Page 1

AN994

Application note

L638xE application guide

Introduction

STMicroelectronics’ L638xE is a versatile, high-voltage gate driver family of devices.

Developed using BCD offline technology, the L6384E, L6385E, L6386E, L6387E and

L6388E devices can operate with high voltage rails up to 600 V. The gate drivers provide all

the functions and current capability necessary for high- and low-side power MOSFETs and

IGBTs.

The devices can be used in all types of applications where high-voltage shifted control is

necessary; they have a relatively high driver current capability and are provided with an

internal patented circuitry that replaces the external bootstrap diode. This feature is

achieved by means of a high voltage DMOS, synchronously driven with the low-side gate

driver.

February 2009 Rev 7 1/25

www.st.com

Page 2

Contents AN994

Contents

1 L6384E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 L6385E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 L6386E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4 L6387E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5 L6388E . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6 Bootstrap driver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.1 C

selection and charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

BOOT

7 Application examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

8 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2/25

Page 3

AN994 List of figures

List of figures

Figure 1. L6384E internal block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. L6384E - schematic diagram of the evaluation circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 3. L6384E - PCB and component layout of the evaluation circuit. . . . . . . . . . . . . . . . . . . . . . . 6

Figure 4. L6385E - internal block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. L6385E - schematic diagram of the evaluation circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6. L6385E - PCB and component layout of the evaluation circuit. . . . . . . . . . . . . . . . . . . . . . . 9

Figure 7. L6386E - internal block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 8. L6386E - schematic diagram of the evaluation circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 9. L6386E - PCB and component layout of the evaluation circuit. . . . . . . . . . . . . . . . . . . . . . 12

Figure 10. L6387E - internal block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 11. L6388E internal block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 12. External bootstrap diode: principle schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 13. Internal bootstrap diode: principle schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Figure 14. External charge pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 15. L6384E µC 3-phase motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 16. L6384E dimmable lamp ballast. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 17. L6384E half bridge converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 18. L6385E horizontal deflection stage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 19. L6385E 2-switch forward converter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 20. L6385E asymmetrical half bridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 21. L6386E h-bridge with cycle-by-cycle control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3/25

Page 4

L6384E AN994

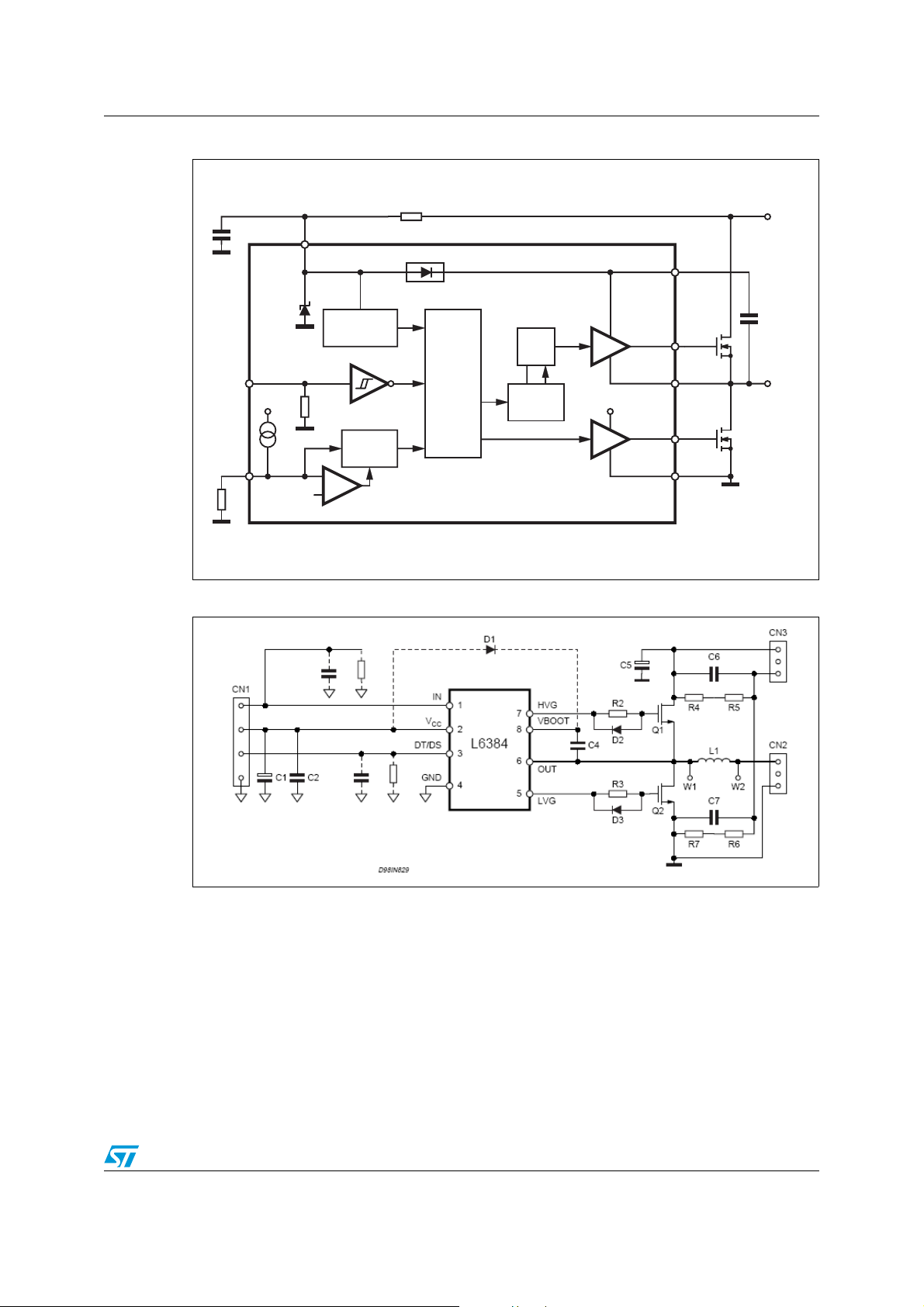

1 L6384E

The L6384E (depicted in Figure 1) is a half-bridge driver with an externally-adjustable dead

time and shut-down function. To disable the driver, the control pin (DT/SD at pin 3) must be

pulled down to below 0.5 V. The dead time can be set from 0.5 µs to 2.7 µs by placing a

resistor between pin 3 and ground. Available in both Minidip and SO-8 packages, this driver

can be used in motor controls, resonant converters and lighting applications. Figure 2 and

Figure 3 show the schematic diagram of the evaluation circuit and the layout of the test PCB.

