Page 1

AN557

APPLICATION NOTE

EASY APPLICATION DESIGN WITH THE L4970A,

MONOLITHIC DC-DC CONVERTERS FAMILY

The L497XA series of high current switching regulator ICs exploit Multipower-BCD technology to

achieve very high output currents with low power dissipation – up to 10A in the Multiwatt power package

and 3.5A in a DIP package .

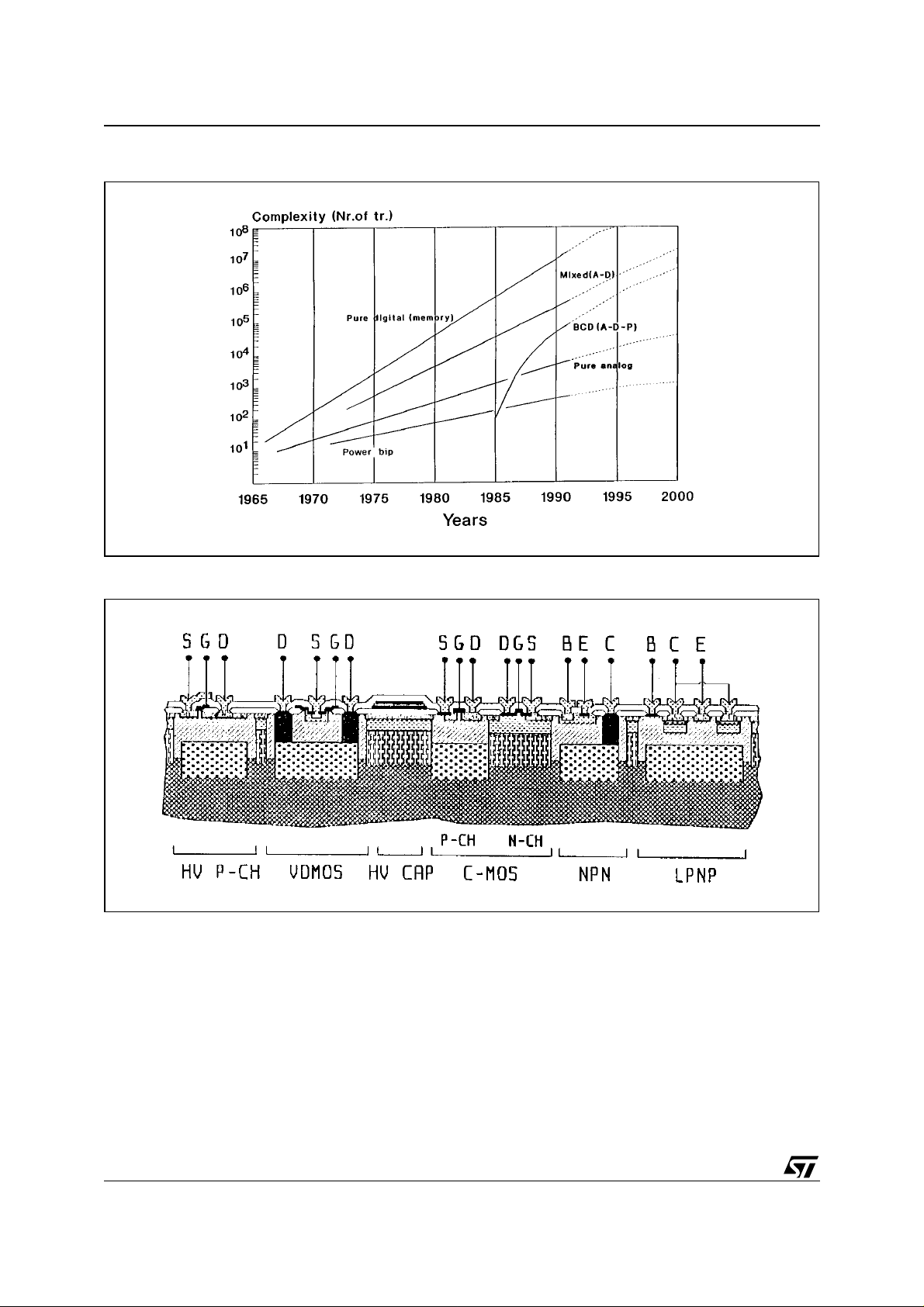

THE TECHNOLOGY

The technology architecture is bas ed on the vertical DMOS sil icon gate process that allows a chan nel

length of 1.5 micron ; using a junction isolation technique it has be en possible to mix on the same chip

Bipolar and CMOS transistors along with the DMOS power components (Fig. 2). Figure 1 shows how this

process brings a rapid increase in power IC complexity compared to conventional bipolar technology. In

the 70’s class B circuits and DC circuits allowed out put power in the range of 70W . By 1980, with the introduction of switching techniques in power ICs, output powers up to 200W were reached ; with BCD technology the output power increased up to 400W.

November 2003

1/52

Page 2

AN557 APPLICATION NO TE

Figure 1. BCD process and increase in power ICs complexity.

Figure 2. Cross Section of the BCD Mixed Technology.

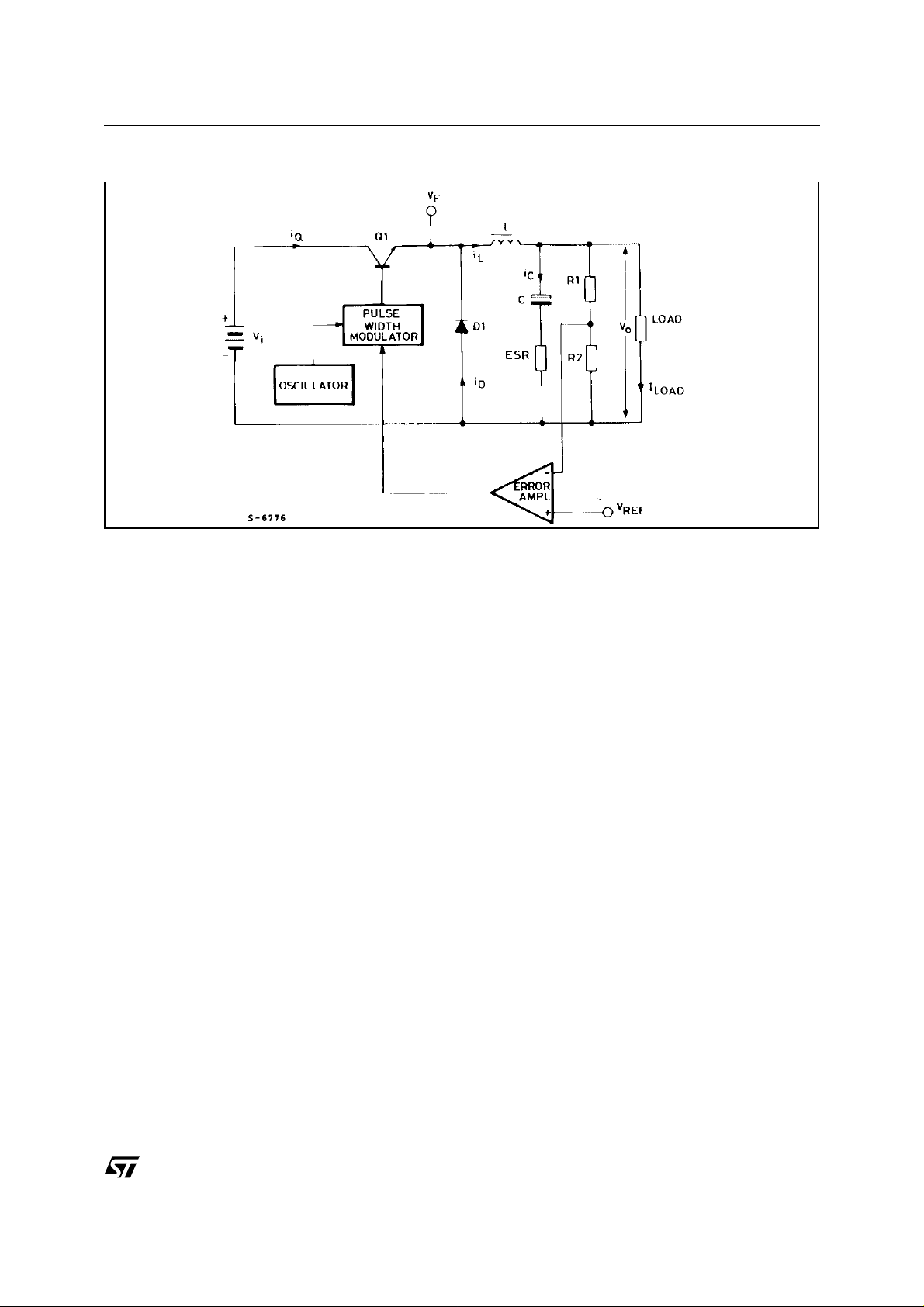

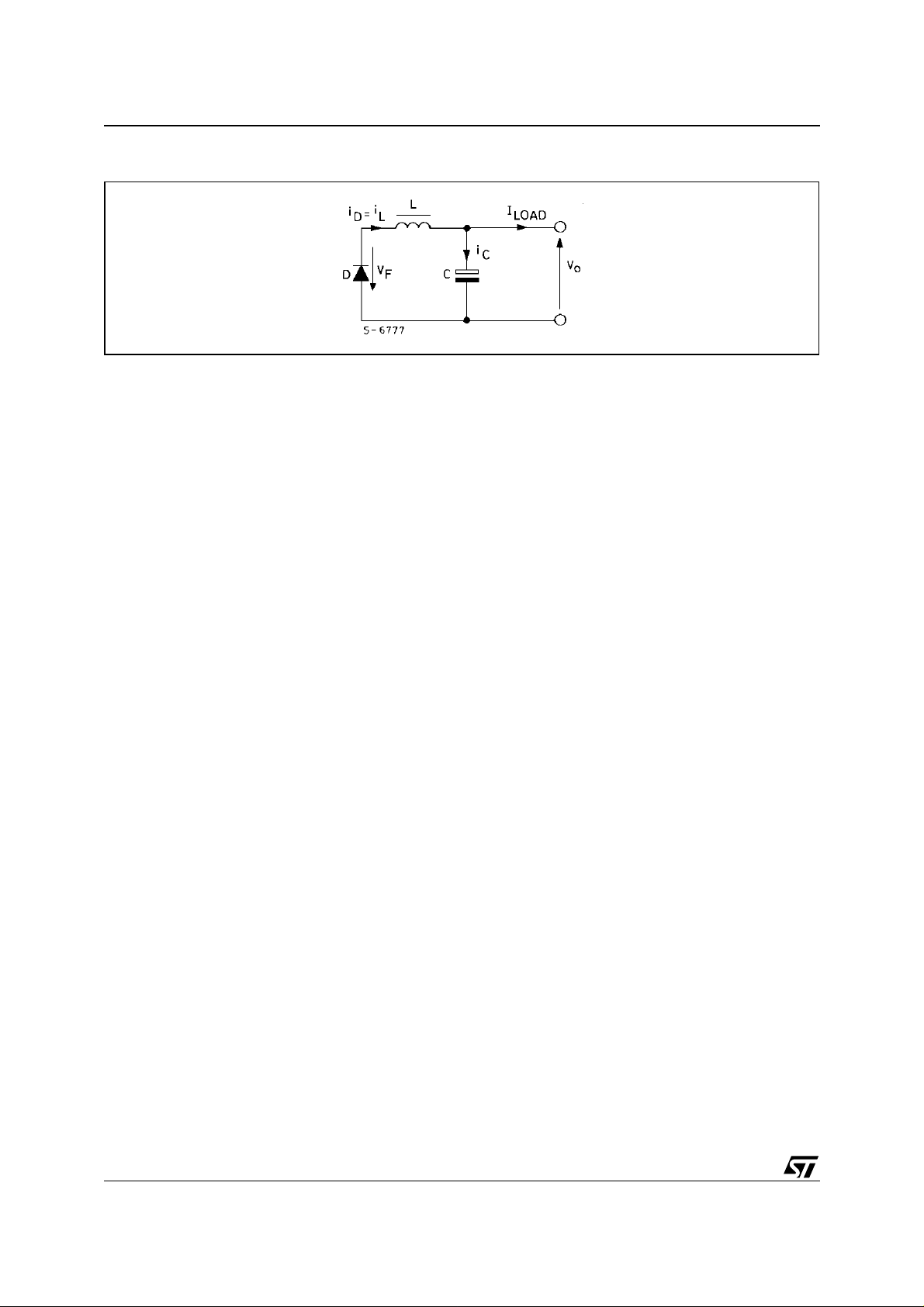

THE STEP-DOWN CONFIGURATION

Fig. 3 shows the simp lified block di agram of the c i rcuit realizin g the s t ep-down c onfiguration. T his circuit

operates as follows : Q1 acts as a switch at the frequency f and the ON and OFF ti mes are suitably c ontrolled by the pulse width modulator circuit. When Q1 is saturated, energy is absorbed from the input which

is transferred to the output through L. The emitter voltage of Q1, V

, is Vi-Vsat when Q is ON and -VF (with

E

VF the forward voltage across the D dio de as indicated) when Q1 is OFF. During t his sec ond phase the

current circulates again through L and D. Consequently a rectangular shaped voltage appears on the emitter of Q1 and this is then filtered by the L-C-D network and converted into a continuous mean value across

the capacitor C and therefore across the load. The current through L consists of a continuous component,

I

, and a triangular-shaped component super-imposed on it, ∆IL, due to the voltage across L.

