Page 1

AN934

Application note

How to use the digital calibration feature in

TIMEKEEPER

Introduction

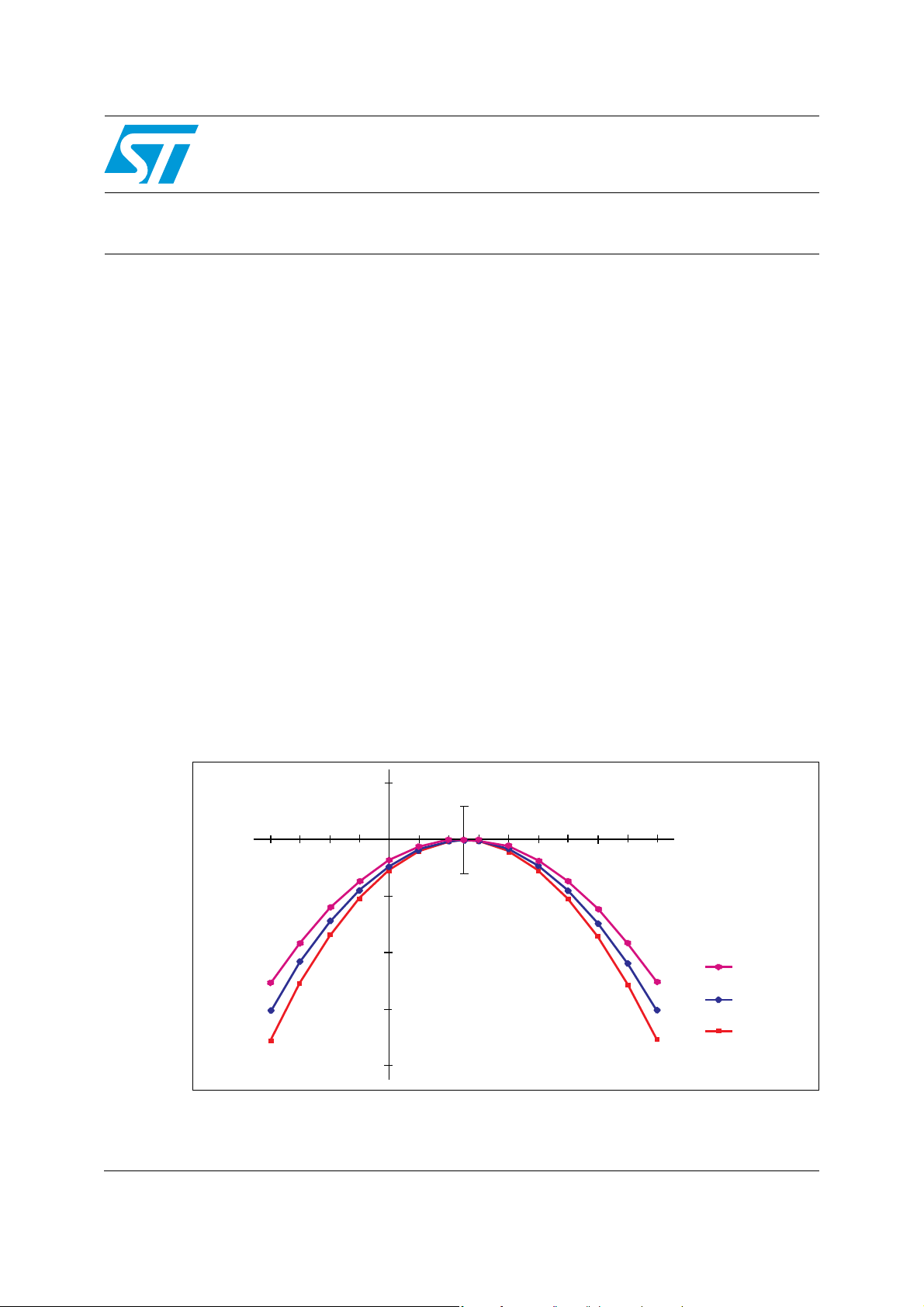

The term “quartz accurate” has become a familiar phrase used to describe the accuracy of

many time keeping functions. Quartz oscillators provide an accuracy far superior to other

conventional oscillator designs, but they are not perfect. Quartz crystals are sensitive to

temperature variations. Figure 1 shows the relationship between accuracy (acc),

temperature (T), and curvature (K) for the 32,768Hz crystal used on STMicroelectronics

TIMEKEEPER

®

products. The curves follow this general formula:

®

and serial real-time clock (RTC) products

acc K T TO–()

×=

2

where T

= 25 °C ± 5 °C and K = –0.036 ppm/°C2 ± 0.006 ppm/°C2.

