From nickel-cadmium to nickel-hydride fast battery charger

1 Introduction

Today, many cordless and portable equipment are supplied by a rechargeable battery

(Nickel-Cadmium, NiCd or Nickel-Hydride, NiMH). Individual applications such as portable

phones, camcorders, cordless power tools, portable appliances and audio equipment

highlight the enormous contribution made by rechargeable batteries to our comfortable

lifestyle. NiCd battery chargers charging in one hour and even less are already widespread.

Ultra fast charging of NiCd batteries in less than 15 minutes is a very attractive feature in

applications where the battery is rapidly discharged, as in power tools such as cordless drills

[1.].

Nevertheless, when fast charging, the use of a non-adapted charge termination method may

lead to a significant reduction of the battery service life. This could cause a prejudice against

the appliance manufacturer's image, as when the battery service life is reduced, the user is

practically led to a costly replacement of the complete battery pack.

AN417

Application note

The trend is now to replace NiCd batteries by the more environmentally friendly NiMH

batteries. Several charger applications such as notebook computers and portable phones

already require NiCd /NiMH compatible battery chargers. In this case, the most common

charge monitoring method used for a NiCd battery (negative delta voltage: [longer suited to the NiMH battery.

In this application, the charge termination method is based on the detection of the inflexion

point in the battery voltage curve. This inflexion point detection method is not only "NiCdNiMH compatible", it also significantly increases the NiCd battery life-time when fast

charging.

Such a high performance charger can be totally managed by a low cost 8-bit microcontroller

(MCU), the ST6210. Safe charging is achieved by the combination of three back-up charge

termination methods: [additional benefit of using such a 20 pin standard microcontroller lies in its high adaptability

of application features.

The proposed charging power converters use the Switched Mode Power Supply technology

(SMPS), operating from AC mains or DC voltage sources. A 35W/100kHz offline and a

15W/100kHz DC/DC chargers are described in this note.

Δ V] detection, temperature monitoring and timer cut-off. An

Δ V]) is no

November 2011 Doc ID 2074 Rev 2 1/21

www.st.com

Contents AN417

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Charge termination methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 The [-Δ V] method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 The inflexion point method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Principle of the inflexion method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Charge control program description . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Charger schematic examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.2 Battery charger examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2.1 Offline charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2.2 DC/DC charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

8 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2/21 Doc ID 2074 Rev 2

AN417 List of tables

List of tables

Table 1. Charge of different battery types with an 2.2 A current source . . . . . . . . . . . . . . . . . . . . . . 13

Table 2. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Doc ID 2074 Rev 2 3/21

List of figures AN417

List of figures

Figure 1. Battery charger circuit diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. The negative delta voltage method fast charge is terminated at point A . . . . . . . . . . . . . . . 6

Figure 3. Fast charge terminates at point B in the inflexion point method . . . . . . . . . . . . . . . . . . . . . . 7

Figure 4. NiMH versus NiCd charging characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 5. Inflexion point method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 6. Simplified program flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 7. Charge of a 1.4 Ah NiCd battery with the -[Δ V] method: charging current 2.2 A, total

time 48 mn, temperature increase 9.6°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 8. Charge of a 1.4 Ah NiCd battery with the inflexion method: charging current 2.2 A,

total time 41 mn, temperature increase 5°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 9. Charge of a 2.2 Ah NiMH battery with the -[Δ V] method: charging current 2.2 A, total

time 63 mn, temperature increase 18.2°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 10. Charge of a 2.2 Ah NiMH battery with the inflexion method: charging current 2.2 A,

total time 57 mn, temperature increase 7.5°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 11. Block diagram of an off-line SMPS charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 12. Block diagram of a DC/DC charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 13. This 35W/100kHz off-line charger is an asymmetrical half-bridge regulated in current

mode from its primary side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 14. This 15W/100kHz DC-to-DC charger is also driven by a low-cost PWM control

integrated circuit, the UC3843 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4/21 Doc ID 2074 Rev 2