LOAD

2/52

Page 3

AN557 APPLICATION NOTE

Figure 3. The Basic Step-down Switching Regulator Configuration

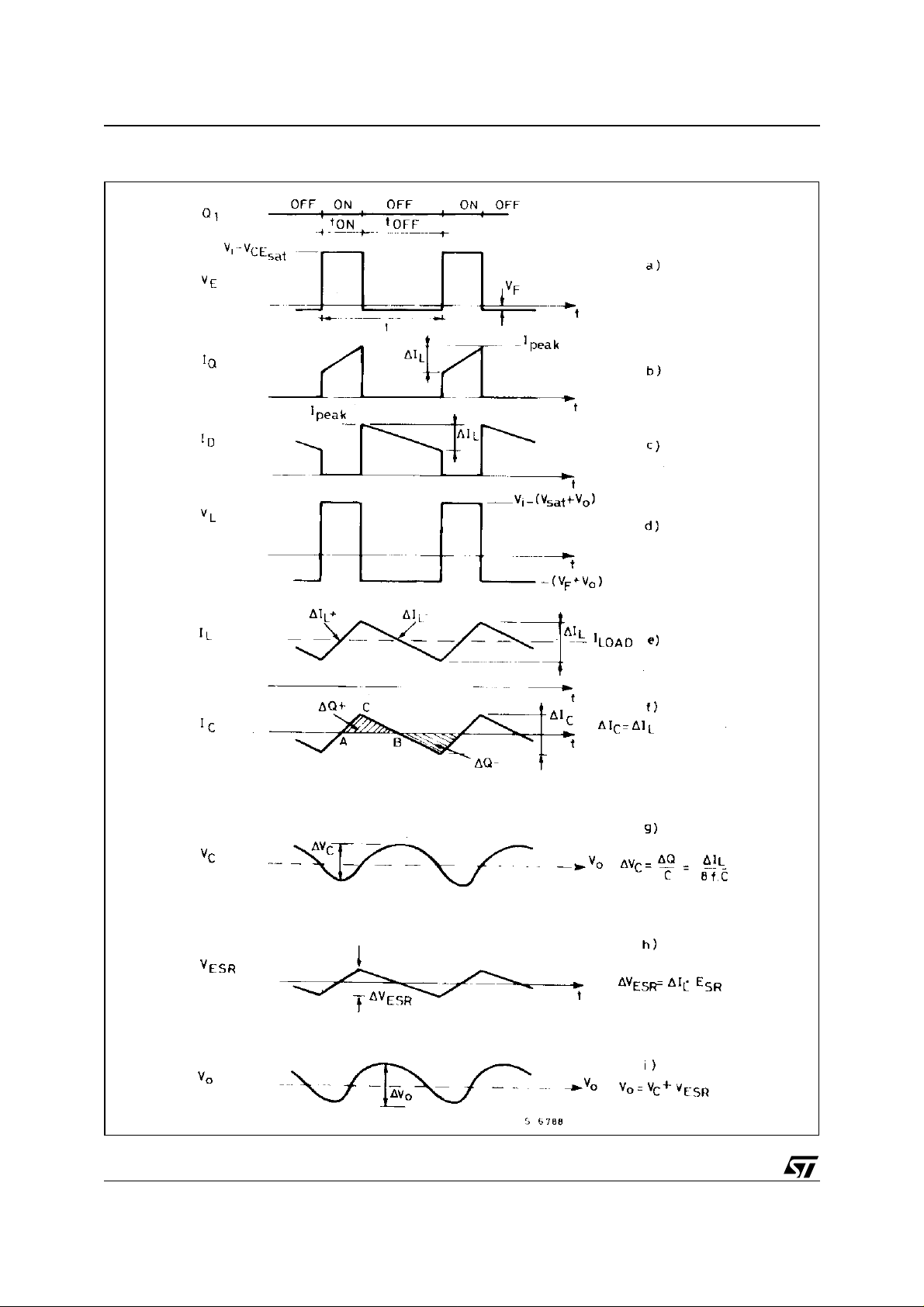

Fig. 4 shows the behaviour of the most significant waveforms, in different points of the circuit, which help

to understand better the operation of the power section of the switching regulator. For the sake of simplicity, the series resistance of the coil has been neglected. Fig. 2a shows the behaviour of the emitter voltage

(which is practically the voltage across the recirculation diode), where the power saturation and the forward VF drop across the diode era taken into account.

The ON and OFF times are established by the following expression :

T

ON

------------------------------- -

V

ViV

o

–()

sat

⋅=

T

+

ONTOFF

Fig. 4b shows the current across the switching tran sistor. The current shape is t rapezoida l and t he operation is in continuous mode . At this stage, the phenom ena due to the c atch diode, that we consider as

dynamically ideal, are neglected. Fig. 4c shows the current circulating in the recirculation diode. The sum

of the currents circulating in the power and in th e diode is the current circul ating in the c oil as s hown in

Fig. 4e. In balanced conditions the ∆

decrease occurring during T

OFF

+

current increase occ uring du ring TON has to be equal to the ∆ I

IL

L

. The mean value of IL corresponds to the charge current. The current rip-

ple is given by the following formula :

+

I

∆ I

L

It is a good rule to respect to I

-

∆

== =

L

oMIN

iVsat

----------------------------------------

≥ IL/2 relationship, that implies go od operation in co ntinuous mode.

–()V

V

–

o

L

T

ON

VoVF+

------------------- -

L

T

OFF

When this is not done, the regulator starts operating in discontinuous mode. This operation is still safe but

variations of the switching frequency may occur and the output regulation decreases.

Fig. 4d shows the behaviour of t he voltage ac ross coil L. In b alanced conditions, the mean value of the

voltage across the coil is zero. Fig. 4f shows the current flowing through the capacitor, which is the difference between I

In balanced conditions, the m ean current is equ al to zero, and ∆I

and I

L

LOAD

.

= ∆IL. The current IC through the ca-

C

pacitor gives rise to the voltage ripple.

This ripple consists of two components : a capacitive component, ∆V

, and a resistive component, ∆V

C

ESR

due to the ESR equivalent series resistance of the capacitor. Fig. 4g shows the capacitive component ∆V

of the voltage ripple, which i s t he i nteg ral of a triangular-shaped curren t as a function of time . Moreo ve r,

it should be observed that v

of charge ∆Q

+

supplied to the capacitor is given by the area enclosed by the ABC triangle in Fig. 4f :

(t) is in quadrature with iC(t) and therefore with the voltage V

C

. The quantity

ESR

–

,

C

3/52

Page 4

AN557 APPLICATION NO TE

Figure 4. Principal Circuit Waveforms of the figure 1 Circuit.

4/52

Page 5

Which therefore gives:

Q∆

∆

V

C

1

-- -

2

Q

----

C

AN557 APPLICATION NOTE

∆

I

T

L

------- -

---

⋅⋅=

2

2

∆

I

L

--------==

8fc

Fig. 4h shows the voltage ripple V

V

(t) = iC (t) × ESR. Fi g. 4i sh ows t he o vera ll ripple Vo, which is t he sum of the two pre vious com po-

ESR

due to the resistive component of the capacitor. This component is

ESR

nents. As the frequency increases (> 20kHz), which is required to reduce both the cost and the sizes of L

and C, the VESR component becomes dominant. Often it is necessary to use capacitors with greater capacitance (or more capacitors connected in parallel to limit the value of ESR within the required level.

We will now examine the stepdown configuration in more detail, referring to fig. 1 and taking the be-haviour

shown in Fig. 4 into account.

Starting from the initial conditions, where Q = ON, v

= Vo and iL = iD = 0, using Kirckoff second principle

C

we may write the following expression:

V

= vL + vC (V

i

is neglected against Vi).

sat

d

IL

i

------- -

L

dt

v

+ L

C

V

(1)

d

IL

+⋅==

------- - V

dt

o

which gives :

d

------- -

dt

V

IL

–()

iVo

---------------------- -=

L

(2)

The current through the inductance is given by :

ViVo–()

I

---------------------- -=

L

(3)

L

When Vi, Vo, and L are constant, IL varies linearly with t. Therefore, it follows that :

V

+

∆

I

L

–()T

iVo

---------------------------------- -=

L

ON

(4)

When Q is OFF the current through the coil has reached its maximum value, Ipeak and because it cannot

very instantaneously, the voltage across the ased to allow the recirculation of the current through the load.

When Q switches OFF, the following situation is present:

vC(t) = Vo, iL (t) = iD (t) = I

peak

And the equation associated to the following loop may be written :

d

IL

------- -

where : vC = V

V

L

++ 0=

F

o

dI

L

------- -

dt

dt

V

------------------------ -–=

v

FVo

C

(5)

+()

(6)

L

It follows therefore that :

+

V

FVo

t()

------------------- -

T

t–=

(7)

5/52

i

L

Page 6

AN557 APPLICATION NO TE

The negative sign may be interpretated with the fact that the current is now decreasing. Assuming that VF

may be neglected against V

therefore :

But, because ∆I

L

+

= ∆I

, during the OFF time the following behaviour occurs :

o

V

o

------

t=

V

------

L

ON

(8)

L

o

T

(9)

OFF

V

oTOFF

---------------------=

L

–

if follows that :

L

I

L

+

I

∆

=

L

–()T

V

iVo

---------------------------------- -

L

which allows us to calculate V

:

o

T

ON

V

------------------------- -

==

V

o

i

TONT

OFF

V

where T is the switching period.

Expression (10) links the output voltage V

to the input voltage Vi and to the duty cycle. The relat ion -sh i p

o

between the currents is the following :

T

ON

---------- -

I

iDCIoDC

⋅=

T

EFFICIENCY

The system efficiency is expressed by the following formula :

P

o

------

100⋅=

P

i

where Po = VoIo (with Io = I

system. P

is g ive n by Po, plus all t he other syst em losses. Th e expression of the effic iency becomes th ere-

i

η %

) is the output power to the load and Pi is the input power absorbed by the

LOAD

fore the following :

P

---------------------------------------------------------------------------------=

η

PoP

+ ++++

satPDPLPqpsw

o

T

ON

-----------

i

T

(11)

(10)

(12)

DC LOSSES

Psat :saturation losses of the power transistor Q. These losses increase as Vi decreases.

T

ON

P

ON

T

V

o

------=

V

i

is the power transistor saturation at current Io.

sat

T

where and V

P

---------- -

: losses due to the recirculatio n diode . These loss es incr ease as Vi increases, as in this case the ON

D

sat

V

satIo

---------- -

T

+⋅=

V

satIo

V

------

V

o

i

(13)

time of the diode is greater.

6/52

ViVo–

VFI

----------------- -

o

V

i

P

==

D

V

1

FIo

V

o

(14)

------–

V

i

Page 7

where VF is the forward voltage of the recirculation diode at current Io.

P

: losses due to the series resistance RS of the coil

L

AN557 APPLICATION NOTE

PL = RS I

o

2

(15)

Pq: losses due to the stand-by current and to the power driving current:

Pq = Vi Iq, (16)

in which Iq is the operat ing supply current at the operating swi tchin g frequency. Iq includes the oscillator

current.

SWITCHING LOSSES

P

: switching losses of the power transistor :

sw

trtf+

------------ -

=

P

sw

ViI

o

2T

The switching losses of the recirculation diode are neglected (which are anyway negligible) as it is assumed that diode is used with recovery time much smaller than the rise time of the power transistor.

We can neglect losses in the coil (it is assum ed that ∆ IL is very small comp ared to I

) and in the output

o

capacitor, which is assumed to show a low ESR.

Calculation of the inductance value, L

Calculation T

ON

and T

through (4) and (9) respectively it follows that :

OFF

T

ON

+

I

∆ L⋅

L

----------------- -= T

V

–

iVo

OFF

∆ L⋅

--------------- -=

-

I

L

V

o

But because :

+

T

ON

+ T

= T and ∆I

OFF

L

–

= ∆I

= ∆IL, it follows tha t :

L

T

ON

IL∆ L⋅

----------------- –

V

iVo

I

∆ L⋅

L

--------------- -+ T==

V

o

(17)

Calculating L, the previous relation becomes :

V

–()V

V

i

o

------------------------------

L

V

o

I

∆

i

L

T=

(18)

Fixing the current ripple in the coil required by the design (for instance 30% of Io), and introducing the frequency instead of the period, it follows that :

V

–()V

L

iVo

-------------------------------- -=

V

0.3 Iof⋅⋅⋅

i

o

where L is in Henry and f in Hz Vi × 0.3 × Io × f

Calculation of the output capacitor C

From the output node in fig. 3 it may be seen that the current through the output capacitor is given by:

ic (t) = iL (t) – I

o

7/52

Page 8

AN557 APPLICATION NO TE

Figure 5. Equivalent Circuit Showing Recirculation when Q1 is Turned Off.

From the behaviour shown in Fig. 4 it may be calculated that the charge curren t of the output capacitor,

within a period, is ∆I

but, remembering expression (4) :

therefore equation (19) becomes :

Finally, calculating C it follows that :

where :

L is in Henrys

C is in Farads

f is in Hz

Finally, the following expression should be true :

It may happen that to satisfy relation (21) a capacitance value much great er than the value calculated

through (20) must be used.

/4, which is supplied for a time T/2. It follows therefore that :

L

∆

------- -

VC∆

4C

V

+

∆

I

L

–()T

i

---------------------------------- -= T

∆

V

I

L

V

L

C

T

---

2

o

ON

V

----------------------------- -=

I

T∆

L

----------- -

8C

and

–()V

iVo

IL∆

--------===

8fc

ON

o

(19)

V

------

V

o

T=

i

8 Vif2LC

V

–()V

C

ESR

------------------------------------- -=

8 Vi VC f∆

max

iVo

∆

---------------------=

V

Cmax

∆

o

2

L

I

L

(20)

(21)

TRANSIENT RESPONSE

Sudden variations of the load current give rise to overvoltages an d und ervo ltages on th e output v oltage.

Since i

= C (dvc/dt) (22), where dvc = ∆Vo, the instantaneous variation of the load current ∆Io is supplied

c

during the transient by the output capacitor. During the transient, also current through the coil tends to

change its value. Moreover, the following is true :

di

L

------- -

=

v

L

(23)

L

dt

where diL = ∆Io

v

= Vi – Vo for a load increase

L

= Vo for a load decrease

v

L

8/52

Page 9

Calculating dt from (22) and (23) and equalizing, it follows that :

di

------- -

L

dt

dv

L

=

C

----------

C

i

C

AN557 APPLICATION NOTE

Calculating dv

and equalizing it to ∆Vo, it follows that :

C

V

∆

o

V

∆

o

LI

---------------------------=

CV

LI

-------------=

C V

∆

iVo

∆

2

o

–()

2

o

o

(24) for + ∆Io

(25) for -

∆

Io

From these two expressions the dependence of overshoots and undershoots on the L and C values may

be observed. To minimize ∆V

it is therefore necessary to reduce the inductance value L and to increase

o

the capacitance value C. Should other auxiliary functions be required in the circuit like reset or crowbar

protections and very variable loads may be p resent, it is worthwhile to t ake special care for minimi zing

these overshoots, which could cause spurious operation of the crowbar, and the under-shoot, which could

trigger the reset function.