O

The clocks used in most applications require a high degree of accuracy, and there are

several factors involved in achieving this accuracy. Typically most crystals are compensated

by adjusting the load capacitance of the oscillator. This method, while effective, has several

disadvantages:

1. It requires external components (trim capacitors); and

2. it can increase oscillator current (an important factor in battery-supported applications).

STMicroelectronics replaced this crude analog method with a digital calibration feature. This

method gives the user software control over the calibration procedure which makes it user

friendly.

Figure 1. Typical crystal accuracy plotted against temperature (and against

different values of K)

50

+35 ppm

–30

–20

–10

–50

–100

10

0

30

20

–35 ppm

50 60 70 80

Temperature (°C)

9040–40

Minimum K at 25°C

Typical K at 25°C

–150

–200

Accuracy (ppm)

Maximum K at 25°C

AI02498

October 2011 Doc ID 6393 Rev 4 1/14

www.st.com

Page 2

Contents AN934

Contents

Methodology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Calculating the needed amount of calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Calculating calibration over a temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Calculating the calibration for multiple operating temperatures . . . . . . . . . . . . . . 9

Enabling the frequency test function (FT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Conclusion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2/14 Doc ID 6393 Rev 4

Page 3

AN934 List of figures

List of figures

Figure 1. Typical crystal accuracy plotted against temperature (and against different values of K) . . 1

Figure 2. Oscillator divider chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 3. Clock splitting and clock blanking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 4. Control register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 5. Crystal accuracy over a temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 6. A day of the week register (for parallel devices) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 7. 512 Hz output to DQ0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Doc ID 6393 Rev 4 3/14

Page 4

Methodology AN934

Methodology

The STMicroelectronics TIMEKEEPER® products are driven by a quartz crystal-controlled

oscillator with a nominal frequency of 32.768 kHz. The crystal is mounted in either a 600 mil

DIP CAPHAT™ package, 600 mil DIP hybrid, 300mil SOIC embedded crystal, or in a

330 mil SOIC SNAPHAT

accurate within ±1.53 minutes (±35 ppm - parts per million) per month at 25 °C without

calibration.

Two sources of clock error are:

● temperature variation

● crystal variation

As mentioned previously, most clock chips compensate for crystal frequency and

temperature shift error with cumbersome “trim” capacitors. The TIMEKEEPER design

employs periodic counter correction. The digital calibration circuit adds or subtracts counts

from the oscillator divider circuit at the 256 Hz stage (see Figure 2).

Figure 3 shows how extra clock pulses are added (by clock splitting) or removed (by clock

blanking). The number of times the pulses are split (added during positive calibration) or

blanked (subtracted during negative calibration) depends upon the value that has been

loaded into the least significant five bits of the control register. Adding counts speeds the

clock up while subtracting counts slows the clock down.

®

package, along with the battery. A typical TIMEKEEPER device is

Figure 2. Oscillator divider chain

32768Hz

Low

Current

Oscillator

512Hz Output

for Frequency Test

div 64

div 2

256Hz

Calibration

64 Minute

Figure 3. Clock splitting and clock blanking

No Calibration

Positive Clock Calibration

Negative Clock Calibration

Circuitry

Cycle

1Hz Signal

Clock

Registers

AI02801

AI02800

4/14 Doc ID 6393 Rev 4

Page 5

AN934 Methodology

The calibration byte occupies the five lower order bits in the control register, as shown in

Figure 4. These bits represent the binary value between 0 and 31. Table 1 on page 6 shows

how many seconds (or ppm) each bit represents in real time for the TIMEKEEPER

®

product

line. The sixth bit is a sign bit. A binary '1' indicates a positive calibration (added pulses), and

a binary '0' indicates a negative calibration (blanked pulses). Calibration occurs within a 64minute cycle. The first 62 minutes in the cycle may, once per minute, have one second either

shortened by 128 or lengthened by 256 oscillator cycles. If a binary '1' is loaded into the

register, only the first 2 minutes in the 64-minute cycle are modified; if a binary “6” is loaded,

the first 12 minutes are affected, and so on.

