Page 1

AN668

APPLICATION NOTE

A New High Power IC Surface Mount Package Family: PowerSO-20

& PowerSO-36 Power IC Packaging from Insertion to Surface Mount

by P. Casati & C. Cognetti

A new, high power IC surface mount package family is

introduced in this note. It is called Power SO famil y and

has the Jedec registration MO-166.

STMicroelectronics developed PowerSO in order to

answer the increasing demand of miniaturization and

quality in power applications. Automotive, industrial,

audio and telecom markets will take advantage of the

new package, by introducing the use of S urface Mount

Technology in the production of power systems.

PowerSO-20 and PowerSO-36 are the elements of the

MO-166 family having 20 leads at 0.050 inch pitch

(1.27 mm) and 36 leads at 0.026 inch pitch (0.65 mm)

respectively. These packages are in mass production

since 1995.

PowerSO-20 – Jedec Registration MO-166

™

ing

This note is intended to compare the PowerSO-20/36 with alternative surface mount solutions and to

the existing Multiwatt package, the well known "double TO-220" developed by STMicroelectronics in

late 70s.

Data presented here demonstrates that PowerSO-20 is the real successor of Multiwatt for surface mount

applications and is becoming a milestone in power package technology with PowerSO-36 as Multiwatt

did 20 years ago.

1. POWER DEVICES AND SURFACE MOUNTING

Use of Surface Mount Technology (SMT) has dramatical ly increased in the last 20 years, moving from consumer

to professional applications and serving highly demanding markets like telecom, industrial and automotive.

Major advantages expected from SMT are size reduction, automated board mounting, high reliability and cost

effectiveness; larger density of functions is achieved in smaller systems.

Evolution of SMT drove the development of several new packages for discrete and IC devices: SOT23,

SOT194, TO263, SO, PLCC, PQFP with many options in pin pitch, size and thickness.

All of them are compatible with the surface mount technique, based on fast picking and placing from tapes or

trays, followed by mass soldering. Mounting lines are almost totally automated, with high throughput and high

yield.

Only a few devices are not y et compati ble w ith SMT princi ples: a few "exotic" components like l arge capac itors,

resistors, inductors, varistors, etc. and almost all the power semiconductor packages. Several drawbacks are

associated with existing power packages:

July 2001

1/19

Page 2

AN668 APPLICATION NO TE

1) They have still the traditional structure for insertion and are mounted manually in the PCB,

with loss of time, productivity, floor space and

money;

2) They force the use of wave soldering techniques and are not compatible with reflow soldering;

3) They are not compatible with increasing need

of miniaturization of power systems.

The above points are so important that the development of totally new power packages fitting the SMT

requirements is a clear demand of the industry and

can pay back the heavy effort needed in terms of

R&D, engineering and production resources.

1.1 INTERMEDIATE SOLUTIONS: INSERTION

PACKAGES CONVERTED TO SMT

The fastest answer to the requirement discussed

above is the adaptation of existing insertion packages to obtain a kind of surface mount configuration.

This can be conveniently done by redesigning the

lead shape, as in the case of the surface mount Heptawatt package (7 lead TO-220) shown in Figure 1

which was introduced in the market by STMicroelectronics in 1989.

The package of Figure 1 is very attractive in terms of

capital expenditure and time to market; as a minor

modification of existing production line can provide

the surface mount version in a short development

time.

However, the experience of STMicroelectronics with

above solutions is not totally satisfactory, for a number of reasons:

Figure 1.

HeptawattTM (surface mount) package

ture, which is asymmetrical in two directions

(height and thickness). Existing pick and place

tools are not readily compatible with this structure, as well as the tape and reel packing;

2) SIZE, which is basically the same as existing

insertion packages; therefore, is not the answer to the demand of miniaturization of power

systems coming from almost all the applications: automotive, audio and industrial;

3) COPLANARITY, which can become an issue

for 4-6 mm (0.16-0.24 inch) long leads. It must

be recalled tha t maj or c oplanar ity im provement

is obtained by reducing the lead length, down

to 1-2 mm (0.04-0.08 inch); this cannot be

readily obtained with Multiwatt, whose average

leadframe thickness is about 0.4 mm.

4) RELIABILITY AFTER THE SOLDERING PROCESS, due to the excess stress caused by the

high temperature (>215°C) even with "zero"

absorbed moisture at the large interface between slug and molded body, with consequent

delamination;

5) INSPECTION OF THE SOLDERED JOINT between slug and substrate, as discussed in next

paragraph;

6) LIMITED PIN COUNT 7, which is no longer

able to cover the requirements of advanced

smart power, needing more I/Os for the logic

circuitry.

Due to the above reasons, STMicroelectronics preferred to invest in new especially developed power

structures, with designed-in surface mount characteristics. Moreover, due to the increasing demand of

quality, led by the automotive market, process and

materials were selected in order to obtain intrinsic

long term reliability and a very low failure rate, targeted at 1 ppm for early life.

1) HANDLING, which unlike all other surface

mount packages, is complicated by the struc-

2/19

1.2 NEW SOLUTI ONS:

ORIGINAL STMicroelectronics P ACKAGES

WITH D ESIGN-IN SMT CHAR ACTERISTIC S

The well understood dual-in-line configuration was

selected for the new housing (Figure 3), which does

not look very much different than the Small Outline

(SO) package; but, from high dissipation capability,

the main difference is the internal massive slug,

which provides the same thermal impedance as traditional insertion packages.In view of the larger pin

count needed for smart power products, a family of

Page 3

AN668 APPLICATION NOTE

packages has been designed, cov eri ng from 2 0 to 36

leads. The well established concept of "variable pitch

in a fixed body" has been used, with 1.27 mm (0.05

inch), 1.0 mm, 0.8 mm and 0.65 mm.

Figure 2.

PowerSO-20 & PowerSO-36 packages

PowerSO-20

The new family, named PowerSO, is Jedec registered as MO-166.

