Page 1

AN3302

Application note

Monolithic power management for high definition ODD with

true shutdown, reset, and programmable step-up voltage

Introduction

Blu-ray disc players have grown rapidly in popularity due to the increasing availability of

digital services and high definition digital media content.

This application note describes how to use STODDO1, a complete power management for

BIu-ray disc players, based on high density optical storage devices. It integrates two stepdown converters and one step-up.

The step-down converters are optimized for powering Iow-voltage digital core, up to 0.8 A, in

ODD applications and, generally, to replace a high current linear solution when the power

dissipation may cause an overheating of the application environment.

The step-up provides the needed voltage for supplying the blue laser in mobile applications

where only 5 V is available. The output voltage is programmable, by using S-wire protocol, in

the range of 6.5 V to 14 V, with a current capability of 0.7 A.

Figure 1. Blu-ray disc player power management architecture based on STODD01

BLUE Laser Driver

BLUE Laser Driver

6 to 12 V

6 to 12 V

Reset

DSP

DSP

DRAM

DRAM

Flash

Flash

Motors

Motors

The integrated low R

Reset

1.2 V

1.2 V

3.3 V

3.3 V

5 V

5 V

, for N-channel and P-channel MOSFET switches, contributes to

DSon

Reset IC

Reset IC

Step Down

Step Down

ADJ 700 mA

ADJ 700 mA

Step Down

Step Down

3.3 V 700 mA

3.3 V 700 mA

Motor

Motor

Control IC

Control IC

5 V

5 V

Step Up

Step Up

ADJ 800mA

ADJ 800mA

STODD01

STODD01

5 V

5 V

ATA Connector with

ATA Connector with

AM07854v1

AM07854v1

Power

Power

obtaining high efficiency.

The enable function for the step-up section, and reset function for monitoring the input

voltage, make the device particularly suitable for optical storage applications.

The high switching frequency (1.2 MHz typ.) allows the use of tiny surface-mounted

components. Furthermore, a low output ripple is guaranteed by the current mode PWM

topology and by the use of X7R or X5R and low ESR SMD ceramic capacitors.

The device includes soft-start control, thermal shutdown, and peak current limit, to prevent

damage due to accidental overload.

January 2011 Doc ID 18163 Rev 1 1/13

www.st.com

Page 2

Contents AN3302

Contents

1 Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Recommended PCB Iayout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Layout considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Programming the output voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 S-wire protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Inductor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Input and output capacitor selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2/13 Doc ID 18163 Rev 1

