD protection

● EMI filterering

● Pull-up resistors

● Card detection circuit

2.1 ESD protection

Each pin is connected to a TVS diode able to withstand 12 kV on all pins except on

DATx_In, CMD_In and CLK_In.

2.2 EMI filtering

DATx, CMD and CLK lines are immunized against EMI radiations thanks to pi-filters. To

avoid any degradation of the signal integrity at high frequency, the total line capacitance

stays lower than 20 pF making the device compatible with a clock frequency up to 52 MHz.

2.3 Pull-up resistors

As recommended by the SD Specifications (Part 1 Physical Layer Version 2.00), all the data

lines DATx and the CMD line must be pulled-up with resistors of 10 to 100 kΩ to avoid bus

floating not only in SD 4-bit mode but also in SD 1-bit and SPI mode.

For the EMIF06-MSD02N16 device the pull-up resistor value has been fixed at 90 kΩ. This

value makes the EMIF06-MSD02N16 compatible with most of the level shifters that may be

used in the circuit including auto direction-sensing translators known to exhibit a weak

current output.

2.4 Card detection circuit

The EMIF06-mSD02N16 provides the flexibility to use either mechanical card detection with

a dedicated pin connected to the memory card slot or the electrical card detection using the

internal pull resistor of DAT3 of the micro SD card/T-Flash card.

In case of mechanical card detection, the user must add a pull-up on the circuit connected to

the CD (Card Detect) of the micro-SD/T-Flash slot as shown in Figure 8.

4/12

EMIF06-MSD02N16 Application information

Figure 8. Mechanical card detection

V

DD

Pull - up

resistor

Host

controller

GND

GND

WP/CD

Contact when

inserting the card

SD card

A pull-up of 90 kΩ is embedded into the EMIF06-MSD02N16. The routing corresponding to

the mechanical card detection configuration is shown in Figure 9.

Figure 9. Circuit routing for mechanical card detection

Card detect pin Card detect host input

Pin 1–DAT2

Pin 2–CD/DAT3

Pin 3–CMD

Pin 4 –VCC

Pin 5–CLK

Pin 6–GND

Pin 7–DAT0

Pin 8–DAT1

Top level

DAT3 pull-up

Card detect pull

NC

HOST CONTROLLERHOST CONTROLLER

NC

HOST CONTROLLERHOST CONTROLLER

-

up

Card detect pinCard detect host input

Pin 1–DAT2

Pin 2–CD/DAT3

Pin 3–CMD

Pin 4–VCC

Pin 5–CLK

Pin 6–GND

Pin 7–DAT0

Pin 8–DAT1

Top level

DAT3 pull-up

Card detect pull-up

Bottom view Top view

In case of electrical card detection, the user must add a pull-down on the circuit connected

to the CD/DAT3 pin of the micro-SD/T-Flash pin as shown in Figure 10.

Figure 10. Electrical card detection

Host

controller

DAT3 (CD)

Pull - down

resistor

GND

50 kΩ

V

DD

0

SD card

5/12

Ordering information scheme EMIF06-MSD02N16

A pull-down of 470k is embedded into the EMIF06-mSD02N16. The routing corresponding

to the electrical card detection configuration is shown in the Figure 11.

Figure 11. Circuit routing for electrical card detection

NC

Pin 1–DAT2

Pin 1–DAT2

Pin 2–CD/DAT3

Pin 2 –CD/DAT3

Pin 3–

Pin 3 –

CMD

CMD

Pin 4–

Pin 4 –

VCC

VCC

Pin 5–

Pin 5–

CLK

CLK

Pin 6–

Pin 6 –

GND

GND

Pin 7–DAT0

Pin 7–DAT0

Pin 8–DAT1

Pin 8–DAT1

Top level

Top level

DAT3 pull

DAT3 pull-down

HOST CONTROLLERHOST CONTROLLER

HOST CONTROLLERHOST CONTROLLER

Bottom view Top view

3 Ordering information scheme

Figure 12. Ordering information scheme

EMI Filter

Number of lines

NC

Pin 1–DAT2

Pin 1–DAT2

Pin 2–CD/DAT3

Pin 2–CD/DAT3

Pin 3–CMD

Pin 3–CMD

Pin 4–VCC

Pin 4–VCC

Pin 5–CLK

Pin 5–CLK

Pin 6–GND

Pin 6–GND

Pin 7–DAT0

Pin 7–DAT0

Pin 8–DAT1

Pin 8–DAT1

EMIF 06 - MSD02 N16

Top level

Top level

DAT3 pull-down

DAT3 pull-down

Information

MSD = application

02 = version

Packag e

N = narrow micro QFN

16 = 16 leads

6/12

EMIF06-MSD02N16 Package information

4 Package information

● Epoxy meets UL94, V0

®

In order to meet environmental requirements, ST offers these devices in ECOPACK

packages. These packages have a lead-free second level interconnect. The category of

second level interconnect is marked on the inner box label, in compliance with JEDEC

Standard JESD97. The maximum ratings related to soldering conditions are also marked on

the inner box label. ECOPACK is an ST trademark. ECOPACK specifications are available at

www.st.com.

