Page 1

®

AN676

APPLICATION NOTE

Battery charger using the ST6-REALIZER

INTRODUCTION

Because competition becomes greater and greater it is important to reduce time to market.

The ST6 Realizer helps to fullfill this duty. The time needed to realize a design is dramatically

reduced. Design of an application takes a few days instead of a few weeks.

Users who develop ST6 applications are systems electronics engineers; Often they do not

know the assembler well and there are reluctant to use it. The ST6 Realizer allows users to

design their applications using symbols known by hardware designers such as comparators,

counters, multiplexers. Once the design is over, the ST6 Realizer generates assembly code or

executable code for the different ST6 target hardware.

June 2008 Rev 2 1/14

Page 2

BATTERY CHARGER USING THE ST6-REALIZER

APPLICATION NOTE GOAL

This note aims at introducing the different features of the ST6 Realizer graphic tool. It is also a

tutorial to firstly help you get started with ST6 Realizer design, then for you to implement

advanced features to optimize your design or to evaluate the target hardware requirements.

The application note describes a battery charger because it illustrates the different features of

the ST6 Realizer throughout it. The charger implements a simple charging method.

Nevertheless charging end points using the negative voltage slope detection method or voltage

inflection points can be implemented with this battery charger ST6 board.

HARDWARE SCHEMATICS

The schematics describes the different hardware parts of the application:

The microcontroller connections

The power supply

The charging indicators

The start push button

The power command

2/14

Page 3

BATTERY CHARGER USING THE ST6-REALIZER

Figure 1 : Simple Battery Charger Circuit Schematic

HIGH

POWER SUPPLY

J1 JACK

GND

Battery cell: AA type / 1.2V - 0.5Ah

GND

22MF

C1

VCC

R10

470

R2

LOW

R8

470

T1

CURRENT

VOLTAGE

68 ohms

GND

U1

10 ohms

R4

BATTERY

NiCd BATTERY

BT1

2 ohms

R6

BD236-PNP-45V

GND

T3

7805

IMAX

VCC

GND

MAX CURRENT

ADJUST

RV1

50K-RV

READY

LED_LO

LED_HI

8MHZ-XT-P

GND

C310pF

GND

10pF

XT1

C2

1MF

CHARGE CURRENT

INDICATOR

LD3

LED-RED-5MM

LED-RED-5MM

LED-RED-5MM

LD2

LD1

GND

GND

470

GND

START PUSH-BUTTON

SW1

R1

470

R2

470

R7

START

C4

VCC

CURRENT

VOLTAGE

ST6210/20 MCU

IMAX

GND

6

7

8

9

10

ST6210

NMI

TEST

RESET/

PB7

PB6

PB5

PB411PB312PB213PB114PB015PA316PA217PA118PA019VSS

START

HIGH

LOW

100K

4

5

OSCOUT

LED_LO

DISCHRG

VCC VDD

1

2

3

U2

TIMER

OSCIN

20

READY

LED_HI

Note that in the circuit diagram the Microcontroller is shown as a simple box. The objective of

the ST6 Realizer is to enable you to write the program code for the microcontroller with the

same ease and in the same manner as you have drawn the hardware schematic.

3/14

Page 4

BATTERY CHARGER USING THE ST6-REALIZER

Figure 2 : Functional Diagram

Start

Imax

READY

HIGH

Icharge

Vcharge

The MCU manages all the functions of the application:

At reset the READY LED blinks to indicate that the charger is ready to charge.

The user pushes the START button to begin the HIGH charge.

The READY LED switches off. The HIGH LED highlights.

The LOW charge takes place when the VOLTAGE threshold of 1.5 V is reached.

The HIGH LED switches off. The LOW LED switches on.

The battery charge is over when the delay of LOW charge is reached.

The LOW LED switches off. The READY LED blinks.

When the current in the battery is too high, HIGH charge or LOW charge are bypassed.