Table 1. L6384E pin description

N. Name Typ. Function

1 IN

2 V

3 DT/SD I

4 GND Ground.

5 LVG O

6 OUT O

(1)

I Logic input. In phase with HVG and in opposition to LVG. Compatible with the VCC voltage.

CC

Supply input voltage. Includes an internal clamp (typically 15.6 V). Also has a UVLO feature

(typical threshold value V

ccth1

= 12 V, V

High impedance pin with double function. When pulled to a voltage lower than V

0.5 V) the device is shut down. A voltage higher than V

ccth2

= 10 V).

(typically

sets the dead time between the high

dt

dt

side and low side gate driver. The dead time value can be set by forcing a certain voltage level on

the pin or by connecting a resistor between pin 3 and ground. Care must be taken to avoid spikes

on pin 3 that could cause an undesired shut down of the IC. For this reason, the connection of the

components between pin 3 and ground must be as short as possible. This pin cannot be left

floating for the same reason. The pin must not be pulled through a low impedance to V

because of the drop on the current source that feeds R

.

dt

Low-side driver output. The output stage can deliver a 400 mA source and a 650 mA sink (typical

values). The circuit guarantees 0.3 V maximum on the pin (at I

= 10 mA) with V

sink

CC

lower than the turn-on threshold. This removes the need for the bleeder resistor connected

between the gate and the source of the external MOSFET normally used to hold the pin low. The

gate driver ensures low impedance in SD conditions as well.

Upper driver floating reference. Attention should be paid to the layout design of the power stage

so as to limit below-ground spikes on this pin.

CC

> 3 V and

High-side driver output. The output stage can deliver a 400 mA source and a 650 mA sink (typical

values). The circuit guarantees 0.3 V maximum between this pin and Vout (at I

> 3 V and lower than the turn-on threshold. This removes the need for the bleeder resistor

7HVG O

V

CC

connected between the gate and the source of the external MOSFET normally used to hold the

pin low. The gate driver ensures low impedance in SD conditions as well.

Bootstrap supply voltage. This is the upper driver floating supply. The bootstrap capacitor

8V

BOOT

connected between this pin and pin 6 can be fed by an internal structure named "bootstrap

driver" (a patented structure). This structure can replace the external bootstrap diode.

1. The pull-down internal resistor is typically some hundred kΩs.

4/25

= 10 mA) with

sink

Page 5

AN994 L6384E

Figure 1. L6384E internal block diagram

H.V.

V

CC

2

BOOTSTRAP DRIVER

V

8

BOOT

V

CC

HVG

DRIVER

DT/SD

UV

DETECTION

R S

1

IN

V

CC

Idt

3

Vthi

DEAD

TIME

LOGIC

LEVEL

SHIFTER

LVG

DRIVER

Figure 2. L6384E - schematic diagram of the evaluation circuit

E

C

BOOT

HVG

7

OUT

6

LVG

5

GND

4

LOAD

AM03415v1

5/25

Page 6

L6384E AN994

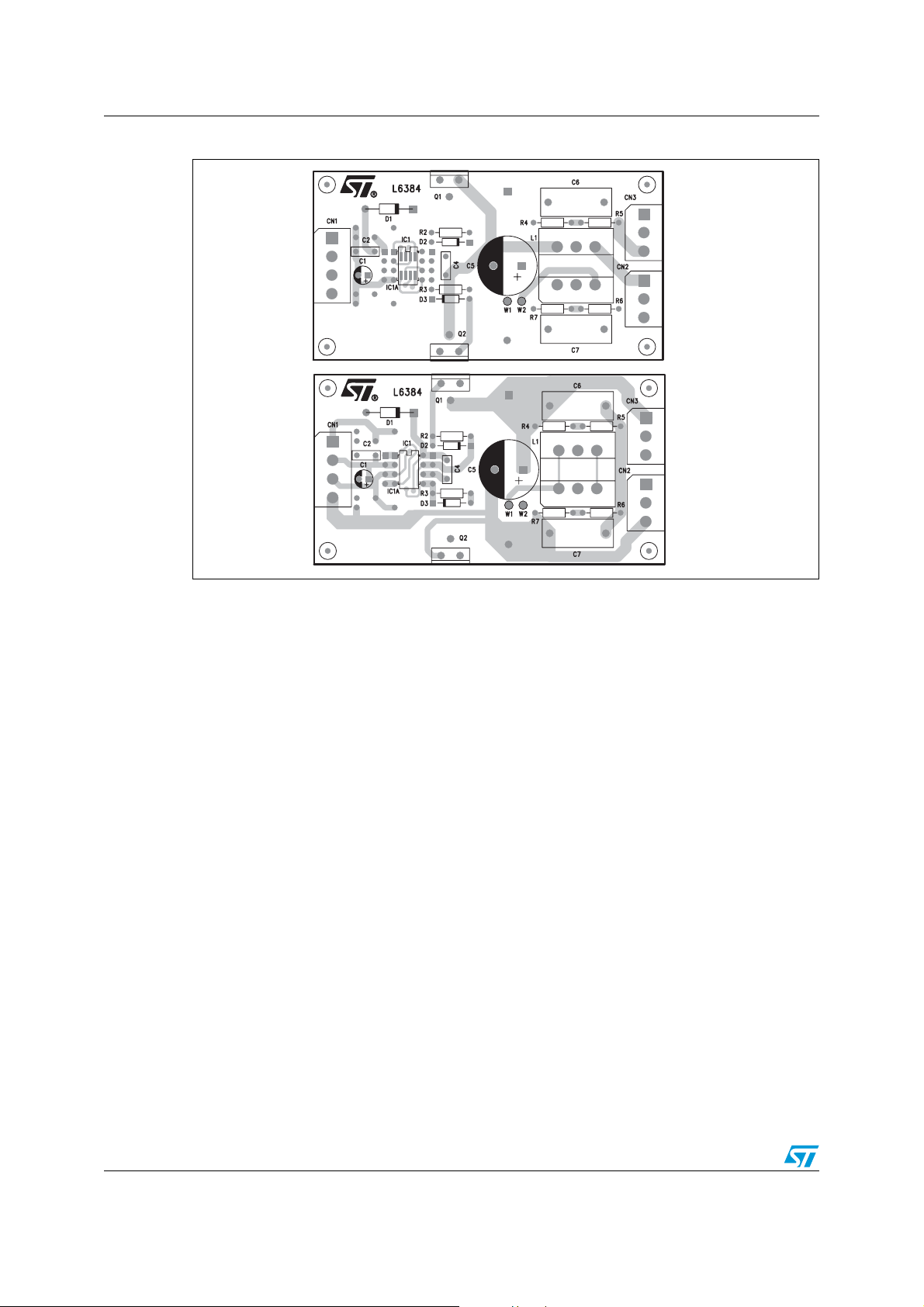

Figure 3. L6384E - PCB and component layout of the evaluation circuit

Top view

Bottom view

AM03413v1

6/25

Page 7

AN994 L6385E

2 L6385E

The L6385E (shown in Figure 4) is a high- and low-side configurable driver. It can control

the high- and low-side outputs (HVG and LVG) seperately, through the two related logic

inputs HIN and LIN. This device is provided with an undervoltage detection function in both

the low voltage V

packages, this driver has been specifically designed for power supplies and motion control

applications.

