AN880

®

THE L6569: A NEW HIGH VOLTAGE IC DRIVER FOR

INTRODUCTION

Electronic lamp ballasts are now popular in both

consumer and industrial lighting. They offer power

saving, flicker free operation and reduced sizes.

Improvements to the light control and cost reduction of the ballast will broaden the ir market acceptance.

Today designers focus on reducing the cost of the

ballast, but also work to add features to the ballast like saving energy by dimming the light, or increasing the life time with better preheat and protections. Such requirements have contributed to

the development of dedicated high voltage controllers like the L6569, which ar e able to driv e the

floating transistor of a symmetric half bridge inverter. This device is a simple, monolithic oscillator-half bridge driver that allows quick design of

the ballast.

HIGH VOLTAGE I C DRI VERS I N B ALL AST APPLICATIONS

The voltage fed half bridge

Voltage fed series resonant half bridge inverters

are currently used for Compact Fl uorescent Lamp

ballasts (CFL), for Halogen Lamp transformers,

and for many European Tube Lamp (TL) ballasts.

This simple converter is preferred for new designs, because it minimizes the off state voltage

of the power transistors to the peak line voltage,

and requires only one resonant choke. In addition

this choke protects the half bridge against short

circuits across lamp terminals. However overheating and overcurrent occur during open load operation. The inverter robustness must be improved, or some protections are required.

The half bridge inverter operates in Zero Voltage

Switching (ZVS) resonant mode [1], to reduce the

transistor switching losses and the electromagnetic interference generated by the output wiring

and the lamp.

Fully integrated ballast controllers

By varying the switching frequency, the half

bridge inverter is able to modulate the lamp

power. However most current designs use a sin-

APPLICATION NOTE

ELECTRONIC LAMP BALLAST

by G. Calabrese and T. Castagnet

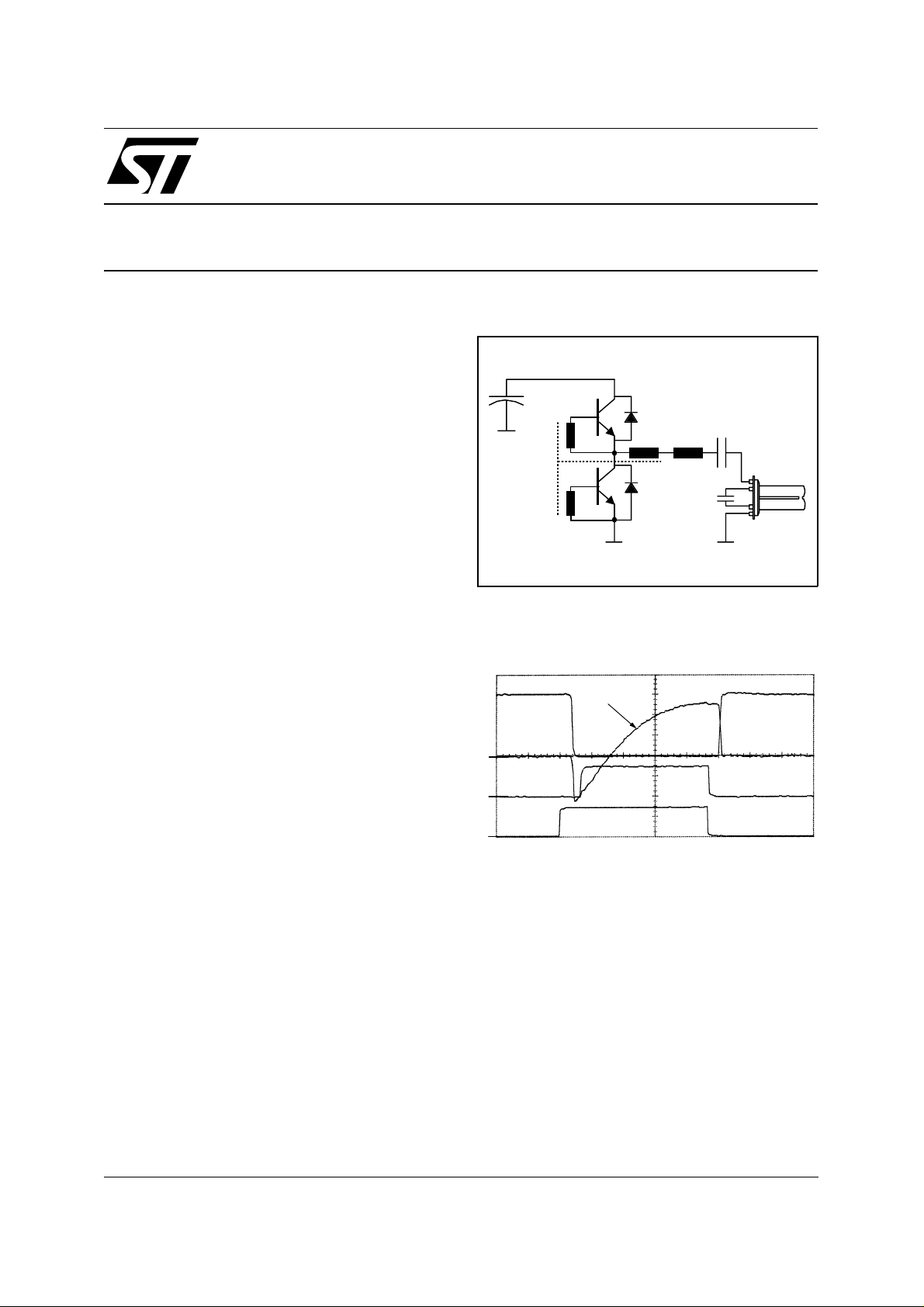

Figure 1: CFL series resonant half bridge inverter.