Page 3

AN3302 Block diagram

1 Block diagram

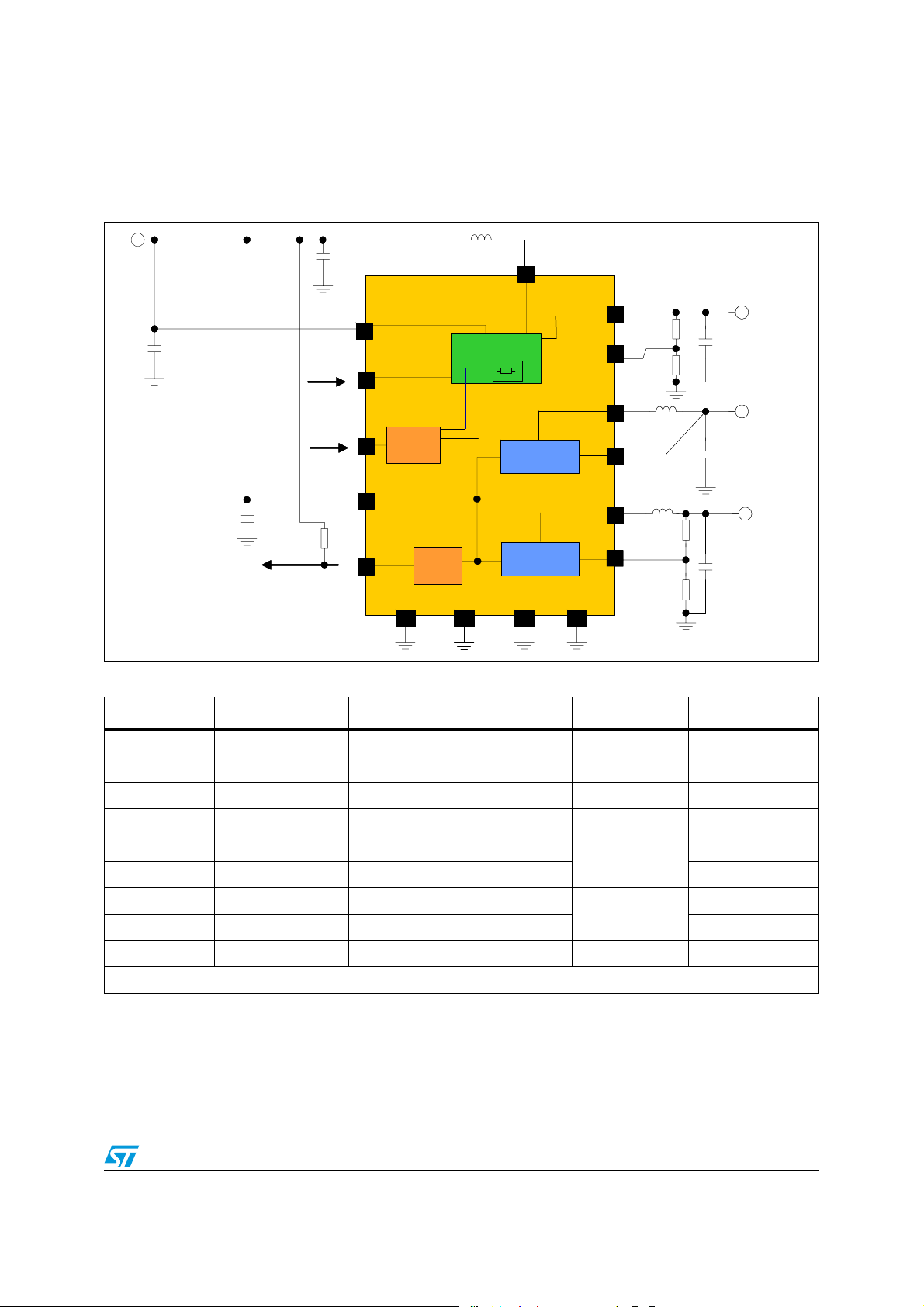

Figure 2. Block diagram and reference circuit

L1

C1

EN

EN

TX

TX

C1

R5

R5

STODD01

STODD01

V

V

IN_A

IN_A

S-Wire

S-Wire

V

V

IN_P

IN_P

Reset

Reset

Reset

Reset

GND

GND

V

V

IN

IN

C3

C3

C2

C2

Reset

Reset

L1

SW1

SW1

Step Up

Step Up

Step Down

Step Down

Step Down

Step Down

GNDGND

GNDGND

GND

GND

Out1

Out1

FB1

FB1

SW2

SW2

FB2

FB2

SW3

SW3

FB3

FB3

L2

L2

L3

L3

R1

R1

R2

R2

R3

R3

R4

R4

V

V

OUT1

OUT1

C4

C4

6.5V-14V

6.5V-14V

V

V

OUT2

OUT2

3.3V

3.3V

C5

C5

V

V

OUT3

OUT3

0.8V-0.94*Vin

0.8V-0.94*Vin

C6

C6

AM07856v1

AM07856v1

Table 1. List of external components

(1)

Component Manufacturer Part number Value Size

C1, C2, C3 Murata GRM21BR61A1O6KE19L 10 µF 0805

C4, C5, C6 Murata GRM32ER61C226KE2OL 22 µF 1210

L1 Coilcraft LPS6225-472MLB 4.7 µH 6 x 6 x 2.5

L2, L3 Coilcraft LPS4O18-332MLB 3.3 µH 4.1 x 4.1 x 1.8

R1 33 k

R2 3.3 k

R3 27 k

R4 47 k

R5 100 k

Ω (V

Ω (V

= 8.8 V)

OUT1

(2)

Ω 0603

= 1.2 V)

OUT3

(3)

Ω 0603

Ω

(4)

0603

0603

0603

If the S-wire function Is not used, the TX pin must be connected to GND. List of external components

1. Components listed above refer to a typical application. Operation of the STODD01 is not limited to the choice of these

external components.