Therefore, each calibration step has the effect of adding 512 or subtracting 256 oscillator

cycles for every 125,829,120 actual oscillator cycles (64 minutes x 60 seconds/minute x

32,768 cycles/second). That is, +4.068 or –2.034 ppm of adjustment per calibration step in

the calibration register. Assuming that the oscillator is running exactly at 32.768kHz, each of

the 31 increments in the calibration byte represent +10.7 or –5.35 seconds per month, which

corresponds to a total range of +5.5 or –2.75 minutes per month.

As can be seen from Figure 1 on page 1, the peak of the curve corresponds to

approximately 25 °C. This is known as the “turnover temperature.” As the temperature rises

or falls from room temperature, the oscillator slows down. Typically the turnover point on the

graph is very close to 32.768 kHz (no error). However, variations from one crystal to another

may cause the turnover point to be slightly above or below 32.768 kHz. The frequency

variation for an uncalibrated device is a function of the crystal frequency variation for the

given load capacitance (C

). Thus, if the crystal has a CL that is different from the actual

L

internal load capacitance of the device, then the oscillator frequency will run faster or slower

than the 32.768 kHz (±1 Hz). At STMicroelectronics, the real-time clock has an internal

capacitance of 12.5 pF (except for the M41T6x series, which has an internal capacitance of

6 pF) across the crystal input pins. For this reason, the calibration feature can be

programmed to adjust for both negative and positive variations. Entering a value into the

6-bit calibration field of the control register will shift the entire curve up or down according to

the values found in Table1 on page6.

Figure 4. Control register

d7

(1)

x

AI05651

1. x = W (Parallel device); OUT (Serial device)

2. y = R (Parallel device); FT (Serial device)

d6

(2)

