Page 1

AN827

APPLICATION NOTE

A 500W HIGH POWER FACTOR WITH THE L4981A

CONTINUOUS MODE IC

The widespread use of passive AC/DC off-line converters causes l ow power fac tor and high line current

harmonic distortion. To reduce these phenomena and to comply with relevant regulatory agency requirements , designers are employing active power factor correction in their off-line SMPS applications. This

paper describes a practical, low c ost and easy to i mpl ement 500W power fac tor corrected application

that employs the L4981A Continuous Mode PFC IC.

INTRODUCTION

Reduction of line current harmonic distortion and improvement of power factor is of great concern to many designers of off-line switched mode power supplies. This concern has been motivated by present and impending

regulatory requirements regarding line current harmonics. The reasons for improving power factor and reducing

line current harmonic distortion are well known and understood. Active power factor correction using the boost

topology and operating in the continuous i nductor current control mode is an excellent method to comply with

these requirements and is well accepted in the industry.

This paper will present a practical power factor corrected design for a 500 Watt output and universal mains input

application. The detail ed derivations of al l power, I C biasing and control component values and t ypes will be

shown. The evaluation results from an actual working demoboard will be presented as well as several relevant

oscillograms.

DESIGN SPECIFICATIONS

The design specifications given below are realized by the implementation of a functional demoboard.

The design target specifications are as follows:

– Universal mains input AC voltage V

– DC regulated output voltage V

– Full load output ripple voltage ∆V

– Rated output power P

– Maximum output overvoltage V

– Switching frequency f

– Maximum inductor current ripple ∆I

– Input power factor PF > 0.99

– Input line current total harmonic distortion <5%

To meet these specifications, the selection of component values and material types is very important. The next

sections will describe the component selection criteria along with some critical derivations. For detailed explanations on the controller operation and pin description, refer to Application

Note AN628

the corresponding Datasheet

Designing A High Power Factor Switching Preregulator With The L4981 Continuous Mode [1]

out

sw

L4981A/B Power Factor Corrector [2].

