Page 1

AN833

APPLICATION NOTE

FREQUENCY MODULATION ON L4981B

Devices Description

Designing PFC, an important parameter to consider and control is the high frequency noise. This noise is produced by the switching itself and its level depends on several parameters such as high frequency current ripple,

PCB layout, active switch performance and also some particular circuital solutions.

The parameter to keep under control is the electromagnetic interference (E MI) content, v ersus the RFI norms

and design requirements (EN60555 and VDE0871B). To get more information about thi s, please ref er al so t o

the CIRCUIT FOR POWER FACTOR CORRECTION WITH REGARDS TO MAINS F ILTERING (AN510). The

PFC controller L4981B version can be useful to solve the EMI problems using the frequency modulation technique that allows to spread the noise spectrum over a wider range, reducing in this way the peak of the associated energy. This section deals with the way to use this device feature getting the best results. The L4981B

performs the frequency modulation function by using Pin16, that in this version is named FREQ-MOD.

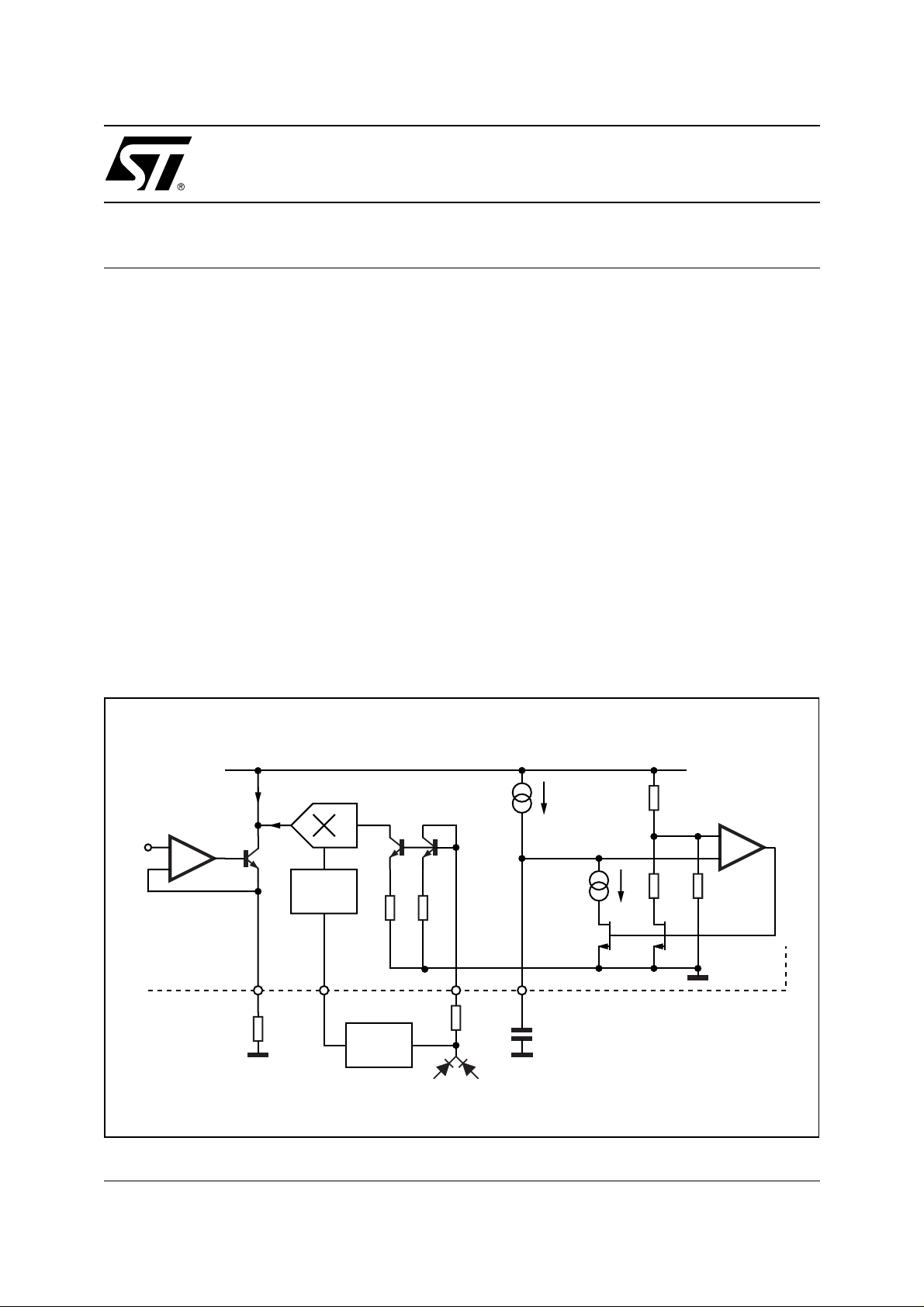

This pin (see fig. 1) is internally connected (with a current mirror) to an input of the multiplier.