2. R

and R2 are calculated according to the following formula: R1 = R2 (V

1

It is recommended to use resistors with values in the range of 1 kΩ to 50 kΩ.

and R4 are calculated according to the following formula: R3 = R4 (V

3. R

3

It is recommended to use resistors with values in the range of 1 kΩ to 50 kΩ.

4. It is recommended to use resistors with values in the range of 100 kΩ to 1 MΩ.

OUT1

OUT3

/ V

/ V

FB1

FB3

-1)

-1)

(1)

Doc ID 18163 Rev 1 3/13

Page 4

Recommended PCB Iayout AN3302

2 Recommended PCB Iayout

Figure 3. Recommended PCB layout

2.1 Layout considerations

The layout is an important design step for all switching power supplies due to the high

switching frequency and peak current. If the layout is not performed carefully, important

parameters such as efficiency and output voltage ripple may be out of specification.

Short, wide traces must be implemented for the main current and for power ground paths.

The input capacitor must be placed as close as possible to the IO pins as well as the

inductor and output capacitor.

The feedback pin (FB) connection to the external resistor divider is a high impedance node,

so interference can be minimized by placing the routing of the feedback node as far as

possible from the high current paths. To reduce pick-up noise, the resistor divider must be

placed very close to the device.

A common ground node minimizes ground noise. The exposed pad of the package must be

connected to the common ground node.

AM07857v1AM07857v1

4/13 Doc ID 18163 Rev 1

Page 5

AN3302 Recommended PCB Iayout

2.2 Programming the output voltage

The output voltage for the step-up (ch1) can be adjusted from 6.5 V up to 14 V by

connecting a resistor divider between the V

must be connected to the FB1 pin, as shown in

The resistor divider should be chosen according to the following equation:

Equation 1

and GND, the middle point of the divider

OUT1

Figure 2.

⎞

⎛

R

1

⎟

⎜

VV

+⋅= 1

1FB1OUT

⎟

⎜

R

2

⎠

⎝

where V

is programmable, by using S-wire protocol, in the range of 0.8 V to 1.25 V (see

FB1

Figure 11).

It is recommended to use a resistor with a value in the range of 1 k

Ω to 50 kΩ. Lower values

may also be suitable, but increase current consumption.

For ch2 the device integrates the resistor divider needed to set the correct output voltage

(3.3 V). This allows to save 2 external components. The FB2 pin must be connected directly

to V

OUT2

.

The output voltage for ch3 can be adjusted from 0.8 V up to 94 % of the input voltage value

by connecting a resistor divider between the V

must be connected to the FB3 pin, as shown in

and GND, the middle point of the divider

OUT3

Figure 2.

The resistor divider should be chosen according to the following equation:

Equation 2

⎛

⎞

R

3

⎜

⎟

VV

+⋅= 1

3FB3OUT

⎜

⎟

R

4

⎝

⎠

It is recommended to use a resistor with a value in the range of 1 kΩ to 50 kΩ. Lower values

may also be suitable, but increase current consumption.

Doc ID 18163 Rev 1 5/13

Page 6

Test results AN3302

3 Test results

Figure 4. Inrush current of step-up Figure 5. Enable startup time of step-up

VIN

VIN

VEN

VEN

VOUT

VOUT

STEP-UP

STEP-UP

IIN

IIN

Figure 6. Efficiency ch1 step-up Figure 7. Efficiency ch2-ch3 step-down

VEN

VEN

VOUT1

VOUT1

VOUT2

VOUT2

VOUT3

VOUT3

100

100

90

90

80

80

70

70

60

60

50

50

40

40

30

30

Efficiency [%]

Efficiency [%]

