Page 1

AN987

APPLICATION NOTE

ST7 SERIAL TEST CONTROLLER PROGRAMMING

by Microcontroller Division Applications

INTRODUCTION

This application note describes:

– The advantages of Serial Test Controller Programming (STCP) vs. programming using an

EPROM programming board (EPB) (see Sec tion 2.1).

– How to implement Serial Test Controller Programming targeting most of the ST7 general pur-

pose microcontrollers (see Section 2.2). These devices include all parts supported by the

ST7 starter kits and ST7 EPBs in the MDT1, MDT2 and MDT4 tool families (see the supported device list in APPENDIX 1).

Note: In this applicatio n note, the term “programming tool” refers to either the EPBs or the

starter kits.

1 PROGRAM M ING TECHNIQU ES

There are two possible ways of programming an ST7 device:

■ Using a programming tool. In this case, the device is first plugged on the programming board

and then programmed. Then, the part is soldered or plugged into a socket on the user board.

This can be done using any of the following ST7 programming tools:

– ST7 Starter Kit

– ST7 EPB (EPROM Programming Board)

– ST7 Gang Programmer

For further details about the above tools, please refer to the user manual supplied with these

devices.

■ Using a Serial Test Controller Programming (STCP) tool. This technique allows a device to

be directly programmed on the user board. This is a two-step procedure where first the

board is first manufactured with a blank ST7, and afterwards the chip is programmed using

a programming tool (Starter Kit or EPB).

This application note describes the STCP method only.

AN987/1000 1/10

1

Page 2

ST7 SERIAL TEST CON TR OLLER PROGR AMM IN G

2 SERIAL TEST CONTROLLER PROGRAMMING

2.1 ADVANTAGES

The advantages of STCP are numerous:

■ Time to market

To reduce manufacturing cycle times, a user board can be designed to be generic,

supporting several functions. These functions can be enabled or disabled by software

according to customer requirements. In this case, STCP allows application boards to be

manufactured in one shot and programmed w ith different functions according to customer

needs and orders.

■ Cost reduction

Software updates may be necessary in some cases because of a bug correction or a newly

implemented feature. The STCP is a flexible and painless way of performing such

modifications and at a lower cost. There is no need to add any sockets to the board or to

unsolder and change components in order to upgrade the application.

■ Security

Because STCP offers an easy w ay to custom ise the user’s program, or part of it, it can be

used to insert different key codes for each board. This could be used, for example, i n a door

lock sys te m.

■ Flexibility

For example, STCP can be used to allow calibration procedures to be performed directly in

the field.

2.2 USER BOARD S PECIFICATION

The user has to design his layout in order to support two modes: programming mode and user

mode.

