Page 1

AN3301

Application note

S-Touch® STMPE812A: a hardware and software guide

Introduction

The STMPE812A is a 4-wire resistive touchscreen controller with an integrated 4-bit port

expander. The touchscreen controller is designed to be fully autonomous, requiring only

minimal CPU intervention for sampling, filtering and preprocessing operations.

The purpose of this document is to highlight the guidelines and information complementary

to the datasheet that is necessary for a proper operation of the STMPE812A device in

applications.

The first part of the document highlights information on the hardware. This includes external

components/connectivity, power, PCB design and etc.

The second part of the document focuses on information in software in which programming

reference codes are shown. This part is to be used in conjunction with the STMPE812A

software library available in www.st.com.

December 2010 Doc ID 18161 Rev 1 1/35

www.st.com

Page 2

Contents AN3301

Contents

1 Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Typical application circuit and external components . . . . . . . . . . . . . . . . . 5

1.2 Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.2.1 Power sequence (fail safe) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Power modes transition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4 Touchscreen tracks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.1 Track resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5 Noise prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.6 Noise filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.7 PWM controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.8 ADC controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.9 GPIO output configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.9.1 Push-pull . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.9.2 Open drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1 Touchscreen controller acquisition modes . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1.1 Data acquisition by internal timer (ACQ_mode “00”) . . . . . . . . . . . . . . . 13

2.1.2 Data acquisition by ACQ command (ACQ_mode “01”) . . . . . . . . . . . . . 14

2.1.3 Data acquisition by host read control (ACQ_mode “10”) . . . . . . . . . . . . 14

2.2 Embedded data valid bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.3 Pen down interrupt mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4 TSC_DATA read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.5 Touchscreen controller sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.6 Programming guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.6.1 Touchscreen initialization and interrupt handling (pen down mode) . . . 19

2.6.2 Touchscreen initialization and interrupt handling (normal interrupt mode)

23

2.6.3 GPIO initialization and interrupt handling . . . . . . . . . . . . . . . . . . . . . . . 28

2.6.4 ADC initialization and interrupt handling . . . . . . . . . . . . . . . . . . . . . . . . 29

2.6.5 PWM initialization and interrupt handling . . . . . . . . . . . . . . . . . . . . . . . 32

3 Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2/35 Doc ID 18161 Rev 1

Page 3

AN3301 List of figures

List of figures

Figure 1. Typical application schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 2. Track resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 3. Noise prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Figure 4. PWM LED driving configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. GPIO push-pull configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6. GPIO open drain configuration (output low) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7. GPIO open drain configuration (output high) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 8. Data acquisition by internal timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Figure 9. Data acquisition by ACQ command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Figure 10. Data acquisition by host read command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Figure 11. TSC data register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 12. Touchscreen controller sampling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Doc ID 18161 Rev 1 3/35

Page 4

List of tables AN3301

List of tables

Table 1. Power modes vs. touchscreen/GPIO/Interrupt/PWM data . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2. Example of sampling time calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Table 3. Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4/35 Doc ID 18161 Rev 1

Page 5

AN3301 Hardware

1 Hardware

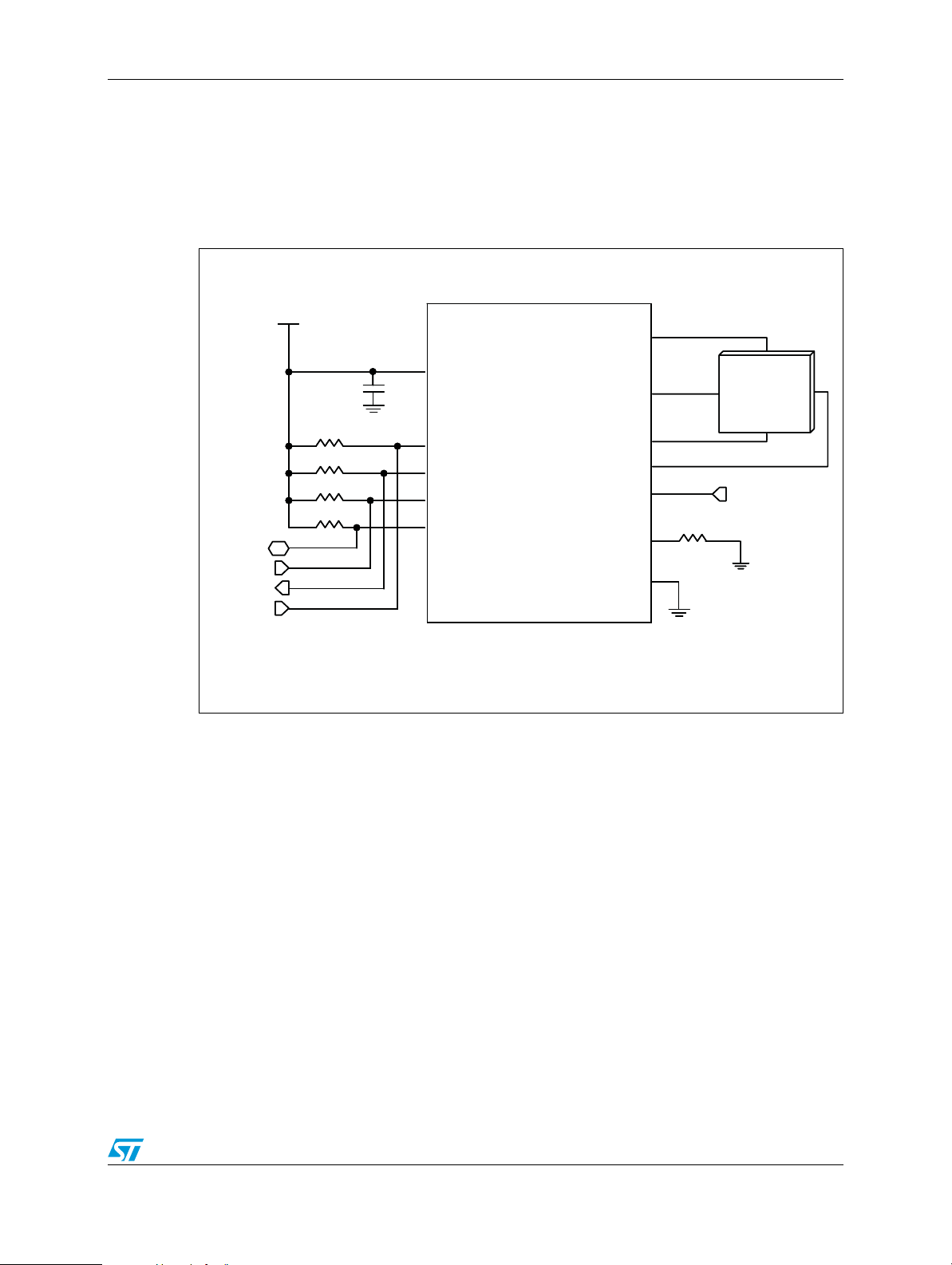

1.1 Typical application circuit and external components

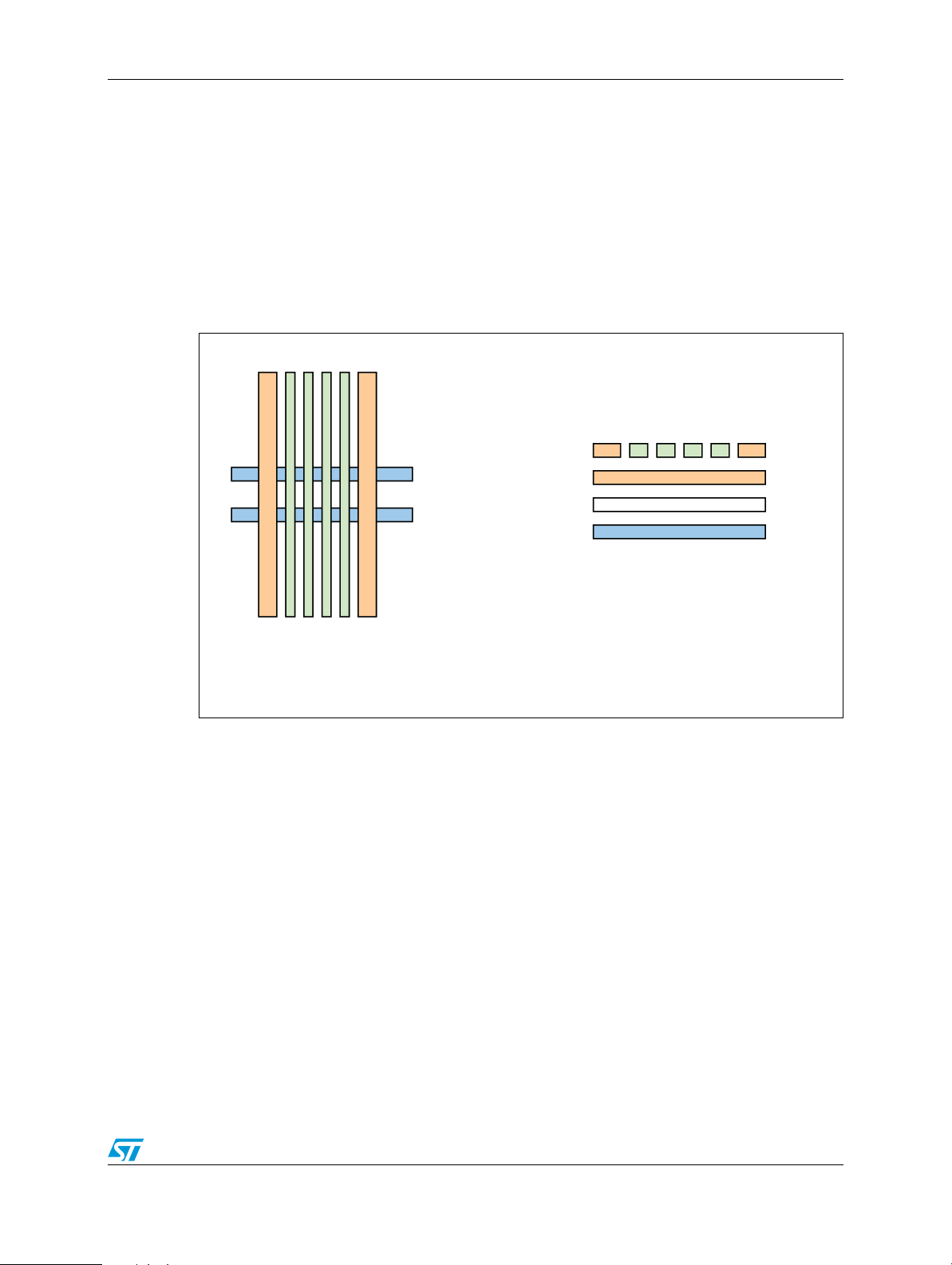

Figure 1. Typical application schematic

1.65V – 3.6V

1.65V – 3.6V

Y+

Y+

VCC

SDA

SDA

SCL

SCL

INT

INT

RESET

RESET

R1

R1

R2

R2

R3

R3

R4

R4

C1

C1

VCC

RESETN

RESETN

INT (P 2)