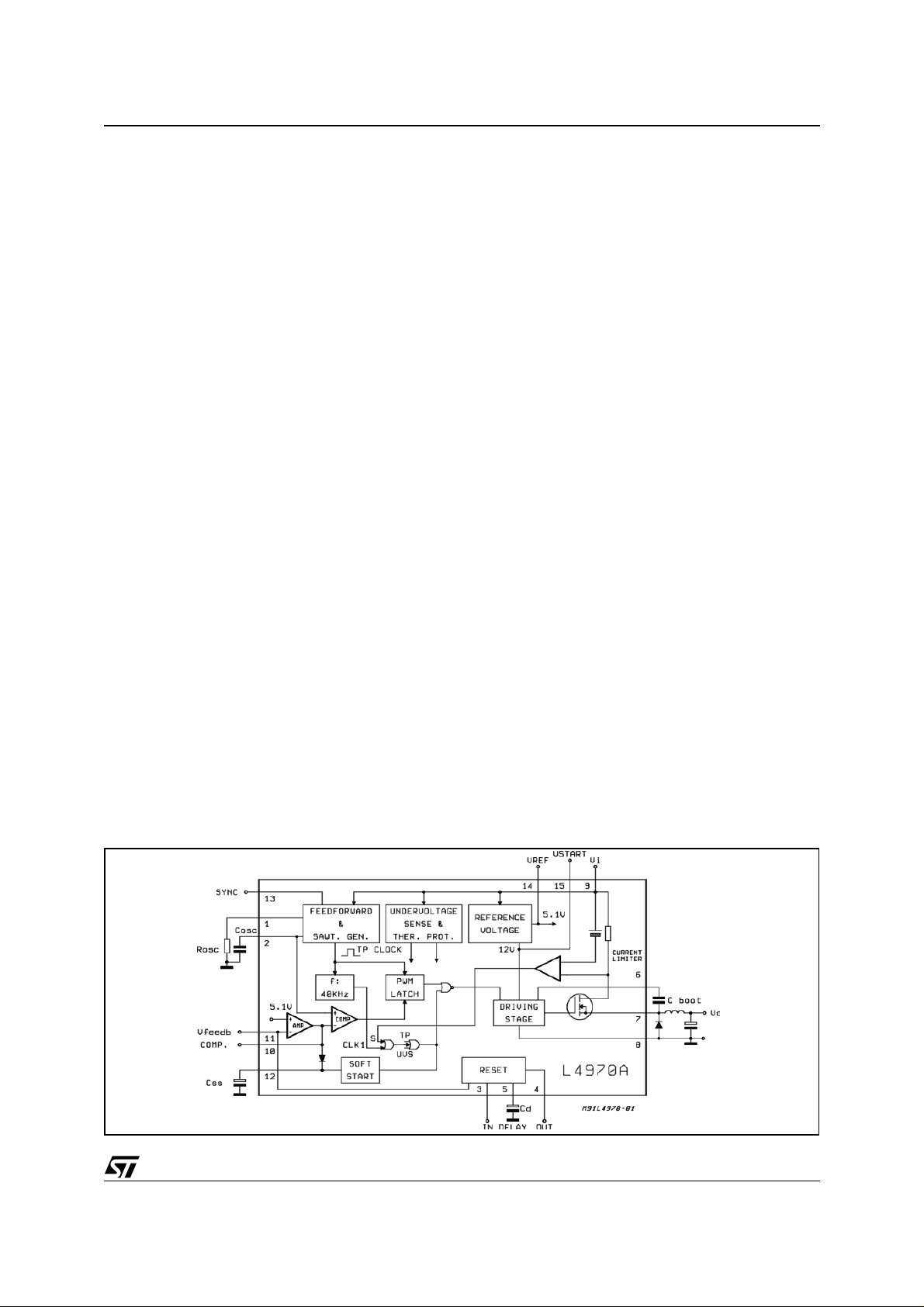

DEVICE DESCRIPTION

For a better understanding of how the dev ice f unc tions , a description will be given of the prin ciple blocks

that compose the device. The block diagram of the device is shown in fig.6

POWE R SU PPLY

The device contains a stabil ized regulator (Vstart = 12V ) that provides powe r to the a nalogic and digit al

control blocks as well as the section of the bootstrap. The Vstart voltage also powers the bl ocks that operates the internal reference voltage of 5.1V, with a precision of ±2%, necessary for the feedback.

OSCILLATOR, SYNC. AND VOLTAGE FEED-FORWARD FUNCTIONS

The oscillator block generates a sawtooh wave signal that sets the switching frequency of the system. This

signal, compared with the output voltage of the error amplifier, generates the PWM signal that will then

sent to the power output stag e. The oscillator also c ontains the voltage feedforward f unction that, be ing

completely integrated, does not require additional external components to function. The VFF function operates with supply voltages from 15V to 45V. The ∆V/∆t of the sawtooh is directly proportional to the supply

voltage Vi.

As Vi increases, the conduction time (ton) of the power transistor decreases in such way as to provide to

the coil, and therefore to the load, the product Volt x Sec constant.

Figure 6. Block Diagram of the 10A Monolithic Regulator L4970A.

9/52

Page 10

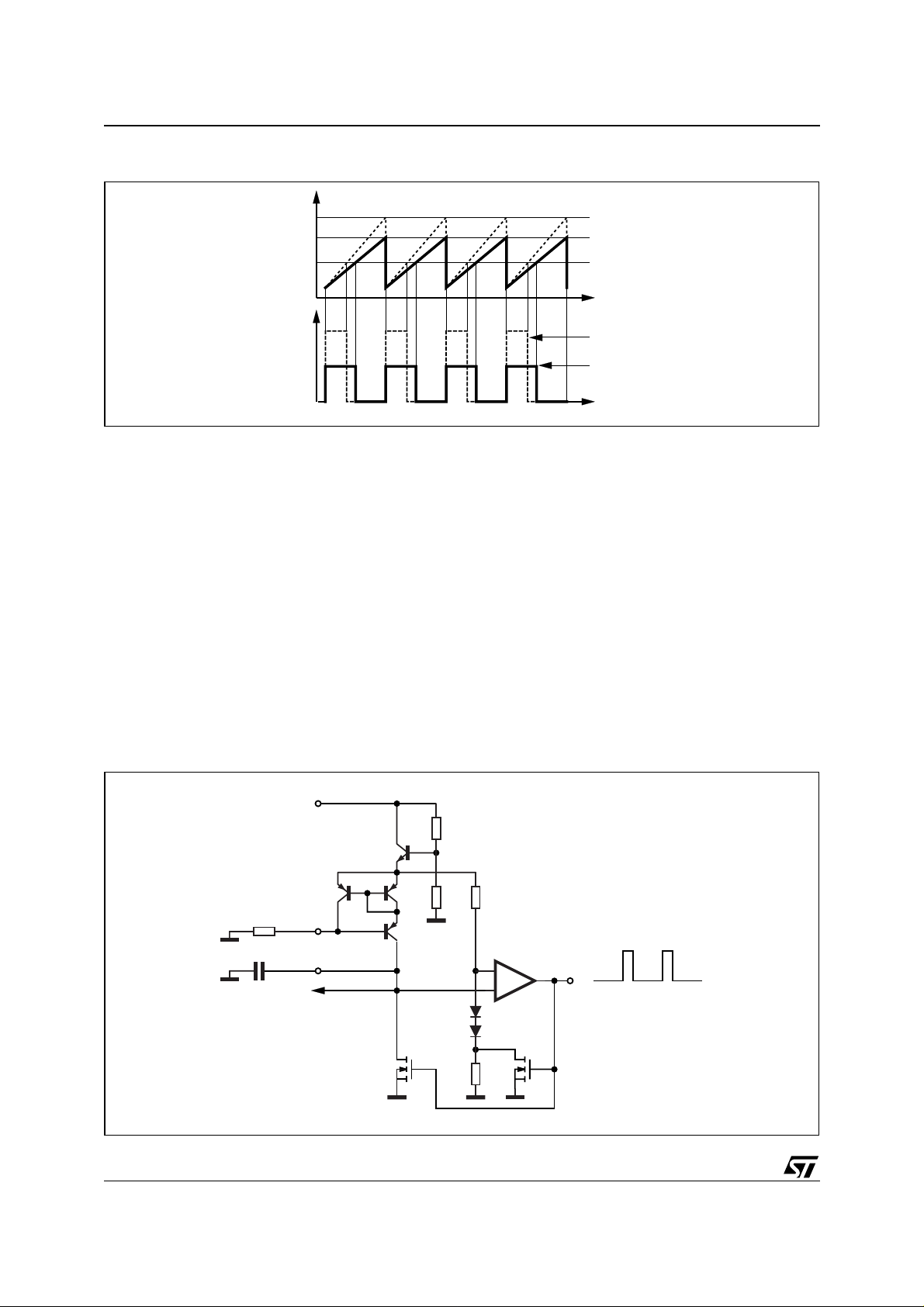

AN557 APPLICATION NO TE

Figure 7. Volta ge Feeforward Wa veform.

V2

V7

D93IN006

Vi=30V

Vi=15V

Vc

t

Vi=30V

Vi=15V

t

Fig. 7 shows the duty-cycle varies as a result of the changes in slope of the ramp with the input voltage

Vi. The output of the error amplifier shou ld not chang e to maintain the out put voltage i n regulation. This

function allows for the increas e of s peed in response to the rapid ch ange o f the supply voltage and for a

greatly reduced ouput ripple at the mains frequency.

In fact, the slope of the ramp is modulated by the ripple, generally present in the order of several volts on

the input of the regulator, particularly when the solution with a mains transformer is used.

Fig. 8 shows the simplified electrical diagram of the oscillator.

A resistor, connected between the Rosc pin and GND, sets the current that is internally reflected in the pin

Cosc, in order to charge the external capacitor to which it is connected. The voltage to the Rosc pin is not

fixed, but is tied to the instantaneous value of Vi; this is needed t o achieve th e feedforward voltage function, in which the slope of the ramp is directly proportional t o the supply voltage. A comparator senses the

voltage at the Cosc capacitor. Wh en the voltage reaches the val ue present at the inverting input o f the

comparator, the output from the comparator goes high and is sent to the two transistors Q1 and Q2. Q1

is responsible for discharging the external Cosc capacitor with a current of approx. 20mA, while Q2 imposes at the inverted input of the comparator a voltage of 2Vbe (approx. 1.3V) that is the low-threshold of

the ramp. Some useful formulas for calculating the various parameters of the oscillator block are:

Figure 8. Osc illator Circuit.

Rosc

Cosc

PWM

COMP.

10/52

Vi

2R

13 2RR

Q1

-

+

Q2

R

CLOCK

D93IN007

Page 11

AN557 APPLICATION NOTE

1) Oscillator charge current:

Vi9V

–

I

CHARGE

-------------------------=

2) Oscillator discharge current:

3) Peak voltage ramp:

V

th H–

This formula is obtained in the following way: indicating with Ve the voltage of the emitter of the NPN transistor connected to Vcc, and V- the voltage at the inverted input of the comparator, one has:

V

V

V

------------------------- -

by substituting (a) into (b), one obtains:

V

i

---- - V

–

3

------------------------------- --------------- 2V

V

be

–

3

be

R

osc

I

= 20mA

DISCH

Vi9V

–

------------------------ - 2V

Rosc

V

i

–=

---- - V

e

3

2V

–

e

be

3R

2V

be

+=–

(For 15V < Vi < 45V)

be

+=

be

(a)

be

R⋅

+=–

be

2V

(b)

be

V

9V

–

i

be

------------------------- 2V

+=

9

be

4) Valley voltage ramp:

V

= 2V

th-L

be

5) Switching frequency:

SW

------------------------- -=

R

oscCosc

f

9

It should be noted that formula (5) does not take into account the discharge time of Cosc which cannot be

neglected when one is working at frequencies equ al or highe r than 20 0KHz. The d ischarge tim e is also

tied to the value of Cosc itsel f.

Analitycally one has:

6)

T

DISCH

V

th H–

-------------------------------------- -

–

20 mA

V

th L–

C

⋅=

osc

from which is obta ined the mor e clo se ly ap p ro x im a te ex pr e ss io n o f the o s c illat o r fr equency:

7)

f

SW

---------------------------------------- -----------------=

R

oscCosc

----------------------------- - T

1

⋅

+

9

DISCH

During the discharge time of Cosc, a clock pulse is generated internally that is made sub sequent ly available on the Sync. pin and that can be used to synchronize other regulators. (3 devices of the same family

maximum). The Sync. pulse generated has a typical range of 4.5V and the current availabi lity is 4.5mA.

In general, it is better that the Sync pulse is at least 300-400ns in order to be able to synchronize a range

of existing regulators; to obtain this result, values of suggested capacitors, in different test circuits, have

11/52

Page 12

AN557 APPLICATION NO TE

been selected. The typical duration of th e synchronizing pu lse with the suggest ed values of C

osc

are as

follo ws :

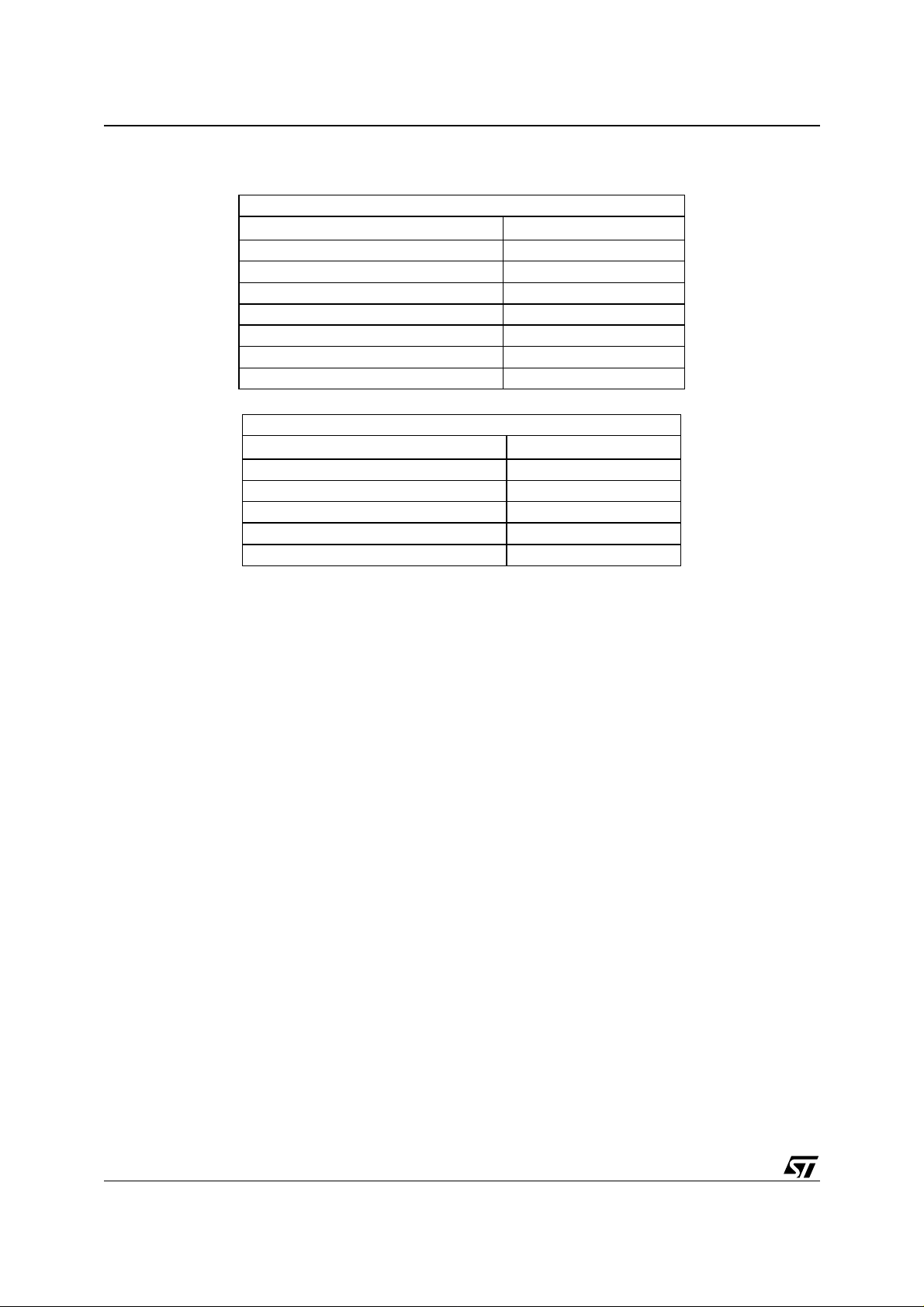

L497X Family (MULTIWATT PACKAGE)

C

(nf) - R

osc

L497X Family (POWERDIP PACKAGE)

C

(nf) - R

osc

= 16KΩ

osc

0.68 140

1230

1.2 270

1.5 330

2.2 450

3.3 680

4.7 1100

= 30KΩ

osc

1.2 230

1.5 280

2.2 420

3.3 600

4.7 900

Sync (ns)

Sync (ns)

Obviously, synchronize pulses of eccessive duration can greatly reduce the max duty-cycle and produce

distortions in the sawtooth of the synchronized regulator working as slave.