out

= 500W

omax

= 80kH z

= 88Vac to 264Vac, 60/50Hz

irms

= 400Vdc

= ±8V

ripple

= 450V

= 23%

L

and

November 2003

1/20

Page 2

AN827 APPLICATION NO TE

POWER COMPONENTS SELECTION

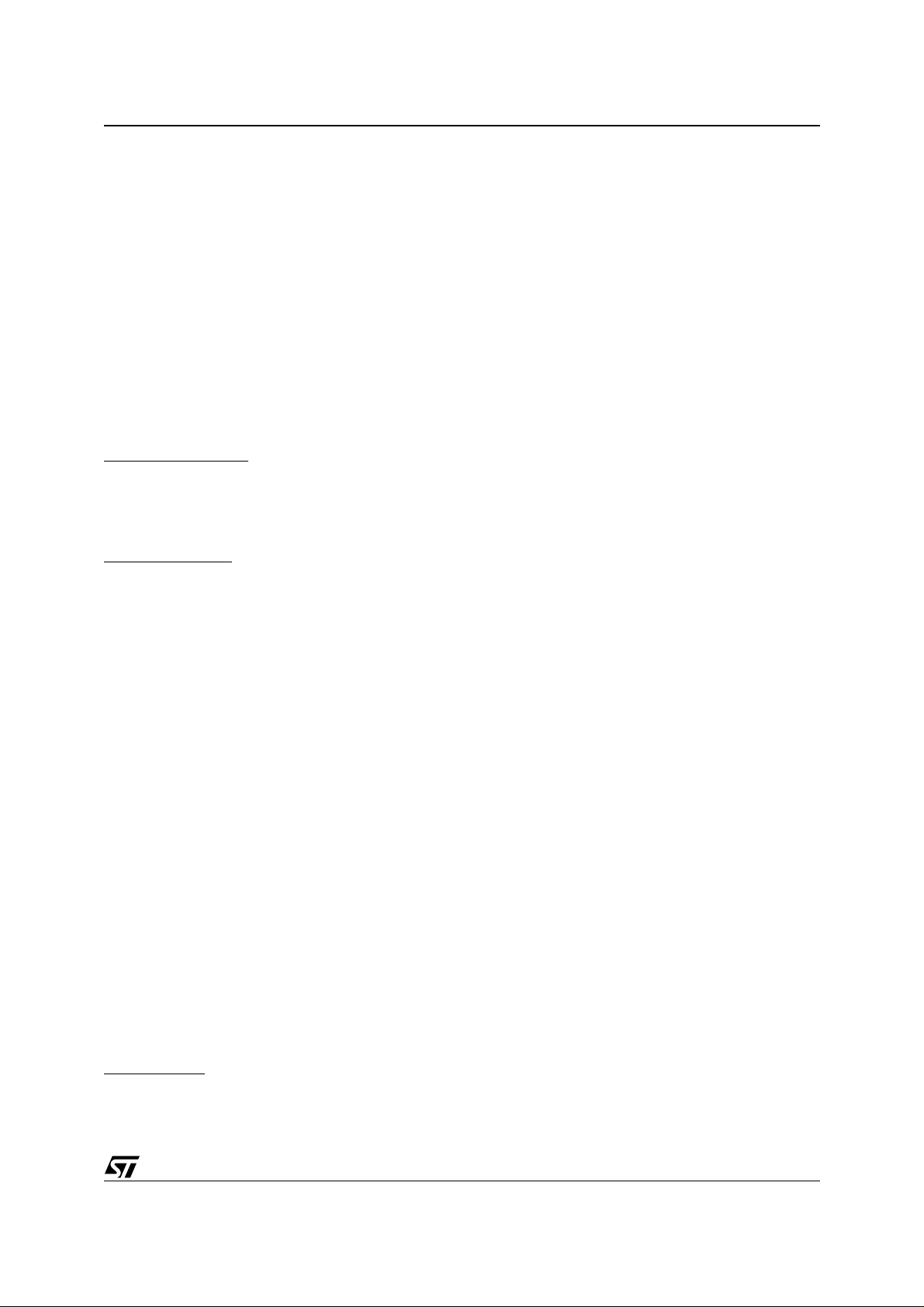

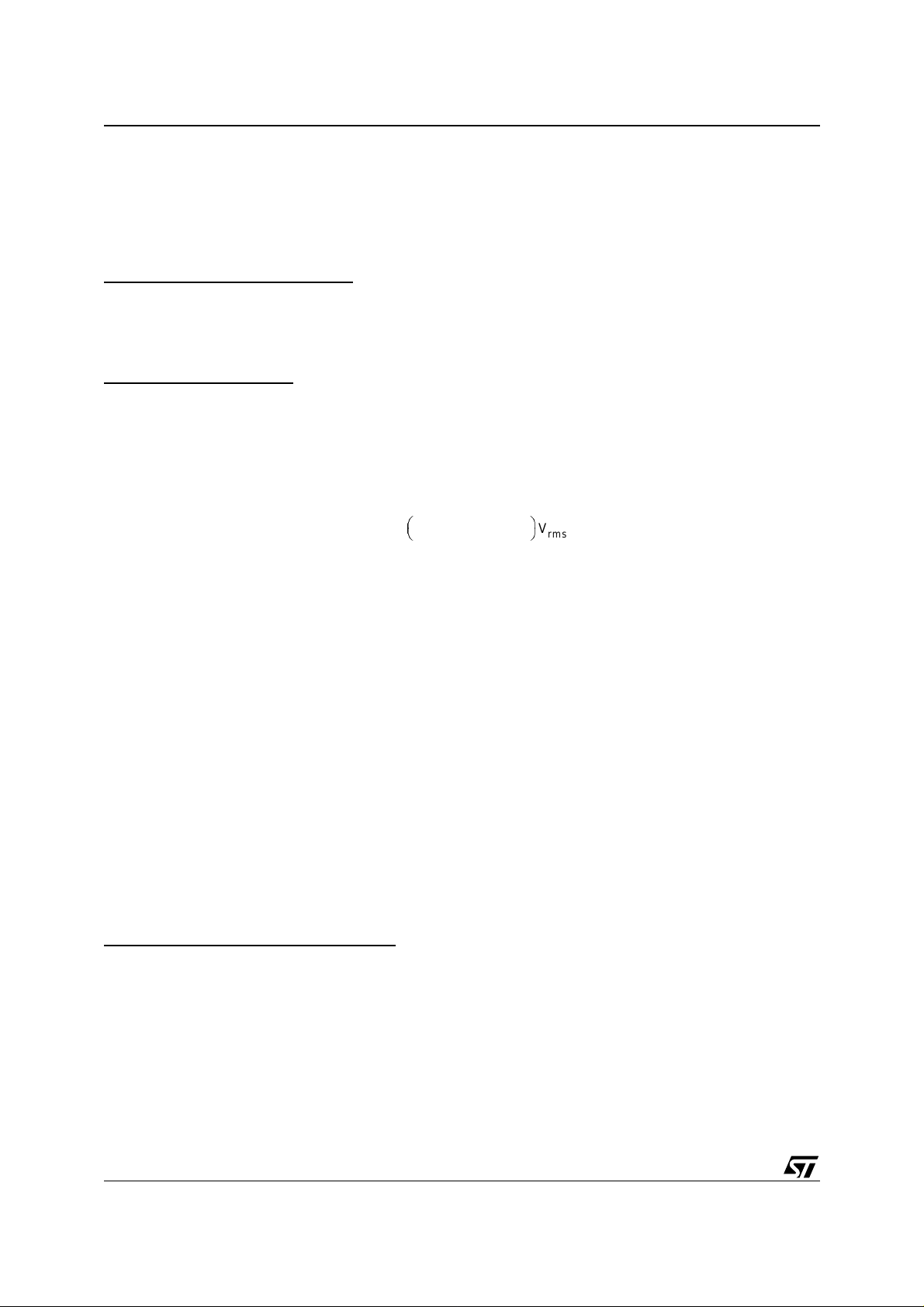

The power component values and types are derived and selected in the next section. Please refer to Figure 2,

500 Watt Demoboard Schematic.

Input Diode Bridge

The input diode bridge, D1, can be a standard slow-recovery type. The selection criteria include the maximum

peak reverse breakdown voltage, maximum forward average c urrent, maximum surge current and thermal considerations.

Maximum peak reverse voltage:

V

prvVirmsmax

2 1.2 safety m inarg()264V 2 1.2 448V=⋅⋅=⋅⋅=

Therefore use a 600V rated diode.

Maximum forward average current:

I

rmsmax

I

fave

The thermal considerations require the I

chosen has a I

of 25A. Additionally, a small heatsink is required to keep the case temperature within speci-

fave

P

OUT

-----------------------------

V

rmsm in

I

rmsmax

--------------------------------

rating to be significantly higher than the value calculated. The part

fave

2⋅

π

500

------------------- 6.31A===

n⋅

88 0.9⋅

6.31 2⋅

----------------------- 2.84A===

π

fication.

Maximum surge current:

There is a significant inrush current at start-up due to the large value bulk capacitor, C6, at the output. There is

minimal impedance from the mains to this capacitor, thus at the peak of the input voltage waveform a large inrush current exists. This inrush current can be significantly reduced by some means of current limiting such as

an NTC or triac/resistor combinati on. The input bridge diode’ s maxi mum surge current rating must not be exceeded. This demoboard has a low cost and simple NTC for current inrush limit ing. The effi ciency c an be i mproved by using the triac/resistor scheme, however the cost and complexity increases.

Input Fuse

The input fuse, F1, must open during severe current overloads without tripping during the transient inrush cur-

rent condition or during normal operation. The fuse must have a current rating above the m aximum continuous

current (6.3Arms) that occurs at the low line voltage (88V). The fuse chosen for this demoboard has a continuous current rating of 10A/250VAC.

Input Filter Capacitor

The input filter capacitor, C3, is placed across the diode bridge output. This capacitor must smooth the high fre-

quency ripple and must sustain the maximum instantaneous input voltage. In a typical application an EMI filter

will be placed between the mains and the PFC circuit. This demoboard does not have the EMI filter except for

2/20

Page 3

AN827 APPLICATION NOTE

this input capacitor. However, the eval uat i on results listed in Table 1 were made with an EMI filter placed between the mains input and the PFC circuit. The design of the EMI filter is not described here. The value of the

input filter capacitor can be calculated as follows:

I

Cin Kr

Cin 0.25

---------------------------------------------------------->

2 π fSwrV

⋅⋅ ⋅⋅

---------------------------------------------------- - 0.59µF=⋅>

2 π 80k 0.06 88⋅⋅ ⋅ ⋅

Where:

Kr is the current ripple coefficient r = 0.02 to 0.08

The maximum value of this capacitor is limited to avoid line current distortion. The value chosen for this demo-

board is 0.68

µ

F.

Output Bulk Capacitor

The choice of the output bulk capacitor, C6, depends on the electri cal parameters that affect the fi lter perf or-

mance and also on the subsequent application.

Capacitance Value:

rms

rms m in

6.31

The value shall be chosen to limit the output voltage ripple according to the following formula:

Assume low ESR and

∆

V

= ±8V

ripple

P

C

--------------------------------------------- -

out

2π 2f ∆VOV

out

⋅⋅ ⋅

O

P

out

------------------------------------------- 207 µF===

2π 120 8 400⋅⋅⋅

The value chosen is 330uf to ensure that the maximum specified voltage ripple is not exceeded.

Although the ESR does not normally affect the voltage ripple, it has to be considered for the power losses due

to the line and switching frequency ripple currents. It is important to verify that the low and high frequency ripple

currents do not exceed the manufacturer’s specified ratings at the operating case temperature. Capacitors may

be connected in parallel to decrease the equivalent ESR and to increase the ripple current handling capability.

If a specific hold-up time is required, that is the capacitor has t o deliver the suppl y voltage for a specifi ed time

and for a specified dropout voltage, then the capacitor value will be determined by the following equation:

2P

⋅⋅

C

out

----------------------------------------------=

V

o min

outthold

2

V

–

op min

2

Where:

P

is the maximum output power

out

V

is the minimum output voltage at max. load

omin

V

is the minimum operating voltage before "power fail" detection

opmin

t

is the required hold-up time

hold

Voltage Rating:

The capacitor output voltage rating should not be exceeded under worst case conditions. The minimum voltage

rating is calculated as follows:

3/20

Page 4

AN827 APPLICATION NO TE

V

> V

cap

out

+ ∆V

ripple

+ V

= 400 + 8 + 40 = 448V

margin

Where: V

is the nominal regulated DC output voltage

out

∆

V

is the ac voltage superimposed on the regulated DC output voltage

ripple

∆

V

is the allowance for tolerances in V

margin

and additional margin before OVP intervention

out

The capacitor chosen has a voltage rating of 450VDC. The overvoltage trip level of P in 3 (OVP) must be set

below 450VDC.

Power Mosfet

The power mosfet, Q1, is used as the active switch due to its high frequency capability, ability to be driven directly from the controller and availability. The main criteria for its selection include the drain to source breakdown

voltage (BVdss), delivered power and temperature considerations.

Voltage Rating:

The power mosfet has to sustain the maximum boosted output dc voltage according to the following equation:

> V

BV

dss

The power mosfet chosen has a BV

+ ∆V

out

of 500V.

dss

ripple

+ V

= 400 + 8 + 40 = 448V

margin

Power Rating:

The main parameters to consider are Rdson and the thermal characteristics of the package and heatsink. The

main losses in the power mosfet are the conduction and switching l osses. The swi tching l osses can be separated into two quantities , c apaciti ve and c rossover l osses. The swit ching l osses are dependent on t he mosfet

current di/dt. The maximum conduction (on-state) power losses can be calculated according to the following

equations:

500

--------- -

0.9

------------------ 2

288⋅

16 2 88⋅⋅

-----------------------------–⋅=⋅=

3π400⋅

I

Qrmsmax

P

onmax

= 5.42A

= I

Qrms

I

Qmsmax

2max · R

P

out

----------------------------------------- 2

η 2 V

⋅

(DS)on max

= 5.422 · 0.54 = 15.86W

irms min

16 2 V

⋅⋅

-----------------------------------------------–

⋅

3πV

irms min

out

Where:

I

max is the max. power mosfet rms current

Qrms

V

min is the min. specified rms input voltage

irms

R

on typ. = 0.27Ω at 25°C at 10 A, VGS = 10V

(DS)