PowerSO-20 and PowerSO-36 are presented in this

technical note (Figure 3 & 4)

PowerSO-36

3/19

Page 4

AN668 APPLICATION NO TE

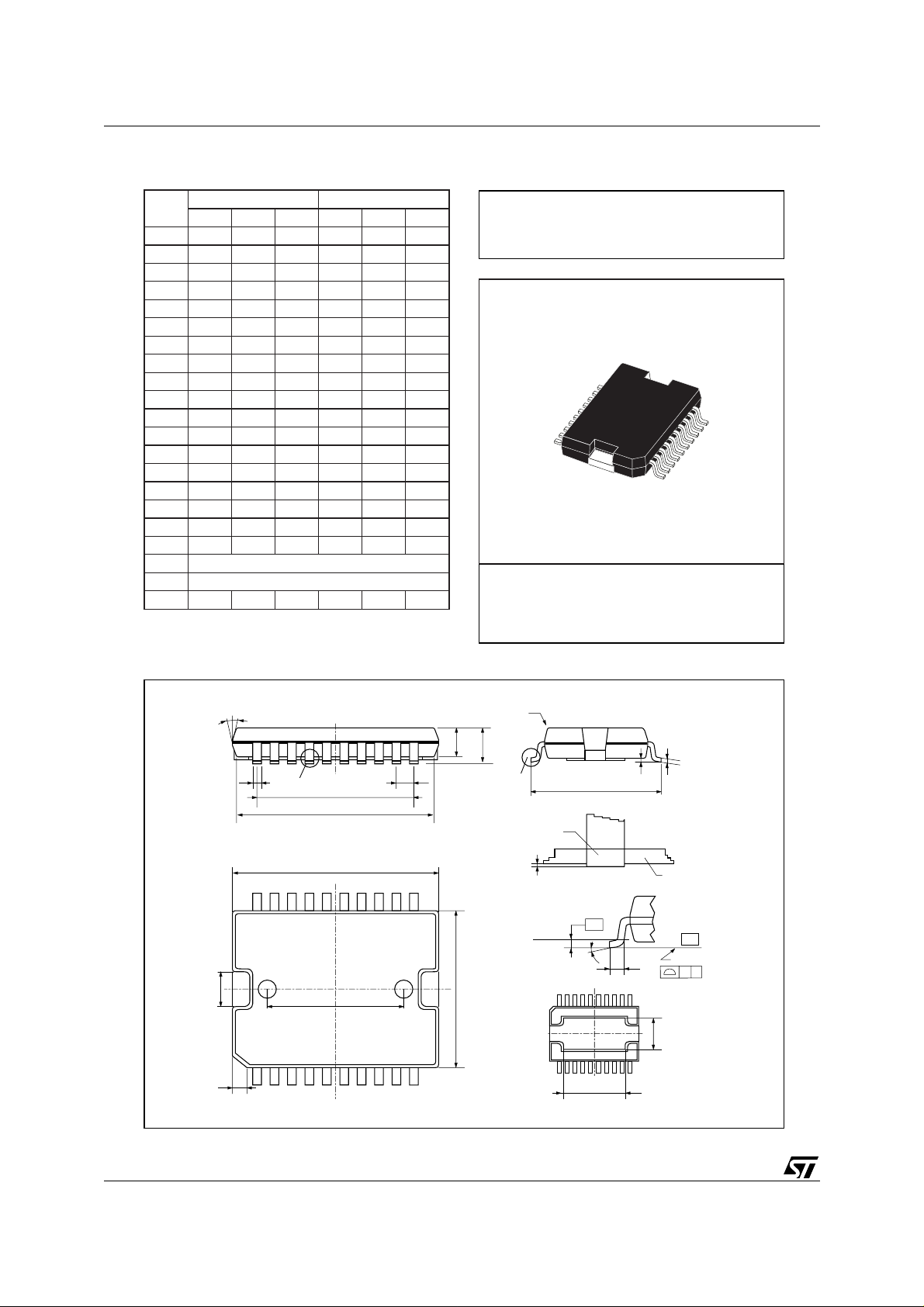

Figure 3. PowerSO-20 package (Jedec MO-166) mechanical data.

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 3.6 0.142

a1 0.1 0.3 0.004 0.012

a2 3.3 0.130

a3 0 0.1 0.000 0.004

b 0.4 0.53 0.016 0.021

c 0.23 0.32 0 .009 0.013

D (1) 15.8 16 0.622 0.630

D1 9.4 9.8 0.370 0.386

E 13.9 14.5 0.547 0.570

e 1.27 0.050

e3 11.43 0.450

E1 (1) 10.9 11.1 0.429 0.437

E2 2.9 0.114

E3 5.8 6.2 0.228 0.244

G 0 0.1 0.000 0.004

H 15.5 15.9 0.610 0.626

h 1.1 0.043

L 0.8 1.1 0.031 0.043

N 10˚ (max.)

S

8˚ (max.)

T10 0.394

(1) "D and F" do not include mold flash or protrusions.

- Mold flash or protrusions shall not exceed 0.15 mm (0.006").

- Critical dimensions: "E", "G" and "a3"

OUTLINE AND

MECHANICAL DATA

JEDEC MO-166

PowerSO20

E2

h x 45

DETAIL B

PSO20MEC

R

lead

a3

Gage Plane

BOTTOM VIEW

E

DETAIL B

0.35

S

D1

L

c

a1

DETAIL A

slug

- C -

SEATING PLANE

GC

(COPLANARITY)

E3

NN

a2

A

b

DETAIL A

e3

H

D

T

1

e

1120

E1

10

4/19

Page 5

Figure 4. PowerSO-36 package (Jedec MO-166) mechanical data.

AN668 APPLICATION NOTE

DIM.

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

A 3.60 0.141

a1 0.10 0.30 0.004 0.012

a2 3.30 0.130

a3 0 0.10 0 0 .004

b 0.22 0.38 0.008 0.015

c 0.23 0.32 0.009 0.012

D (1) 15.80 16.00 0.622 0.630

D1 9.40 9.80 0.370 0.385

E 13.90 14.50 0.547 0.570

e 0.65 0.0256

e3 11.05 0.435

E1 (1) 10.90 11.10 0.429 0.437

E2 2.90 0.114

E3 5.80 6.20 0.228 0.244

E4 2.90 3.20 0.114 0.126

G 0 0.10 0 0.004

H 15.50 15.90 0.610 0.626

h 1.10 0.043

L 0.80 1.10 0.031 0.043

N10°(max.)

