Page 1

ISO14443 type-B contactless coupler chip

SO16 (MQ)

150 mils width

16

1

Features

■ Single 5 V ±500 mV supply voltage

■ SO16N package

■ Contactless communication

– ISO14443 type-B protocol

– 13.56MHz carrier frequency using an

external oscillator

– 106 Kbit/s data rate

– 36-byte input/output frame register

– Supports frame answer with/without

SOF/EOF

– CRC generation and check

– Automated ST anti-collision exchange

■ I²C communication

– Two-wire I²C serial interface

– Supports 400 kHz protocol

– 3 chip enable pins

– Up to 8 CR14 connected on the same bus

CR14

with anti-collision and CRC management

March 2010 Doc ID 11922 Rev 2 1/47

www.st.com

1

Page 2

Contents CR14

Contents

1 Summary description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Signal description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Oscillator (OSC1, OSC2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Antenna output driver (RF

2.3 Antenna input filter (RF

IN

2.4 Transmitter reference voltage (V

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OUT

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

REF

2.5 Serial clock (SCL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6 Serial data (SDA) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.7 Chip enable (E0, E1, E2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.8 Power supply (V

, GND, GND_RF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CC

3 CR14 registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1 Parameter register (00h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2 Input/Output Frame Register (01h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Slot marker register (03h) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 CR14 I²C protocol description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 I²C start condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 I²C stop condition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 I²C acknowledge bit (ACK) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4 I²C data input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.5 I²C memory addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.6 CR14 I²C write operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.7 CR14 I²C read operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 Applying the I²C protocol to the CR14 registers . . . . . . . . . . . . . . . . . 22

5.1 I²C parameter register protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 I²C input/output frame register protocol . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.3 I²C slot marker register protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.4 Addresses above location 06h . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2/47 Doc ID 11922 Rev 2

Page 3

CR14 Contents

6 CR14 ISO14443 type-B radio frequency data transfer . . . . . . . . . . . . . 26

6.1 Output RF data transfer from the CR14 to the PICC (request frame) . . . 26

6.2 Transmission format of request frame characters . . . . . . . . . . . . . . . . . . 26

6.3 Request start of frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.4 Request end of frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.5 Input RF data transfer from the PICC to the CR14 (answer frame) . . . . . 28

6.6 Transmission format of answer frame characters . . . . . . . . . . . . . . . . . . . 28

6.7 Answer start of frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.8 Answer end of frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.9 Transmission frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.10 CRC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7 Tag access using the CR14 coupler . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.1 Standard TAG command access description . . . . . . . . . . . . . . . . . . . . . . 31

7.2 Anti-collision TAG sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8 Maximum rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9 DC and AC parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10 Package mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Appendix A ISO14443 type B CRC calculation . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Doc ID 11922 Rev 2 3/47

Page 4

List of tables CR14

List of tables

Table 1. Signal names . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. CR14 control registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 3. Parameter register bits description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Table 4. Input/output frame register description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 5. Slot marker register description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Table 6. Device select code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Table 7. CR14 request frame character format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table 8. Absolute maximum ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Table 9. I²C AC measurement conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 10. I²C Input Parameters(1,2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 11. I²C DC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Table 12. I²C AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Table 13. RF

Table 14. RF

Table 15. SO16 narrow - 16 lead plastic small outline, 150 mils body width,

package mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Table 16. Ordering information scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Table 17. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

OUT

AC characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

IN

4/47 Doc ID 11922 Rev 2

Page 5

CR14 List of figures

List of figures

Figure 1. Logic diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

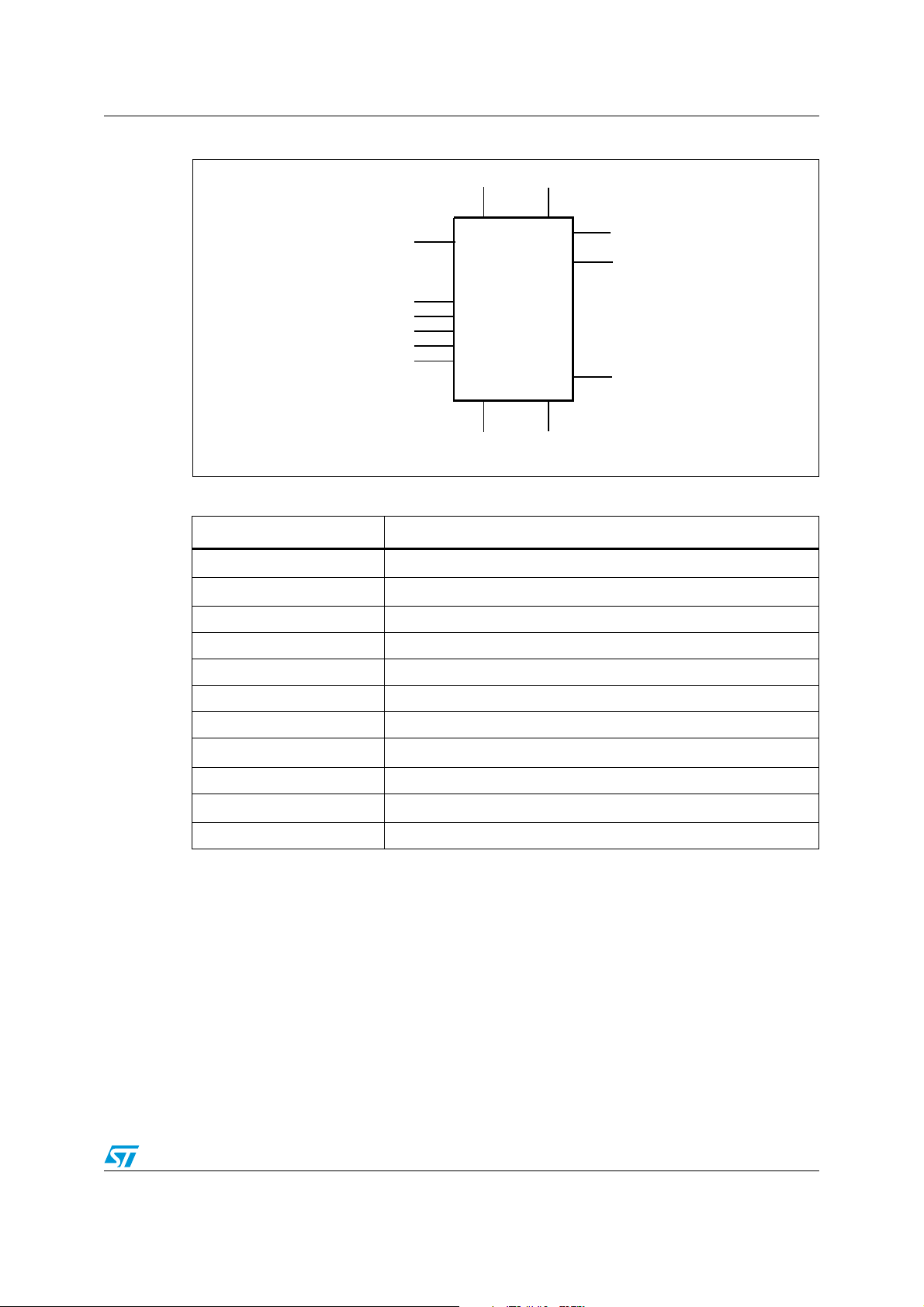

Figure 2. Logic block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. SO pin connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