R(

on max = 0.54Ω at 100°C

DS)

The capacitive switching losses at turn-on are calculated as follows:

P

capaci c etan

1.5

3.3 C

ossVout

1

-- - C

extVout

2

2

⋅+⋅

f

2W=⋅⋅=

sw

4/20

Page 5

AN827 APPLICATION NOTE

Where:

C

= 650pF is the mosfet drain capacitance at 25V

oss

C

= 100pF is the equivalent stray capacitance of the layout and external parts

ext

The estimated crossover switching losses (turnon and turn-off) are calculated as follows:

P

crossover

= V

out

· I

Qrms

· fsw · t

+ Prec = 400 · 5.42 · 80k · 40ns + 1.5 = 8.43W

cr

Where:

is the crossove r tim e

t

cr

P

is the boost diode recovery power loss contribution

rec

To reduce the turn-off losses in the mosfet, an RCD turn-off snubber has been employed. The capacitor value

is calculated as follows:

C11

I

Q1pktrise

-----------------------------

∆V

out

8.92 40 ns⋅

----------------------------- - 892pF===

400

⋅

Therefore, use C11 = 820pF, 1000VDC rating

The resistors, R23-24, must dissipate the energy stored in the snubber capacitor upon t urn-on of the power

mosfet. The capacitor must fully disc harg e during the sw itching cycl e.

The time constant of the RC combination is determined as follows:

1

1

------

10

----------------------- - 1524=⋅≤

C11⋅

f

sw

R

The power dissipated in the resistors, R23-24, is calculated as follows:

P

diss

1

-- - C11 V

2

out

2

1

-- - 820p F 400

f

sw

2

2

80 k 5.25W=⋅⋅⋅=⋅⋅=

Therefore, use R23 = R24 = 510

Ω

, 3W rating.

The power mosfet chosen is the STMicoelectonics Part Number STW20NA50.

This part has a BV

= 500V, R

dss

= 0.27Ω, and is in a TO-247 package. In order to keep the junction tem-

DSon

perature at a safe level, the mosfet is attached to an AAVID Heatsink Part Num ber 61085 with a thermal resistance of 3.0°C/W. This will keep the mosfet junction temperature at a safe level at worst case conditions, lowline input voltage (88V) and full load (500W).

The thermal resistance of the heatsink may need to decrease depending upon the ambient temperature, type

of enclosure (vented or non-vented) and the method of cooling (natural or forced convection).

Boost Diode

The main criteria for the selection of the boost diode, D2, include the repetitive peak reverse breakdown voltage

(V

), average forward current (I

rrm

), reverse recovery time (trr) and thermal considerations.

fave

Voltage Rating:

The voltage rating of the boost diode i s determined by the same equati on as for t he power mosfet. T he value

chosen is V

= 600V.

rrm

5/20

Page 6

AN827 APPLICATION NO TE

Current Rating:

The power losses in the boost diode consist of the conduction and switching losses. The switching losses are

a function of the reverse recovery ime (t

pared to the conduction losses if a suitable ultra fast recovery diode is chosen. The conduction power losses

can be calculated as follows:

) and output voltage (V

rr

) . The switching losses are negligible com-

out

I

I

Drms

P

condVtoIoutIDrms

----------------------------------

2V

out

P

in

in rms min

2

P

-----------

V

out

out

Rd 1.15 1.25 3.2420.043 1.89W=⋅+⋅=⋅+⋅=

500

--------- - 1.25A===

400

⋅⋅

16 2 V

------------------------------------------------- 3.24A==

3πV

⋅⋅

in rms min

out

Where:

V

= 1.15V is the threshold voltage of the diode Rd = 0.043W is the diode differential resistance

to

The diode must sustain the average output current and also keep the power losses to a minimum in order to

keep the diode junction temperature within acceptable limits. The switching losses can be significantly reduced

if an ultra-fast diode is employed. Since this circuit operates in the continuous current mode, the mosfet has to

recover the boost diode minority carrier charge at turn-on.

Thus, a diode with a small reverse recover time, t

, must be used. This circuit employs the STMicroelectronics

rr

Turboswitch Diode Part Number STTA806D. This part offers the best solution for the continuous current mode

operation due to its very fast reverse recovery time, 25ns typical. This part has a breakdown voltage rating (V

of 600V, average forward current rating (I

) of 8A and reverse recovery time (trr) of 25ns.

fave

rrm

The diode is attached to the same heatsink as the power mosfet, Q1. The STTA806D is non-isolated thus requiring a thermal insulator with good heat transfer characteristics. The STTA806DI is an isolated package and

can be attached directly to the heatsink. Silicone thermal grease may be applied to improve the thermal contact

between the diode and heatsink.

)

Boost Inductor

The boost inductor, T1, design starts with defining the minimum inductance value, L, to limit the high frequency

current ripple,

∆

IL. The next step is to define the number of turns, air gap length, ferrite core geometry, size and

type for the specified power level. Finally, the wire size and type are determined.

In the continuous mode approach, the acceptable current ripple factor, K

, can be considered between 10% to

r

35%. For this design, the maximum specified current ripple factor is 23%. The maximum current ripple occurs

when the peak of the input voltage is equal to Vout/2.

Occurs at V

6/20

inpk

= V

= 200V; V

out/2

V

∆I

∆I

L

-------------------------

Lmax

4fSWL⋅⋅

= 141V

inrms

V

inpkVoutVinpk

--------------------------------------------------=

V

outfsw

out

–()

L⋅⋅

400

---------------------------------------- - 2.50A==

4 80k 0.5mH⋅⋅

For all other input voltages

Page 7

AN827 APPLICATION NOTE

K

r

∆I

L

----------------- - I

2I

⋅

Lpk

Lpk

2I

Lrms

------------------- -=⋅=;=

V

2Pin⋅

inrms

The minimum boost inductor value can be calculated as follows:

V

out

min

-------------------------------------- -

4fsw∆I

⋅⋅

Lmax

L

400

------------------------------------------ 0.5mH== =

480kHz2.50⋅⋅

The Table shown below relates the current ripple to the input voltage.

V

in (rms)

88 124 6.31 8.92 2.13 0.119

120 170 4.63 6.55 2.44 0.186

141 199 3.94 5.57 2.50 0.224

180 255 3.09 4.37 2.31 0.264

200 283 2.78 3.93 2.07 0.263

220 311 2.53 3.58 1.73 0.242

240 339 2.31 3.27 1.29 0.197

264 373 2.10 2.97 0.63 0.106

V

in(peak)

I

L(rms) Iin (rms)

I

L(peak)

Current Ripple

The number of turns, N, can be calculated according to the following formula:

K

r

LI

⋅

N

Lpk

----------------------------

⋅

A

effBmax

0.5mH 8.92mA⋅

---------------------------------------------------- 59 Turns== =

211 10

6m2

0.36T⋅⋅

Where:

L is the calculated inductance value to limit the ripple current,

I

is the worst case inductor current occurring at low-line input voltage (88V)

Lpk

A

is the effective cross-sectional area of the core

eff

B

is the maximum allowable flux density of the core

max

∆

IL.

The air gap is determined by referring to the magnetic core manufacturer’s AL vs. air gap curves. The air gap

needed for the specified inductance, tur ns and core type i s found to be 2.8mm in t he center post. To approximate the minimum core size needed for the conversion, the following equation may be used:

114

--------- - 468=⋅==

2.8

+()⋅[]⋅≥

) and the effective length

gap

3

:

=⋅⋅≥

3

.

Volume K L I

LpkILpk∆IL

Where K is the specific energy constant that depends on the ratio of the gap length (l

(l

) of the core set and the maximum ∆B swing. Practically, K can be estimated as follows:

eff

I

K11.5

eff

---------- 11.5

I

gap

Thus, we have the following calculation for the minimum core set volume in cm

Volume 468 0.5 10

3–

8.92 8.92 2.5+()⋅[]23.8cm

The core chosen for this design is an ETD geometry ferrite core set with the following characteristics:

7/20

Page 8

AN827 APPLICATION NO TE

Core type ETD4916A

Effective core volume = 24.0 cm

Effective magnetic path length = 114 mm

Effective core area = 211 mm

Ferrite material is 3C85 or equivalent

Np = 59T Ns = 5T

The ETD geometry has the following advantages:

1) Round center post for ease of winding

2) Commercially available from Philips, Siemens, Thomson, Magnetics, etc..