y

d5

S

Sign Bit

d4

Doc ID 6393 Rev 4 5/14

d3

d2

Calibration Value

d1

d0

Page 6

Methodology AN934

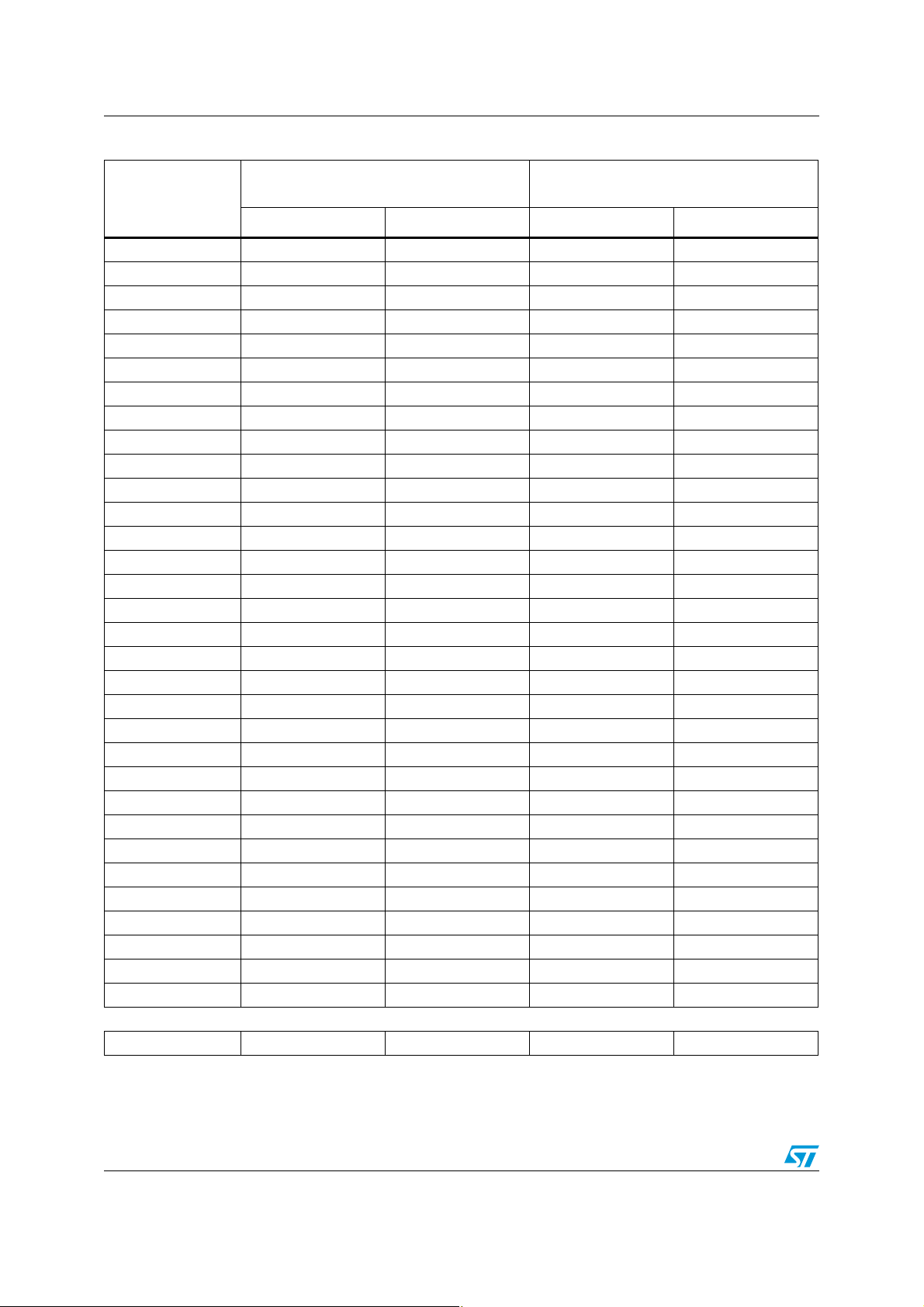

Table 1. Calibration table: compensation values in seconds per month (30 days) and in ppm

Calibration

value (binary)

00000 0 0 0 0

00001 11 5 4 2

00010 21 11 8 4

00011 32 16 12 6

00100 42 21 16 8

0010153262010

0011063322412

0011174372814

0100084423316

0100195473718

01010 105 53 41 20

01011 116 58 45 22

01100 127 63 49 24

01101 137 69 53 26

01110 148 74 57 29

01111 158 79 61 31

10000 169 84 65 33

10001 179 90 69 35

10010 190 95 73 37

10011 200 100 77 39

10100 211 105 81 41

10101 221 111 85 43

10110 232 116 89 45

10111 243 121 93 47

11000 253 127 98 49

11001 264 132 102 51

11010 274 137 106 53

11011 285 142 110 55

11100 295 148 114 57

11101 306 153 118 59

11110 316 158 122 61

11111 327 163 126 63

In general:

N 337*N/32 169*N/32 337*N/(32*2.592) 169*N/(32*2.592)

Value in seconds per month (30 days)

rounded to the nearest second

Plus Minus Plus Minus

rounded to the nearest ppm

Value in ppm

6/14 Doc ID 6393 Rev 4

Page 7

AN934 Calculating the needed amount of calibration

Calculating the needed amount of calibration

There are two methods for establishing how much calibration are required in a given

application.

The first method can be easily implemented in the user environment simply by setting the

clock to a known accurate reference and then storing the time in some unused location in

the RAM. Over a period of time (30 days), the reference time is compared to the current time

(the average ambient temperature should be considered as well). This will tell the user how

fast or slow the clock operates for a period of 30 days. While it may seem crude, it allows the

designer to give the end user the ability to calibrate the clock according to the specified

environment. The ability to calibrate the clock can also be accomplished even after the final

product is packaged in a non-user serviceable enclosure by providing a simple utility to

access the calibration byte.

Table 1 on page 6 provides a direct look-up table for calibration values based upon the

number of seconds lost or gained during a one month (30 day) period. For example, if the

system were to lose 20 seconds during one month, the needed calibration would be +20

seconds. The user could look up a +20 second value in the table under the appropriate

column. In this case, the nearest value is +21. The appropriate sign bit in this case is a

logical '1,' indicating the clock needs to speed up to compensate for the lost time. This yields

a calibration value of “100010.” In this example, the inaccuracy would be reduced from –20

seconds per month to +1 second per month.