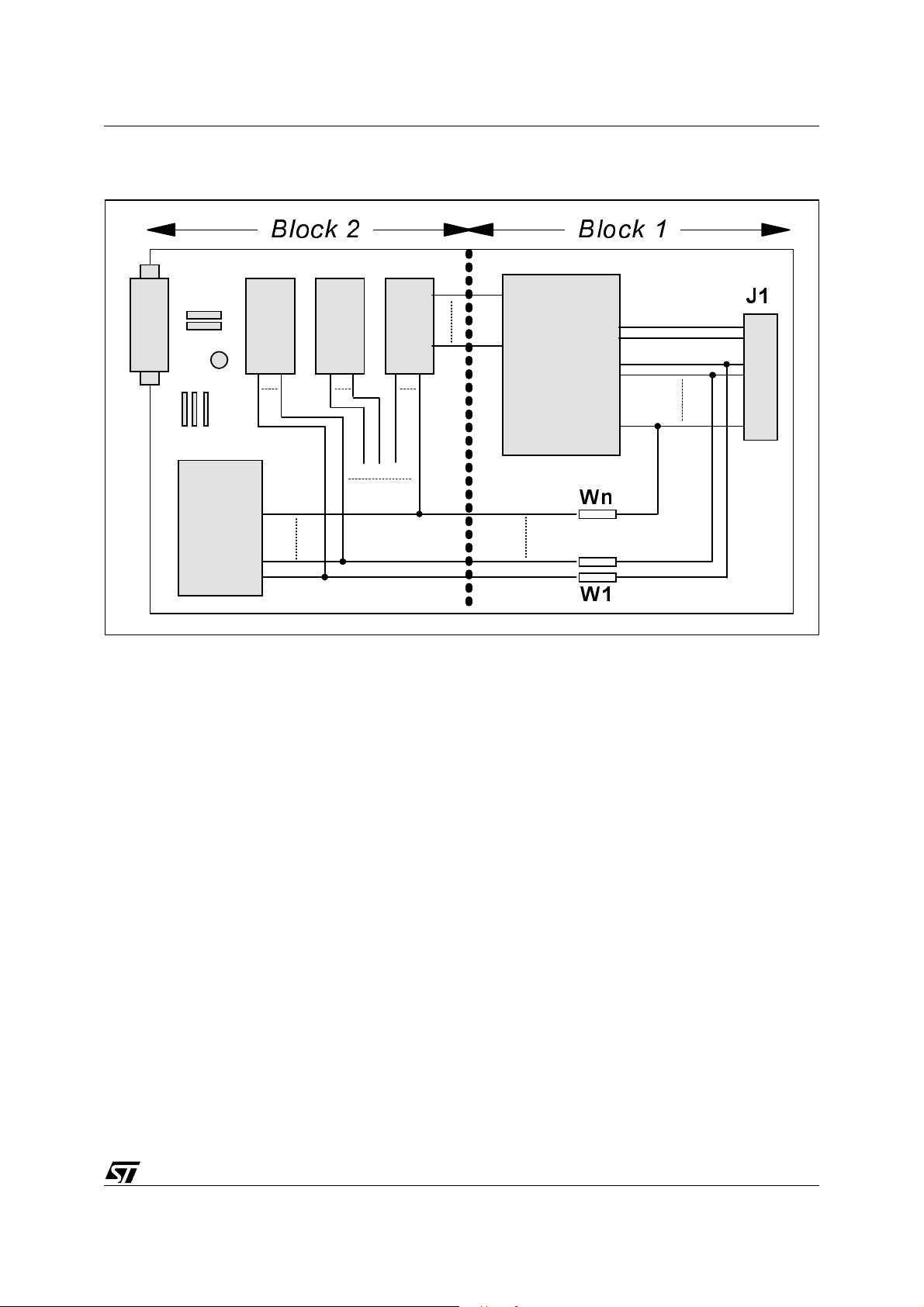

Figure 1. shows the user board divided into two blocks:

■ Block 1:

Includes all the components that play a role during programming mode:

– Connector J1, which links the user board to the programming tool.

– The ST72 MCU, which is the device to be programmed.

– Jumpers W1 to Wn, whose purpose is to isolate the pins used for programming the ST72

from the other components in Block 2. In some application configurations, isolation resistors (47 kΩ) can be used instead of jumpers.

■ Block 2:

This block consists of all the other components soldered on the user board.

2/10

2

Page 3

Figure 1. User Board

ST7 SERIAL TEST CONTROLLER PROGRAMMING

%ORFN %ORFN

-

67

:Q

:

Now, let’s define the pins used for pr ogrammin g the ST7. T hese pins a re put tog ether in the

W1 connector implemented in all the ST programming tool boards (see Section 3 APPENDIX

1 for the pin connector assignment).

All the ST7 programming tools referred to in this note (ST7 starter kits and ST7 EPBs in the

MDT1, MDT3 and MDT4 tool families) use a programming technique called JTAG (Joint Test

Action Group).

These programming tools control 11 pins:

■ 5 JTAG pins and 3 test mode pins, which are used for loading the software code into the

ST7. These pins are:

– Pin TCK: the test clock (input),

– Pin TMS: the Test Mode Select (input, weak pull-up),

– Pin TRST0: the Reset (Input, weak pull-up, active low)

– Pin TDI: the Test Data In (input, weak pull-up). This is the serial data input, sampled on

the rising edge of TCK.

