Page 1

AN3361

Application note

Schottky diode avalanche performance in automotive applications

Introduction

Electronic modules connected to automotive power rails may be affected by polarity

inversion due to poor battery handling and load-dump surges when the battery is

disconnected while the alternator is still charging. To protect against these phenomena,

module manufacturers add reverse-battery protection, usually using diodes.

Schottky diodes are preferred over bipolar ones because of their higher performance in

direct conduction. Schottky diodes feature a low forward voltage drop, and are able to

withstand the pulses defined in ISO 7637-2.

However, the diode needs a breakdown voltage higher than 150 V in order to pass the tests

for negative pulses 1 and 3a, whereas this tends to lower the forward performances. For

Schottky diodes, the intrinsic trade-off obeys the rule: the higher the breakdown voltage, the

higher the forward voltage drop.

There is a way to reconcile these conditions. Some Schottky diodes (depends on the

technology) have the ability to dissipate some power in reverse condition. This concerns the

P

parameter (Repetitive Peak Avalanche Power). For instance a 100 V breakdown

ARM

voltage Schottky diode may on the one hand support the negative pulse 1 and pulse 3a of

the ISO 7637-2 standard and on the other hand offer a very good performance in forward

voltage drop.

This Application note explains how to choose the best Schottky diode trade off in automotive

applications in order to preserve the low forward voltage drop performance and the ability to

pass the ISO 7637-2 pulses.

September 2011 Doc ID 018589 Rev 1 1/15

www.st.com

Page 2

Definition of the electrical transients and tests AN3361

1 Definition of the electrical transients and tests

Two ISO standards are applicable to this situation.

● ISO 16750

● ISO 7637-2

The ISO 16750 standard defines the variations that automotive power rails may undergo. A

reverse battery connection due to poor maintenance is described as a key condition to be

considered. Electronic modules thus usually have a reverse battery protection device to

guard against this condition. Most of the time this protection consists of a diode in series

that prevents negative current from flowing if the battery connection is reversed (see

Figure 1).

This solution involves a voltage drop across the diode and therefore some power

dissipation. This is why a Schottky diode is preferred as its forward voltage drop is less than

that of a conventional bipolar diode.

Figure 1. typical schematic of a powered automotive module using a Schottky

diode as reverse battery protection

Battery reverse protection

I

F

V

F

+

Transient protection

Electronic module

ISO 7637-2 specifies the methods and procedures to test for compatibility with conducted

electrical transients of equipment installed on passenger cars and commercial vehicles fitted

with 12 V or 24 V electrical systems, whatever the propulsion system (spark ignition or

diesel engine, electric motor). The standard describes bench tests for both the injection and

measurement of transients.

The bench tests consist in applying positive or negative pulses to the modules. The test is

successful if there is no damage on the device. Each pulse models an abnormal behavior.

The most sever cases are given in Table 1.

2/15 Doc ID 018589 Rev 1

Page 3

AN3361 Definition of the electrical transients and tests

Table 1. ISO 7637-2 main surge pulses

12V system

V

peak

t

p

Pulse Origin

Pulse

polarity

N° 1 Supply disconnection from inductive loads Negative -100 V 2 ms

The sudden interruption of current through a

N° 2a

device connected in parallel with the device

under test (DUT) due to the inductance of the

Positive +50 V 50 µs

wiring harness

N° 2b

DC motor acting as a generator after the

ignition is switched off

Positive 10 V 2 s

N° 3a Occur as a result of the switching processes Negative -150 V 100 µs

N° 3b Occur as a result of the switching processes Positive 100 V 200 µs

N° 4

Voltage reduction caused by energizing the

starter-motor of internal combustion engines

Negative -7 V 40 ms

Load-dump transient occurring in the event

N° 5b

of a discharged battery being disconnected

while the alternator is generating charging

Positive 87 V

Application

dependant

current, case with auto-protected alternator

The most severe positive pulse is pulse 5b (Figure 2). Its voltage range commonly varies

from +24 V to +48 V with a pulse duration up to 400 ms and a minimum series resistance

that can be as low as 0.5 Ω.