Figure 2: Current and voltage of the STD3NA50

MOSFETs when driven in ZVS with

the L6569.

I

V

DS

GND

GND

GND

gle frequency with a saturable pulse transformer

(see fig. 1) to drive the transistors. This type of

design has a higher component count, a higher

tolerance on the switching frequency, and it cannot adjust the lamp power.

The only way to design a cost effective, compact

and smart control of the lamp is to use a dedicated I.C. that is able to drive the upper transistor

of an symmetric half bridge inverter. Such controllers require a high voltage capability for the floating transistor driver [2]. MOSFETs are preferred

over Bipolar transistors as power switches because their gate driver requires a lower supply

current and a smaller silicon size [3].

D

LVG

RF

2 µs/dv ; 50 V/dv ; 0.1 A/dv

February 2003

1/14

AN880 APPLICATION NOTE

THE L6569 AND ITS APPLICATIONS

The L6569

The L6569 is able to directly control a symmetric

half bridge inverter of a fluorescent lamp ballast,

or a low voltage halogen lamp transformer.Two

270mA buffers drive the inverter MOSFETs in

complementary fashion with a 1.25µs built-in

dead time to prevent cross conduction. The buffer

for the upper Mosfet is driven through a 600V

level shifter realized in BCD off line technology.

The oscil lator, simil ar to a CMOS 555 timer, ope rates fr om 25 to 150 kHz wi th a +/-5% maximu m

tolerance. The in ternal 15V shunt regulator has a

9V Unde r Volt age Lock Ou t with an 1V hysteres is,

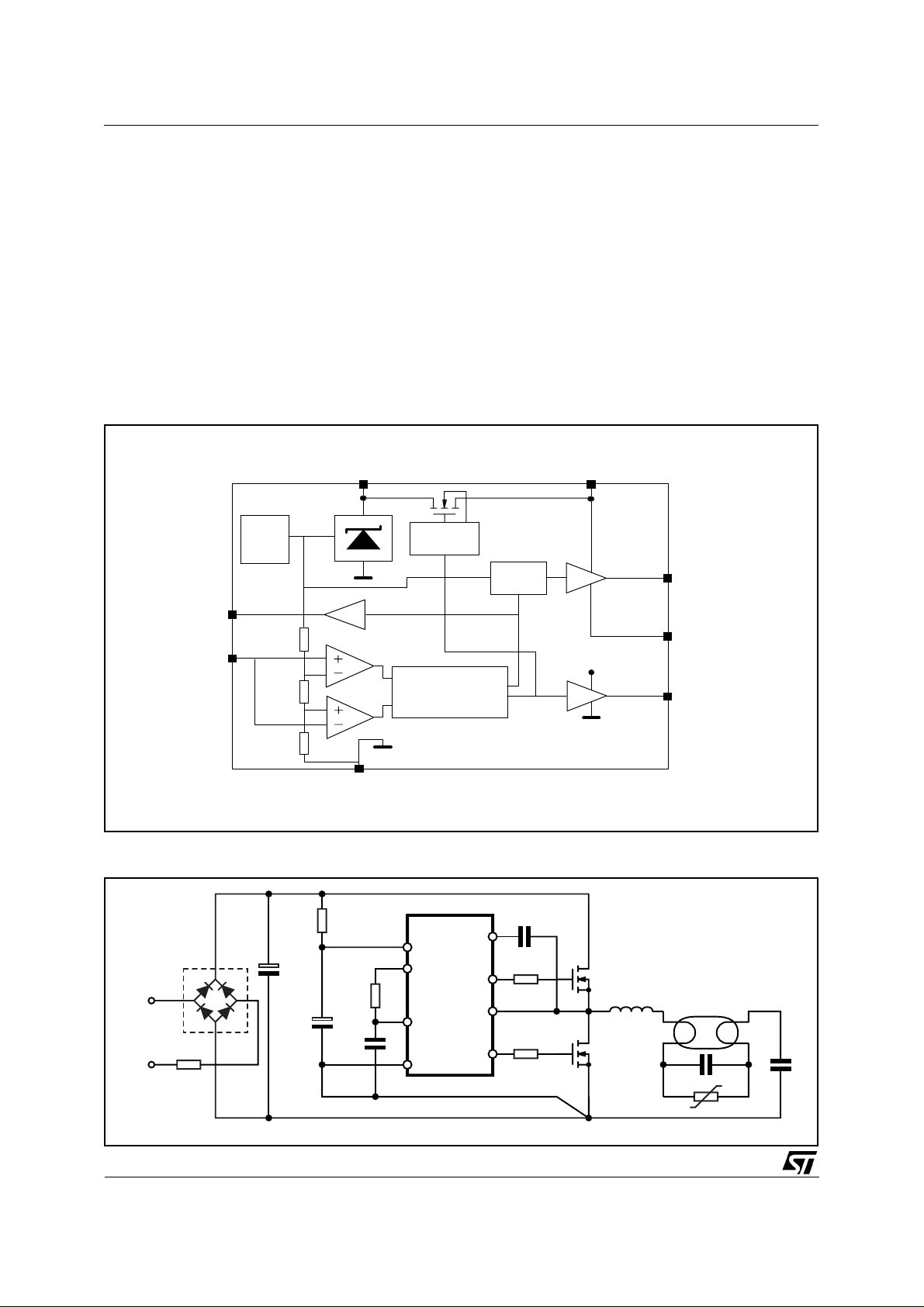

Figure 3: Block diagram of the L6569.