– Pin TDO: the Test Data Out (tri-state output). This is the serial data output, updated on the

falling edge of TCK.

– Pins M0, M1 and M2: These 3 pins are used to force the test modes.

Depending on the d evice selected, t hese 8 pins will be as sociated with different p in num -

bers (see APPENDIX 1).

3/10

Page 4

ST7 SERIAL TEST CON TR OLLER PROGR AMM IN G

If these pins need to be tied to VDD or VSS, or if they are us ed by the user’s application, they

must be isolated from the user circuitry during programming. To do so, a jumper can be

added for each of the eight pins (see Figure 2.).

Note: Isolation resistors (47 kΩ) can be used instead of jumpers only if these pins are used

by the application as input (without Pull-up, without pull-down, or analog input configuration).

■ 3 system pins, VPP/TEST, RESET and OSCIN, which must be connec ted as follows:

– The VPP/TEST pin must not be directly connected to GND/V

on the application board

SS

in order to avoi d any confl ict with the programming voltage. T his pin should be pulled down

by a 10 kΩ resistor (see Figure 2.).

– The RESET

pin controls the entry into programming mode. This pin must be connected to

a 10 kΩ pull-up resistor and a 1 nF c apacitor connected to GND ( see Figure 2.) to av oid

any direct connections to V

. This pin can be connected to a 47 kΩ isolation resistor if an

SS

external reset is provided by the application board.

– The OSCIN pin synchronizes the programming operation using a clock generated by the

programming tool. The OSCIN pin can be directly connected to the J1 connector. No isolation is needed as long as a quartz crystal or ceramic resonator is used in the application.

If an external clock generator is used in the application, it must be disconnected during

STC programming.

Note: The OSCOUT pin does not need to be disconnected during the programming phase

as long as a crystal, a ceramic resonator or an external clock source is used to drive the

internal oscillator (user mode only).

■ The V

and VSS power supply pins. The use of the VDD connection is optional, depending

DD

on whether the application board supply can be disconnected or not.

If the application board supply is disconnected, the chip can be supplied through the

programming tool (as long as the total current load does not exceed 100 mA and the

capacitive load is less than 50 µF). In this case, only 1 jumper needs to be added in order to

disconnect the VPP pin from the user circuitry during the programming sequence. No jumper

is needed for V

(see Figure 2.).

SS

If you want to use the application board power supply, its voltage must be 5 V, so that logic

levels are compatible with those of the programming tool.

Note: In any case, the ground from the application board and the ground from the

programming tool must be connected together (see Figure 2.).

4/10

Page 5

Figure 2. Block 1

ST7 SERIAL TEST CONTROLLER PROGRAMMING

To

block2

VDD appli

To

block2

10 kΩ

10 kΩ

M0

M1

M2

/TEST

V

PP

V

DD

Reset

OSCIN

OSCOUT

V

SS

Tck

Tms

Trst0

Tdi

Tdo

J1

Jumper or 47 kΩ isolation resistor

(depending on the application configuration, refer to the note on page 3).

Jumper use to disconnect the Application board supply if it is not 5 V.

If the application board supply can be used, remove this jumper and

remove the connection between pin VDD and connector J1.

The ST7 programming tool is connected to the user board via connector J1.

