Page 1

AN900

APPLICATION NOTE

INTRODUCTION TO SEMICONDUCTOR TECHNOLOGY

by Microcontroller Division Applications

INTRODUCTION

An integrated circuit is a small but sophisticated device implementing several electronic functions. It is made up of two major parts: a tiny and very fragile silicon chip (die) and a package

which is intended to protect the internal silicon chip and to provide users with a practical way

of handling the component. This note describes the various “front-end” and “back-end” manufacturing processes and tak es the transistor as an example, beca use it uses the MOS technology. Actually, this technology is used for the m a jority of the ICs manufactu red at STMicroelectronics.

AN900/1100 1/15

1

Page 2

INTRODUCTION TO SEMICONDUCTOR TECHNOLOGY

1 THE FABRICATION OF A SEM ICONDUCTOR DEVICE

The manufacturing phase of an integrated c ircui t can be d ivided into two steps. The firs t,

wafer fabrication , is the extreme ly sop histicated and intricate proces s of manufa cturing the

silicon chip. The second, assembly, is the highly precise and automated process of pack-

aging the die. Those two phases are commonly known as “Front-End” and “Back-End”. They

include two test steps: wafer probing and final t est.

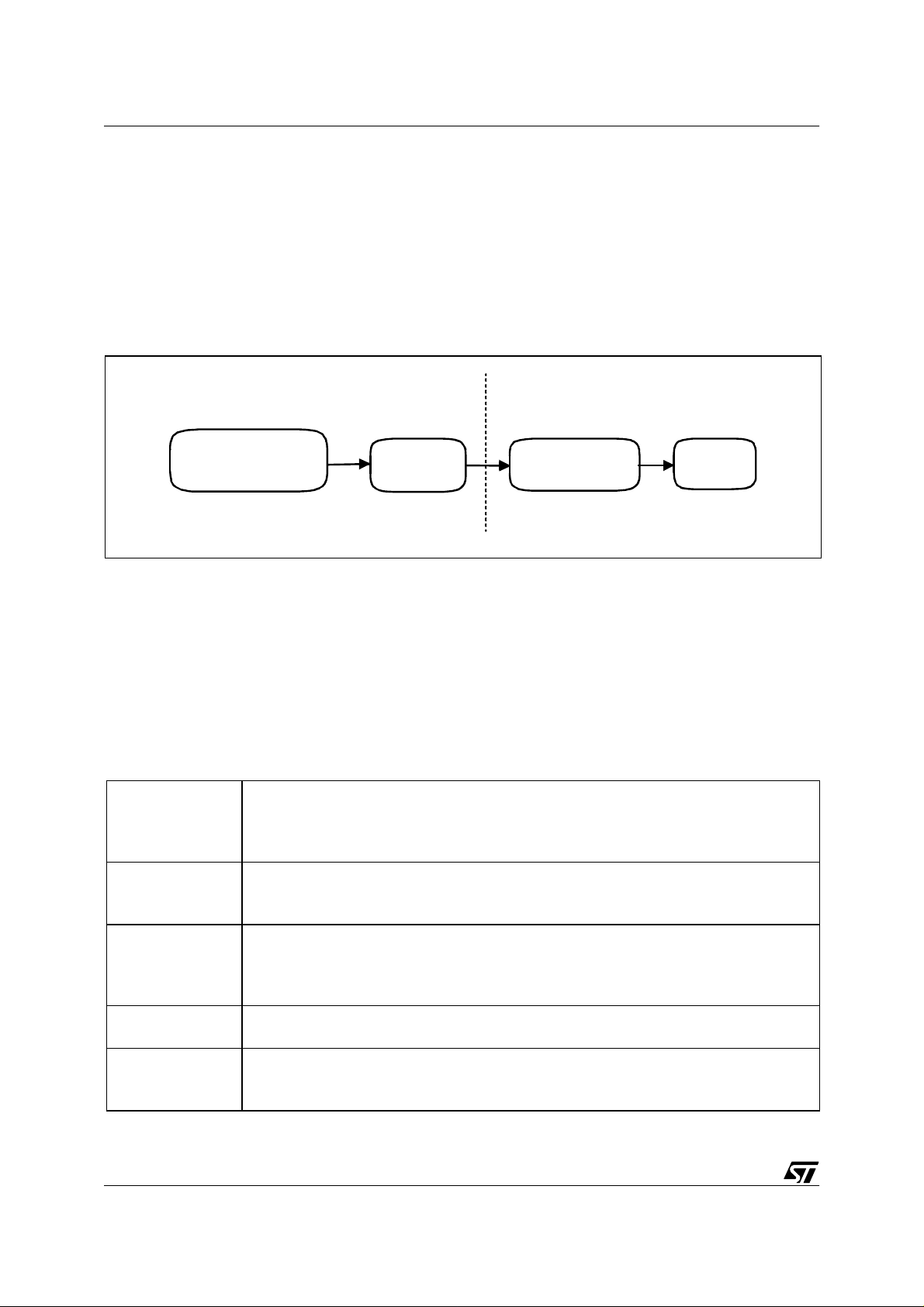

Figure 1. Manufacturing Flow Chart of an Integrated Circuit

"Front-End" "Back-End"

WAFER

FABRICATION

Wafer

Probing

ASSEMBLY

Final

Test

VR02103A

1.1 WAFER FABRICATION (FRONT-END)

Identical integrated circuits, called die, are made on each wafer in a multi-step process. Each

step adds a new la ye r t o th e w afer or mod ifies the e xis ting o ne . Thes e l ayer s fo rm t he e lements of the individual electronic circuits.

The main steps for the fabrication of a die are summarized in the following table. Some of

them are repeated several times at different stages of the process. The order given here

doesn't reflect the real order of fabrication process.

This step shapes the different components. The principle is quite simple (see draw-

PhotoMasking

Etching

Diffusion

Ionic

Implantation

Metal

Deposition

ing on next page). Resin is put down on the wafer which is then exposed to light

through a specific mask. The lighten part of the resin softens and is rinsed off with

solvents (developing step).

This operation removes a thin film material. There are two different methods: wet

(using a liquid or soluble compound) or dry (using a gaseous compound like oxygen

or chlorine).

This step is used to introduce dopants inside the material or to grow a thin oxide

layer onto the wafer. Wafers are inserted into a high temperature furnace (up to