Figure 5 and Figure 6 show the schematic diagram of the evaluation circuit and the layout of

the relevant PCB.

Table 2. L6385E pin description

N. Name Type Function

1 LIN

2 HIN

3

4 GND Ground.

5 LVG O

6 OUT O

7 HVG O

(1)

I Low-side driver logic input. Compatible with the VCC voltage (V

(1)

I High-side driver logic input. Compatible with the VCC voltage (V

VCC Supply input voltage with UVLO (typically V

Low-side driver output. The output stage can deliver a 400 mA source and a 650 mA sink

(typical values). The circuit guarantees 0.3 V maximum on the pin (at Isink = 10 mA) with

V

CC

resistor connected between the gate and the source of the external MOSFET normally

used to hold the pin low. The gate driver ensures low impedance in SD conditions as well.

High-side driver floating reference. Attention should be paid to the layout design of the

power stage so as to limit below-ground spikes on this pin.

High-side driver output. The output stage can deliver a 400 mA source and a 650 mA sink

(typical values). The circuit guarantees 0.3 V maximum between this pin and Vout (at Isink

= 10 mA) with V

the bleeder resistor connected between the gate and the source of the external MOSFET

normally used to hold the pin low.

supply and high-voltage bootstrapped supply. Delivered in 8-pin

CC

ccth1

= 9.6 V, V

ccth2

= 1.5 V, V

il Max

= 1.5 V, V

il Max

= 8.3 V).

ih Min

ih Min

= 3.6 V)

= 3.6 V)

> 3 V and lower than the turn-on threshold. This removes the need for the bleeder

> 3 V and lower than the turn-on threshold. This removes the need for

CC

Bootstrap supply voltage. This is the floating supply of the high-side driver. Includes a

8 V

BOOT

UVLO function (typically, V

between this pin and pin 6 can be fed by an internal structure named "bootstrap driver" (a

BSth1

patented structure). This structure can replace the external bootstrap diode.