P.W.M.

Comparing the sawtooth signal generated by the oscillator and the output of the error amplifier, generates

the PWM signal which is sent to the driver of the output power stage. The PWM signal, in the path towards

the output stage, also encounters a latch block to prevent other pulses from being sent at same period to

the output, possibly damaging the power stage. In the PWM bl ock, a dut y-cycle limiter has al so been introduced. Such a limiter is obtained by taking advantage of the synchronizing pulse generated, the power

output stage is inhibited. Even if the error amplifier gives a large signal to the peak of the ramp, the power

stage will not b e able to op er ate in DC , but w ill be s wit ched of f at ea ch clock puls e. The max . obt ainable

duty-cycle is higher than 90%; this, however depends on the working frequency and the value of Cosc.

Using the formulas 6) and 7) a precise calculation can be done.

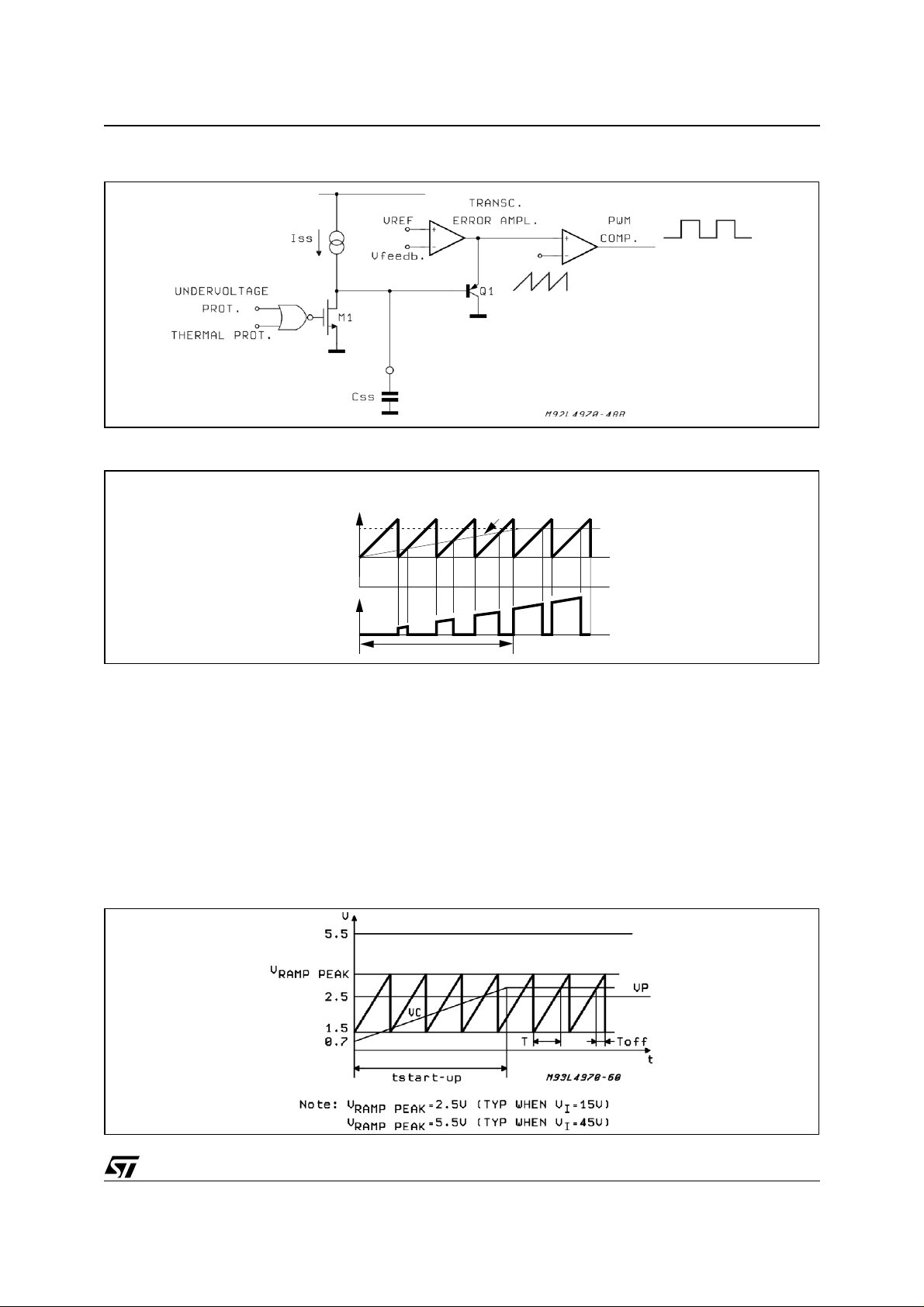

SOFT START

The Soft Start function is essential for a correct startup of the device and for an output voltage that, at the

switch on, increases in a monotonous mode without dangerous output overvoltages and without overstress for the power stage.

Soft Start operates at the startup of the system and after an intervention of the th ermal prot ection. Fig. 9

shows the simplified diagram of the startup functions. The function is carried out by means of an external

capacitor connected to the Soft Start pin, which is charged with a constant current of about 100µA to a

value of around 7V. During the charging time, the output of the error transcon-ductance amplifier, because

of Q1, is forced to increase at the same rising edge time of the external softstart capacitor Css.

12/52

Page 13

Figure 9. Soft Start Circuit.

Figure 10. Soft Start Waveforms.

Vc

AN557 APPLICATION NOTE

CLAMPED

ERROR AMPLIFIER

OUTPUT

t

OUTPUT

CURRENT

SOFT START TIME

D93IN011

t

The PWM signal begins to be generated as soon as the output voltage of the error amplifier crosses the

ramp; at this point the output stage begins to commutate, slowly increasing its ON time (see fig. 10).

The charge of the Css capacitor, as already mentioned, begins each time the device is supplied with power and after which an anomalou s condition is creat ed, as the intervent ion of thermal prot ection or of the

undervoltage lockout.

CALCULATING THE DUTY-CYCLE AND SOFT-START TIME

Let us suppose that the discharge tim e o f the osc illator capac itor, Cos c, is neglected. This is an approx.

valid for switching frequencies up to 200KHz. Let us indicate with Vr the output voltage of the error amplifier, and with Vc the voltage of the oscillator ramp.

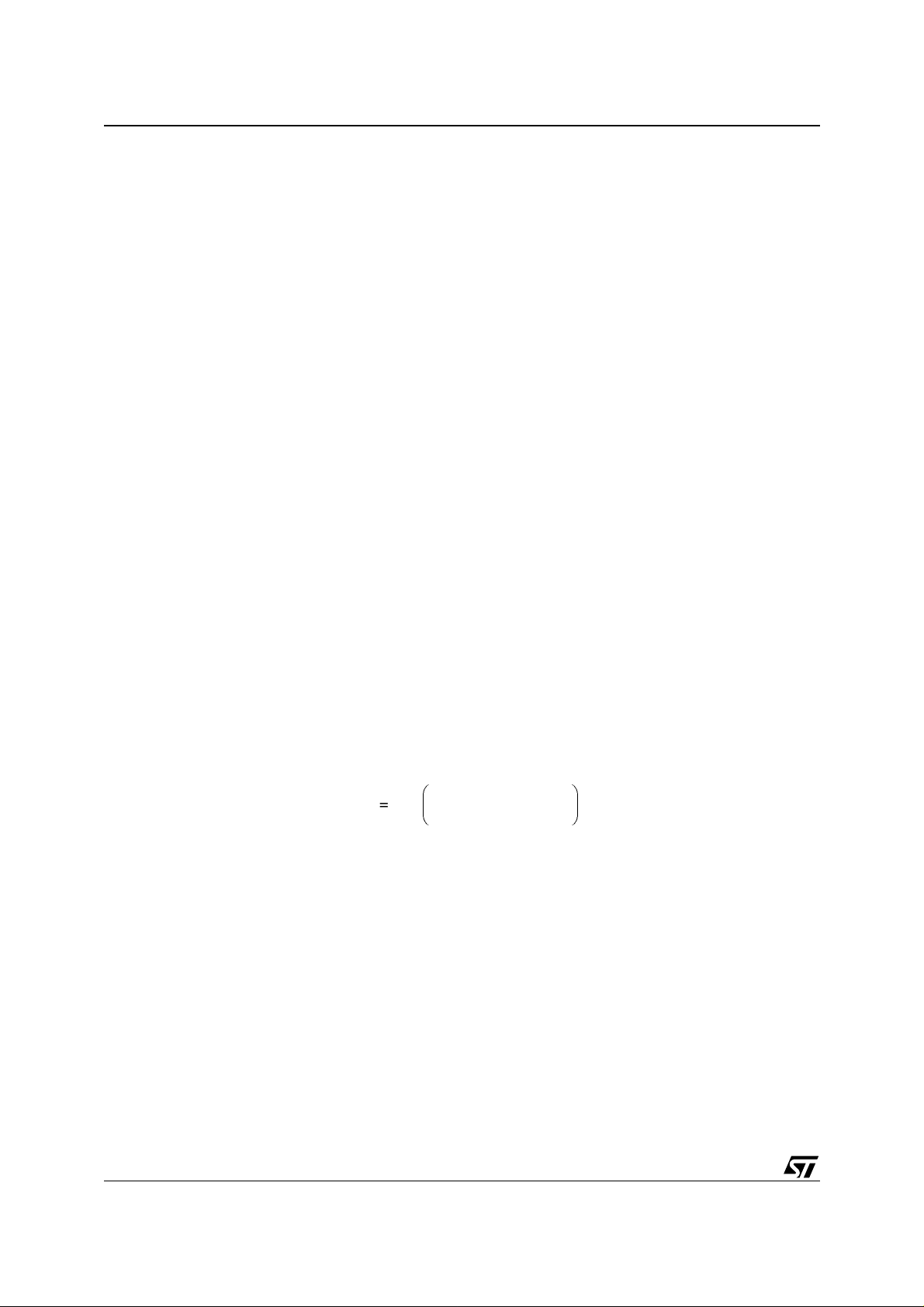

Figure 11. Soft Sart Time Waveform.

13/52

Page 14

AN557 APPLICATION NO TE

The PWM comparator block commutates when Vr = Vc. Therefore:

i

9

t⋅

9V

–()⋅⋅

V

9V

–

i

------------------------ -

be

be

9T⋅

t⋅== =

8)

from which is obtained

9)

V

r

V

t

V

pp

--------- -

c

T

Vr T V

------------------------------------------------ -=

The time t obtained from this equation is equal to the ON time of the power transistor. The corresponding

duty-cycle is given by:

10)

Vr T V

t

on

-------

D

------------------------------------------------ -

T

9T

9V

–()⋅⋅

i

be

VrVi9V

--------------------------------------- -

–()⋅

be

9

V

o

------== = =

V

i

Consequently, after leaving the discharged capacitor of Soft Start, the output of the regulator will reach its

value when the voltage across the Css capacitor, charged w ith constant current, has reached the value

Vr - 0.5V.

The time necessary in order that the output rises from zero to the nominal value is given by:

Vr0.5V–()

11)

in which C

is the Soft Start capacitor and Iss the Soft Start current. Considering Soft Start time as tss,

ss

t

start up–

C

ss

---------------------------- -

⋅=

I

ss

the required time for the Soft Start capacitor to change itself approx from (2Vbe - 0.5V) = (1.2V - 0.5V) to

Vr - 0.5V, is:

Vr1.2V–()

12)

t

ss

C

ss

---------------------------- -

⋅=

I

ss

By taking Vr from (10):

13)

V

o

------

V

r

V

i

9

------------------------ -

⋅=

9V

–

V

i

be

and substituting it in (12), we obtain:

14)

o

---------

t

=

ss

------

I

V

ss

i

9

------------------------ - 1.2V–⋅

9V

–

V

i

be

V

C

ss

UNDERVOLTAGE LOCKOUT

The device contains the protection block of under-voltage lockout which keeps the power stage turned-off

as long as the supply voltage does not reach at least 12V. At this point the device starts up with Soft Start.

The function of undervoltage is also provided with an hysteresis of 1V to make it better immune to the ripple present on the supply voltage.