5/10

Page 6

ST7 SERIAL TEST CON TR OLLER PROGR AMM IN G

2.3 PROGRAMMING PROCEDURE

Depending on the device you need to program, use one of these ST7 programming tools:

■ ST7 MDT1-KIT or ST7 MDT1- EPB. They cover the following devices:

– ST72101G1 or G2

– ST72212G2

– ST72213G1

– ST72251G1 or G2

■ ST7 MDT2-KIT or ST7 MDT4- EPB. They cover the following devices:

– ST72121J2 or J4

– ST72311J2 or J4

– ST72311N2 or N4

– ST72331J2 or J4

– ST72331N2 or N4

■ ST7 MDT4-KIT or ST7 MDT4-EPB. They cover the following devices:

– ST72272K2 or K4

– ST72372J4

– ST72371N4

– ST72671N4 or N6

After selecting the appropriate programming tool, proceed as follows:

1. On the application board, remove all jumpers.

2. Locate the 16 pin connector W1 (8x2 header HE10) on the programming tool which contains the 12 signals necessary for performing STCP (see Section 3 APPENDIX 1 for the pin

identification).Then connect the W1 connector of the pr ogramming tool to the application

board connector (J1 in Figure 1.).

3.Using the parallel interface cable, connect the PC parallel port to the parallel connector of

the programming tool.

4.Power on the PC and the board. On the programming tool, LED 1 must light up.

5.Start the Windows EPROMer, target the programming tool, then the correct device. Open

the file containing the code to program. And... program your device!

6. Close the operating software, power down the programming tool, disconnect the application board from the programming tool and replace any jumpers that were disconnected on

the application board. Your application is now ready to run!

6/10

Page 7

ST7 SERIAL TEST CONTROLLER PROGRAMMING

3 APPENDIX 1

The following table lists the devices supported by this application note and the specific starter

kit required for each sales type.

Sales Type Starter Kit supporting the device

ST72x101G1

ST72x101G2

ST72x212G2

ST72x213G1

ST72x251G1

ST72x251G2

ST72x121J2

ST72x121J4

ST72x311J2

ST72x311J4

ST72x311N2

ST72x311N4

ST72x331J2

ST72x331J4

ST72x331N2

ST72x331N4

ST72x272K2

ST72x272K4

ST72x371N4

ST72x372J4

ST72x671N4

ST72x671N6

ST7 MDT1 Starter kit or EPB

ST7 MDT2 Starter kit or EPB

ST7 MDT4 Starter kit or EPB

x = T, if the device is an OTP,

E, if the device is an EPROM.

7/10

Page 8

ST7 SERIAL TEST CON TR OLLER PROGR AMM IN G

4 APPENDIX 2

This appendix provides t he required i nformati on for pr ogrammin g a device suppor ted by the

MDT1, MD T2 and MD T4 E PBs or s ta rter k its. T he fiv e JT AG pins an d t hree test mod e p ins

(M0, M1 and M2) with their associated pin numbers are specified for each device.

4.1 ST7 MDT1 EPB OR STARTER KIT

ST7 Device Pin Numbers

JTDI

JTCK

JTRST

JTMS

Sales type EPROM E2RAM Package

ST72x101G1 4K - 256

ST72x101G2 8K - 256

ST72x212G2 8K - 256

ST72x213G1 4K - 256

ST72x251G1 4K - 256

ST72x251G2 8K - 256

SO28

SDIP322226232724282529141691110121113263011

SO28

SDIP322226232724282529141691110121113263011

SO28

SDIP322226232724282529141691110121113263011

SO28

SDIP322226232724282529141691110121113263011

SO28

SDIP322226232724282529141691110121113263011

SO28

SDIP322226232724282529141691110121113263011

PA3

PA2

PA1

Programming tool W1 connector 5 1 9 3 7 12 10 8 16 4 2 N.C 15

JTDO

PA0

PC3M2PB2M1PB1M0PB0

Vpp Reset Oscin Vdd Vss

22283227

31

22283227

31

22283227

31

22283227

31

22283227

31

22283227

31

x = T, if the device is an OTP,

E, if the device is an EPROM,

N.C., means not connected.