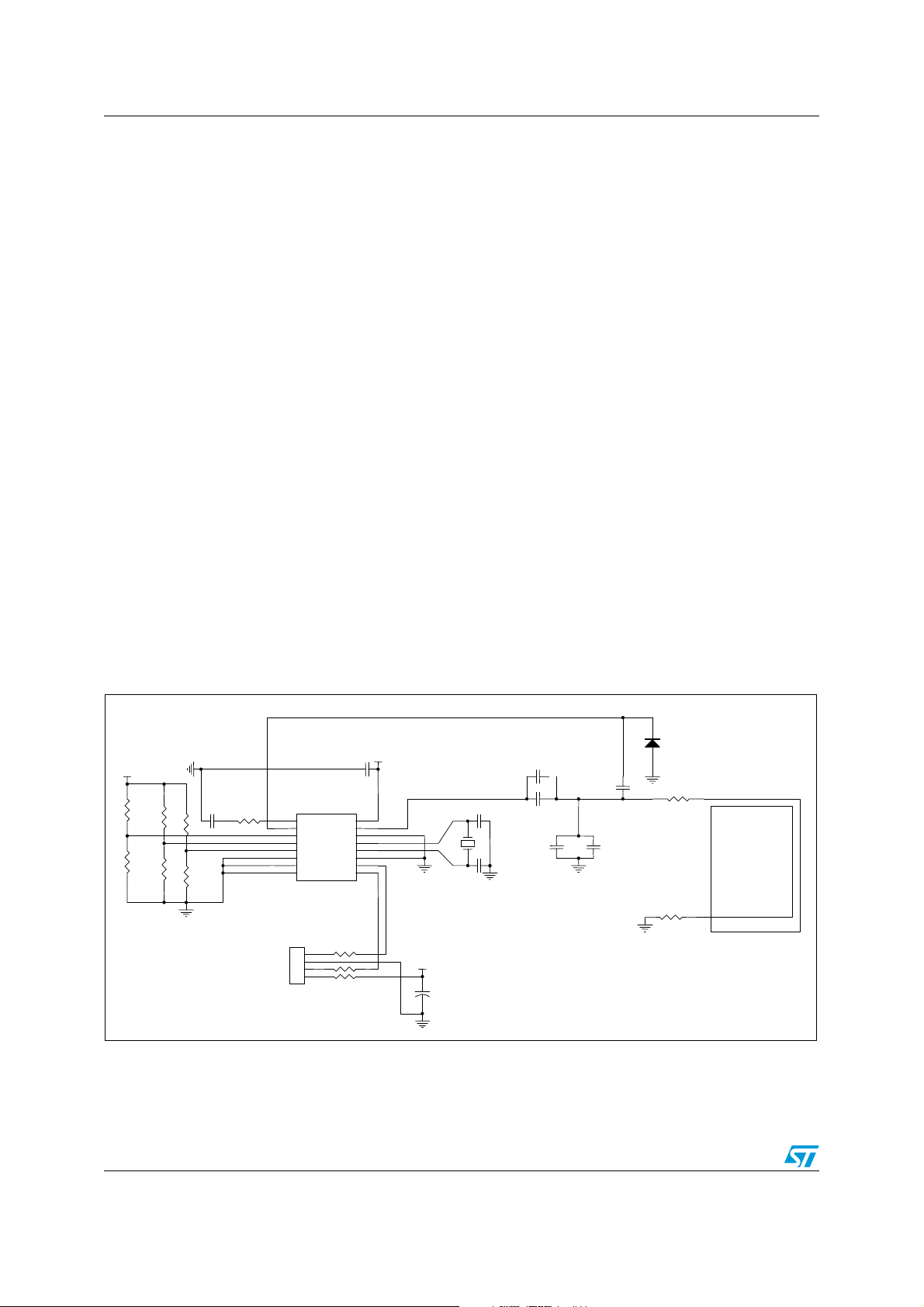

Figure 4. CR14 application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

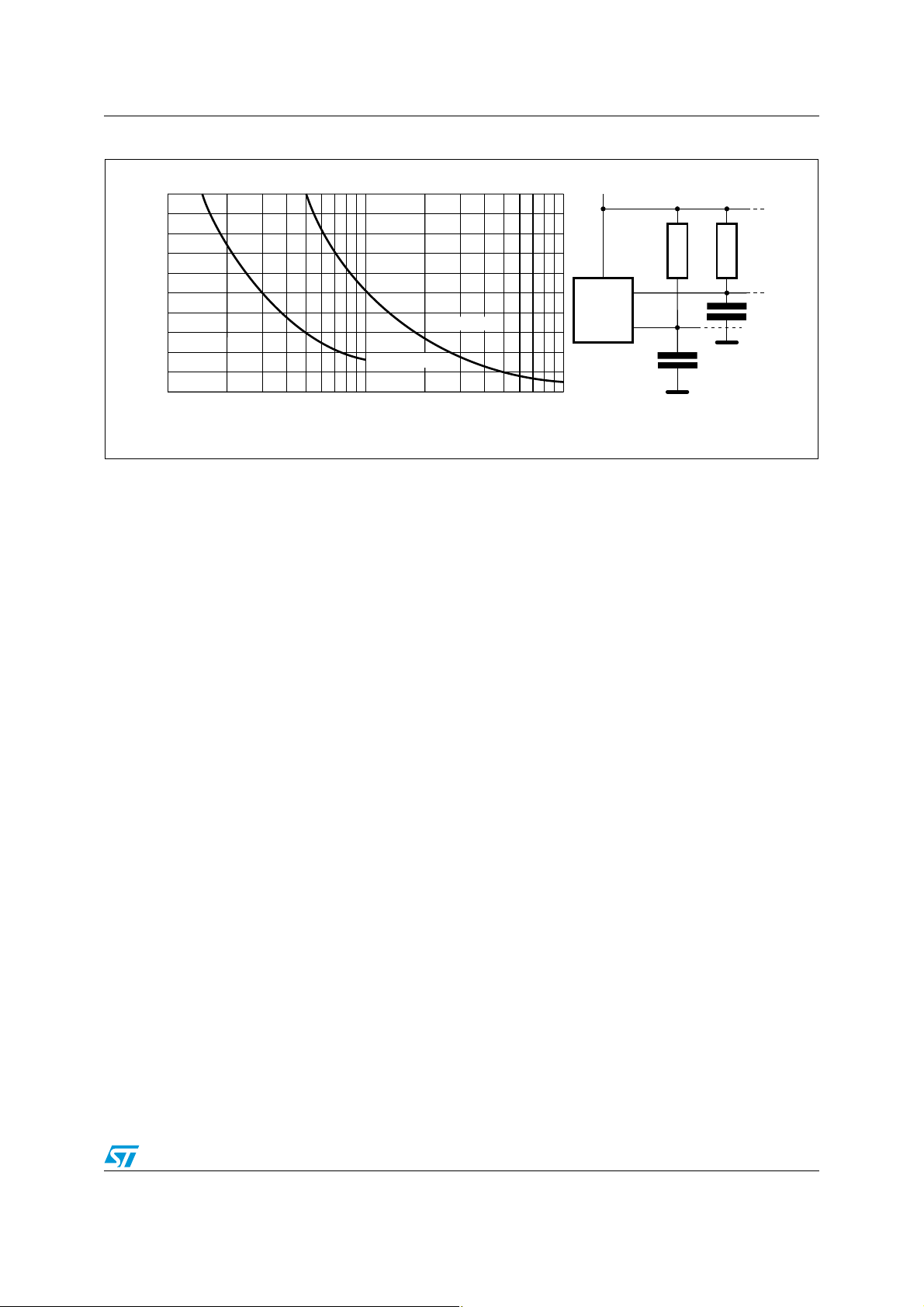

Figure 5. Maximum R

Figure 6. I²C bus protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 7. CR14 I²C write mode sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 8. I²C polling flowchart using ACK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 9. CR14 I²C read modes sequences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 10. Host-to-CR14 transfer: I²C write to parameter register . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 11. CR14-to-host transfer: I²C random address read from parameter register . . . . . . . . . . . . 22

Figure 12. CR14-to-host transfer: I²C current address read from parameter register . . . . . . . . . . . . . 22

Figure 13. Host-to-CR14 transfer: I²C write to I/O frame register for ISO14443B . . . . . . . . . . . . . . . . 23

Figure 14. CR14-to-host transfer: I²C random address read from I/O frame register for ISO14443B 23

Figure 15. CR14-to-host transfer: I²C current address read from I/O frame register for ISO14443B . 24

Figure 16. Host-to-CR14 transfer: I²C write to slot marker register . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 17. CR14-to-host transfer: I²C random address read from slot marker register . . . . . . . . . . . 24

Figure 18. CR14-to-host transfer: I²C current address read from slot marker register . . . . . . . . . . . . 25

Figure 19. Wave transmitted using ASK modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 20. CR14 request frame character format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 21. Request start of frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 22. Request end of frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 23. Wave received using BPSK sub-carrier modulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 24. Answer start of frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 25. Answer end of frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 26. Example of a complete transmission frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 27. CRC transmission rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 28. Standard TAG command: request frame transmission. . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 29. Standard TAG command: answer frame reception . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 30. Standard TAG command: complete TAG access description. . . . . . . . . . . . . . . . . . . . . . . 32

Figure 31. Anti-collision ST short range memory sequence (1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 32. Anti-collision ST short range memory sequence continued . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 33. I²C AC testing I/O waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 34. I²C AC waveforms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 35. CR14 synchronous timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 36. SO16 narrow - 16 lead plastic small outline, 150 mils body width, Package outline . . . . . 42

value versus bus capacitance (C

L

) for an I²C bus . . . . . . . . . . . . . . . . . . 11

BUS

Doc ID 11922 Rev 2 5/47

Page 6

Summary description CR14

1 Summary description

The CR14 is a contactless coupler that is compliant with the short range ISO14443 type-B

standard. It is controlled using the two wire I²C bus.

The CR14 generates a 13.56 MHz signal on an external antenna. Transmitted data are

modulated using Amplitude Shift Keying (ASK). Received data are demodulated from the

PICC (Proximity integrated Coupling Card) load variation signal, induced on the antenna,

using Bit Phase Shift Keying (BPSK) of a 847kHz sub-carrier. The Transmitted ASK wave is

10% modulated. The Data transfer rate between the CR14 and the PICC is 106 Kbit/s in

both transmission and reception modes.

The CR14 follows the ISO14443 type-B recommendation for Radio frequency power and

signal interface.

The CR14 is specifically designed for short range applications that need disposable and

reusable products.

The CR14 includes an automated anti-collision mechanism that allows it to detect and

select any ST short range memories that are present at the same time within its range. The

anti-collision mechanism is based on the STMicroelectronics probabilistic scanning method.

The CR14 provides a complete analog interface, compliant with the ISO14443 type-B

recommendations for Radio-Frequency power and signal interfacing. With it, any ISO14443

type-B PICC products can be powered and have their data transmission controlled via a

simple antenna.

The CR14 is fabricated in STMicroelectronics High Endurance Single Poly-silicon CMOS

technology.

The CR14 is organized as 4 different blocks (see Figure 2):

● The I²C bus controller. It handles the serial connection with the application host. It is

compliant with the 400kHz I²C bus specification, and controls the read/write access to

all the CR14 registers.

● The RAM buffer. It is bi-directional. . It stores all the request frame Bytes to be

transmitted to the PICC, and all the received Bytes sent by the PICC on the answer

frame.

● The transmitter. It powers the PICCs by generating a 13.56MHz signal on an external

antenna. The resulting field is 10% modulated using ASK (amplitude shift keying) for

outgoing data.

● The receiver. It demodulates the signal generated on the antenna by the load variation

of the PICC. The resulting signal is decoded by a 847kHz BPSK (binary phase shift

keying) sub-carrier decoder.

The CR14 is designed to be connected to a digital host (Microcontroller or ASIC). This host

has to manage the entire communication protocol in both transmit and receive modes,

through the I²C serial bus.

6/47 Doc ID 11922 Rev 2

Page 7

CR14 Summary description

ai12059

RF

OUT

CR14

RF

IN

OSC1

SCL

SDA

E0

E1

E2

GND GND_RF

V

CC

V

REF

Antenna

OSC2

Figure 1. Logic diagram

Table 1. Signal names

Signal Description

RF

RF

OUT

IN

Antenna Output Driver

Antenna Input Filter

OSC1 Oscillator Input

OSC2 Oscillator Output

E0, E1, E2 Chip Enable Inputs

SDA I²C Bi-Directional Data

SCL I²C Clock

V

CC

Power Supply

GND Ground

V

REF

Transmitter Reference Voltage

GND_RF Ground for RF circuitry

Doc ID 11922 Rev 2 7/47

Page 8

Summary description CR14

AI12060

RF

OUT

CR14

RF

IN

OSC1

SCL

SDA

E0

E1

E2

GND

GND_RF

V

CC

V

REF

Antenna

TransmitterReceiver

I²C Bus Controller

RAM Buffer

OSC2

1

AI10911

2

3

4

16

15

14

13

GND

E1

OSC2

OSC1

RF

IN

V

REF

GND_RFE0

SO16

5

6

7

8

12

11

10

9

SDAGND

SCL

GND_RF

E2

GND

RF

OUT

V

CC

Figure 2. Logic block diagram

Figure 3. SO pin connections

8/47 Doc ID 11922 Rev 2

Page 9

CR14 Signal description

2 Signal description

See Figure 1: Logic diagram, and Table 1: Signal names, for an overview of the signals

connected to this device.

2.1 Oscillator (OSC1, OSC2)

The OSC1 and OSC2 pins are internally connected to the on-chip oscillator circuit. The

OSC1 pin is the input pin, the OSC2 is the output pin. For correct operation of the CR14, it is

required to connect a 13.56MHz quartz crystal across OSC1 and OSC2. If an external clock

is used, it must be connected to OSC1 and OSC2 must be left open.

2.2 Antenna output driver (RF

The Antenna Output Driver pin, RF

antenna. Care must be taken as it will not withstand a short-circuit.

RF

schematic The LRC antenna circuitry must be connected across the RF

has to be connected to the antenna circuitry as shown in Figure 4: CR14 application

OUT

OUT

)

OUT

, generates the modulated 13.56MHz signal on the

2.3 Antenna input filter (RFIN)

The antenna input filter of the CR14, RFIN, has to be connected to the external antenna

through an adapter circuit, as shown in Figure 4.

The input filter demodulates the signal generated on the antenna by the load variation of the

PICC. The resulting signal is then decoded by the 847kHz BPSK decoder.

2.4 Transmitter reference voltage (V

The Transmitter Reference Voltage input, V

output driver for ASK modulation.

The Transmitter Reference Voltage input should be connected to an external capacitor, as

shown in Figure 4.

REF

pin and GND.