MCU

LOW

HIGH CHARGE

LOW CHARGE

4/14

Page 5

Figure 3 : Flow Chart

BATTERY CHARGER USING THE ST6-REALIZER

Start

HIGH charge

Voltage > 1,5V

Yes

LOW charge

Charging time

expired

Yes

No

Current Too High

No

No

No

Current Too High

Yes

5/14

Page 6

BATTERY CHARGER USING THE ST6-REALIZER

HARDWARE RESOURCES

The application can run in stand-alone mode using an ST6215 microcontroller. It can be driven

by the ST622X, ST624X, ST626X Starter Kit.

The microcontroller requires:

3 analog inputs for:

Imax: the maximum current

Icharge: the charging current

Vcharge the actual voltage at the + connection of the cell

a digital input to connect the start push button

2 digital outputs to switch the LOW charge current and the HIGH charge current

3 digital outputs to switch the three LEDs that supply the user with information status

SOFTWARE DESIGN

The flow chart is implemented in the schematic editor of the Realizer as a state machine.

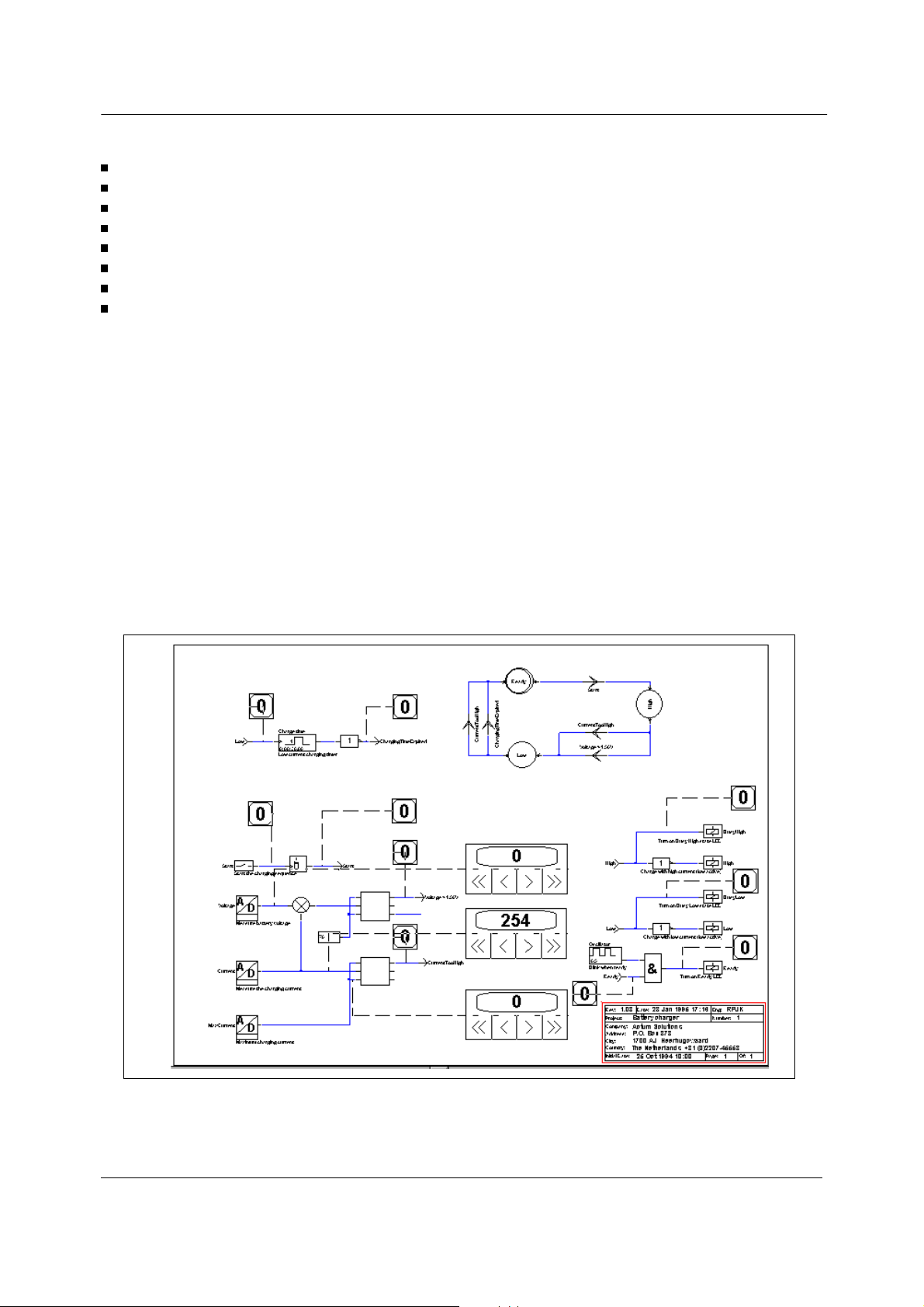

Figure 4 : State Machine

The state machine sums up the behaviour of the application. Due to the fact that the ST6

Realizer is a graphic tool, it is easy to explain how the application works with symbols and state

machines.

Symbols named condition are events that allow the switching from state to state.

The condition symbols are connected either to an external input (Start, CurrentTooHigh,

Voltage>1.5V) or to internal outputs (ChargingTimeExpired).

Symbols named state are linked to actions. In this application:

HIGH STATE starts high charging current and switches on high level status LED

LOW STATE starts low charging current and switches on low level status LED

READY STATE indicates by blinking an LED that the charge is over or the application is

waiting for a new battery to be charged.

6/14

Page 7

BATTERY CHARGER USING THE ST6-REALIZER

Software schematics

internal output & internal input condition

external input conditions

external output actions

Figure 5 : Internal Output & Internal Input Condition

Figure 6 : External Input Conditions

7/14

Page 8

BATTERY CHARGER USING THE ST6-REALIZER

Figure 7 : External Output Actions

Selecting the I/O

Symbols such as digin, digout or ADC are connected to I/O pin ports. By selecting the target

hardware and by double clicking on the symbol it is possible to assign a pin port to this symbol

and to program it respectively as a digital input, a digital output or an analog input.