INT (P 2)

SCLK

SCLK

SDATA

SDATA

STMPE812A

X+

X+

Y-

Y-

X-

X-

(P1)ADC

(P1)ADC

(P0)ADDR

(P0)ADDR

GND

GND

R5

R5

4-wire

resistive

touchscreen

ADC input

ADC input

Note: 1 P0 pin is the I

2 P1 pin is configurable to GPIO/ADC/PWM (ADC Vin must be less than V

3 P2 pin is configurable to GPIO/INT

4 Assuming GPIO controlling RESET input is of open drain type

In a typical application, the following external components are required:

● R1: 2.2k-10kΩ pull up resistor at RESET

● R2: 2.2k-10kΩ pull up resistor at INT.

● R3: 2.2k-10kΩ pull up resistor at SCLK

● R4: 2.2k-10kΩ pull up resistor at SDATA

● R5: 2.2k-10kΩ pull up resistor at ADDR

● C1: 100 nF capacitor at V

2

C address bit upon power up or reset and is configurable to GPIO

)

CC

CC

Doc ID 18161 Rev 1 5/35

AM004192V1

Page 6

Hardware AN3301

1.2 Power supply

The implementation and layout of the power connection’s section is fundamental for the

correct operation of the STMPE812A touchscreen controller.

The STMPE812A device is equipped with a 12-bit ADC that is used during the touchscreen

controller and auxiliary voltage measurement operations.

The analog blocks require a clean and stable supply voltage in order to operate in optimum

performance. In the STMPE812, the analog blocks and the digital core are supplied by V

The operating V

with the increase in V

voltage range is 1.65 V to 3.6 V. Power consumption will be increased

CC

. The lowest power consumption is at VCC = 1.8 V.

CC

It is a good practice to connect a 0.1

pin.

1.2.1 Power sequence (fail safe)

All GPIOs and sense pins of STMPE812A are NOT fail safe. This means that it is necessary

to make sure that the V

inputs.

All other pins (SCL and SDA) are with fail safe structure. It is possible to turn on the pull-up

supply before V

CC

.

supply to STMPE812A is first turned before driving the GPIO

CC

µF filtering capacitor as close as possible to the V

CC

CC

.

6/35 Doc ID 18161 Rev 1

Page 7

AN3301 Hardware

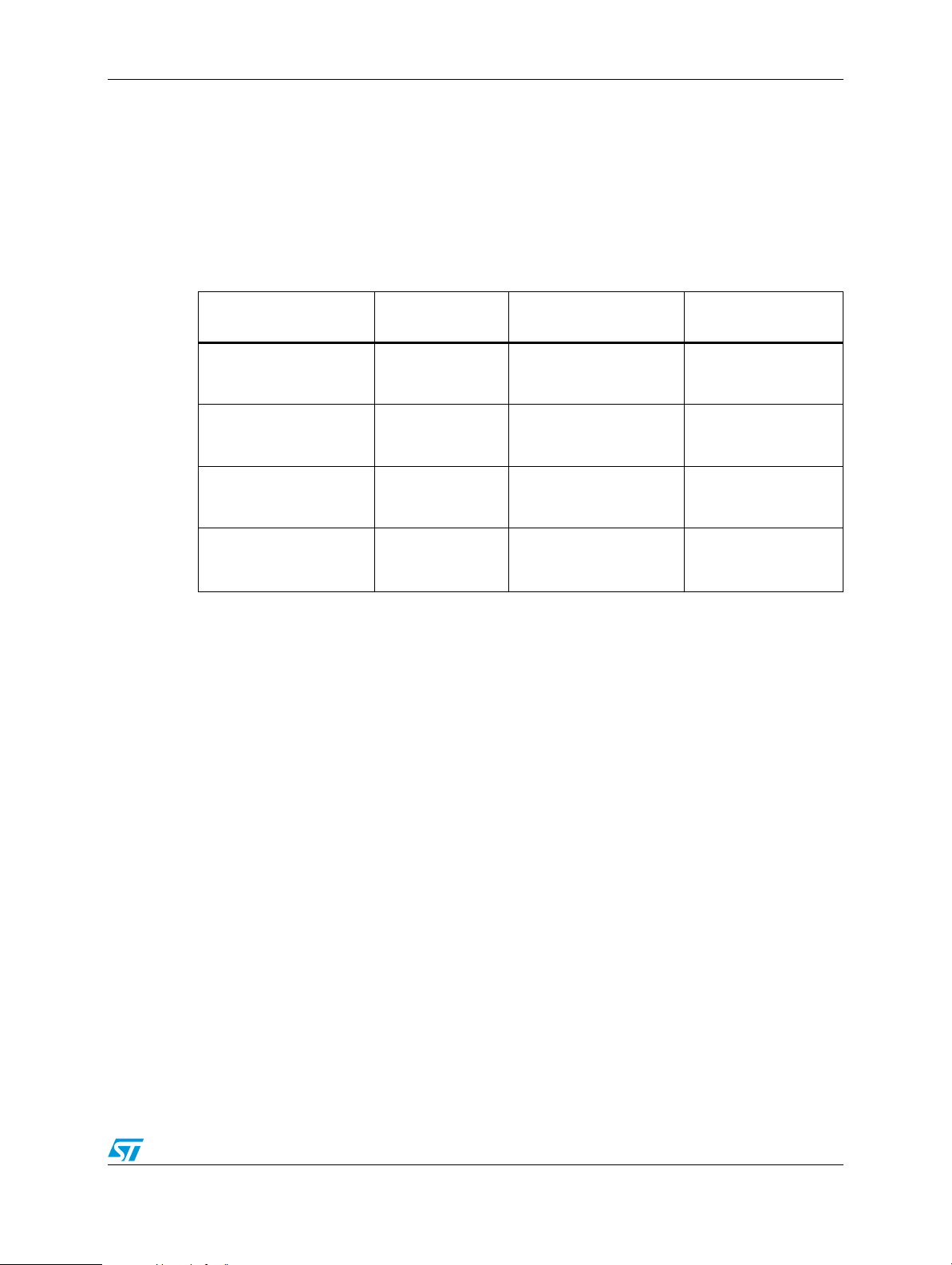

1.3 Power modes transition

The following table highlights the states of touchscreen FIFO, GPIO, Interrupt and PWM

during the various power modes:

– Active mode

– Hibernation mode

– Reset

Table 1. Power modes vs. touchscreen/GPIO/Interrupt/PWM data

Description Active mode Hibernation mode

Touchscreen FIFO data Active Sustained Cleared

GPIO configuration, pin

state and data

Interrupt configuration

and data

PWM configuration and

data

Active Sustained Cleared

Active Sustained Cleared

Active Sustained Cleared

Reset (HW, SW, POR

and General call)

Hibernation mode is entered automatically when ALL of the following listed activities are

met:

● Absent of I

● PWM disabled

● ADC disabled

● Absent of GPIO input transition for 10 ms

● Absent of touchsceen or pen down interrupt for 10 ms

2

C transaction with valid STMPE812A slave address for 10 ms

Doc ID 18161 Rev 1 7/35

Page 8

Hardware AN3301

1.4 Touchscreen tracks

The touchscreen tracks (X+, X-, Y+, Y-) are sensitive lines. Noise may be captured by the

touchscreen tracks if the line is too long and if placed nearby noisy lines, for example the

digital data lines and the I2C/SPI lines.

Although there is no recommended standard for track sizes, tracks that are too long reduce

the resolution of the touchscreen controller. As a matter of fact, long tracks introduce a

voltage drop during the measurement cycle at the terminal of the touchscreen panel.