AN417 Charge termination methods

micro controller

cell voltage

I charge

battery

Vin

NiCd

or

NiMH

ST62xx

-36

2 Charge termination methods

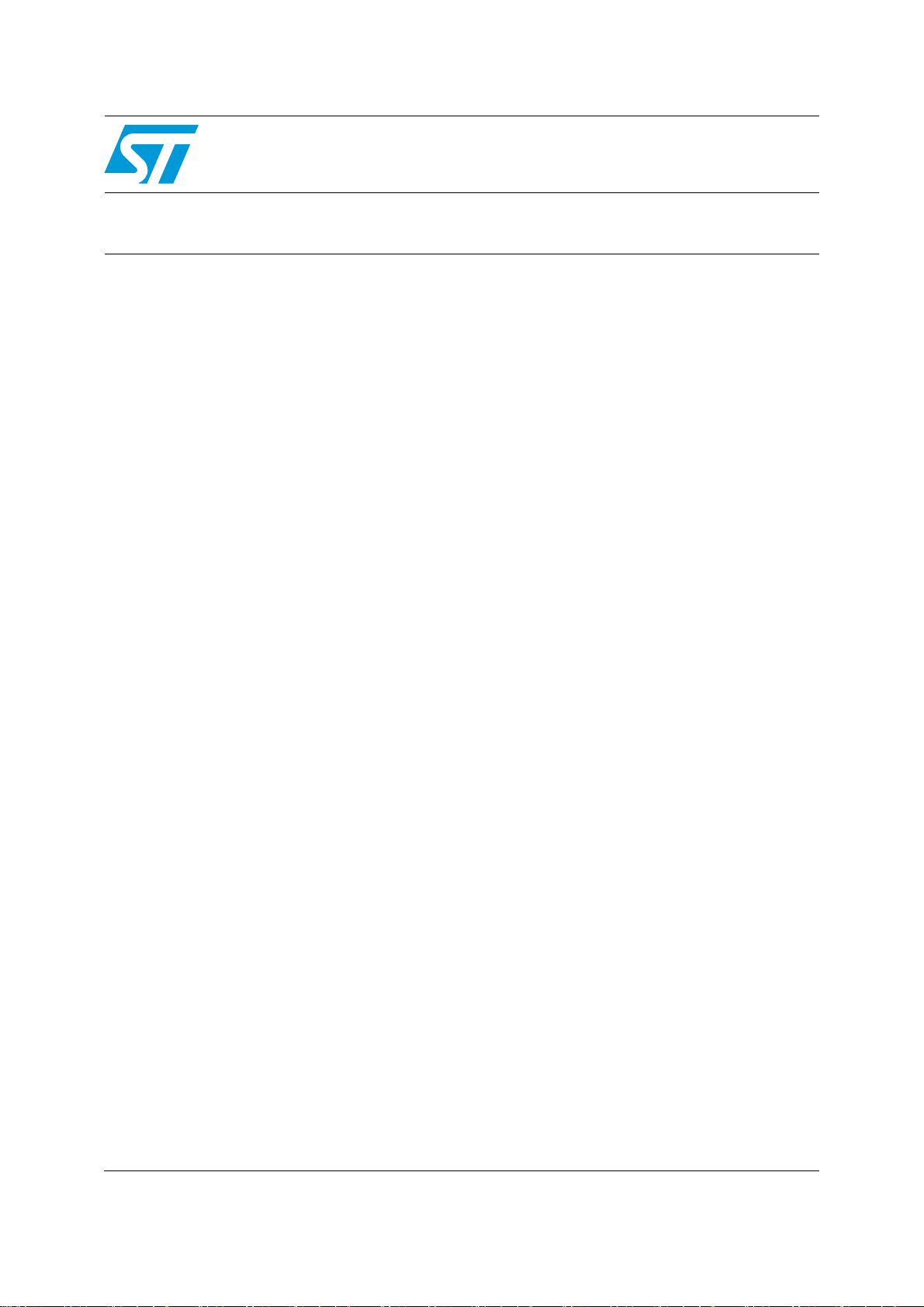

Basically, NiCd and NiMH batteries are charged by a constant current source (see Figure 1).

A battery charger is made of a constant current source controlled by a microcontroller which

monitors the battery voltage variation with its internal analog-to-digital converter

Figure 1. Battery charger circuit diagram

As soon as the full capacity of the battery has been detected by the microcontroller, the

charging is stopped by turning the current off. Schematic examples of power converters

operating as current sources are given later. The same converter hardware can be used in

two different charging methods depending upon the appliance requirements.