OUT

)

REF

, provides a reference voltage used by the

2.5 Serial clock (SCL)

The SCL input pin is used to strobe all I²C data in and out of the CR14. In applications

where this line is used by slave devices to synchronize the bus to a slower clock, the master

must have an open drain output, and a pull-up resistor must be connected from the Serial

Clock (SCL) to V

calculated).

In most applications, though, this method of synchronization is not employed, and so the

pull-up resistor is not necessary, provided that the master has a push-pull (rather than open

drain) output.

. (Figure 5 indicates how the value of the pull-up resistor can be

CC

Doc ID 11922 Rev 2 9/47

Page 10

Signal description CR14

V

REF

RF

IN

E0

E1

E2

GND_RF

GND

GND

SDA

SCL

GND

OSC2

12

OSC1

GND_RF

RF

OUT

V

CC

U1

CR14

X1

13.56MHz

C1 7pF50V

C2 7pF50V

C3

22nF50V

C8

100pF50V

C8'

8pF50V

C7

120pF50V

C7'

33pF50V

V

CC

V

CC

C6

100nF50V

C4

22uF 10V

FL4

0R

FL5

0R

FL6

0R

FL7

WURTH 742-792-042

R7

0R

R8

0R

R1

OPT

ANT1

ANT2

E0

E1

E2

SCL SDA

J1

R2

0R

R3

OPT

R4

0R

R5

OPT

R6

0R

V

CC

D1

1N4148 (OPTIONAL)

C5

10pF50V

AI12061

2.6 Serial data (SDA)

The SDA signal is bi-directional. It is used to transfer I²C data in and out of the CR14. It is an

open drain output that may be wire-OR’ed with other open drain or open collector signals on

the bus. A pull-up resistor must be connected from Serial data (SDA) to V

. (Figure 5

CC

indicates how the value of the pull-up resistor can be calculated).

2.7 Chip enable (E0, E1, E2)

The Chip Enable inputs E0, E1, E2 are used to set and reset the value on the three least

significant bits (b3, b2, b1) of the 7-bit I²C Device Select Code. They are used for hardwired

addressing, allowing up to eight CR14 devices to be addressed on the same I²C bus. These

inputs may be driven dynamically or tied to V

(note that the V

and VIH levels for the inputs are CMOS compatible, not TTL compatible).

IL

or GND to establish the Device Select Code

CC

When left open, E0, E1 and E2 are internally read at the logic level 0 due to the internal pull-

down resistors connected to each inputs.

2.8 Power supply (VCC, GND, GND_RF)

Power is supplied to the CR14 using the VCC, GND and GND_RF pins.

V

is the Power Supply pin that supplies the power (+5V) for all CR14 operations.

CC

The GND and GND_RF pins are ground connections. They must be connected together.

Decoupling capacitors should be connected between the V

Supply Voltage pin, the GND

CC

Ground pin and the GND_REF Ground pin to filter the power line, as shown in Figure 4.

Figure 4. CR14 application schematic

10/47 Doc ID 11922 Rev 2

1

2

3

4

5

6

7

8

4

3

2

1

16

15

14

13

11

10

9

+

Page 11

CR14 Signal description

AI01665

V

CC

C

BUS

SDA

R

L

MASTER

R

L

SCL

C

BUS

100

0

4

8

12

16

20

C

BUS

(pF)

Maximum RP value (kΩ)

10

1000

fc = 400kHz

fc = 100kHz

Figure 5. Maximum RL value versus bus capacitance (C

) for an I²C bus

BUS

Doc ID 11922 Rev 2 11/47

Page 12

CR14 registers CR14

3 CR14 registers

The CR14 chip coupler contains six volatile registers. It is entirely controlled, at both digital

and analog level, using the three registers listed below and shown in Ta bl e 2 :

● Parameter Register

● Input/Output Frame Register

● Slot Marker Register

The other 3 registers are located at addresses 02h, 04h and 05h. They are “ST Reserved”,

and must not be used in end-user applications.

In the I²C protocol, all data Bytes are transmitted Most Significant Byte first, with each Byte

transmitted Most significant bit first.

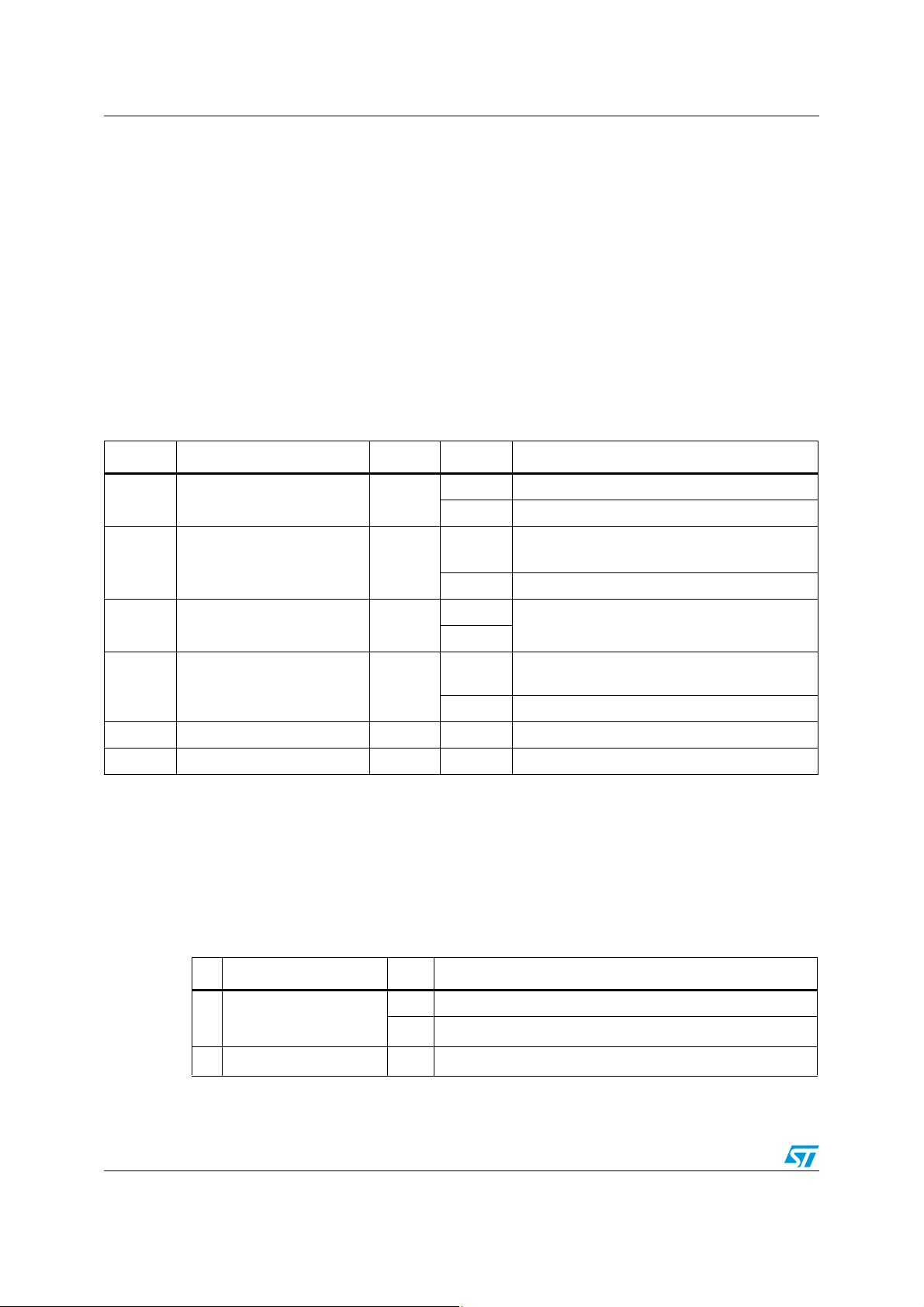

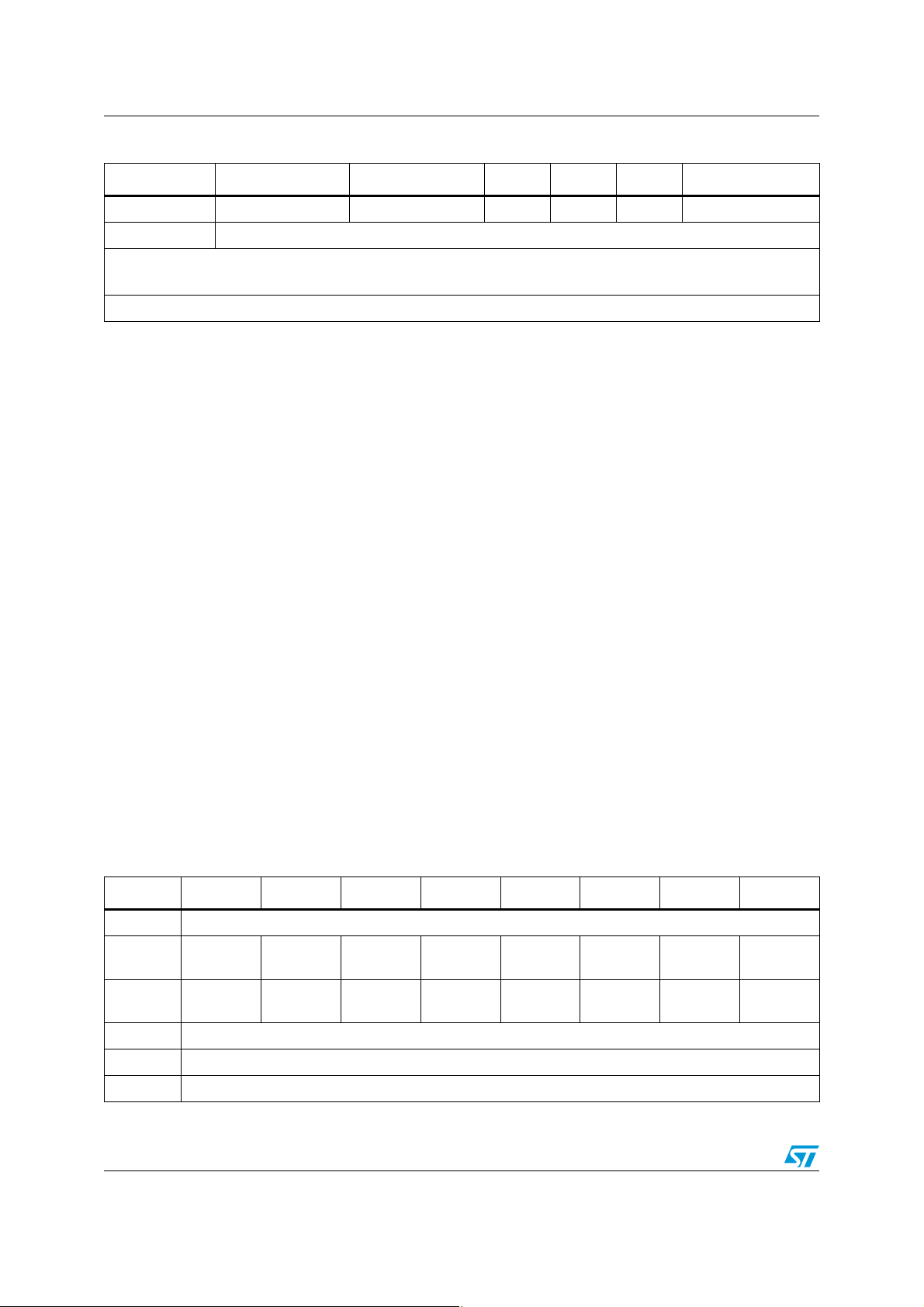

Table 2. CR14 control registers

Address Length Access Purpose

00h Parameter Register 1 Byte

01h Input/output Frame Register 36 Bytes

02h ST Reserved NA

03h Slot Marker Register 1 Byte

04h ST Reserved NA R and W ST Reserved. Must not be used

05h ST Reserved NA R and W ST Reserved. Must not be used

W Set parameter register

R Read parameter register

W

R Transfer PICC answered frame data to Host

W

R

W

R Return data FFh

Store and send request frame to the PICC.