VS

UVLO

CHARGE

PUMP

RF

CF

LOGIC CONTROL

with DEAD TIME

and the circui t req uires o nly 150 µA at power up.

The L6569 integrates a high voltage Lateral

DMOS transistor in place of the usual external diode [2] to charge the bootstrap capacitor for the

upper buffer. Figure 5 shows DMOS operating as

a synchronous rectifier.

The applications

The primary application for the L6569 is the Compact Fluorescent Lamp. With the oscillator, the

supply and the Mosfet drivers it is the core of the

application, and designers can customize the circuit to their requirements.

BOOT

LEVEL

SHIFTER

HIGH

SIDE

DRIVER

HVG

OUT

LVG

LOW

SIDE

DRIVER

GND

Figure 4: Basic application diagram using the L6569 and two STD4NK50Z MOSFETs.

100nF

22Ω

STD4NK50Z

22Ω

D02IN1385

2/14

AC LINE

180KΩ

10µF

10µF

10KΩ

1nF

L6569

LAMP

Figure 5: Bootstrap capacitor charge.

AN880 APPLICATION NOTE

15.6 V

600V 120

CHARGE PUM P CIRCUIT

LOGIC

ON

Ω

L6569

Figure 6: Basic diagram for 2x105 W lamp ballast in full bridge configuration.

HV

100nF

BOOT

HVG

OUT

LVG

47

47

EXTERNAL

OSCILLATOR

V

V

S

RF

CF

GND

S

L6569

100nF

47

47

ON

BOOT

HVG

OUT

LVG

L6569

V

S

RF

CF

GND

D02IN1386

Typical industrial TL ballasts requires complex

control with dimming or automation interface.

Here the L6569 is a driver between the power

and control blocks. To use it with an external oscillator, pin CF is used as an 0-12V logic input,

and the L6569 becomes a high voltage buffer.

Applications with power above 150W require a full

bridge inverter. Figure 6 shows how two L6569

drive such a MOSFET bridge. If no external control is required, t he fir st L6569 m aster can control

the switching with its oscillator, and synchronizes

the other driver as (slave).

STB9NK50Z

The L6569 start up

Two versions of the L6569 are available with different start up characteristics. The L6569 drives

the lower MOSFET ON at power-up until the supply voltage reaches the Under Voltage Lock Out.

The bootstrap capacitor is precharged to 4.6V

and both the lower and the upper MOSFETs will

switch immediately with the oscillator. This is intended for inverters which use only one DC blocking capacitor connected to the power ground, as

shown on figure 4 for CFL ballast.

3/14

AN880 APPLICATION NOTE

The L6569A holds both MOSFETs OFF until the

Under Voltage Lock Out is reached. This is intended for inverters using 2 decoupling capacitors

in half bridge as shown on figure 12. The inverter

is totally off, so that the voltage at the capacitors

center node is not unbalanced by the leakage

path during power on.

CONSIDERATIONS ON THE L6569 ENVIRONMENT

To illustrate the benefits of the L6569 in t he CFL

applications, a demonstration board was developed to supply Sylvania 18W DULUX lamp (ref:

CF18DT/E). The following chapters summarize

the application considerations applied in t his design. The schematic, lay out and components list

are shown in appendix A.

Symmetric half bridge operation

To supply a fluorescent lamp, the ballast has to

achieve 3 functions: pre heat, ignition, and normal

lamp operation. The serial resonance occurs between the choke and the capacitor in parallel with

the lamp. The choice of these components determines the lamp ignition voltage a nd the nominal

lamp current.

Since the inverter using the L6569 and MOSFETs

can operate at a higher frequency than conventional solutions, the size of the passive components will be reduced. Such inverter can operate

up to 150 kHz in ZVS mode, and the switching

losses of the power transistors only limits t he frequency. In new design this frequency should be

set between 50 and 100 kHz. For instance with

an 18W lamp, a frequency increase from 33 to 50

kHz will lead to a 40% reduction of the choke

size.

To operate in Zero V oltage Switching (ZVS), the

switching frequency is higher than the resonant

frequency. All operation phases of the ballast ar e

secure in this mode. When the bootstrap transistor is conducting, no pulse c urrent will flow from

pin BOOT to pin V

, as it might happen in Zero

S

Current Switching. The bootstrap transistor remains in its Safe Operating Area, and its dissipation is negligible.

The MOSF ET dri ve

The ZVS drive technique requires only a fast turn

off capability as shown on f igure 2, and the transistor buffers are designed with a stronger sink

current. The two MOSFET buffers of the L6569

can sink a 400 mA peak current on capacitive

load. Typically these buffers can drive any MOSFETs in TO220 package.

Figure 7 shows an example with the STP8NA50

that has an 0.85 Ω resistance R

DS-ON

.

Figure 7: Cur re nt and voltage of the STP8NA50

MOSFET at turn off with the L6569.

T

= 245 ns ,Tc = 95 ns, E = 93 µJ

GD

@ Tj = 50°C, RG = 22 Ω.

GD

T

D

I

GS

V

D

V

50 ns/dv ; 1 A/dv ; 5 V/dv ; 50V/dv

Tc

GND

GND

GND

The built-in dead time circuit acts whe n a MOSFET turns off, delaying the turn on of the opposite

transistor for 1.25 µs. The voltage V

between

OUT

the 2 MOSFETs must switch within the minimum

dead time (0.85 µs), as shown on figure 8, to

avoid bridge cross conductions and transistors

overheat.

