®

MAIN PRODUCT CHARACTERISTICS:

Where EMI filtering in ESD sensitive equipment is

required :

■ Mobile phones and communication systems

■ Computers, printers and MCU Boards

DESCRIPTION

The EMIF02-MIC03 is a highly integrated device

designed to suppress EMI/RFI noise in all systems

subjected to electromagnetic interferences. The

EMIF02 Flip-Chip packaging means the package

size is equal to the die size.

This filter includes an ESD protection circuitry

which prevents damage to the application when

subjected to ESD surges up 15 kV.

BENEFITS

■ EMI symmetrical (I/O) low-pass filter

■ High efficiency in EMI filtering

■ Very low PCB space consuming:

1.07 mm x 1.47 mm

■ Very thin package: 0.65 mm

■ High efficiency in ESD suppression

■ High reliability offered by monolithic integration

■ High reducing of parasitic elements through

integration & wafer level packaging

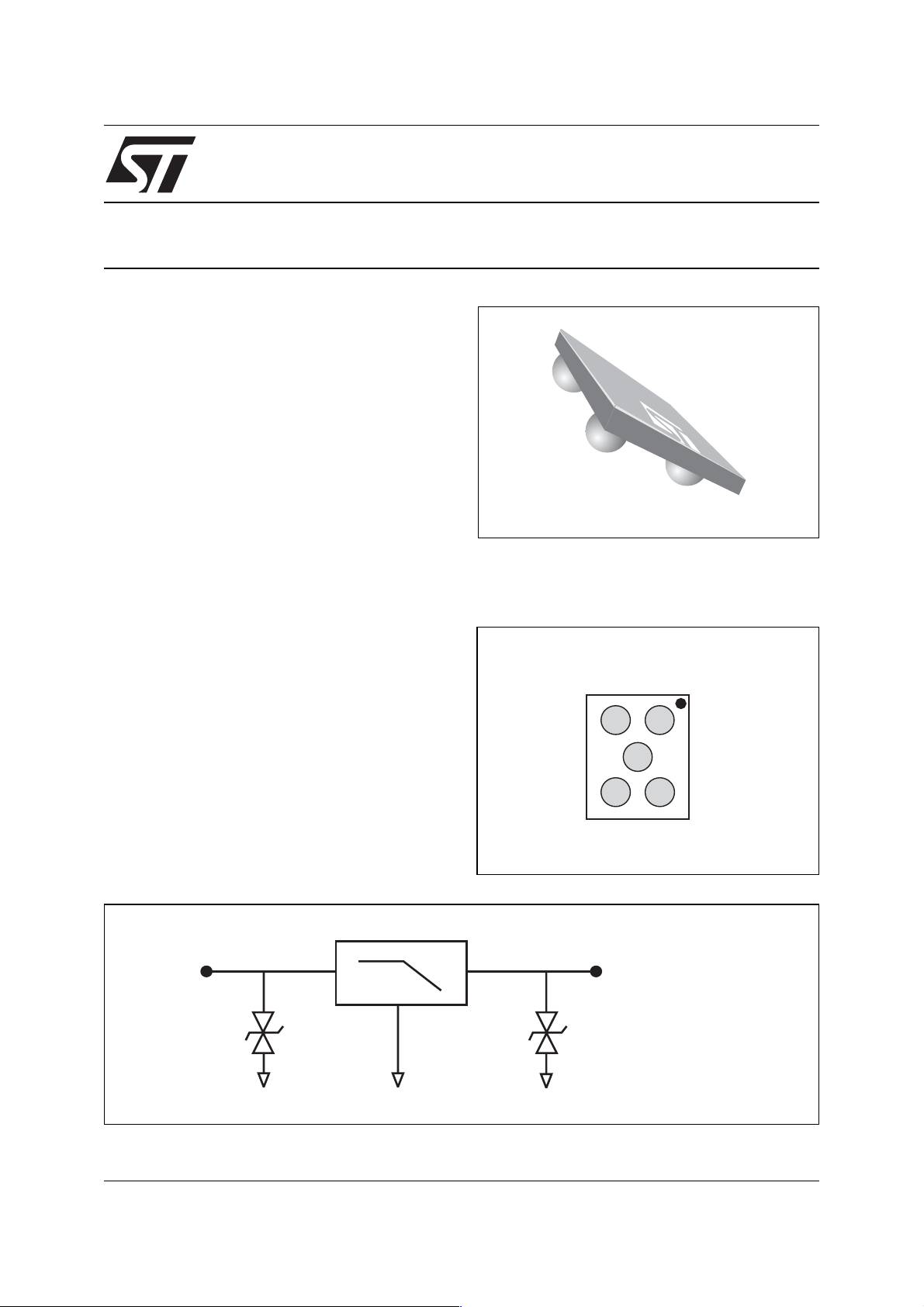

EMIF02-MIC03F2

2 LINE EMI FILTER

AND ESD PROTECTIONIPAD™

Flip-Chip package

