Page 1

AN836

APPLICATION NOTE

LOW FORWARD VOLTAGE SCHOTTKY DIODE

INTRODUCTION

In power supplies, the major portion of power losses is due to output rectifiers. The impact of these losses

on the efficiency can be expressed by:

IOUT()

V

η

η :efficiency drop due to the diodes.

V

V

This formula shows that the influence of the forward voltage increases when the output voltage of the power supply decreases.

This parameter becomes very important for the new standard of 3.3V output voltage. Another key parameter is the leakage current which we have to take into account to develop high efficiency low forward voltage drop Schottky with the best trade-off.

F

-------------------------- -=

V

OUT

F(IOUT)

OUT

:voltage drop at the output current

(IOUT) of the converter.

:output voltage of the converter.

TRADE-OFF

The 3 most important application characteristics of a Schottky are:

– forward voltage

– reverse leakage current

– reverse blocking voltage

Generally for a given application, the first step is to fix the reverse blocking voltage. We then study the

best trade-off (choice of a metal barrier) between the forward voltage and the leakage current.

A decrease of the forward voltage increases the efficiency of the converter but increases at the same time

the leakage current and limits operating range where we can keep the reverse losses under control. In the

datasheet this range is defined by Tj max.

To define the best trade off of a low forward voltage schottky we have to take into account its application

condition. STMicroelectronics has developed two families of low forward voltage Schottky well suitable to

two applications: the OR-ing Schottky and Schottky for 3.3V output power supply secondary.

SCHOTTKY DIODES FOR 3.3V SWITCHED MODE POWER SUPPLY

When a Schottky works in a switched mode power supply (forward, flyback,...), it sees during the same

switching period conduction losses and reverse losses.

In these configurations the trade-off between the forward voltage and the leakage current has to be chosen to have the best efficiency with a sufficient safety margin. This is to keep the reverse losses under

control (Tj max = 125°C).

REV. 2

1/5May 2004

Page 2

AN836 APPLICATION NOTE

Table 1. Main Characteristics of Schottky

V

PART NUMBER PACKAGE Io

typ Max Max

AmVmVmA

STPS125U SOD6 1

390

(1)