S8°(max.)

(1): "D" and "E1" do not include mold flash or protrusions

- Mold flash or protrusions shall not exceed 0.15mm (0.006 inch)

- Critical dimensions are "a3", "E" and "G".

OUTLINE AND

MECHANICAL DATA

PowerSO36

NN

a2

A

1936

0.12 AB

⊕

e

M

E1

DETAIL B

lead

a3

B

Gage Plane

PSO36MEC

BOTTOM VIEW

DETAIL B

0.35

S

L

E

DETAIL A

(COPLANARITY)

E2

h x 45˚

DETAIL A

118

A

e3

H

D

b

c

a1

slug

E3

D1

- C -

SEATING PLANE

GC

5/19

Page 6

AN668 APPLICATION NO TE

The most important features of PowerSO-20/36 are:

1) High power structure and process;

2) High current capability;

3) Miniaturization

4) Designed-in surface mount characteristics:

a] Handling;

b] Tape and reel packing;

c] Co-planarity;

d] Solder joint quality and inspection;

e] High reliability after soldering process.

5) Designed-in "hermeticity", for low failure rate (1

ppm).

2. STRUCTURE AND CHARACTERISTICS

OF POWERSO-20/36

.

In this section, design criteria listed in previous paragraph are presented and discussed.

2.1 High power structure and process (>20 W)

The main feature of the power package structure is

the existence of a massive copper slug in the package onto which the silicon chip is soldered. Its function is twofold:

a) To provide a low thermal resistance path from

the chip to the external heatsink;

b) To provide a large thermal capacitance, able to

absorb power peaks in switching conditions.

The slug of PowerSO-20/36, is optimized in order to

get a good compromise between miniaturization and

thermal performance. As a result of this work, PowerSO-20 has the same junction to case thermal resistance Rth(j-c) of Multiwatt package and the same

thermal impedance up to 0.5 sec. Therefore the

range of application exceeds 20 W, the same as for

traditional power packages.

Section 3 will present thermal design in detail. Here

we will recall the importance of the die attach process, typical of power IC packages, which uses a

high melting temperature (300°C) tin based alloy.

The control of this process, in terms of solder thickness and void reduction, is based on SPC methods

and has a CPK > 1.33.

2.2 High current capability (10-20 A)

At first glance, leads of the PowerSO-20/36 seem

very fragile, thin and not compatibl e with the high c ur-

rents (10-20 A) associated with a large number of

power ICs, which require the utilization of large aluminum wires having a diameter ranging between

0.010 and 0.020 inch (0.25 to 0.5 mm).

Table 1 reports the comparison of PowerSO-20 with

insertion and surfac e mount Mul tiwatt and the following considerations are possible:

1) Electrical resistance of PowerSO-20 leads is

about 760

µΩ

, i.e. it is equivalent to insertion

Multiwatt or better;

2) Electrical resistance of PowerSO-20 leads is

worse than Surface Mount Multiwatt by a factor

of 1.3 to 2;

3) In any case, lead resistance of PowerSO-20 is

much lower than the wire resista nce. Wire resistance is 450-1800

µΩ

/mm and it must be

considered that the minimum wire length is 2.5

mm corresponding to 1150-4500

µΩ

;

4) If needed, two or more leads are short circuited

and different frame designs can be developed

providing flexible options (Figure 6). With multiple wire bonding, current capability can be

very large; for 45A current, if 3 leads are used

with 10 mil diameter, 3 mm long wires, electrical resistance of the interconnection is about

Ω

2m

.

Table 1.

Electrical resistance data of PowerSO-20

and Multiwatt 15 leads

Dimensions

(mm)

Long lead

MW15

23x0.9x0.5

18x0.9x0.5

Short lead

MW15

14x0.9x0.5

9x0.9x0.5

Lead

PowerSO-20

5x0.5x0.25 – – 760µΩ

Multiwatt15

Insertion

970µΩ

–

590µΩ

–

Multiwatt15

Surf. Mount

–

760µΩ

–

380µΩ

PowerSO-20

–

–

–

–

Copper resistivity : 1.9mW x cm

Aluminum wire resistance:

∅

10 mils: 1800 mW / mm

∅

20 mils: 450 mW / mm

6/19

Page 7

AN668 APPLICATION NOTE

2.3 Miniaturization

The whole story of microelectronics has been a continuous race towards smaller products. This is also

true for power systems.

The PowerSO-20 and PowerSO-36 offer excellent

possibilities in miniaturization, without compromising

power dissipation.

From Table 2, which compares the PowerSO-20 with

the surface mount version of Multiwatt, advantages in

terms of size, weight, height and vol ume ar e evident.

They range between 22 and 64% improvement.

Table 2. Miniaturization of PowerSO-20 vs Sur-

face Mount Multiwatt

footprint

2

(mm

height

(mm)

volume

3

(mm

SM MW15L

320 227 -30%

)

4.5 3.5 -22%

1160 590 -49%

)

PowerSO-20

Difference

2.4 Designed-in surface mount characteristics

A] Handling

The PowerSO-20/36 structure is similar to the

SO outline, which was introduced more than 20

years ago in STMicroelecrtronic s. Ther efore, the

experience associated with the different aspects

of production, testing, burn-in and on board

mounting are quite solid.

Due to their optimized outline and reduced

weight, handling of the PowerSO-20/36 packages does not present any particular problem and

is fully compatible with existing equipment.

B] Packing

Tube and Tape & Reel packing are both possi ble

with the PowerSO-20/36. Embossed cavity tape

has been produced with a special design, able to

minimize the mechanical effect of packing and

shipment on the lead coplanarity (Figure 6).

weight (gr) 5.6 1.9 -64%

Figure 5. Frame options for high current

D94IN001

7/19

Page 8

AN668 APPLICATION NO TE

Figure 6. Embossed cavity tape.