Wait for PICC answer frame

ST Reserved, must not be used.

Launch the automated anti-collision process

from Slot_0 to Slot_15

3.1 Parameter register (00h)

The Parameter Register is an 8-bit volatile register used to configure the CR14, and thus, to

customize the circuit behavior. The Parameter Register is located at the I²C address 00h

and it is accessible in I²C Read and Write modes. Its default value, 00h, puts the CR14 in

standard ISO14443 type-B configuration.

Table 3. Parameter register bits description

Bit Control Value Description

b

Frame Standard

0

b

RFU 0 Not used

1

12/47 Doc ID 11922 Rev 2

0 ISO14443 type-B frame management

1

RFU

(1)

Page 13

CR14 CR14 registers

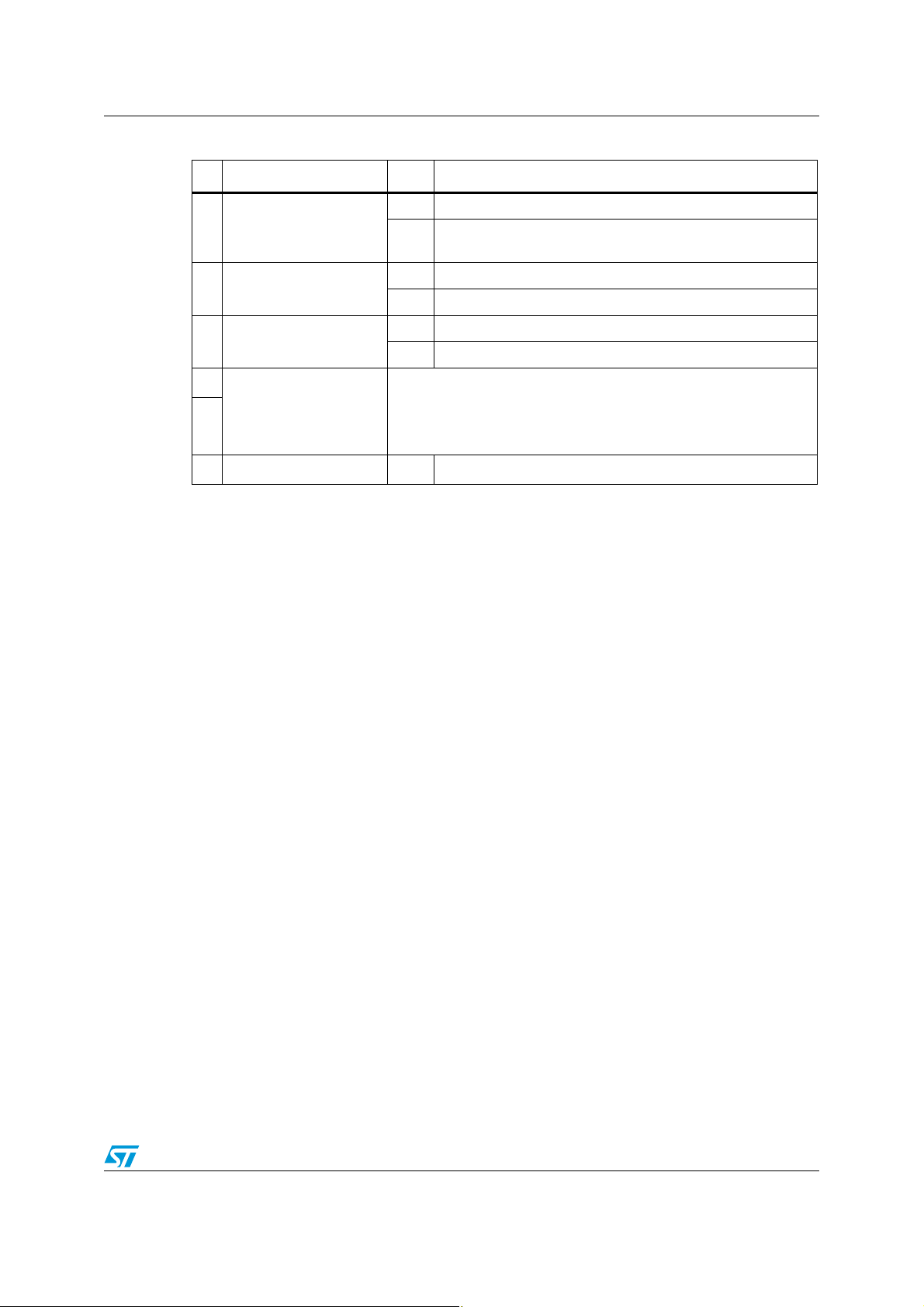

Table 3. Parameter register bits description (continued)

Bit Control Value Description

0 Answer PICC Frames are delimited by SOF and EOF

b

Answer Frame Format

2

b

ASK Modulation Depth

3

b

Carrier Frequency

4

1

0 10% ASK modulation depth mode

1RFU

0 13.56MHz carrier on RF OUT is OFF

1 13.56MHz carrier on RF OUT is ON

Answer PICC Frames do not provide SOF and EOF

delimiters

b

5

t

WDG

Answer delay watchdog

b

6

b

RFU 0 Not used

7

1. RFU = Reserved for Future Use.

b5=0, b6=0: Watchdog time-out = 500µs to be used for read

b5=0, b6=1: Watchdog time-out = 5ms to be used for read

b5=1, b6=0: Watchdog time-out = 10ms to be used for write

b5=1, b6=1: Watchdog time-out = 309ms to be used for MCU timings

3.2 Input/Output Frame Register (01h)

The Input/Output Frame Register is a 36-Byte buffer that is accessed serially from Byte 0

through to Byte 35 (see Ta b l e 4 ). It is located at the I²C address 01h.

The Input/Output Frame Register is the buffer in which the CR14 stores the data Bytes of

the request frame to be sent to the PICC. It automatically stores the data Bytes of the

answer frame received from the PICC. The first Byte (Byte 0) of the Input/Output Frame

Register is used to store the frame length for both transmission and reception.

When accessed in I²C Write mode , the register stores the request frame Bytes that are to

be transmitted to the PICC. Byte 0 must be set with the request frame length (in Bytes) and

the frame is stored from Byte 1 onwards. At the end of the transmission, the 16-bit CRC is

automatically added. After the transmission, the CR14 wait for the PICC to send back an

answer frame. When correctly decoded, the PICC answer frame Bytes are stored in the

Input/Output Frame Register from Byte 1 onwards. Byte 0 stores the number of Bytes

received from the PICC.

When accessed in I²C Read mode, the Input/Output Register sends back the last PICC

answer frame Bytes, if any, with Byte 0 transmitted first. The 16-bit CRC is not stored, and it

is not sent back on the I²C bus.

The Input/Output Frame Register is set to all 00h between transmission and reception. If

there is no answer from the PICC, Byte 0 is set to 00h. In the case of a CRC error, Byte 0 is

set to FFh, and the data Bytes are discarded and not appended in the register.

The CR14 Input/Output Frame Register is so designed as to generate all the ST short range

memory command frames. It can also generate all standardized ISO14443 type-B

command frames like REQB, SLOT-MARKER, ATTRIB, HALT, and get all the answers like

ATQB, or answer to ATTRIB. All ISO14443 type-B compliant PICCs can be accessed by the

CR14 provided that their data frame exchange is not longer than 35 Bytes in both request

and answer.

Doc ID 11922 Rev 2 13/47

Page 14

CR14 registers CR14

Table 4. Input/output frame register description

Byte 0 Byte 1 Byte 2 Byte 3 ... Byte 34 Byte 35

Frame Length First data Byte Second data Byte Last data Byte

00h No Byte transmitted

FFh CRC Error

xxh Number of transmitted Bytes

<------------- Request and Answer Frame Bytes exchanged on the RF ------------->

3.3 Slot marker register (03h)

The slot Marker Register is located at the I²C address 03h. It is used to trigger an automated

anti-collision sequence between the CR14 and any ST short range memory present in the

electromagnetic field. With one I²C access, the CR14 launches a complete stream of

commands starting from PCALL16(), SLOT_MARKER(1), SLOT_MARKER(2) up to

SLOT_MARKER(15), and stores all the identified Chip_IDs into the Input/Output Frame

Register (I²C address 01h).

This automated anti-collision sequence simplifies the host software development and

reduces the time needed to interrogate the 16 slots of the STMicroelectronics anti-collision

mechanism.

When accessed in I²C Write mode, the Slot Marker Register starts generating the sequence

of anti-collision commands. After each command, the CR14 wait for the ST short range

memory answer frame which contains the Chip_ID. The validity of the answer is checked

and stored into the corresponding Status Slot Bit (Byte 1 and Byte 2 as described in

Ta bl e 5 ). If the answer is correct, the Status Slot Bit is set to ‘1’ and the Chip_ID is stored

into the corresponding Slot_Register. If no answer is detected, the Status Slot Bit is set to

‘0’, and the corresponding Slot_Register is set to 00h. If a CRC error is detected, the Status

Slot Bit is set to ‘0’, and the corresponding Slot_Register is set to FFh.

Each time the Slot Marker Register is accessed in I²C Write mode, Byte 0 of the

Input/Output Frame Register is set to 18, Bytes 1 and 2 provide Status Bits Slot information,

and Bytes 3 to 18 store the corresponding Chip_ID or error code.

The Slot Marker Register cannot be accessed in I²C Read mode. All the anti-collision data

can be accessed by reading the Input/Output Frame Register at the I²C address 01h.