Table 3. Micro QFN 3.5x1.2 16L dimensions

Dimensions

E

Index area

Pin 1

E2

k

1

D

M

D2

b

e

1

b1

Figure 13. Micro QFN 3.5x1.2 16L

footprint (dimensions in mm)

3.00

Ref.

A

Millimeters Inches

Min. Typ. Max. Min. Typ. Max.

A 0.45 0.50 0.55 0.018 0.020 0.022

A1 0.00 0.05 0.000 0.002

b 0.15 0.20 0.25 0.006 0.008 0.010

b1 0.25 0.30 0.35 0.010 0.012 0.014

A1

D 3.45 3.50 3.55 0.136 0.138 0.140

D2 2.70 2.80 2.90 0.106 0.110 0.114

E 1.15 1.20 1.25 0.045 0.047 0.049

L

L1

E2 0.25 0.30 0.40 0.010 0.012 0.016

e 0.40 0.016

k 0.20 0.008

L 0.20 0.25 0.30 0.008 0.010 0.012

L1 0.15 0.006

M 0.20 0.008

Figure 14. Marking

Dot : Pin 1 Identification

N6 = Marking

1.6 0.70

0.40

2.30

0.30

0.45

0.20

N6

7/12

Package information EMIF06-MSD02N16

Figure 15. Tape and reel specification

12.00 ± 0.3

3.70 ± 0.1

0.80 ± 0.1

All dimensions in mm

Dot identifying Pin A1 location

2.00 ± 0.1

4.00 ± 0.1

N6 N6

1.70 ± 0.1

N6

User direction of unreeling

N6

4.00 ± 0.1

N6

Ø 1.55 ± 0.05

N6

1.75 ± 0.1 5.5 ± 0.1

Note: Product marking may be rotated by 90° for assembly plant differentiation. In no case should

this product marking be used to orient the component for its placement on a PCB. Only pin 1

mark is to be used for this purpose.

8/12

EMIF06-MSD02N16 Recommendation on PCB assembly

5 Recommendation on PCB assembly

5.1 Stencil opening design

1. General recommendation on stencil opening design

a) Stencil opening dimensions: L (Length), W (Width), T (Thickness).

Figure 16. Stencil opening dimensions

L

T

W

b) General design rule

Stencil thickness (T) = 75 ~ 125 µm

W

Aspect Ratio

Aspect Area

-----

1.5≥=

T

LW×

---------------------------2T L W+()

0.66≥=

2. Reference design

a) Stencil opening thickness: 100 µm

b) Stencil opening for central exposed pad: Opening to footprint ratio is 50%.

c) Stencil opening for leads: Opening to footprint ratio is 90%.

Figure 17. Recommended stencil window position

5µm 5µm

15 µm

450 µm

300 µm

350 µm

200 µm

420 µm

190

200

µm

µm

2800 µm

2100

15 µm

1.6 0.70

50 µm

µm

50 µm

350 µm

3.00

2.30

0.40

Footprint

Stencil window

Footprint

0.30

0.45

0.20

9/12

Recommendation on PCB assembly EMIF06-MSD02N16

5.2 Solder paste

1. Halide-free flux qualification ROL0 according to ANSI/J-STD-004.

2. “No clean” solder paste is recommended.

3. Offers a high tack force to resist component movement during high speed

4. Solder paste with fine particles: powder particle size is 20-45 µm.

5.3 Placement

1. Manual positioning is not recommended.

2. It is recommended to use the lead recognition capabilities of the placement system, not

the outline centering

3. Standard tolerance of ± 0.05 mm is recommended.

4. 3.5 N placement force is recommended. Too much placement force can lead to

squeezed out solder paste and cause solder joints to short. Too low placement force

can lead to insufficient contact between package and solder paste that could cause

open solder joints or badly centered packages.

5. To improve the package placement accuracy, a bottom side optical control should be

performed with a high resolution tool.

6. For assembly, a perfect supporting of the PCB (all the more on flexible PCB) is

recommended during solder paste printing, pick and place and reflow soldering by

using optimized tools.

5.4 PCB design preference

1. To control the solder paste amount, the closed via is recommended instead of open

vias.

2. The position of tracks and open vias in the solder area should be well balanced. The

symmetrical layout is recommended, in case any tilt phenomena caused by

asymmetrical solder paste amount due to the solder flow away.