1. The pull-down internal resistor is typically some hundred kΩs.

= 9.5 V, V

= 8.2 V). The bootstrap capacitor connected

BSth2

7/25

Page 8

L6385E AN994

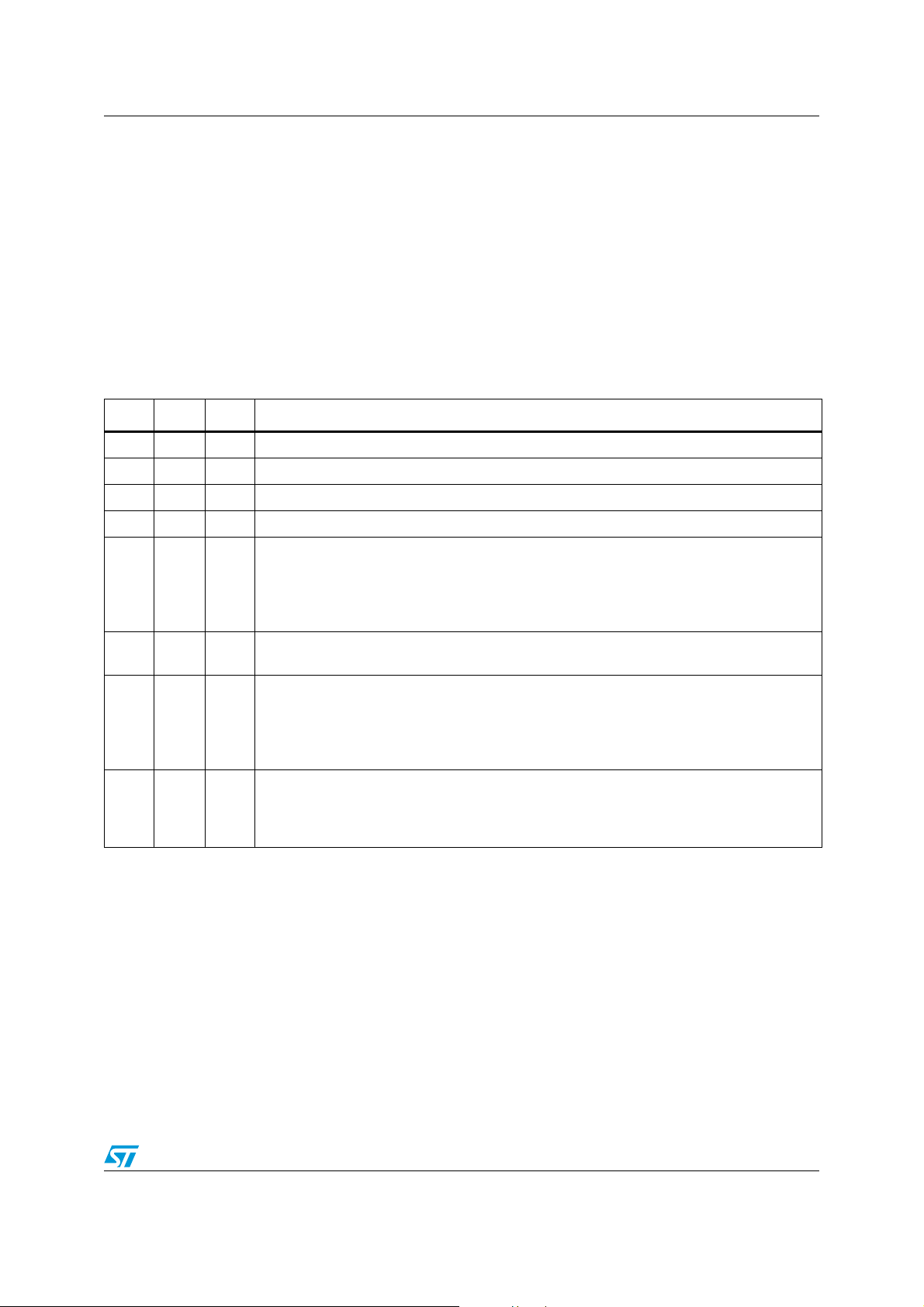

Figure 4. L6385E - internal block diagram

Figure 5. L6385E - schematic diagram of the evaluation circuit

E

8/25

Page 9

AN994 L6385E

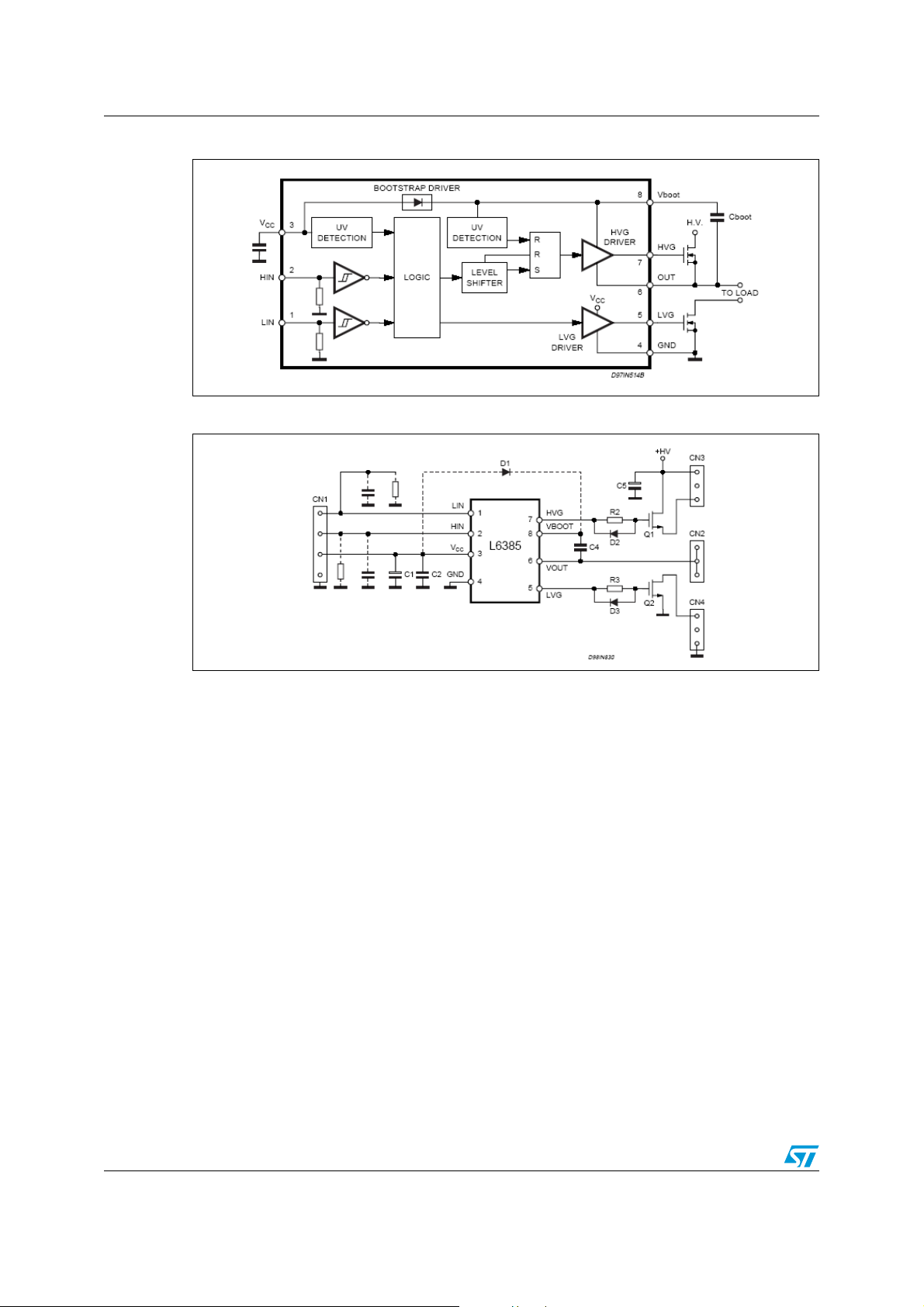

Figure 6. L6385E - PCB and component layout of the evaluation circuit

Top view

Bottom view

AM03414v1

9/25

Page 10

L6386E AN994

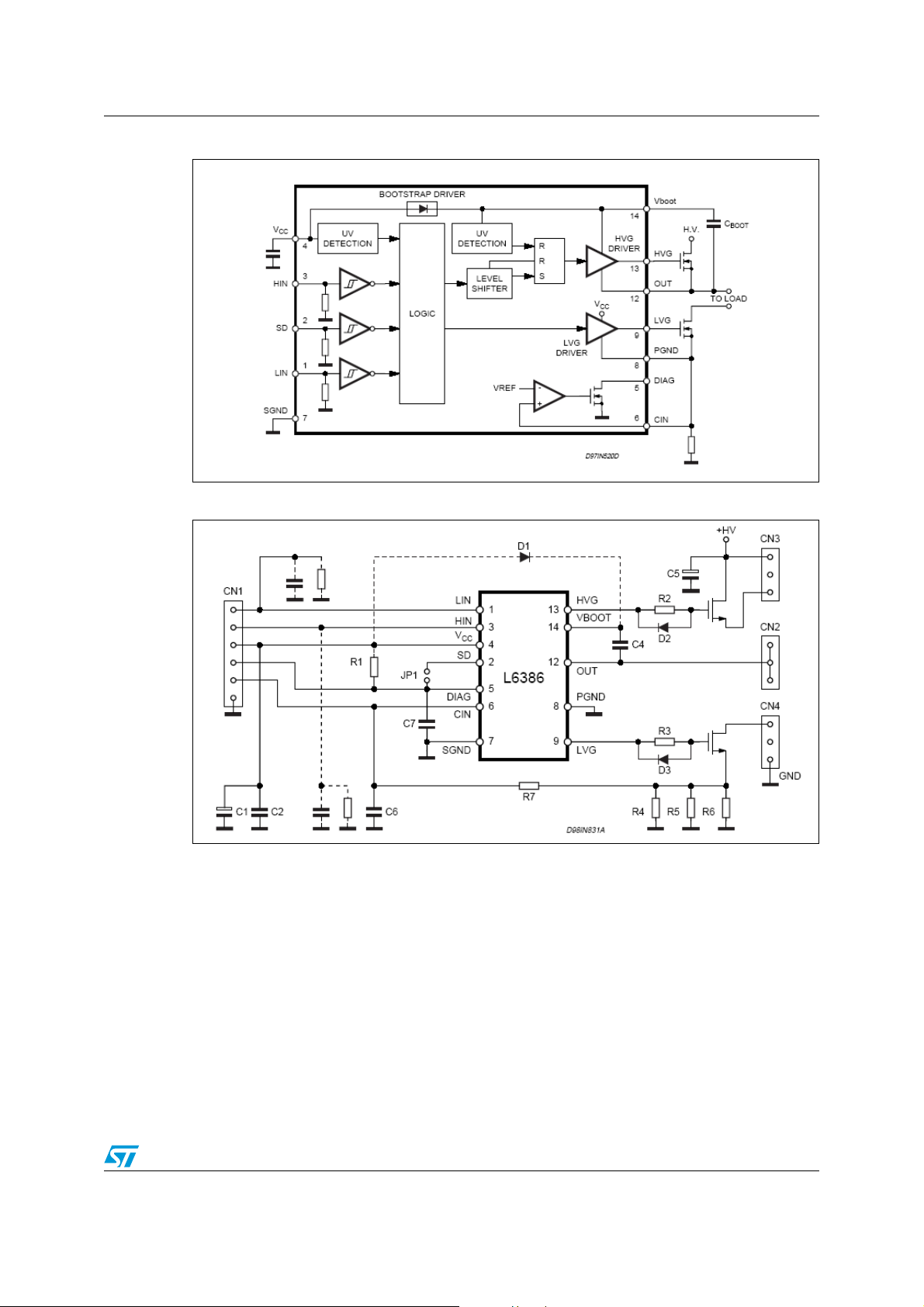

3 L6386E

The L6386E (shown in Figure 7) is a configurable driver based on the structure of the

L6385E, with added functions. This device is available in DIP14 or SO-14 packages.

The added shutdown function (active low) and the current sense comparator (0.5-V

threshold) with diagnostic output, make this device particularly suitable for motion control

applications with cycle-by-cycle current feedback. The DIAG and CIN pins can be used to

stop the device (by acting on the SD pin). Figure 8 and Figure 9 show the schematic

diagram of the evaluation circuit and the layout of the relevant PCB.

Table 3. L6386E pin description

N. Name Type Function

1 LIN

2 SD

3 HIN

4

5 DIAG O Diagnostic output: open drain.

6 CIN I Comparator input.

(1)

I Lower driver logic input. Compatible with the V

(1)

(1)

VCC Supply input voltage with UVLO (typically V

Shut-down logic input. Compatible with the V

I

suggested resistor value is 5 to 10 kΩ. (V

il Max

I Low-side driver logic input. Compatible with the VCC voltage.

voltage (V

CC

voltage. If it needs to be pulled up, the

CC

= 1.5 V, V