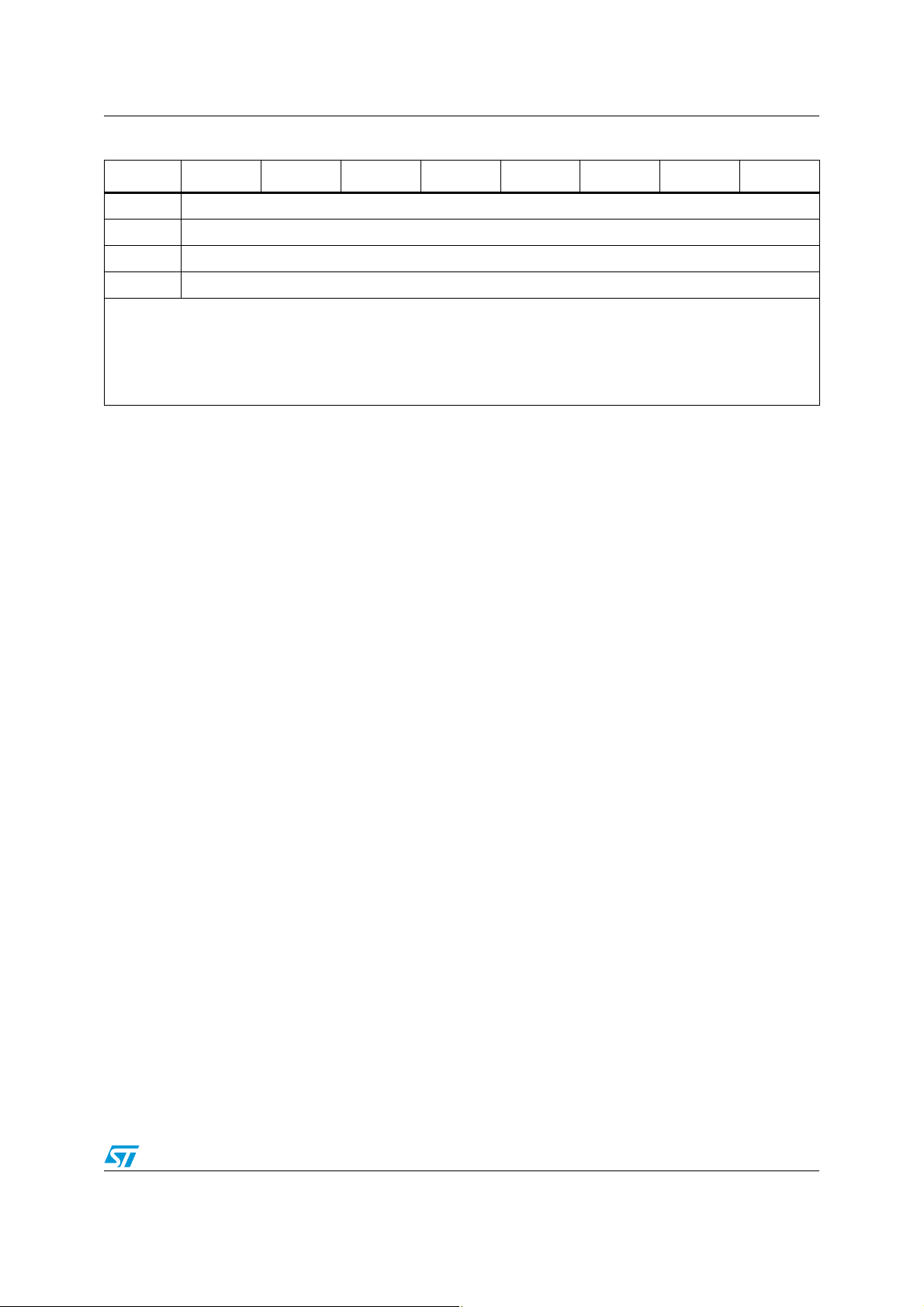

Table 5. Slot marker register description

Byte 0 Number of stored Bytes: fixed to 18

Byte 1

Byte 2

Byte 3 Slot_Register 0 = Chip_ID value detected in Slot 0

Byte 4 Slot_Register 1 = Chip_ID value detected in Slot 1

Byte 5 Slot_Register 2 = Chip_ID value detected in Slot 2

14/47 Doc ID 11922 Rev 2

b

7

Status Slot

Bit 7

Status Slot

Bit 15

b

6

Status Slot

Bit 6

Status Slot

Bit 14

b

5

Status Slot

Bit 5

Status Slot

Bit 13

b

4

Status Slot

Bit 4

Status Slot

Bit 12

b

3

Status Slot

Bit 3

Status Slot

Bit 11

Status Slot

Status Slot

Bit 10

b

2

Bit 2

b

1

Status Slot

Bit 1

Status Slot

Bit 9

b

0

Status Slot

Bit 0

Status Slot

Bit 8

Page 15

CR14 CR14 registers

Table 5. Slot marker register description (continued)

b

7

b

6

b

5

b

4

b

3

b

2

Byte 6 Slot_Register 3 = Chip_ID value detected in Slot 3

Byte n .....

Byte 17 Slot_Register 14 = Chip_ID value detected in Slot 14

Byte 18 Slot_Register 15 = Chip_ID value detected in Slot 15

Status bit value description:

1: No error detected. The Chip_ID stored in the Slot register is valid.

0: Error detected

– Slot register = 00h: No answer frame detected from ST short range memory

– Slot register = FFh: Answer Frame detected with CRC error. Collision may have occurred

b

1

b

0

Doc ID 11922 Rev 2 15/47

Page 16

CR14 I²C protocol description CR14

4 CR14 I²C protocol description

The CR14 is compatible with the I²C serial bus memory standard, which is a two-wire serial

interface that uses a bi-directional data bus and serial clock.

The CR14 has a pre-programmed, 4-bit identification code, ’1010’ (as shown in Ta bl e 6 ),

that corresponds to the I²C bus definition. With this code and the three Chip Enable inputs

(E2, E1, E0) up to eight CR14 devices can be connected to the I²C bus, and selected

individually.

The CR14 behaves as a slave device in the I²C protocol, with all CR14 operations

synchronized to the serial clock.

I²C Read and Write operations are initiated by a START condition, generated by the bus

master.

The START condition is followed by the Device Select Code and by a Read/Write bit (R/W

It is terminated by an acknowledge bit. The Device Select Code consists of seven bits (as

shown in Ta bl e 6 ):

● the Device Code (first four bits)

● plus three bits corresponding to the states of the three Chip Enable inputs, E2, E1 and

E0, respectively

When data is written to the CR14, the device inserts an acknowledge bit (9th bit) after the

bus master’s 8-bit transmission.

When the bus master reads data, it also acknowledges the receipt of the data Byte by

inserting an acknowledge bit (9th bit).

Data transfers are terminated by a STOP condition after an ACK for Write, or after a NoACK

for Read.

The CR14 supports the I²C protocol, as summarized in Figure 6.

Any device that sends data on to the bus, is defined as a transmitter, and any device that

reads the data, as a receiver.

The device that controls the data transfer is known as the master, and the other, as the

slave. A data transfer can only be initiated by the master, which also provides the serial

clock for synchronization. The CR14 is always a slave device in all I²C communications. All

data are transmitted Most Significant Bit (MSB) first.

Table 6. Device select code

).

Device code Chip enable RW

b7 b6 b5 b4 b3 b2 b1 b0

CR14 Select 1 0 1 0 E2 E1 E0 RW

4.1 I²C start condition

START is identified by a High-to-Low transition of the Serial Data line, SDA, while the Serial

Clock, SCL, is stable in the High state. A START condition must precede any data transfer

command.

16/47 Doc ID 11922 Rev 2

Page 17

CR14 CR14 I²C protocol description

The CR14 continuously monitors the SDA and SCL lines for a START condition (except

during Radio Frequency data exchanges), and will not respond unless one is sent.

4.2 I²C stop condition

STOP is identified by a Low-to-High transition of the Serial Data line, SDA, while the Serial

Clock, SCL, is stable in the High state.

A STOP condition terminates communications between the CR14 and the bus master.

A STOP condition at the end of an I²C Read command, after (and only after) a NoACK,

forces the CR14 into its stand-by state.

A STOP condition at the end of an I²C Write command triggers the Radio Frequency data

exchange between the CR14 and the PICC.

4.3 I²C acknowledge bit (ACK)

An acknowledge bit is used to indicate a successful data transfer on the I²C bus.

The bus transmitter, either master or slave, releases the Serial Data line, SDA, after sending

8 bits of data. During the 9th clock pulse the receiver pulls the SDA line Low to acknowledge

the receipt of the 8 data bits.

4.4 I²C data input

During data input, the CR14 samples the SDA bus signal on the rising edge of the Serial

Clock, SCL. For correct device operation, the SDA signal must be stable during the Low-to-

High Serial Clock transition, and the data must change only when the SCL line is Low.

Doc ID 11922 Rev 2 17/47

Page 18

CR14 I²C protocol description CR14

SCL

SDA

SCL

SDA

SDA

START

CONDITION

SDA

INPUT

SDA

CHANGE

AI00792

STOP

CONDITION

1 23 7 89

MSB

ACK

START

CONDITION

SCL

1 23 7 89

MSB ACK

STOP

CONDITION

Figure 6. I²C bus protocol

4.5 I²C memory addressing

18/47 Doc ID 11922 Rev 2

To start up communication with the CR14, the bus master must initiate a START condition.

Then, the bus master sends 8 bits (with the most significant bit first) on the Serial Data line,

SDA. These bits consist of the Device Select Code (7 bits) plus a RW

According to the I²C bus definition, the seven most significant bits of the Device Select Code

are the Device Type Identifier. For the CR14, these bits are defined as shown in Tab le 6 .

The 8th bit is the Read/Write bit (RW

). It is set to ‘1’ for I²C Read, and to ‘0’ for I²C Write

operations.

If the data sent by the bus master matches the Device Select Code of a CR14 device, the

corresponding device returns an acknowledgment on the SDA bus during the 9

The CR14 devices whose Device Select Codes do not correspond to the data sent,

generate a No-ACK. They deselect themselves from the bus and go into stand-by mode.

bit.

th

bit time.

Page 19

CR14 CR14 I²C protocol description

AI12062

STOP

DATA N

ACK ACK

START

CR14 WRITE

DEV SEL BYTE ADDR

DATA 1 DATA 2 DATA 3

ACK ACK ACK

ACK

R/W

BUS Master

BUS Slave

4.6 CR14 I²C write operations

The bus master sends a START condition, followed by a Device Select Code and the R/W

bit set to ’0’. The CR14 that corresponds to the Device Select Code, acknowledges and

waits for the bus master to send the Byte address of the register that is to be written to. After

receipt of the address, the CR14 returns another ACK, and waits for the bus master to send

the data Bytes that are to be written.

In the CR14 I²C Write mode, the bus master may sends one or more data Bytes depending

on the selected register.

The CR14 replies with an ACK after each data Byte received. The bus master terminates

the transfer by generating a STOP condition.

The STOP condition at the end of a Write access to the Input/Output Frame Register causes

the Radio Frequency data exchange between the CR14 and the PICC to be started.

During the Radio Frequency data exchange, the CR14 disconnects itself from the I²C bus.

The time (t

command format. To know when the exchange is complete, the bus master uses an ACK

polling sequence as shown in Figure 8. It consists of the following:

● Initial condition: a Radio Frequency data exchange is in progress.

● Step 1: the master issues a START condition followed by the first Byte of the new

instruction (Device Select Code plus R/W

● Step 2: if the CR14 is busy, no ACK is returned and the master goes back to Step 1. If

the CR14 has completed the Radio Frequency data exchange, it responds with an

ACK, indicating that it is ready to receive the second part of the next instruction (the

first Byte of this instruction being sent during Step 1).

) needed to complete the exchange is not fixed as it depends on the PICC

RFEX

bit).