3) Increased winding area

4) The center leg area is equal to the sum of the areas of the two external legs. The legs are working with the

same flux density

The wire size is determined by the maxim um copper losses allowed and available winding area. For this design

the wire size selected was 30AWG, 30 strand Litz.

An auxiliary winding is used to supply power to the controller. The number of turns was determined experimentally to be 5. The worst case conditions for the auxiliary winding power supply voltage are at low-line input voltage (88V) and full load (500Watts) and at high-line input voltage (264V) and light-load.

The a uxilia ry w ind ing mu st s upply sufficient voltage to prevent turn-off (UVLO) during normal operation and also

must not supply excessive voltage causing burn-out of the controller.

3

.

2

CoilCraft Part Number R4849-A meets the above specifications and is available.

IC BIASING AND CONTROL COMPONENTS SELECTION

The IC biasing and control component values are derived and selected in the next section. Please refer to

Figure2, 500 Watt Demoboard Schematic.

Pin 1 P-GND (Power stage ground)

This pin should be connected to the source of the power mosfet, Q1, with a short length and wide copper trace

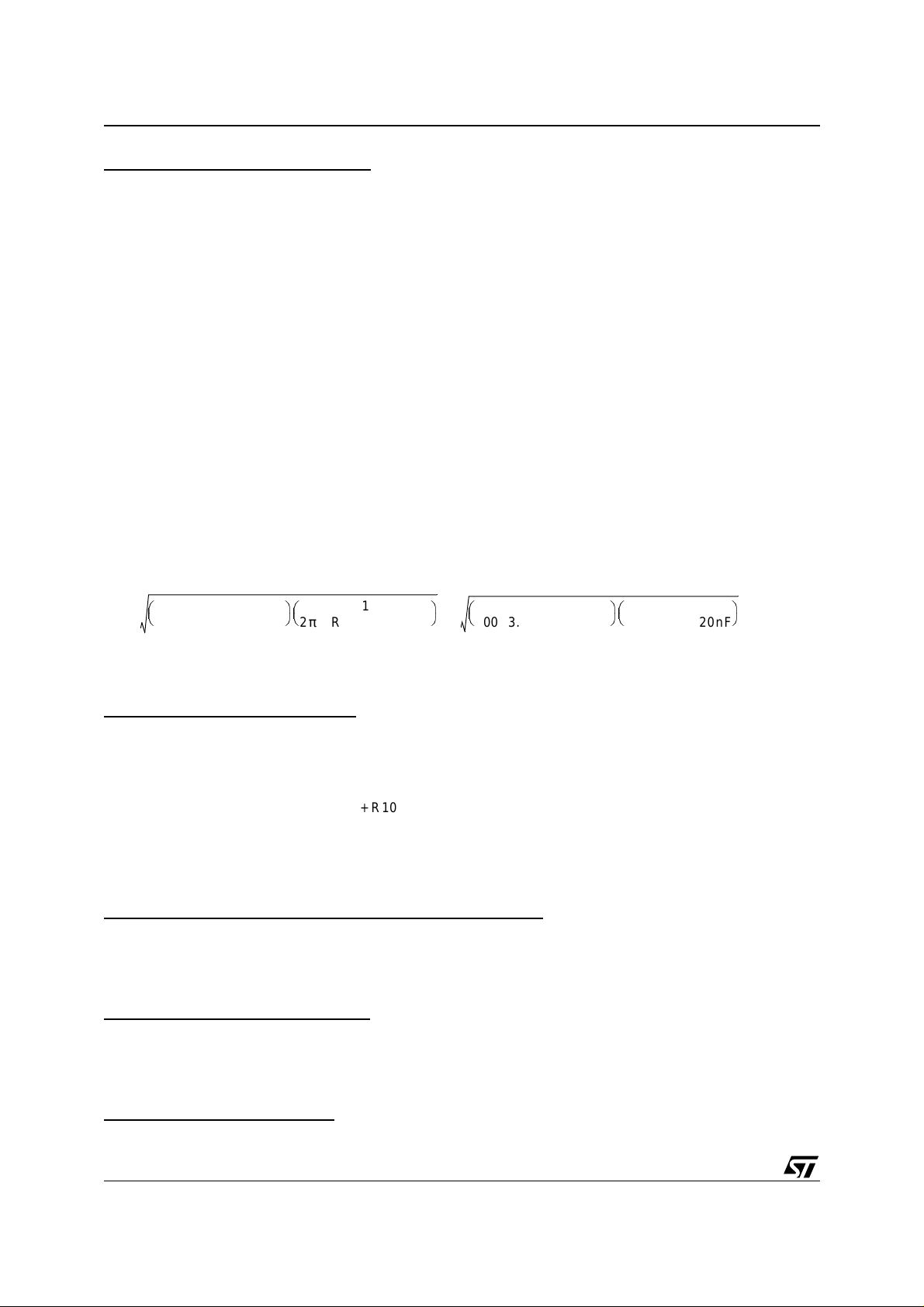

on the printed circuit board to minimize the copper trace resistance and inductance. Refer to Figure 3, 500 Watt

Demoboard printed circuit board layout.

Pin 2 IPK (Overcurrent protection input)

In order to obtain a very precise overcurrent protection trip level, R12 and R13 are calculated as follows:

R12

V

---------- -

I

aux

R13

R

⋅

senseIpeak

------------------------------------

Iaux

ref

5.1

----------- 1mA===

5.1 k

0.033 17⋅

------------------------- - 561 Ω===

0.001

Use R12 = 562 ohms, R13 = 5.1k

The peak current threshold is set at 17A and R

8/20

is chosen as 0.033 ohms.

sense

Page 9

AN827 APPLICATION NOTE

Pin 3 OVP (Overvoltage protection input)

The overvoltage protection trip level is determined by the voltage divider across the output bulk capacitor, C6.

The resistor values R11, R21 and R22 are calculated as follows:

V

∆V

R21 R22+

---------------------------- -

R11

+

out

--------------------------------- 1

out

V

ref

400 47+

---------------------- - 1

5.1

909k 909k+

---------------------------------=–=–=

21k

Where

∆

V

= 47V is the maximum overvoltage limit.

out

The overvoltage limit selection is dependent upon the voltage rating of the output bulk capacitor (450VDC) and

the power mosfet (500BVdss). Care must be taken that the level is not set too low, thus causing false tripping

of the OVP.

Pin 4 IAC (AC current input)

This pin must be connected through resistors R1 and R2 to the rectified line to drive the multiplier with a current

IIAC proportional to the instantaneous line voltage as shown below:

Thus I

V

inpk

88 V()

I

IAC

I

IAC

ranges from 77µA to 231µA. The relationship between I

IAC

----------------------

R1 R2+

264 V()

--------------------------------- 231µA==

806 k 806k+

288⋅

--------------------------------- 77µA== =

806 k 806k+

2264⋅

and multiplier output current, Imult, is de-

IAC

scribed in section Pin 8 (MULTOUT).

Pin 5 CA-OUT (Current amplifier output)

The current amplifier output delivers its signal to the PWM comparator. An external network defines the suitable

loop gain to process the multiplier output and the inductor current si gnals. To avoi d oscillat ion problems, the

maximum inductor downslope (Vout/L) must be lower than the oscillator ramp-slope (Vsrp*fsw). The current amplifier high frequency gain can be described as follows:

R15

---------- - 1

G

ca

R14

V

srpfSW

----------------------------------

V

outRsense

L⋅⋅

5.0 80 k 0.5m⋅⋅

-----------------------------------------=≤+=

⋅

400 0.033⋅

Where:

V

= 5.0V is the oscillator ramp peak-peak voltage

srp

G

is the current amplifier gain

ca

f

= 80kHz is the switching frequency

sw

R

= 0.033Ω is the parallel combination of R30-32

sense

Thus, use R14=R16=2.7k, and R15=36K.