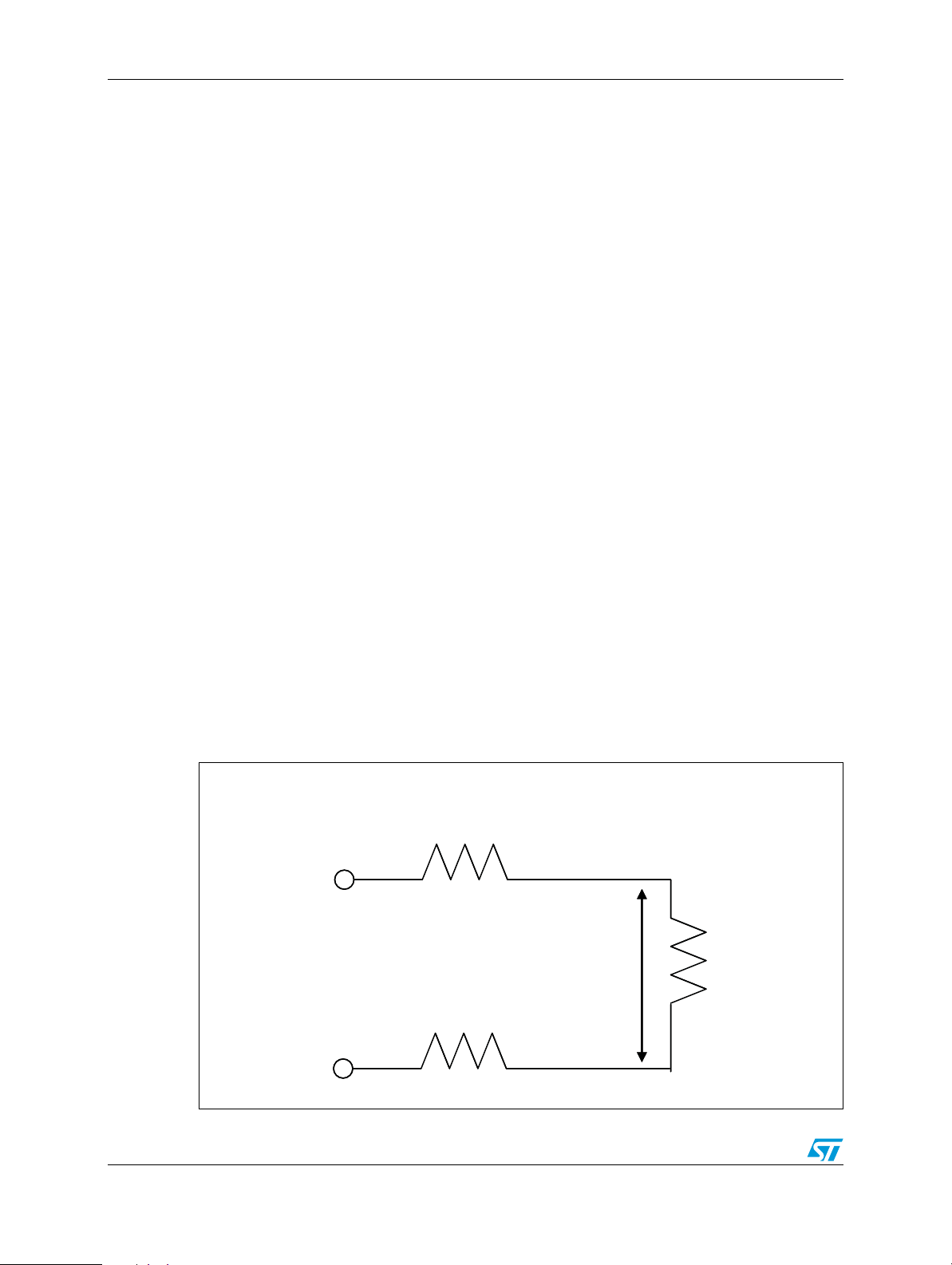

1.4.1 Track resistance

Any track has a certain amount of resistance, thus reducing the effective resolution of the

touchscreen controller.

During the measurement, the current flows to the touchscreen panel through the tracks. If

the resistance is too high, the voltage in the panel terminal is no longer at the same level as

VIO and GND.

From Figure 2 it can be seen that, during the measurement cycle, the device bias the

touchscreen panel with the VIO voltage. Due to the track resistance, the voltage at panel's

terminals is:

Equation 1

Vx V

IO

R

R1 R2 Rx++()⁄⋅=

x

Hence, the effective resolution is reduced by the same factor as well. The track resistance

may be reduced by designing the track as short as possible with a reasonable width.

Figure 2. Track resistance

Tr ack resistance, R1

VIO

To uch panel

Vx

Tr ack resistance, R2

GND

resistance, Rx

8/35 Doc ID 18161 Rev 1

AM004193V2

Page 9

AN3301 Hardware

s

1.5 Noise prevention

Noise may be coupled to the tracks connecting the touchscreen and this should be

prevented as much as possible.

Two practices may be applied:

1. Prevent the tracks overlap with other noisy signal tracks, such as I2C/SPI lines and

digital data lines. If the overlap is not avoidable, GND lines separation between

touchscreen lines and noisy lines is recommended (in more than 2 layers PCB).

2. Put GND shielding at each side of touchscreen tracks routing.

Figure 3. Noise prevention

TSC

TSC tracks

Top Layer

1.6 Noise filtering

A filtering capacitor can be placed on the touchscreen tracks to further suppress the noise.

In this case, the best location for the filtering capacitor is as near as possible to the

STMPE812A sense pins (X+, X-, Y+, Y-).

The values recommended for the filtering capacitor are:

1. 1-2 nF for an LCD less than 6 inches

2. 5-10 nF for an LCD bigger than 6 inches

Noisy tracks

Bottom Layer

GNDGND

GND

Oth er

Noisy lin e

AM004194V2

The Settling time and Touch detect delay registers must be set correctly to adapt to the

filtering capacitor, otherwise the touchscreen controller may not work properly. Additional

information is found in the STMPE812A datasheet.

Doc ID 18161 Rev 1 9/35

Page 10

Hardware AN3301

1.7 PWM controller

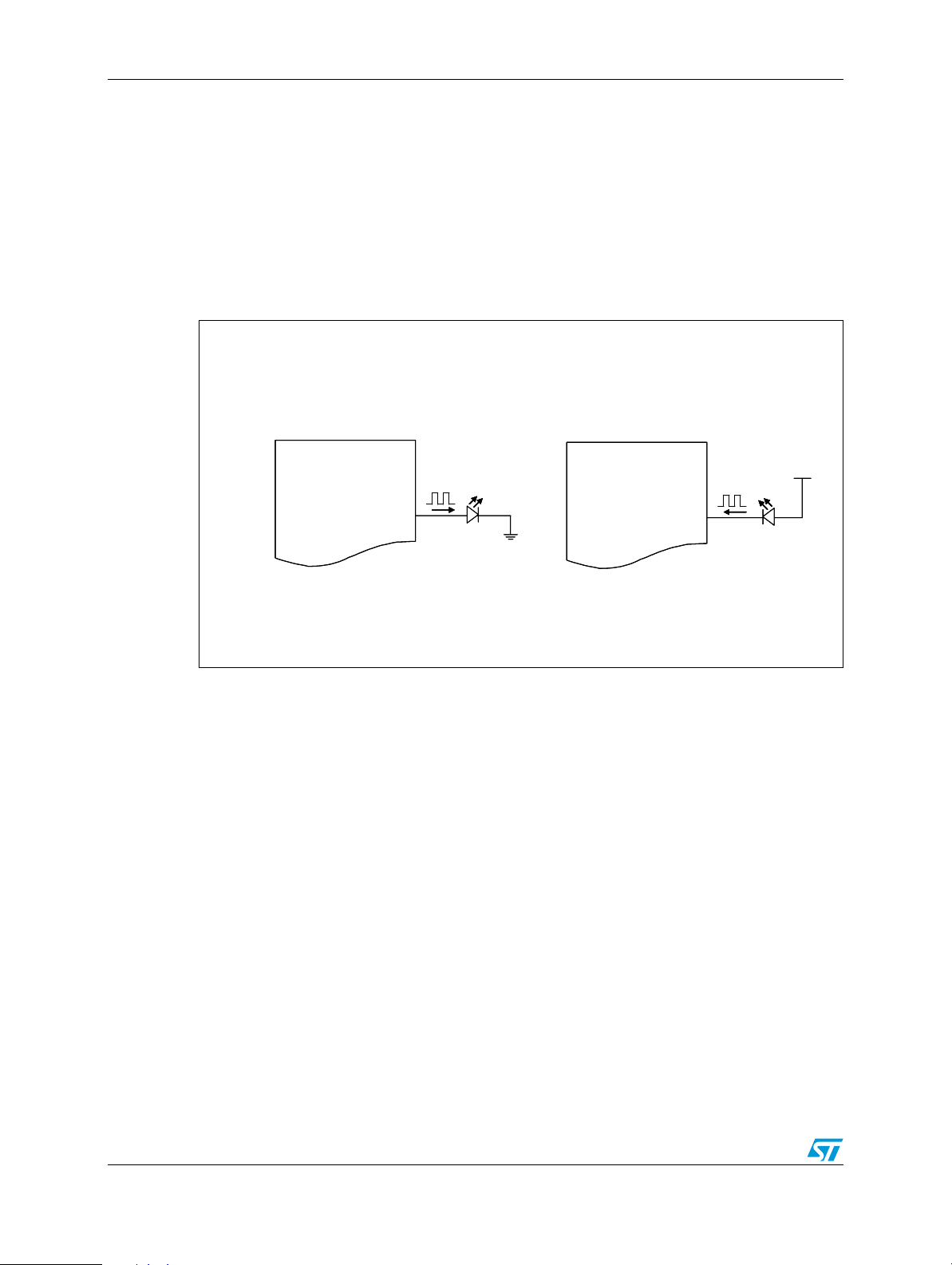

The STMPE812A is integrated with push-pull type of GPIO/PWM outputs. At VCC of 3.3 V,

the outputs are able to provide 8mA of sourcing (out of device) and 12mA of sinking (into

device) current capability. As such, STMPE812A is able to support LED driving in both

sourcing and sinking configuration.

Note: the PWM timing and duty cycle settings in datasheet are based on a LED sourcing

configuration. When used in sinking configuration, the inversion must be executed

accordingly.

Figure 4. PWM LED driving configurations

C u rrent s o urcing

configu ra tion (8 mA)

S TMPE8 12A

S TMPE8 12A

PWM(A1)

PWM(A1)

C u rrent s inking

configu ra tion (12mA)

S TMPE8 12A

S TMPE8 12A

PWM(A1)

PWM(A1)

VCC

VCC

AM004194V1

10/35 Doc ID 18161 Rev 1

Page 11

AN3301 Hardware

1.8 ADC controller

The STMPE812A is equipped with a 12-bit analog-to-digital converter (ADC). Besides the

use for ADC conversion during touchsceen controller operation, it is possible to be used as

general purpose ADC conversion for up to maximum two external auxiliary analog signals

feed through pins B2 and C2.