PIN CONFIGURATION (bump side)

132

I1

I2

A

COMPLIES WITH THE FOLLOWING STANDARDS:

IEC 61000-4-2

Level 4 on input pins 15 kV (air discharge)

8 kV (contact discharge)

Level 1 on output pins 2 kV (air discharge)

2 kV (contact discharge)

MIL STD 883E - Method 3015-6 Class 3

BASIC CELL CONFIGURATION

Low-pass Filter

Input

GND GND GND

TM: IPAD is a trademark of STMicroelectronics.

October 2004

REV. 1

GND

O2

Output

B

O1

C

Ri/o = 68

Ω

Cline = 100 pF

1/6

EMIF02-MIC03F2

ABSOLUTE RATINGS (limiting values)

Symbol Parameter and test conditions Value Unit

T

T

op

T

stg

Maximum junction temperature

j

Operating temperature range - 40 to + 85

Storage temperature range - 55 to 150

125 °C

°C

°C

ELECTRICAL CHARACTERISTICS (T

Symbol Parameter

V

I

RM

V

V

R

I

R

C

Breakdown voltage

BR

Leakage current @ VRM

Stand-off voltage

RM

Clamping voltage

CL

Dynamic impedance

d

Peak pulse current

PP

Series resistance between Input & Output

I/O

Input capacitance per line

line

= 25 °C)