2.1 The [-Δ V] method

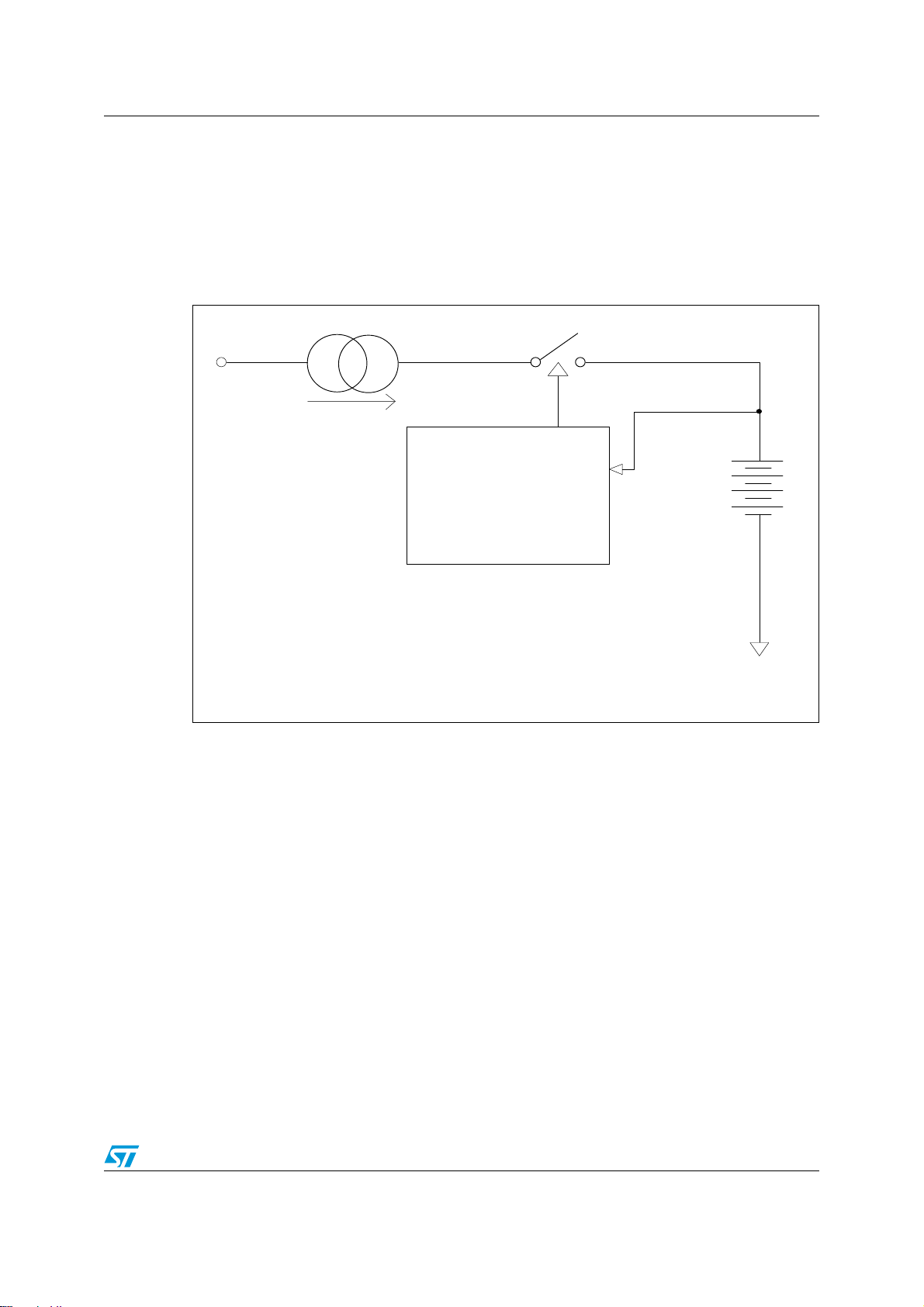

When a NiCd battery reaches full charge, its voltage decreases slightly (see Figure 2). The

negative delta voltage method [-

slope versus time becomes negative. This first charge termination technique is optimized to

fast charge a NiCd battery to its full capacity.

Δ V] consists of stopping the charge as soon as the voltage

Doc ID 2074 Rev 2 5/21

Charge termination methods AN417

charging time

cell voltage

battery voltage

battery temperature

temperature

1.2

1.3

1.4

1.5

1.6

20

30

40

50

60

-dV

deg C

V

A

-36

Figure 2. The negative delta voltage method fast charge is terminated at point A

In fact, a NiCd battery charged with the [-

Δ V] method is slightly overcharged: Figure 2

shows that the battery temperature has substantially increased at point A when charge is

terminated, which may decrease the life-time of the battery. More precisely in Figure 3, most

of the current fed to the battery between point B and the negative voltage drop A is not

directly converted into active battery charge, but into heat. This can be seen in the

temperature curve shown in Figure 3. The point B corresponds to the inflexion point of the

battery voltage curve versus time.