Figure 8: STD3NA50 MOSFET turn off when

driven by the L6569. T

D

T

I

D

C

T

GD

T

200 ns/dv ; 50 V/dv ; 0.1 A/dv

C

+ T

LVG

RF

GD

V

< T

DS

D

GND

GND

GND

The MOSFET voltage selection

Since the ballast is connected to the ac mains, it

must handle any spurious voltage spikes. When

the front end RFI filter and t he clamping device,

such as a varistor, absorbes totally the spike energy, MOSFETs can have the same 600V minimum breakdown voltage BV

as the L6569.

DSS

Otherwise when the upper MOSFET is on, the residual default may be applied to the L6569. Although the pin OUT breakdown voltage is higher

than 600V, it has a poor avalanche robustness.

Therefore the lower MOSFET protects the driver

by having a lower BV

mum BV

up to 500V will achieve safely this

DSS

. A MOSFET with a mini-

DSS

task.

4/14

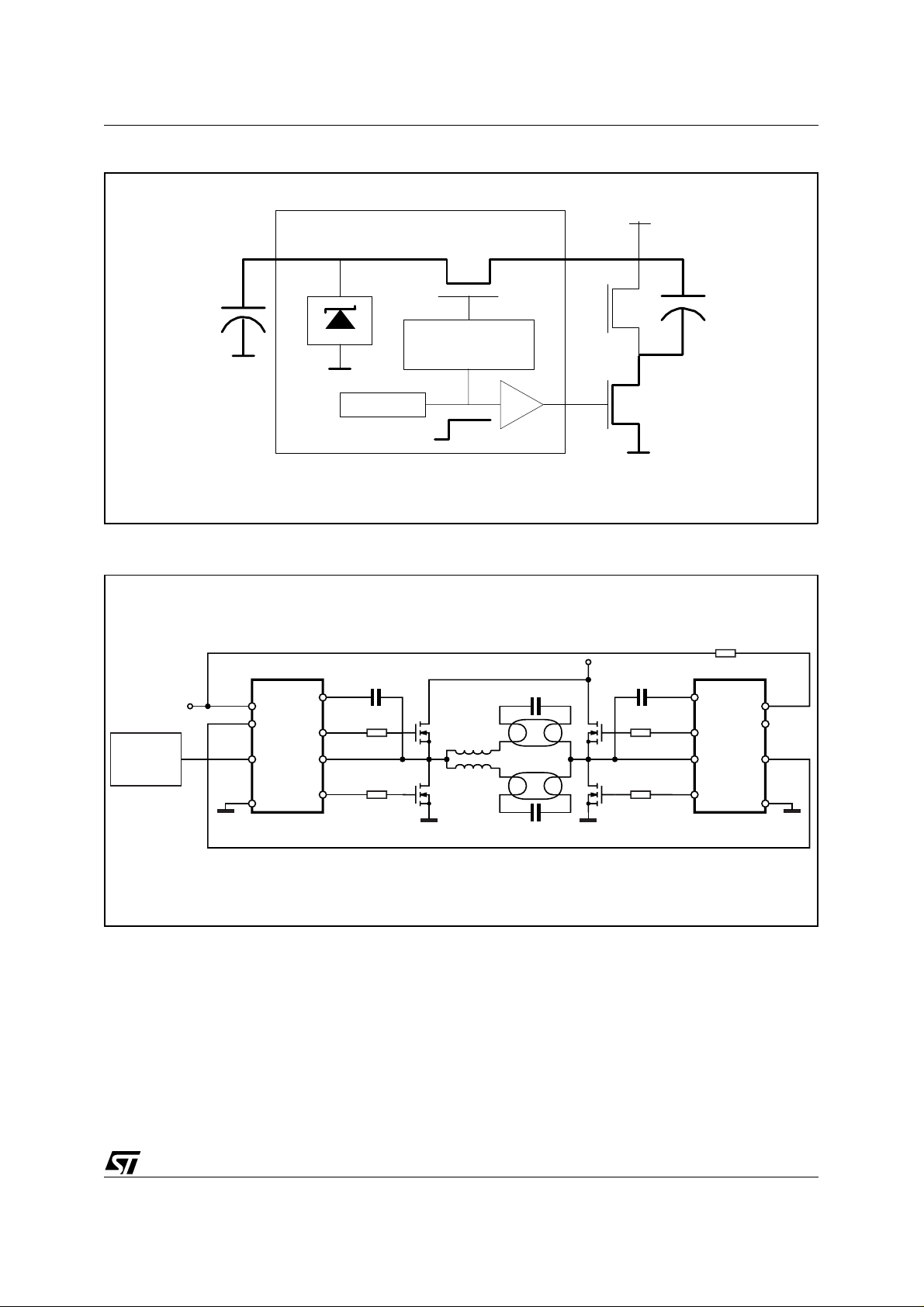

Figure 9. L6569 driver protection against voltage spikes.

AN880 APPLICATION NOTE

OUT

BV

> 600V

15V

L6569

The auxiliary supply of the converter

The circuit consumption is defined by the MOS-

H.V.+

ON

V

OUT

OFF

mA, a secondary winding on the resonant choke

is an easy supply alternative.

FETs gate charge, the I. C. consumption, the oscillator, and the shunt regulator. Several circuits

are possible.

In many applications a snubber i s used to reduce

the dissipation in the MOSFETs. When this snubber is used in conjunction with a start up resistor

in Figure 10), a non dissipative supply is

(R

S

achieved almost for free.

At start up t he I. C. i s co ns uming 150 µA, and the r e-

fore only a small supply resistor is required. During

operat ion the capacitor provides the supply current.