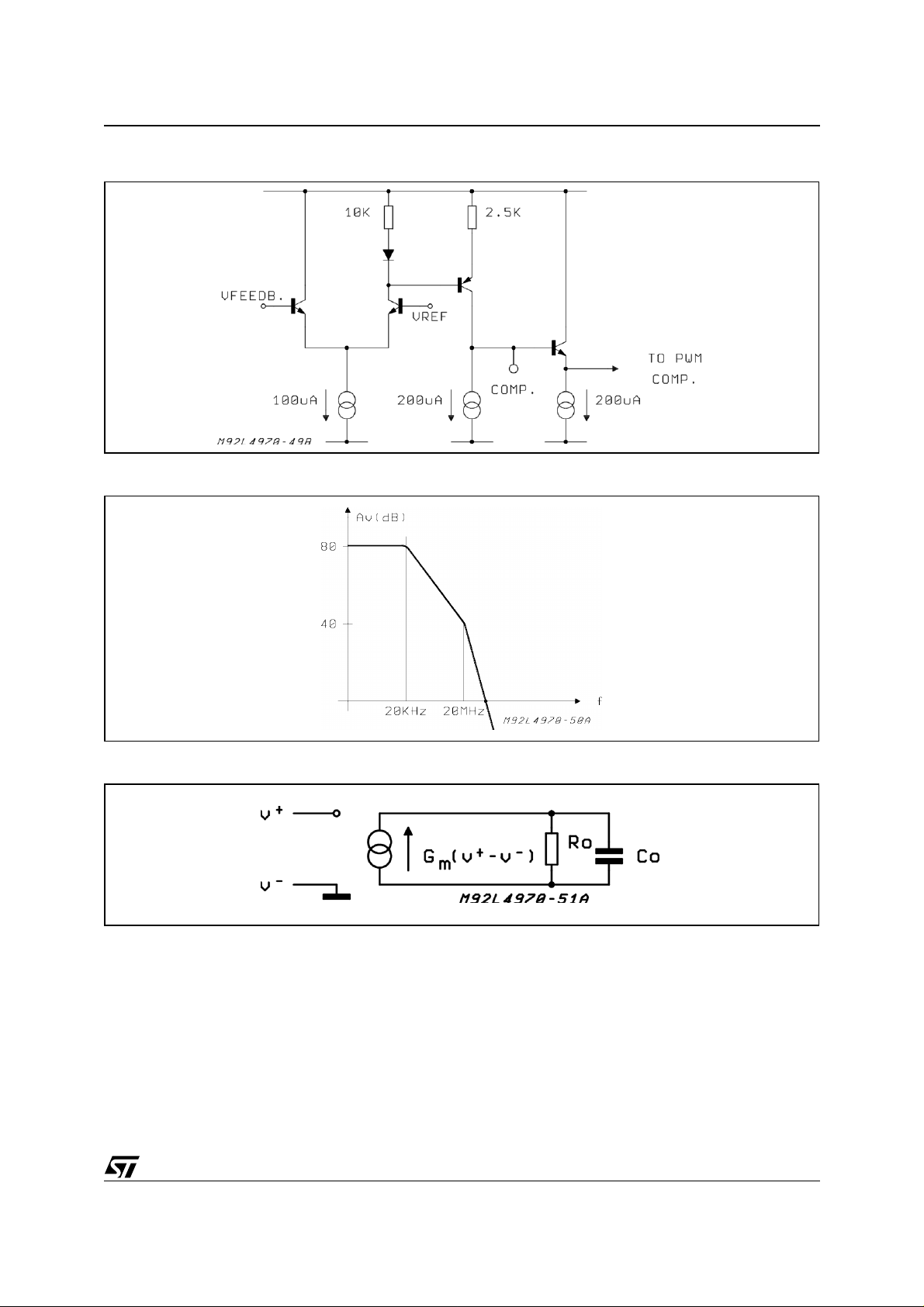

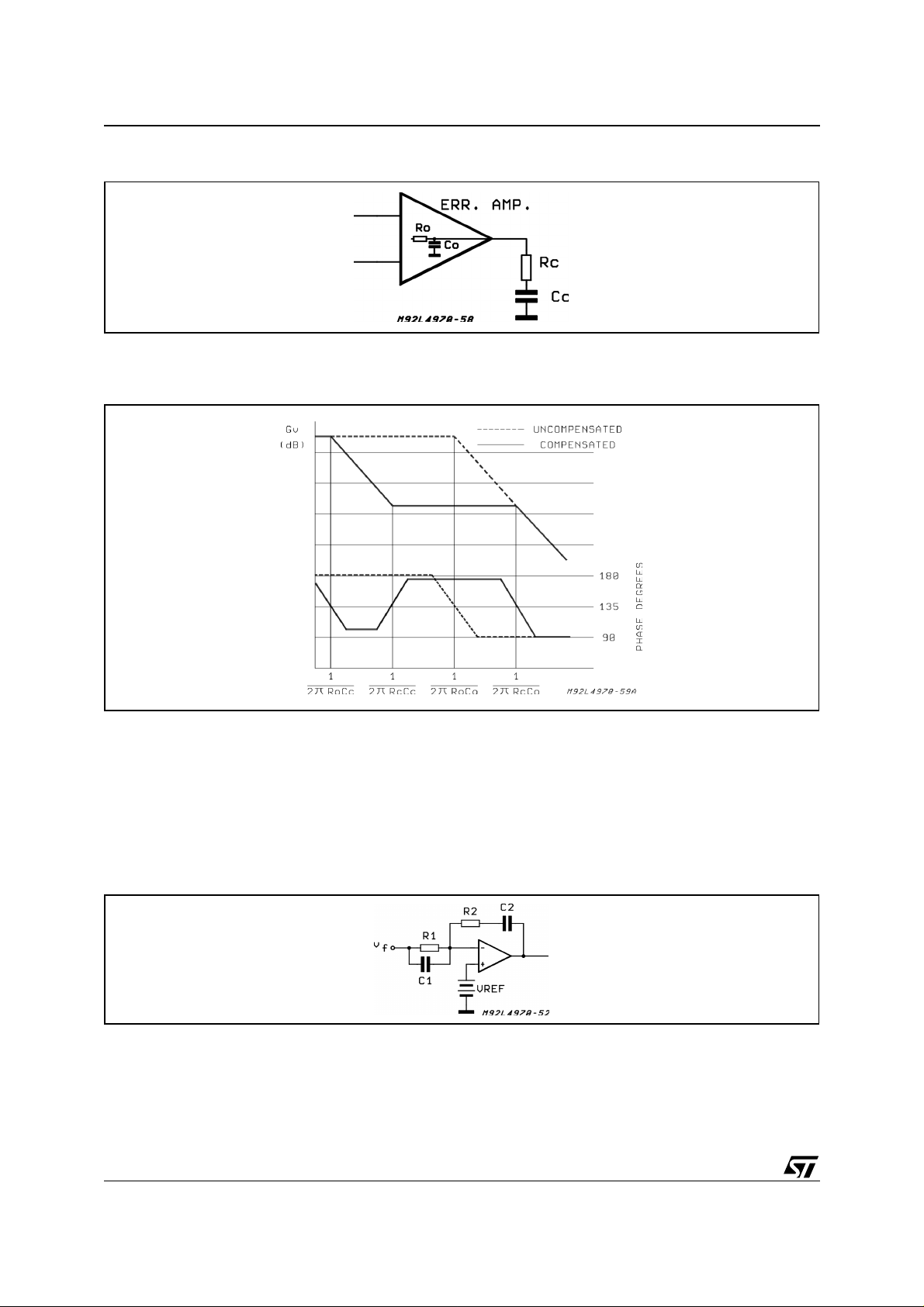

ERROR AMPLIFIER

The error amplifier is a transconductance type and deliver an output current proportional to the voltage inbalance of the two inputs . The s i mplified diagram is presented in f i g 12. Th e pri ncipal characteristics of t hi s

uncompensated operational ampl ifier are the following: Gm = 4mA/V, Ro = 2.5Mohm, Avo = 80dB, Isourcesink = 200

µ

A, Input Bias Current = 0.3µA. The frequency response of the op. amp. is given in fig. 13.

Ignoring the high frequency response and hypothesizing that the second pole is below the 0 dB axis in the

all the conditions of loop compensation, it is possible to make a first approximation with the equivalent circuit of fig. 14

14/52

Page 15

Figure 12. Error Amplifier Circuit.

Figure 13. Ope n l oop gai n ( error amplifier onl y )

AN557 APPLICATION NOTE

Figure 14. Error amplifier equivalent circuit.

In whic h :

15) where C

Av s() Gm

R

c

--------------------------- -

⋅=

1sRoC

+

o

= 3pF

o

The error amplifier can be easily compensated thanks to the high output impe dance (see fig. 14) The resulting transfer function is as in the following:

R

1sRcC

+()⋅

(16)

Av s() Gm

---------------------------------------------------------------------------------------------------------------------

⋅=

2

s

R

C

R

o

o

o

C

sRoCcRoCoRcC

c

c

c

++()1++

c

15/52

Page 16

AN557 APPLICATION NO TE

Figure 15. Compensation network of the error ampli fier

The Bode diagram is shown in fig.16.

Figure 16. Bode plot showing gain and phase of compens ated erro r ampl ifier

The compensation circuit introduces a pole at low frequency and a zero that is generally calculated to be

put in the proximity of the resonance frequency of the output LC filter.

The second pole at high frequency generally falls in a zone of no interest (for the system stability, one must

consider the zero introduced by ESR characteristic of the output capacitor. Not all the designers agree on

this solution).

If necessary, however, one c an turn t o m ore sophisticated compensation circuitry. An ex am ple is s hown

in fig. 17.

Figure 17. One pol e, tw o ze ro com p e nsation netw ork

Such a circuit introduces a pole at low-frequency and two zeros.

17

16/52

Z1

1

-----------------------------

2Π R1 C1

Z2

1

-----------------------------==

2Π R2 C2

Page 17

AN557 APPLICATION NOTE

It must be remembered, however, that because of the high out put impedance of t he error amplifier, a second pole is also present:

18)

P2

Gm

----------------- -=

2Π C1

We normally suggest a high value for R1 to reduce the value of the capacitor C1 and allocate the pole P2

at the highest possible frequency. The ess ential limitation t o the max v alue of R1 is the offset introduc ed

by the input bias current of the error amplifier. In the case of output voltage regulated higher than 5.1V, an

external divider should be introduced. It’s than possible to introduce a second zero using the following network:

Figure 18. Compensation network for output voltages higher than 5.1V

Two zeros and two poles are introduced:

19)

Z1

1

---------------------------

2Π R

o Cc

Z2

1

-----------------------------==

2Π R1 C1

Where

Rx

R1 R2⋅

--------------------- -=

R1 R2+

P1

1

---------------------------

2Π R

o Cc

P2

1

---------------------------- -==

2Π Rx C1

APPLICATION EXAMPLE

Consider the block diagram of fig. 19, represent ing the internal cont rol loop section, with the appl ication

values:

Fswitch = 200KHz, L = 100µH, C = 1000µF, Po = 50W, Vo = 5.1V, Io = 10A and Fo = 500Hz. G

loop

= PWM

× Filter

Figure 19. Block diagram used in stability calculation

17/52

Page 18

AN557 APPLICATION NO TE

Figure 20. Frequency behaviour of the circuit of fig. 19

The system requires that DC gain is maximum to achieve good accuracy and line rejection. Beyond this

a bandwidth of some KHz is usually required for a good load transient response. The error amplifier transfer function must guarantee the above constrainst. A compensation network that could be used is shown

in fig. 21.

As()

1sR1 C1+()1sR2C2+()

----------------------------------------------------------------------=

sR1 C1 (1+s

C1

--------- -

Gm

Figure 21. Compensation network.

Figure 22. Bod e pl ot of th e regulation loo p wi th t he com pensatio n net work of fig. 21.

dB

Gloop

ACSJ

40

PWM+FILTER

20

18/52

50Hz 500Hz 5Kz 50KHz

D93IN012

Page 19

AN557 APPLICATION NOTE

The criterium is to define Z1, Z2 close to the resonant pole of the output LC filter. The Gm/2ΠC1 pole must

be placed at a frequency at which open loop gain is below 0dB axis (fig. 22).

CURRENT LIMITING

A complete regulation system will be equipped with a good current limiter able to protect from load breaking and operator error controlls. The current limiting function is totally integrated and does not require any

external component. The output current is sensed by an internal low-value resistor, in series with the drain

of the DMOS vertical power transistor..

A precision current limitation of ± 10% relative at the peak current is guaranted. During overcurrent situation the pulse by pulse current limitation produce an output stage switching frequency reduction. The block

diagram of the current limiting is shown in fig. 23.

Figure 23. Current protection circuit.

In overcurrent situation the comparator send a signal at the flip-flop set input, an inhibit pulse is immediatly

generated from it and sended at the output stage switching off the power mos.

A reset pulse input in generated from an 40KHz internal oscillator.

After the first reset pulse the control loop will start to regulate the system an the output current will increase

following the principal oscillator frequency. If overcurrent condition is still present the current limiting will

be activate again.

This type of current limiting ensure a constant output current in overload or short circuit condition and allow

a good reliability at high frequency (500KHz) reduc ing the problems relative at the interna l signal delay

through the protection blocks. The inductor current in overload condition in shown in fig. 24.

Figure 24. Overload inductance current.

19/52

Page 20

AN557 APPLICATION NO TE

The 40K Hz i nte rnal o scil lato r is syn chro nized wit h t he p rincip al o ne . If t he syst em w ork with a osc illator

tracks the principal oscillator frequenc y. In t his w ay the s witching frequenc y w i ll not increase in overload

situation.

A particular care has to be taken in the inductor value in order to avoid problems during overload or short

circuit conditions. A critical situation is present with high switching frequency, (more than 200KHz) where

a small inductor value is used and with high capacitive load.

In order to return in nominal condition after a short circuit the inductor ripple at 40KHz with the nominal

output voltage and current has to be lower than the current limitation value.

Example

Let us consider L4970A, 10A. (the same approach can be used for all the family).

The inductor ripple current is given by the following formula:

V

–()V

⋅

I

∆

L

iVo

--------------------------------- -=

fsw L⋅⋅

V

i

where fsw = 40KHz ±10%

In order to get the maximum inductor ripple current, the previous formula becomes:

V

–()V

imaxVomax

---------------------------------------------------------------- -=

I

∆

L

V

imaxfswmin

The current limitation for L4970A will start to work at 13A. therefore:

I

lim minIonom

o

⋅

L⋅⋅

IL∆

--------+>

2

omax

where I

= 10A for L4970A.

onom

POWER FAIL-RESET CIRCUIT

The L4970A include a voltage sensing c ircuit that may be used to g enerate a power on power off re set

signal for a microprocessor system. The circuit senses the input supply voltage and the output generated

voltage and will generate the required reset signal only when both the sensed voltages have reached the

required value for correct system operation. The Reset signal is generated after a delay time programmable by an external capacitor on the delay pin. Fig 25 shows the circuit implementation of Reset circuit. The

supply v oltag e is s ens ed on a n ex ter nal pin, for pr ogra mmab ilit y of the th resh old, by a f irst com par ato r.

The second comparator ha s the ref erence t hreshold set at s lightly les s the ref . voltag e for t he regulation

circuit and the other input connected internally at the feedback point on the regulated voltage. When both

the supply voltage and the regulated voltage are in the c orrect range, t ransistor Q1 turns off and a llows

the current generator to charge th e delay capacitor discharges c ompletely before initialization of a new

Reset cycle. The output gate assures immediate take of reset signal without waiting for complete discharge of delay capacitor. Reset output is an open collector transistor capable of sinking 20mA at 200mV

voltage. Fig 26 shows reset waveforms.