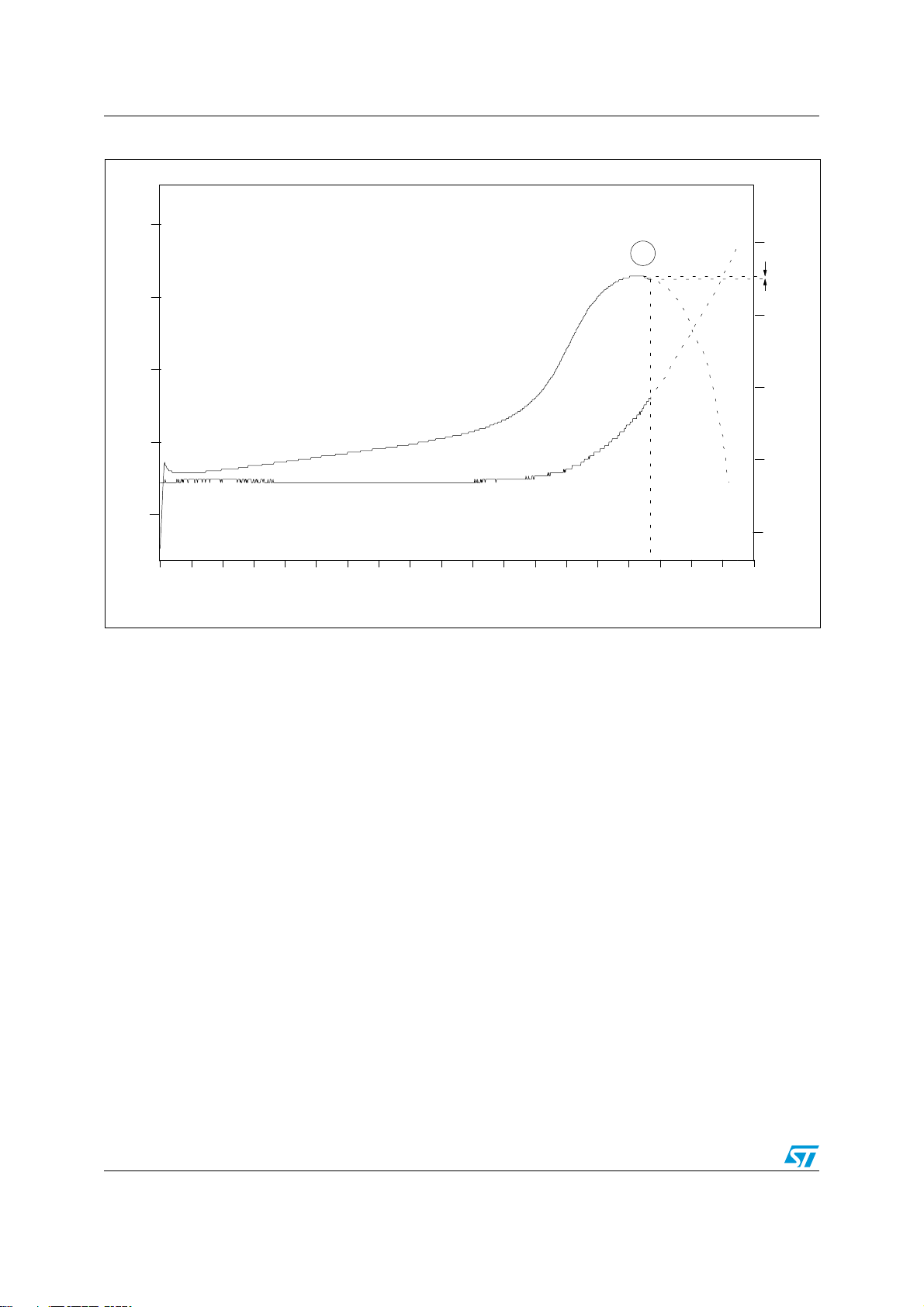

The [-

Δ V] method is definitely no longer suited when it comes to charging NiMH batteries:

the NiMH charging reaction is permanently exothermic (releases heat), so the battery

temperature would become excessive in its [-

Another characteristic of the NiMH batteries makes the [-

types of NiMH batteries do not exhibit a significant voltage drop as NiCd batteries do when

reaching their full capacity.