STPS5L25B DPAK 5 310 350 175

STPS10L25D TO220AC 10 300 350 400

STPS15L25D/G D2PAK/TO220AC 15 300 350 640

STPS20L25CT TO220AB 2x10 300 350 400

STPS20L25CG D2PAK 2x10 300 350 400

Note: 1. Main characteristics of the 25V low VF Schottky

OR-ING SCHOTTKY

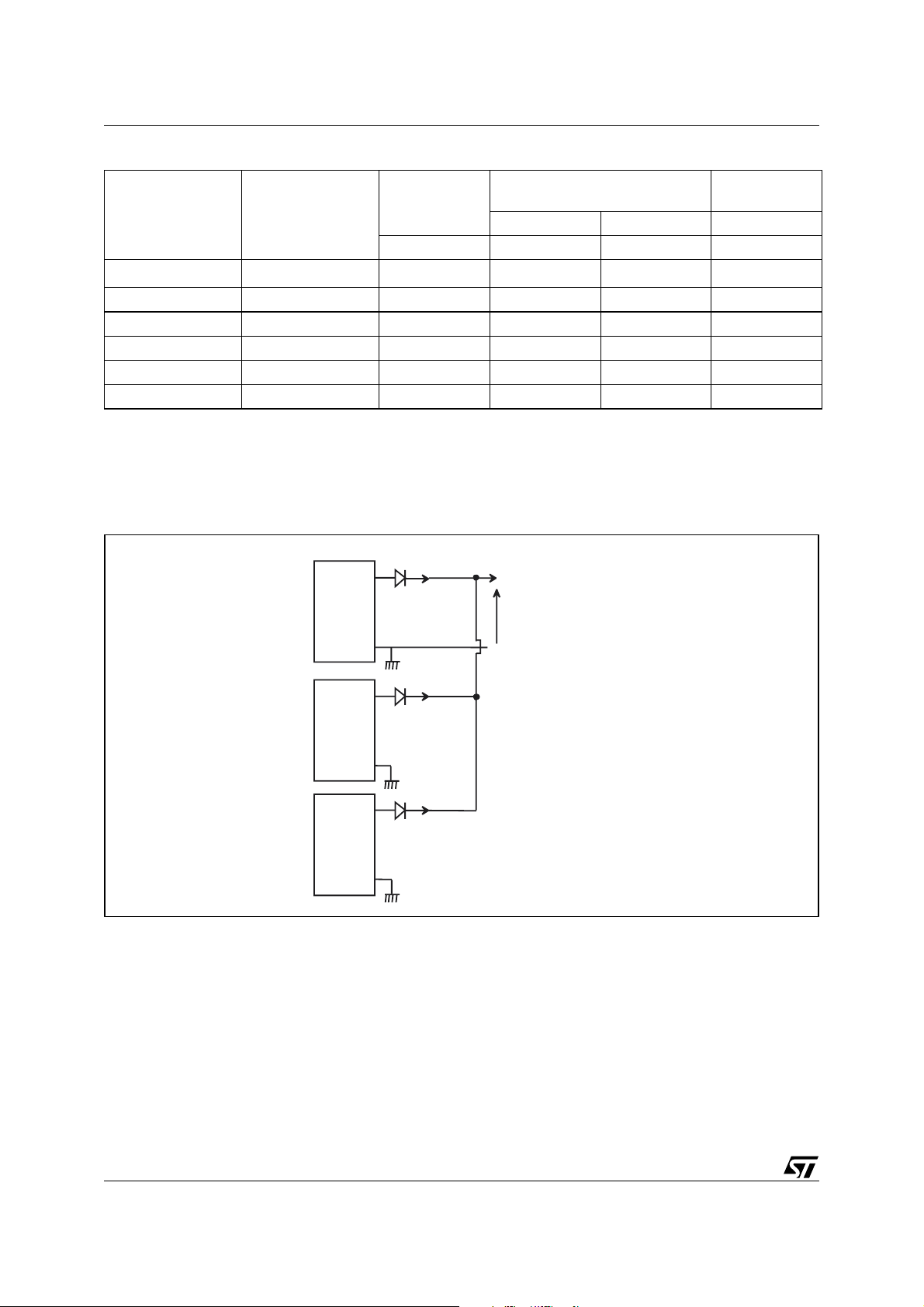

To increase system reliability, power supplies are sometimes connected in parallel (Fig.1).

Figure 1. OR-ing Schottky in redundant power supply

F

(Io,125°C)

460

(125°C, 25V)

(1)

I

R

(1)

2

POWER

SUPPLY

1

POWER

SUPPLY

2

POWER

SUPPLY

n

I

OUT/n

I

OUT/n

I

OUT/n

I

OUT

V

OUT

3.3V, 5V or 12V

The Schottky diodes are connected in series with the output of each power supply. In the steady state a

continuous current (I

T/n) flows in each Schottky. Obviously in this case there are no reverse losses.

OU

When a power supply fails, the corresponding ORING diodes ceases to carry current and the system output voltage is not disturbed. The OR-ing diode then sees the reverse voltage V

OUT

.

In this application the most critical parameter is the forward voltage drop in order to maintain the best efficiency of the system. A breakdown voltage of 10V is sufficient for output voltage of 5V and 3.3.V.

The trade-off has been chosen to obtain a low forward voltage. In this application we can accept a high

leakage current because when the diode is blocked the reapplied voltage is low (3.3V or 5V), the junction

temperature is also low because there are only reverse losses. So it’s easy to keep reverse losses under

control.

2/5

Page 3

AN836 APPLICATION NOTE

Table 2 gives the main characteristics of the 10V and 15V schottky.

Table 2. Main Characteristics of 10V and 15V Schottky

V

PART NUMBER PACKAGE Io

F

(Io,105°C)

typ Max Max

AmVmVA

STPS15L10D TO220AC 15

270 320 0.42

STPS80L10TV ISOTOP 2x40 270 320 1.2

STPS20L15D TO220AC 20

STPS40L15CW TO247 2x20

Note: 1. I=19A

2. VR=12V

3. I=19A per diode

0.31

0.31

(1)

(3)

0.36

0.35

(1)

(3)

CONCLUSION

The equilibrium between efficiency and safety margin against thermal runaway has been best solved with

25V, 15V and 10V Power Schottky diodes. One being suitable for 3.3V supplies and the other for the redundant Powers supplies.

Moreover, the inclusion of Power Factor correction will significantly change the choice of the Schottky diode for the secondary Power supply rectification.

With PFC, the reapplied voltage across the output rectifiers will be lower. For example we can consider

using 25V Schottky in a 5V forward converter, whereas today a 45V Schottky diode is needed.

I

R

(100°C, 10V)

(2)

0.55

(2)

0.55

Per diode

3/5

Page 4

AN836 APPLICATION NOTE

REVISION HISTORY

Table 3. Revision History

Date Revision Description of Changes

August-1995 1 First Issue

10-May-2004 2 Stylesheet update. No content change.

4/5

Page 5

AN836 APPLICATION NOTE

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implication or otherwise under any patent or patent rights of STMicroelectronics. Specifications mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devices or systems without express written approval of STMicroelectronics.

The ST logo is a registered trademark of STMicroelectronics.

All other names are the property of their respective owners

© 2004 STMicroelectronics - All rights reserved

STMicroelectronics GROUP OF COMPANIES

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States

www.st.com

5/5

Loading...

Loading...