20/52

Page 21

Figure 25. Power fail and reset circuit.

Figure 26. Reset and power fail and reset circuit.

Vi

RISING P.FAIL

THRESHOLD

TURN-ON

THRESHOLD

11V

FALLING P.FAIL

THRESHOLD

10V

AN557 APPLICATION NOTE

TURN-OFF THRESHOLD

t

Vo=5.1V

RISING RESET

THRESHOLD

OUTPUT RESET

DELAY RESET POWER FAIL TIME

Figure 27. Power stage circuit.

5V

4.9V

FALLING

RESET

THRESHOLD

tDR tDR

HISTERESIS

t

5.1V

100mV

t

t

D93IN013

21/52

Page 22

AN557 APPLICATION NO TE

POWE R STAGE

The simplified diagram of the output stage is shown in the fig. 27.

The power stage and the circuit connected with it are by far the m ost important and critical com ponents

when one wants to obtain good performance at high switching frequency.

The power transistor must have excellent characteristics from the point of view of both the switching speed

and the robustness.

The transistor DMOS, with its intrinsic characteristics of elevated speed, no second breakdown phenomenom and

easy dr iving proves to be particularly suitab le for this type of applic ation that no rmally works at high frequ ency.

For a properly driving of the DMOS gate it is necessary to use an external bootstrap capacitor. When the

voltage Vs is low the Cboot capacitor is charged through the internal diode D1, at the value of voltage

equal to that of Vstart, which is about 12V; the next step oversees that Q3 is turned off, Q2 is driven in

gate by Q1 so that Q1 can go in saturation, and its source can go up rise towards Vi.

Cboot maintains its charge and guarantees a voltage equal Vi+12V a t the gate of Q7, so t hat can enter

into region of low resistance.

At this point the diode D1 turns o n to be inversely polarized, disc onnecting the 12V sect ion from that of

the driving power stage.

When Q2 is ON the driven current of the power stage requires from the bootstrap capacitor a typical current of 400uA.

When Q2 is Off a curren t of 2.5mA is required to mantain Q2 in that state. This current however is not

delivered from the bootstrap capacitor, but rather from the internal regulator of 12V, while the output current flowing in the freewheeling diode. The circuit described is capable of obtaining commutation, rise and

fall time, a typical value of 50ns.

In principle, it would have been feasible to reduce furthermore the commutation time whithout any reliability problems.

This was not believed to be advantageous since it would not have been of any benefit if one thinks of the

trr time of the catch diode (with trise of 50ns also the Schottky diodes begin to show limitations) and of the

conseguent increase of different disturbances caused bt too higly elevated dI/dt. The following table

shows the main features of the DMOS transistor.

Figure 28. Gate-charge curve for the power

Table 1.

B

VDSS > 60V at ID = 1mA VGS = 0V

DS(ON) = 100mΩ at ID = 10A Tj = 25°CVGS = 10V

R

R

DS(ON) = 150mΩ at ID = 10A Tj = 150°CVGS = 10V

TH = 3V at ID = 1mA

V

22/52

Page 23

AN557 APPLICATION NOTE

THERMAL SHUTDOWN

The thermal protection intervenes when the junction temperature reaches 150°C; it intervenes directly on

the output stage turning it off quikly and in the meantime discharging the soft start capacitor.

The reference voltage and the oscillator will continue to work regularly.

The thermal shutdown has a hysteresis, after its intervention, it is ne cessary to wai t for t he junction tem-

perature to lower around 30°C before the device will begi n to work properly again.

The device restart to work by using the soft start function.

Table 2. High Current Switching Regulator ICs.

L497X FAMILY

Parameter

Max. Input Operating

Voltage

Output Voltage Range 5.1V (±2%) to 40V

Max. Output Current 10A 7A 5A 3.5A 2A 2A

Power Switch

at 25°C

R

DSON

Switching Mode Control

System

Max. Switching Freq. 500KHz 500KHz 500KHz 200KHz 200KHz 200KHz

Efficiency

V

= 35V

INPUT

V

= 5.1V

OUT

Current Limiting Constant Current

Soft Start Yes

Reset and Power Fail Yes

Synch Yes

Crowbar No

Package

Max. R

th j-case (pin)

R

th j-amb

L4970A L4977A L4975A L4974A L4972A

50V 50V 50V 50V 50V 50V

0.13Ω typ.

Continuous Mode, Direct Duty Cycle Control with Voltage Feed-Forward

10A

80%

at 200KHz

Multiwatt15

1°C/W

35°C/W

7A

80%

at 200KHz

Multiwatt15

1°C/W

35°C/W

5A

85%

at 200KHz

Multiwatt15

1°C/W

35°C/W

3.5A

85%

at 100KHz

Powerdip

16+2+2

12°C/W

60°C/W

2A

85%

at 100KHz

Powerdip

16+2+2

12°C/W

60°C/W

L4972AD

Surf. Mount.

2A

85%

at 100KHz

SO20L

6°C/W

80°C/W

APPLICATIONS

Even though the regulators of the L4970A family has been designed to work only in step down configuration we will see next how these regu lators can be u se in large range of applications. In sam e cases the

L4970A device will be u sed as an example for t he entire family assembled in Multiwatt pac kage and the

L4974A will be used for the types in powerdip package.

Anyway the suggested applications can be extended to any other device of the family by adjusting if necessary the external components using the given equation for the calculation.

Typical Application

The Fig. 29 shows the electrical diagram of the typical application, complete with all the auxiliary functions.

The same application suggested in the data sheet as test circuit and is the same used for the final dynamic

test. All our devices are 100% tested both in static and dynamic conditions.

Included in the dynamic t est a re obviousl y the ex terna l com ponents : the coil, c atch diode and ou tput c apacitor which have been defined for all regulators.

Shown below are the electrical diagram s of 5 dev ices th at compos e the f am ily of th is regulator c om plete

23/52

Page 24

AN557 APPLICATION NO TE

with the value of the external components and with the relative pcb layout.

Output voltages higher than 5.1V are possible using an output resistive divider. For Vo > 24V, for safety

reasons it must be avoided the zero load condit ion. In the app lication with high current, co nnecte d to the

output divider are added two other res istanc es that perm it th e separat ion of sens ing and f orcing, in suc h

way as to compensate the fall of voltage on the connecting cables between the output and the load.

Connecting directly the output to the feedback pin a 5.1V ±2% is obtained. The following table can be help

for a rapid calculation of a resistor divider to obtain some of the most standard output voltage.

Figure 29. L4970A Typical Application Circuit.

Figure 30. Test and Evaluation Board Circuit

TYPICAL PERFORMANCES (using evaluation board) :

n = 83% (V

V

o RIPPLE

Line regulation = 5mV (V

Load regulation = 15mV (I

= 35V ; Vo = V

i

; Io = 10A ; fSW = 200KHz)

REF

= 30mV (at 10A) with output filter capacitor ESR ≤ 60m Ω

= 15 to 50V)

i

= 2 to 10A)

o

For component values, refer to test circuit part list.

24/52

Page 25

AN557 APPLICATION NOTE

PARTS LIST

R1 = 30KΩ * C1, C2 = 3300µF 63VL EYF (ROE)

R2 = 10KΩ C3, C4, C5, C6 = 2.2µF

R3 = 15KΩ C7 = 390pF Film

R4 = 16KΩ C8 = 22nF MKT 1817 (ERO)

R5 = 22Ω 0,5W

R6 = 4K7 C9 = 2.2nF KP1830

R7 = 10Ω C10 = 220nF MKT

R8 = see tab. A C11 = 2.2nF MP1830

R9 = OPTION **C12, C13, C14 = 220µF 40VL EKR

R10 = 4K7 C15 = 1µF Film

R11 = 10Ω

D1 = MBR 1560CT (or 16A/60V or equivalent)

L1 = 40µH core 58071 MAGNETICS 27 TURNS Ø 1,3mm (AWG 16) COGEMA 949178

* 2 capacitors in parallel to increase input RMS current capability

** 3 capa c i tors in parall e l t o reduce total ou tput ESR

Table A

V0 R10 R8

12V 4.7KΩ 6.2KΩ

15V 4.7KΩ 9.1KΩ

18V 4.7KΩ 12KΩ

24V 4.7KΩ 18KΩ

Table B

SUGGESTED BOOTSTRAP CAPACITORS

Operating Frequency Bootstrap Cap.c10

f = 20KHz ≥680nF

f = 50KHz ≥470nF

f = 100KHz ≥330nF

f = 200KHz ≥220nF

f = 500KHz ≥100nF

25/52

Page 26

AN557 APPLICATION NO TE

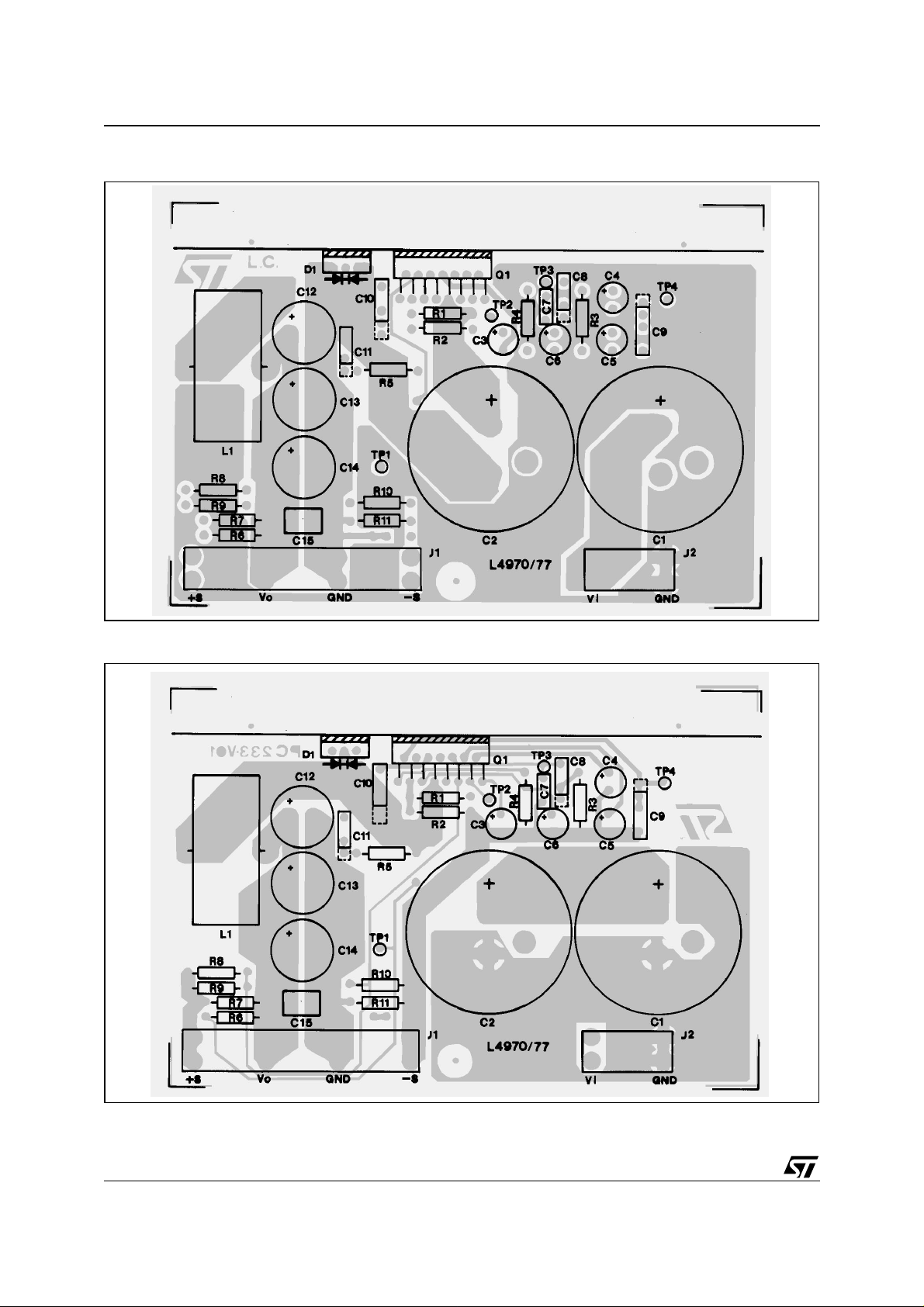

Figure 31. P.C. Board (co m po ne n t side) and Comp onents Lay out of t he C ir c ui t of Fig . 30.

Figure 32. P.C. Board (back side) and Components Layout of the Circuit of Fig. 30.

26/52

Page 27

AN557 APPLICATION NOTE

Figure 33. Test and Evaluation Board Circuit.

TYPICAL PERFORMANCES (using evaluation board) :

n = 83% (V

= 15 to 50V); Load regulation = 7mV (Io = 0.5 to 2A); for component values Refer to the fig. 32 (Part list).

(V

i

= 35V ; Vo = V

i

PARTS LIST

R1 = 30KΩ C3, C4, C5, C6 = 2.2µF 50V

R2 = 10KΩ C7 = 390pF Film

R3 = 15KΩ C8 = 22nF MKT 1837 (ERO)

R4 = 30KΩ C9 = 2.7nF KP1830 (ERO)

R5 = 22Ω C10 = 0.33µF Film

R6 = 4K7 C11 = 1nF

R7 = see tab. A **C12, C13, C14 = 100µF 40VL EKR (ROE)

R8 = OPTION C15 = 1µF Film

* C1, C2 = 1000µF 63V EYF (ROE) D1 = SB 560 (or equivalent)

L1 = 150µH core 58310 MAGNETICS 45 TURNS 0.91mm (AWG 16) COGEMA 949181

* 2 capacitors in parallel to increase input RMS current capability

** 3 capacit ors in parallel t o reduce tot al out put ESR

Table A

V0 R10 R8

12V 4.7KΩ 6.2KΩ

15V 4.7KΩ 9.1KΩ

18V 4.7KΩ 12KΩ

24V 4.7KΩ 18KΩ

Note: In th e T est and App l ication Circ ui t for L4972D are not mounted C2, C14 and R8.

; Io = 2A ; fsw = 100KHz); V

REF

o RIPPLE

= 30mV (at 1A); Line regulation = 12mV

Table B - SUGGESTED BOOTSTRAP CAPACITORS

Operating Frequency Bootstrap Cap.c10

f = 20KHz ≥680nF

f = 50KHz ≥470nF

f = 100KHz ≥330nF

f = 200KHz ≥220nF

f = 500KHz ≥100nF

27/52

Page 28

AN557 APPLICATION NO TE

Figure 34. Com p onent Lay ou t of f ig . 33. Eval uation Boar d

Figure 35. Board and Component Layout of the ciruit of fig. 33.