Δ V] area of the voltage curve (see Figure 3).

Δ V] method unsuitable: some

6/21 Doc ID 2074 Rev 2

AN417 Charge termination methods

charging time

cell voltage

battery voltage

battery temperature

temperature

1.2

1.3

1.4

1.5

1.6

20

30

40

50

60

deg C

V

B

A

-36

2.2 The inflexion point method

A second charge termination method much more adapted to NiMH batteries consists of

detecting the inflexion point of the voltage curve, thus avoiding any excessive overheating of

the battery. This method therefore significantly increases the battery life-time.

Figure 3. Fast charge terminates at point B in the inflexion point method

Doc ID 2074 Rev 2 7/21

Charge termination methods AN417

charging time

NiCd voltage

NiMH voltage

NiCd temperature

NiMH temperature

-36

Figure 4. NiMH versus NiCd charging characteristics

Note: The NiMH battery temperature rise is larger during fast charge, and its -[

important, than its voltage slope variation.

Detecting the inflexion point of the voltage curve with the MCU requires the evaluation of the

first derivative of the battery voltage curve versus time, and to detect its summit.

Δ

V] is less

8/21 Doc ID 2074 Rev 2

AN417 Principle of the inflexion method

battery voltage

voltage derivative

smoothed derivative

charging time ->

B

battery voltage and derivative

-36

3 Principle of the inflexion method

Every 4 seconds, the analog to digital converter (ADC) of the ST6210 microcontroller

measures the battery voltage and temperature. If the temperature is above a predetermined

threshold (40 degrees Celsius for example), fast charge is terminated.

The battery voltage is actually measured several times in series, and an average of the

measurements is made, to reduce measurement errors due to high frequency noise (for

example generated by a switched mode charging current).

Further, a rolling average of the present and previous measurements is made, to remove

low frequency noise due to electrochemical battery voltage variations (see previous

description of this technique in References [1.]).

This averaged battery voltage data is used to extract a time derivative, by calculating the

difference between present voltage and the voltage n samples earlier. Because of the

voltage digitization, which is measured by the ADC of the MCU, the first derivative curve

features a typical discontinuous aspect (see Figure 5).

For this reason, the MCU calculates a digital smoothing of this discontinuous derivative. The

inflexion point is then identified by detecting the first highest summit encountered on the

smoothed derivative curve (point B in Figure 5).

Figure 5. Inflexion point method

When this summit is detected, fast charge is terminated.

Doc ID 2074 Rev 2 9/21

Charge control program description AN417

NEW BATTERY

INSERTED ?

START

NOISE FILTERING AND AVERAGING

CALCULATE DERIVATIVE

SMOOTH DERIVATIVE

ARE WE AT INFLEXION ?

ARE WE AT DELTA-V ?

IS TIMER EXPIRED ?

WAIT 4 SECONDS

IS TEMPERATURE ABOVE THRESHOLD ?

IS BATTERY PRESENT ?

TRICKLE MODE

MEASURE BATTERY VOLTAGE 256 TIMES

Y

Y

Y

Y

N

Y

N

N

N

N

YN

-36

4 Charge control program description

The microcontroller detects the inflexion point in the battery voltage versus time curve while

charging. When full charge is detected, the MCU puts the charger in trickle charge mode.

As safety protection, the MCU also terminates fast charge if -[

temperature exceeds a predetermined threshold, or a timer with programmable time

duration expires.

Figure 9 shows the simplified flowchart of the program for the complete charge control. The

overall system is reset after each new input source voltage connection. It is also reset when

a charged battery is removed, and replaced by a discharged battery.

Figure 6. Simplified program flowchart

Δ V] is detected, or the battery

10/21 Doc ID 2074 Rev 2

AN417 Test results

charging time

cell voltage

temperature

voltage

temperature

22.4 deg

32 deg

-36

5 Test results

Figure 7 and Figure 8 show curves of a NiCd battery charge respectively terminated by

-[

Δ V] and inflexion point methods. A similar comparison is made with a NiMH battery in

Figure 9 and Figure 10. The charging current is 2.2 A, the NiCd battery was a 1.4 Ah type

and the NiMH battery a 2.2 Ah type. These measurement results clearly show that the

battery temperature increase is much smaller with the inflexion method than with the

conventional -[

NiMH batteries can be properly monitored by the ST6210 MCU.