1200 ° C) and doping gazes penetrate the silicon or react with it to grow a silicon

oxide layer.

It allows to introduce a dopant at a given depth into the material using a high energy

electron beam.

It allows the realization of electrical connections between the different cells of the

integrated circuit and the outside. Two different methods are used to deposit the

metal: evaporation or sputtering.

2/15

2

Page 3

INTRODUCT ION TO SEMICO NDUCTOR TE CHNOLOGY

Wafers are sealed with a passivation layer to prevent the device from contamina-

Passivation

Back-lap

tion or moisture attack. This layer is usually made of silicon nitride or a silicon oxide

composite.

It’s the last step of wafer fabrication. Wafer t hickness is reduced (for microcontroller

chips, thickness is reduced from 650 to 380 microns), and sometimes a thin gold

layer is deposited on the back of the wafer.

Initially, the silicon chip forms part of a very thin (usually 650 microns), round silicon slice: the

raw wafer. Wafer diameters are typically 125, 150 or 200 mm (5, 6 or 8 inches). However raw

pure silicon has a main electrical property: it is an isolating material. So some of the features

of silicon have to b e altered, b y means of well controlled proc esses. This is obtained by

"doping" the silicon.

Dopants ( or do ping a tom s) ar e purp osely ins e rted in th e silic on lat tice, he nce c han ging t he

features of the material in predefined areas: they are divided into “N” and “P” categories representing t he negative and positive carriers they hold. M any di ffere nt do pants a re u se d to

achieve these desired features: Phosphorous, Arsenic (N type) and Boron (P type) are the

most frequently used ones. Semiconductors manufacturers purchase wafers predoped with N

or P impurities to an i mpurity level of.1 ppm (one doping atom per ten million atoms of silic on).

There are two ways to dope the silicon. The first one is to insert the wafer into a furnace.

Doping gases are then introduced which impregnate the silicon surface. This is one part of the

manufacturing process called diff usi on (the other part being the oxide grow th). The second

way to dope the silicon is called ionic impl antation. In this case, doping atoms are introduced

inside the silicon using an ele ctron beam. Un like diffusion, ionic implant ation allows to put

atoms at a g iven de pth ins ide the silicon and bas ically allows a better contr ol of all t he ma in

parameters dur ing the pr ocess . Io ni c im plant ation proc ess is si mpler than d iffus ion proc ess

but more costly (ionic implanters are very expensive machines).