To define the value of the compensation capacitor, C9, it is useful to consider the open loop current gain, defined

by the ratio of the voltage across the sense resistor and the current amplifier output voltage. The crossover frequency is given by the following equation:

f

80k

sw

f

---------- -

c

2 π⋅

To ensure a good phase margin, the zero frequency, fz, should equal approximately f

---------- - 12.7kHz===

2 π⋅

/2.

c

9/20

Page 10

AN827 APPLICATION NO TE

V

f

sw

------- -

f

z

4π

C9

2

------------------------ 692pF==

R15 f

⋅

Sw

1

--------------------------------------- therefore,==

2 π C9 R15⋅⋅ ⋅

use C9 = 680pF

Pin 6 LFF (Load feed-forward input)

This pin allows the modification of the multiplier output current proportionally to the load in order to improve the

load transient response time. This function is not used in this circuit and the pin is connected to VREF.

Pin 7 VRMS (Voltage input)

This function is very useful for universal input mains applications to compensate the gain variation related to

the input voltage change. This pin is connected through an external network to the rectified line input. The best

control is achieved when the VRMS voltage level is in the range of 1.5 to 5.5V.

To avoid the rectified mains line ripple (2f), a two pole low-pass filter is realized with R3-R6 and C1-2. The lowest

pole is set near 3Hz and the highest pole near 13 Hz to reduce the gain to -80dB at 100 Hz.

---------------------------------------------------

rmsp in 7

=

R3 R4 R5 R6+++

f

pole1

f

pole2

--------------------------------------- - 3.66Hz==

R5 R6+()C2⋅

-------------------- 12.6 3.66()Hz==

R4 C1⋅

R3

1

1

V

rmsline

Where:

R3 = 33k

Ω

, R4 = 360kΩ, R5 = R6 = 620kΩ,

C1 = C2 = 220nF

At 88 Vrms, Vpin7 = 1.78 Vrms

At 264 Vrms, Vpin7 = 5.33 Vrms

Gain at 2f (100Hz) = -80dB

For single mains operation, this pin can be connected directly to Vref (pin 11) or to ground and the RC network

can be removed. If connected to ground, the Vrms multiplier input is clamped at 1.5V.

Pin 8 MULT-OUT (Output of the Multiplier)

This pin delivers the current Imult that is used to fix the reference voltage for the current amplifier. Pin 8 is connected through R14 to the negative side of the sense resistor, R30-32, to sum the (I

signals, where I

is the inductor current. The sum is the error voltage signal at the current amplifier non-inverting

L

· Rs) and the (I

L

mult

· R14)

input. The multiplier output current is determined by the equation given below:

I

mult

0.37 I

V

va out–

-------------------------------------------------------------------------------------------------- - I

AC

1.28V–()0.8 V

V

rms

⋅ 1.28V–()⋅

2

lff

IAC

V

va out–

------------------------------------------------⋅=⋅⋅=

1.28V–()

2

V

rms

10/20

Page 11

AN827 APPLICATION NOTE

Where:

V

= Error amplifier output voltage range

va-out

V

= V

lff

V

rms

I

IAC

To optimize the multiplier biasing f or each appl icati on, the rel ationshi ps between Imult and other i nput s i gnals

are reported in the

Application Note [1], Figures 13a-13h.

Pin 9 ISENSE (Current amplifier inverting input)

This pin is the current amplifier inverti ng i nput. It is externall y connected to t he network described at CA-OUT

(pin 5). Note that R14=R16=2.7k have the same value because of the high impedance feedback network. The

sense resistors, R30-R32, have a combined resistance of 0.033 ohms. The low value is chosen to minimize the

power losses since the total Inductor current flows through this resistor. The value must be large enough to provide a good signal to noise ratio signal to the current amplifier.

= 5.1V if not used for load feed-forward

ref

= Voltage at pin 7

= Input current at pin 4

Designing A High Power Factor Switching Preregulator With The L4981 Continuous Mode

Pin 10 SGND (Signal ground)

This pin should be connected close to the reference voltage filter capacit or (C7). Refer to Figure 3, 500 Watt

Demoboard printed circuit board layout.

Pin 11 VREF (Voltage reference)

An external capacitor filter of 1µF, C7, should be connected from pin 11 (Vref) to ground. This reference voltage

of 5.1V is externally avai lable and can deli ver up to 10mA for exter nal circuit needs such as the fast s tart-up

power supply circuit as described in Pin 19.

Pin 12 SS (Soft start)

This feature avoids current overload through the power mosf et duri ng t he ramp-up of the out put boosted vol tage. An internal switch discharges the capacitor if an output overvoltage (OVP) or a VCC undervoltage (UVLO)

is detected. The voltage at the soft-star t pin acts on the output of t he error amplifi er and the soft start t ime is

calculated as follows:

t

ssCss

V

va out–

--------------------- 1 µ F

I

ss

5.1V

------------------ 51ms===

100µ A

Where:

Css = C8 = 1

V

va-out

I

is the internal soft start current generator

ss

µ

F

= 5.1V is the typical error amplifier voltage swing

11/20

Page 12

AN827 APPLICATION NO TE

Pin 13 Vva-out (Error amplifier output)

To ensure system stability, the compensation network must be designed with sufficient phase margin. Additionally, the system must not regulate the twice mains frequency output ripple voltage in order to avoid line current

distortion. The compensation capacitor, C10, can be calculated as follows:

--------------------------------------------------------------------------------- K

C10

⋅⋅ ⋅ ⋅

4 π f

mains

1

R9 R10+()G

ea

------------------------- -=>

a

R9 R10+

∆ V

out

Where:

R9 + R10 are the resistors from the output voltage feedback resistor divider

G

is the small signal gain of the error amplifier

ea

∆

V

is the maximum output voltage ripple

out

1

------

Ka = for 50Hz and for 60Hz mains frequency

60

8

1

------

60

------------- 162nF=⋅>

824k

C

10

1

------

72

, therefore use standard value 220nF

The voltage open loop gai n contains two poles at the origin, causing stability problems. This c an be avoided by

shifting the error amplifier pole from the origin to near the crossover frequency. This can be accomplished by

placing a resistor, R19, in parallel with the compensation capacitor, C10. The crossover frequency is calculated

as follows:

P

f

---------------------------------------------------------

c

V

out∆Vea

out

⋅⋅⋅

2π C

out

--------------------------------------------------------- -

2πR9 R10+()C10⋅⋅

1

----------------------------------------------------------- -

400 3.82 2π 330πF⋅⋅⋅

500

---------------------------------------------- -

2π824k 220nF⋅⋅

1

11.77Hz===

Use R19 = 120k to increase error amplifier dc gain.

Pin 14 VFEED (Error amplifier input)

This pin is the error amplifier inverting input. This pin is connected to the resistor divider connected across the

boosted output voltage to provide regulation. The boosted output voltage is specified at 400VDC. The resistor

divider network is calculated as follows:

R9 R10+

------------------------- -

R20

824k

-------------- -

10.6k

V

out

----------- 1

V

ref

400

--------- - 1–=–==

5.1

Use R9 = R10 = 412k

Pin 15 P-UVLO (Programmable supply undervoltage threshold)

This pin may be used to modify the turn-on and turn-off power supply thresholds. This circuit does not employ

this feature and the pin is left floating. The typical turn-on threshold is 15.5V and the turn-off threshold is 10V.

Pin 16 SYNC (In/Out synchronization)

This function allows for synchronization i n master or slave mode wit h other cir cuits i n the sy stem. This demoboard does not use this function and the pin is left floating.

Pin 17 ROSC (Oscillator resistor)

12/20

Page 13

AN827 APPLICATION NOTE

Pin 18 COSC (Oscillator capacitor)

These pins determine the oscillator frequency of the circuit. A resistor, R17, is connected from pin 17 to ground.

A capacitor, C4, is connected from pin 18 to ground. The operating frequency is calculated as follows:

f

sw

2.44

-----------------------------

R

⋅

oscCosc

2.44

-------------------------- 80kHz approx.===

30.1k 1n⋅

Pin 19 VCC (Supply voltage input)

The IC must be supplied with a very low current, 0.3mA typical, during start-up. The turn-on threshold is 15.5V

typical with 5.5 Volts typical of hysteresis. The start-up current is provided by the resistor/capacitor network driven off the rectified line voltage. A fast start-up circuit i s employed to quickly turn on the IC and reduce power

consumption in the start-up resistor, R28. The capacit or, C12, has a value of 220

µ

F to ensure sufficient holdup time to allow the auxiliary winding to provide voltage after initial start-up. The fast start-up is realized with Q2,

Q3, R25, R26, R27, R28, D5 and C12. The fast start-up circuit is turned-off when the controller turn-on threshold

is reached and Vref forward biases Q2, pulling the gate of Q3 to ground.