20

20

10

10

0

0

10 100 1000

10 100 1000

Figure 8. Step-down load transient OUT2 Figure 9. Step-down load transient OUT3

V

V

I

I

OUT2

OUT2

V

V

IN_A

IN_A

OUT2

OUT2

= V

= 5 V, VEN= 1.2 V

= V

= 5 V, VEN= 1.2 V

IN_P

IN_P

Step-down

Step-down

Step-down

Step-down

[mA]

[mA]

I

I

OUT

OUT

V

= 7 V

V

= 7 V

OUT

OUT

V

= 9.2 V

V

= 9.2 V

OUT

OUT

100

100

90

90

80

80

70

70

60

60

50

50

40

40

Efficiency [%]

Efficiency [%]

30

30

20

20

10

10

0

0

10 100 1000

10 100 1000

Step-down

Step-down

I

I

OUT3

OUT3

V

Step-down

V

Step-down

OUT3

OUT3

V

= V

V

= V

IN_A

IN_A

I

I

[mA]

[mA]

OUT

OUT

V

V

V

V

= 5 V, VEN= 5 V

= 5 V, VEN= 5 V

IN_P

IN_P

OUT

OUT

OUT

OUT

= 3.3 V

= 3.3 V

= 1.2 V

= 1.2 V

V

V

= V

IN_A

IN_P

= 100-700 mA, C

4.7 µH, L

= 5 V, VEN from 0 to 5 V, V

= L3 = 3.3 µH, T

2

IN1,2,3

= 10 µF, C

= T

rise

fall

OUT2

OUT1,2,3

= 1 µs

= 3.2 V, I

OUT2

= 22 µF, L1 =

= V

IN_A

= 100-700 mA, C

4.7 µH, L

6/13 Doc ID 18163 Rev 1

= 5 V, VEN from 0 to 5 V, V

IN_P

= L3 = 3.3 µH, T

2

IN1,2,3

= 10 µF, C

rise

= T

OUT3

OUT1,2,3

= 1 µs

fall

= 1.2 V, I

OUT3

= 22 µF, L1 =

Page 7

AN3302 Test results

3.1 S-wire protocol

The device implements an S-wire bus communication that uses one control signal coming

from the microprocessor to program the STODD01 output voltage (see

Figure 10. Wire connection

µP

µP

GND

GND

GND

GND

S-wire protocol allows to change the feedback voltage of the step-up section from 0.8 to

1.25 V, with steps of 15 mV. This feature allows complete and easy control of the laser diode

power during read and write operation.

Reset

Reset

EN

EN

TX

TX

Reset

Reset

EN

EN

TX

TX

GND

GND

Figure 10).

STODD01

STODD01

GND

GND

AM07858v1

AM07858v1

If this function isn't used, the TX pin must be connected to GND.

Table 2. Feedback one voltage level

S-wire pulses V

0 (Default Value) 0.800 11 0.965 22 1.130

1 0.815 12 0.980 23 1.145

2 0.830 13 0.995 24 1.160

3 0.845 14 1.010 25 1.175

4 0.860 15 1.025 26 1.190

5 0.875 16 1.040 27 1.205

6 0.890 17 1.055 28 1.220

7 0.905 18 1.070 29 1.235

8 0.920 19 1.085 30 1.250

9 0.935 20 1.100

10 0.950 21 1.115

(V) S-wire pulses V

FB1

(V) S-wire pulses V

FB1

The TX pin must be set to '1' after programming. If TX is programmed with 0 S-wire pulses,

the V

is programmed to 0.8 V.