ccth1

= 12 V, V

ih Min

ccth2

il Max

= 3.6 V).

= 10 V).

= 1.5 V, V

ih Min

= 3.6 V).

7 SGND Ground reference for logic signals.

8 PGND Power ground reference for the low voltage gate driver.

Low-side driver output. The output stage can deliver a 400 mA source and a 650 mA sink

(typical values). The circuit guarantees 0.3 V maximum on the pin (at I

V

9 LVG O

> 3 V and lower than the turn-on threshold. This removes the need for the bleeder

CC

resistor connected between the gate and the source of the external MOSFET normally

used to hold the pin low. The gate driver ensures low impedance in SD conditions as well.

10, 11 N.C. Not connected.

12 OUT O

High-side floating driver. Attention should be paid to the layout design of the power stage

so as to limit below-ground spikes on this pin.

High-side driver output. The output stage can deliver a 400 mA source and a 650 mA sink

(typical values). The circuit guarantees 0.3 V maximum between this pin and Vout (at

13 HVG O

= 10 mA) with V

I

sink

for the bleeder resistor connected between the gate and the source of the external

> 3 V and lower than the turn-on threshold. This removes the need

CC

MOSFET normally used to hold the pin low. The gate driver ensures low impedance in SD

conditions as well.

Bootstrapped supply voltage. This is the floating supply of the high-side driver. Includes a

14 V

BOOT

UVLO function (typically, V

between this pin and pin 12 can be fed by an internal structure named "bootstrap driver" (a

Bth1

= 11.9V, V

= 9.9 V). The bootstrap capacitor connected

Bth2

patented structure). This structure can replace the external bootstrap diode.