The second approach is better suited for a manufacturing environment, and involves the use

of a special test mode (as described in the section entitled, “Enabling the frequency test

function (FT)” which derives a 512Hz signal from the clock divider chain, as indicated in

Figure 2. This signal can be used to measure the accuracy of the crystal oscillator. The

right-hand pair of columns in Table 1 on page 6 provides a look-up table similar to that in the

left-hand pair of columns, except that the error values are expressed in “ppm” units instead

of seconds per month. The error in ppm can be quickly calculated by dividing the measured

error from 512 Hz by 512 and multiplying the result by 1 million. For example, if the

frequency measured during the test mode is 511.998 Hz, the delta is –0.002. Dividing by

512 and multiplying by 1 million, the result is –3.906 ppm. In this case, the nearest

compensation value is a +4.068. The appropriate sign bit in this case is a logical '1,'

indicating the clock needs to speed up to compensate for the lost time. This yields a

calibration value of “100001.”

Doc ID 6393 Rev 4 7/14

Page 8

Calculating calibration over a temperature range AN934

Calculating calibration over a temperature range

The calibration procedure described so far has centered around calculating the correction

for a specific temperature. This section considers the procedure for minimizing the

frequency error over a wider temperature range. This involves adjusting the frequency curve

so that there is an equal amount of error above and below the zero (0) ppm point. Figure 5

shows how the frequency error can be minimized over a given temperature range.

The variables in the equation (see Introduction on page 1) are as follows:

K = Curvature characteristic = –0.036 ppm/°C

2

± 0.006 ppm/°C

acc = Accuracy, in ppm, of the frequency, at the turnover temperature

T

= Turnover temperature, in degrees Celsius = 25 °C ± 5 °C

O

T = Working temperature, in degrees Celsius

For example, if a device is in error by +20 ppm at room temperature, but will actually operate

at –20 °C in the application, the equation on page 1 may be used to calculate the required

calibration value as follows:

acc = 20 ppm + (–0.036ppm/°C

2

) * (–20°C – 25°C)

2

acc = –52.9 ppm

Since the unit will be slow by 52.9 ppm, the required correction is +52.9 ppm, and this can

be looked up in Table 1 on page 6; the nearest value is a +53. The appropriate sign bit in

this case is a logical '1,' indicating the clock needs to speed up to compensate for the lost

time. This yields a calibration value of “101101.”

2

Figure 5. Crystal accuracy over a temperature range

50

20

–30

–20

–10

–50

–100

–150

–200

10

0

Accuracy (ppm)

30

20

50 60 70 80

After calibration

9040–40

Temperature °C

Before calibration

AI02499

8/14 Doc ID 6393 Rev 4

Page 9

AN934 Calculating the calibration for multiple operating temperatures

Calculating the calibration for multiple operating temperatures

For applications that spend significant time at more than one temperature, the following

equation may be used to calculate the appropriate amount of calibration required:

N

t

t

acc K TiTo–()

PERi

Σ

i1=

×+()106–×=

2

where:

K = Curvature characteristic = –0.036 ppm/°C

2

± 0.006 ppm/°C

2

acc = Accuracy, in ppm, of the frequency, at the turnover temperature

T

= Turnover temperature, in degrees Celsius = 25°C ± 5°C

O

T

= Working temperature, in degrees Celsius

i

t

= Amount of time it is in the temperature range (in seconds)

PERi

t = Amount of time lost during t

PERi

N = Number of temperature ranges

Consider a piece of portable equipment used outdoors for 8 hours per day, then stored at

room temperature for the remainder of the day. The equation below calculates the

calibration value at –20°C for a period of 8 hours and then room temperature for the rest of

the day for a device that is currently in error by +5 ppm at room temperature:

8hours 28800 ondssec=

16h o u r s 57600 o n d ssec=

2

28800 ssec()50.036– ppm

=

57600 ssec()50+()×[]

°C2⁄()20° C25°C––()

×()+()×[]

6–

10

}

×

+{

t1.67– ssec day⁄=

The unit is losing 1.67 seconds per day (or 50 seconds per month). The appropriate sign bit

in this case is a logical “1,” indicating the clock needs to be sped up to compensate for the

lost time. This yields a calibration value of “100101.”