The output of the multiplier is used to dynamically change the current forced into the external oscillator capaci-

tance changing in this way the switching frequency. The second terms (input) of the multipl ier is connected to

the divider (1/Vrms) that, through the VRMS (Pin7), s enses the input mains making the fr equency modulation

not affected by the line variations (see also Pin 16 description in AN628).

Figure 1. Frequency Modulation with L4981B.

I

Ifm

1.28V

+

1/V

MRS

17

ROSC

R

OSC

VRMS

1

7

FREQ-MOD

2 POLES

FILTER

10

16

Rfm

· I

COSC

18

200 · I

C

OSC

8.5V

-

+

D94IN065B

November 2003

1/3

Page 2

AN833 APPLICATION NO TE

Connecting pin16 at the rectified mains through a resistor, it is possible to define the modulation depth using the

formula:

∆f

SW

------------- - K

=

f

SW

⋅

V

IPKROSC

-------------------------------- R

V

RMSRfm

⇒

⋅

fm

V

IPK mains()

---------------------------------------------------------------⋅=

K

V

RMS pin7()

R

⋅⋅

OScfSw

∆f

⋅

sw

where:

R

is the programming current resistor.

fm

K is a constant value = 0.1157

V

is the

V

RMSmAINS

is the voltage at pin 7

V

IPK

RMS

2⋅

Typically a good compromise can be 10% to 20% of the starting frequency. Designing the frequency modulation

it is useful to remind few points :