amb

I

I

PP

I

R

I

V

CL

BR

RM

VRMV

I

RM

I

R

I

PP

VBRV

RM

V

V

CL

Symbol Test conditions Min. Typ. Max. Unit

V

BR

I

RM

R

I/O

C

line

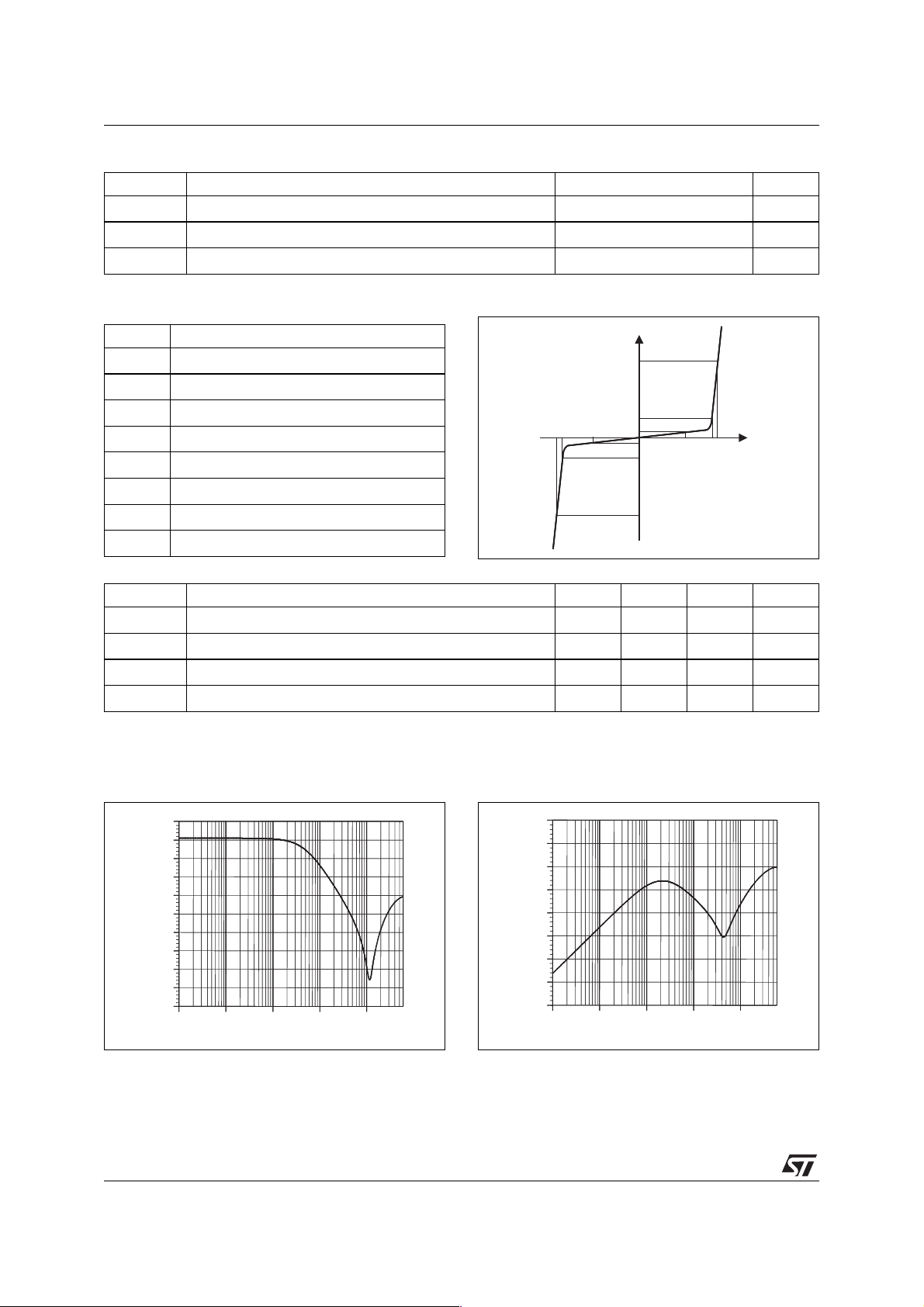

Fig. 1: S21 (dB) attenuation measurements and

IR = 1 mA 6 8 V

VRM = 3 V per line

500 nA

Tolerance ± 20 % 68 Ω

VR = 0 V

100 pF

Fig. 2: Analog crosstalk measurements.

Aplac simulation.

2/6

0.00

0.00

dB

dB

-5.00

-5.00

-10.00

-10.00

-15.00

-15.00

-20.00

-20.00

-25.00

-25.00

-30.00

-30.00

-35.00

-35.00

-40.00

-40.00

-45.00

-45.00

-50.00

-50.00

100.0k 1.0M 10.0M 100.0M 1.0G

100.0k 1.0M 10.0M 100.0M 1.0G

f/Hz

f/Hz

0.00

0.00

dB

dB

-10.00

-10.00

-20.00

-20.00

-30.00

-30.00

-40.00

-40.00

-50.00

-50.00

-60.00

-60.00

-70.00

-70.00

-80.00

-80.00

100.0k 1.0M 10.0M 100.0M 1.0G

100.0k 1.0M 10.0M 100.0M 1.0G

f/Hz

f/Hz

®

EMIF02-MIC03F2

Fig. 3: ESD response to IEC61000-4-2 (+15kV air

discharge) on one input V(in) and one output V(out).

Fig. 5: Line capacitance versus applied voltage.

C(pF)

140

120

100

80

60

40

20

0

012345

V(V)R

V

F=1MHz

=30mV

osc

Tj=25°C

RMS

Fig. 4: ESD response to IEC61000-4-2 (–15kV air

discharge) on one input V(in) and one output V(out).