Figure 7. CR14 I²C write mode sequence

Doc ID 11922 Rev 2 19/47

Page 20

CR14 I²C protocol description CR14

Radio Frequency

data exchange

in progress

START Condition

DEVICE SELECT

CODE with R/W=1

ACK

returned

Next

operation is

addressing

the CR14

ReSTART

STOP

STOP

Proceed to READ

Operation

YES

NO

First byte of instruction

with R/W = 1 already

decoded by the CR14

NO YES

ai12063

Figure 8. I²C polling flowchart using ACK

4.7 CR14 I²C read operations

20/47 Doc ID 11922 Rev 2

To send a Read command, the bus master sends a START condition, followed by a Device

Select Code and the R/W

bit set to ’1’.

The CR14 that corresponds to the Device Select Code acknowledges and outputs the first

data Byte of the addressed register.

To select a specific register, a dummy Write command must first be issued, giving an

address Byte but no data Bytes, as shown in the bottom half of Figure 9. This causes the

new address to be stored in the internal address pointer, for use by the Read command that

immediately follows the dummy Write command.

In the I²C Read mode, the CR14 may read one or more data Bytes depending on the

selected register. The bus master has to generate an ACK after each data Byte to read all

the register data in a continuous stream. Only the last data Byte should not be followed by

an ACK. The master then terminates the transfer with a STOP condition, as shown in

Figure 9.

Page 21

CR14 CR14 I²C protocol description

START

CR14 READ

DEV SEL

DATA 1 DATA 2 DATA 3

AI12064

STOP

DATA N

ACK

ACK ACK

R/W

ACK NoACK

BUS Master

BUS Slave

ACK

DATA 4

START

CR14 READ

DEV SEL ADDRESS

ACK

BUS Master

BUS Slave

R/W

ACK

DEV SEL

DATA 1

STOP

DATA N

ACK

ACK

R/W ACK NoACK

DATA 2

Re-START

I²C CURRENT ADDRESS READ

I²C RANDOM ADDRESS READ

After reading each Byte, the CR14 waits for the master to send an ACK during the 9th bit

time. If the master does not return an ACK within this time, the CR14 terminates the data

transfer and switches to stand-by mode.

Figure 9. CR14 I²C read modes sequences

Doc ID 11922 Rev 2 21/47

Page 22

Applying the I²C protocol to the CR14 registers CR14

S

T

A

R

T

1010XXX 00h data

S

T

O

P

ACK

ACKACK

Register Byte

Value

Parameter Register

Address

Device Select

Code

Bus Master

CR14 Write

Bus Slave

ai12038

R/W

S

T

A

R

T

1010XXX 00h data

S

T

O

P

ACK

ACK

ACK

Register Byte

Value

Parameter Register

Address

Device Select

Code

Bus Master

CR14 Read

Bus Slave

ai12039

R

E

S

T

A

R

T

1010XXX

R/W

Device Select

Code

R/W NoACK

data

S

T

O

P

ACK

Register Byte

Value

Bus Master

CR14 Read

Bus Slave

ai12040

S

T

A

R

T

1010XXX

Device Select

Code

R/W NoACK

5 Applying the I²C protocol to the CR14 registers

5.1 I²C parameter register protocol

Figure 10 shows how new data is written to the Parameter Register. The new value

becomes active after the I²C STOP condition.

Figure 11 shows how to read the Parameter Register contents. The CR14 sends and re-

sends the Parameter Register contents until it receives a NoACK from the I²C Host.

The CR14 supports the I²C Current Address and Random Address Read modes. The

Current Address Read mode can be used if the previous command was issued to the

register where the Read is to take place.

Figure 10. Host-to-CR14 transfer: I²C write to parameter register

Figure 11. CR14-to-host transfer: I²C random address read from parameter register

Figure 12. CR14-to-host transfer: I²C current address read from parameter register

22/47 Doc ID 11922 Rev 2

Page 23

CR14 Applying the I²C protocol to the CR14 registers

S

T

A

R

T

1 0 1 0 XX X 01h N

S

T

O

P

ACK

ACKACK

Request Frame

Length N

Input/Output

Register

Address

Device

Select

Code

Bus

Master

CR14

Write

Bus

Slave

ai12041

R/W

Data 1 Data 2

PICC

Command

Parameter

PICC

Command

Code

Data N

PICC

Command

Parameter

PICC

Command

Parameter

ACK

ACKACKACK

S

T

A

R

T

1010XXX 01h N

S

T

O

P

ACK

ACKACK

Received

Frame

Length

Input/Output

Register

Address

Device

Select

Code

Bus

Master

CR14

Read

Bus

Slave

ai12042

R/W

Data1 Data 2

Answer

Frame

Data

Answer

Frame

Data

Data N

Answer

Frame

Data

Answer

Frame

Data

NoACK

ACKACKACK

R

E

S

T

A

R

T

101 0XXX

Device

Select

Code

R/W

ACK

5.2 I²C input/output frame register protocol

Figure 13 shows how to store a PICC request frame command of N Bytes into the

Input/Output Frame Register.

After the I²C STOP condition, the request frame is RF transmitted in the ISO14443 type-B

format. The CR14 then waits for the PICC answer frame which will also be stored in the

Input/Output Frame Register. The request frame is over-written by the answer frame.

Figure 14 shows how to read an N-Byte PICC answer frame.

The two CRC Bytes generated by the PICC are not stored.

The CR14 continues to output data Bytes until a NoACK has been generated by the I²C

Host, and received by the CR14. After all 36 Bytes have been output, the CR14 “rolls over”,

and starts outputting from the start of the Input/Output Frame Register again.

The CR14 supports the I²C Current Address and Random Address Read modes. The

Current Address Read mode can be used if the previous command was issued to the

register where the Read is to take place.

Figure 13. Host-to-CR14 transfer: I²C write to I/O frame register for ISO14443B

Figure 14. CR14-to-host transfer: I²C random address read from I/O frame register for

ISO14443B

Doc ID 11922 Rev 2 23/47

Page 24

Applying the I²C protocol to the CR14 registers CR14

S

T

A

R

T

1010XXX N

S

T

O

P

ACK

ACK

Answer Frame

Data

Device

Select

Code

Bus Master

CR14 Write

Bus Slave

ai12043

R/W

Data 1 Data 2

Answer Frame

Data

Answer Frame

Data

Data N

Answer Frame

Data

Received

Frame Length

ACKACK NoACKACK

03h

S

T

O

P

ACK

Slot Marker

Register

Address

Bus Master

CR14 Write

Bus Slave

ai12044

S

T

A

R

T

1010XXX

Device Select

Code

R/W

ACK

S

T

A

R

T

1010XXX 00h FFh

S

T

O

P

ACK

ACK

ACK

Slot Marker

Register

Address

Device Select

Code

Bus Master

CR14 Read

Bus Slave

ai12045

R

E

S

T

A

R

T

1010XXX

R/W

Device Select

Code

R/W NoACK

Figure 15. CR14-to-host transfer: I²C current address read from I/O frame register for ISO14443B

5.3 I²C slot marker register protocol

An I²C Write command to the Slot Marker Register generates an automated sixteencommand loop (See Figure 16 for a description of the command).

All the answers from the ST short range memory devices that are detected, are written in

the Input/Output Frame Register.

Read from the I²C Slot Marker Register is not supported by the CR14. If the I²C Host tries to

read the Slot Marker Register, the CR14 will return the data value FFh in both Random

Address and Current Address Read modes until NoACK is generated by the I²C Host.

The result of the detection sequence is stored in the Input/Output Frame Register. This

Register can be read by the host by using I²C Random Address Read.

Figure 16. Host-to-CR14 transfer: I²C write to slot marker register

Figure 17. CR14-to-host transfer: I²C random address read from slot marker register

24/47 Doc ID 11922 Rev 2

Page 25

CR14 Applying the I²C protocol to the CR14 registers

FFh

S

T

O

P

ACK

Bus Master

CR14 Read

Bus Slave

ai12047

S

T

A

R

T

1010XXX

Device Select

Code

R/W NoACK

Figure 18. CR14-to-host transfer: I²C current address read from slot marker register

5.4 Addresses above location 06h

In I²C Write mode, when the CR14 receives the 8-bit register address, and the address is

above location 06h, the device does not acknowledge (NoACK) and deselects itself from the

bus. The Serial Data line, SDA, stays at logic ‘1’ (pull-up resistor), and the I²C Host receives

a NoACK during the 9th bit time. The SDA line stays High until the STOP condition is issued.

In the I²C Current and Random Address Read modes, when the CR14 receives the 8-bit

register address, and the address is above location 06h, the device does not acknowledge

the Device Select Code after the START condition, and deselects itself from the bus.

Doc ID 11922 Rev 2 25/47

Page 26

CR14 ISO14443 type-B radio frequency data transfer CR14

DATA BIT TRANSMITTED

BY THE CR14

10% ASK MODULATION

OF THE 13.56MHz WAVE,

GENERATED BY THE RF

OUT

DRIVER

Transfer time for one data bit is 1/106 kHz

AI12048

10% ASK MODULATION

OF THE 13.56MHz WAVE,

GENERATED ON THE CR14

ANTENNA

6 CR14 ISO14443 type-B radio frequency data transfer

6.1 Output RF data transfer from the CR14 to the PICC (request frame)

The CR14 output buffer is controlled by the 13.56MHz clock signal generated by the

external oscillator and by the request frame generator. The CR14 can be directly connected

to an external matching circuit to generate a 13.56MHz sinusoidal carrier frequency on its

antenna.

The current driven into the antenna coil is directly generated by the CR14 RFOUT output

driver.

If the antenna is correctly tuned, it emits an H-field of a large enough magnitude to power a

contactless PICC from a short distance. The energy received on the PICC antenna is

converted to a Power Supply Voltage by a regulator, and turned into data bits by the ASK

demodulator. The CR14 amplitude modulates the 13.56MHz wave by 10% as represented

in Figure 19. The data transfer rate is 106 kbit/s.

Figure 19. Wave transmitted using ASK modulation

6.2 Transmission format of request frame characters

26/47 Doc ID 11922 Rev 2

The CR14 transmits characters of 10 bits, with the Least Significant Bit (b0) transmitted first,

as shown in Figure 20.

Several 10-bit characters, preceded by the Start Of Frame (SOF) and followed by the End Of

Frame (EOF), constitute a Request Frame, as shown in Figure 26.

A Request Frame includes the SOF, instructions, addresses, data, CRC and the EOF as

defined in the ISO14443 type-B.

Each bit duration is called an Elementary Time Unit (ETU). One ETU is equal to 9.44µs

(1/106kHz).

Page 27

CR14 CR14 ISO14443 type-B radio frequency data transfer

1

ETU

Start

'0'

LSB MSB

Stop

'1'

Information Byte

b0 b1 b2 b3 b4 b5 b6 b7 b8 b9

ai12049

b0b1b2b3b4b5b6b7b8b9b10b

11

ETU000000000011

ai12050

b0b1b2b3b4b5b6b7b8b

9

ETU0000000000

ai09252

Figure 20. CR14 request frame character format

Table 7. CR14 request frame character format

Bit Description Value

b

0

b

1 to b8

b

9

Start bit used to synchronize the transmission

Information Byte (instruction, address or data)

Stop bit used to indicate the end of the character

6.3 Request start of frame

The Start Of Frame (SOF) described in Figure 21 consists of:

● a falling edge,

● followed by ten Elementary Time Units (ETU) each containing a logical ‘0’

● followed by a single rising edge

● followed by two ETUs, each containing a logical ‘1’.

