Aerospace 40 A - 200 V fast recovery rectifier

Features

■ Very small conduction losses

■ Negligible switching losses

■ High surge current capability

■ High avalanche energy capability

■ Hermetic package

■ Target radiation qualification:

– 150 krad (Si) low dose rate

– 1 Mrad high dose rate

■ Package mass: 10 g

■ ESCC qualified

BYV54HR

TO-254AA

Description

Figure 1. Device configuration

Packaged in a hermetic TO-254AA, this device is

intended for use in medium voltage, high

frequency switching mode power supplies, high

frequency DC to DC converters, and other

aerospace applications.

The complete ESCC specification for this device

Terminal 1:

Terminal 2:

Terminal 3:

is available from the European space agency web

site. ST guarantees full compliance of qualified

The case is not connected to any lead

parts with such ESCC detailed specifications.

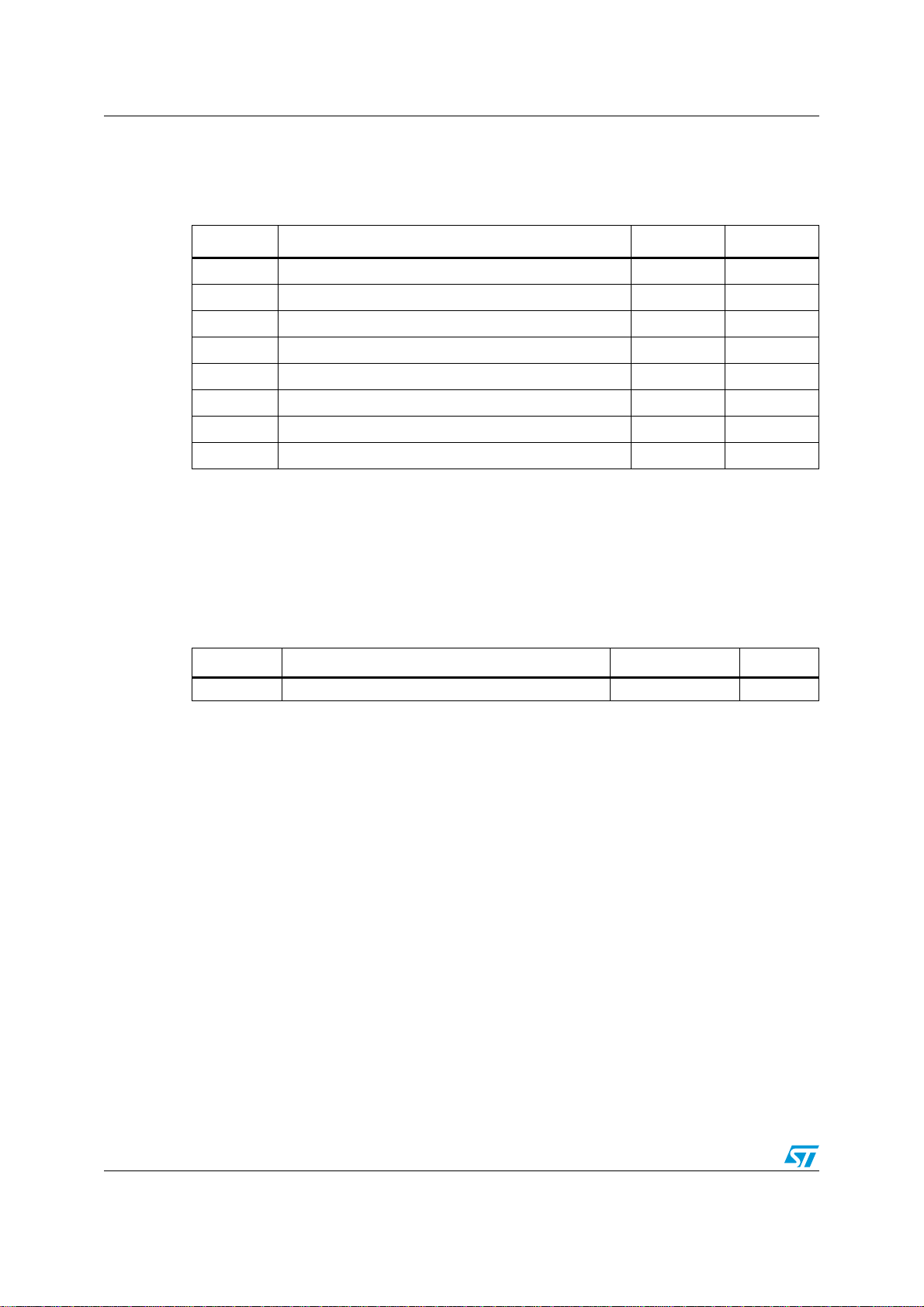

Table 1. Device summary

Order code

ESCC detailed

BYV54S200FSY1 -

BYV54S200FSYHRB 5103/031/05 Flight part

1. Contact ST sales office for information about the specific conditions for products in die form and QML-Q versions.

(1)

specification

Quality level

Engineering

model

Lead

finish

Gold -

Solder

dip

Cathode

Anode

Anode

EPPL I

Y

V

F(AV)