The realizer process

It is of interest to know how the ST6 Realizer works to avoid misunderstandings about the

design application .

Here is how the realizer builds up its code:

general definitions, like device name, registers

reset entry

initialisation of the port registers according to the connections made in the ST6 Realizer

create backup register for output ports

initialisation of the AD converter

initialisation of the timer for the 10 ms tick

initialisation of the RAM used by the Realizer application.

call symbols initialisation macros

start of the main loop (Realmain)

restart the AD converter when it is ready

read the number of 10ms ticks and copy them for use by the ST6 Realizer application

call symbol main macros, first all input symbol macros then all "normal" symbol macros and

finally the output symbol macros.

8/14

Page 9

BATTERY CHARGER USING THE ST6-REALIZER

call state machine macros

call edge-sensitive input macros

copy the backup values to the output ports

trigger the watchdog if this option is enabled

jump to the start of the loop (Realmain)

AD converter interrupt routine

timer 10ms interrupt routine

interrupt vector table

Generating code

Before generating the ST6 program code it is necessary to define the target hardware where

the executable code will be loaded. The ST6210 microcontroller suits the application well. Then

the analyse step is run with all the selected options to get the executable code.

Debugging the application

Once the design of the application is over, the the executable code is available. The next step

is to verify that the design corresponds to the design specifications. The validation of the design

is made with the simulator.

In the application state machine items are involved with the inputs and outputs of the system.

The way to debug the application is to verify that each condition activates the corresponding

state machine.

Figure 8 : Debugging Scheme With The Simulator

9/14

Page 10

BATTERY CHARGER USING THE ST6-REALIZER

The external inputs of the system are connected to adjusters. In this way it is easy to activate

the system. Numeric adjusters are used to get fixed input values. It is forbiden to put probes on

the state machine, however they can be put on the statein and stateout symbols.

At reset it is interesting to set adjusters to inactive values and to verify that the application

states are inactive but the initial state.