28/52

Page 29

AN557 APPLICATION NOTE

Figure 36. Test and Evaluation Board Circuit.

TYPICAL PERFORMANCES (using evaluation board) :

n = 83% (V

12mV (V

= 35V ; Vo = V

i

= 15 to 50V); Load regulation = 7mV (Io = 0.5 to 3.5A); for component values Refer to t he fig. 35

i

(Part list).

PART S L I ST

R1 = 30KΩ C3, C4, C5, C6 = 2.2µF 50V

R2 = 10KΩ C7 = 390pF Film

R3 = 15KΩ C8 = 22nF MKT 1837 (ERO)

R4 = 30KΩ C9 = 2.7nF KP1830 (ERO)

R5 = 22Ω C10 = 0.33µF Film

R6 = 4K7 C11 = 1nF

R7 = see tab. A **C12, C13, C14 = 100µF 40VL EKR (ROE)

R8 = OPTION C15 = 1µF Film

* C1, C2 = 1000µF 63V EYF (ROE) D1 = SB 560 (or equivalent)

L1 = 150µH core 58310 MAGNETICS 45 TURNS 0.91mm (AWG 16) COGEMA 949181

* 2 capacitors in parallel to increase input RMS current capability

** 3 capacit ors in parallel t o reduce tot al out put ESR

Table A

V0 R10 R8

12V 4.7KΩ 6.2KΩ

15V 4.7KΩ 9.1KΩ

18V 4.7KΩ 12KΩ

24V 4.7KΩ 18KΩ

Note: In th e T est and App l ication Circ ui t for L4974D are not mounted C2, C14 and R8.

; Io = 3.5A ; fsw = 100KHz); V

REF

o RIPPLE

= 30mV (at 1A ); Line regulation =

Table B - SUGGESTED BOOTSTRAP CAPACITORS

Operating Frequency Bootstrap Cap.c10

f = 20KHz ≥680nF

f = 50KHz ≥470nF

f = 100KHz ≥330nF

f = 200KHz ≥220nF

f = 500KHz ≥100nF

29/52

Page 30

AN557 APPLICATION NO TE

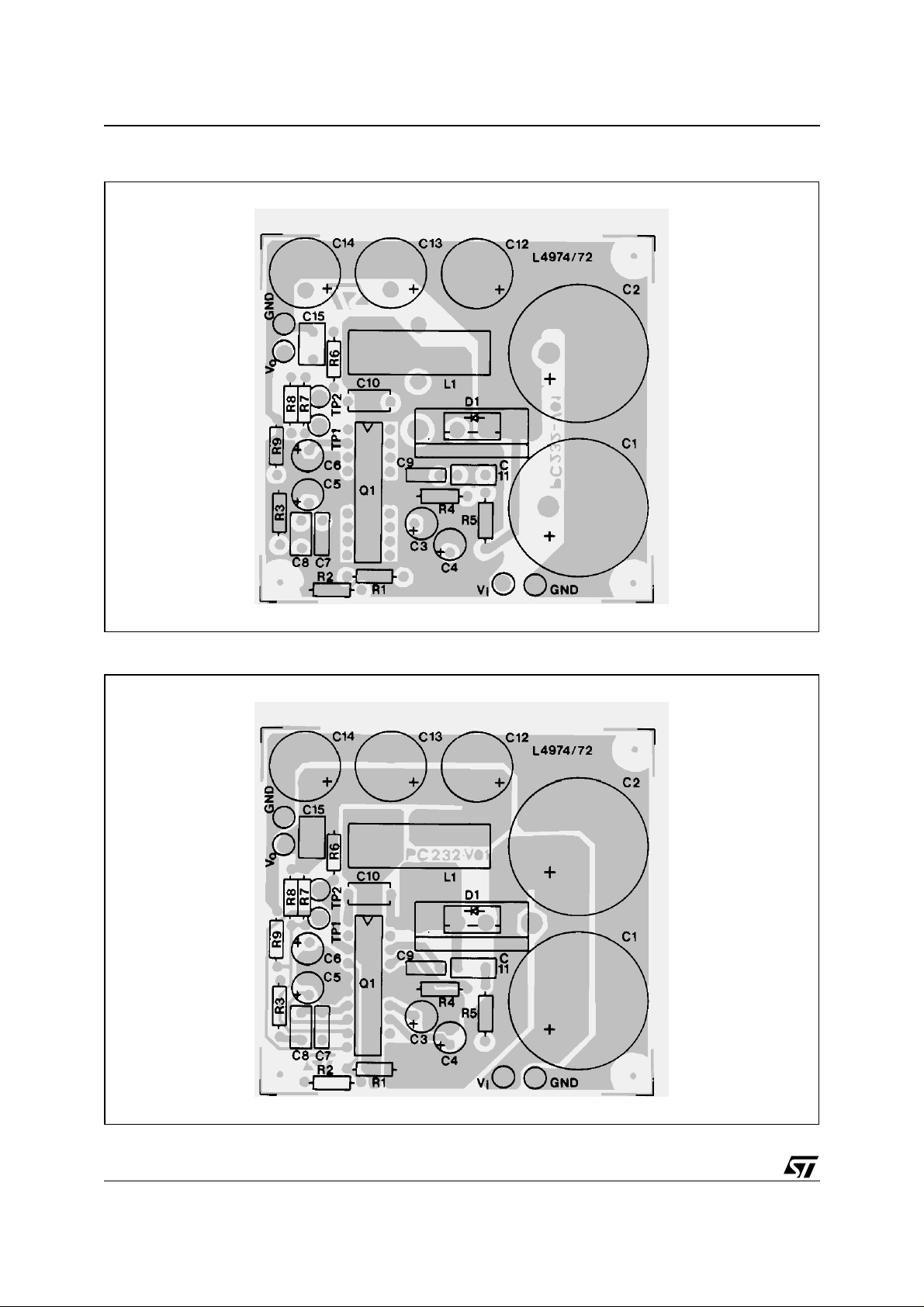

Figure 37. Com p onent Lay ou t of f ig . 36. Eval uation Boar d

Figure 38. Board and Component Layout of the ciruit of fig. 36.

30/52

Page 31

AN557 APPLICATION NOTE

Figure 39. Test and Evaluation Board Circuit

TYPICAL PERFORMANCES (using evaluation board) :

n = 83% (V

= 35V ; Vo = V

i

capacitor ESR ≤ 60mΩ; Line regulation = 5mV (V

For component values, refer to test circuit part list.

PARTS LIST

R1 = 30KΩ R11 = 10Ω

R2 = 10KΩ * C1, C2 = 3300µF 63V

R3 = 15KΩ C3, C4, C5, C6 = 2.2µF

R4 = 16KΩ C7 = 390pF Film

R5 = 22Ω 0,5W C8 = 22nF MKT 1817 (ERO)

R6 = 4K7 C9 = 2.2nF KP1830

R7 = 10Ω C10 = 220nF MKT

R8 = see tab. A C11 = 2.2nF MP1830

R9 = OPTION **C12, C13, C14 = 220µF 40VL EKR

R10 = 4K7 C15 = 1µF Film

D1 = MBR 760CT (or 7.5A/60V or equivalent)

L1 = 80µH core 58930 MAGNETICS 47 TURNS Ø 1,13mm (AWG 76) COGEMA 949178

* 2 capacitors in parallel to increase input RMS current capability

** 3 capa c i tors in parall e l t o reduce total ou tput ESR

Table A

V0 R10 R8

12V 4.7KΩ 6.2KΩ

15V 4.7KΩ 9.1KΩ

18V 4.7KΩ 12KΩ

24V 4.7KΩ 18KΩ

Table B - SUGGESTED BOOTSTRAP CAPACITORS

Operating Frequency Bootstrap Cap.c10

f = 20KHz ≥680nF

f = 50KHz ≥470nF

f = 100KHz ≥330nF

f = 200KHz ≥220nF

f = 500KHz ≥100nF

; Io = 5A ; fSW = 200KHz); V

REF

= 15 to 50V); Load regulation = 15mV (Io = 2 to 5A);

i

EYF (ROE)

L

o RIPPLE

= 30mV (at 10A) with output filter

31/52

Page 32

AN557 APPLICATION NO TE

Figure 40. P.C. Board (co m po ne n t side) and Comp onents Lay out of t he C ir c ui t of Fig . 39.

Figure 41. P.C. Board (back side) and Components Layout of the Circuit of Fig. 39.

32/52

Page 33

AN557 APPLICATION NOTE

Figure 42. Test and Evaluation Board Circuit

TYPICAL PERFORMANCES (using evaluation board) :

n = 83% (V

= 35V ; Vo = V

i

pacitor ESR ≤ 60mΩ; Line regulation = 5mV (V

component values, refer to test circuit part list.

PART S L I ST

R1 = 30KΩ R11 = 10Ω

R2 = 10KΩ * C1, C2 = 3300µF 63V

R3 = 15KΩ C3, C4, C5, C6 = 2.2µF

R4 = 16KΩ C7 = 390pF Film

R5 = 22Ω 0,5W C8 = 22nF MKT 1817 (ERO)

R6 = 4K7 C9 = 2.2nF KP1830

R7 = 10Ω C10 = 220nF MKT

R8 = see tab. A C11 = 2.2nF MP1830

R9 = OPTION **C12, C13, C14 = 220µF 40VL EKR

R10 = 4K7 C15 = 1µF Film

D1 = MBR 1560CT (or 16A/60V or equivalent)

L1 = 40µH core 58071 MAGNETICS 27 TURNS Ø 1,3mm (AWG 16) COGEMA 949178

* 2 capacitors in parallel to increase input RMS current capability

** 3 capa c i tors in parall e l t o reduce total ou tput ESR

Table A

V0 R10 R8

12V 4.7KΩ 6.2KΩ

15V 4.7KΩ 9.1KΩ

18V 4.7KΩ 12KΩ

24V 4.7KΩ 18KΩ

Table B - SUGGESTED BOOTSTRAP CAPACITORS

Operating Frequency Bootstrap Cap.c10

f = 20KHz ≥680nF

f = 50KHz ≥470nF

f = 100KHz ≥330nF

f = 200KHz ≥220nF

f = 500KHz ≥100nF

; Io = 7A ; fSW = 200KHz); V

REF

= 15 to 50V); Load regulation = 15mV (Io = 2 to 7A); For

i

EYF (ROE)

L

o RIPPLE

= 30mV (at 7A ) with out put filter ca-

33/52

Page 34

AN557 APPLICATION NO TE

Figure 43. P.C. Board (co m po ne n t side) and Comp onents Lay out of t he C ir c ui t of Fig . 42.

Figure 44. P.C. Board (back side) and Components Layout of the Circuit of Fig. 42.

34/52

Page 35

AN557 APPLICATION NOTE

Resistors value for standard output voltages.

Vo

(V)

12 4.7 6.2

15 4.7 9.1

18 4.7 12

24 4.7 18

Rx

(kΩ)

Ry

(kΩ)

Rx corresponds to R9 for L4974A and L4972A Ry

corresponds to R10 for L4970A, L4977A and

L4975A

Rx corresponds to R7 for L4974A and L4972A Ry

corresponds to R8 for L4970A, L4977A and

L4975A

The suggested switching frequency, and used in

the dynamic tests, is 200KHz for t he Multiwatt

package (MW) and 100KHz for the powerdip plastic package (PDIP). The maximum switching frequency allowed is 500KHz.

For the types in plastic package (Powerdip), the

lower switching frequency suggested is on ly depended by the minor dissipating power of a plastic

package versus a "power package" becau se it is

well known that switching losses are directly proportional to the commutation frequency. Higher

switching frequencies are possible if limited output

current is required and the operating ambient temperature are lower than 7 0°C. Infact the os cillator

of the devices ass embled in dual in line is completely equivalent to Multiwatt

®

package.

The most important external components which

need a little more attention (because a properly dimensioning affects on the performance of t he application) are the input and output capacitors, the

freewheeling diode and the coil.

Figure 45. Oscillator waveform and sync. pulse

for V

= 35V

i

Figure 46. Oscillator waveform and sync. pulse

for V

= 15V

i

®

Figure 47. Os cillo s co pe ph ot og ra p h s ho wi ng

the short circuit output voltage and

current waveforms .

INPUT OUTPUT CAPACITORS

The output voltage ripple ∆Vo, essentially depends on the current ripple in the coil and the ESR

of the output capacitor at the switching frequency.

The capacitor that present a low ESR are capable

of supporting higher current ripples.

Today, the majorit y of the cons tructors of el ec -trolithic capaci tors offe r in their da ta book also a wide

range of "low ESR" types generally suggested for

switching power supply application. In our case

EKR and EKE series (ROE ) has been preferred.

Such a series capacitors are designed for applications at high frequency, 200KHz, and built to have

a low ESR in order of supporting high current ripple.

In order to minimize the effects caused by the ESR

of the capacitors on the output voltage ripple 3 capacitors of 220uF/40V (for high output current application) are connected in parallel.

35/52

Page 36

AN557 APPLICATION NO TE

It is necessary much attention also into the choice input capacitors. Also them be at low ESR, because

they must sustain high current ripples. Such current ripples in presents of an inadeguate ESR, would produce a heating of the capacitor itself (which could affect on the reliability of the component, since in general it is sensitive to temperature.

Therefore choosing input capacitor at low ESR is necessary for problems of reliability. In fact such capacitors, when used in applications that make use a mains transformer, must support quite elevated peak current for short periods a double the mains frequency and the same time be capable to deliver the

instantaneous peak of energy to the load at the switching frequency.

Some other considerations of a general nature can be done on low ESR capacitors. For example of equal

value and type (i.e.: 220µF - EKR), the ESR of the capacitor decreases at the increasing of its value voltage rating, just like its RMS current.

Still, two capacitors of the same va lue, connected in parallel, withstand an R MS current hig her then the

only one of double value, and with the same voltage rating.

When however, more capacitors are connected together in parallel, it is important to design with care the

layout of the printed circuit, in order to distribute as eventy as possible amongst between the different capacitors the total current ripple.

This is used to avoid dangerous current unbalances in the distribution of the total current between the various capacitors charging some more others, that could damage the reliability of the system.

Often it is very difficult to know exactly the RMS current flowing throught the capacitors. To know if the

operating condition is a "safe"operat ing condition or not, a mea surement of the pack age temperat ure of

the capacitor should be done.

The following table 3 and 4, included in the dat-abook of electrical Roederstain, shows the maximum RMS

current sustainable by the EKR and EKE capacitor versus the ambient temeperature and overtemperature

allowed on the capacitor package.

Table 3. Low-voltage electro lytic ca paci tors for sw itch-m od e power supplies with low im p edan ce

values, radial, polarized styles

Rated cap.

(µF)

EKR

100

220

470

100

220

470

100

220

470

100

220

470

Rated volt.