1. The pull-down internal resistor is typically some hundred kΩs.

= 10 mA) with

sink

10/25

Page 11

AN994 L6386E

Figure 7. L6386E - internal block diagram

Figure 8. L6386E - schematic diagram of the evaluation circuit

E

11/25

Page 12

L6386E AN994

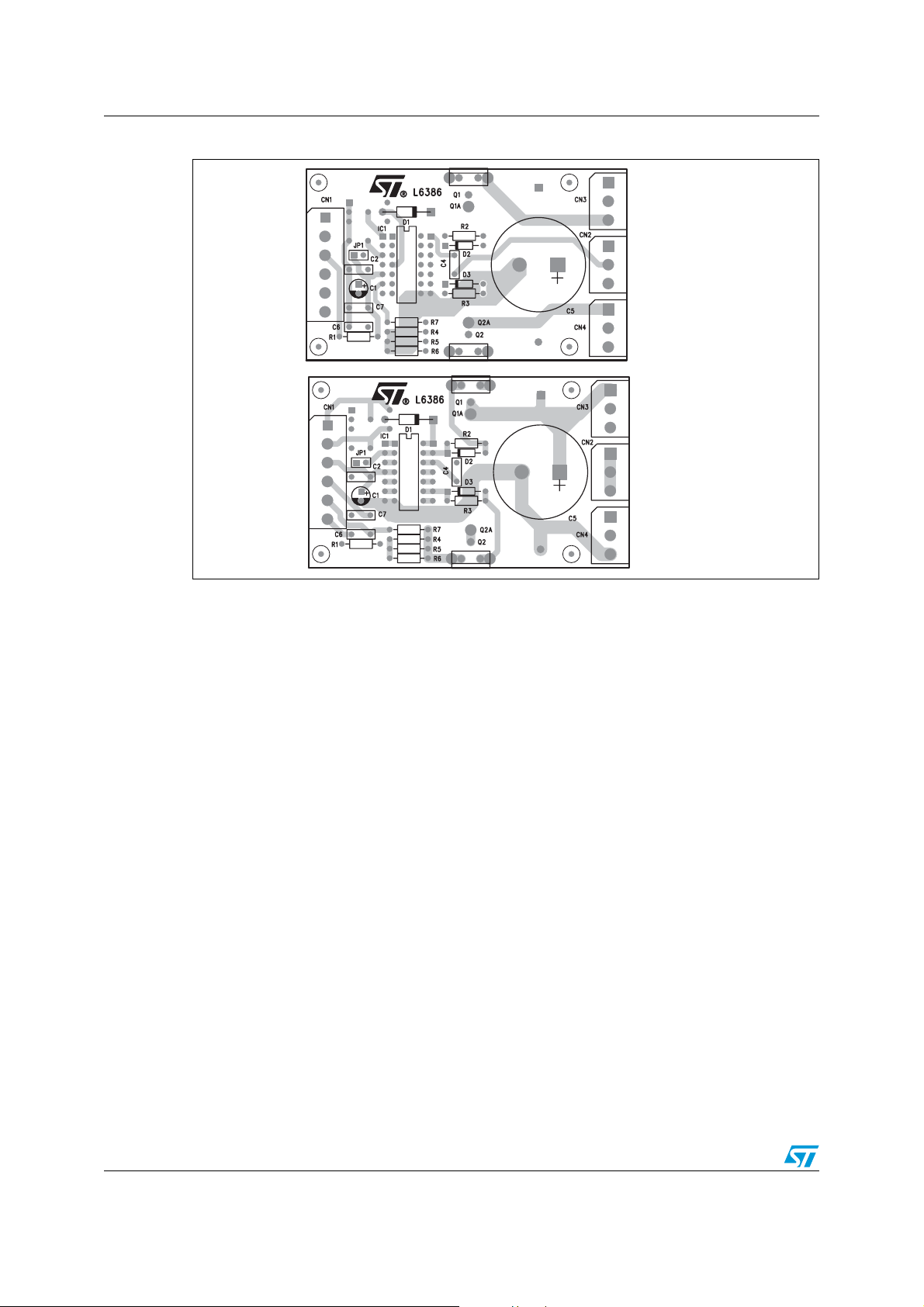

Figure 9. L6386E - PCB and component layout of the evaluation circuit

Top view

Bottom view

AM03417v1

12/25

Page 13

AN994 L6387E

4 L6387E

The L6387E (shown in Figure 10) is based on the structure of the L6385E. It has two

separate inputs and also includes an interlocking function to avoid both power switches from

being unintentionally switched on at the same time (see Ta bl e 5 ).

The V

turn-on and turn-off thresholds have been lowered to 6 and 5.5 V respectively

CC

(typical). There is no UVLO on the upper driving section.

The L6387E can be evaluated using the L6385E board.

Table 4. L6387E pin description

N. Name Type Function

1 LIN

2 HIN

3

4 GND Ground.

5 LVG O

6 OUT O

7 HVG O

(1)

I Low-side driver logic input. Compatible with VCC voltage (V

(1)

I High-side driver logic input. Compatible with VCC voltage (V

V

Supply input voltage (with very low UVLO: V

CC

ccth1

Low-side driver output. The output stage can deliver a 400 mA source and a 650 mA sink

(typical values). The circuit guarantees 0.3 V maximum on the pin (at I

V

> 3 V and lower than the turn-on threshold. This removes the need for the bleeder

CC

resistor connected between the gate and the source of the external MOSFET normally

used to hold the pin low.

High-side driver floating reference. Attention should be paid to the layout design of the

power stage so as to limit below-ground spikes on this pin.

High-side driver output. The output stage can deliver a 400 mA source and a 650 mA sink

(typical values). The circuit guarantees 0.3 V maximum between this pin and Vout (at

= 10 mA) with V

I

sink

> 3 V and lower than the turn-on threshold. This removes the need

CC

for the bleeder resistor connected between the gate and the source of the external

MOSFET normally used to hold the pin low.

= 6 V and V

il Max

il Max

ccth2

= 1.5 V, V

= 1.5 V, V

= 5.5 V)

sink

= 3.6 V).

ih Min

= 3.6 V).

ih Min

= 10 mA) with

Bootstrap supply voltage. This is the floating supply of the high-side driver. The bootstrap

8 V

BOOT

capacitor connected between this pin and pin 6 can be fed by an internal structure named

"bootstrap driver" (a patented structure). This structure can replace the external bootstrap

diode.

1. The pull-down internal resistor is typically some hundred kΩs.

13/25

Page 14

L6387E AN994

Figure 10. L6387E - internal block diagram

Table 5. Truth table

INPUT HIN 0 0 1 1

LIN 0 1 0 1

OUTPUT HVG 0 0 1 0

LVG 0 1 0 0

14/25

Page 15

AN994 L6388E

5 L6388E

The L6388E (see Figure 11) is based on the structure of the L6385E. It has two separate

inputs that are 3.3-V compatible, a fixed dead time of approximately 320 ns and an

interlocking function to avoid both power switches from being unintentionally switched on at

the same time (seeTa b le 5 ).

The UVLO thresholds of V

CC

and V

are the same as for the L6385E.

BOOT

The L6388E can be evaluated using the L6385E board.

Table 6. L6388E pin description

N. Name Type Function

1 LIN

2 HIN

3 V

4 GND Ground

5 LVG O

6 VOUT O

7HVG O

(1)

I Low-side driver logic input. Compatible with the VCC voltage (V

(1)

I High-side driver logic input. Compatible with the VCC voltage (V

CC

Supply input voltage with UVLO (typical V

= 9.6 V and typical V

ccth1

Low-side driver output. The output stage can deliver a 400 mA source and a 650 mA sink

(typical values). The circuit guarantees 0.3 V maximum on the pin (at I

3 V and lower than the turn-on threshold. This removes the need for the bleeder resistor

connected between the gate and the source of the external MOSFET normally used to hold the

pin low.

High-side driver floating reference. Attention should be paid to the layout design of the power

stage so as to limit below-ground spikes on this pin.

High-side driver output. The output stage can deliver a 400 mA source and a 650 mA sink

(typical values). The circuit guarantees 0.3 V maximum between this pin and V

mA) with V

>3 V and lower than the turn-on threshold. This removes the need for the bleeder

CC

resistor connected between the gate and the source of the external MOSFET normally used to

hold the pin low.

il Max

il Max

= 1.1 V, V

= 1.1 V, V

= 8.3 V).

ccth2

= 10 mA) with V

sink

ih Min

ih Min

out

= 1.8 V).

= 1.8 V).

(at I

sink

CC

= 10

>

Bootstrap supply voltage. This is the high-side driver floating supply (with UVLO: typical V

8V

BOOT

= 9.5 V, V

fed by an internal structure named "bootstrap driver" (a patented structure). This structure can

= 8.2 V). The bootstrap capacitor connected between this pin and pin 6 can be

BSth2

replace the external bootstrap diode.

1. The pull-down internal resistor is typically some hundred kΩs.

BSth1

15/25

Page 16

L6388E AN994

Figure 11. L6388E internal block diagram

16/25

Page 17

AN994 Bootstrap driver

6 Bootstrap driver

A bootstrap circuitry is required to supply the high voltage section. This function is normally

accomplished by a high-voltage fast recovery diode (see Figure 12). In the L638xE, a

patented integrated structure replaces the external diode. This structure is comprised of a

high-voltage DMOS—driven synchronously with the low-side driver (LVG)—with a diode in

series, as shown in Figure 13.