Figure 21. Request start of frame

b

= 0

0

Information Byte is sent Least

Significant Bit first

= 1

b

9

6.4 Request end of frame

The End Of Frame (EOF) shown in Figure 22 consists of:

● a falling edge,

● followed by ten Elementary Time Units (ETU) containing each a logical ‘0’,

● followed by a single rising edge.

Figure 22. Request end of frame

Doc ID 11922 Rev 2 27/47

Page 28

CR14 ISO14443 type-B radio frequency data transfer CR14

V

DYN

V

RFIN

t

V

OFFSET

1/106kHz

1/847kHz

phase shift

V

RET

Load modulation effect on

the H-Field received on the

CR14 RFIN input pad

PICC data bit to be transmitted

to the CR14.

847kHz BPSK, resulting signal

generated by the PICC for the

load modulation.

ai12051

6.5 Input RF data transfer from the PICC to the CR14 (answer frame)

The CR14 uses the ISO14443 type-B retro-modulation scheme which is demodulated and

decoded by the RF

The modulation is obtained by modifying the PICC current consumption (load modulation).

This load modulation induces an H-field variation, by coupling, that is detected by the CR14

RF

input as a voltage variation on the antenna. The RFIN input demodulates this variation

IN

and decodes the information received from the PICC.

circuitry.

IN

Data must be transmitted using a 847kHz, BPSK modulated sub-carrier frequency, f

shown in Figure 23, and as specified in ISO14443 type-B. In BPSK, all data state transitions

(from ‘0’ to ‘1’ or from ‘1’ to ‘0’) are encoded by phase shift keying the sub-carrier.

Figure 23. Wave received using BPSK sub-carrier modulation

, as

S

6.6 Transmission format of answer frame characters

The PICC should use the same character format as that used for output data transfer (see

Figure 20).

An Answer Frame includes the SOF, data, CRC and the EOF, as illustrated in Figure 26. The

data transfer rate is 106 kbit/s.

The CR14 will also accept Answer Frames that do not contain the SOF and EOF delimiters,

provided that these Frames are correctly set in the Parameter Register. (See Figure 26).

28/47 Doc ID 11922 Rev 2

Page 29

CR14 CR14 ISO14443 type-B radio frequency data transfer

b0b1b2b3b4b5b6b7b8b9b10b

11

ETU000000000011

ai09254

b

12

1

b0b1b2b3b4b5b6b7b8b9b10b

11

ETU000000000011

ai09254

b

12

1

6.7 Answer start of frame

The PICC SOF must be compliant with the ISO14443 type-B, and is shown in Figure 24

● Ten or eleven Elementary Time Units (ETU) each containing a logical ‘0’,

● Two ETUs containing a logical ‘1’.

Figure 24. Answer start of frame

6.8 Answer end of frame

The PICC EOF must be compliant with the ISO14443 type-B, and is shown in Figure 25:

● Ten or eleven Elementary Time Units (ETU) each containing a logical ‘0’,

● Two ETUs containing a logical ‘1’

Figure 25. Answer end of frame

6.9 Transmission frame

The Request Frame transmission must be followed by a minimum delay, t0 (see Ta bl e ), in

which no ASK or BPSK modulation occurs, before the Answer Frame can be transmitted. t

is the minimum time required by the CR14 to switch from transmission mode to reception

mode, and should be inserted after each frame. After t

modulated by the PICC at 847kHz for a minimum time of t

to synchronize. After t

bit (‘0’) of the Answer SOF (or the start bit ‘0’ of the first data character in non SOF/EOF

mode).

, the first phase transition generated by the PICC represents the start

1

, the 13.56MHz carrier frequency is

0

(see Ta bl e ) to allow the CR14

1

0

Doc ID 11922 Rev 2 29/47

Page 30

CR14 ISO14443 type-B radio frequency data transfer CR14

SOF Cmd Data CRC CRC EOF

12 bits

at 106Kb/s

10 bits 10 bits10 bits 10 bits 10 bits

Sent by

the CR14

t

0

64/fs Min

t

1

80/fs Min

Sync

fs = 847.5kHz

SOF Data

CRC CRC

EOF

12 or 13

bits

10 bits 12 or 13

bits

10 bits 10 bits

t

WDG

Case of Answer Frame with SOF & EOF

Sent by the PICC

Sync Data

Data CRC

t

WDG

Case of Answer Frame without SOF & EOF

Data CRC

t

0

64/fs Min

t

1

80/fs Min

10 bits 10 bits 10 bits10 bits 10 bits

Output Data Transfer using ASK Modulation Input Data Transfer using 847kHz BPSK Modulation

ai12052

t

DR

LSByte MSByte

CRC 16 (8 bits) CRC 16 (8 bits)

LSBit MSBit LSBit MSBit

ai09256

Figure 26. Example of a complete transmission frame

6.10 CRC

The 16-bit CRC used by the CR14 follows the ISO14443 type B recommendation. For

further information, please see Appendix A on page 44.

The two CRC Bytes are present in all Request and Answer Frames, just before the EOF.

The CRC is calculated on all the Bytes between the SOF and the CRC Bytes.

Upon transmission of a Request from the CR14, the PICC verifies that the CRC value is

valid. If it is invalid, it discards the frame and does not answer the CR14.

Upon reception of an Answer from the PICC, the CR14 verifies that the CRC value is valid. If

it is invalid, it stores the value FFh in the Input/Output Frame Register.

The CRC is transmitted Least Significant Byte first. Each Byte is transmitted Least

Significant Bit first.

Figure 27. CRC transmission rules

30/47 Doc ID 11922 Rev 2

Page 31

CR14 Tag access using the CR14 coupler

S

T

A

R

T

Device

Select

Code

Input/

Output

Register

Address

Request

Frame

Length

TAG

Cmd

Code

Param Param Param

S

T

O

P

SOF EOFData 1 DataData 2 Data N CRC CRC

CR14

SOF

TAG

Cmd

Code

Param Param Param

SR14

EOF

CRC CRC

I²C

RF

ai12053

Data 1 DataData 2 Data N01h N

7 Tag access using the CR14 coupler

In all the following I²C commands, the last three bits of the Device Select Code can be

replaced by any of the three-bit binary values (000, 001, 010, 011, 100, 101, 110, 111).

These values are linked to the logic levels applied to the E2, E1 and E0 pads of the CR14.

7.1 Standard TAG command access description

Standard PICC commands, like Read and Write, are generated by the CR14 using the

Input/Output Frame Register.

When the host needs to send a standard frame command to the PICC, it first has to

internally generate the complete frame, with the command code followed by the command

parameters. Only the two CRC Bytes should not be generated, as the CR14 automatically

adds them during the RF transmission.

When the frame is ready, the host has to write the request frame into the Input/Output Frame

Register using the I²C write command specified in Figure 13 on page 23. After the I²C STOP

condition, the CR14 inserts the I²C Bytes in the required ISO character format ( Figure 20)

and starts to transmit the request frame to the PICC. Once the RF transmission is over, the

CR14 waits for the PICC to send an answer frame.

If the PICC answers, the characters received (Figure 26) are demodulated, decoded and

stored into the Input/Output Frame Register, as specified in Ta bl e 4 . During the entire RF

transmission, the CR14 disconnects itself from the I²C bus. On reception of the PICC EOF,

the CR14 checks the CRC and reconnects itself to the I²C bus.

The host can then get the PICC answer frame by issuing an Input/Output Frame Register

Read on the I²C bus, as specified in Figures 14 and 15.

If no answer from the PICC is detected after a time-out delay, fixed in the Parameter

Register (bits b

and b6), the Input/Output Frame Register is set as specified in Ta bl e 4 .

5

Figure 28. Standard TAG command: request frame transmission

Doc ID 11922 Rev 2 31/47

Page 32

Tag access using the CR14 coupler CR14

S

T

A

R

T

Device

Select

Code

Input/

Output

Register

Address

Answer

Frame

Length

TAG

Data

S

T

O

P

SOF EOFData 1 DataData 2 Data P CRC CRC

TAG

SOF

TAG

Data

TAG

Data

TAG

Data

TAG

Data

TAG

EOF

TAG

CRC

TAG

CRC

I²C

RF

ai09261

Data 1 DataData 2 Data P01h P

TAG

Data

TAG

Data

TAG

Data

Device

Select

Code

Write

I/O

Register

Address

Request

Frame

Length

Request

Frame

Bytes

I²C

START STOP

CRC

Request

Frame

Characters

SOF EOF

CRC

TA G

Answer Frame

Characters

SOF EOF

T

0

<-->

T

1

<-->

Device

Select

Code

Read

Answer

Frame

Length

Request

Frame

Bytes

START STOP

RF

ai09262

Figure 29. Standard TAG command: answer frame reception

Figure 30. Standard TAG command: complete TAG access description

7.2 Anti-collision TAG sequence

The CR14 can identify an ST short range memory using a proprietary anti-collision system.

Issuing an I²C Write command to the Slot Marker Register (Figure 16) causes the CR14 TO

automatically generate a 16-slot anti-collision sequence, and to store the identified Chip_ID

in the Input/Output Frame Register, as specified in Tab le 4 .

After receiving the Slot Marker Register I²C Write command, the CR14 generates an RF

PCALL16 command followed by fifteen SLOT_MARKER commands, from

SLOT_MARKER(1) to SLOT_MARKER(15). After each command, the CR14 waits for a tag

answer. If the answer is correctly decoded, the corresponding Chip_ID is stored in the

Input/Output Frame Register. If there is no answer, or if the answer is wrong (with a CRC

error, for example), the CR14 stores an error code in the Input/Output Frame Register. At

the end of the sequence, the host has to read the Input/Output Frame Register to retrieve all

the identified Chip_IDs.

32/47 Doc ID 11922 Rev 2

Page 33

CR14 Tag access using the CR14 coupler

03hI²C

S

T

A

R

T

Device

Select

Code

Slot

Marker

Register

Address

S

T

O

P

SOFSlot 0

06h 04h CRC CRC EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOF

CR14

SOF

PCALL 16 TAG

Command

CRC CRC CR14

EOF

TAG

SOF

TAG

Chip_ID

TAG

CRC

TAG

CRC

TAG

EOF

RF

I²C

SOFSlot 1 16h CRC CRC EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOFRF...

I²C

SOFSlot 2 26h CRC CRC EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOFRF...

I²C

SOFSlot 3 36h CRC CRC EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOFRF...

I²C

SOFSlot 4 46h CRC CRC EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOFRF...

I²C

SOFSlot 5 56h

CRC CRC

EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOFRF...

I²C

SOFSlot 6 66h CRC CRC EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOFRF...

I²C

SOFSlot 7 76h CRC CRC EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOFRF...

I²C

SOFSlot 8 86h CRC CRC EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOFRF...

I²C

SOFSlot 9 96h CRC CRC EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOFRF...

CR14

SOF

Slot Marker

Command

CRC CRC CR14

EOF

TAG

SOF

TAG

Chip_ID

TAG

CRC

TAG

CRC

TAG

EOF

ai12054

Figure 31. Anti-collision ST short range memory sequence (1)

Doc ID 11922 Rev 2 33/47

Page 34

Tag access using the CR14 coupler CR14

I²C

SOFSlot 10 96h

CRC CRC

EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOFRF ...