Figure 2. ISO 7637-2 pulse 5b clamped load-dump

t

U

0.1xU

S

Table 2. Parameter values for test pulse 5b

Parameter 12 V system

U

S

* As specified by customer

U

S

t

d

R

i

d

U

65 V to 87 V

40 ms to 400 ms

0.5 to 4 Ω

U

S

*

S

t

Doc ID 018589 Rev 1 3/15

Page 4

Definition of the electrical transients and tests AN3361

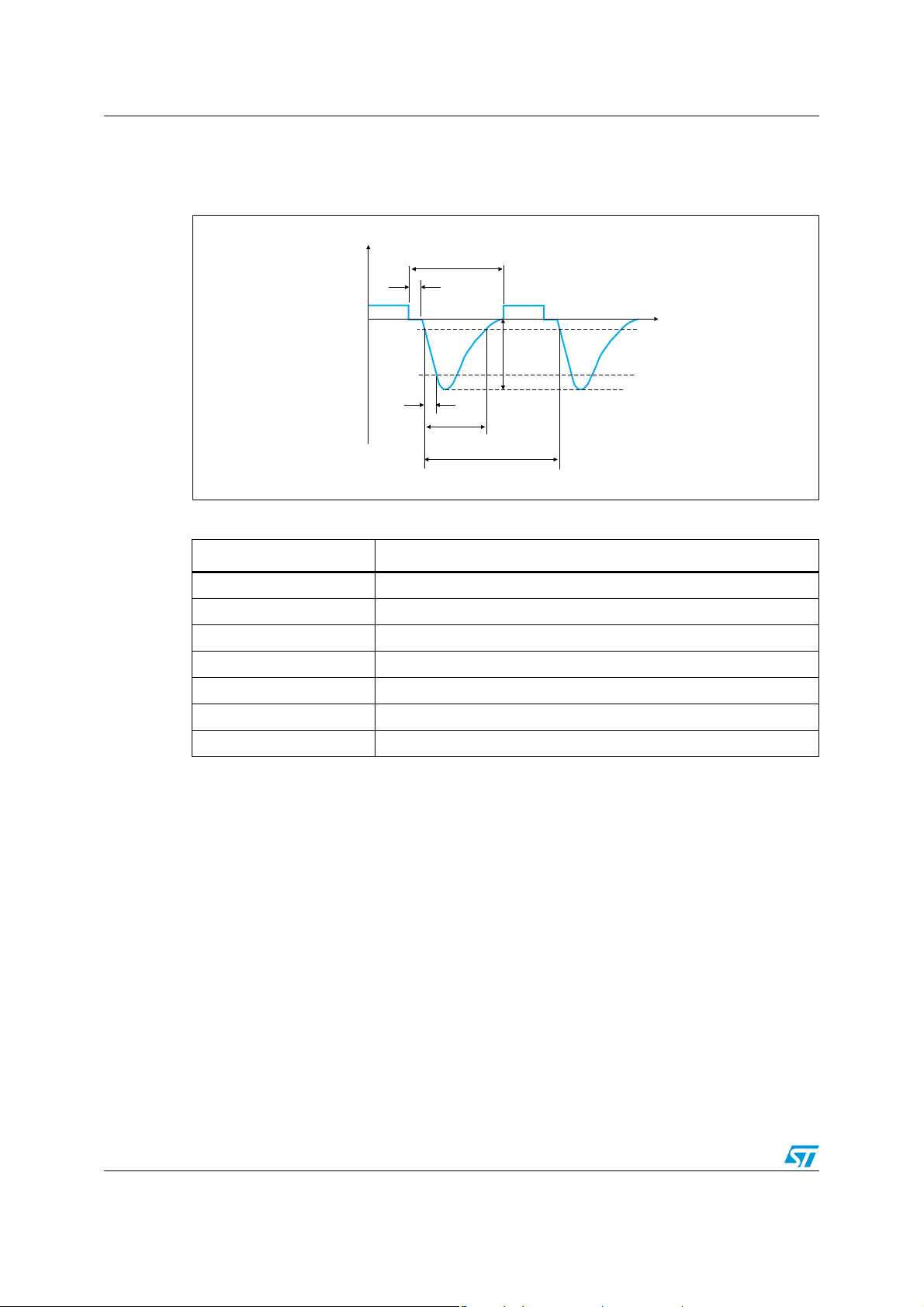

The most severe negative pulse is pulse 1 (Figure 3). It can reach -100 V during 2 ms and a

peak current of 10 A in shorted conditions.

