AN4046

Application note

EnFilm™ micro battery EFL700A39

recommendations for manual assembly on PCB

Introduction

This document provides recommendations to manually mount EnFilmTM micro battery

EFL700A39 on printed circuit board (PCB) for prototyping purposes (mount 1 to 6 micro

batteries to assemble in one step on PCB).

This prototype mounting process is intended for use at room temperature (glue

polymerization has to be done at room temperature).

STMicroelectronics has developed micro battery packaging with reduced thickness and

weight.

Figure 1. Micro battery package overview

EnFilm

®

EFL700A39

700µAh/3V9

- anode

+ cathode

March 2012 Doc ID 022792 Rev 1 1/9

www.st.com

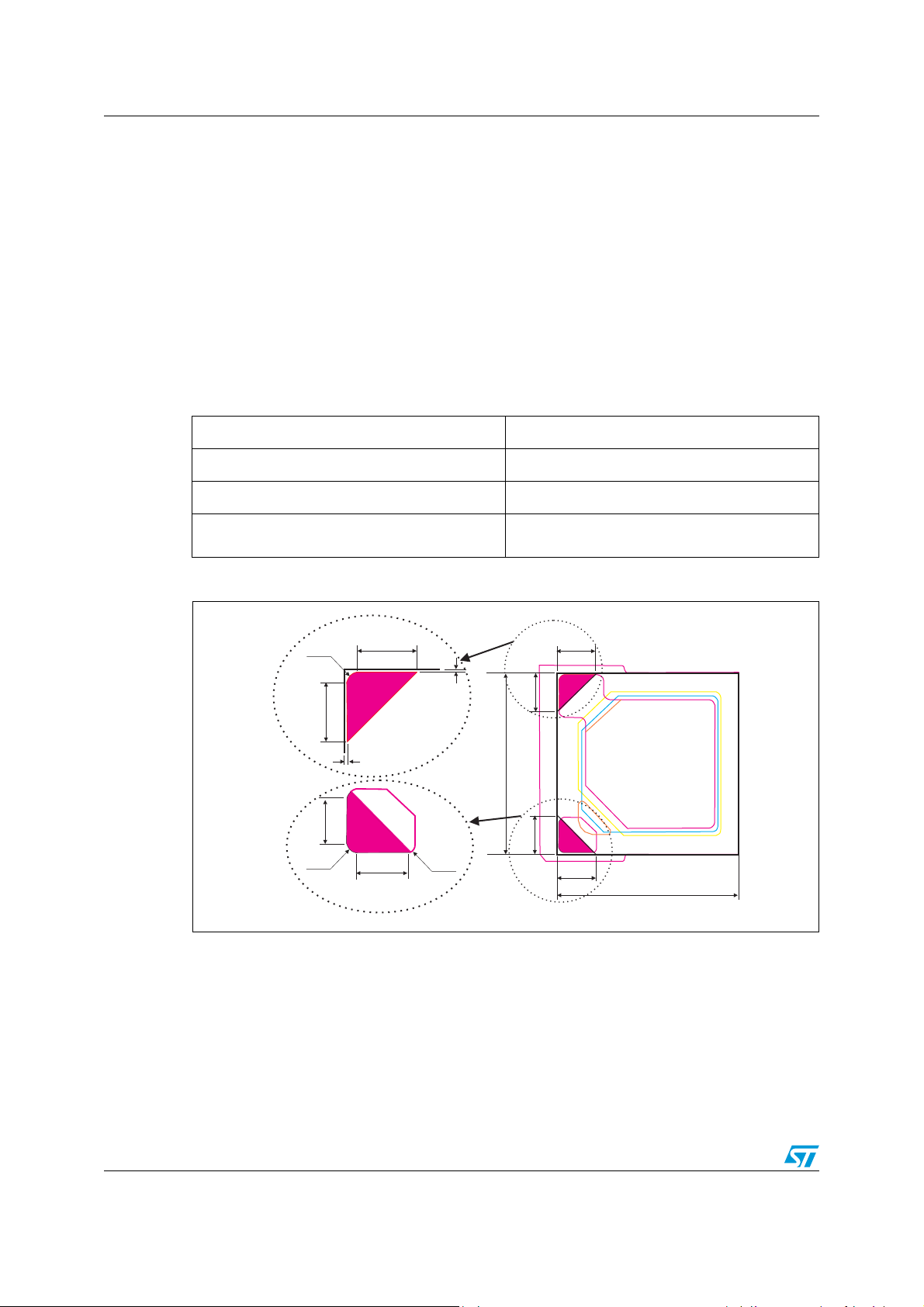

PCB design recommendations AN4046

1 PCB design recommendations

For optimum electrical performance and highly reliable solder joints, STMicroelectronics

recommends the PCB design guidelines listed in Tab l e 1 .

Note: A too thick gold layer finishing on the PCB pad is not recommended (low joint reliability).

1.1 Micro vias

An alternative to routing on the top surface is to route on buried layers. To achieve this, the

pads are connected to the lower layers using micro vias.

.

Table 1. PCB design recommendations

PCB pad design Micros vias under pad are not allowed

PCB pad size (NSMD design) Same pad size as micro battery (see Figure 2)

Solder mask opening (SMD design) Same pad size as micro battery (see Figure 2)

PCB pad finishing

Figure 2. Contact dimensions

R 0.75

4.21

0.25

3.45

R 0.75

4.21

3.71

Cu-Ni (2-6µm max) or Cu OSP (organic substrate

protection)

0.25

5.46

25.4

5.46

R 0.75

Dimensions in mm

5.46

5.46

Pink colour:

contact pad Pt

25.4

2/9 Doc ID 022792 Rev 1

AN4046 Conductive glue assembly recommendations

2 Conductive glue assembly recommendations

Circuit Works® Conductive epoxy CW 2400.

Suppliers: Radio Spares n° 496265 or Farnell n° 604057.