8/10

Page 9

4.2 ST7 MDT2 EPB OR STARTER KIT

ST7 Device Pin Numbers

Sales type EPROM E

ST72x121J2 8K - 384

ST72x121J4 16K - 512

ST72x311J2 8K - 384

ST72x311J4 16K - 512

ST72x311N2 8K - 384

ST72x311N4 16K - 512

ST72x331J2 8K 256 384

ST72x331J4 16K 256 512

ST72x331N2 8K 256 384

ST72x331N4 16K 256 512

Programming tool W1 connector 5 1 9 3 7 12 10 8 16 4 2

2

RAM Package

TQFP44

SDIP4237303629

TQFP44

SDIP4237303629

TQFP44

SDIP4237303629

TQFP44

SDIP4237303629

TQFP64

SDIP5652405139

TQFP64

SDIP5652405139

TQFP44

SDIP4237303629

TQFP44

SDIP4237303629

TQFP64

SDIP5652405139

TQFP64

SDIP5652405139

ST7 SERIAL TEST CONTROLLER PROGRAMMING

JTDI

JTCK

PA7

JTRST

PA6

PA5

35

28

35

28

35

28

35

28

50

38

50

38

35

28

35

28

50

38

50

38

JTMS

JTDO

PA4

PA3M2PB2M1PB1M0PB0

342731244413402393831393242

342731244413402393831393242

342731244413402393831393242

342731244413402393831393242

493746347556545535341544259

493746347556545535341544259

342731244413402393831393242

342731244413402393831393242

493746347556545535341544259

493746347556545535341544259

Vpp Reset Oscin

35

35

35

35

45

45

35

35

45

45

4.3 ST7 MDT4 EPB OR STARTER KIT

ST7 Device Pin Numbers

JTDI

JTCK

JTRST

JTMS

Sales type EPROM E2RAM Package

ST72x272K2 8K - 384

ST72x272K2 16K - 512

ST72x371N4 16K - 512

ST72x372J4 16K - 512 SDIP42 34 35 36 37 31 2 1 42 41 40 33 25 23

ST72x671N4 16K - 512

ST72x671N6 32K - 1K

SO34

SDIP32292730283129323025243322113432333128268877

SO34

SDIP32292730283129323025243322113432333128268877

TQFP64

SDIP56284629473048314920384334224114056385427451131929

TQFP64

SDIP56284629473048314920384334224114056385427451131929

TQFP64

SDIP56284629473048314920384334224114056385427451131929

PA7

PA6

PA5

Programming tool W1 connector 5 1 9 3 7 12 10 8 16 4 2 N.C 15

x = T, if the device is an OTP,

E, if the device is an EPROM,

N.C., means not connected.

JTDO

PA4

PC6M2DA3M1DA2M0DA1

Vpp Reset Oscin Vdd Vss

9/10

Page 10

ST7 SERIAL TEST CON TR OLLER PROGR AMM IN G

THE PRESENT NOTE WHICH IS FOR GUIDANCE ONLY AIMS AT PROVIDING CUSTOMERS WITH INFORMATION

REGARDING THE IR PRO DUCT S IN OR DER FO R THEM TO SAV E TIME . AS A RES ULT, STMIC ROEL ECTR ONI CS

SHALL NOT BE HELD LIABLE FOR ANY DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES WITH RESPECT TO

ANY CLAIMS ARISING FROM THE CONTENT OF SUCH A NOTE AND/OR THE USE MADE BY CUSTOMERS OF

THE INFORMATION CONTAINED HEREIN IN CONNEXION WITH THEIR PRODUCTS."

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or patent ri ghts of STM i croelectr oni cs. Specifications mentioned in thi s publicati on are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri tical comp onents in life support dev i ces or systems wi thout the express written approv al of STMicroel e ctronics.

The ST logo is a registered trademark of STMicroelectronics

Purchase of I

Australi a - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malt a - Morocco - Singapore - Spain

2

C Components by STMicroelectronics conveys a license under the Philips I2C Patent. Rights to use the se components in an

2

I

C system i s granted pro vid ed that the sy stem conforms to the I2C Standard Specification as defined by Philips.

2000 ST Microelectronics - All Rights Reserved.

STMicroelectronics Group of Compan i es

Sweden - Switzerland - United K i ngdom - U.S. A.

http://www.s t. com

10/10

Loading...

Loading...