(V DC)

10

10

10

16

16

16

25

25

25

40

40

40

Dimensions

D x L (mm)

(nominal

dimen-

sions)

8.7 x 12.7

10 x 12.7

10 x 20

10 x 12.7

10 x 16

12.5 x 20

10 x 12.7

10 x 16

12.5 x 20

10 x 16

12.5 x 20

12.5 x 30

Dissipation

factor tan δ

(100Hz;

20°C) Lim.

Values

0.12

0.12

0.12

0.11

0.11

0.11

0.09

0.09

0.09

0.08

0.08

0.08

Impedance

Z (Ω)

(10KHz;

20°C)

(Lim. val-

ues)

0.85

0.39

0.20

0.60

0.32

0.16

0.5

0.25

0.13

0.4

0.17

0.09

Impedance

Z (Ω)

(10KHz;

20°C)

(Lim. val-

ues)

0.65

0.31

0.18

0.40

0.25

0.13

0.35

0.17

0.09

0.23

0.13

0.08

Admissible

ripple curr.

(mA/100Hz)

85°C

160

300

530

200

350

600

250

450

650

450

650

1000

Admissible

ripple curr.

(mA/eff/10-

100Hz)

85°C

250

450

800

300

550

900

400

700

1000

700

1000

1500

36/52

Page 37

AN557 APPLICATION NOTE

Table 3. Low-voltage electro lytic ca paci tors for sw itch-m od e power supplies with low im p edan ce

values, radial, polarized styles (continued)

Rated cap.

(µF)

EKE

Rated volt.

(V)

Dimensions

D x L (mm)

(nominal

dimen-

sions)

Dissipation

factor tan δ

(100Hz;

20°C) Lim.

Values

Impedance

Z (Ω)

(100KHz;

20°C)

(Lim. val-

ues)

Impedance

Z (Ω)

(100KHz;

-10°C)

(Lim. val-

ues)

Impedance

Z (Ω)

(100KHz;

-40°C)

(Lim. val-

ues)

Admissible

ripple curr.

(mA)100Hz)

105°C

22

33

47

100

220

330

330

470

100

220

220

330

470

100

220

330

470

100

100

220

330

470

10

10

10

10

10

10

10

10

16

16

16

16

16

25

25

25

25

35

35

35

35

35

5 x 11

5 x 11

5 x 11

5 x 11

6.3 x 11

8 x 11.5

8.5 x 12.5

8 x 11.5

6.3 x 11

8 x 11.5

8.5 x 12.5

8 x 11.5

10 x 12.5

6.3 x 11

8 x 11.5

10 x 12.5

10 x 16

8 x 11.5

8.5 x 12.5

10 x 12.5

10 x 16

10 x 20

Table 4. Admissible ripple current

Ambient Temp.

in ×C

δ

u

≤ 40 220 % 55 230 % 55

45 210 % 59 220 % 60

50 200 % 63 210 % 64

55 190 % 67 200 % 68

60 180 % 70 190 % 72

65 170 % 74 180 % 76

70 155 % 77 170 % 80

75 140 % 81 160 % 84

80 120 % 84 150 % 88

85 100 % 88 140 % 92

90 90 % 92 130 % 96

95 80 % 97 120 % 100

100 70 % 101 110 % 104

105 60 % 106 100 % 108

Admissible % of the

85°C value

0.19

0.19

0.19

0.19

0.19

0.19

0.19

0.19

0.16

0.16

0.16

0.16

0.16

0.14

0.14

0.14

0.14

0.12

0.12

0.12

0.12

0.12

Surface Temp.

in °C

1.30

1.30

1.30

1.30

0.60

0.33

0.33

0.33

0.60

0.33

0.33

0.33

0.25

0.60

0.33

0.25

0.19

0.33

0.33

0.25

0.19

0.14

Admissible % of the

105°C value

3.90

3.90

3.90

3.90

1.80

0.99

0.99

0.99

1.80

0.99

0.99

0.99

0.75

1.80

0.99

0.75

0.57

0.99

0.99

0.75

0.57

0.42

20

20

20

20

9.80

5.80

5.80

5.80

9.80

5.80

5.80

5.80

3.20

9.80

5.80

3.20

2.20

5.80

5.80

3.20

2.20

1.50

Surface Temp.

154

154

154

1 54

260

400

400

400

260

400

400

400

510

260

400

510

635

400

400

510

635

860

in °C

37/52

Page 38

AN557 APPLICATION NO TE

CATCH DIODE

Because of quickly rise and fall time of the current

(about 40-50ns) the use Schottky diode is reccomanded. Ultra-fast diodes with 30-50ns of trr (reverse recovery time) are not considered

sufficient ly fa st f or t his f am ily of c on verte rs, sinc e

they would give too elevated peaks of current at

the turn on of the internal power transistor, so high

thatcould affect the reliabi lity of the c om ple te s ystem, as well as drastically reduce the efficiency.

The oscilloscope photographs show the Output

Voltage and Output Current waveforms obtained

with diode having different trr value.

Figure 48. Schottky Diode.

Figure 49. Ultra Fast Diode (trr < 100ns).

In the test circu its use d for this famil y of conv erters, Schottky diodes from 60V (breakdown reverse voltage) are suggested since the device can

support a max. input power voltage of 55V (for

specific applications, Schottky diodes with a reverse breakdown voltage higher or equal to the

maximum supply voltage should be used), with

current rating and packaging to satisfy all the conditions of duty cycle, and therefore also of power

dissipation.

COIL

Concerning the coil, a molypermalloy toroidal

cores has been suggested, so that it would be

easy for everybody to obtain samples, wrap them

with a right number of turns i n order to evaluate

and correlate the measurements and performance

of the devices.

In addition since the devices are dynamically tested 100% in production, with a "jig" of testing which

uses the same coil suggested in the applicatio ns,

in the case of conte sts for example on a guaranteed parameter like the efficiency, should be easier to solve the objections; in this case s hould be

remembered that changing the magnetic material,

the dimension, the wire and the number of the

winding, also change the losses in the coil reducing the total efficiency of the application.

This can be easily verify using for example toroidal cores in iron powered rather that those suggested in molypermalloy.

Moreover, it is important to dimension properly the

coil in order to avoid its saturation, a good c hoice

is to dimension that its saturat ion; current is not

equal to the maximum nom inal current cap able t o

deliver to the load, but rather higher by about 20%

then the maximum guaranted current of the device, in short circuit condition.

Only in this way it is possible to guarantee that the

coil never saturate in all the possible working conditions, i.e.: in presence of a load transient, in short

circuit in output and in the case of elev ated temperature of the magnetic part.

At last, it should be remembered that the suggested inductors values, are referred to the inductors

values that the coil must have at the maximum output current of the application. Oscilloscope Photographs showing the device output voltage and

current waveforms obtained with different inductor.

38/52

Page 39

AN557 APPLICATION NOTE

Figure 50. Waveforms for L = 50µH

Figure 51. Waveforms for L = 230µH

Figure 52. Waveforms in case of core satura-

tion

Anyway some general rules should be observed in

order to avoid any "poor functioning". Th es e rules

include:

a) the catch diode, that further to be the suggested

type in the test circuit, it has to be assembled on

the printed circuit very close to the output of the

regulator, in order to minimize the leakage inductance and avoid over voltage due to the long

connection:

b) The inductor, avoiding the saturation at the

maximum current guaranted by the current

limitation of the device.

If oscillations on the output voltage at low ambient

temperature (i.e.: below 0°C) are originated an

output low ESR capacitor has to be used. Oscillations on the output al low frequency indicate instability of the control loop; in this case a changing of

the network compensation is suggested (see Error

Amplifier section).

LOW COST APPLICATION

The fig. 53 shows the low cost application of a

power supply of 10A and 5.1V.

In comparison of the complete application (and

this is valid for all the devices of t he f amily) t he external components relative to the reset and power

fail functions can be missed.

When a lower output voltage ripple is not required

it is possible to eliminate the capacitors connected

at the reference voltage pin of 5.1V (i.e.: pin 14 for

Multiwatt package. pin 13 for plastic package) The

reset input pin is suggested to connect it to

ground.

The soft start capacitor value can b e reduced to

100nF for 5V output voltage.

39/52

Page 40

AN557 APPLICATION NO TE

Figure 53. Low C ost Application Circ u it.

POWER SUPPLY COMPLETE WITH MAINS TRANSFORMER

The fig. 54 shown a power supply with mains 110/220Vac transformer, diode bridge and filter capacitor

with output voltage adjustable between 5.1V. and 24V.

Output capacitors have to be chosen with low ESR in order to reduce the output ripple.Particular care has

to be taken for input filter ca pacit ors, in fa ct they hav e to support high current sp ikes at m ains fr equency

and at the same time current peak bigger than the output current at the switching frequency.

Therefore they must be chosen with low ESR and able to substain high current ripple in order to guarantee

a good reliability to all the system. The trasformer can be chosen with a single winding and 4 diodes or a

center tap with only 2 diodes with higher reverse voltage.

A cost reduction of the trasformer can be reached using an active power factor corrector.

It work at low voltage and the external components are relatively cheap, more details can be obtained

looking on the power factor corrector application note.

POWER SUPPLY WITH MAINS HI GH FREQUENCY PREREGULATOR.

When it is necessary to eliminate the mains trasformer at 50/60Hz for reasons like weight, dimensions or

cost, a high frequency preregulator can be used.

A ferrite trasformer reduces the rectifier and filtered mains voltage in a convenient voltage to supply directly the device, providing for the isolation requirements.

Using a free running solution or one of the voltage/current mode controller available, it is possible to compensate the input variation while the output voltage variations due to the load are usually very low. Some

examples regarding how to use this regulator in off-line power supply are now showed:

Flyback Topology

Using a flyback topology with single or double transistors is possible to fix a single output voltage of 3540V; it can be a bit increased if using a backup battery of 48 nominal Volts.

From this preregulator (±10%) tolerancevoltage is possible to get one or more indipend ent outputs, with

its own current limitation and thermal protection.

Moreover a possibility to syncronize more devices together is available, remembering to fix the master

frequency at least 5% higher than the others device (working as slave) one.

In case of necessity is possible to synronize devices on the trasformer secondary with the swith-cing frequency of the controller (See Fig. 55).

40/52

Page 41

Figure 54. Typical power supply showing the mains transformer.

Figure 55.

AN557 APPLICATION NOTE

Forward Top ol ogy

Further is showed an smps forward circuit, where the dc-dc converter is used as post-regulator for an auxiliary output, (35V.) while the main one (5.1V. or 3.3V) is controlled directly with the feedback (See Fig. 56).

Using a PFC preregulation

When an optimized power factor is required it is possible to use t he f ollowing two pricinpl e diag ram that

make use of an active power factor corrector.

1) using the standard boost topology (Fig. 57)

2) using a flyback topology (Fig. 58)

The idea is that to generate a stabilized voltage, around 30V - 35V, already isolated, av oiding to use an

isolation after the PFC section.

41/52

Page 42

AN557 APPLICATION NO TE

Figure 56.

Figure 57.

Figure 58.

POWER SUPPLY WITH 0 TO 25V ADJUSTABLE OUTPUT VOLTAGE

a) It is a classical solution with high performanc e that m ake us e of a n egat ive referenc e volt age eq ual to

the value of the internal voltage of the device (5.1V).

To generate this negative reference voltage, it is useful to equip the mains trnsformer with another sec-

ondary winding at a low voltage of around 8Vac and capable of delivering a few dozen of mA.

During the phase of starting up and stopping of the mains, it is important to avoid generating oscillations

around the value of the output voltage , including the zero voltage.

For this reason a network con sisting of two NPN sign al transistors TR 1 an d TR2 a nd some resistors

has been introduced.

The transistor TR2 remains is saturation when TR1 is off, untill the output voltage of the negative reg-

ulator reaches 4.3V At this point TR1 goes in saturation, sending of f TR2. In this way the s oft start is

42/52

Page 43

AN557 APPLICATION NOTE

blocked and the device begins to work starting in soft start. Sw itching of f the mai ns v oltage, th e regulator generating the negative volatge is still in regulation when t he input voltage of the switching converter has already dropped below the turn on threshold.

Carefull attention must be given theref ore to calculate the input c apacitor of the two sectio ns in order

to avoid possible malfunctioning during the turning on and turning off.

b) a solution that presents a cheaper costs and tha doesn’t use a negative reference voltage is the follow-

ing: Setting the c ursor "P" to the adjustable resist ance at 0V, using R1 and R2 the maximum output

voltage can be fixed. In this case we set R1 = 24Kohm and R2 = 4K7ohm.

In R1 the m aximum f lowing current will be limited a t 1m A; with 1mA flowing in R1, V o = 30V. Now by

reducing the current in R1 the output voltage Vo can be adjusted till to 0V.

Figure 59.

Figure 60.

43/52

Page 44

AN557 APPLICATION NO TE

The current, flowing in backward, to have 0V it will be:

V

I1

----------

R1

= R2 · 0.21 = 4.7k · 0.21 = 1V

∆V

R2

Therefore, when the cursor "P" reaches Vref + 1V the output voltage goes to zero.

At this point we are able to define as well the values of P1 and R3.

When the "P" cursor is compl etely m ove d to high, there should be 6V of dropping to "P", and i n this way

0.6mA will f low .

The current flowing in R3, considering that the voltage at pin 15 has a typical value of 12V, it will be of

0.8mA.

In this case the R3 value will be 7K5ohm.

3.3V / 10A DC-DC CONVERTER

When an output voltage lower to the reference voltage of 5.1V must be stabilized with a good result from

stability and regulation point of view, and not having available the not-inverting input of the error amplifier,

it is possible to use an external reference.

In this case a TL431C referen ce has been chosen, which is cheaper and widespread us ed. I n this c ase

more than a simple reference, it is a true shunt regulator, containing a reference, an error amplifier and a

transistor capable of absorbing a max current of 100mA.

Such component can be compensated like a common OP/AMP, and therefore in our application can substitute both the internal reference and the error amplifier.

The fig. 61 represents the electrical diagram of the application at 3.3V.

The operating input voltage is between 12V (due to the internal UVLO) and 35V, with a minimum operating

switching frequency of 100KHz.

The maximum operating input voltage is limited only 35V because the minimum "ON" time, which should

not be reduced below 1 microsecond. At input voltage of 35V, output voltage of 3.3V and fs=100K Hz the

Ton time is already about of 1 microsecond.

ref

5.1V

------------ 0.21m A== =

24K

Figure 61.

2200

44/52

12V <Vi <35V

8

3

11

µF

CORE TYPE 58071 MAGNETICS

1 2 14 15

36K

2.2nF

L4970A

2.2µF

0.22µF

69

7

10

22K

TL431

2.2µF

1K

0.1µF

50µH

STPS