The touchscreen controller has the priority for the ADC conversion. Selection of conversion

of the two external auxiliary analog signals is programmed through Bit[0] of the ADC control

register (0x20).

Whenever the touchscreen data acquisition is initiated, the ADC conversion is triggered

automatically without needs to program the ADC control register. Writing ‘1’ to Bit[6] of ADC

Control register to initialize conversion for Touchscreen data is redundant and will result in

higher current consumption if ADC is in continuous capture mode.

The STMPE812A is integrated with an internal charge pump in order to ensure ADC

performance in low V

ADC control register in the device initialization phase whenever the V

Important: If V

CC

disabled to prevent possible reliability issue or permanent damage of the device.

condition. The internal charge pump should be turned on through

CC

is less than 2.5 V.

CC

is higher than 2.5 V, it is important to ensure the charge pump is

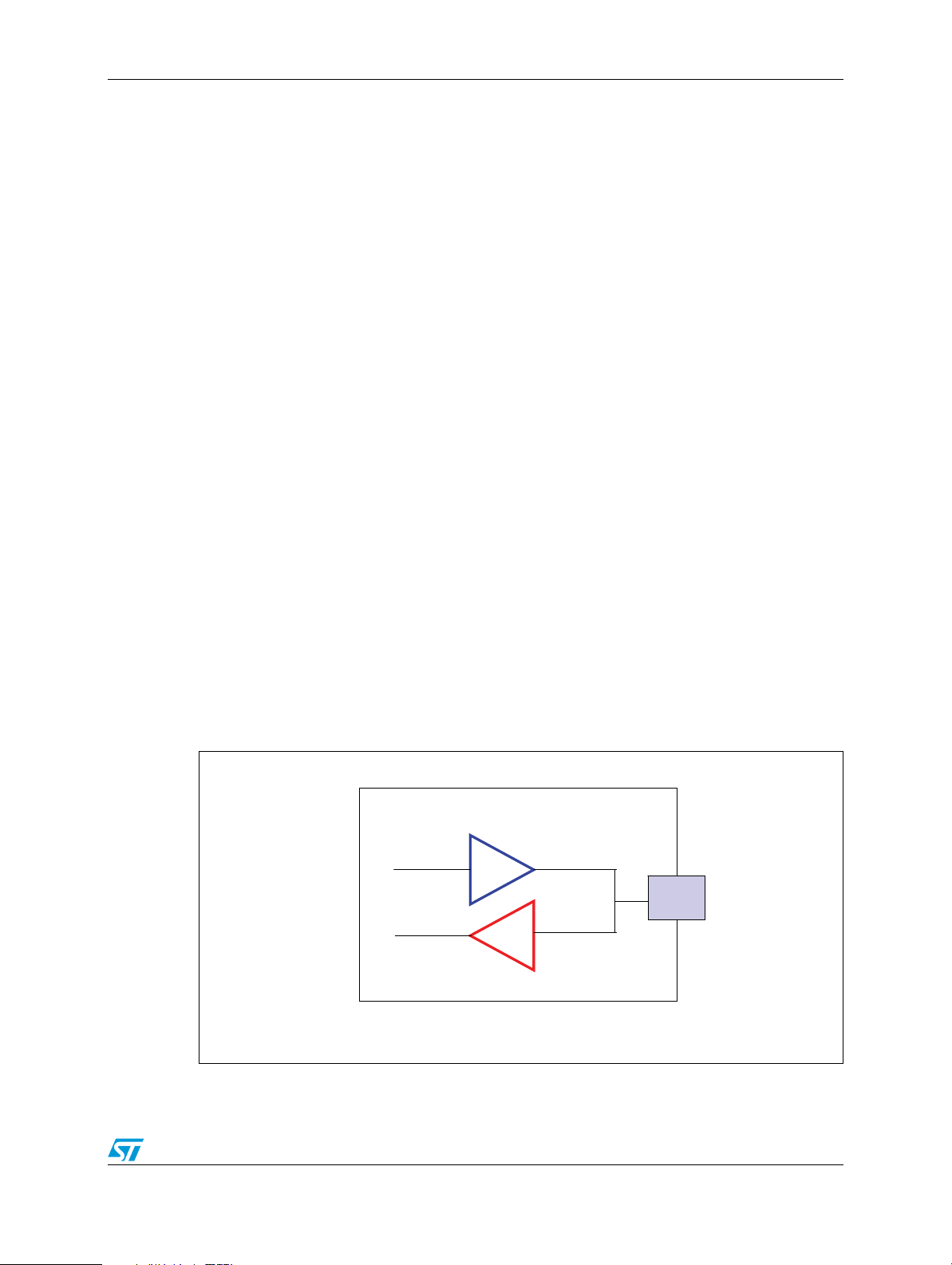

1.9 GPIO output configurations

The STMPE812A provides push-pull type of GPIO output. If open drain GPIO outputs are

required, it is configurable, with a tweak to the software programming routine. See Figure 5,

Figure 6 and Figure 7.

1.9.1 Push-pull

Set the GPIO to output state through PORT_FUNTION (0x04) register. Input path will be

disabled. Output path will be enabled in push-pull configuration.

Figure 5. GPIO push-pull configuration

OUTPUT

INPUT

STMPE812A

disabled

enabled

GPIOxGPIOx

AM004195V1

Doc ID 18161 Rev 1 11/35

Page 12

Hardware AN3301

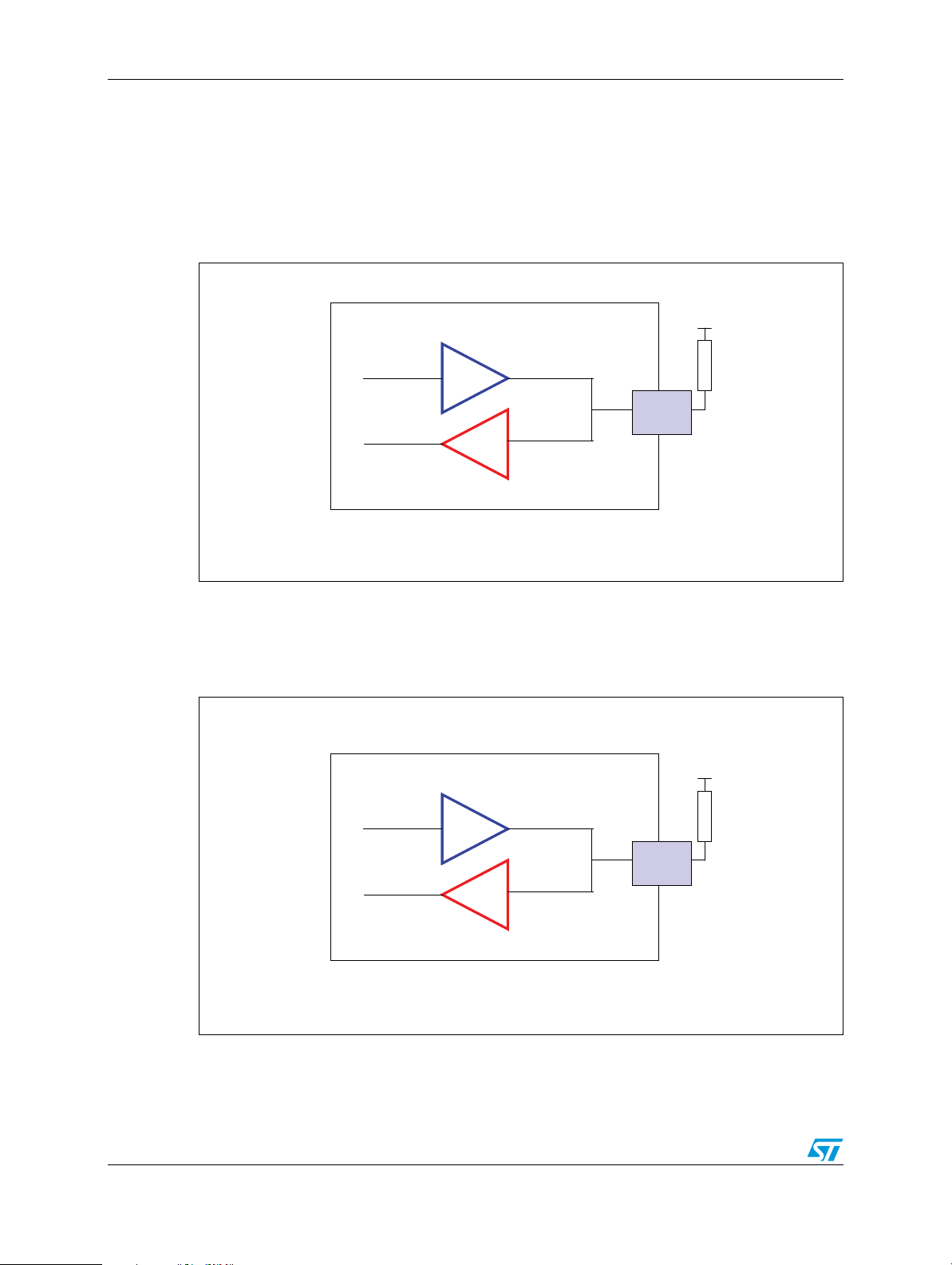

1.9.2 Open drain

GPIO output driven low by STMPE812A

Set the GPIO to output state through PORT_FUNTION (0x04) register. Input path is

disabled. Set the output state to LOW through GPIO_CLR_PIN (0x11) register. Output path

is enabled and pull GPIO pin LOW.

Figure 6. GPIO open drain configuration (output low)

STMPE812A

enable

OUTPUT

GPIOx

INPUT

disable

VCC

External

pull up

GPIOx

GPIO = LOW

AM004197V1

GPIO output pulled high by external pull up resistor

Set the GPIO to input state through PORT_FUNTION (0x04) register. Input path is enabled

and output path disabled. GPIO will be pulled high by external pull up resistor.