1.5 +0.1/-0.0

8.6013.00Bo

4.50

11.50

Ao

30 ±0.05

STRETCH

FORM

C] Coplanarity

Lead coplanarity is considered a major issue for

surface mount devices. In the case of Power surface mount packages, whose slug is eventually

soldered on a substrate, coplanarity is also referenced to the relative position of the slug and the

leads.

In the PowerSO-20/36, lead extremities and

package slug are positioned inside a 4 mil (0.1

mm) layer; this condition provides a high yield

mounting and soldering process.

D] Solder joint quality and inspection

When the package slug is soldered onto the sub-

strate, as in the many applications developed so

far, the need exists for producing a high quality

solder joint between the slug and its solder pad on

the board.

The PowerSO-20/36 structure is ideal from this

viewpoint: symmet ry exis ting in the x- y plane provides a very good balance of the wetting forces,

once the solder paste is melted. A kind of self

centering effect has been observed, which is

mostly due to the dual-in-line outline and to the

excellent wettability of both leads and slug. This

2.00

4.00

24.00

Ko

1.00

A

A

1.75

11.50

24.00 ±0.3

R0.50 Typical

1.50 min

D94AN002

results in a solder joint well contr olled in thicknes s

and consistency.

An additional advantage of the PowerSO-20/36

outline is the presence of two exposed inspection

points on the slug, which has been intentionally

obtained in the package body (Figure 7). Proprietary processes keeps these two points free of

molding compound flash and allows evident solder fillets after the soldering process.

Due to the symmetrical structure of PowerSO20,/36 the presence of solder fillet in both inspection points is a good indicator of joint quality and

planarity. It should be noticed that the same kind

of control is not possible in the surface mount

Multiwatt structure, which can show a good solder

fillet in the exposed section of the slug even with

a non-parallel joint and possible voiding. In this

case, the degradation of the junction to substrate

thermal resistance Rth(j-s) is more evident, as

shown in Figure 8.

E] Reliability after soldering process

Extensive evaluation of frame design and materi-

als provides the PowerSO-20/36 excellent reliability performance after the soldering process,

as discussed in section 5. No degradation of the

8/19

Page 9

AN668 APPLICATION NOTE

A

package structure has been observed after the

high temperature stress, up to 260°C.

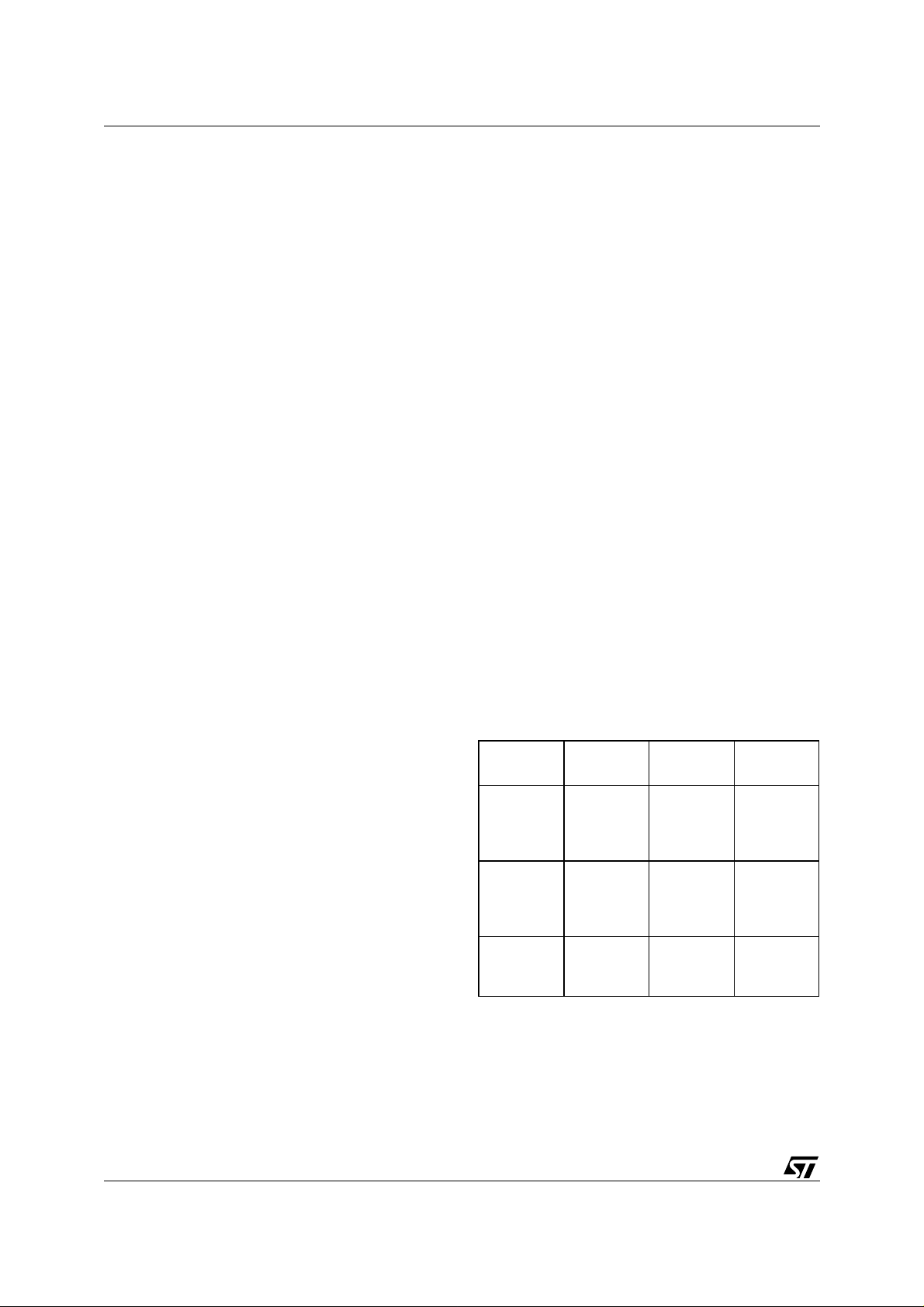

Figure 7. Exposed slug edge for solder joint in-

spection

slug edge accessible

for visual inspection

D94AN003

Figure 8. Loss of thermal performance due to

poor co-planarity and uneven solder

joints

100

%

80

60

40

20

0

Power SO-20/36

MW SMT

VERSION

D94AN004

R

th(j-s)

quence, Scanning Acoustic Microscopy (SAM)

analysis and die penetration test confirms the robustness of the PowerSO-20/36. Figure 9 shows a typical

map of adhesion obtained in SAM evaluation after

stress analysis.