Figure 3. ISO 7637-2 pulse 1

t

U

t

3

2

0.1xU

S

U

0.9xU

S

t

r

t

d

t

1

Table 3. Parameter values for test pulse 1

S

t

Parameter 12 V system

U

s

R

i

t

d

t

r

(1)

t

1

t

2

(2)

t

3

1. Period t1 shall be chosen such that the DUT is correctly initialized before the application of the next pulse.

2. Period t3 is the smallest possible time necessary between this disconnection of the supply source and the

application of the pulse.

-75 V to -100 V

10 Ω

2 ms

1 µs

0.5 s to 5 s

200 ms

<100 µs

4/15 Doc ID 018589 Rev 1

Page 5

AN3361 Definition of the electrical transients and tests

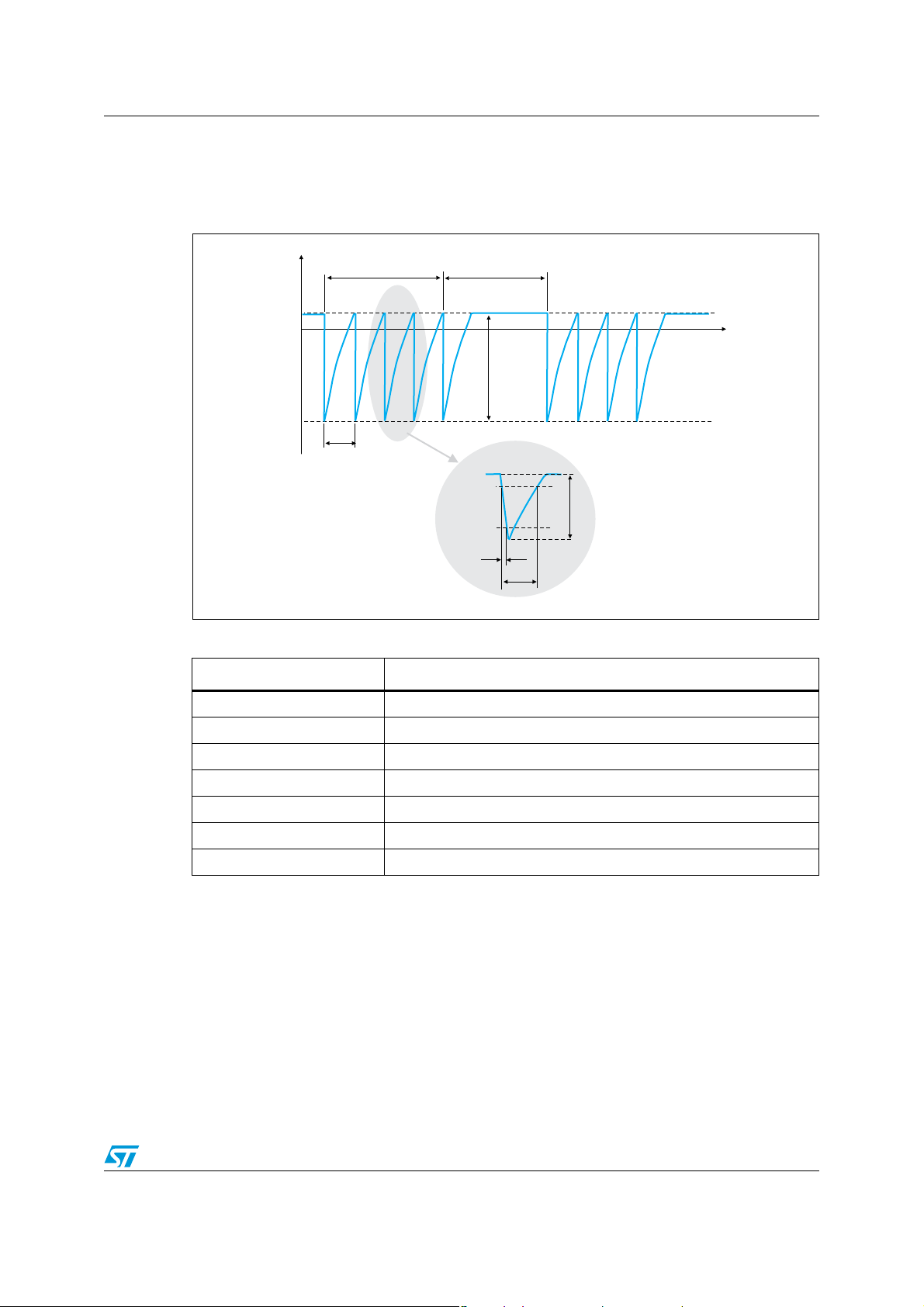

Pulse 3a (Figure 4) is specified at -150 V but with 50 Ω series resistor and 100 ns duration

which is far less energy than for pulse 1. This means that, if the Schottky diode specification

is compliant with pulse 1, pulse 3a will be covered as well.

Figure 4. ISO 7637-2 pulse 3a

0.1xU

0.9xU

t

5

U

S

S

S

t

r

t

U

t

4

1

t

Table 4. Parameter values for test pulse 3a

Parameter 12 V system

U

s

R

i

t

d

t

r

t

1

t

4

t

5

U

d

-112 V to -150 V

t

S

50 Ω

0.1 µs

5 ns

100 µs

10 ms

90 ms

Doc ID 018589 Rev 1 5/15

Page 6

Choosing the appropriate Schottky diode AN3361

2 Choosing the appropriate Schottky diode

Schottky diode choice for reverse battery protection is determined by the electronic module

normal operating current on the one hand, and the need to pass the ISO 7637-2 pulse tests

on the other. Each module has its own normal operating current, which is defined by its

characteristics. So here we will consider only the method to choose an appropriate Schottky

diode to meet the ISO 7637-2 requirements.

2.1 Load-dump surge compatibility criteria

The first criterion is the compatibility between surge current and I

datasheet.

2.1.1 Load-dump peak current calculation

Figure 6 shows the current shape through the Schottky diode during a load-dump surge

according to the schematic described in Figure 5.