Δ V] method. Moreover, these curves demonstrate that a one hour charge of

Figure 7. Charge of a 1.4 Ah NiCd battery with the -[

time 48 mn, temperature increase 9.6°C.

Δ V] method: charging current 2.2 A, total

Doc ID 2074 Rev 2 11/21

Test results AN417

charging time

cell voltage

temperature

voltage

temperature

21 deg

26 deg

smoothed derivative

-36

charging

time

cell

voltage

temperature

voltage

temperature

22.8

deg

41

deg

-36

Figure 8. Charge of a 1.4 Ah NiCd battery with the inflexion method: charging current 2.2 A,

total time 41 mn, temperature increase 5°C.

Figure 9. Charge of a 2.2 Ah NiMH battery with the -[

time 63 mn, temperature increase 18.2°C.

Δ V] method: charging current 2.2 A, total

12/21 Doc ID 2074 Rev 2

AN417 Test results

charging time

cell

voltage

temperature

voltage

temperature

19 deg

26.5 deg

smoothed voltage

derivative

-36

Figure 10. Charge of a 2.2 Ah NiMH battery with the inflexion method: charging current 2.2 A,

total time 57 mn, temperature increase 7.5°C.

Table 1. Charge of different battery types with an 2.2 A current source

Battery Monitoring Duration Temperature increase

-[

NiCd 1.4 Ah

NiMH 2.2 Ah

ΔV]

inflexion point

-[

ΔV]

inflexion point

48 min.

41 min.

63 min.

57 min.