FB1

FB1

(V)

Doc ID 18163 Rev 1 7/13

Page 8

Test results AN3302

Figure 11. Single wire programming

V

= no change or 0.8 V at startup

V

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

S-WIRE

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

= no change or 0.8 V at startup

FB1

FB1

V

= 0.8 V

V

= 0.8 V

FB1

FB1

= 0.815 V

= 0.815 V

V

V

FB1

FB1

V

2

2

32

32

32

32

32

32

32

32

32

32

23

23

3

3

2

2

2

2

3

3

432

432

4

4

4

4

4

4

4

4

4

4

4

4

4

4

V

FB1

FB1

5

5

5

5

5

5

5

5

5

5

5

5

5

5

= 0.83 V

= 0.83 V

V

V

6

6

67

67

67

67

67

67

6

6

6

6

= 0.845 V

= 0.845 V

FB1

FB1

V

V

7

7

7

7

= 0.86 V

= 0.86 V

FB1

FB1

V

V

FB1

FB1

8

8

8

8

8

8

8

8

= 0.875 V

= 0.875 V

V

V

= 0.89 V

= 0.89 V

FB1

FB1

V

V

FB1

FB1

9

9

9

9

10

10

9

9

10

10

= 0.905 V

= 0.905 V

= 0.92 V

= 0.92 V

V

V

FB1

FB1

V

V

FB1

FB1

11

11

12

12

= 0.935 V

= 0.935 V

V

V

= 0.95 V

= 0.95 V

FB1

FB1

1 3

1 3

V

28

28

29

29

30

30

V

FB1

FB1

= 1.25 V

= 1.25 V

AM07859v1

AM07859v1

Figure 12. Example of S-wire programming

VEN

VEN

5 PULSES SEQUENCE

5 PULSES SEQUENCE

DEFAULT VALUE

DEFAULT VALUE

VFB1

VFB1

30 PULSES SEQUENCE

30 PULSES SEQUENCE

8/13 Doc ID 18163 Rev 1

Page 9

AN3302 Test results

(

)

(

)

(

)

(

3.2 Inductor selection

The inductor is the key passive component for switching converters. The inductor selection

must take the boundary conditions in which the converter works into consideration; for the

buck, the maximum input voltage, and for the boost, the minimum input voltage. The critical

inductance values are then obtained according to the following formulas:

for the step-down:

Equation 3

VVV

−⋅

OUTMAX_INOUT

IFV

Δ⋅⋅

LSWMAX_IN

VVV

−⋅

MIN_INOUTMIN_IN

IFV

Δ⋅⋅

LSWOUT

and for the step-up:

Equation 4

L

L

MIN

MIN

=

=

where:

F

: switching frequency.

SW

ΔI

= the peak-to-peak inductor ripple current. As a rule of thumb, the peak-to-peak ripple

L

can be set at 20 % - 40 % of the output current for the step-down and can be set at 20 % 40 % of the input current for the step-up.

The peak current of the inductor must be calculated as:

Equation 5

VVV

−⋅

−−

()

8.0II

OUTDOWNSTEPPEAK

+=

OUTMAX_INOUT

LFV2

⋅⋅⋅

SWMAX_IN

Equation 6

⎛

I

⎜

=

UPSTEPPEAK

−−

⎜

V

⋅η

⎝

⎞

IV

⋅

OUTOUT

⎟

+

⎟

MIN_IN

⎠

VVV

−⋅

SWOUT

)

MIN_INOUTMIN_IN

LFV2

⋅⋅⋅

In addition to the inductance value, in order to avoid saturation, the maximum saturation

current of the inductor must be higher than that of the I

PEAK

.

3.3 Input and output capacitor selection

It is recommended to use ceramic capacitors with X5R or X7R dielectric and Iow ESR as

input and output capacitors in order to filter any disturbance present in the input line and to

obtain stable operation. The output capacitor is very important to satisfy the output voltage

ripple requirement.

Doc ID 18163 Rev 1 9/13

Page 10

Test results AN3302

(

The output voltage ripple (V

OUT_RIPPLE

) in continuous mode, for the step-down channel,

must be calculated as:

Equation 7

⎡

ESRIV

+⋅Δ=

⎢

LRIPPLE_OUT

⎣

⎤

1

⎥

FC8

⋅⋅

SWOUT

⎦

where: ΔIL is the ripple current and FSW is the switching frequency.