The auxiliary winding on the main boost inductor provides the normal operating voltage for the controll er. The

voltage induced on this winding is rectified by diodes D7-D10. Resistor R29 provides current limiting and zener

D6 regulates the supply voltage to 18 Volts.

Pin 20 GDRV (Gate driver output)

The output of this pin is internally clamped at 15V to prevent breakdown of the power mosfet gate oxide. A resistor, R18, of 15

Ω

is placed in series with the gate of the power mosfet to avoid overshoot and limit the di/dt of

the switch. A 1N4148 diode, D3, is connected to the gate to provide fast turn-off of the power mosfet.

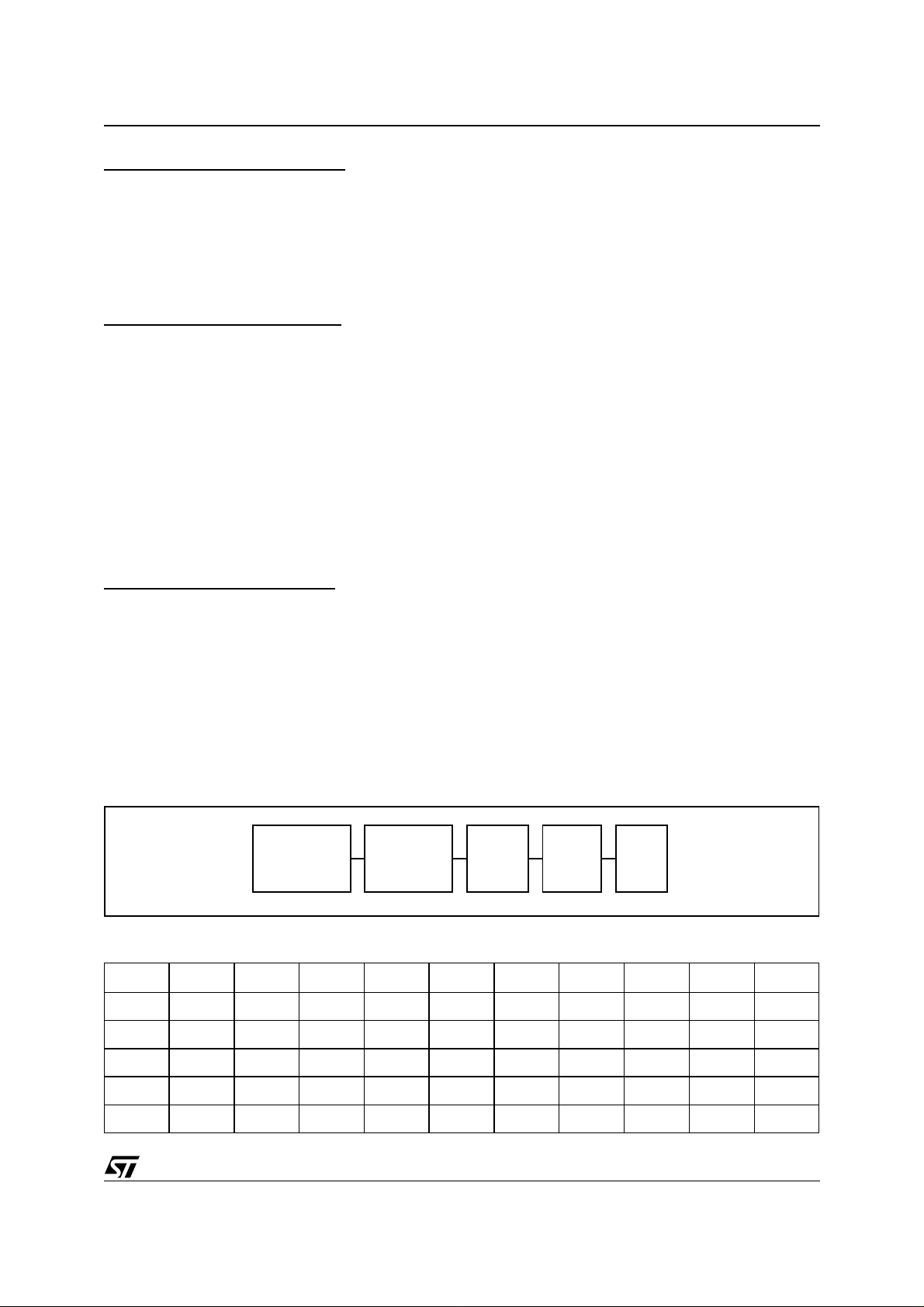

EVALUATION RESULTS

The 500W demoboard has been evaluated for the foll owing parameters: PF (power factor), % THD (percent

total harmonic distortion), H3.. H7 (percentage of current ’ s nth har monic amplitude), V out (out put voltage) and

efficiency (n). The test configuration and test results are shown below:

Test Set-Up and Equipment

AC POWER

SOURCE

LARCET 3KW

PM1200

AC POWER

ANALYSER

EMI

FILTER

PFC

L4981

DEMO

LOAD

Table 1. 500W Demoboard Evaluation Results

V

in

Vrms (Hz) (W) (%) (%) (%) (%) (V) (W) (%)

88 60 560 99.9 2.9 1.3 1.7 1.2 402 490 87.5

110 60 543 99.9 2.8 1.4 1.8 1.3 403 492 90.6

220 50 525 99.8 3.3 1 2.4 1.1 4 06 499 95.1

270 50 523 99.8 3.4 1 2.6 1.1 408 504 96.3

f

P

i

PF THD H3 H5 H7

V

out

P

o

η

13/20

Page 14

AN827 APPLICATION NO TE

EMI/RFI FILTER

The harmonic content measurement was made with the EMI/RFI filter interposed between the AC source and

the demoboard under test, while the efficiency has been calculated without the filter contribution.

Figure 1.

EMI/RFI Test Filter

LINE PFC

EARTH

T1 T2

C1

C

D94IN052

Part List of the Figure 2

Part Des. Description Vendor’s Part #

Fuse F1 Fuse, 3AG Fast Acting 10A, 250VAC Digi-Key #F127-ND

Fuse Clip 3AG Fuse Clips Digi-Key #F048-ND

C1 Met. Poly. Film Cap., 0.22µF, 100V Panasonic ECQ-E1224KF Digi-Key #EF1224

C2 Met. Poly. Film Cap., 0.22µF, 100V Panasonic ECQ-E1224KF Digi-Key #EF1224

C3 Met. Poly. Film, .68uF, 250VAC, Panasonic ECQU2A684MV Digi-Key #P4615-ND

C4 Polyester Cap., .001µF, 50V, Panasonic ECQ-B1H102JF Digi-Key #P4551-ND

C5 Polyester Cap., .012µF, 50V Panasonic ECQ-B1H123JF Digi-Key #P4583-ND

C6 Alum. Electrolytic Cap., 330µF, 450VDC, 85°C Digi-Key#P6443-ND

C7 Electrolytic Cap., 1.0µF, 63V, Panasonic ECE-A1JU010,85°C Digi-Key #P6275-ND

C8 Electrolytic Cap., 1.0µF, 63V, Panasonic ECE-A1JU010,85°C Digi-Key #P6275-ND

C9 Polyester Cap. 680pfd., 50V, Panasonic ECQ-B1H681JF Digi-Key # P4580-ND

C10 Met. Poly. Film Cap., 0.22µF, 100V Panasonic ECQ-E1224KF Digi-Key #EF1224

C11 Ceramic Capacitor, 820pfd.,1000VDC Digi-Key #P4127-ND

C12 Electrolytic Cap., 220µF, 25V,Panasonic ECE-A1EU101,85°C Digi-Key #P6240-ND

D1 Diode Bridge, 600V, 25A Digi-Key #MB256-ND

D2 STTA806D/DI,, 600V, 8A, Isolated TO220AC Package STMicroelectronics STTA806D/DI