An internal charge pump (also shown in Figure 13) provides the DMOS driving voltage. The

diode connected in series to the DMOS has been added to avoid current flowing in the

opposite direction.

6.1 C

To choose the proper C

capacitor. This capacitor C

The ratio between the capacitors C

loss. It must be:

For example, if Q

would be 300 mV. If HVG needs to be supplied for a long time, the C

to take into account the leakage losses.

Another example: HVG’s steady state consumption is lower than 200 µA (which is the case

for L6385E, L6386E and L6388E, whereas for L6384E and L6387E it is lower than 100 µA).

Therefore, if HVG t

capacitor means a voltage drop of 1 V.

The internal bootstrap driver provides great advantages; it avoids use of the external fast

recovery diode (which usually has a high leakage current). This type of structure can only

work if V

of C

charge the capacitor.

BOOT

selection and charging

value the external MOSFET can be seen as an equivalent

BOOT

is related to the total gate charge of the MOSFET.

EXT

Q

C

EXT

and C

EXT

C

BOOT

is 30 nC and V

gate

is 5 ms, C

on

is close to GND (or lower) and while the LVG is ON. The charging time (T

OUT

is the time it takes for both conditions to be fulfilled and must be long enough to

BOOT

BOOT

is 10 V, C

gate

has to supply 1 µC to C

gate

-------------- -=

V

gate

is proportional to the cyclical voltage

BOOT

>>>C

EXT

is 3 nF. With C

EXT

. This charge on a 1-µF

EXT

= 100 nF the drop

BOOT

selection also has

BOOT

charge

)

The bootstrap driver introduces a voltage drop due to the DMOS R

(typical for L638xE

DS(on)

is 125 Ω). At low frequencies this drop is negligible, but when the frequency is increased it

must be taken into account.

The following equation is useful to compute the drop on the bootstrap DMOS.

Q

gate

-------------------

V

dropIch eargRDS on()Vdrop

Q

is the gate charge of the external power MOSFET, R

gate

bootstrap DMOS, and T

is the charging time of the bootstrap capacitor.

charge

17/25

=→⋅=

T

ch earg

R

DS on()

is the ON resistance of the

DS(on)

Page 18

Bootstrap driver AN994

For example, using a power MOSFET with a total gate charge of 30 nC, the drop on the

bootstrap DMOS is about 1 V if T

charge

is 5 µs.

In fact:

30 nC

-------------- -

V

drop

V

must be taken into consideration when the voltage drop on C

drop

5 µs

125 Ω 0.8 V≈⋅=

is calculated. If the

BOOT

drop is too high or the circuit topology does not provide for a sufficient charging time (like the

examples shown in Figure 18, Figure 19 and Figure 20), an external diode can be used.

This is the reason why the external diode D1 is dotted in Figure 2, Figure 5 and Figure 8.

When operating at very low frequencies, the high-side ON time can be very long. The

C

voltage can drop because of the steady state consumption of the HGV. To avoid

BOOT

having to use extremely large capacitors (> 1 to 2 µF), an external charge pump can be

added (see Figure 14 as an example). The diodes are signal diodes because the high

voltage drops on C1 and C2. It is mandatory that the diodes have a low parasitic

capacitance because C1 and C2 have to be greater than the diodes’ capacitance. The

oscillator has to balance the consumption of the high-voltage side and the minimum

frequency is fixed by the values of C1 and C2 (with C1 and C2 = 33 pF -> f > 250-300 kHz).

Additionally, the oscillator has to be able to sustain the dV/dt of the OUT pin.

Figure 12. External bootstrap diode: principle

schematic

Figure 13. Internal bootstrap diode: principle

schematic

18/25

Page 19

AN994 Bootstrap driver

Figure 14. External charge pump

HV

VBOOT

Cboot

200nF

LOAD

L638x

HVG

OUT

E

LVG

GND

330pF

VCC

C1

33pF

HCF4069UB

C2

33pF

Cx

19/25

Page 20

Application examples AN994

7 Application examples

This section provides several application suggestions that highlight the versatility and

flexibility of this family of high- and low-side drivers. Their simplicity and compactness make

these devices a cost-effective solution.

For further information on these ICs, refer to the following documents.

● AN1263: "Using the internal bootstrap current capability of the L638xE in driving a six

transistor inverter bridge".

● AN1299: "L638xE tricks and tips".