Figure 7. GPIO open drain configuration (output high)

STMPE812A

VCC

enable

OUTPUT

INPUT

disable

12/35 Doc ID 18161 Rev 1

GPIOx

GPIOx

GPIO = HIGH

External

pull up

AM004198V1

Page 13

AN3301 Software

2 Software

2.1 Touchscreen controller acquisition modes

2.1.1 Data acquisition by internal timer (ACQ_mode “00”)

In this mode, the system configures STMPE812A to sample at a predefined rate (e.g. 10ms)

through TSC_Sampling_Rate register (0x43). On detecting a touch, it starts the sensing

sequence and on completion of sampling (thus data available for reading), it interrupts the

Host. If the Host does not access the data by the time the next data is available, the old data

is overwritten.

Programming sequence:

1. Initialize touchscreen controller

2. Initialize interrupt

3. Wait for interrupt

4. Upon interrupt, read ISR

5. Upon touch data available, read touch data

Figure 8. Data acquisition by internal timer

Initialization No Touch Touched No Touch

Initializ ation

Agenda:

STMPE812A sens interrupt to Host

Host read ISR

Host read touch data when available

No Touch

Sampling

Sampling

Touched

Sampling

Sampling

Sampling

Sampling

AM004199V1

Doc ID 18161 Rev 1 13/35

Page 14

Software AN3301

2.1.2 Data acquisition by ACQ command (ACQ_mode “01”)

In this acquisition mode, the STMPE812A merely informs the system host on detecting a

touch. As and when sampling is desired, host issues an “ACQ” command that sets

STMPE812A into a complete sampling cycle. Host may read the data after a period of time,

or poll the interrupt status bit for data availability.

Programming sequence:

1. Initialize touchscreen controller

2. Initialize interrupt (Pen Down mode)

3. Wait for interrupt

4. Upon interrupt, issue ACQ command

5. Poll ACQ bit for data available

6. Upon touch data available, read touch data

Figure 9. Data acquisition by ACQ command

Initialization No Touch Touched No Touch

Initializ ation

Agenda:

STMPE812A sens touched interrupt to Host

Host issues ACQ command

Host polls ACQ bit or ISR for sampling completion

Host read touch data when available

No Touch

Sampling

Sampling

Touched

Sampling

Sampling

Sampling

Sampling

2.1.3 Data acquisition by host read control (ACQ_mode “10”)

The data acquisition by the host read control is the most bandwidth efficient method for

touchscreen interfaces. For 100 Hz sampling with 12-bit X, 12-bit Y, 8-bit Z, only one I

transaction (5 bytes data read) is required for every 10 ms. Inclusive of overheads, this

translates to approximately 100 bit time.

At 400 kHz I

A new sample is taken every time the host reads the previously sampled data. If host reads

the data late, the device simply stays longer in hibernation.

2

C speed, this is just 2.5% of total bandwidth.

AM004200V1

2

C

Note: It is necessary to counter check with the data valid bit for each data read.

14/35 Doc ID 18161 Rev 1

Page 15

AN3301 Software

Programming sequence:

1. Initialize touchscreen controller

2. Initialize interrupt (pen down mode)

3. Wait for interrupt

4. Upon interrupt, issue data read (counter check with the embedded data valid bit for the

validity of the corresponding data)

5. Start host timer (typical 10ms depends on the programmed sampling time)

6. Upon time out, issue data read (counter check with the embedded data valid bit for the

validity of the corresponding data)

Figure 10. Data acquisition by host read command

Touched

Initialization

Initialization

No Touch No Touch

No Touch No Touch

Sampling

Sampling

Touched

Sampling

Sampling

Sampling

Sampling

Agenda:

Agenda:

STMPE812 sends touched interrupt to Host

STMPE812 sends touched interrupt to Host

Host read touch data

Host read touch data

Doc ID 18161 Rev 1 15/35

Page 16

Software AN3301

2.2 Embedded data valid bit

In order to facilitate a more bandwidth efficient for data read, it is possible to program

through Bit[5] of TSC_DET_CFG2 register (0x42) whereby the data valid bit is embedded in

within the first byte of the touch data (FIFO).

Figure 11. TSC data register

TSC_DET_CFG2 Register

TSC_DET_CFG2 Register

Bit[4]

Bit[4]

OpMode

OpMode

Bit[5]

Bit[5]

StatusRead

StatusRead

Number of

Number of

bytes to

bytes to

read from

read from

TSC_Data

TSC_Data

510

510

411

411

[11:4] of X400

[11:4] of X400

[11:4] of X301

[11:4] of X301

Da ta valid

Da ta valid

status

status

Da ta valid

Da ta valid

status

status

[3:0] of X

[3:0] of X

[11:8] of Y

[11:8] of Y

[3:0] of X

[3:0] of X

[11:8] of Y

[11:8] of Y

[11:4] of X

[11:4] of X

[11:4] of X

[11:4] of X

[3:0] of X

[3:0] of X

[11:8] of Y

[11:8] of Y

[3:0] of X

[3:0] of X

[11:8] of Y

[11:8] of Y

[7:0] of Y

[7:0] of Y

RSVDVALIDRSVD

RSVDVALIDRSVD

01234567

01234567

Byte4Byte3Byte2Byte1Byte0

Byte4Byte3Byte2Byte1Byte0

-[7:0] o f Z[7:0] of Y

-[7:0] o f Z[7:0] of Y

--[7:0] of Y

--[7:0] of Y

[7:0] of Z[7:0] of Y

[7:0] of Z[7:0] of Y

-

-

AM08680V1

In applications whereby no GPIO input/PWM/ADC is used and Pen Down interrupt mode is

selected, it is no longer necessary to read the ISR register. The data valid info can be

obtained through the embedded data valid bit and the touch release info can be obtained

merely by observing the INT pin signal. (ie. INT low: touched; INT high: release).

2.3 Pen down interrupt mode

In Pen down interrupt mode, the INT pin signal is an OR function of the Pen Down and other

enabled GPIO/PWM/ADC interrupts at Port 0 to Port 3.

It is recommended to use Pen Down mode when the GPIO/PWM/ADC functions are not

required or the GPIO/PWM/ADC interrupts are not enabled. In this condition, the INT signal

provides the exclusive indication for touched (INT low) and release (INT high).

16/35 Doc ID 18161 Rev 1

Page 17

AN3301 Software

2.4 TSC_DATA read

The TSC_DATA contains the converted data for touchscreen controller. Three to five bytes

readings are required depending on the programmed value in TSC_DET_CFG2 register.

In order to preserve the integrity of the data, it is mandatory to ensure the following:

– System host to read exactly the number of bytes according to the programmed

operating mode

2

–I

C host to insert a STOP condition after each data read command

2.5 Touchscreen controller sampling

The touchscreen controller sampling time is determined by the following programmable

parameters:

– Touch detect delay

– Settling time

– ADC conversion time

– MAV (median average filter)

– TSC operating mode (X/Y or X/Y/Z acquisition)

Figure 12 illustrates the diagram of a complete sampling cycle. MAV is acting within the

Sampling period of X, Y and Z respectively.

Figure 12. Touchscreen controller sampling

-

-

Settling Time

To uch Detect Delay

Sampling X

A complete sampling cycle

Settling Time

Sampling Y

Settling Time

Sampling Z

To uch Detect Delay

AM08681V2

The overall sampling time/frequency can be calculated with below formulae.

Sampling time in X/Y/Z mode = touch detect delay *2 + (settling time + (ADC conversion

time * MAV)) * 3

Time taken for sampling in X/Y/Z mode = touch detect delay *2 + (settling time + (ADC

conversion time * MAV)) * 2

Doc ID 18161 Rev 1 17/35

Page 18

Software AN3301

Table 2. Example of sampling time calculation

Sampling

ADC

conversion time

50 µs

Touch detect

delay

Settling time MAV

40 µs 40 µs None

50 µs 40 µs 40 µs 10-2

50 µs 640 µs 640 µs 20-4

time/freq

(complete X/Y/Z

sample sets)

40*2 +

3*(40+(50*1))

=350 µs (2.8 K

sample sets/sec)

40*2 + 3*(40+

(50*10))

=1700 µs (588

sample sets/sec)

640*2 + 3*(640+

(50*20))

=6200 µs (161

sample sets/sec)

18/35 Doc ID 18161 Rev 1

Page 19

AN3301 Software

2.6 Programming guide

In this section, the reference software programming code is shared based on the general

application of the STMPE812A. This includes the initialization and interrupt handling

routines for touchscreen controller (in all 3 acquisition modes and both normal and pen

down interrupt modes), GPIO, ADC and PWM.

The reference code is supplemented by the STMPE812A software library.

2.6.1 Touchscreen initialization and interrupt handling (pen down mode)

The following is an example for touchscreen initialization, interrupt servicing routine in pen

down mode, whereby all other interrupt sources (eg. GPIO, PWM and ADC) are not used in

the application.