I²C

SOFSlot 11

56h CRC CRC

EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOFRF ...

I²C

SOFSlot 12

66h CRC CRC

EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOF

RF ...

I²C

SOFSlot 13

76h CRC CRC EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOFRF ...

I²C

SOFSlot 14 86h CRC CRC EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOF

RF ...

I²C

SOFSlot 15

96h CRC CRC EOF SOF

t

0

<-->

t

1

<-->

Chip_ID CRC CRC EOF

RF ...

01h

I²C ...

S

T

A

R

T

Device

Select

Code

I/O

Register

Address

R

E

S

T

A

R

T

Device

Select

Code

Answer

Frame

Length

Slot 0

Chip_ID

Answer

Status12h Status Chip_ID Chip_IDChip_ID Chip_ID Chip_ID Chip_IDChip_ID Chip_ID Chip_ID

Status

Slot Bits

b0 to b

7

Status

Slot Bits

b8 to b

15

Slot 1

Chip_ID

Answer

Slot 2

Chip_ID

Answer

Slot 3

Chip_ID

Answer

Slot 4

Chip_ID

Answer

Slot 5

Chip_ID

Answer

Slot 6

Chip_ID

Answer

Slot 7

Chip_ID

Answer

Slot 8

Chip_ID

Answer

RF

I²C ...

Chip_IDChip_ID Chip_ID Chip_ID

Chip_IDChip_ID

Chip_ID

RF

ai09264

Slot 9

Chip_ID

Answer

Slot 10

Chip_ID

Answer

Slot 11

Chip_ID

Answer

Slot 12

Chip_ID

Answer

Slot 13

Chip_ID

Answer

Slot 14

Chip_ID

Answer

Slot 15

Chip_ID

Answer

S

T

O

P

Figure 32. Anti-collision ST short range memory sequence continued

34/47 Doc ID 11922 Rev 2

Page 35

CR14 Maximum rating

8 Maximum rating

Stressing the device above the rating listed in the Absolute Maximum Ratings table may

cause permanent damage to the device. Exposure to Absolute Maximum Rating conditions

for extended periods may affect device reliability. These are stress ratings only and

operation of the device at these or any other conditions above those indicated in the

Operating sections of this specification is not implied. Refer also to the STMicroelectronics

SURE Program and other relevant quality documents.

Table 8. Absolute maximum ratings

Symbol Parameter Value Unit

P

T

V

STG

V

V

V

OUT

ESD

IO

IO

CC

Storage Temperature –65 to 150 °C

Input or Output range (SDA) –0.3 to 6.5 V

Input or Output range (others pads) –0.3 to Vcc+0.3 V

Supply Voltage –0.3 to 6.5 V

Output Power on Antenna Output Driver (RF

Electrostatic Discharge Voltage (Human Body model)

Electrostatic Discharge Voltage (Machine model)

1. MIL-STD-883C, 3015.7 (100 pF, 1500 ).

2. EIAJ IC-121 (Condition C) (200 pF, 0 )

OUT

)

(1)

(2)

100 mW

4000 V

500 V

Doc ID 11922 Rev 2 35/47

Page 36

DC and AC parameters CR14

AI09235

0.8V

CC

0.2V

CC

0.7V

CC

0.3V

CC

9 DC and AC parameters

This section summarizes the operating and measurement conditions, and the DC and AC

characteristics of the device. The parameters in the DC and AC Characteristic tables that

follow are derived from tests performed under the Measurement Conditions summarized in

the relevant tables. Designers should check that the operating conditions in their circuit

match the measurement conditions when relying on the quoted parameters.

Table 9. I²C AC measurement conditions

Parameter Min. Max. Unit

V

Supply Voltage

CC

Ambient Operating Temperature (TA)

Input Rise and Fall Times 50 ns

Input Pulse Voltages

Input and Output Timing Reference Voltages

Figure 33. I²C AC testing I/O waveform

4.5 5.5 V

–20 85 °C

0.2V

0.3V

CC

CC

0.8V

0.7V

CC

CC

V

V

Table 10. I²C Input Parameters

(1,2)

Symbol Parameter Min. Max. Unit

C

Input Capacitance (SDA) 8 pF

IN

C

Input Capacitance (SCL, E0, E1, E2)) 6 pF

IN

t

Low Pass Filter Input Time Constant (SCL & SDA Inputs) 100 400 ns

NS

1. Sampled only, not 100% tested.

= 25 °C, f = 400kHz.

2. T

A

Table 11. I²C DC characteristics

Symbol Parameter Test condition Min. Max. Unit

Input Leakage Current

I

LI

(SCL, SDA, E0, E1, E2)

Output Leakage Current

I

LO

(SCL, SDA, E0, E1, E2)

0V V

0V VIN V

OUT

36/47 Doc ID 11922 Rev 2

V

CC

CC

SDA in Hi-Z

,

±2 µA

±2 µA

Page 37

CR14 DC and AC parameters

tCHCL CLCH

tDLCL

tCHDX

START

CONDITION

tDXCX

tCLDX

tCHDH

tDHDL

SDA

INPUT

SDA

CHANGE

STOP &

BUS FREE

SCL

SDA IN

SCL

SDA OUT

DATA VALID

tCLQV tCLQX

DATA OUTPUT

SCL

SDA IN

tCHDH

tRFEX

tCHDX

STOP

CONDITION

CR14 command execution START

CONDITION

ai12055

Table 11. I²C DC characteristics (continued)

Symbol Parameter Test condition Min. Max. Unit

= 5 V, fC = 400 kHz

V

I

Supply Current

CC

I

Supply Current (Stand-by)

CC1

Input Low Voltage (SCL,

SDA)

V

IL

Input Low Voltage (E0, E1,

E2)

Input High Voltage (SCL,

SDA)

V

IH

Input High Voltage (E0, E1,

E2)

CC

(rise/fall time < 30ns), RF OFF

VCC = 5V, fC = 400 kHz (rise/fall

time < 30ns), RF ON

V

= VSS or VCC, V

IN

= 5 V, RF

CC

OFF

–0.3

–0.3

0.7V

0.7V

CCVCC

CCVCC

6mA

20 mA

5mA

0.3V

0.3V

+ 1

+ 1

CC

CC

V

V

V

V

V

Output Low Voltage (SDA)

OL

Figure 34. I²C AC waveforms

I

= 3 mA, VCC = 5 V

OL

0.4 V

Doc ID 11922 Rev 2 37/47

Page 38

DC and AC parameters CR14

Table 12. I²C AC characteristics

Symbol Alt. Parameter

t

CH1CH2

(1)

(1)

t

CL1CL2

t

DH1DH2

)

(1)

t

DL1DL2

(2)

t

CHDX

t

CHCL

t

DLCL

t

CLDX

t

CLCH

t

DXCX

t

CHDH

t

DHDL

t

CLQV

t

CLQX

f

C

1. Sampled only, not 100% tested.

2. For a reSTART condition, or following a write cycle.

t

Clock Rise Time 300 1000 ns

R

t

Clock Fall Time 300 300 ns

F

(1

t

SDA Rise Time 20 300 20 1000 ns

R

t

SDA Fall Time 20 300 20 300 ns

F

t

SU:STA

t

HIGH

t

HD:STA

t

HD:DAT

t

LOW

t

SU:DAT

t

SU:STO

t

BUF

t

t

f

SCL

Clock High to Input Transition 600 4700 ns

Clock Pulse Width High 600 4000 ns

Input Low to Clock Low (START) 600 4000 ns

Clock Low to Input Transition 0 0 µs

Clock Pulse Width Low 1.3 4.7 µs

Input Transition to Clock Transition 100 250 ns

Clock High to Input High (STOP) 600 4000 ns

Input High to Input Low (Bus Free) 1.3 4.7 µs

Clock Low to Data Out Valid 1000 3500 ns

AA

Data Out Hold Time After Clock Low 200 200 ns

DH

Clock Frequency 400 100 kHz

Fast I²C

400 kHz

I²C

100 kHz

MinMaxMinMax

Unit

38/47 Doc ID 11922 Rev 2

Page 39

CR14 DC and AC parameters

t

RFSBL

t

RFF

t

RFR

BA

t

POR

V

RFOUT

f

CC

RF

OUT

ASK Modulated Signal

1 0 1 EOFDATA

FRAME transmitted by the CR14 in ASK

847kHz SOF 1 1 0 DATA 1 0 DATA 1 0

FRAME transmitted by the PICC in BPSK

t

DR

t

DR

t

0

t

1

t

DA

t

DA

0

START

t

RFSBL

t

RFSBL

t

RFSBL

t

RFSBL

t

RFSBL

t

JIT

t

JIT

t

JIT

t

JIT

t

JIT

Data jitter on FRAME transmitted by the CR14 in ASK

ai12056

FRAME transmission between the reader and the contactless device

Figure 35. CR14 synchronous timing

Table 13. RF

Symbol Parameter Condition Min. Max. Unit

f

CC

MI

CARRIER

t

RFR,tRFF

t

RFSBL

t

JIT

t

0

t

1

AC characteristics

OUT

External Oscillator Frequency

Carrier Modulation Index MI=(A-B)/(A+B) 10 14 %

10% Rise and Fall time 0.5 1.5 µs

Pulse Width on RF

OUT

ASK modulation bit jitter CR14 to PICC -0.5 0.5 µs

Antenna Reversal delay

Synchronization delay

= 5 V

V

CC

1 ETU = 128/f

Min = 64/f

Min = 80/f

S

S

CC

13.553 13.567 MHz

9.44 µs

75 µs

94 µs

Doc ID 11922 Rev 2 39/47

Page 40

DC and AC parameters CR14

Table 13. RF

AC characteristics (continued)

OUT

Symbol Parameter Condition Min. Max. Unit

t

WDG

t

WDG

t

WDG

t

WDG

t

DR

P

A

t

POR

Table 14. RFIN AC characteristics

Symbol

t

RFSBL

f

S

t

DA

V

DY N

V

OFFSET

V

RET

1. Data specified in the table above are estimated or target values. All values can be updated during product qualification.

Answer delay watchdog (b5=0, b6=0)

500 µs

Request EOF

Answer delay watchdog (b5=0, b6=1)

Answer delay watchdog (b5=1, b6=0)

Answer delay watchdog (b5=1, b6=1)

rising edge to

first Answer

start bit

5ms

10 ms

309 ms

Time Between Request characters CR14 to PICC 9.44 µs

RF

output power

OUT

CR14 Power-On delay 20 ms

1. Data specified in the table above are estimated or target values. All values can be updated

during product qualification.

Parameter

(1)

PICC Pulse Width

PICC Sub-carrier Frequency

Condition Min. Max. Unit

1 ETU = 128/f

f

CC

CC

/16

90 mW

9.44 µs

847.5 KHz

Time Between Answer characters PICC to CR14 1, 2, 3 ETU

RFIN Dynamic Voltage Level V

RFIN Offset Voltage Level

RFIN Retro-modulation Level

Max for V

DYN

OFFSET

= VCC/2

VCC/2

0.5

23V

120 mV

V

40/47 Doc ID 11922 Rev 2

Page 41