Figure 5. Pulse 5b surge test schematic

Schottky diode

I

R = 0.5iΩ

Pulse 5b:

V =13.5 V

bat

V = [24-48 V]

g

t = 300 ms

ps

specified in the diode

FSM

p

V

F

V

cl

Electronic module

6/15 Doc ID 018589 Rev 1

Page 7

AN3361 Choosing the appropriate Schottky diode

I

p

10.0 V/div

-30.20 V ofst

10.0 V/div

-30.00 V ofst

50.0 ms/div

50.0 kS 100 kS/s

Stop 16.8 V

Edge Positive

Figure 6. Current and voltage at the transient suppressor side (with a 24 V Vbr

clamping device and V

max

C1

= 36V)

g

V

cl

C2

Measure

value

status

10.0 V/div

-30.20 V ofst

max

P1:max(C1)

10.0 V/div

-30.00 V ofst

29.9 V

I

p

P2:max(C2)

35.9 V

P3:mean(F1) P4:rise@Iv(C3) P5:--- P6:---

50.0 ms/div

50.0 kS 100 kS/s

The equations below apply to the circuit shown in Figure 5.

Equation 1

VVV +=

batgsurge

IR)(IVVV ++=

pipFclsurge

·IRV)(IV +=

pdT0pF

The calculation of V

and Rd is explained in the application note AN604: “Calculation of

T0

conduction losses in a power rectifier”. Values are provided in the datasheets.

Then:

Stop 16.8 V

Edge Positive

Equation 2

VVV

−−

I

=

p

In the example presented in Figure 6 the generator surge voltage (V

T0clsurge

RR

+

id

) is 36 V, its internal

g

series resistor is 0.5 Ω, the battery voltage is 12 V and the protection voltage clamping level

of the protection device is 29.9 V. The diode dynamic resistor R

As V

T0

<< V

- Vcl the above relation can be simplified to:

surge

is 0.009 Ω.

d

Equation 3

29.912)(36

I

=

p

So the peak current I

−+

0.50.009

+

is equal to 35.56 A.

p

Doc ID 018589 Rev 1 7/15

Page 8

Choosing the appropriate Schottky diode AN3361

2.1.2 Method to compare Ip and I

I

is the maximum peak current of a sinusoidal waveform pulse during 10 ms. The load-

FSM

dump peak current can be approximated with a constant and an exponential waveform

pulse. To compare both peak currents, I

calculate the equivalent sinusoidal surface of the exponential waveform in order to deduce

the equivalent pulse duration.