The output voltage ripple (V

OUT_RIPPLE

) in continuous mode, for the step-up channel, is:

Equation 8

⎡

ESRIV

+⋅=

⎢

OUTRIPPLE_OUT

⎣

VV

−

⎤

)

INOUT

⎥

FCV

⋅⋅

SWOUTOUT

⎦

where FSW is the switching frequency.

The use of ceramic capacitors with voltage ratings in the range higher than 1.5 times the

maximum input or output voltage is recommended.

Figure 13. Inductor with high I

current Figure 14. Inductor with low I

SAT

The inductors with low saturation current dramatically increase the inductor peak current

value; as shown, using an inductor with low saturation current, the inductor current is higher

than 2.4 A. With the LPS6225-472MLB inductor (I

1 A.

current

SAT

= 3 A) the peak current value is about

SAT

10/13 Doc ID 18163 Rev 1

Page 11

AN3302 Test results

p-Up

p-Up

p-Up

]

p-Up

]

Figure 15. Efficiency Figure 16. Inductor peak current

100

100

98

98

96

96

94

94

92

92

90

90

88

88

86

86

84

84

82

82

Efficiency [%]

Efficiency [%]

80

80

78

78

76

76

74

74

72

72

70

70

290 300 310 320 330 340 350 360 370 380 390 400 410

290 300 310 320 330 340 350 360 370 380 390 400 410

STODD01 Step-UP Section

STODD01 Step-UP Section

BOM Comparison on ST Board

BOM Comparison on ST Board

Ste

Ste

Efficiency vs Load Current

Efficiency vs Load Current

L1=4.7µH (LPS6225-472MLB)

L1=4.7µH (LPS6225-472MLB)

C

C

=22µF (GRM32ER61C226KE20L)

=22µF (GRM32ER61C226KE20L)

4

4

L1=4.7µH (low I

L1=4.7µH (low I

C

C

=22µF (LMK212BJ2226MD)

=22µF (LMK212BJ2226MD)

4

4

current)

current)

sat

sat

Load Current [mA]

Load Current [mA]

VCC = 4V

VCC = 4V

VCC =4.5V

VCC =4.5V

VCC = 5V

VCC = 5V

STODD01 Step-UP Section

STODD01 Step-UP Section

BOM Comparison on ST Board

BOM Comparison on ST Board

Ste

Ste

Inductor Curre nt vs Load Current

2600

2600

L1=4.7µH (low I

L1=4.7µH (low I

2400

2400

=22µF (LMK212BJ2226MD)

=22µF (LMK212BJ2226MD)

C

C

2200

2200

4

4

2000

2000

1800

1800

1600

1600

1400

1400

1200

1200

1000

1000

800

800

600

600

Indu ctor P eak C urrent [ mA

Indu ctor P eak C urrent [ mA

L1=4.7µH (LPS6225-472MLB)

L1=4.7µH (LPS6225-472MLB)

400

400

C

C

=22µF (GRM32ER61C226KE20L)

=22µF (GRM32ER61C226KE20L)

4

4

200

200

0

0

290 300 310 320 330 340 350 360 370 380 390 400 410

290 300 310 320 330 340 350 360 370 380 390 400 410

Inductor Curre nt vs Load Current

current )

current )

sat

sat

Load Current [mA]

Load Current [mA]

The resistance RDC and low saturation current of this inductor have a strong impact on

efficiency and output voltage ripple.

Figure 17. Capacitive change vs. voltage C4

GRM32ER61C226KE20L

Figure 18. Impedance/ESR characteristics C4

GRM32ER61C226KE20L

VCC = 4V

VCC = 4V

VCC =4.5V

VCC =4.5V

VCC = 5V

VCC = 5V

Output voltage ripple depends on output capacitor ESR and by increasing the voltage rating

of the capacitor, as suggested by the BOM list, the switching ripple is minimized.

Doc ID 18163 Rev 1 11/13

Page 12

Revision history AN3302

4 Revision history

Table 3. Document revision history

Date Revision Changes

03-Jan-2011 1 Initial release.

12/13 Doc ID 18163 Rev 1

Page 13

AN3302

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2011 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 18163 Rev 1 13/13

Loading...

Loading...