Then adjusters are activated with fixed values so that the system can react to external

stimulation. At this point it is useful to choose the step by step mode to detect spurious state

transitions and to verify state sequences.

It is advised to use host time instead of target time for time transitions because it takes less

time. But for benchmark timing it is more convenient to choose the target time to keep the

compatibility between instruction execution and time calculation. This information is given by

the information loop box.

Once the schematics has been tested, the executable code can be programmed into an

EPROM-based version of the ST6 microcontroller using the ST6 Starter Kits or EPROM

programmers.

10/14

Page 11

BATTERY CHARGER USING THE ST6-REALIZER

HARDWARE CONSTRAINTS

It is found that the real application in stand alone mode does not work as well as the simulated

application. The battery charge goes directly into low level current without charging the battery.

The problem is identified as coming from voltage fluctuations .

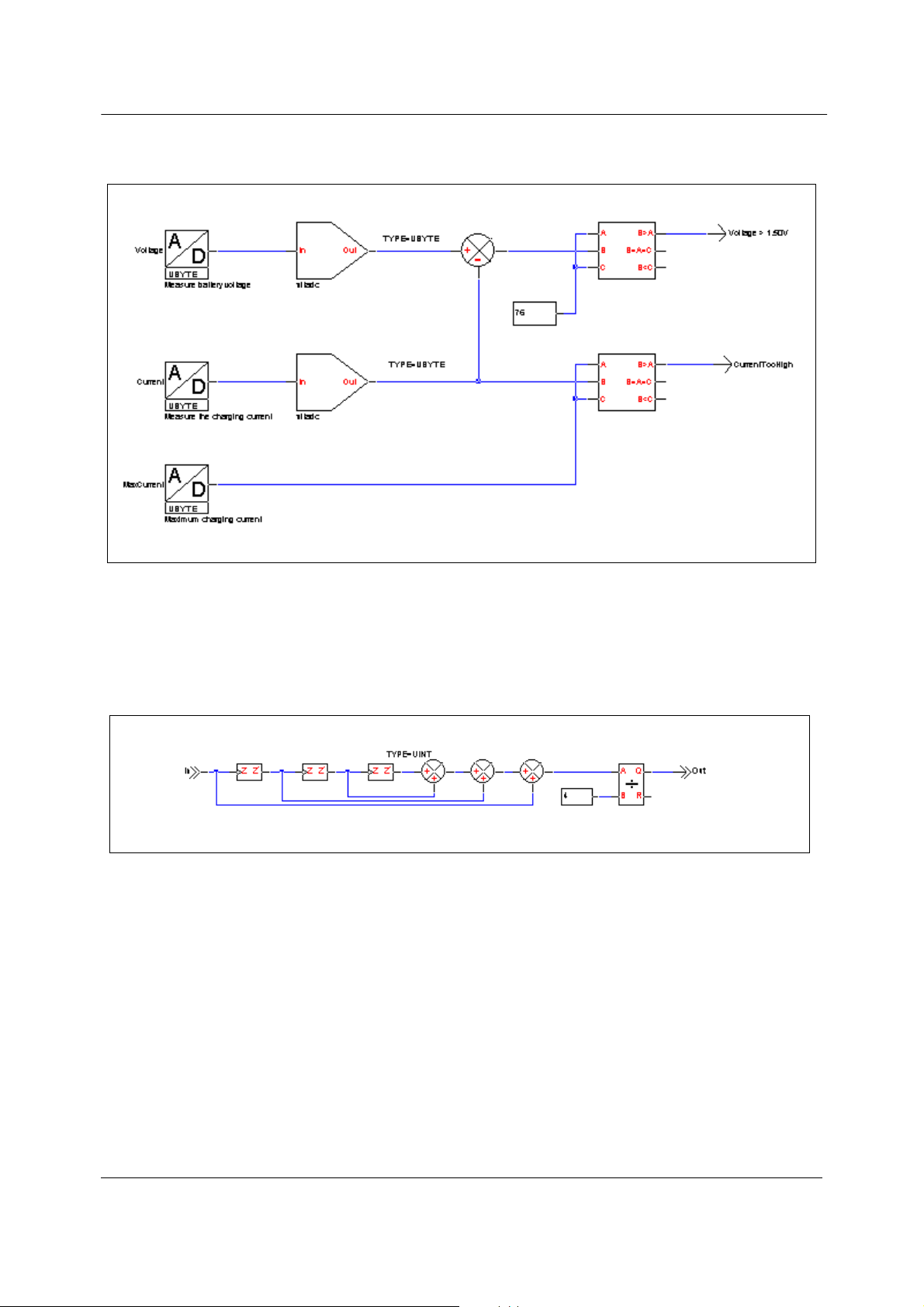

The first solution

The first solution considered was to average the ADC values to decrease the influence of the

voltage fluctuations. The average is designed in the figure below :

Figure 9 : Averaging Scheme

It takes four loops before the ADC voltage can be correctly averaged every loop. The input of

the first add2 symbol must be cast to UINT type because the output can be superior to an

UBYTE type. This way the UINT type is expanded to all following symbols.

In real terms it takes less than 1ms to run a loop. So it takes less than 4 ms to get a correct

average voltage. In addition the start push button must not be pressed while the average is not

stabilized.

The schematic design for the average is quite large. As it must be implemented on the ADC

that converts the charging current and the voltage, the root scheme drawing will be overloaded

with symbols and be confusing to read. On the other hand, the implementation of these ADC

converters is memory consuming. These drawbacks have been solved by creating

sub-schemes. The figure below shows the use of sub-schemes:

11/14

Page 12

BATTERY CHARGER USING THE ST6-REALIZER

Figure 10 : Use Of Sub-Schemes

The output of the sub-scheme symbol is cast to UBYTE type because the average result fits to

the values of an unsigned byte. In addition it is not worth keeping UINT 16-bit type because it

wastes RAM memory.

Inside the sub-scheme the treatment of the average looks like this:

Figure 11 : A Generic Averaging Sub-Scheme

The symbols portin and portout allow the sub-scheme to be link ed to the root scheme. The

label of portin and portout must match the names of the sub-scheme symbol.