The surge load-dump surface is modeled using the following equation:

Equation 4

t

0

Where I

0

Equation 5

t

sin

=

∫

0

The equivalent pulse duration is t

Equation 6

SS =

surgesin

∞

1

+=

0surge

−−

)1t(t

τ

0

∫∫

t

1

dt·eI·dtIS

is the maximum load-dump current. The equivalent sinusoidal waveform is:

2ð

2·t

)dtt

sin

sin

·sin(IS

0sin

FSM

FSM

, since:

and load-dump peak current, one method is to

Then:

Equation 7

π

t

=

2

Where

Equation 8

t1t

−

I

0

2

=τ

ln2

)t(

+τ

1sin

8/15 Doc ID 018589 Rev 1

Page 9

AN3361 Choosing the appropriate Schottky diode

Figure 7. Equivalent sinusoidal surface of clamped load-dump surge surface

I0

2.1.3 I

t1

I (t)

surge

I

(ti)

sin

40

30

I0/2

20

10

t

sin

0

0 0.1 0.2

tI0/2

t, ti

In our example the equivalent sinusoidal waveform pulse time duration t

value versus pulse time

FSM

Using the equations:

Equation 9

4

I

x t = C

3

I

x t = C

2

I

x t = C

for t

ste

ste

ste

sin

for 20 µs <t

for t

sin

>10 ms

sin

<20 ms

>10 ms

In the example for the STPS20L60C in Figure 7, as the pulse duration t

following law from Equation 9 can be used:

is 140 ms.

sin

is 140 ms, the

sin

Equation 10

4

FSM@ tsin

10·10ItI

×=×

FSMsin

34

−

Where:

I

is the non repetitive forward surge current given in the data sheet.

FSM

I

FSM @ t sin

For the example of Figure 6, the I

is the non repetitive forward surge current for a pulse duration t

= 220 A

FSM

Equation 11

−

43

I10·10

×

I

FSM@140ms

I

FSM@140ms

4

=

4

=

140·10

The equivalent peak current is I

The peak current delivered by the test system is I

I

@140 ms. So the STPS20L60C meets the ISO 7637-2 requirements.

FSM

FSM

t

sin

−

43

22010·10

×

3

−

@140 ms = 113.73 A.

FSM

= 35.56 A and it is less than

p

Doc ID 018589 Rev 1 9/15

sin

.

Page 10

Choosing the appropriate Schottky diode AN3361

Ta bl e 5 gives a matrix of which Schottky diode is compatible with load-dump surge (pulse

5b) depending on surge voltage level and with the conditions: V

= 13.5 V, Ri = 0.5 Ω and

bat

with load-dump surge duration of 300 ms.

Table 5. Which Schottky diodes are good for which load-dump surge level

Pulse 5b load-dump surge voltage (Vg) 2430364248

STPS160AY Yes

STPS3L60SY Yes Yes

STPS20L60CGY Yes Yes Yes Yes Yes

STPS1H100UY Yes

STPS2H100UY Yes Yes

STPS5H100BY Yes Yes Yes

STPS8H100GY Yes Yes Yes Yes Yes

2.2 Most severe negative surge compatibility criteria

Now if we consider pulse 1 as shown in Figure 3, things are different since the Schottky

diode is reverse polarized.

For instance, the voltage applied on a diode with a maximum repetitive reverse voltage

(V

) of 100 V will be VR = -113.5 V (VR = V

RRM

+ Vc due to the charge of the capacitor).

surge

Figure 8. Example of application with pulse 1 using an STPS5H100BY

STPS5H100BY

I

Pulse 1:

V = 13.5 V

bat

V = -100

surge

R = 10

t = 2 ms

Ω

i

p

V

RRM

Electronic module

V = 13.5 V

c

10/15 Doc ID 018589 Rev 1

Page 11

AN3361 Choosing the appropriate Schottky diode

A Pspice simulation shows the power involved in an STPS5H100BY, for example, as shown

in Figure 10, according to the schematic of Figure 9.