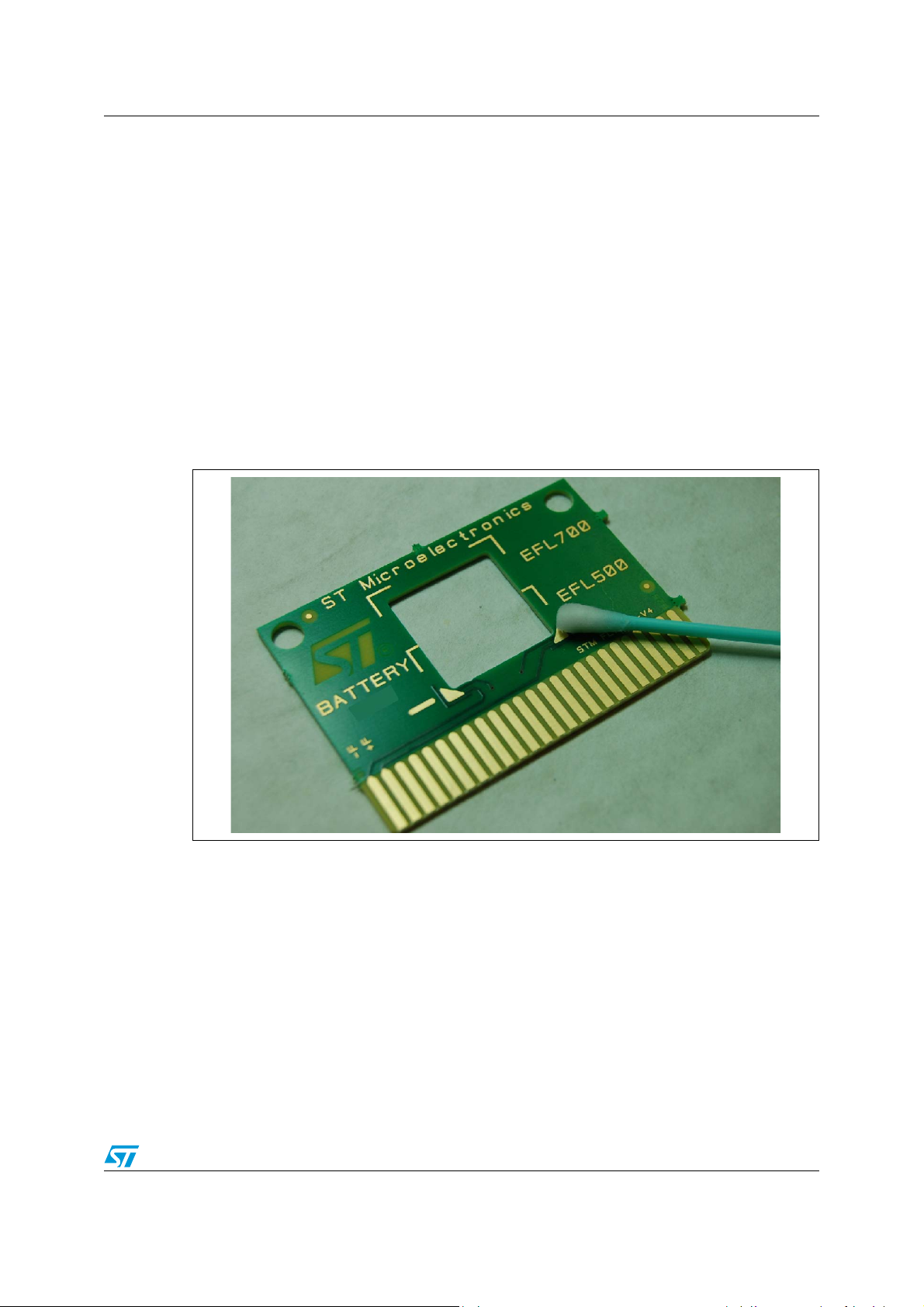

3 Mounting procedure

1. Read conductive epoxy MSDS carefully prior to use.

2. Use surgical gloves and goggles.

3. Clean surface to be contacted with cotton bud soaked with isopropyl alcohol (IPA).

Figure 3. Clean contact surface

Doc ID 022792 Rev 1 3/9

Mounting procedure AN4046

4. Mix equal amounts (1:1) by volume of 2 dots 4 mm diameter only. Mix thoroughly for at

least 2 minutes with plastic stick supplied with Conductive epoxy CW 2400.

Figure 4. Dot sizing

5. Apply a small quantity, 1mm diameter dot, on each contact of PCB maximum 12 dots.

Glue pot life is 10 minutes at 24 °C (75°F).

Figure 5. Application of 1mm dot glue

4/9 Doc ID 022792 Rev 1

AN4046 Mounting procedure

6. Flip the micro battery.

Figure 6. Placement of the micro battery

7. Put a weight of 30 g (for example a nut M16 mm) on the micro battery.

Figure 7. Place a weight on the micro battery

Room temperature curing can be achieved in 4 hours at or above 24 °C (75°F). Do not use

temperature higher than room temperature to accelerate curing.

Doc ID 022792 Rev 1 5/9

Underfilling AN4046

4 Underfilling

Underfilling is not needed.

5 Manual rework

The conductive glue doesn’t allow micro battery assembly rework.

6/9 Doc ID 022792 Rev 1

AN4046 Gauge for glue dot dimension optimization

DOT TEST

Appendix A Gauge for glue dot dimension optimization

Print paper and laminate it with plastic coating.

Figure 8. Gauge for glue dot dimension optimization

DOT TEST

4 mm

1 mm

Doc ID 022792 Rev 1 7/9

Revision history AN4046

Revision history

Table 2. Document revision history

Date Revision Changes

15-Mar-2012 1 Initial release.

8/9 Doc ID 022792 Rev 1

AN4046

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2012 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 022792 Rev 1 9/9

Loading...

Loading...