To avoid cross conduction, the capacitance is limited by the dri ver de ad tim e T

. Henc e the capaci-

D

tive supply current IC is also limited.For a CFL ballast this circuit easily supplies the required

operat ing c ur rent . Usi ng a CF18 DT lamp ( I

> 230

L

The ballast shutdown

The L6569 allows several ways (see figg. 11, 12

and 13) to shutdown the ballast [4]: by acting on

the C

input oscillator pin to turn off the upper

F

MOSFET or by acting on the VS supply pin with

the Under Voltage Lock Out.

Acting on C

(Fig. 11) a limiting resistor RL has to

F

be used, and it has to be: RL ⋅ CF > 1µs.

When the shutdown is realized acting on Vs pin,

(see fig. 12) a limiting resistor Rs must be used to

slow down the discharge of the supply filter Cs.

The constant time of the discharge must be

greater than 10 periods of the switching frequency:

mA) the required capacitance is 470 pF on 230 Vac

line. At 50 kHz the average capacitive current is 6

mA, as described in appendix B.

When the required driver current is higher than 10

Connecting the CF pin to ground GND stops the

oscillator, and the lower MOSFET will remain ON.

Therefore the bootstrap capacitor remains

Figure 10: Non dissipative auxiliary supply using the transistor snubber.

I

10

≥

R

S

⋅ f

C

s

sw

1mA WHEN STARTING

220k

Rs

Cs

Ω

6 mA WHEN 50 kHz SWITCHING

C

470 pF

310 V

bootstrap

circuit

L6569

5/14

AN880 APPLICATION NOTE

charged and the circuit can restart immediately.

This method is suitable when the inverter uses

only one DC blocking capacitor c onnected to the

power ground, as used on figure 11 for Compact

Fluorescent Lamp. Pulling the V

voltage below

S

the UVLO turns off the oscillator and gives the

same bridge configuration.

For the L6569A, discharging the V

supply below

S

the UVLO turns off bot h MOSFETs. An SCR like

the X0202MA may be used for the reset function.

If the current flowing through the supply resistor is

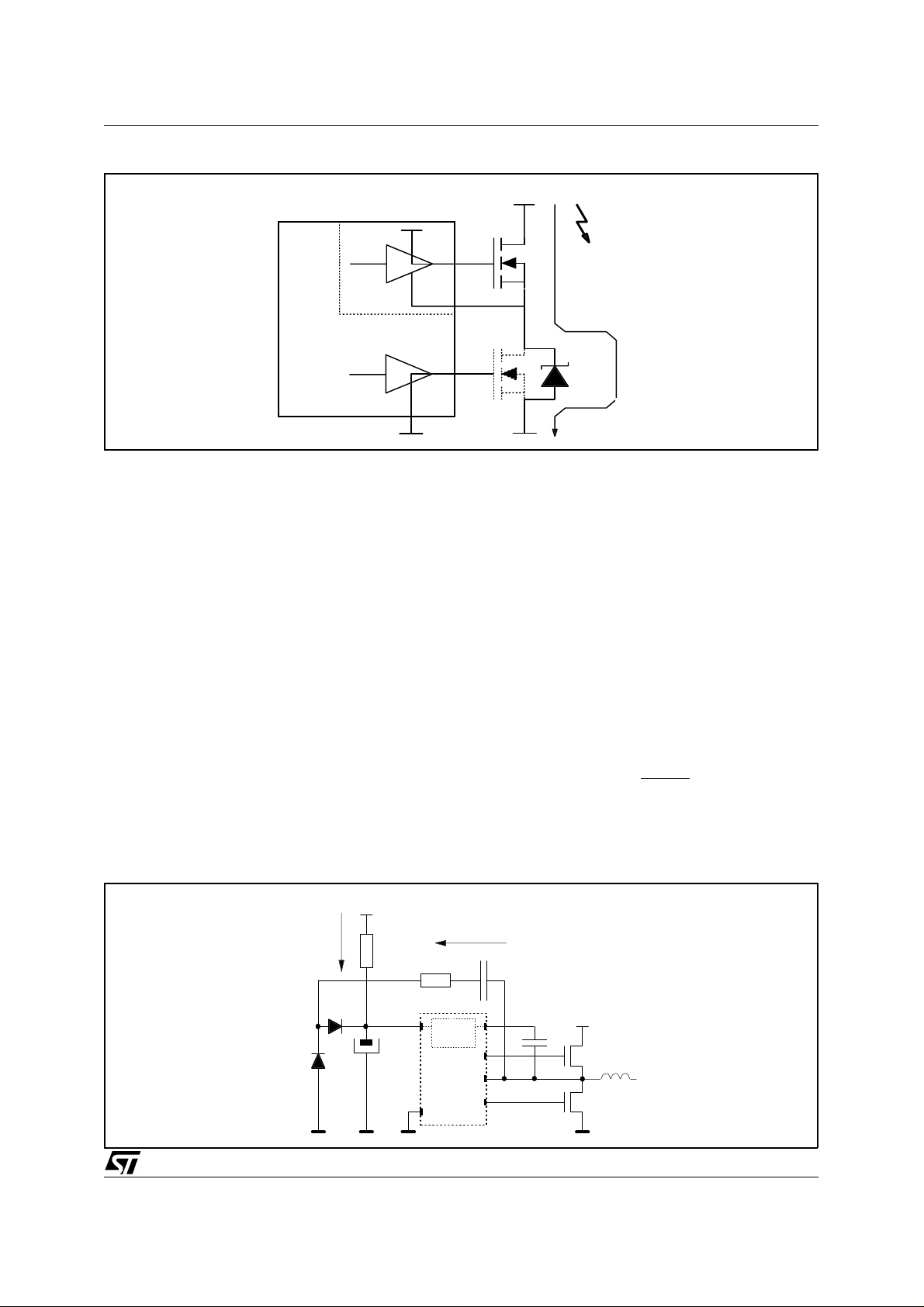

Figure 11: L6569 shutdown through the C

oscillator pin.