A: Initialization

void STMPE812A_Initialization (void) {

/*Enabling the Soft Reset in the System Control Register (0x03)*/

STMPE812A_SoftReset ();

/*Enabling the ADC and TSC Clocks in the System Control Register (0x03)*/

STMPE812A_SetClock (STMPE812A_ENABLE, STMPE812A_ADC_CLK|STMPE812A_TSC_CLK);

/*Setting the Port - 2 as a special function in the Port Function Control Register

(0x04)*/

STMPE812A_SetPortFunction (STMPE812A_PORT2, STMPE812A_PORT_FUNC_SPECIAL_FUNC);

/*Setting the MAV_MODE [2:0] as ‘20 remove 4’, Precharge [1:0] as ‘no pre-charge’ and

Current _Limit [1:0] as ‘20mA’ in the TSC Control Register (0x40) respectively*/

STMPE812A_SetTSCController (STMPE812A_TSC_MAV_20_4, STMPE812A_TSC_NO_PRE,

STMPE812A_TSC_Current20M);

/*Setting the PenStrength [1:0] as ‘Most Sensitive (20K Pull-Up)’, TDetDly [2:0] as

‘40us’ and Settling [2:0] as ‘40us’ in the TSC Detection Configuration 1 Register

(0x41) respectively*/

STMPE812A_ConfigureTSC (STMPE812A_TSC_MOST_SEN, STMPE812A_TSC_TDD40,

STMPE812A_TSC_PDST40);

/*Setting the TSC operating mode OpMode [4] as ’12-bit X, 12-bit Y, 8-bit Z

acquisition’ in the TSC Detection Configuration 2 Register (0x42)*/

STMPE812A_SetTSCOpMode (STMPE812A_DISABLE);

/*Enabling the StatusRead [5] in the TSC Detection Configuration 2 Register (0x42)*/

STMPE812A_SetTSCStatusRead (STMPE812A_ENABLE);

/*Setting the Acq_Mode [7:6] as ‘Data acquisition timed by internal timer’ in the TSC

Detection Configuration 2 Register (0x42)*/

STMPE812A_SetTSCAcquisitionMode (STMPE812A_TSC_INTERNAL_TIMER);

/*Setting the Acq_Mode [7:6] as ‘Data acquisition triggered by a write to “ACQ” bit’

in the TSC Detection Configuration 2 Register (0x42)*/

//STMPE812A_SetTSCAcquisitionMode (STMPE812A_TSC_TRI_ACQ);

/*Setting the Acq_Mode [7:6] as ‘Data acquisition using Host-Controlled Sampling Rate

Control’ in the TSC Detection Configuration 2 Register (0x42)*/

//STMPE812A_SetTSCAcquisitionMode (STMPE812A_TSC_HC_SRC);

/*Setting the TSC sampling rate value of ‘0x0A’ in the TSC Sampling Rate Register

(0x43)*/

STMPE812A_SetTSCSamplingRate (0x0A);

Doc ID 18161 Rev 1 19/35

Page 20

Software AN3301

/*Setting the INT_Mode [7] as ‘Pendown Interrupt Mode’ in the Interrupt Control

Register (0x08)*/

STMPE812A_SetInterruptMode(STMPE812A_INT_MODE_PEN_DOWN);

/*Enabling the Global Interrupt in the Interrupt Control Register (0x08)*/

STMPE812A_EnableGlobalInterrupt (TRUE);

/*Enabling the interrupt from the system related source of TSC_TOUCH and TSC_DATA to

the host in the Interrupt Enable Register (0x09)*/

STMPE812A_EnableInterrupt (STMPE812A_INT_TSC_TOUCH|STMPE812A_INT_TSC_DATA, TRUE);

/*Enabling the TSC operation in the System Control Register (0x03)*/

STMPE812A_EnableTouchscreen (TRUE);}

B: Interrupt handling (pen down mode)

Data acquisition timed by internal timer

void IRQHandler (void) {

u8 data [5];

if (GetITStatus (INTERRUPT_LINE)! = RESET)

{

/*Clearing the Interrupt pending bit from the Micro-controller*/

ClearITPendingBit (INTERRUPT_LINE);

/*Checking the Interrupt Pin Status goes low*/

if ((GPIO_INTERRUPT->IDR & GPIO_PIN_INTERRUPT) == 0)

{

/*Start host timer with an interval of 13ms*/

/*Check below for the timer routine*/

TIM_Cmd (TIM2, ENABLE);

}

}

}

Data acquisition triggered by a write to “ACQ” bit

void IRQHandler (void) {

u8 data [5];

if (GetITStatus (INTERRUPT_LINE)! = RESET)

{

/*Clearing the Interrupt pending bit from the Micro-controller*/

ClearITPendingBit (INTERRUPT_LINE);

/*Checking the Interrupt Pin Status goes low*/

if ((GPIO_INTERRUPT->IDR & GPIO_PIN_INTERRUPT) == 0)

{

/*Start host timer with an interval of 0ms*/

/*Check below for the timer routine*/

TIM_Cmd (TIM2, ENABLE);

}

}

}

20/35 Doc ID 18161 Rev 1

Page 21

AN3301 Software

Data acquisition using host-controlled sampling rate control

void IRQHandler (void) {

u8 data [5];

if (GetITStatus (INTERRUPT_LINE)! = RESET)

{

/*Clearing the Interrupt pending bit from the Micro-controller*/

ClearITPendingBit (INTERRUPT_LINE);

/*Checking the Interrupt Pin Status goes low*/

if ((GPIO_INTERRUPT->IDR & GPIO_PIN_INTERRUPT) == 0)

{

/*Reading the Interrupt status register and Dummy data of 4 bytes of x, y & z data

from the register address of 0x44 to 0x48*/

I2C_Read_Data (STMPE812A_SLAVE_ADDR, STMPE812A_TSC_DATA, 5, &data [0]);

/*Start host timer with an interval of 13ms*/

/*Check below for the timer routine*/

TIM_Cmd (TIM2, ENABLE);

}

}

}

Micro-controller timer routine

Data acquisition timed by internal timer or data acquisition using host-controlled sampling

rate control:

void TIM2_IRQHandler (void) {

if (TIM_GetITStatus (TIM2, TIM_IT_CC1) != RESET)

{

/*Clearing the Timer 2 Interrupt pending bit from the Micro-controller*/

TIM_ClearITPendingBit (TIM2, TIM_IT_CC1);

/*Reading the Interrupt status register and 4 bytes of x, y & z data from the

register address of 0x44 to 0x48*/

I2C_Read_Data (STMPE812A_SLAVE_ADDR, STMPE812A_TSC_DATA, 5, &Touch_Data [0]);

Doc ID 18161 Rev 1 21/35

Page 22

Software AN3301

/*Sets the global variable (Is_Pen_Down) to handle the global variables (Touch_Data

[1] to Touch_Data [4] i.e. 4 bytes of x, y & z data coordinates) in the main while

loop*/

Is_Pen_Down = TRUE;

/*Handling Coordinates codes should be here */

/*Checking either the bit 0 or 1 or both (touch bit [or] data bit [or] touch and

data bits) value from Interrupt status register goes high*/

if ((Touch_Data [0] & 0x03) > 0)

{

/*Getting the Captured value from the Micro-controller Timer2 CNT register*/

Capture = TIM2->CNT;

/*Setting the (Captured value+CCR1_VAL) to the Micro-controller Timer2

CCR1 register.*/

TIM_SetCompare1 (TIM2, capture + CCR1_Val);

/*Enabling the Micro-controller Timer2 for 13ms*/

TIM_Cmd (TIM2, ENABLE);

}

else

{

/*Disabling the Micro-controller Timer2*/

TIM_Cmd (TIM2, DISABLE);

/*Resets the global variable (Is_Pen_Down) to clear the point (x, y & z data

coordinates) in the main while loop*/

Is_Pen_Down = FALSE;

}

}}

Data acquisition triggered by a write to “ACQ” bit

void TIM2_IRQHandler (void) {

if (TIM_GetITStatus (TIM2, TIM_IT_CC1) != RESET)

{

/*Clearing the Timer 2 Interrupt pending bit from the Micro-controller*/

TIM_ClearITPendingBit (TIM2, TIM_IT_CC1);

/* Sets the ACQ [4] in the TSC Control Register (0x40) */

STMPE812A_InitiateAcquisition ();

/* Waiting until the ACQ [4] in the TSC Control Register (0x40) goes low */

while (!STMPE812A_IsAcquisitionComplete ())

22/35 Doc ID 18161 Rev 1

Page 23

AN3301 Software

{}

/*Reading the Interrupt status register and 4 bytes of x, y & z data from the

register address of 0x44 to 0x48*/

I2C_Read_Data (STMPE812A_SLAVE_ADDR, STMPE812A_TSC_DATA, 5, &Touch_Data [0]);

/*Sets the global variable (Is_Pen_Down) to handle the global variables (Touch_Data

[1] to Touch_Data [4] i.e. 4 bytes of x, y & z data coordinates)*/

Is_Pen_Down = TRUE;

/*Handling Coordinates codes should be here */

/*Checking either the bit 0 or 1 or both (touch bit [or] data bit [or] touch and

data bits) value from Interrupt status register goes high*/

if ((Touch_Data [0] & 0x03) > 0)

{

/*Getting the Captured value from the Micro-controller Timer2 CNT register*/

Capture = TIM2->CNT;

/*Setting the (Captured value+CCR1_VAL) to the Micro-controller Timer2

CCR1 register.*/

TIM_SetCompare1 (TIM2, capture + CCR1_Val);

/*Enabling the Micro-controller Timer2 for 0ms*/

TIM_Cmd (TIM2, ENABLE);

}

else

{

/*Disabling the Micro-controller Timer2*/

TIM_Cmd (TIM2, DISABLE);

/*Resets the global variable (Is_Pen_Down) to clear the point (x, y & z data

coordinates) in the main while loop*/

Is_Pen_Down = FALSE;

}

}}

2.6.2 Touchscreen initialization and interrupt handling (normal interrupt mode)

The following is an example for device initialization, interrupt servicing routine in normal

interrupt mode.