Figure 9. Scanning Acoustic Microsco pe m ap

3. THERMAL DESIGN AND APPLICATIONS

Thermal characteristics of the new PowerSO-20/36

package can cover a wide r ange of applications , both

in the medium power (1-5W) and in the high power

range (up to 20W). Moreover, as sufficiently large

thermal capacitance is associated with the new package, performance in switching conditions is equivalent to that of available insertion packages.

2.5 Hermeticity

Good hermeticity of package interfaces has been obtained by means of slug design and of the selection

of low stress, high adhesion molding compounds.

State-of-the-art molding equipment and process is

used, with CPK in excess of 1.33 for all the key parameters. This provides repeatability of the results in

large volumes.

Moreover, improved mechanical clamping of the

molding compound is obtained by using a new, proprietary finishing of the slug all along its periphery,

which is provided with undercutting and controlled

surface roughness.

After severe tests consisting of alternate thermal cycling and pressure pot, and after the "pop corn" se-

In this section, a number of typi cal applicati ons of the

PowerSO-20/36 will be considered and compared

with existing solutions, taki ng into acc ount that a major role in the thermal design is played by the temperature increase Tj-Ta specified in the different

applications. "Delta" Tj can be as low as 25-30°C in

extreme conditions for automotive or as large as

100°C in more relaxed systems.

Unless differently indicated,

∆

Tj of 50°C is assumed

in all the considerations of this note.

3.1 JUNCTION-TO-CASE THERMAL RESISTANCE

The main feature of PowerSO-20/36 packages are

optimization of junction-to-case thermal resistance,

from the junction to the external surface of the slug.

Unlike standard SO packages, which use epoxy die

9/19

Page 10

AN668 APPLICATION NO TE

attach and thin leadframes, the PowerSO-20/36 take

advantage of power package technology, with a massive copper slug and tin based alloy die soldering.

This results in minimum junction-to-case thermal resistance Rth(j-c). Figur e 10 shows how muc h Rth(j-c)

is affected by the die size, assuming that the power

source is uniformly distributed on the die.

For actual applications , Rth(j-c) ranges between 2°C/

W for small dice and 0.5°C/W for the maximum die

size of 60k sq mils. Therefore, the PowerSO-20/36

are equivalent to inserti on power packages li ke TO-220

and Multiwatt; this is due to the optimization of the

slug dimensions, obtained by removal of any copper

in excess, without affecting the thermal cone where

the heat flows from the silicon to the substrate.

The PowerSO-20/36 offer a new possibility for a power package: direct soldering of the slug onto the

board during the surface mount process; therefore

junction to substrate thermal resistance is close to

Rth(j-c) and reaches the very attractive value of 0.5-

2.0°C/W.

Figure 10. Thermal resistance junction-case

vs. dissipating area of PowerSO-20/36

with a modified leadframe in order to have a number

of leads connected to the die pad (bat wing structure).

This solution, shown in Figure 11, is effective in minimizing the Junction-to-Pin thermal resistance Rth(jp), i.e. the thermal path between the junction and

suitable dissipating areas obtained on the PCB and

connected to the heat transfer leads (Figure 12).

Figure 11. Lead frame for medium power SO

Figure 12. Foot print for medium power SO

R

th

2.5

2.3

2.1

1.9

1.7

1.5

1.3

1.1

0.9

0.7

0.5

012345

die thickness: 0.375mm

Pd=5W

on die dissipating area

silicon

side L(mm)

D94AN005

side L

3.2 APPLICATIONS WITH 1-2 WATT DISSIPATION

3.2.1 On board dissipating elements

In this power range, state of the art technology is

based on the medium power SO.

It has the same outline of a standard SO package but

D94AN006

Typical representatives of the medium power SO

package family are the 300 mils SO20 and SO28 with

8 heat transfer leads, reported as SO(12+4+4) and

SO(20+4+4) respectively.

Referring to STMicroelectronics guideline "Thermal

management in Surface Mount Technology" (July

1988), thermal performance of medium power

SO(12+4+4) is defined by the relationship:

Rth(j-a) = Rth(j-p) + Rth(sub-amb)

where Rth(j-p) is the ther mal path from the juncti on to

the board and Rth(sub-amb) is the thermal resistance of the two areas shown in Figure 12.

Rth(j-p) ranges between 12 and 14°C/W, depending

10/19

Page 11

AN668 APPLICATION NOTE

on the efficiency of the heat transfer leads (design

and thermal conductivity) and on the die size.

Rth(j-a) is due to the size of the dissipating elements

on the board, according to Figure 13, which shows

improved thermal resistance from 76 to 50°C/W

when the dissipating area is incr eased from 0 to 6 cm

sq.

The PowerSO-20/36 can be used in place of medium

power SO, with the slug soldered on the board.

Figure 13. Rth(j-a) vs. board dissipating area

R

(˚C/W)

th(j-a)

80

75

70

65

60

55

50

45

012345678910

on board heat sink area (sq.cm)

die pad = 140 x 220sq.mils

die size = 120 x 130sq.mils

Pd = 1W

D94AN007

The first experimental evidence shows a very good

heat exchange with the substrate, due to the large

contact area associated with the basic footprint of

Figure 14. Rth(j-a) is about 50°C/W in this configuration.