3/15

Page 4

INTRODUCTION TO SEMICONDUCTOR TECHNOLOGY

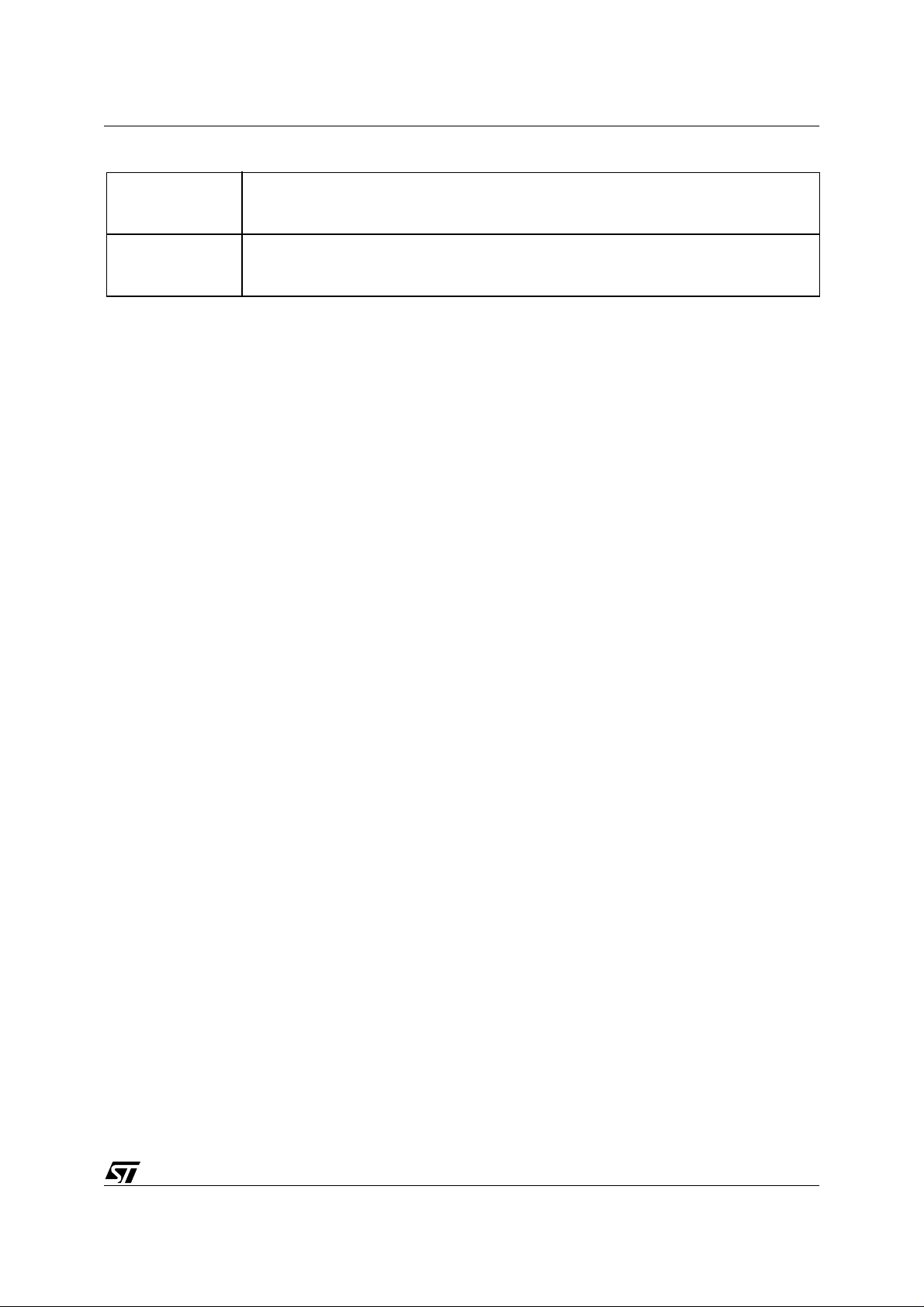

Figure 2. Diffusion and Ionic Implanta tion Processes

DIFFUSI ON PROCESS

OXIDE GROWTH

Oxygen (O )

2

SiO

DIFFUSION FURNACE

DOPING DOPING

HIGH TEMPERATURE

Doping atoms

2

IONIC IMPLANTATION

PROCESS

Electron Beam

VACUUM

IONIC IMPLANTER

VR02103B

Photomasking (or masking) is an operation that is repeated many times dur ing the process.