A: Initialization

void STMPE812A_Initialization (void) {

/*Enabling the Soft Reset in the System Control Register (0x03)*/

STMPE812A_SoftReset ();

/*Enabling the ADC and TSC Clocks in the System Control Register (0x03)*/

STMPE812A_SetClock (STMPE812A_ENABLE, STMPE812A_ADC_CLK|STMPE812A_TSC_CLK);

/*Setting the Port - 2 as a special function in the Port Function Control Register

(0x04)*/

STMPE812A_SetPortFunction (STMPE812A_PORT2, STMPE812A_PORT_FUNC_SPECIAL_FUNC);

/*Setting the MAV_MODE [2:0] as ‘20 remove 4’, Precharge [1:0] as ‘no pre-charge’ and

Current _Limit [1:0] as ‘20mA’ in the TSC Control Register (0x40) respectively*/

Doc ID 18161 Rev 1 23/35

Page 24

Software AN3301

STMPE812A_SetTSCController (STMPE812A_TSC_MAV_20_4, STMPE812A_TSC_NO_PRE,

STMPE812A_TSC_Current20M);

/*Setting the PenStrength [1:0] as ‘Most Sensitive (20K Pull-Up)’, TDetDly [2:0] as

‘40us’ and Settling [2:0] as ‘40us’ in the TSC Detection Configuration 1 Register

(0x41) respectively*/

STMPE812A_ConfigureTSC (STMPE812A_TSC_MOST_SEN, STMPE812A_TSC_TDD40,

STMPE812A_TSC_PDST40);

/*Setting the TSC operating mode OpMode [4] as ’12-bit X, 12-bit Y, 8-bit Z

acquisition’ in the TSC Detection Configuration 2 Register (0x42)*/

STMPE812A_SetTSCOpMode (STMPE812A_DISABLE);

/*Disabling the StatusRead [5] in the TSC Detection Configuration 2 Register (0x42)*/

STMPE812A_SetTSCStatusRead (STMPE812A_DISABLE);

/*Setting the Acq_Mode [7:6] as ‘Data acquisition timed by internal timer’ in the TSC

Detection Configuration 2 Register (0x42)*/

STMPE812A_SetTSCAcquisitionMode (STMPE812A_TSC_INTERNAL_TIMER);

/*Setting the Acq_Mode [7:6] as ‘Data acquisition triggered by a write to “ACQ” bit’

in the TSC Detection Configuration 2 Register (0x42)*/

//STMPE812A_SetTSCAcquisitionMode (STMPE812A_TSC_TRI_ACQ);

/*Setting the Acq_Mode [7:6] as ‘Data acquisition using Host-Controlled Sampling Rate

Control’ in the TSC Detection Configuration 2 Register (0x42)*/

//STMPE812A_SetTSCAcquisitionMode (STMPE812A_TSC_HC_SRC);

/*Setting the TSC sampling rate value of ‘0x0A’ in the TSC Sampling Rate Register

(0x43)*/

STMPE812A_SetTSCSamplingRate (0x0A);

/*Setting the INT_Mode [7] as ‘Normal Interrupt Mode’ in the Interrupt Control

Register (0x08)*/

STMPE812A_SetInterruptMode(STMPE812A_INT_MODE_NORMAL);

/*Setting the INT_Type [1] as ‘Edge Interrupt Type’ in the Interrupt Control Register

(0x08)*/

STMPE812A_SetInterruptType (STMPE812A_INT_TYPE_EDGE);

/*Enabling the Global Interrupt in the Interrupt Control Register (0x08)*/

STMPE812A_EnableGlobalInterrupt (TRUE);

/*Enabling the interrupt from the system related source of TSC_DATA and TSC_RELEASE

to the host in the Interrupt Enable Register (0x09)*/

/*For Acq_Mode [7:6] in the TSC Detection Configuration 2 Register (0x42) is set as

‘Data acquisition timed by internal timer’*/

STMPE812A_EnableInterrupt (STMPE812A_INT_TSC_DATA|STMPE812A_INT_TSC_REL, TRUE);

/*Enabling the interrupt from the system related source of TSC_TOUCH, TSC_DATA and

TSC_RELEASE to the host in the Interrupt Enable Register (0x09)*/

/*For Acq_Mode [7:6] in the TSC Detection Configuration 2 Register (0x42) is set as

either ‘Data acquisition triggered by a write to “ACQ” bit’ (OR) ‘Data acquisition

using Host-Controlled Sampling Rate Control’*/

//STMPE812A_EnableInterrupt

(STMPE812A_INT_TSC_TOUCH|STMPE812A_INT_TSC_DATA|STMPE812A_INT_TSC_REL, TRUE);

/*Enabling the TSC operation in the System Control Register (0x03)*/

STMPE812A_EnableTouchscreen (TRUE);}

24/35 Doc ID 18161 Rev 1

Page 25

AN3301 Software

B: Interrupt handling (normal interrupt mode)

Data acquisition timed by internal timer

void IRQHandler (void) {

if (GetITStatus (INTERRUPT_LINE)! = RESET)

{

/*Clearing the Interrupt pending bit from the Micro-controller*/

ClearITPendingBit (INTERRUPT_LINE);

/*Reading the Interrupt status register*/

STMPE812A_GetInterruptStatus (&Touch_Data [0]);

/*Reading the 4 bytes of x, y & z data from the register address of 0x44 to 0x47*/

I2C_Read_Data (STMPE812A_SLAVE_ADDR, STMPE812A_TSC_DATA, 4, &Touch_Data [1]);

/*Checking the bit 6(release bit) value from Interrupt status register goes low*/

if ((Touch_Data [0] & 0x40) == 0x00)

{

/*Sets the global variable (Is_Pen_Down) to handle the global variables (Touch_Data

[1] to Touch_Data [4] i.e. 4 bytes of x, y & z data coordinates) in the main while

loop*/

Is_Pen_Down = TRUE;

}

/*Handling Coordinates codes should be here */

}

/*Checking the bit 6(release bit) value from Interrupt status register goes

high*/

if ((Touch_Data [0] & 0x40) == 0x40)

{

/*Resets the global variable (Is_Pen_Down) to clear the point (x, y & z data

coordinates) in the main while loop*/

Is_Pen_Down = FALSE;

}

}}

Data acquisition triggered by a write to “ACQ” bit

void IRQHandler (void) {

if (GetITStatus (INTERRUPT_LINE)! = RESET)

{

/*Clearing the Interrupt pending bit from the Micro-controller*/

ClearITPendingBit (INTERRUPT_LINE);

/*Reading the Interrupt status register*/

STMPE812A_GetInterruptStatus (&Touch_Data [0]);

/*Checking either the bit 0 or 1(touch bit or data bit) value from Interrupt status

register goes high*/

Doc ID 18161 Rev 1 25/35

Page 26

Software AN3301

if (((Touch_Data [0] & 0x01) == 0x01) || ((Touch_Data [0] & 0x02) == 0x02))

{

/*Reading the 4 bytes of x, y & z data from the register address of 0x44 to 0x47*/

I2C_Read_Data (STMPE812A_SLAVE_ADDR, STMPE812A_TSC_DATA, 4, &Touch_Data [1]);

/* Sets the ACQ [4] in the TSC Control Register (0x40) */

STMPE812A_InitiateAcquisition ();

/* Waiting until the ACQ [4] in the TSC Control Register (0x40) goes low */

while (!STMPE812A_IsAcquisitionComplete ())

{}

}

/*Checking the bit 1(data bit) value from Interrupt status register goes high*/

if ((Touch_Data [0] & 0x02) == 0x02)

{

/*Sets the global variable (Is_Pen_Down) to handle the global variables (Touch_Data

[1] to Touch_Data [4] i.e. 4 bytes of x, y & z data coordinates) */

Is_Pen_Down = TRUE;

/*Handling Coordinates codes should be here */

}

/*Checking the bit 6 (release bit) value from Interrupt status register goes high*/

if (((Touch_Data [0] & 0x40) == 0x40))

{

/*Resets the global variable (Is_Pen_Down) to clear the point (x, y & z data

coordinates) in the main while loop*/

Is_Pen_Down = FALSE;

}

}}

Data acquisition using host-controlled sampling rate control

void IRQHandler (void) {

if (GetITStatus (INTERRUPT_LINE)! = RESET)

{

/*Clearing the Interrupt pending bit from the Micro-controller*/

ClearITPendingBit (INTERRUPT_LINE);

26/35 Doc ID 18161 Rev 1

Page 27

AN3301 Software

/*Reading the Interrupt status register*/

STMPE812A_GetInterruptStatus (&Touch_Data [0]);

/*Checking either the bit 0 or 1(touch bit or data bit) value from Interrupt status

register goes high*/

if (((Touch_Data [0] & 0x01) == 0x01) || ((Touch_Data [0] & 0x02) == 0x02))

{

/*Reading the 4 bytes of x, y & z data from the register address of 0x44 to 0x47*/

I2C_Read_Data (STMPE812A_SLAVE_ADDR, STMPE812A_TSC_DATA, 4, &Touch_Data [1]);

}

/*Checking the bit 1(data bit) value from Interrupt status register goes high*/

if ((Touch_Data [0] & 0x02) == 0x02)

{

/*Sets the global variable (Is_Pen_Down) to handle the global variables (Touch_Data

[1] to Touch_Data [4] i.e. 4 bytes of x, y & z data coordinates) in the main while

loop*/

Is_Pen_Down = TRUE;

/*Handling Coordinates codes should be here */

}

/*Checking the bit 6 (release bit) value from Interrupt status register goes high*/

if (((Touch_Data [0] & 0x40) == 0x40))

{

/*Resets the global variable (Is_Pen_Down) to clear the point (x, y & z data

coordinates) in the main while loop*/

Is_Pen_Down = FALSE;

}

}}

Doc ID 18161 Rev 1 27/35

Page 28

Software AN3301

2.6.3 GPIO initialization and interrupt handling

The following is an example for GPIO initialization and interrupt servicing routine.