F

L 6569

R

R

F

L

C

F

higher than the SCR holding current (see figure

12), the SCR will remain on and the two MOSFETs off. Removing power or commutating the

SCR allows a new start up [4].

Otherwise a disable circuitry that turns off the two

MOSFETs (see figure13), can achieve the shutdown function. Compared to the SCR solution,

the shutdown is immediate and the inverter can

restart on the disable order.

ON

Figure 12: Shutdown with a thyristor & a serial resistor to slow down the supply voltage decay.

L 6569A

C

Rs

R

OFF

R

shutdown

OFF

Figure 13: L6569 disable circuitry with both MOSFETs off.

H.V.

22

V

IN

DISABLE

HCF4011

5.6k

Vs

VS BOOT

HVG

RF

OUT

CF

LVGGND

100nF

200

200

L6569

W

4.7 k

BC327

6/14

AN880 APPLICATION NOTE

THE LAMP SEEN BY THE ELECTRONIC DESIGNER

The lamp equivalent impedance

The compact fluorescent lamps are specified at

25 kHz (IEC 929). The MOSFETs and the L6569

allow to increase the switching frequency, but the

sensitivity of the lamp to the frequency needs to

be analyzed.

A few samples of the CF18DT/E lamp were

tested by varying the frequency and the current of

the lamp. The figure 14 shows the lamp impedance versus its current as it varies from 0.1A to

0.23A with 5 frequencies from 25 to 150 kHz

= 25°C).

(T

AMB

Figure 14: Variation of the lamp impedance

versus its cu rren t for seve r a l

switching frequencies.

R lamp (Ohms)

1200

1000

800

600

400

200

25 kHz

50 kHz

100 kHz

150 kHz

The preheat

Preheat techniques are used in CFL ballasts to

reduce the ignition lamp voltage. During this

phase the lamp is characterized by a high impedance that forces the electrical conduction through

the preheat filaments. These filaments initially

have a low resistance that will increase by 5 times

during the preheat. The preheat typically lasts

from 400 ms to 1 s, and is achieved by controlling

either the current or the voltage of the filaments.

For a current control the filaments are in series

with the resonant network as shown on figure

16a. When the inverter frequency is constant, a

positive temperature coefficient thermistor (PTC)

in parallel with the lamp achieves the t ask by adjusting both the filament current and the preheat

duration. The board uses a 150Ω PTC with two

8.2 nF capacitors. The preheat lasts 0.8s and the

filament current is 0.45 Arms. The PTC is a cheap

device, but it is dissipative and works only once at

power-up.

Figure 16: Basic preheat current control diagram

(a); preheat filament energy curve (b)

0

0.05 0.1 0.15 0.2 0.25 0.3

I lamp (A)

From the tests the impedance appears insensitive

to the frequency for such lamps. The specified impedance might be valid for higher frequency operation. The relative lamp light output was measured as proposed in reference [5]. The light flux

increases slightly in that frequency range, but can

be considered constant.

Obviously the impedance is sensitive to the current with a negative coefficient, and the ballast

operates with a non linear impedance [6]. When

current is half the nominal one, the impedance is

2.6 times higher, and the voltage is only 25%

higher (see figure 15).

Figure 15: Variation of the average impedance

and voltage of the lamp

R (Ohms) U (V)

1200

900

600

300

0

0.05 0.1 0.15 0.2 0.25

I (A)

200

150

100

50

0

Rlamp

Vlamp

I

CTL

(A)

LAMP

E

If

E=R.I²

CTL

(B)

I

t

The preheat can be achieved with a filament voltage control. The filaments are supplied by two

auxiliary windings of the resonant choke as

shown figure 17a. During the preheat the L6569

frequency is increased, and the choke operates

7/14

AN880 APPLICATION NOTE

as a transformer supplying the voltage to the filaments. Only few components are added around

the L6569 (see figure 18), and the control of the

preheat energy is less sensitive to the preheat duration and the inverter frequency (see figure 17b).

Figure 17: Basic preheat voltage control diagram (a); preheat filament energy curve (b)

The start up initialization

The initial conditions of t he power switching start

up requires care; especially if the resonant and

switching frequencies are close to each other.

The resonant network is not loaded and the full

(A)

CTL

V

LAMP

E

Vf

CTL

V

(B)

E=V²/R

t

Figure 18: Double frequency control for the L6569 with programmed frequency and duration.

1_Vs

2_RF

F

R

3_CF

R

C

F

L6569

C

8/14

C

F_ST

AN880 APPLICATION NOTE

line voltage VDC is applied when the oscillator

starts. The ballast has to start directly with its

nominal conditions to remove any transient oscillation. Hence the operation runs in ZVS mode

with no spurious lamp ignition. Th is situation does

not occur with the saturable transformer drive, because the saturation limits naturally the cur rent by

increasing the frequency.

In the example the resonant capacitors are preset to be compatible with the choke current rise

(see figure 19). The blocking capacitor is precharged to approximately half V

by 2 biasing

DC

resistors, and the lower Mosfet also discharges

the resonant capacitor to ground (see figure 20).