This operation is described on the above graph. This step is called photomasking because the

wafer is “masked” in some areas (using a specific pattern), in the same way one “masks out”

or protects the windscreens of a car before painting the body. But even if the process is somewhat similar to the painting of a car body, in the case of a silicon chip the dimensions are

measured in tenth of m icro ns. The photoresi st will replicate this pattern on the wafer. The exposed p art of th e photor esist is then rinsed o ff wit h a solve nt (usu ally hy drofl uoric or phos phoric acid).

Figure 3. Photomasking Process

4/15

Page 5

INTRODUCT ION TO SEMICO NDUCTOR TE CHNOLOGY

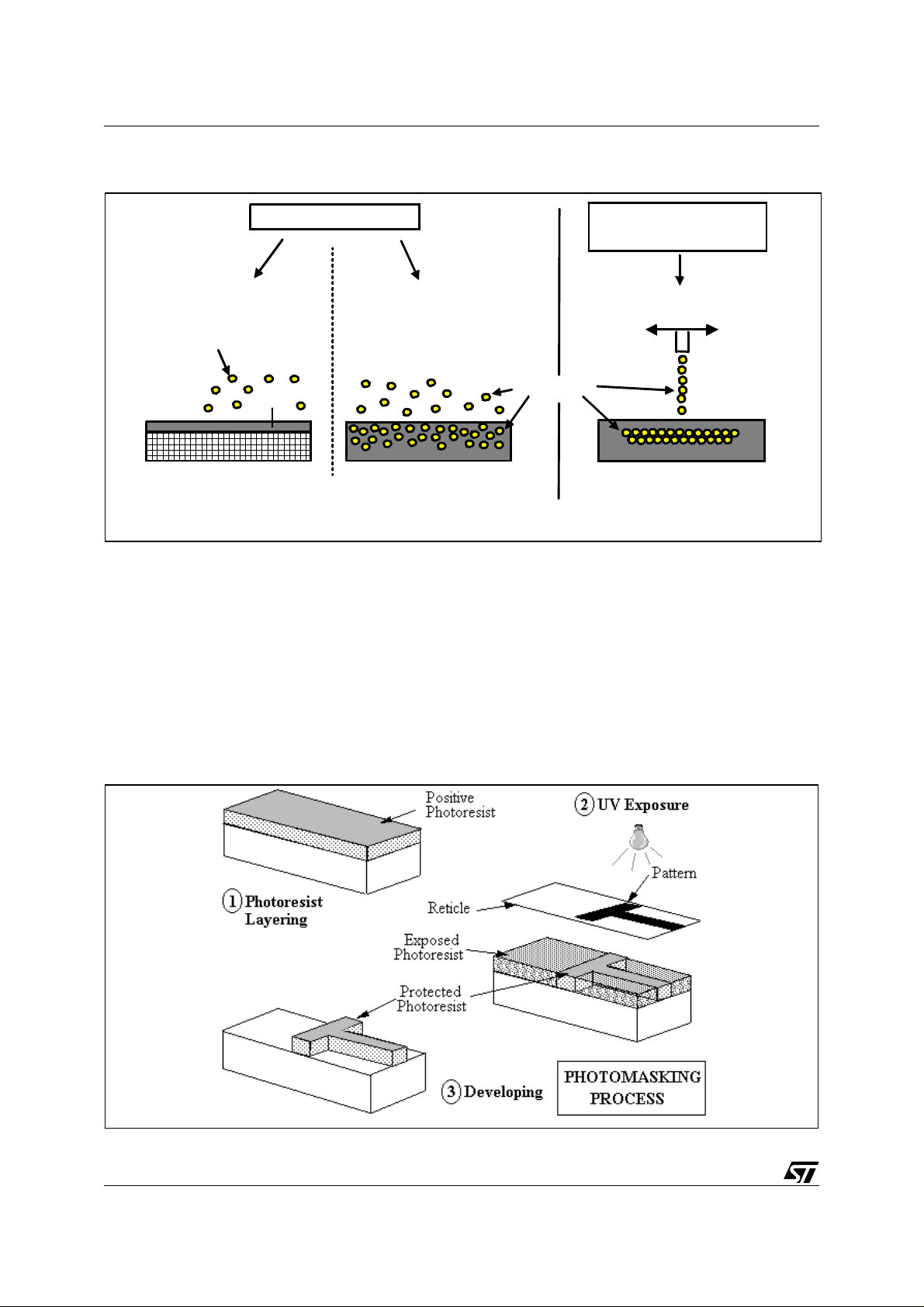

Metal dep osi ti o n is used to put down a metal layer on the wafer surface. There are two ways

to do that. The process shown on the graph below is called sputtering. It consists first in creating a plasma with argon ions . These ions bump into the target surface (composed of a metal,

usually aluminium) and rip metal atoms from the target. Then, atoms are projected in all the directions and most of them condense on the substrate surface.