While ADC values were averaged the behaviour of the real application were the same.The High

current charge did not occur.

Second solution

The use of a numeric oscilloscope proves that the problem came from voltage fluctuations that

occur during the establishment of the high current charging circuit. This problem is solved by

adding a new state to invalidate the voltage threshold during the setup time of the high current

charge. The new state is connected to a fixed timer whose duration is the setup time of the high

current charge.

12/14

Page 13

BATTERY CHARGER USING THE ST6-REALIZER

CONCLUSION

The ST6 Realizer is a powerful graphic tool that aims at designing software without requiring

knowledge of assembly language. It uses symbols that hardware designers know well. Another

advantage is that users can develop their application independently from the hardware board.

The ST6 simulator is included in the ST6 Realizer, so that users can validate their design

without the ST6 board. Many applications in automotive and home appliances can be

developped with the ST6 realizer.

13/14

Page 14

BATTERY CHARGER USING THE ST6-REALIZER

Revision History

Date Revision Description of changes

March-1995 1 Initial release

30-June-2008 2 Logo modified

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”)

reserve the right to make changes, corrections, modifications or improvements, to this document, and the products and services

described herein at any time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST

assumes no liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any

part of this document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such

third party products or services, or any intellectual property contained therein or considered as a warranty covering the use in any

manner whatsoever of such third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE

LAWS OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY

RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE

SUSTAINING APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN

PERSONAL INJURY, DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT

SPECIFIED AS "AUTOMOTIVE GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall

immediately void any warranty granted by ST for the ST product or service described herein and shall not create or extend in any

manner whatsoever, any liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy -

Japan - Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

Information in this document supersedes and replaces all information previously supplied.

© 2008 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

www.st.com

14/14

Loading...

Loading...