Therefore the blocking capacitor never goes

above 2/3 of the line voltage V

(250V rating),

DC

the operation is safe in ZVS mode. The L6569 is

here preferred to the L6569A, because the lower

Figure 19: Waveforms of the choke current and

the capacitor voltages in steady state

preheat.

IDEAL INITIAL TIME

I

I

GND

The lamp removal protection

Used in TL ballast, the lamp removal protection is

frequently also requested in the "plug-in" CFL ballast . Depending of the topology and the preheat

mode, the lamp removal behaves as:

- a noload resonant mode when the choke and

the capacitor are still connected to the inverter ; a required overcurrent protection increases the frequency to reduce the current;

- an open circuit mode when the lamp filaments

are inserted in the resonant circuit.

When the circuit is open, the choke is not supplied. The MOSFETs turn off slowly generating

bridge cross conduction, and undesirable dissipation losses (see figure 21). The detection stops

the switching to eliminate the cross conduction.

Figure 21: Drain current and voltage STP8NA50

MOSFET operating with noload.

ID = 2 A peak

V

D

V

GS

GND

I

D

BI

V

5 µs/dv ; 50 V/dv ; 0.5 A/dv

B

V

GND

10 0 n s/d v ; 5 0 V/d v ; 5 V/dv ; 1 A/d v

Mosfet is on at power-up.

Figure 20: Configuration of the resonant network during the initialization of the driver.

VS<UVLO

2.4 mH

I

I

ON

L6569

2 x 180 k

V

B

Ω

100 nF

V

GND

GND

BI

4nF

9/14

AN880 APPLICATION NOTE

Figure 22: Open load detection example.

L6569

3_CF

4_GND

LAMP

18V

Several ways can achieve the protection task.

First it can be done by sensing the resonant current through a MOSFET source resistor or a secondary winding on the choke. The switching is

stopped when a large current reduction is detected by analog means.

A logic circuit can also detect t he presence of t he

lamp filaments. One end of a filament is always

connected to a fixed voltage . If the other end of

the filament is connected through a high impedance resistor to another volt age, the absence of

the filament can be easily detected by monitori ng

the resistor voltage change as shown on figure

22.

CONCLUSION

The foregoing note shows how high voltage drivers, like the L6569, simplify the design of the

lamp ballast. These devices includes all the circuitry to drive MOSFETs in half bridge inverter.

Since the optimized switching frequency increases above 50 kHz with a low tolerance, the

size of the passive resonant components is re-

10.R

100.R

11.R

10.R

duced, and the ballast becomes cheaper.With its

supply and its oscillator the L6569 is versatile,

and its flexibility permits to design any improved

power control.

BIBLIOGRAPHY

[1]: AN 527 "Electronic fluorescent lamp ballast"

A.Vitanza, R.Scollo, SGS-THOMSON

[2]: Smart Power ICs, Chapter 8, High voltage integrated circuits for off-line power applications.

C.Diazzi, SGS-THOMSON

[3]: AN 512 "Characteristics of power semiconductors" JM Peter, SGS -T H O M SO N

[4] : "The L6569 half bridge driver: the shutdown

function"

[5] : "Compatibility test of dimming electronic ballasts used in daylighting and environment controls", A.Buddenberg, Rensselaer Polytechnic Institute

[6]: "PSpice High Frequency Dynamic Fluorescent Lamp Model", Bryce Hesterman, APEC’96,

p.641

10/14

AN880 APPLICATION NOTE

APPENDIX A: CF L DEMONSTRATION BOARD

WITH THE L6569

A demonstration board was developed as an example for Compact Fluorescent Lamp ballast. It is

optimised for a CF18DT/E/830 18W lamp from

Osram-Sylvania. Using the L6569 the circuit

achieves preheat, ignition and normal lamp operation. The power transistors are two STD3NA50

500V-3Ω MOSFETs in I-PACK package.

Board description

The three sections of the board are an AC input

rectifier, the half bridge inv erter, and the resonant

ballast. By changing the connection on the input

mains, the ballast can operate either on 120 Vac

mains with a voltage doubler rectification, or on

230 Vac mains with a full wave rectification. The

input resistor R

limits the initial inrush current

1

charging the bulk capacitors. The L6569 operates

with a single 50 kHz switching frequency programmed by R

and C1. Two fast diodes D2 & D

4

synchronize the oscillator to keep the switching in

ZVS mode. The control circuit requires 4.5 mA to

supply the I.C., the MOS gate drives, and the oscillator. Its supply delivers at least 6.5 mA as described in appendix B. The start up resistor also

balances the voltage across the two bulk capacitors.

Figure 23. CFL ballast diagram for a 18W

CFD18T/E lamp with 120/230 Vac inputs.

The resonant ballast

The value of the choke (L

tors (C

& C8) in parallel with the lamp determine

7

) and the two capaci-

1

the lamp ignition voltage and the nominal lamp

current. During the ignition the lamp impedance is

essentially infinite, and the filaments resistance is

only the serial load. To generate the ignition voltage, the switching frequency is set close to the

resonance frequency. In normal operation the

choke resonates with the capacitors C

(parallel loading), but also with the decoupling capacitor C

(serial loading). The current mode pre-

6

heat uses a 150Ω Positive Temperature Coefficient thermistor. Inserted in the capacitive series

& C8), the PTC produces a 0.45 Arms fila-

(C

7

ment current during the initial 0.8 s (reference:

307C1253BHEAB from CERA-MITE).