Figure 4. Metal Deposition Process

POWER SUPPLY

CATHODE

METAL

ATOMS

PLASMA

Thin Metal Layer

SUBSTRATE

ANODE

VR02103C

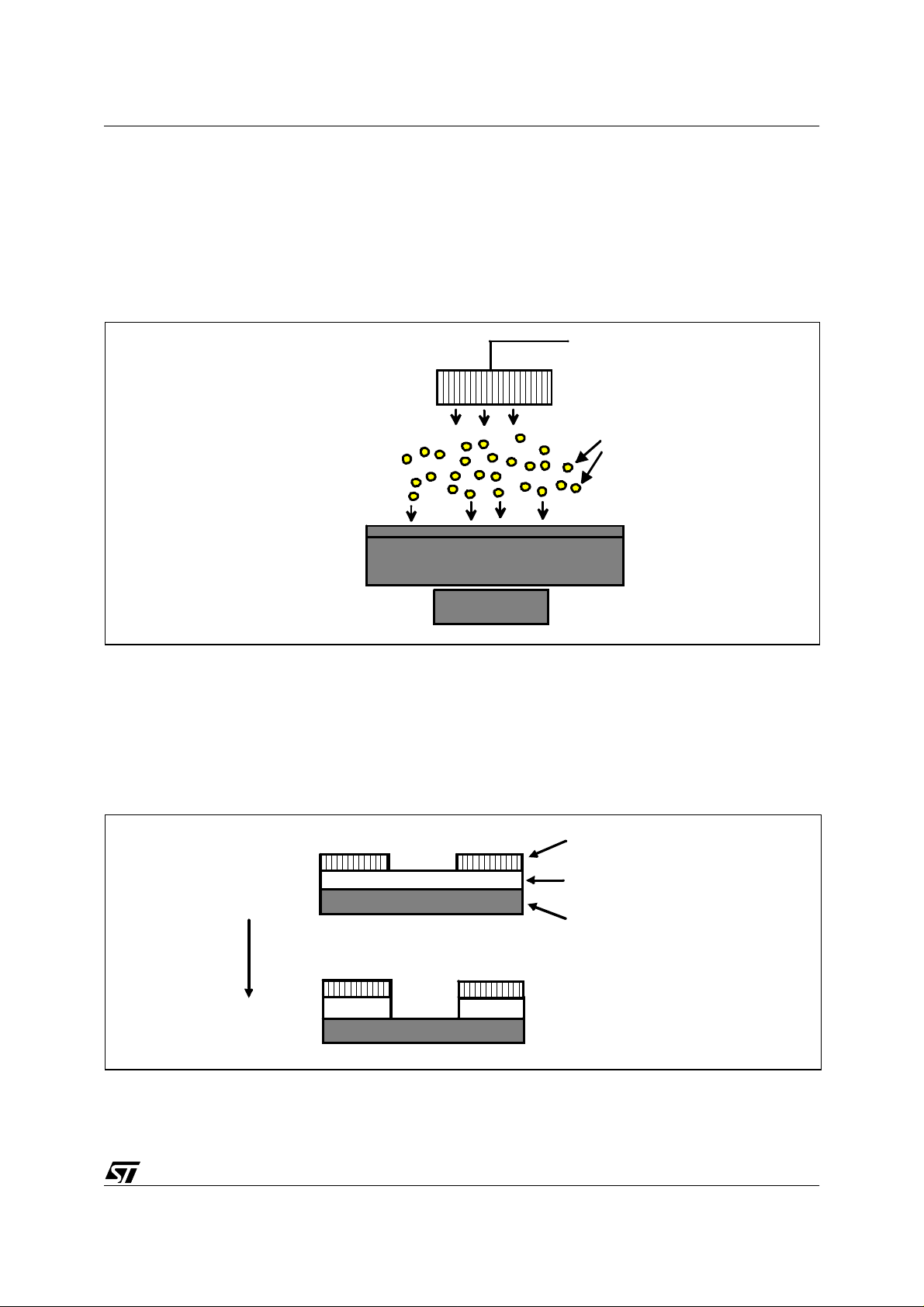

Etching process is used to etch into a specific layer the circuit pattern that has been defined

during the photomasking process. Etching process usually occurs after deposition of the layer

that has to be etched. Fo r instance, the poly gates of a transistor are obtained by etching the

poly layer. A second example are the aluminium connections obtained after etching of the aluminium layer.

Figure 5. Etching Process

Photoresist Mask

Thin Film to be etched

BEFORE

Substrate

AFTER

VR02103D

5/15

Page 6

INTRODUCTION TO SEMICONDUCTOR TECHNOLOGY

Photomasking, ionic implantation, diffusion, metal deposition, and etching processes

are repeated many tim es, us ing differen t m ateri als and do pant s at di fferen t tempe ratures in

order to achieve all the operations needed to produce the requested characteristics of the silicon chip. The resolution limi t (mini mal line s ize inside the circuit) of current technology is 0.35

microns. Achieving such results requires very sophisticated processes as well as superior

quality levels.

Backlap is t he fi na l step of wa fe r fa br ic ati on . The w af er th i ckn ess is re du c ed fr om 6 50 m icrons to a minimum of 180 microns (for smartcard products).

Wafer fabrication takes place in an extremely clean environment, where air c leanliness is one

million times b e tter than the air we normally breathe in a city, or some orders of magnitude

better than the air i n a heart t ransplant operating th eatr e. Photom a sking, for e xampl e, tak es

place in rooms where there’s maximum one particle whose diameter is superior to 0.5 micron

(and doesn’t exceed 1 micron) inside one cubic foot of air.

All these processes are part of the m anufacturing phase of the chip itself. Si licon chips are

grouped on a silicon wafer (in the same w ay postage stamps are printed on a single sh eet of