9.6 °C

5 °C

18.2 °C

7.5 °C

Doc ID 2074 Rev 2 13/21

Charger schematic examples AN417

AC mains

SMPS

MCU

ST6210

PWM

current

mode

UC3845

NiMH

or

NiCd

battery

temperature

voltage

-36

DC voltage

SMPS

MCU

ST6210

PWM

current

mode

UC3843

NiMH

or

NiCd

battery

temperature

voltage

-36

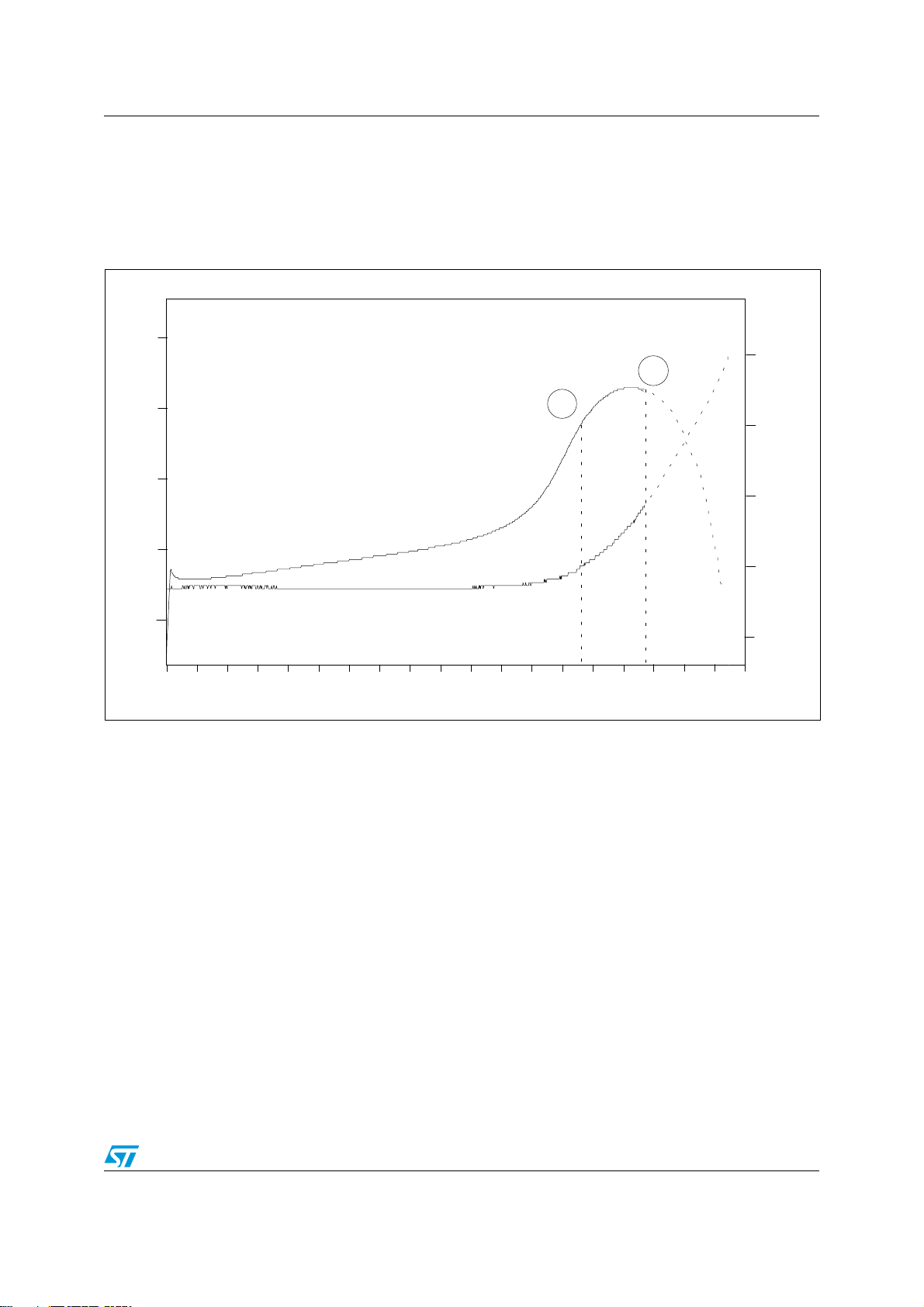

6 Charger schematic examples

6.1 Block diagram

The charger is a power supply operating as a constant current source. Such a current

source can be made with a SMPS working from the AC mains or from a DC voltage source.

Figure 11 and Figure 12 give block diagrams of an offline SMPS charger and a DC to DC

charger.

Figure 11. Block diagram of an off-line SMPS charger

Figure 12. Block diagram of a DC/DC charger

14/21 Doc ID 2074 Rev 2

AN417 Charger schematic examples

6.2 Battery charger examples

6.2.1 Offline charger

Figure 13 gives an example of an offline 35 watt battery charger working at 100 kHz. This

SMPS can deliver up to 3.5 amps DC to a 6 cell battery. Typical charging time of a 1.4 Ah

7.2v NiCd battery pack is around 30 minutes. This offline charger is an asymmetrical half

bridge totally controlled from the primary side with a standard PWM control IC, the UC3845,

regulating in current mode (see References [3.]).

The asymmetrical half bridge structure allows the use of two standard 500V power

MOSFETS IRF820 without snubber network, as voltage across each power MOSFET is

systematically clamped to the input DC voltage by two demagnetization diodes

(BYT01/400). The MCU controls the SMPS section through a single optocoupler, either in

battery charge mode or in trickle mode.

Note that the high side power MOSFET is simply driven by an auxiliary winding of the power

transformer, avoiding the use of an additional pulse transformer.

The switching frequency is set at 100 kHz in order to keep the magnetic parts to a

reasonable manufacturing cost level (see References [2.]. The power transformer and the

output inductor can be integrated on a single ferrite core to allow a significant shrinking of

the power converter size. This integrated magnetic technique has been used in a 80 watts /

15 minutes charger (see References [2.]).

By a simple resizing of the discrete power devices ratings, and by applying the [termination method, the same off-line converter hardware has been used to charge a typical

7V2/1.2 Ah NiCd pack of cordless drill in less than 15 minutes (see References [1.] [2.]).

6.2.2 DC/DC charger

Figure 14 shows a 15 watt 100 kHz battery charger supplied from a 12 Vdc input voltage.

The DC input voltage can be supplied from a car battery, or from a 50/60 Hz transformer

rectified voltage. This DC/DC charger is controlled by the PWM control circuit UC3843.

For example, such a 15 watt converter is able to deliver 1.5 amp DC, charging five 1500

mAh NiMH cells in approximately 1 hour.