A: Initialization

void STMPE812A_GPIO_Initialization (void) {

/*Enabling the Soft Reset in the System Control Register (0x03)*/

STMPE812A_SoftReset ();

/*Enabling the GPIO Clock in the System Control Register (0x03)*/

STMPE812A_SetClock (STMPE812A_ENABLE, STMPE812A_GPIO_CLK);

/*Setting the Port - 2 as a special function in the Port Function Control Register

(0x04)*/

STMPE812A_SetPortFunction (STMPE812A_PORT2, STMPE812A_PORT_FUNC_SPECIAL_FUNC);

/*Setting the Port - 1 as a GPIO Input in the Port Function Control Register (0x04)*/

STMPE812A_SetPortFunction (STMPE812A_PORT1, STMPE812A_PORT_FUNC_GPIO_IP);

/*Enabling the IO-1 [1] as GPIO Falling Edge Detection in the GPIO Falling Edge

Detection Register (0x14)*/

STMPE812A_EnableGPIOFallingEdgeInterrupt (STMPE812A_IO1, TRUE);

/*Setting the INT_Mode [7] as ‘Normal Interrupt Mode’ in the Interrupt Control

Register (0x08)*/

STMPE812A_SetInterruptMode(STMPE812A_INT_MODE_NORMAL);

/*Setting the INT_Type [1] as ‘Level Interrupt Type’ in the Interrupt Control

Register (0x08)*/

STMPE812A_SetInterruptType (STMPE812A_INT_TYPE_LEVEL);

/*Enabling the Global Interrupt in the Interrupt Control Register (0x08)*/

STMPE812A_EnableGlobalInterrupt (TRUE);

/*Enabling the interrupt from the system related source of P1 to the host in the

Interrupt Enable Register (0x09)*/

STMPE812A_EnableInterrupt (STMPE812A_INT_P1, TRUE);

}

28/35 Doc ID 18161 Rev 1

Page 29

AN3301 Software

B: Interrupt handling

void IRQHandler (void) {

if (GetITStatus (INTERRUPT_LINE)! = RESET)

{

/*Clearing the Interrupt pending bit from the Micro-controller*/

ClearITPendingBit (INTERRUPT_LINE);

/*Checking the Interrupt Pin Status goes low*/

while ((GPIO_INTERRUPT->IDR & GPIO_PIN_INTERRUPT) == 0)

{

/*Reading the Interrupt status register*/

STMPE812A_GetInterruptStatus (&Touch_Data [0]);

/*Checking the bit 3(P1 bit) value from Interrupt status register goes high*/

if ((Touch_Data [0] & 0x08) == 0x08)

{

/*Printing“GPIO Falling Edge is Detected” on the monitor screen*/

printf (“GPIO Falling Edge is Detected”);

}

}

}}

2.6.4 ADC initialization and interrupt handling

The following is an example for ADC initialization and interrupt servicing routine.

A: Initialization

void STMPE812A_ADC_Initialization (void) {

/*Enabling the Soft Reset in the System Control Register (0x03)*/

STMPE812A_SoftReset ();

/*Enabling the ADC and GPIO Clocks in the System Control Register (0x03)*/

STMPE812A_SetClock (STMPE812A_ENABLE, STMPE812A_ADC_CLK|STMPE812A_GPIO_CLK);

/*Setting the Port - 2 as a special function in the Port Function Control Register

(0x04)*/

STMPE812A_SetPortFunction (STMPE812A_PORT2, STMPE812A_PORT_FUNC_SPECIAL_FUNC);

Doc ID 18161 Rev 1 29/35

Page 30

Software AN3301

/*Setting the Port - 1 as an ADC Input in the Port Function Control Register (0x04)*/

STMPE812A_SetPortFunction (STMPE812A_PORT1, STMPE812A_PORT_FUNC_ADC_IP);

/*Setting the ADC_MODE [7] as 'One-shot capture', ADC_FREQ [5:4] as '15Ksamples/sec'

and ADC_PORT in the ADC Control Register (0x20) respectively*/

STMPE812A_SetADC (STMPE812A_ADC_1_SHOT_CAPTURE, STMPE812A_ADC_FREQ_15K,

STMPE812A_ADC_PORT);

/*Setting the INT_Mode [7] as ‘Normal Interrupt Mode’ in the Interrupt Control

Register (0x08)*/

STMPE812A_SetInterruptMode(STMPE812A_INT_MODE_NORMAL);

/*Setting the INT_Type [1] as ‘Level Interrupt Type’ in the Interrupt Control

Register (0x08)*/

STMPE812A_SetInterruptType (STMPE812A_INT_TYPE_LEVEL);

/*Enabling the Global Interrupt in the Interrupt Control Register (0x08)*/

STMPE812A_EnableGlobalInterrupt (TRUE);

/*Enabling the interrupt from the system related source of P1 to the host in the

Interrupt Enable Register (0x09)*/

STMPE812A_EnableInterrupt (STMPE812A_INT_P1, TRUE);

/*Starting the ADC Conversion (Initiate Data Acquisition by setting the bit [6]) in

the ADC Control Register (0x20)*/

STMPE812A_StartADC (TRUE);

}

Interrupt handling

void IRQHandler (void) {

if (GetITStatus (INTERRUPT_LINE)! = RESET)

{

/*Clearing the Interrupt pending bit from the Micro-controller*/

ClearITPendingBit (INTERRUPT_LINE);

/*Checking the Interrupt Pin Status goes low*/

while ((GPIO_INTERRUPT->IDR & GPIO_PIN_INTERRUPT) == 0)

{

/*Reading the Interrupt status register*/

STMPE812A_GetInterruptStatus (&Touch_Data [0]);

30/35 Doc ID 18161 Rev 1

Page 31

AN3301 Software

/*Checking the bit 3(P1 bit) value from Interrupt status register goes high*/

if ((Touch_Data [0] & 0x08) == 0x08)

{

/*Getting the12 bits ADC data from the ADC Data Register (0x21 & 0x22) */

STMPE812A_GetADCData (&adcdata);

/*Printing the received “adcdata” value on the monitor screen*/

printf ("%ld\n\r", adcdata);

/*Starting the ADC Conversion (Initiate Data Acquisition by setting the bit [6]) in

the ADC Control Register (0x20)*/

STMPE812A_StartADC (TRUE);

}

}

}}

Doc ID 18161 Rev 1 31/35

Page 32

Software AN3301

2.6.5 PWM initialization and interrupt handling

The following is an example for PWM initialization and interrupt servicing routine.

A: Initialization

void STMPE812A_PWM_Initialization (void) {

/*Enabling the Soft Reset in the System Control Register (0x03)*/

STMPE812A_SoftReset ();

/*Enabling the PWM and GPIO Clocks in the System Control Register (0x03)*/

STMPE812A_SetClock (STMPE812A_ENABLE, STMPE812A_PWM_CLK|STMPE812A_GPIO_CLK);

/*Setting the Port - 2 as a special function in the Port Function Control Register

(0x04)*/

STMPE812A_SetPortFunction (STMPE812A_PORT2, STMPE812A_PORT_FUNC_SPECIAL_FUNC);

/*Setting the Port - 1 as a special function in the Port Function Control Register

(0x04)*/

STMPE812A_SetPortFunction (STMPE812A_PORT1, STMPE812A_PORT_FUNC_SPECIAL_FUNC);

/*Setting the Burst_Length [1:0] as ‘8mS’ in the PWMClockDiv Register (0x50) */

STMPE812A_SetPWMBurstLengh (STMPE812A_PWM_BURSTLENGTH_8MS);

/*Setting the Div [4:0] value as ‘0’ in the PWMClockDiv Register (0x50)

respectively*/

STMPE812A_SetPWMClockDivider (0);

/*Setting the Brightness [7:4] as ‘Duty Cycle Ratio 8: 8 (50.00%)’, BurstMultiplier

[3:2] value as ‘1’ and Off_State [1] as ‘PWM Output “LOW” when PWM not running’ in

the PWMControl1 Register (0x51) respectively*/

STMPE812A_ConfigurePWM (STMPE812A_PWM_DUTY_CYCLE_50_00, 1,

STMPE812A_PWM_OFF_STATE_HIGH);

/*Setting the INT_Mode [7] as ‘Normal Interrupt Mode’ in the Interrupt Control

Register (0x08)*/

STMPE812A_SetInterruptMode(STMPE812A_INT_MODE_NORMAL);

/*Setting the INT_Type [1] as ‘Level Interrupt Type’ in the Interrupt Control

Register (0x08)*/

STMPE812A_SetInterruptType (STMPE812A_INT_TYPE_LEVEL);

/*Enabling the Global Interrupt in the Interrupt Control Register (0x08)*/

STMPE812A_EnableGlobalInterrupt (TRUE);

32/35 Doc ID 18161 Rev 1

Page 33

AN3301 Software

/*Enabling the interrupt from the system related source of P1 to the host in the

Interrupt Enable Register (0x09)*/

STMPE812A_EnableInterrupt (STMPE812A_INT_P1, TRUE);

/*Enabling the PWM Controller Sequence in the PWMControl1 Register (0x51)*/

STMPE812A_EnablePWM (TRUE);

}

B: Interrupt handling

void IRQHandler (void) {

if (GetITStatus (INTERRUPT_LINE)! = RESET)

{

/*Clearing the Interrupt pending bit from the Micro-controller*/

ClearITPendingBit (INTERRUPT_LINE);

/*Checking the Interrupt Pin Status goes low*/

while ((GPIO_INTERRUPT->IDR & GPIO_PIN_INTERRUPT) == 0)

{

/*Reading the Interrupt status register*/

STMPE812A_GetInterruptStatus (&Touch_Data [0]);

/*Checking the bit 3(P1 bit) value from Interrupt status register goes high*/

if ((Touch_Data [0] & 0x08) == 0x08)

{

/*Enabling the PWM Controller Sequence in the PWMControl1 Register (0x51)*/

STMPE812A_EnablePWM (TRUE);

}

}

}}

Doc ID 18161 Rev 1 33/35

Page 34

Revision history AN3301

3 Revision history

Table 3. Document revision history

Date Revision Changes

14-Dec-2010 1 Initial release.

34/35 Doc ID 18161 Rev 1

Page 35

AN3301

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (“ST”) reserve the

right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any

time, without notice.

All ST products are sold pursuant to ST’s terms and conditions of sale.

Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no

liability whatsoever relating to the choice, selection or use of the ST products and services described herein.

No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this

document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products

or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such

third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN ST’S TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED

WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED

WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS

OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT.

UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT

RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING

APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY,

DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE

GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USER’S OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void

any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any

liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries.

Information in this document supersedes and replaces all information previously supplied.

The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

© 2010 STMicroelectronics - All rights reserved

STMicroelectronics group of companies

Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan -

Malaysia - Malta - Morocco - Philippines - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America

www.st.com

Doc ID 18161 Rev 1 35/35

Loading...

Loading...