paper) before being separated from each other at the beginning of the assembly phase.

Wafer Probing. This step takes place between wafer fabrication and assembly. It verifies the

functionality of the device performing thousands of electrical tes ts, by means of special microprobes (see graph on next page). Wafer probing is composed of two different tests:

1. Process parametric test: this test is performed on some test samples a nd checks the

wafer fabrication process itself.

2. Full wafer probing test: this test verifies the functionality of the finished product and is performed on all the dies.

Figure 6. Description of the Wafer Probing Operation

The bad di e are au toma tical ly mark ed wi th a bl ack dot so they can be separated from the

good die after the wafer is cut. A record of what went wrong with the non-working die is closely

examined by fa ilure an alysis en gin eers to de term ine w here th e problem occ urred s o that it

may be corrected. The percentage of good die on an individual wafer is called its yield.

6/15

Page 7

INTRODUCT ION TO SEMICO NDUCTOR TE CHNOLOGY

1.2 ASSEMBLY (BACK-END)

The first step of assembly is to separate the silicon chips: this step is called die cutting.

Then, the die are placed on a lead frame: the “leads” are the chip legs (which will be soldered

or placed in a socket on a printed circuit board. On a surface smaller than a baby's fingernail

we now have thousands (or millions) of electronic components, all of them interconnected and

capable of implementing a subset of a complex electronic function. At this stage the device

is completely func tional , but i t wo uld be imp ossible to u se it w ithout som e sor t of s upporting

system. Any scratch would alter its behaviour ( or impact its r eliabili ty), any shock would cause

failure.

Therefore, the die must be put into a ceramic or plastic package to be protec ted fr om the external world. A number of operations have to be made to realize this: they are described on the

following graph.