40 A 200 V 150 °C 1.10 V

BYV54S200FSY1

2

3

T

RRM

j(max)VF (max)

HRBBYV54S200FSY

1

July 2010 Doc ID 17416 Rev 1 1/8

www.st.com

8

Characteristics BYV54HR

1 Characteristics

Table 2. Absolute maximum ratings

Symbol Characteristic Value Unit

I

FSM

V

RRM

I

O

I

F(RMS)

T

OP

T

T

STG

T

SOL

Forward surge current

Repetitive peak reverse voltage

Average output rectified current (50% duty cycle):

Forward rms current 60 A

Operating case temperature range

Junction temperature +150 °C

J

Storage temperature range

Soldering temperature

1. Sinusoidal pulse of 10 ms duration

2. Pulsed, duration 5 ms, F = 50 Hz

3. For T

4. For devices with hot solder dip lead finish all testing performed at T

inert atmosphere.

5. Duration 10 seconds maximum at a distance of not less than 1.5 mm from the device body and the same

lead shall not be resoldered until 3 minutes have elapsed.

> +99 °C, derate linearly to 0 A at +150°C.

case

(1)

(5)

(4)

(2)

(4)

400 A

200 V

(3)

40 A

-55 to +150 °C

-55 to +150 °C

+260 °C

> +125 °C are carried out in a 100%

amb

Table 3. Thermal resistance

Symbol Parameter Value Unit

R

Junction to case

th (j-c)

1. Package mounted on infinite heatsink.

(1)

1.0 °C/W

2/8 Doc ID 17416 Rev 1

BYV54HR Characteristics

Table 4. Electrical measurements at ambiant temperature (per diode), T

Symbol Characteristic

I

R

(2)

V

F1

(2)

V

F2

V

BR

C Capacitance 4001 V

t

rr

Z

th(j-c)

s

MIL-STD-750

test method

Test conditions

(1)

= 22 ±3 °C

amb

Limits

Min. Max.

Reverse current 4016 DC method, VR = 200 V - 50 µA

Forward voltage 4011

Pulse method, I

= 20 A - 0.95 V

F

Pulse method, IF = 30 A - 1.1 V

Breakdown voltage 4021 IR = 100 µA 200 - V

= 10 V, F = 1 MHz - 400 pF

R

= 1 A, VR = 30 V,

I

Reverse recovery time 4031

Relative thermal impedance,

(3)

junction to case

3101

F

/dt = -50 A/µs

dI

F

= 15 to 40 A, tH = 50 ms

I

H

= 50 mA, tmd = 100 µs

I

M

-60ns

Calculate ΔV

(4)

F

1. Testing performed with both anode terminals 2 and 3 tied ttogehter

2. Pulse width ≤ 680 µs, duty cycle ≤ 2%

3. Performed only during screening tests parameter drift values (initial measurements for HTRB), go-no-go.

4. The limits for ΔVF shall be defined by the manufacturer on every lot in accordance with MIL-STD-750 Method 3101 and

shall guarantee the R

Table 5. Electrical measurements at high and low temperatures (per diode)

limits specified in maximum ratings.

th(j-c)

Units

°C/W

Symbol Characteristic

I

Reverse current 4016

R

(2)

V

F1

Forward voltage 4011

(2)

V

F2

1. Read and record measurements shall be performed on a sample of 5 components with 0 failures allowed. Alternatively a

100% inspection may be performed.

MIL-STD-750

test method

Test conditions

T

= +125 (+0, -5) °C

case

DC method, V

= +125 (+0, -5) °C

T

case

pulse method, I

T

= -55 (+0, -5) °C

case

pulse method, I

T

= +125 (+0, -5) °C

case

pulse method, I

R

= 200 V

= 20 A

F

= 20 A

F

= 30 A

F

(1)

Limits

Min. Max.

-40mA

-0.85V

-1.15V

2. Pulse width ≤ 680 µs, duty cycle ≤ 2%

To evaluate the conduction losses use the following equation:

P = 0.74 x I

F(AV)

+ 1.00 x I

F2(RMS )

Units

1.0

Doc ID 17416 Rev 1 3/8

Loading...

Loading...