D3 Switching Diode, 1N4148, 100V Digi-Key #1N4148CT-ND

D4 Fast Recovery Diode, STTB406, 600V, 4A STMicroelectronics STTB406

D5 Zener Diode, 22V, 1/2W, DO-35 Package Digi-Key #1N5251BCT-ND

D6 Zener Diode, 18V, 1/2W, DO-35Package Digi-Key #1N5248BCT-ND

D7 Fast Recovery Rectifier Diode, 100V, 1.5A STMicroelectronics BYW-100-100

D8 Fast Recovery Rectifier Diode, 100V, 1.5A STMicroelectronics BYW-100-100

D9 Fast Recovery Rectifier Diode, 100V, 1.5A STMicroelectronics BYW-100-100

D10 Fast Recovery Rectifier Diode, 100V, 1.5A STMicroelectronics BYW-100-100

R1 Metal Film Res., 806K, 1/4W, 1% Digi-Key #806KXBK-ND

R2 Metal Film Res., 806K, 1/4W, 1% Digi-Key #806KXBK-ND

R3 Carbon Film Res., 33K, 1/4W, 5% Digi-Key #33KQBK-ND

14/20

Page 15

AN827 APPLICATION NOTE

Part List of the Figure 2 (continued)

Part Des. Description Vendor’s Part #

R4 Carbon Film Res., 360k, 1/4W, 5% Digi-Key #360KQBK-ND

R5 Carbon Film Res., 620k, 1/4W, 5% Digi-Key #620KQBK-ND

R6 Carbon Film Res., 620k, 1/4W, 5% Digi-Key #620KQBK-ND

R9 Metal Film Res., 412k, 1/4W, 1% Digi-Key #412KXBK-ND

R10 Metal Film Res., 412k, 1/4W, 1% Digi-Key #412KXBK-ND

R11 Metal Film Res., 21k, 1/4W, 1% Digi-Key #21.0KXBK-ND

R12 Metal film Res., 562, 1/4W, 1% Digi-Key #562XBK-N D

R13 Metal Film Res., 5.11k, 1/4W, 1% Digi-Key #5.11KXBK-ND

R14 Carbon Film Res., 2.7k, 1/4W, 5% Digi-Key #2.7KQBK-ND

R15 Carbon Film Res., 36k, 1/4W, 5% Digi-Key #36KQBK-ND

R16 Carbon Film Res., 2.7k, 1/4W, 5% Digi-Key #2.7KQBK-ND

R17 Metal Film Res., 30.1k, 1/4W, 1% Digi-Key #30.1KXBK-ND

R18 Carbon Film Res., 15 ohms, 1/4W, 5% Digi-Key #15QBK-ND

R19 Carbon Film Res., 120k, 1/4W, 5% Digi-Key #120KQBK-ND

R20 Metal Film Res., 10.7k, 1/4W, 1% Digi-Key # 10.7KXBK-ND

R21 Metal Film Res., 909k, 1/4W, 1% Digi-Key #909KXBK-ND

R22 Metal Film Res., 909k, 1/4W, 1% Digi-Key #909KXBK-ND

R23 Metal Oxide Resistor, 510 ohms, 3 Watts, 5% Digi-Key#P510W-3BK-ND

R24 Metal Oxide Resistor, 510 ohms, 3 Watts, 5% Digi-Key#P510W-3BK-ND

R25 Carbon Film Resistor, 10k, 1/4W, 5% Digi-Key #10KQBK-ND

R26 Carbon Film Resistor, 1.1M, 1/4W, 5% Digi-Key #1.1MQBK-ND

R27 Carbon Film Resistor, 1.1M, 1/4W, 5% Digi-Key #1.1MQBK-ND

R28 Carbon Film Res., 10k, 1/2W, 5% Digi-Key #10KH-ND

R29 Carbon Film Resistor, 33 ohms, 1/2W, 5% Digi-Key #33H-ND

R30 3 Watt, non-inductive 0.1 ohms, Type LO-3-.010 Newark #96F3616

R31 3 Watt, non-inductive 0.1 ohms, Type LO-3-.010 Newark #96F3616

R32 3 Watt, non-inductive 0.1 ohms, Type LO-3-.010 Newark #96F3616

NTC 1 20 Ga (0.8mm) Jumper Wire 22 Ga Jumper

NTC 2 20 Ga. (0.8mm) Jumper Wire 22 Ga Jumper

Heatsink 1 AAVID type 61085, 1.5Deg C/W/3in., 1.5" length AAVID #61085

Heatsink 2 Bridge Diode attachable heatsink datogliere

PCB 1 FR-4 Material CALS 95 001_A

T1 Coilcraft Part# R4849-A 0.5mH CoilCraft ’Part # R4849-A

Standoffs Aluminum Hex Standoff 0.375", 4-40 Thread Newark#89F1949

Q1 STW20NA50, 500V, 20A, 2.7 ohms TO-247 STMicroelectronics STW20NA50

Q2 NPN transistor high speed, 30V, .8A, TO-18 Package STMicroelectronics 2N2222

Q3 N-Channel Mosfet, STK2N50, 500V, 2A, SOT-82 STMicroelectronics STK2N50

J1 3 Pole, 15A, Terminal Block Newark #93F7182

J2 3 Pole, 15A, Terminal Block Newark #93F7182

U1 L4981A, PFC IC STMicroelectronics L4981A

IC Socket 20 Pin DIP Socket, Gold Pin and Clip Digi-Key #ED56203-ND

Misc. Mounting screws, nuts, insulators

15/20

Page 16

AN827 APPLICATION NO TE

Figure 2. 500W Demoboard Schematic

Vout

C6

450V

330µF

R21

909K

R9

412K

D2 STTA806DI

R27

R28

1.1M

R6

R5

R4

10K

5%

620K

620K

360K

-

1/4W

5%

5%

5%

T1

1%

1%

D8

D7

R26

R29

1.1M

1%

R22

909K

1%

R10

412K

D10D9

+

BYW100-100

33

1/4W

Q3

STK2N50

D5

5%

Q2

C2

100V

220nF

R3

5%

33K

1/4W

D6 18V

C12

220µF

22V

1/4W

2N2222

25V

C10

R19

120K 5%

VFEED

R7 R8

PUVLO VCC

R25 10K 5%

220nF

14

19

15

16

S/FM

100V

VAOUT

13

VRMS

OVP

U1

7

C11

D3 1N4148

3

L4981A

4

IPK

IAC

820pF

R18

GDRVMOUT

20

2

R11

R20

1000V

STW20NA50

Q1

15Ω 5%

1

6

11

1217 101895

SSC

8

CAOUT

1%

21K

1%

10.7K

LFF

R13

R23

510Ω

PGND

SGND

VREF

ROSC

COSC

ISENSE

C9

0.68nF 50V

5%

R15 36K

1%

5.11K

3W

C5

C7

12nF

D4

1µF

R16

R14

R24

2.7K

2.7K

50V

3W

510Ω

STTB-406

63V

C8

1µF

63V

1%

R17

30.1K

C4

1nF

50V

5%

R30 0.1Ω 3W

5%

D95IN258B

R31 0.1Ω 3W

R32 0.1Ω 3W

16/20

R1

806K

F1

10A

Vi (88 to 264V)