7/15

Page 8

INTRODUCTION TO SEMICONDUCTOR TECHNOLOGY

Figure 7. Description of The Assembly Process

Wires thinner than a human hair (for microcontrollers the typical v alue is 33 microns) are re-

quired to connect chips to the external world and enable electronic signals to be fed through

the chip. The process of connecting these thin wires from the chip’s bond pads to the package

lead is called wire bonding (see also graph on next page for more details).

Figure 8. Wire Bonding

8/15

Page 9

INTRODUCT ION TO SEMICO NDUCTOR TE CHNOLOGY

Figure 9. Wire Bonding Operation

The chip is then mounted in a ceramic or plastic package. The package not only protects the

chip from e xternal shock s, bu t als o ma kes the whol e de vice eas ier to hand le. T heses pack ages come in a variety of shapes and sizes depending on the die itself and the application in

which it will be used.

9/15

Page 10

INTRODUCTION TO SEMICONDUCTOR TECHNOLOGY

Figure 10. Different Kinds of Plastic Packages

Products are then marked with a “tr aceability co de” which is used by the m anufacturer and

the user to identify the function of the device (and its date of fabrication). At the end of the assembly proc ess, th e int egrat ed cir cuit is tes te d b y aut omat ed test equ ipment. O nly the inte grated circuits that passed the tests will be packed and shipped to their final destination.

10/15

Page 11

INTRODUCT ION TO SEMICO NDUCTOR TE CHNOLOGY

2 BASIC IC ELEMENT: THE TRANSISTOR

2.1 MOS TECHNOLOGY

We will examine first the basics of MOS (Metal Oxide Semiconductor) technologies as they

are used for the majority of the integrated circuits manufactured at STMicroelectronics.

. There are three major MOS technology families: PMOS, NMOS and CMOS. They refer to the

channel type of the MOS transistors made with the technology.

– PMOS technologies implement P-channel transistors by diffusing P-type dopants (usually

Boron) into an N-type silicon substrate to form the source and the drain. P-channel is so

named because the channel is composed of positively charged carriers.

– NMOS technologies are similar, but use N-type dopants (usually Phosphorus or Arsenic)

to make N-channels transistors in P-type silicon substrate. N-channel is so named because

the channel is composed of negatively charged carriers.

– CMOS (Complementary MOS) technologies combine both P-channel and N-channel de-

vices on the same silicon. Either P or N-type silicon substrates can be used. However, deep

areas of the opposite doping type (called wells) must be defined to allow fabrication of the

complementary transistor type.

Figure 11. MOS Technologies

11/15

Page 12

INTRODUCTION TO SEMICONDUCTOR TECHNOLOGY

Most of the early semiconductor devices were made with PMOS technologies because it was

easier to obtain stable manufacturing process with this technology. As higher speeds and

greater densities were needed, new devices were implemented with NMOS. This was due to

the higher speed of N-channel charge carriers (electrons) in silicon and also to the progress in

the control of silicon doping. But CMOS technology has begun to see widespread commercial

use in memory devices: it allowed the use of very low power devices. At the beginning, CMOS

were slower than NMO S devices. T oday, CMO S technology has been improved to pr oduce

higher speed devices.

2.2 FABRICATION OF A TRANSISTOR

The fabrication begins with a slice of single crystal silicon, uniformly doped P-type.

The wafer is oxidized in a furnace to grow a thin

layer of silicon dioxide (SiO

) on the surface. Sil-

2

icon nitride is then deposited on the oxidized

wafer in a gas phase chemical reactor. The wafer

is now ready to receive the first patt e rn of what is

to become a many layered complex circuit. The

first pattern defines the boundaries of the active

regions of the integrated circuit, whe re transistors, capacitors, diffused resistors and first level

interconnects will be made.

The patterned wafer is th en im plante d wi th bor on

atoms. Boron will only reach the etched zones of

the silicon substrate, creating P-type doped

areas that will electrically separate active are as.

Wafer is oxidized again and the thick oxide only

grows in the etched areas due to silicon nitride’s

properties as an oxidation barrier.

The remaining silicon nitride layer is re moved.