Figure 9. Pspice model of Pulse 1 surge test using STPS5H100BY Schottky diode

STPS5H100 Pspice Model

R1

10

V1 = 0

V2 = -100

TD1 = 0.1 m

TC1 = 400 n

TD2 = 0.1004 m

TC2 = 0.85 m

V2

ISO7637-2 Pulse 1 Pspice Model

Figure 10. Pspice simulation result

W

200

2

100

W

W

0

Diode dissipation power

D3

D5

V3

-

100

0

+

C1

1000 u

I = 13.5

C

Probe Cursor

A1 = 103.192 u, 118.574

A2 = 222.340 u, 1.3069

dif = -119.149 u, 117.267

I1

1

>

SEL>

W

-100

120V

2

1

V (I 1: +, D3 : C)* I ( V3: +)

2. 0A

Diode reverse voltage

80V

40V

1. 0A

>

0V

>

0A

0s 0. 1ms 0. 2ms 0. 3ms 0. 4ms 0. 5ms 0. 6ms 0. 7ms 0. 8ms 0.

1

V (I 1: +, D3 : C)

Diode reverse current

2 I(V3)

9ms 1. 0ms

Time

The blue curve in Figure 10 is the power dissipated in the diode avalanche. It is a triangular

shape curve with a peak power at 118 W during 120 µs. This waveform is equivalent to a

59 W square shape pulse of 120 µs duration.

In order to evaluate if the diode is able to dissipate this energy in the avalanche, two

elements are relevant:

● P

● P

(1 µs, Tj = 25° C) is the repetitive peak avalanche power

ARM

ARM(Tp

)/ P

(1 µs, Tj = 25 °C) curve Figure 11.

ARM

Doc ID 018589 Rev 1 11/15

Page 12

Choosing the appropriate Schottky diode AN3361

In the example, we have selected the STPS5H100BY where:

P

(1 µs, Tj = 25 °C) = 7200 W.

ARM

The derating curve Figure 11 shows the equivalent avalanche power the STPS5H100BY is

able to dissipate is 0.035 · P

(1 µs, Tj = 25 °C) = 252 W

ARM

Therefore in this example the STPS5H100BY meets the ISO 7637-2 requirements and

ensures a good reverse battery protection.

Figure 11. Normalized avalanche power derating versus pulse duration for

STPS5H100BY

P(t)

ARM p

P (1µs)

ARM

1

0.1

0.035

0.01

t (µs)

0.001

0.10.01 1

10 100

120 µs

p

1000

Note: The derating curve for STPS5H100BY can be found as Figure 3 in the datasheet for this

device.

Ta bl e 6 indicates which Schottky diode can withstand Pulse 1 of ISO 7637-2 standard.

Table 6. Compliance of Schottky diodes with ISO 7637-2 Pulse 1

Pulse 1 surge voltage (V) Vs = -100 V

STPS2H100UY Yes

STPS5H100BY Yes

STPS8H100GY Yes

Ta bl e 6 shows that only a few Schottky diodes can handle this constraint.

12/15 Doc ID 018589 Rev 1

Page 13

AN3361 Conclusion

3 Conclusion

Protecting automotive electronic modules from polarity inversion due to poor battery

handling and load-dump surge during battery disconnection while the alternator is still

charging usually involves the use of diodes, especially Schottky diodes rather than bipolar

ones because of their better performance in direct conduction. The choice must consider

the worst-case surge conditions of ISO 7637-2 which are pulses 1 and 5b.

Usually Schottky diodes with a breakdown voltage of 150 V are preferred for this application.

This article shows that a breakdown voltage of 100 V may be selected to withstand

avalanche mode during the negative pulse 1 test (starting from a 2 A Schottky type). This

results in the saving of power during direct conduction.

Note: ST parts numbers listed in this application note were given as examples and are not an

exhaustive list. Please contact your sales or marketing representative for more automotive

grade rectifier devices.

Doc ID 018589 Rev 1 13/15

Page 14

Revision history AN3361

4 Revision history

Table 7. Document revision history

Date Revision Changes

09-Sep-2011 1 Initial release.

14/15 Doc ID 018589 Rev 1

Page 15

AN3361

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY TWO AUTHORIZED ST REPRESENTATIVES, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 018589 Rev 1 15/15

Loading...

Loading...