Basic ballast electrical characteristics

Input voltage: 120 or 230 Vac by input connections change

3

Switching frequency: 50kHz

Average dc line voltage range: Vdc from 260 to 355

Nominal supply current: 0.17A rms @ 310 Vdc

Nominal output power: 17W

Minimum ignition voltage: 700V peak @ 260 Vdc

Nominal preheat current: 0.45 Arms during 0.8s

@ 310 Vdc

& C

7

8

Figure 23.

4 x 1N4006

D7 D4

220V

N

R1 15 1W

110V

R8

120K

1/2W

D5D6

L1=2.4mH core TH LCC E2006-B4 Ref also VOGH 575 0409200 2.4mH

C7-C8=PS8n2J H3 630-2A TH

(*) Polypropylene, Capacitors 630V rated V

C5

47µF

250V

C2

47µF

250V

R5 100K

1/2W

C3

4.7µF

25V

R4

27K

1/4W

D8

1N4148

ZPD 18V

V

S

RF

L6569

CF

C1

560pF

50V

D1

L

C9 470pF 630V

R6 47 1/4W

BOOT

HVG

OUT

LVG

GND

(*)

C4100nF 50V

R2 22 1/4W

R3 22 1/4W

D96IN419C

R10 10K

1/4W

Q1

STD4NK50

Q2

STD4NK50

R7

180K

1/4W

BYW100-100

D2

D3 BYW100-100

R9

180K

1/4W

L1=2.4mH

C6

100nF

250V

CFL LAMP

SYLVANIA DELUX T/E 18W

C7

8.2nF

630V

(*)

C8

8.2nF

630V

(*)

RV1

PTC 150

350V

11/14

AN880 APPLICATION NOTE

Figure 24: PCB Layout of the board.

Comp.

Side

Copper

Side

Figure 25: PCB component placement diagram.

The resonant choke

The inductance of the choke is 2.4 mH with a

minimum saturation current of 0.65 A. In the practical example it has been done with:

Core: Thomson LCC E2006 material B4;

Air gap: 2 spacers of 0.4 mm each (total 0.8 mm);

AL = 75 nH;

Bobbin: HC2006BA-06;

Number of turns: 175;

Measured saturation current: 1 A peak @ 25 °C;

Customization of the board

Some flexibility is added to the board to extend its

evaluation. The MOSFETs have two foot prints to

mount either I-PAK or TO220 packages. And two

choke footprints are also avalaible for E1905A

and E2006A magnetic cores.

12/14

AN880 APPLICATION NOTE

APPENDIX B: Rating of the capacitive supply

with the L6569 driver

The supply is made with the snubber and a start

up resistor R

.

S

A snubber circuit is used to minimize the MOSFETs dissipation. It also achieves a non dissipative supply as shown on figure 10.

The MOSFETs gate charge, the driver consumption, the oscillator, and the shunt regulator, define

the circuit consumption. We can estimate this

current is I

:

S AV

> 2 ⋅ IG + IQS + I

I

SAV

= 2 ⋅ Q

⋅ fsw + IQS +

G

+ I

OSC

V

S

RF ⋅ 2

REG

+ I

=

REG

Where QG the MOSFET gate charge

I

V

R

the driver supply current

QS

the supply voltage

S

the oscillator resistor and VS the driver

F

supply voltage

I

When VS is lower than the UVLO threshold U

the shunt regulator current.

REG

UVLO

, the

driver is only consuming. Its current must be minimal to reduce the dissipation of the resistor R

The L6569 has a 150 µA start up current, and the

maximum resistance is 2MΩ for a 230Vac line application.

We can also reduce the resistor value to get a

faster start up time T

T

.

S

S

⋅ C

⋅ U

S

UVLO

V

DC

R

=

S

Where CS is the supply capacitor, and VDC the

line voltage.

When the timer oscillates, the capacitor C sup-

plies the lamp current during the lower MOS turn

off. To avoid any cross conduction its capacitance

is limited by the driver dead time T

26). Hence the capacitive supply current I

limited.

I

= C ⋅ VDC ⋅ FSW < IL ⋅ TD ⋅ F

CAV

C <

TD ⋅ I

V

L

DC

Where IL is the peak lamp current, and F

switching frequency.

For a ballast such as a CFL one this circuit supplies easily the required current. For instance with

a CF18DT lamp ( I

> 230 mA) the capacitor is

L

1nF on 120Vac line, 470 pF on 230 Vac line. At

50 kHz the average capacitive current is 6 mA in

both cases.

Figure 26: Cross conduction of the snubber

capacitor with the upper MOSFET:

capacitor current and voltage

waveforms.

.

S

GND

GND

GND

200 ns/dv ; 50 V/dv ; 0.1 A/dv

D

T

(see figure

D

is also

C

SW

SW

V

+ V

HVG

I

C

RF

the

OUT

13/14

AN880 APPLICATION NOTE

Information furnished is bel ieved to be accurate and reliable. Howev er, STM icroele ctronics ass umes no respons ibilit y for the consequence s

of use of such i nformation nor for any i nfringement of patents or ot her rights of third parties which may result from its use. No l icense is

granted by impli cation or otherwis e under any patent or patent righ ts of STMicroelectro nics. Specification mentioned i n this publication are

subject to change withou t notice. This publica tion supersed es and replac es all informat ion previousl y supplied. STMic roelectro nics products

are not authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics

© 2003 STMicroelectronics – Printed in Italy – All Rights Reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Brazil - Canada - China - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan - Malaysia - Malta - Morocco -

Singapore - Spain - Sweden - Switzerland - United Kingdom - United States.

http://www.st.com

14/14

Loading...

Loading...