®

3/6

EMIF02-MIC03F2

Aplac model

IN1

IN2 OUT2

Rbump Lbump Lbump Rbump

model = D1 model = D2

model = D1

Rbump Lbump Lbump RbumpRmic Lmic

Rmic Lmic

model = D3

model = D2

EMIF02-MIC03F1 model

Aplac parameters

Model D1

CJO=Cdiode1

BV=7

IBV=1u

IKF=1000

IS=10f

ISR=100p

N=1

M=0.3333

RS=0.7

VJ=0.6

TT=50n

Model D3

CJO=Cdiode3

BV=7

IBV=1u

IKF=1000

IS=10f

ISR=100p

N=1

M=0.3333

RS=0.12

VJ=0.6

TT=50n

Model D2

CJO=Cdiode2

BV=7

IBV=1u

IKF=1000

IS=10f

ISR=100p

N=1

M=0.3333

RS=0.3

VJ=0.6

TT=50n

OUT1

GND

Cgnd

aplacvar Rmic 68

aplacvar Lmic 10p

aplacvar Cdiode1 100pF

aplacvar Cdiode2 3.6pF

aplacvar Cdiode3 1.17nF

aplacvar Lbump 50pH

aplacvar Rbump 20m

aplacvar Rsub 0.5m

aplacvar Rgnd 10m

aplacvar Lgnd 50pH

aplacvar Cgnd 0.15pF

aplacvar Lsub 10pH

GND

Lsub

Rsub

Rbump

Lbump

Lgnd

Rgnd

Ground return

ORDER CODE

EMI Filter

Number of lines

4/6

EMIF yy F x- xxx zz

1: Pitch = 500µm

Bump = 315µm

2: Leadfree Pitch = 500µm

Bump = 315µm

Flip Chip

x: resistance value (Ohms) z: capacitance value / 10(pF)

or

Application (3 letters) and Version (2 digits)

®

PACKAGE MECHANICAL DATA

5

FLIP CHIP

500µm ± 10

250µm ± 10

315µm ± 50

EMIF02-MIC03F2

650µm ± 50

00µm ± 15

1.07mm ± 50µm

FOOT PRINT RECOMMENDATIONS

Copper pad Diameter :

250µm recommended , 300µm max

Solder stencil opening : 330µm

Solder mask opening recommendation :

340µm min for 300µm copper pad diameter

MARKING

1.47mm ± 50µm

Dot, ST logo

xx = marking

z = manufacturing location

yww = datecode

(y = year ww = week)

E

xyxwz

w

®

5/6

EMIF02-MIC03F2

PACKING

Dot identifying Pin A1 location

4 ± 0.1

Ø 1.5 ± 0.1

1.75 ± 0.1

3.5 ± 0.1

0.73 ± 0.05

All dimensions in mm

8 ± 0.3

E E E

ST

xxz

yww

ST

xxz

yww

4 ± 0.1

User direction of unreeling

ST

xxz

yww

In order to meet environmental requirements, ST offers these devices in ECOPACK® packages. These

packages have a Lead-free second level interconnect . The category of second level interconnect is

marked on the inner box label, in compliance with JEDEC Standard JESD97. The maximum ratings related to soldering conditions are also marked on the inner box label. ECOPACK is an ST trademark. ECOPACK specifications are available at: www.st.com

.

OTHER INFORMATION

Ordering code Marking Package Weight Base qty Delivery mode

EMIF02-MIC03F2 FW Flip-Chip 2.1 mg 5000 Tape & reel (7”)

Note: More packing informations are available in the application notes

AN1235: ''Flip-Chip: Package description and recommendations for use''

AN1751: "EMI Filters: Recommendations and measurements"

REVISION HISTORY

Date Revision Changes

14-Oct-2005 1 Initial release.

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2005 STMicroelectronics - All rights reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States

www.st.com

6/6

®

Loading...

Loading...