Now that the areas for active transistors have

been defined and isolated, the transistor types can be determined. The wafer is patterned and

implanted with dopant atoms.The energy and dose at which the dopant atoms are implanted

determines much of the transistor’s characteristics.

The transistor types defined, the gate oxide of the

active transistors are grown in a high temperature

furnace. The gate oxide layer is then mas ked and

holes are etched to provide direct access to buried

contacts where needed . A po lycristalin e sili con

layer is deposited on th e w afer. The gate layer is

then patterned to define the actual transistor gates

and interconnect paths.

12/15

Page 13

INTRODUCT ION TO SEMICO NDUCTOR TE CHNOLOGY

Wafer is diffused with N-type dopant s to form the

source and drain junction. The transistor gate

material ac ts a s a b ar rier t o th e dop ant p r ovidi ng

an undiffused channel self-aligned to the two j unc-

tions. The wafer is then oxidized to seal the junc-

tions from contamination with a layer of SiO

.

2

A thick glass layer is then deposited over the wafer

(to provide better insulation), patterned with con-

tact holes and placed in a high temperature fur-

nace. Metal is deposited on the wafer and the in-

terconnect patterns and external bonding pads are

defined and etched. To prevent the device from

contami nation or moistu re attac k, wafers are

sealed with a passivation layer. Patterning is

done for the last time opening up windows only

over the bond pads where external connections

will be made.

This completes basic fabrication sequence for a

single poly and single metal layer process.

13/15

Page 14

INTRODUCTION TO SEMICONDUCTOR TECHNOLOGY

2.3 HOW DOES A TRANSISTOR WORK?

Transist or is the basic elem ent of an MCU device. There c an be hu ndred s of thou san ds of

them and the size of their gate can go down to 0.35 microns.

Let’s explain the way a N MOS trans istor o perates . Basic ally, T here’s a lack of ele ctrons be tween the Source (S) and the Drain (D ) because this area has been implanted with a P-type

dopant (Boron for instance). Therefore, when no voltage is applied, there’s no current between

the source and the drain (case of the enhancement tran sistor).

If we apply a positive voltage on the gate and the drain, then this will attract electrons in the

channel existing between the source and the drain, therefore making it possible for an elec-

trical current to flow between S and D.

There are two main types of transistor:

– Enhancement Transistor: channel is permanently OFF. It requires a positive applied gate

voltage to turn on. Microcontrollers, for instance, mainly use this type of transistor.

– Depletion Transistor: channel is permanently ON. It requires a negative applied gate volt-

age to turn off.

This schem e is a c ross s ection of

a real transistor obtained after

about 100 steps of fabrication

(see previous paragraph for the

explanation of the different fabrication steps). The last layer is

called a passivation layer and protects the transistor.

14/15

Page 15

INTRODUCT ION TO SEMICO NDUCTOR TE CHNOLOGY

“THE PRESENT NOTE WHICH IS FOR GUIDANCE ONLY AIMS AT PROVIDING CUSTOMERS WITH INFORMATION

REGARDING THE IR PRO DUCT S IN OR DER FO R THEM TO SAV E TIME . AS A RES ULT, STMIC ROEL ECTR ONI CS

SHALL NOT BE HELD LIABLE FOR ANY DIRECT, INDIRECT OR CONSEQUENTIAL DAMAGES WITH RESPECT TO

ANY CLAIMS ARISING FROM THE CONTENT OF SUCH A NOTE AND/OR THE USE MADE BY CUSTOMERS OF

THE INFORMATION CONTAINED HEREIN IN CONNEXION WITH THEIR PRODUCTS.”

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or patent ri ghts of STM i croelectr oni cs. Specifications mentioned in thi s publicati on are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri tical comp onents in life support dev i ces or systems wi thout the express written approv al of STMicroel e ctronics.

The ST logo is a registered trademark of STMicroelectronics

2000 STMicroelectronics - All Rights Reserved.

Purchase of I

Australi a - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malt a - Morocco - Singapore - Spain

2

C Components by STMicroelectronics conveys a license under the Philips I2C Patent. Rights to use the se components in an

2

C system i s granted pro vid ed that the sy stem conforms to the I2C Standard Specification as defined by Philips.

I

STMicroelectronics Group of Compan i es

Sweden - Switzerland - United K i ngdom - U.S. A.

http://www.s t. com

15/15

Loading...

Loading...