1%

R2

NTC2

806K

+

1%

D1

C1 220nF 100V

C3

0.68µF

+-

BRIDGE

250VAC

NTC1

R12 562 1%

+

-

Page 17

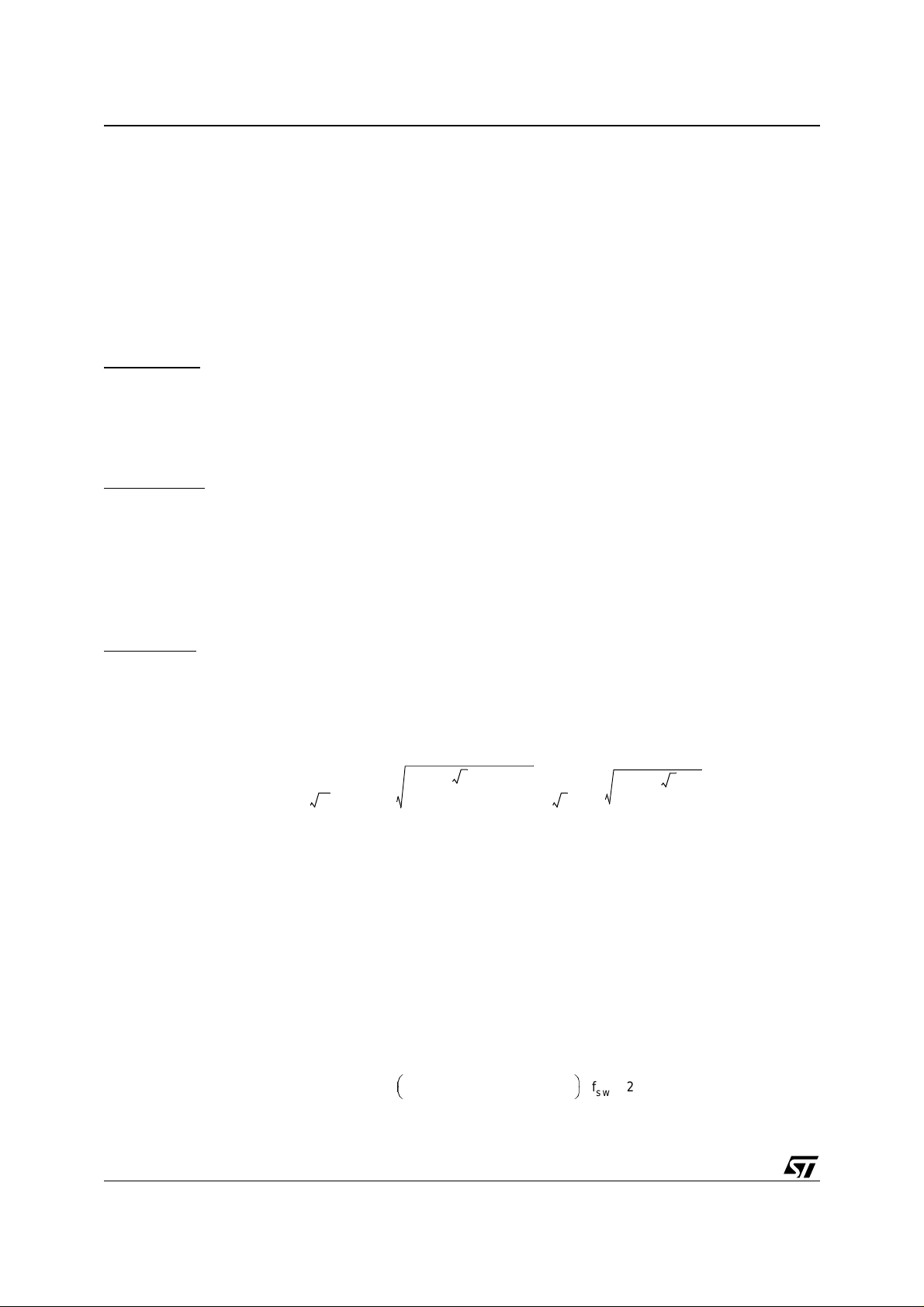

Figure 3. 500W Demoboard Printed Circuit Board Layout

AN827 APPLICATION NOTE

17/20

Page 18

AN827 APPLICATION NO TE

An Application Program named Designing PFC [3] is available for the designer. This program allows the designer to make changes to the input/output design specifications and calculates and selects the component values

and types. For example, this program can easily convert this design to single mains operation (120 or 240 Volts).

The results are presented in two screens, the schematic and parts list, and may be sent to a printer for a hardcopy for future reference. Two solutions at 110Vac (fig. 4) and 220Vac (fig. 5) are shown below.

Figure 4. 400W/230V; Vin = 110V ± 20V

C6

315V

Vout=230V

680µF

R21

360K

R9

330K

D2 BYT08P-400

-

T1

2W

10K

R28

5%

R27

1.1M

1%

1%

D8

D7

R26

R22

R10

BYW100-100

33

R29

1/4W

Q3

5%

1.1M

1%

360K

1%

330K

D10D9

+

STK2N50

D5

Q2

1/4W

D6 18V

25V

C12

220µF

22V

1/4W

2N2222

R25 10K 5%

R7 R8

R19

220K 5%

VFEED

PUVLO VCC

C10

120nF

14

19

15

16

S/FM

100V

13

OVP

VAOUT

U1

7

VRMS

D3 1N4148

3

L4981A

4

IAC

C11

IPK

330pF

R18

GDRVMOUT

20

2

250V

Q1

15Ω 5%

1

6

11

1217 101895

8

1%

15K

R11

1%

15K

R20

R23

STP9N30

LFF

SSC

CAOUT

R13

5.11K

2W

680Ω

PGND

SGND

VREF

ROSC

COSC

ISENSE

C9

0.47nF 50V

5%

R15 47K

1%

C5

12nF

R24

D4

C7

R17

R16

R14

50V

680Ω

STTB-406

1µF

63V

C8

1µF

1%

24K

C4

1.2nF

5%

6.2K

5%

6.2K

D95IN284C

2W

63V

60V

R30 120mΩ 2W

R31 120mΩ 2W

R32 120mΩ 2W

18/20

R1

200K

F1

10A

Vi (88 to 132V)

R2

1%

NTC2

200K

+

1%

D1

+-

BRIDGE

R12 360 1%

C3

470nF

250VAC

NTC1

+

-

Trasformer T1:

core: ETD 39 x 20 x 13 / gap ≈1.8mm.

Primary Inductance =0.25mH

44 Turns 15 x AWG29.

Secondary = 5 Turns

Page 19

Figure 5. 800W/400V; Vin = 220V ± 20V

C6

470µF

Vout=400V

AN827 APPLICATION NOTE

450V

R21

909K

R9

412K

D2 STTA806DI

R27

R28

1.1M

10K

5%

-

4W

T1

1%

1%

D8

D7

R26

R29

1.1M

1%

R22

909K

1%

R10

412K

D10D9

+

BYW100-100

33

1/4W

STK2N50

Q3

D5

5%

Q2

1/4W

D6 22V

25V

C12

220µF

22V

1/4W

2N2222

R25 10K 5%

R7 R8

R19

130K 5%

VFEED

PUVLO VCC

C10

220nF

14

19

15

16

S/FM

100V

VAOUT

13

VRMS

OVP

U1

7

C11

D3 1N4148

3

L4981A

4

IPK

IAC

820pF

R18

GDRVMOUT

20

2

R11

R20

1000V

Q1

15Ω 5%

1

6

11

1217 101895

SSC

8

CAOUT

1%

21K

1%

10.7K

3W

R23

510Ω

STH14N50/FI

PGND

SGND

LFF

VREF

ROSC

COSC

ISENSE

C9

0.47nF 50V

5%

R15 36K

1%

R13

5.11K

C5

12nF

R24

D4

C7

R17

R16

R14

50V

3W

510Ω

STTB-406

1µF

63V

C8

1µF

1%

24K

C4

1.2nF

5%

7.5K

5%

7.5K

63V

60V

R30 120mΩ 2W

D95IN283C

R31 120mΩ 2W

R32 120mΩ 2W

R1

510K

F1

10A

Vi (176 to 264V)

1%

R2

NTC2

510K

+

1%

D1

+-

BRIDGE

C3

220nF

250VAC

NTC1

+

R12 390 1%

Trasformer T1:

core: ETD 44 x 22 x 14 / gap =2mm.

Primary Inductance =0.43mH

53 Turns 10 x 0.36mm

Secondary = 5 Turns

-

19/20

Page 20

AN827 APPLICATION NO TE

REFERENCES

[1]

G. Comandatore and U. Moriconi, Application Note 628 Designing A High Power Factor Switching

Preregulator With The L4981 Continuous Mode, STMicroelectronics, Inc., STMicroelectronicsMay, 1994.

[2]

Datasheet Power Factor Corrector, STMicroelectronics, Inc., May, 1994.

[3]

Designing PFC Application Program, ST Microelectronics, Inc., April, 1995.

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or oth erwise under any patent or patent rights of STMicroelectronic s. Specific ations mentioned in this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics products are not

authorized for use as critical components in life support devi ces or systems wi thout express written ap proval of STMi croelectronics.

The ST logo is a registered tradema rk of STMicroe l ectronics.

All other n am es are the pro perty of their respective owners

© 2003 STMi croelectro ni cs - All rights reserved

Australi a - B elgium - Brazil - Canad a - China - Czech Republic - F i nl and - France - Germany - Hong Kong - India - Is rael - Italy - Japan -

Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States

STMicroelectronics GROUP OF COMPANIES

www.st.com

20/20

Loading...

Loading...