Figure 14. Pad layout

17.7

14.8

When the two dissipating elements are added and

the footprint of Figure 15 is used, additional improvement is observed. For example, Rth(j-a) is 35°C/W

with dissipation elements of 6 sq cm.

Figure 15. Footprint with dissipating elemen t

D94AN009

Margin over the traditional medium power

SO(12+4+4) is about 40%, w ith dissipati on increased

from 1 W to 1,4 W always with Delta Tj = 50°C. Improvement can be also understood taking into account that the junction to substrate thermal

resistance is equivalent to Rth(j-p) = 12-14°C/W for

medium power SO(12+4+4) and equivalent to Rth(jc) = 0.5-2.0°C/W for PowerSO-20/36.

3.3 APPLICATIONS WITH 2-5 WATT DISSIPATION

3.3.1 Dissipating elements and ground layer

It must be noticed that previous data are observed

with a simple PCB, with single or double face. In applications using mult ilayer boards , a much better efficiency is observed due to the heat spreading effect of

the ground layer.

Looking at the board s tructure of Fi gure 16, heat generated at the junction is transferred to the dissipating

areas on the board surface and then to the ground

layer, which works as a large heat exchan ge element

with the ambient.

Rth(j-a) offered by this solution is 20-25°C/W for 2.0

- 2.5W dissipation.

5

1.7

0.7 1.27

9.4 15.4

D94AN008

Figure 16. M ounting on PCB wi th gro und laye r

Ground

layer

D94AN010

11/19

Page 12

AN668 APPLICATION NO TE

3.3.2 Via holes and ground layer

If via holes are used as in Figure 17, a more direct

thermal path is obtained from the slug to the ground

layer. The number of vias is chosen according to the

desired performance.

Figure 18 shows a typical high performance foot print

for PowerSO20/36 with via holes

Rth(j-a) can be reduced down to 15-20°C/W and dissipation increased up to 2.5-3.3W with Delta Tj =

50°C.

Figure 17. Mounting on epoxy FR4 using via

holes for heat transfer of ground layer

Copper

foil

Ground

layer

via holes

D94AN011

Figure 18. Footprint of PowerSO20/36 with via

holes

3.3.3 Via holes and external heatsink

The solution considered in Figure 19 combines a PowerSO-20/36 soldered onto a via hole structure, with a

metal plate glue d on the opposite side of the boar d.

The final thermal resistance value is given by the resistance of via holes added to the resistance of the

plate to the ambient.

Figure 20 shows the thermal resistance associated

with 16 holes and reports its behavior with the dissipated power. Hole depth of 1.5 mm is an extreme

case, existing in rather thick substrates only; the experimental value is about 9°/W, including the contribution of Rth(j-c). In practical cases, structures with

Rth(j-a) = 12-15°C/W are obtained for 3.3-4.2W dissipation.

Figure 19. Mounting on epoxy FR4 using via

holes for heat transfer and external

metal plate

Copper

foil

FR4 board

Metal plate

Via holes

D94AN012

Figure 20. Thermal Resistance junction-su b-

strate

R

(˚C/W)

thj-s

9.4

Mounted on FR4

9.2

Infinite heatsink

9.0

8.8

8.6

8.4

012345678910

Dissipated Power (W)

substrate with

Thickness: 1.5mm

D94AN013

vias holes

12/19

Page 13

AN668 APPLICATION NOTE

3.4 HIGH POWER APPLICATIONS (UP TO 20

W)WITH STANDARD SUBSTRATE

In order to get an Rth(j-a) of few °C/W, high power

applications requir e large and massiv e external he atsinks in close contact with the power device.

This is not a simple requirement when cost effective

systems using the standard surface mount technology and the standard PCB substrate are considered.

Major concerns are related to the critical assem bly of

a large heatsink onto a s mall package; vi brations and

thermal excursions c an gener ate unwanted mechanical stress, thus damaging the package leads or the

integrity of the contact between slug and heatsink.

However, the fact that we have a well established,

PCB based surface mount technology is pushing the

industry to test several directions, similar to those

sketched in Figure 21.

Rather than proven soluti ons, they should b e consi dered here as early attempts aimed to explore the capability of existing surface mount processes and

materials in the direction of increased heat dissipation at reduced cost.

3.4.1 "Slug-up" package and extern al heat-

sink

In the example of Figure 21a, PowerSO-20 is shown

in "reverse" or "slug-up" configuration, with a clip

mounted external heatsink, which was studied for

3.5W dissipation in still air and 5-6W dissipation in

forced ventilation.

Figure 21a. "Slug up"package with extern al

heatsink

Heatsink

Epoxy board

D94AN014

To minimize the mechanical stess on leads and solder joints derived from any pressure applied on top of

package, the slug-up formi ng is specifically designed

(Fig. 22).

3.4.2 Cavity board and extern al heatsink

In the example of Figure 21b, the PowerSO-20/36 is

mounted onto an epoxy board, with a through cavity

fabricated to correspond to the package slug. The external heatsink is directly applied in contact with the

slug, secured by means of a spring system or glued.

Also in this case, a high level of dissipation can be

achieved with properly designed heatsinks.

Figure 21b. Mounting on cavity board and ex-

ternal heatsink applied

Epoxy board

with through cavity

A similar concept can be used for other applications

and the sink size adapted to their specific requirements. A lar ge variety of solutions w ill exi st whic h will

take advantage of the metal box in which the board

can eventually be housed.

Heatsink

D94AN015

13/19

Page 14

AN668 APPLICATION NO TE

Figure 22. PowerSO-36 Slug-up

DIM.