Figure 15. L6384E µC 3-phase motor control

E

E

E

20/25

Page 21

AN994 Application examples

Figure 16. L6384E dimmable lamp ballast

E

Figure 17. L6384E half bridge converter

E

21/25

Page 22

Application examples AN994

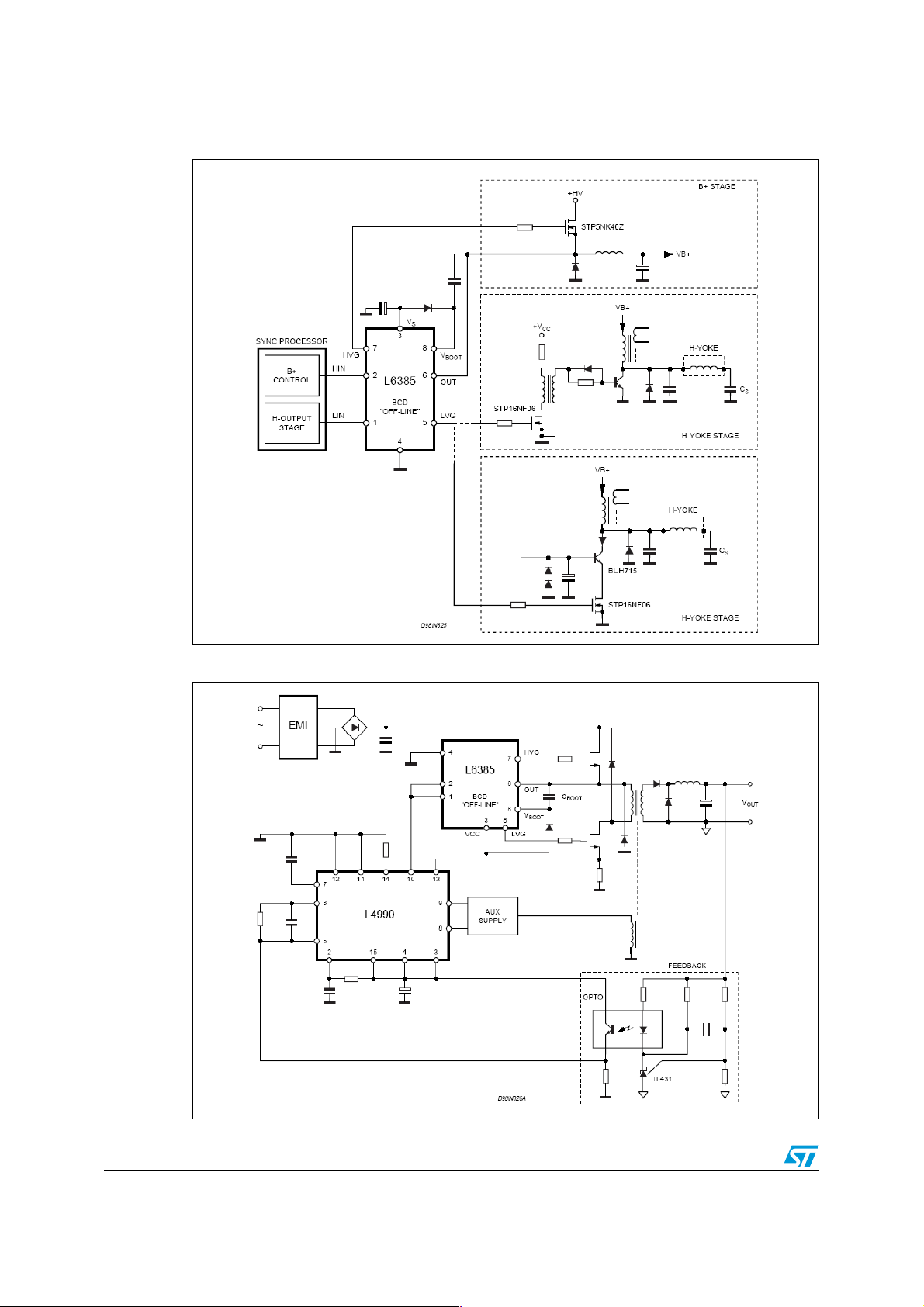

Figure 18. L6385E horizontal deflection stage

E

Figure 19. L6385E 2-switch forward converter

E

22/25

Page 23

AN994 Application examples

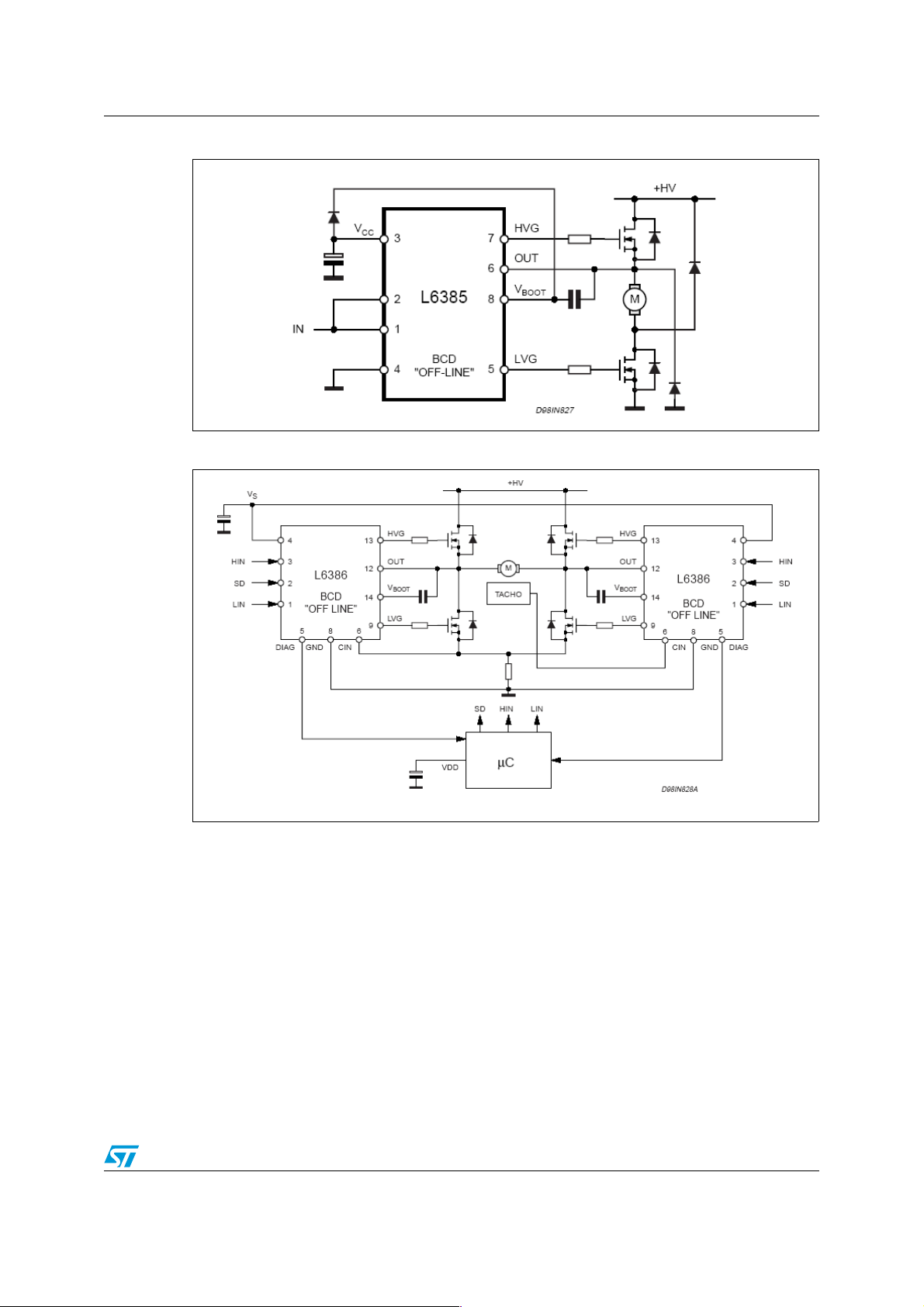

Figure 20. L6385E asymmetrical half bridge

E

Figure 21. L6386E h-bridge with cycle-by-cycle control

E

E

23/25

Page 24

Revision history AN994

8 Revision history

Table 7. Document revision history

Date Revision Changes

09-Sep-2004 6 Minor text changes

Added: Section 5: L6388E

17-Feb-2009 7

– L6384 replaced by L6384E, L6385 replaced by L6385E, L6386

replaced by L6386E, L6387 replaced by L6387E, L6388 replaced

by L6388E, L638x replaced by L638xE.

24/25

Page 25

AN994

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2009 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

25/25

Loading...

Loading...