Δ V]

Doc ID 2074 Rev 2 15/21

Charger schematic examples AN417

47uF

200V

1A

400V

10R

220

110

MAINS

90/260VAC

1A

+

47UF

200V

IRF820

470K

270K

1/2W

1N4148

BYT01/ 400

4.7R

BZX83C18

BZX83C18

EF25

BZW04P15

220uF

25V

STPS3045CT

70uH /4A

-

4N25

1.5K

680

1.8K

1K

27pF

27pF

VDD1TIMER2OSCIN3OSCOUT

4

NMI

5

VPP/TES6RESET7PB7

8

PB6

9

PB5

10

VSS

20

PA019PA118PA217PA316PB0

15

PB1

14

PB213PB312PB4

11

ST62E10

2MHz

1K

1K

IN

G

N

D

OUT

78L05

4.7uF

10V

BYV10/40

100uF

25V

IRF820

BYT01/400

1.8R

VIN7VREF8RT/CT

4

GND

5

C/SEN

3

COMP

1

VFB2OUT

6

UC3845

8.2K

4.7R

39K

4.7uF

25V

BZX85C18V

BC327

1nF

680pF

220R

1N4148

100K

1uF

10V

10K

22K

4.7uF

10V

5.6K

27K

78

6

541

2

3

TS271

120K

3.3K

6.8V

4.7uF

5.6K

15K

5.6K

5.6K

4.7uF

10V

-36

Figure 13. This 35W/100kHz off-line charger is an asymmetrical half-bridge regulated in current

mode from its primary side

16/21 Doc ID 2074 Rev 2

AN417 Charger schematic examples

BATTERY

PAC K 6 V

1500mAH

+Vbatt

100uF

25V

+

5

3

1

7

2

64

L4962

BYV10-40

BYV10-40

80uH

1.5A

VIN7VREF8RT/CT

4

G

N

D

5

C/SEN

3

COMP

1

VFB

2

OUT

6

UC3843

10K

15K

1nF

2A

+

DC

+

GND

11 TO 25V

-

4.7uF

10V

220uF

25V

22nF

12K

2.2uF

10V

I=1.5A

-

0.33R

1.5W

680

On

4.7uF

16V

VDD1TIMER2OSCIN

3

OSCOUT

4

NMI

5

VPP/TES

6

RESET7PB78PB6

9

PB5

10

VSS20PA019PA118PA2

17

PA3

16

PB015PB114PB2

13

PB3

12

PB4

11

ST62E10

33pF

2MHz

33pF

LED

Temp

Stop

15K

680

1K

15K

BZX55C3V3

6.8K

1K

R12

18K

27K

3

2

41 5

6

7

8

uA741

6.2K

9.1K

6.8K

2.2uF

10V

2.2uF

10V

2.2uF

10V

6.8K

-36

Figure 14. This 15W/100kHz DC-to-DC charger is also driven by a low-cost PWM control

integrated circuit, the UC3843

Doc ID 2074 Rev 2 17/21

Conclusion AN417

7 Conclusion

A relevant feature dominates today's electronic appliances - true portability. In these

cordless appliances, fast charging of the battery packs is often considered by the user as a

significant comfort improvement. Such an improvement can be achieved with a safe and

cost-effective charger concept using an off-the-shelf microcontroller, the ST6210.

Moreover, the present battery charger concept is NiCd/NiMH compatible, meeting the

current trend to progressively replace the NiCd battery by the more environmentally friendly

NiMH battery.

The charge termination method is based on the detection of the battery voltage inflexion

point in order to avoid any excessive overheating of the battery. Such a charge technique

significantly improves the battery service life, preventing the user from untimely replacing his

battery pack by a costly new pack. In addition, this low cost microcontroller provides a safe

charge by combining three other back-up termination methods typical of high end dedicated

control circuits: [-

The natural programmability benefit of such a microcontroller-based charger design allows

the designer to easily implement additional user interface functions. For example, a "gas

gauge" function indicating the remaining battery capacity to the user could be easily added

to the present basic program, whilst retaining the same charger hardware structure. Finally,

the major benefit of using this off-the-shelf ST6210 approach lies in the high adaptability of

its application features.

Δ V] detection, battery temperature monitoring and timer cut-off.

18/21 Doc ID 2074 Rev 2

AN417 References

8 References

1. Ultra-fast NiCd battery charger using ST6210 Microcontroller AN433

(STMicroelectronics)

2. An ultra-fast NiCd battery charger concept 43rd International Appliance Technical

Conference, May 5-6, West Lafayette, Indiana U.S.A. / L. Wuidart

3. A cost effective ultra-fast NiCd battery charger AN486 STMicroelectronics

Doc ID 2074 Rev 2 19/21

Revision history AN417

9 Revision history

Table 2. Document revision history

Date Revision Changes

01-Jan-1994 1 Initial release.

02-Nov-2011 2 Updated format and company logo.

20/21 Doc ID 2074 Rev 2

AN417

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 2074 Rev 2 21/21

Loading...

Loading...