A 3.25 3.5 0.128 0.1 38

A2 3.15 0.124

A4 0.8 1 0.031 0.0 39

A5 0.2 0.008

a1 0 0.1 0 0.004

b 0.22 0.38 0.008 0.015

c 0.23 0.32 0.009 0.012

D 15.8 16 0.622 0.630

D1 9.4 9.8 0.37 0.38

D2 1 0.039

E 13.9 14.5 0.547 0. 57

E1 10.9 11.1 0.429 0.437

E2 2.9 0.114

E3 5.8 6.2 0.228 0.244

E4 2.9 3.2 0.114 1.259

e 0.65 0 .026

e3 11.05 0.435

G 0 0.1 0 0.004

H 15.5 15.9 0.61 0.625

h 1.1

L 0.8 1.1 0.031 0.043

N 10˚ (max)

s 8˚ (max)

mm inch

MIN. TYP. MAX. MIN. TYP. MAX.

0.043

OUTLINE AND

MECHANICAL DA TA

PowerSO-36 (SLUG UP)

14/19

Page 15

AN668 APPLICATION NOTE

3.5 HIGH POWER APPLICATIONS (UP TO

20W) WITH INSUL A TE D ME TAL SUBSTRATES - IMS

In the last few years, several Companies developed

the idea of a cost effective Insulated Metal Substrate

(IMS) having:

a) A copper printed layer supported by an alumi-

num base, with epoxy or polyimide isolation in

between; or

b) A flexible printed circuit (polyimide) glued onto

an aluminum base.

In both cases, the following conditions are offered:

a) The substrate is compatible with s tandard SMT

processes, including infrared reflow soldering;

b) It is compatible with passive and active devic-

es, including PowerSO-20/36;

c) It has an acceptable thermal resistance loss

between the PowerSO-20/36 slug and the aluminum base, due to optimized thermal conductivity of the isolating layer;

d) The aluminum baseplate has variable thick-

ness, up to 5 mm, in order to sink different

amounts of heat.

Utilization of IMS is considered for several applications both for automotive and industrial systems and

is particularly fruitful when associated with PowerSO20/36 packages (Figure 23)

to the IMS by means of screws, bolts or rivets. The

total thermal resistance is obtained by adding the

heat sink resistance to the junction to baseplate resistance (1.0-2.5°C/W).

This solution is capable of 20-25 W per device and if

a large sink is used, as massive parts existing in the

car, more than one device can be assembled on the

same ISM, thus obtaining a functional power subsystem with several tens of Watt dissipation.

It is interesting to notice that the aluminum plate itself

has good dissipation properties to the ambient, depending on its size.

The PowerSO-20/36 soldered onto a 40 mm square,

1.5 mm thick IMS shows a thermal r esi stance of 7°C /

W, for about 7 W dissipation.

3.6 HIGH POWER PULSES AND THERMAL

IMPEDANCE

In several applications, large power pulses are delivered by the device for a short time.

In this case, discussed in the STMicroelect roni cs paper "Designing with Thermal Impedance" (Semitherm Conf. 1988), the quanti ty which rules the junc tion

temperature up to the time t0 is the thermal impedance of the three different elements: silicon chip,

package slug and heatsink.

Figure 23.

Copper

foil

Aluminium

Insulation

D94AN016

Thermal performance has been measured for both

substrates described above. The fir st result is related

to the contribution of isolation to the total thermal resistance. When the footprint of Figure 14 is used,

with the 96 sq mm slug soldered onto a 155 sq mm

pattern, this contribution is about 0.5°C/W .

Therefore, the thermal resis tance from the junction to

the aluminum baseplate ranges from 1.0 to 2.5°C/W

depending on the chip size.

For large dissipation, an external heat sin k is applied

For pulse durations in the range of 0.1-1.0 sec, the

package slug has the strongest influence on the system performance, depending on the associated thermal capacitance, i.e. the capability of heat

accumulation.

In the presence of properly sized slugs with suitable

capacitance, it is possible to maintain a low junction

temperature for the switching time of most applications, which seldom exceeds 1 sec.

For popular power packages like TO-220 and Multiwatt, the value of the thermal impedance in the first

second is lower than the value of Rth(j-c) in steady

state.

In order to compare the PowerSO-20/36 packages

with the insertion equivalent, Fig. 24 is very helpful. It

shows the thermal impedance of different packages

in the first second of the power pulse, in the same

conditions of power intensity and die size.

When similar comparisons are performed with medium power "bat wing" SO, the enhancement provided

15/19

Page 16

AN668 APPLICATION NO TE

by the copper sl ug becomes v ery evident ( Figure 2 5).

Due to the thermal capacitance of the slug, the tran-

sient thermal impedance of PowerSO-20/36 after 1

sec pulse duration is 4 times lower.

A summary of the thermal per formance of PowerSO20/36 considering the different mounting approaches

is given in Table 3, assum ing that the max imum rated

temperature of the device is 150°C and that the

∆

Tj

is 50°C.

Table 3. Thermal performance (∆Tj: 50°C)

PowerSO-20/36 packages

mounted on

1. FR4 using the reccomended pad lay-out

2. FR4 with heat sink on

board (6 cm2)

3. FR4 with heatsink (6

cm2) and ground

4. FR4 with 16 via holes

and ground layer

5. FR4 with 16 via holes

and external heatsink

6. IMS floating in air

7. IMS with external heat-

2

(40cm

)

sink applied

R

th(j-a)

50°C/W 1.0W

35°C/W 1.4 W

20°C/W 2.5W

15°C/W 3.3W

12°C/W 4.2W

7°C/W 7W

2.5°C/W 20W

Pdiss

Figure 24. Th erm a l impedance of di fferent

packages

Figure 25.

4. SOLDE R I NG INFORMAT IO N

The soldering process causes considerable thermal

stress to a s emiconduc tor com ponent. This has to be

minimized to ensure a reliable and extended lifetime

of the device.

PowerSO-20/36 are certified as MSL3 according to

Jedec STD 020A

As eflow techniques ar e the m ost c ommon in s urface

mounting, typical heating profiles are given in Figure

26, with a preheating at 130 - 150°C for 80 -100 seconds, either for mounting on FR4 epoxy substrate or

mounting on metal-backed boards (IMS). Peak temperature should be at least 30°C higher than the

melting point of the solder chosen.

Figure 26.