Doc ID 6393 Rev 4 9/14

Page 10

Enabling the frequency test function (FT) AN934

Enabling the frequency test function (FT)

Figure 4 and 6 show the location of the Frequency Test (FT) bit, DQ6, of the day-of-the-

week register for the parallel device or DQ6 in the control register for the serial device.

Setting the FT bit to a '1' turns on the frequency test mode. The user needs to make sure

that the Stop (ST) bit in the second register, is set to a '0.' Exactly where the 512 Hz signal is

output depends on which TIMEKEEPER

the M48T02, M48T12, M48T08, M48T18, and M48T35 devices, the 512 Hz signal is output

on the DQ0 pin when the device is reading the Seconds register. The address and control

signals must be valid during the measurement process, as shown in Figure 7 on page 10.

On the M41T62, M41T63, and M41T64, the 512 Hz signal is output on the SQW pin. To

enable the 512 Hz signal, the SQWE bit = 1 (DQ6 of the alarm month register), RS3 = 0,

RS2 = 1, and RS1 = 0 (DQ7-DQ4 in the day register). The SQW output pin is an open drain

output for M41T64 and a full CMOS output for the M41T62 and M41T63.

For all other devices listed in Tab le 2 , the 512 Hz signal is output on the FT/OUT, FT,

IRQ

/FT, and IRQ/FT/OUT pins. These outputs are open drain, and require a pull-up resistor.

A 500 Ω to 10 kΩ resistor is recommended in order to control the rise time. Measurement

should be taken from negative edge to negative edge due to the slow rise time on the

positive edge. If the IRQ

function is enabled, the FT function is inhibited.

®

device is being used, as indicated in Tab le 2 . On

Note: Setting or changing the calibration byte does not affect the frequency test output frequency

as the adjustment is made at the 256 Hz stage.

Once the amount of calibration has been determined, either from the test mode or by

monitoring it over a period of time, the user can enter the values from the calibration tables

into the control register.

Figure 6. A day of the week register (for parallel devices)

d4

d7

Freq.

Test Bit

d5

d6

FT

d3

d2

Day of the Week

d0

d1

AI05652

Figure 7. 512 Hz output to DQ0

Address Bus

E

G

DQ0

Address for Seconds Register

512Hz Output

AI02802

Note: Care should be taken when writing to the control register so as not to overwrite the

calibration value.

10/14 Doc ID 6393 Rev 4

Page 11

AN934 Enabling the frequency test function (FT)

Table 2. 512 Hz output pin

Device Pin name

M41T00, M41T00S, M41T11, M41T56, M41T00CAP FT/Out

M48T02, M48T12, M48T08, M48T08Y, M48T18, M48T35, M48T35AV, M48T35Y DQ0

M41T60, M48T58, M48T58Y FT

IRQ

/FT

/FT/OUT

M48T37V, M48T37Y, M48T201V, M48T201Y IRQ

M41ST85W, M41ST87W, M41ST87Y, M41ST95W, M41T65, M41T81, M41T81S,

M41T94, M41T00AUD, M41T93

M41T62, M41T63, M41T64, M41T66 SQW

M41T82 FT/RST

M41T83 IRQ1/OUT/FT

Doc ID 6393 Rev 4 11/14

Page 12

Conclusion AN934

Conclusion

Software calibration is a convenient feature which allows the user to adjust the clock

accuracy during manufacturing (or later) at minimal cost. This feature also provides a

method whereby “drift” (due to temperature variation) can be corrected and/or anticipated.

See http://www.st.com for additional details as well as an online calibration calculation

tool.

12/14 Doc ID 6393 Rev 4

Page 13

AN934 Revision history

Revision history

Table 3. Document revision history

Date Revision Changes

Dec-1998 1 First edition

20-May-2003 1.1 Clarify compensation required (Ta b le 1, 2); add Conclusion

16-Feb-2004 2 Update web reference information

11-Nov-2004 3 Reformatted; updates to content (Figure 4, 6;Ta b le 2 )

07-Oct-2011 4

Updated products, title of application note, Ta bl e 2 ; revised document

presentation.

Doc ID 6393 Rev 4 13/14

Page 14

AN934

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

14/14 Doc ID 6393 Rev 4

Loading...

Loading...