10/12

EMIF06-MSD02N16 Ordering information

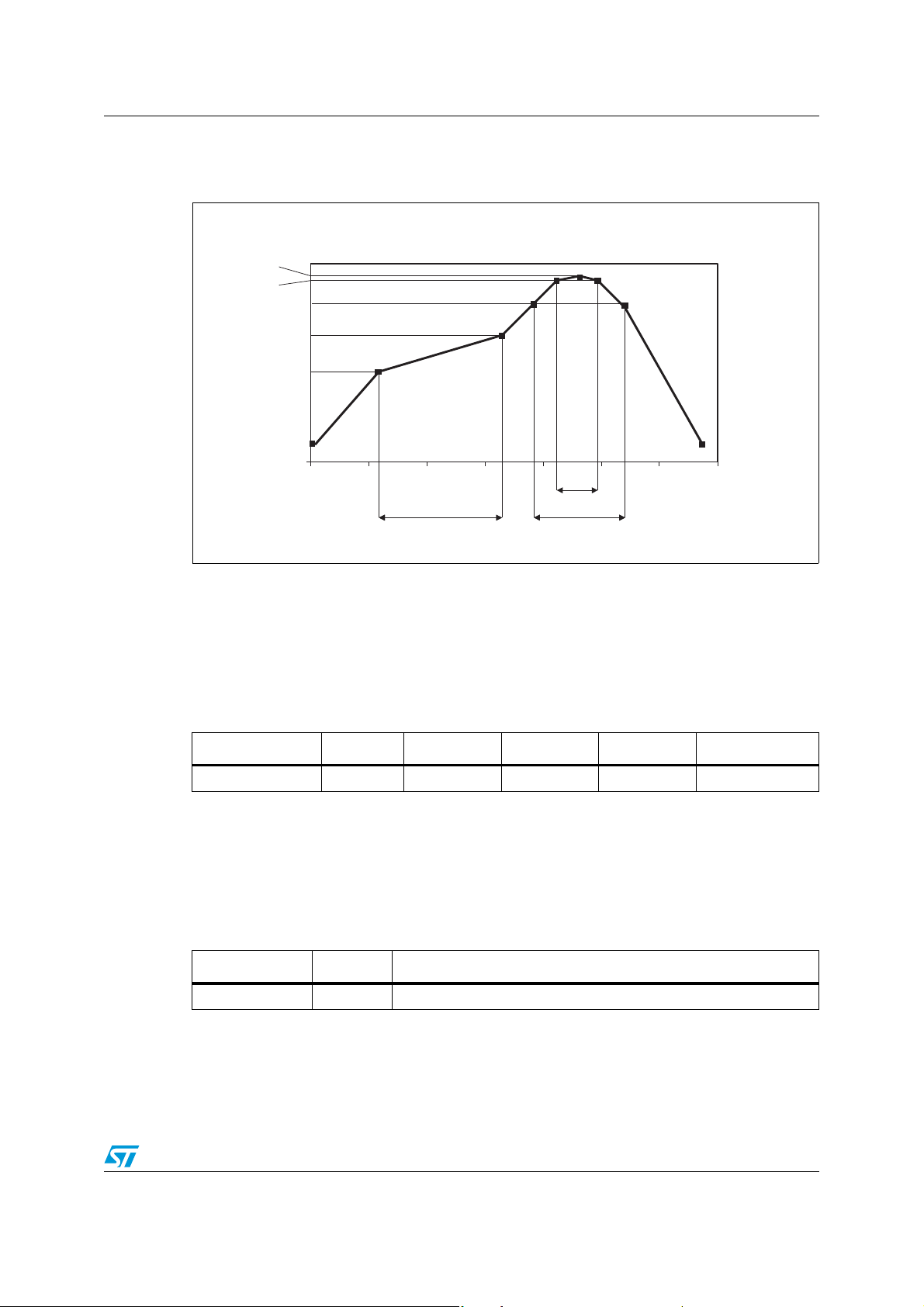

5.5 Reflow profile

Figure 18. ST ECOPACK® recommended soldering reflow profile for PCB mounting

Temperature (°C)

Temperature (°C)

260°C max

260°C max

255°C

255°C

220°C

220°C

180°C

180°C

125 °C

125 °C

3°C/s max

3°C/s max

0

0

012345 67

012345 67

10-30 sec

10-30 sec

90 to 150 sec

90 to 150 sec

90 sec max

90 sec max

2°C/s recommended

2°C/s recommended

6°C/s max

6°C/s max

Time (min)

Time (min)

Note: Minimize air convection currents in the reflow oven to avoid component movement.

6 Ordering information

Table 4. Ordering information

Order code Marking Package Weight Base qty Delivery mode

EMIF06-MSDN16 N6

1. The marking can be rotated by 90° to differentiate assembly location

(1)

Micro QFN 6.17 mg 3000 Tape and reel (7”)

7 Revision history

Table 5. Document revision history

Date Revision Changes

21-Nov-2008 1 Initial release.

11/12

EMIF06-MSD02N16

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

12/12

Loading...

Loading...