T (˚C)

250

200

150

100

EPOXY FR4

BOARD

245˚C

215˚C

Soldering

Preheating

D94AN017

Cooling

16/19

50

0

0 40 80 120 160 200 240 280 320 360

METAL-BACKED

BOARD

Time (sec)

Page 17

AN668 APPLICATION NOTE

5. RELIABILITY DATA

The information presented in this section shows that

PowerSO-20/36 are able to work reliably in severe

environments, like automotive, where the requested

reliability target is 1 ppm failure rate.

In order to evaluate the reliability behavior of the

present package a complete qualification program

was compiled with two test vehicles:

- TDA7350A (Audio Power Amplifier)

- ABS voltage regulator

A list of the tests, their features and the fail ure modes

associated to these tests is given in Table 4.

Tables 5 and 6 show the results of the quali fication; all

the package and die oriented tests were passed successfully. The test conditions and acceptance criteria

are the same as those for standard power packages.

Table 4. Reliability tests description.

Test Features Purpose

High Temperature Reverse Bias

(H.T.R.B.)

Operating Life Test (O.L.T.) Device submitted to application condi-

Thermal Humidity Bias (T.H.B.) Biased in presence of steam Metal corrosion detection

Power ambient Detect craked die, wire bond break-

Pressure Pot Test (P.P.T.) High temperature and pressure with

Reverse biased device at elevated

temperature

tions

ing, mechanical damage to package

saturated steam

To detect surface defects like poor

passivation and contamination

T o put in evedence thermomechanical

sresses induced by internal power

dissipation

Electrochemical and galvanic corro-

sion

Solderability Test (S.T.) Verifies tinning process Detects poor solder joint

Enviromental Sequence (E.S.) Thermal cycling combined with pres-

sure pot

Surface Mount (S.M.) Simulation of soldering process in the

presence of humidity

Resistance toSolvens (R.S.) Mil-Std-883 Meth. 2015 To verify the marking permanency

To stdy corrosion mechanism after

thermal cycling stress

To point out the package resistance to

the tresses due to surface mounting

in presence of humidity

Table 5. ABS Voltage Regulator (die size 5.3 x 5.28mm)

Test Condition Sample Duration Failure

T.C.T. Tamb = -65°C to +150°C air to air 153 pcs. x 3 lots

T.S.T. Tamb = -65°C to +150°C liquid to liquid 60 pcs. x 3 lots 1000 cy 0

P.P.T. Tamb = 121°C P = 2atm 77 pcs. x 3 lots 500hr 0

S.T. 1 Tamb = 215°C; precond. 8h vapor 22 pcs. x 3 lots – 0

S.T. 2 Tamb = 215°C; precond. 8h vapor at

Tamb = 155°C

E.S. 100cy at -65°C to +150°C 48hr of PPT at

3atm (5 Times Repeated)

S.M. 24hr at 85°C/85%dipping at 260°C 10"48h

PPT at 2.5atm

153 pcs. x 1 lots

22 pcs. x 3 lots – 0

25 pcs. x 3 lots – 0

22 pcs. x 3 lots – 0

1000 cy

2000 cy

0

0

R.S. Mil-Std-883 Meth 2015 22 pcs. x 3 lots – 0

17/19

Page 18

AN668 APPLICATION NO TE

Table 6. TDA7350A (Bridge Audio Amplifier)

Test Condition Sample Duration Failure

H.T.R.B. V

O.L.T. Vs = 16V; Pd = 10W; TJ = 150°C 90 pcs. x 3 lots 2000hr 0

T.H.B. Vs = 18V; T

P. T. C . Vs = 14V; ton = t

= 18V; TJ = 150°C 77 pcs. x 3 lots 200hr 0

s

= 85°C; R.H. = 85% 77 pcs. x 3 lots 2000hr 0

amb

T

= -40 to +85°C;

amb

off

= 5";

33 pcs. x 3 lots 1000hr 0

6. CONCLUSION

The PowerSO-20/36 packages, belonging to a new surface mount power package fam ily, have been i ntroduced

(Jedec MO-166 registered).

They have been designed specifically for the surface mount industry and they can replace Multiwatt in many

applications.

The main advantages of PowerSO-20/36 are:

1) Good thermal characteristics. They are able to handle die with the same size as Multiwatt.

2) Versatility. A wide variety of intelligent power products with a wide range of options can be managed.

3) Symmetrical package design. Slug up and slug down versions can be delivered giving more opportuniti es

to the customers for power dissipation.

4) High power density through reduced package volume and height.

5) Compatibility with automatic placement equipment and soldering techniques used in surface-mount assembly. Reliable and inspectable solder joints can be achieved.

6) High reliability in terms of hermeticity. The correct choice of the materials and particular design features

allow the PowerSO-20/36 to pass successfully severe tests like pressure pot and die penetrant.

It was demonstrated that this package family well meets the high demands in surface-mount power applications,

where power ICs are becoming more and and more common.

18/19

Page 19

AN668 APPLICATION NOTE

Information furnished is believed to be accurate and reliable. However, STMicroelectronics assumes no responsibility for the consequences

of use of such information nor for any infringement of patents or other rights of third parties which may result from its use. No license is granted

by implic ation or otherwise under any patent or patent r i ght s of STMi croelectr oni cs. Spec i fications mentione d i n this publication are subject

to change without notice. This publication supersedes and replaces all information previously supplied. STMicroelectronics product s are not

authorized for use as cri tical comp onents in lif e support devi ces or systems without express written approva l of STMicroe l ectronics.

The ST logo is a registered trademark of STMicroelectronics

®MULTIWATT, PENT A WATT are re gi stered trademarks of S T M i croelectr oni cs

Australi a - Brazil - China - Finland - France - Germany - Hong Kong - India - Italy - Japan - Malaysia - Malt a - Mo rocco - Sing apore - Spain

2001 STMi croelectronics - All Ri ghts Reserved

PowerSO-20™ is a trademark of STMicroelect ronics

STMicroelectronics GROUP OF COMPANIES

- Sweden - Sw itzerlan d - United Kin gdom - U.S.A.

http://www.s t. com

19/19

Loading...

Loading...