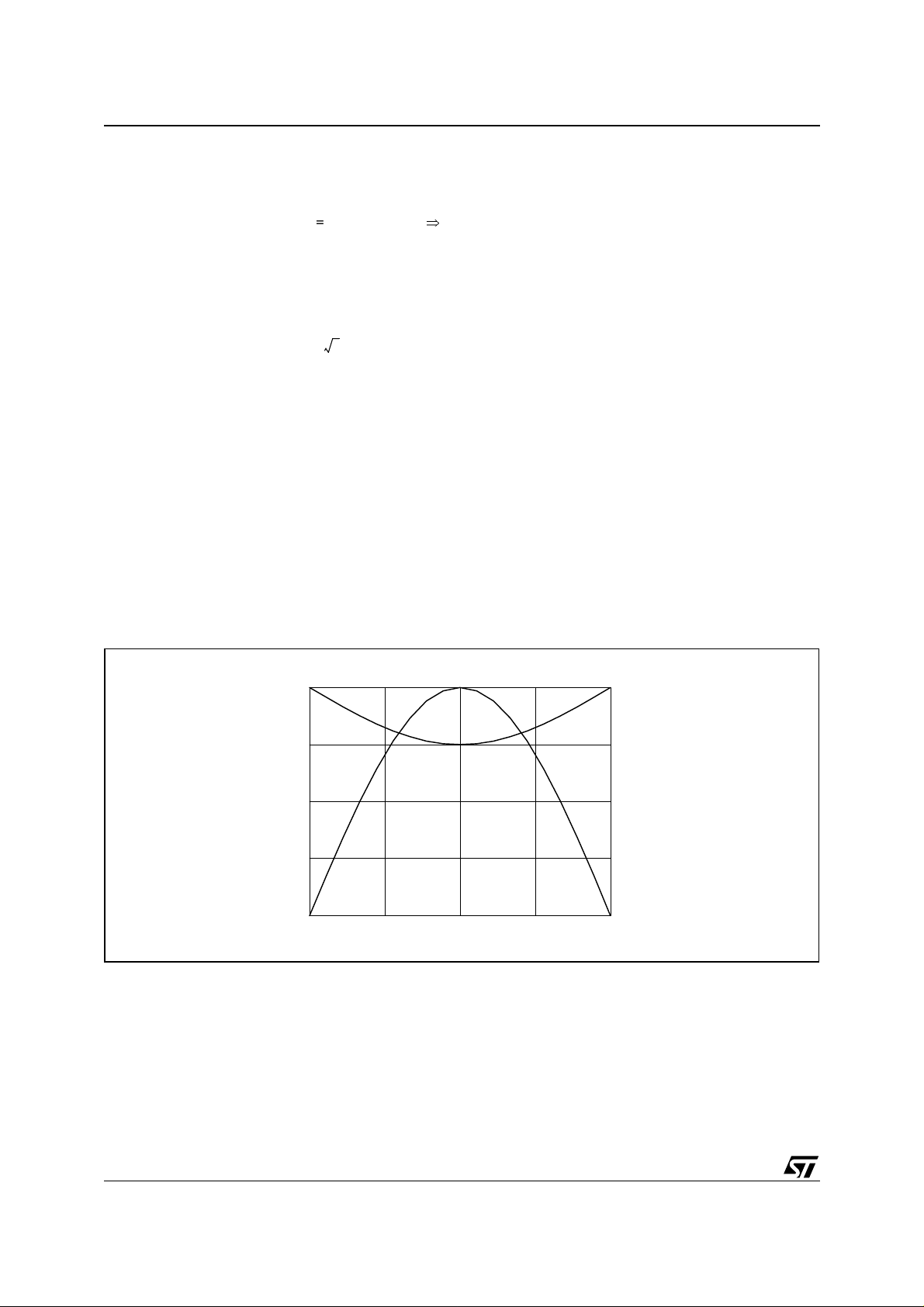

a) The switching frequency (fsw) is modulated by the mains instantaneo us value and de creases as the

rectified voltage increases, so the minimum fsw occurs at the input peak voltage and current (see fig.

2).

b) The switching losses increase with the frequency (and obviously with the current).

c) The current ripple increases (for the same boost inductor value) as the switching frequency decreases,

the higher current ripple produces an higher EMI.

Figure 2. Modu lation Freque nc y Normalized in a Half Cycle of the Mains Voltage. (eg. RFM = 1100kΩ,

Rosc = 24kΩ, Cosc = 820pF).

fsw

1

0.8

0.4

0.2

0

180

0.8

0.4

0.2

Vl

1

0

0

45 90

135

Electrical degrees

Considering the above mentioned points, to make a reasonable comparison with an equivalent fixed frequency

PFC application in terms of EMI, it is recommended to modify the starting frequency (oscillator).

The suggested criterion for designing a L4981B applicati on i s to fol l ow the same procedure used for t he fixed

frequency version (L4981A) except for the oscillator t h at m u st b e de signed for the desired frequency (fmin) that

occurs at the peak of the current, plus the modulation contribution, that is:

2.44

f

SW

∆fswf

min

-----------------------------------=+=

R

⋅

OSCCOSC

2/3

Page 3

eg. designing a 100kHz minimum fsw with a modulation depth » 20%:

AN833 APPLICATION NOTE

f

SW

124KHz

------------------------------------------------------- -==

24 10

2.44

3–

0.82 10

⋅⋅⋅

9–

fIn this way the advantage, in terms of reduction of the peak of energy in the noise spectrum, is remarkable. On

the other hand the increase of switc hing losses c an be neglec ted bec ause t he maximum frequency occurs at

the minimum line current.

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or p atent right s of STMicroelectr oni cs. Spec i fications mentioned i n this publication are subje ct

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as cri tical comp onents in life support dev i ces or systems wi thout express written approval of STMicroel ectronics.

The ST logo is a registered trademark of STMicroelectr oni cs.

All other n am es are the pro perty of thei r respectiv e owners

© 2003 STMi croelectro ni cs - All rights reserved

Australi a - B elgium - Brazil - Canada - China - Czech Republ i c - Finland - France - Germ any - Hong Kong - India - Is rael - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States

STMicroelectronics GROUP OF COMPANIES

www.st.com

3/3

Loading...

Loading...